Recent active thermal management technologies for the development of energy-optimized aerospace vehicles in China

Jixing WANG, Yunz LI, Xingong LIU, Choqun SHEN,Hongshng ZHANG, Ki XIONG

a College of Electrical, Energy, and Power Engineering, Yangzhou University, Yangzhou 225009, China

b School of Aeronautic Science and Engineering, Beihang University, Beijing 100083, China

c Institute of Engineering Thermophysics, North China University of Water Conservancy and Electrical Power,Zhengzhou 450045, China

d HiWING General Aviation Equipment Corporation Limited, Beijing 100074, China

e School of Mechanical Engineering and Automation, Harbin Institute of Technology, Shenzhen Graduate School,Shenzhen 518117, China

KEYWORDS Aerospace engineering;Efficiency promotion;Fluid dynamics;Heat and mass transfer;Thermal management

Abstract Recently, the development of modern vehicles has brought about aggressive integration and miniaturization of on-board electrical and electronic devices.It will lead to exponential growth in both the overall waste heat and heat flux to be dissipated to maintain the devices within a safe temperature range.However,both the total heat sinks aboard and the cooling capacity of currently utilized thermal control strategy are severely limited, which threatens the lifetime of the on-board equipment and even the entire flight system and shrink the vehicle’s flight time and range. Facing these thermal challenges,the USA proposed the program of‘‘INVENT”to maximize utilities of the available heat sinks and enhance the cooling ability of thermal control strategies. Following the efforts done by the USA researchers,scientists in China fought their ways to develop thermal management technologies for Chinese advanced energy-optimized airplanes and spacecraft. This paper elaborates the available on-board heat sinks and aerospace thermal management systems using both active and passive technologies not confined to the technology in China.Subsequently,active thermal management technologies in China including fuel thermal management system, environment control system, non-fuel liquid cooling strategy are reviewed. At last, space thermal control technologies used in Chinese Space Station and Chang’e-3 and to be used in Chang’e-5 are introduced.Key issues to be solved are also identified,which could facilitate the development of aerospace thermal control techniques across the world.

1. Introduction

Recently,several profound and dramatic revolutions are spotted in the development of the world-wide aerospace industry:(A) the design concept of the More Electric Aircraft (MEA)of All Electric Aircraft(AEA) has been applied to several certain new-generation atmospheric vehicles1such as F-22, F-35,Airbus A380, and Boeing 787; (B) powered by the project of Integrated Vehicle Energy Technology(INVENT),the concept of Energy-Optimized Aircraft (EOA) has been proposed;2(C)marked by the successful operation of the X-37B,3boundaries between space and aviation vehicles have become vague with the advancement of reusable and hypersonic technology,accelerating the historic integration of the trans-atmospheric vehicles. It is a great advancement from the project of MEA/AEA to the project of ‘‘INVENT” in which the entire energy source will be regarded as an organic unity.Through the optimization of the energy management system, consumption of primary energy can be minimized while the operating range can be maximized, which facilitates the integration of space and aviation systems. The rapid development of aerospace brings thermal management challenges for various air or space vehicles.

The Thermal Management System (TMS) is originally a subsystem for a spacecraft which maintains the on-board thermal properties such as temperature, temperature difference,and humidity within the design requirement. The TMS is an indispensable system for a space vehicle as the outer space of the vehicle is a vacuum where only radiative heat transfer occurs, which does not satisfy the heat removal requirement even for the early space-oriented equipment. In contrast, airplanes of early stage were not equipped with the TMS as the introduced cold air can cool the heated components. With the development of the power system, propulsion system,and high-performance avionics, the TMS also becomes a vital subsystem of the atmospheric vehicles. There are similarities between space-based TMS and air-based TMS. For example,the fuel cooling loop of an airplane can be regarded as the single-phase Mechanically Pumped Fluid Loop (MPFL) that has been utilized in many spacecraft as an active liquidbased TMS.4,5Also, coating technology as a passive thermal control strategy to enhance radiative heat transfer in spacecraft was proposed to be applied to the hypersonic vehicles.6It means that different from other subsystem such as propulsion system and control system,the TMSs of both atmospheric and space vehicles have many common properties and face several problems in common as well.In other words,the TMSs of both atmospheric and space vehicles can be integrated to some extent.

Back in the 1970’s,Cronin from Lockheed put forward the concept of MEA or AEA in which the electric power will be the main or single secondary power7instead of the multienergy system including electric, hydraulic, and pneumatic power. As mentioned before, F-22, F-35, Airbus A380, and Boeing 787 are successful models of new generation MEAs with the advancement of the micro-electro-mechanical system.Due to the high energy conversion of the electrical power, a low-carbon flight can be realized with the rapid development of the MEA or AEA technology. However, problems emerge in the development of the MEA/AEA project as increasing number of traditional hydraulic, pneumatic, and mechanic components have been replaced by the electrical ones such as the electro-driven actuators, leading to an explosive growth in the power requirements. For example, the peak heat load of the equipment cabin in the F-22 can approach 50 kW and the total heat load of the entire F-22 can be up to 100 kW.8,9It is acknowledged that all electric/electronic devices should be operated within an acceptable temperature range to guarantee high operating efficiency and prevent overheating-induced destruction. Murshed and de Nieto10suggested that the operating temperature of the majority of power-electronics should be below 85°C. Another article unveiled that most Insulated Gate Bipolar Transistors (IGBTs) are not recommended to be operated above 125°C.11In addition, a report from the USA Department of Defence indicates that the failure factor,which is defined as the ratio of the failure rate at any temperature to the failure rate at 75°C, would rise exponentially as the device temperature increases as shown in Fig.1.12In addition,several special equipment such as space infrared detection system and laser system needs extremely low temperature ranges. The Yb:YAG laser is recommended to be operated at 77 K to gain the efficiency of up to 91.9%13and the European infrared telescope –Infrared Space Observatory– should be operated at 1.8 K.14Hence, in order to guarantee a high reliability of the on-board device, the generated waste heat must be dissipated equally to maintain a temperature balance with the assistance of the TMS.15What’s worse,the aggressive microminiaturization of the electronic component would greatly shrink the effective surface area for the heat dissipation, which leads to an exponential growth in the heat flux.It is reported that the heat flux can be up to an order of 102–103W/cm2.16Therefore, the total and local heat removal capabilities and temperature should be satisfied simultaneously, which poses a great challenge for the TMS. Such challenge would be even huger in the near-future as high-energy laser system and pulsed power directed energy applications would be soon equipped.

Fig. 1 Failure factor of electronic devices as a function of operating temperature.12

Other than the three tough challenges brought by the deployment of the high-performance equipment, challenges from the outer tough thermal environment also deserve attention. As the operating ranges of the new generation vehicles enlarge constantly from atmosphere to the outer space, severe thermal environment outside the aerospace vehicle also weakens the operating capability of the TMS. For example, the near-space hypersonic vehicle such as X-37B usually executes flight missions in an altitude from 20 to 100 km17where the atmosphere in this area is extremely thin, which determines that the quantity of the ram air is severely depressed. What’s worse, the temperature of the ram air is pretty high due to the aerodynamic heating caused by the high Mach number.It is reported that the stagnation temperature has exceeded 2200°C at only Ma=5.18Even in the atmospheric flight,requirements of advanced aerodynamics and stealth make it impossible to obtain sufficient ram air by opening holes in the fuselage. It determines that the traditional air-based heat sink is severely depressed in the current development of the aerospace planes. Instead, the fuel-based heat sink is regarded as a primary heat sink for the most advanced aircraft such as F-22.19,20Almost all the waste heat generated from the flight system is injected into the Fuel Thermal Management System(FTMS),which leads to a significant rise in the temperature of the fuel.The excessive high temperature of the fuel will,on one hand, fail to satisfy the heat dissipation demands in the late phase of flight missions. On the other hand, it could also produce carbon deposit from cracking reaction or some insoluble substances in fuel tanks and pipelines,21threatening the security and reliability of the flight.

In response to these thermal management challenges, the project of the‘‘INVENT”was initiated by the USA Air Force Research Laboratory in 2008.22This project plans to address thermal management challenges from a vehicle energy perspective through a TMS integration and energy optimization approach in which the entire energy picture addresses all energy forms including energy stored, converted, distributed,and most significantly, dissipated.2The core part of the‘‘INVENT” lies in the adaptive power and thermal management system for resolving thermal challenges through, on one hand, increasing the total cooling ability of the overall heat sinks including looking for new heat sinks and, on the other hand, improving the efficiency of the thermal management attained from more rational structure, which enhanced heat transfer approaches and advanced thermal control strategies/algorithms. Compared with passive TMSs, active TMSs will be adopted more extensively as their heat transfer rates and independence are relatively high and their thermal management capacity can be controlled easily through the management of their active power source. Resolving the thermal management issue is the target for the first stage of the‘‘INVENT” and this stage is now ongoing for the USA part.Indisputably, the USA led and is leading the tide of the aerospace revolution in all aspects,which manifests its overwhelming superiority in the field of aerospace science and engineering. China, as the third largest country in terms of aerospace technology, is keeping pace with the USA in the aerospace area and is attaining tremendous achievements that have attracted worldwide attentions.In response to these thermal challenges, this paper details the contributions to the active TMS in terms of energy saving,energy utility efficiency,and heat&mass transfer in the past two decades made by scientists and engineers from China Aerospace Science and Technology Corporation,Aviation Industry Corporation of China,and other Chinese research institutes and universities. Note that the active TMSs in China for thermal management of the on-board electronic and electrical equipment as well as the passenger/crew will be reviewed in this paper for their high cooling capacity and controllability, but review of passive TMSs and thermal protection for the internal aero-engine and aerodynamic heating where the temperature is above 1000°C will not be included in this paper.

The following structure of this paper is described as follows: brief descriptions of the currently utilized and nearfuture promising available heat sinks and TMSs are provided in Section 2 where both active and passive TMSs from not only China but all over the world are included for an overall understanding of the TMS aboard.Section 3 focuses on the development of the active TMS in China where contributions to the FTMS, air cooling, non-fuel liquid cooling strategy, and currently applied TMS in famous Chinese spacecraft are reviewed.Conclusions and perspectives towards the active TMS in China are presented in Section 4.

2. Thermal management schemes and strategies

2.1. Heat sinks in aerospace vehicles

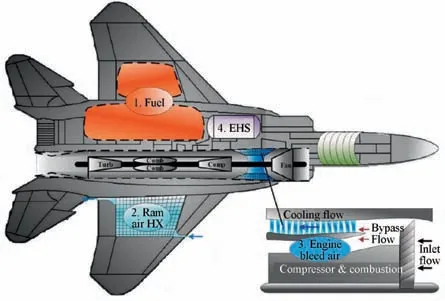

The heat sink is the substance that absorbs the generated unwanted heat. Fig. 2 illustrates four typical airborne heat sinks: (A) the most basic and most significant heat sink of modern aircraft is the fuel which is stored in the fuel tank system distributed in the fuselage and wings; (B) the ram air is also a traditional sink that is introduced from the ambient.The ram air can be directly charged into the equipment cabin to cool the device in it or be delivered into independent ram air Heat Exchangers (HEs) to cool the heated high-temperature fuel or coolant. The latter usage is more extensively adopted for the modern aircraft as the former one is severely depressed in an airspace of high altitude and low environmental pressure;(C) the engine bleed air is a newly-exploited heat sink which comes from the external duct of the turbofan engine. Generally, the bleed air will either be delivered into the fan duct HE embedded inside the engine to cool the components of the fan engine such as compressor or be utilized to be introduced into the passenger cabin to sustain the temperature and pressure of the cabin;(D)in response to the thermal challenge of the high-power-density devices, Expendable Heat Sinks (EHSs), which utilize the latent heat of the coolant or endothermic chemical reaction to cool the object, have been developed recently. Common EHSs are water, liquid nature gas, and liquid ammonia which will be stored in special containers and be vented to the atmosphere after exhausting.

Fig. 2 Distribution of heat sinks on an aircraft.

As the spacecraft usually operates in a vacuum,the conventional heat sink for a spacecraft is the vacuum space and EHS.No matter how the waste heat from satellite electronics is transported, most of the heat is dissipated into the vacuum space through the radiator finally.23The rest of the heat could be dissipated through the EHS.Water sublimators24and water evaporators25are typical components for the operation of the expandable heat sink. Recently, the fuel such as the liquid hydrogen and hydrocarbon fuel was also proposed to be used as the heat sink.26

2.2. Brief introduction of aerospace TMSs

2.2.1. Single-phase TMS

The single-phase TMS uses the sensible heat of the cooling medium to transport the waste heat from the object to the heat sink.Due to its design flexibility,gravity immunity,technological maturity, and solid reliability, single-phase thermal management system has been deployed as an overall thermal management strategy. A typical single-phase cooling system should be the FTMS which is the overall structure of the integrated TMS, equipped in the F-22 aircraft.27Fig.3 elaborates an aircraft-based FTMS which consists of a fuel tank system,fuel pump, HEs, and fuel cooling pipelines, and fuel backflow pipelines.The fuel in the tank will be pressurized by the pump to increase the safety threshold temperature of the fuel.28The various HEs are the critical connection between FTMS and other system such as Environment Control System (ECS),Electro-mechanical Actuation System(EMAS),and Hydraulic Actuating System(HAS),where the waste heat generated from these systems is injected into the FTMS. A part of the heated fuel will be delivered into the aero-engine and the rest into fuel tank system through the fuel backflow pipelines. Prior to entering the fuel tank,the backflow fuel will be cooled by other heat sinks such as ram air, engine bleed air, etc. and the fuel will also be depressurized by depressurization turbines.Specifically,air cooling strategy using the ram air or the engine bleed air can also be classified into the single-phase TMS.

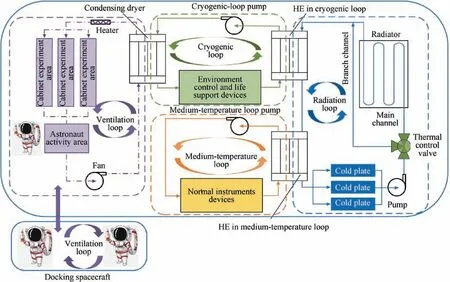

The single-phase TMS for a spacecraft is commonly the MPFL which is shown in Fig. 4. The fluid loop consists of a Cold Plate(CP)array where the waste heat is transferred from the on-board equipment to the coolant, a radiator where the collected heat is rejected to the outer space and a pump which supplies the cycling power of the whole system. Dynamic control of coolant Mass Flow Rate (MFR) through each CP can realize the temperature control of the electronic/electrical equipment. Detailed mechanism of a typical temperature control strategy is elaborated as follows. The three-way valve can regulate the bypass ratio,which is the MFR ratio between the bypass line and radiator one (between 0 and 100%), by comparing the location A’s temperature with the referenced one,through which the pump’s inlet temperature can be optimally regulated and thus a flexible heat rejection ability can be attained. Besides, each thermal control valve residing the upper stream of each corresponding CP can adjust the realtime MFR travelling through each CP to determine each branch’s heat rejection ability dynamically based on the dynamic temperature of the CP output flow.This thermal control solution has been entered the practical space applications such as Mars Pathfinder and International Space Station due to its mechanical and electrical compatibility,strong flexibility,high robustness, and gravity immunity.

2.2.2. Two-phase TMS

Fig. 3 Structure of FTMS.

Fig. 4 Schematic view of a single-phase MPFL in a spacecraft TMS.

Fig. 5 Performance comparison among various heat transport methods.30

The two-phase TMS utilizes both the sensible and latent heat to realize the transport of the waste heat so the heat transfer capability29and efficiency of the two-phase TMS are superior to those of the single-phase ones including the single-phase forced air convection and liquid forced convection which are shown in Fig.5.30It is shown that the obtained heat flux using two-phase cooling strategy can cover the range from 101to 103W/cm2with the heat transfer coefficient of 10 W·cm-2·°C-1.Therefore, the two-phase TMS has great potential to satisfy the cooling demand of high energy density devices. Capillary Pumped Loops(CPLs),Loop Heat Pipes(LHPs),sublimators,and evaporators are the traditional realization of the twophase TMS. Fig. 631shows the photographic view of the CPL and LHP both of which use the reusable coolant to absorb the heat with latent heat in the evaporator and reject the heat in the condenser repeatedly.Such devices have a great immunity of gravity as the capillary forces generated from the porous material inside the loop provide the coolant cycling power. A clear difference between the CPL and LHP is that the reservoir of the CPL is installed outside the coolant loop while that of the LHP is inserted into the loop. Sublimators and evaporators are also two-phase TMS which utilizes the coolant water as the EHS.The sublimator must operate under the triple point of the water (0.61 kPa, 273.16 K) where the solid ice can be vaporized, directly absorbing a large amount of heat using sublimation heat. The space suit has relied on a portable life support system which uses water sublimation to dissipate waste heat since the USA Apollo Program. This technology has also been applied to the space execution of other countries including Chinese manned space program.Similar to the sublimator,a space water membrane evaporator was proposed by NASA to replace sublimator in 2009.32Without the common issue of water contamination during the operation of the sublimator,the evaporator can be operated under or above the triple point like the Mars atmospheric lowpressure environment, which has a wider application range.

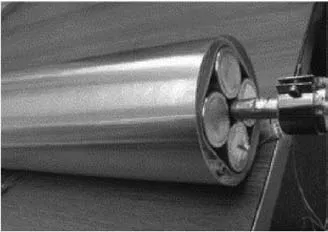

Fig. 6 General view of CPL and LHP (adapted from Santos’work31).

Another two-phase TMS technology using Phase Change Material (PCM)was also investigated and has been promoted to practical applications. PCMs store heat ‘‘sensibly” before reaching its fusion point and after that the storage continues‘‘latently” with nearly constant temperature in which the temperature control process can be attained. Paraffin waxes are the common PCM to be utilized to function as a temperature control medium for the on-board devices. Dodecane and hexadecane were used in thermal storage capsules for cooling the batteries in NASA Mars Rovers.33Fig. 7 illustrates a typical hardware for battery thermal control application. The PCM usually functions as a thermal buffer to alleviate the thermal impact caused by a transient high energy density attack through solid–liquid phase transition, where the huge latent heat could prevent the temperature from excursing further.However,the stored heat needs to be discharged by other heat sinks to be prepared for cycling usage. It determines that the PCM-based TMS could be applied to pulsed equipment as the stored heat can be removed during idle time.

Fig. 7 PCM-based thermal control application for Mars Rovers.33

As the cooling demands become increasingly tough, more advanced two-phase thermal management strategies emerged.Two-phase TMSs using microchannel cooling, jet impingement cooling, and spray cooling have attracted more attentions from researchers over the last decade.34As shown in Fig.8(a),liquid flows across the multi-arranged microchannels where flow boiling occurs to dissipate the heat from the electronics. The hydraulic diameters of the microchannel should range from 1 μm to 1000 μm,which contributes to the compact cooling demand. The jet impingement cooling, as shown in Fig.8(b),means that the liquid ejected from the nozzle as a liquid column to impact the heated surface where a strong convection can be obtained. The impinged liquid flow would form a sustainable liquid film where convection, evaporation,and boiling occur, which is responsible for the enhancement of the heat transfer. Fig. 8(c) illustrates the schematic view of the spray cooling technology. The liquid is atomized into numerous fine liquid droplets to impinge the heated surface with a high velocity, which guarantee a strong convection. A liquid film would be formed as well,which shows a heat transfer similarity with the jet impingement cooling. Generally speaking, the spray cooling has two major superiorities over the jet cooling in terms of the heat transfer characteristics:(A)as the area of the impact is larger,a better uniform temperature distribution can be attained for the spray cooling; (B)as the specific area of the droplet is higher than the liquid column,the cooling capacity of the spray cooling is larger than not only that of the jet cooling but that of the microchannel cooling.Pais et al.35experimentally demonstrated that the maximum dissipated heat flux of the spray cooling could be up to 1200 W/cm2with the surface temperature of 100°C under normal gravity. It means that the spray cooling can satisfy both the high-heat flux dissipation and required temperature range for the optimized operation of the electronic/electrical devices.Therefore,the spray cooling has been applied to many applications such as the thermal control of ground-based data center36and cooling of electronics in the ground.37

However, aerospace applications of the spray cooling are rather rare as numerous problems arise. Fig. 9 demonstrates the difference in the flow pattern between the ground-based spray cooling and the space-based one. The gravity flow is observed in Fig. 9(a)38while a strong surface-tension flow occurs in Fig. 9(b),39which indicates a significant divergence.It will absolutely bring about a clear difference in the heat transfer behavior which is coupled with the flow configuration.As shown in Fig.9(b),the large bubbles caused by the surface tension phenomenon deteriorate the heat transfer performance. What’s worse, the vapor–liquid separation and liquid droplet recollection can hardly be realized in the absence of gravity, which makes it difficult to organize a closed-loop aerospace-based spray cooling system. Utilizing the technology spray flash cooling, scientists from NASA have designed a compact flash spray evaporator to assist the radiator to reject the heat during the heat-load peak time.40,41As shown in Fig. 10,42the sprayed droplets impinge a HE in a space vacuum environment with rapid cooling methods such as convection and flash boiling/evaporation and then are exhausted as an EHS.

2.2.3. Radiation-based TMS

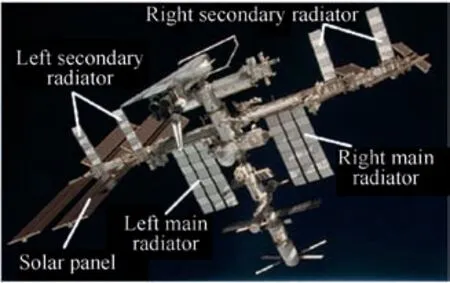

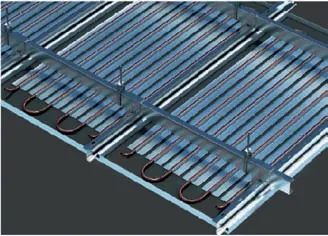

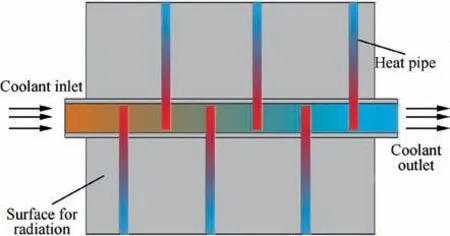

Radiation is the primary means for dissipating the waste heat from the spacecraft into space.43,44Fig. 11 demonstrates that multi-radiator panels are deployed in the International Space Station. Traditional radiators adopt the convection-based radiation scheme. Special paints, coatings, multi-layer structure, and transformable material were proposed to enhance the surface emissivity or even acquire a variable-emissivity to promote or control the radiative heat transfer. As shown in Fig.12,the hot coolant flows through the radiant panel where the heat is rejected through radiation. In order to satisfy the increasing heat dissipation demand, new type radiators such as heat-pipe radiator45and liquid-droplet radiator46have been proposed recently. Both radiators utilize the liquid two-phase heat transfer to enhance the radiative heat transfer.

Fig. 8 Three promising two-phase liquid cooling methods.

Fig. 9 Comparison between spray cooling under ground normal gravity and that under microgravity.

Fig.10 Photographic view of flash spray cooling in Orion Crew Exploration Vehicle.42

Fig. 11 Radiators deployed in International Space Station.

Fig. 12 Configuration of traditional convection-based radiator.

3. Development of aerospace active TMSs in China

3.1. FTMS

Scholars from China pay more attention to the optimization and improvement of the FTMS as it is the overall TMS for the current advanced aircraft. Their efforts mainly cover two research emphases:(A)enhance the cooling capacity of the fuel and (B) promote the cooling efficiency of the TMS. The cooling capacity of the fuel can be augmented through the endothermic chemical reaction such as thermal cracking and catalytic reaction. Scientists from Chinese Academy of Sciences did tremendous systematic research about the thermal cracking process of the fuel. A comprehensive understanding of the fuel decomposition process and fuel property alteration under the supercritical and cracking state was uncovered by Yu et al.47They experimentally compared the performance of model supersonic combustors with the injected liquid kerosene48and vaporized supercritical kerosene.49Fuel cracking characteristics and associated effects were studied experimentally through a set of fuel heating and delivery apparatus in their following studies.50Fan et al.51analysed the thermal performance of catalytic cracking of China No.3 aviation kerosene under supercritical conditions (1050 K and 7.0 MPa). It was found that the extra heat sink from the chemical thermal cracking can reach nearly 1.5 MJ/kg.Instead of thermal cracking reaction, researchers in China suggested that catalytic cracking reaction is more suitable for the heat sink enhancement of the FTMS as the thermal cracking is not selective and several competitive exothermic reactions such as coking could take place. Through the proper usage of catalysts,desired heat-absorbing reaction can be selectively realized and the cracking rate can be enhanced compared with that of the thermal cracking reaction.A novel idea of pseudohomogeneous catalyst systems was proposed by Bao et al.52to overcome traditional problems (rapid deactivation and high heat resistance)in the catalytic cracking reaction.Synthesized functional zeolite nanoparticles are dispersed into the hydrocarbon fuels to be functioned as catalyst. The fuel-based nanofluid shows an excellent catalytic activity and dispersibility where an enhanced cracking rate can be obtained. Several novel methods to fabricate the specialized catalytical nanoparticle were uncovered in their following studies53,54.Guo et al.55proposed a fabrication method of a highly dispersed resorcinarene-encapsulated nickel nanoparticles for the analytic decomposition of JP-10 which is a hydrocarbon fuel served as the propellant for air force and navy.Catalytic cracking of JP-10 by this kind of nickel nanoparticle is investigated in a quasi-homogeneous phase system. Experimental data show that the conversion of the JP-10 catalyzed by these nanoparticles is all significantly higher than that of thermal cracking at the whole tested temperature range, even 20%higher in the low temperature region (<570°C).56Various nanoparticles such as composite oxides and metals were investigated to be functioned as the catalysts to assist the catalytic decomposition of the fuel and they were proven to be effective approaches.57,58Jiao et al.59adopted Mn, Fe, Mo or W as a promotor to be introduced into ZrO2-TiO2-Al2O3composite oxides to prepare the catalyst. Experiments indicates that the Mo-supported ZrO2-TiO2-Al2O3have the highest catalytic activity where an 88.4% conversion and a total heat sink 3.79 MJ/kg can be obtained. In general, compared with the thermal cracking, the catalytic cracking can be realized in a lower temperature range and intensity of the conversion is higher through the proper utilization of the catalyst.Nanoparticle-based catalyst can enlarge such superiority at the maximum range as increased specific surface area and Brownian movement can facilitate reaction process effectively,which is highly preferred for the endothermic reaction of fuels.However, problems of nanoparticle deposition and deactivation need to be properly solved in the future before its practical application. Recently, platinum-nanoparticle-dispersed hydrocarbon nanofluids with hyperbranched polymer as stabilizer and initiator were designed by Wu et al.,60which has great potential to resolve the problems mentioned above.

Though the fuel-based heat sink can be enhanced from chemical reaction, such technology has not been applied to practical applications extensively. Another approach for the enhancement of fuel-based heat sink can be practically attained by the cooling efficiency enhancement through the smart usage of fuel, which is also a critical part of the USA INVENT project. For the purpose of optimized energy management,the subsystem of Adaptive Power and Thermal Management System (APTMS) plays a significant role in the optimized dynamic option of the power source and heat sink source according to the flight state including flight height,Mach number, flight phase, etc. The FTMS which could account for more than a half of the weight of the plane possesses the largest heat sink among all the available heat sinks,which determines that the FTMS is the core component of the APTMS.Admittedly,researches regarding this aspect in China are now in the start-up stage. Researchers from Beihang University contributed a lot to the development of the onboard FTMS. In early twenty-first century, Wang et al.61introduced aircraft utility system integration technology from the USA in which the F-22’s integrated ECS/TMS was elaborated. In addition, integrated utilities management system,more electric aircraft, and integrated FTMS were introduced in detail.Gao and Yuan62built static and dynamic simulation platforms to estimate the system performance and fuel penalties during the flight of a certain high-performance aircraft by using MATLAB simulation tools.The FTMS in this article is proposed to replace the traditional air cooling system for the equipment thermal protection system which is prepared for hypersonic vehicle. Simulation shows that compared with air cooling system, the cooling ability is significantly improved when the quantity of the ram air is severely depressed,suggesting that the FTMS is a promising candidate to supply abundant heat sink when air cooling is hardly available. Later, a more detailed FTMS model containing two symmetrical subsystems (each subsystem consists of one combustor, six fuel pumps, four fuel tanks, and two pumps) was established by Zhang et al.63using the simulation software Flowmaster.Dynamic fuel cooling capacity was carried out under various fuel consumptions where the dynamic distribution of MFR,pressure, and temperature in the FTMS can be derived in the meantime. Mao et al.64estimated cooling capacity and exergy penalty,which refers to exergy loss caused by the extra weight,drag,and energy consumption of the each heat sink,of various heat sinks including fuel,ram air,engine bleed air,and expendable heat sink under different flight conditions (flight altitude and Mach number). The comparison among various heat sinks was also conducted to identify which heat sink should be utilized for the sufficient heat sink and minimized performance penalty according to the certain flight parameters. Their proposed model could promote the real-time estimation of various available heat sinks to realize the optimized dynamic management and allocation for the purpose of avoiding the waste of heat sinks and prolonging the operating time of the TMS. In their following study, Yu and Mao65used Matlab/Simulink to establish a fuel-assisted single-phase TMS model where thermal control algorithm based on heat load identification and temperature feedback and heat sink allocation method based on cooling capacity estimation and heat load matching were also put forward.The simulation results demonstrate that the proposed model can satisfy the cooling demand and allocate the heat sink efficiently.

FTMS is becoming a critical part of the integrated TMS for the future advanced aircraft in the background of the USAproposed ‘‘INVENT” project. It is acknowledged that researches regarding FTMS in China mainly focus on the thermal control strategy under single flight condition and lack the entire real-time scheduling planning of utilization of the fuel in the whole flight profile.Enlightened by integrated TMS developed by the ‘‘INVENT”, investigations of intelligent management, selection, and control of various heat sinks where the fuel accounts for the biggest share for sure according to flight phases and modes are imperatively demanded also.

3.2. Air cooling and organization system

The air cooling strategy is severely depressed due to the development of the hypersonic vehicles. As the total quantity and cooling capacity of the ram or bleed air decline and heat load of the on-board equipment increases,air,as a cooling medium in modern aircraft, is primarily charged into the air-cooling HEs to cool the fuel or other heated coolant as shown in Fig. 3. It means that using air cooling alone cannot fulfil the cooling task of the on-board advanced equipment. However,the air cooling, as a primary scheme, still plays a significant role in the thermal management of the ECS in the commercial civil airplanes. The ECS functions to protect the on-board humans and electronics in the passenger/crew cabin from the extreme ambient environment at high altitude where the air temperature is about -55°C and the pressure is around or below 20 kPa. Humans, as another primary heat source,should be not only‘‘temperaturely”but also‘‘pressurely”controlled while considering the thermal comfort and health issue.Traditional air organization for the ECS is elaborated as follows: the bleed air is divided into two streams. One stream is directed depressurized and the other is first cooled by the ram air and then depressurized. These two streams are mixed with each other, and then charged into the passenger/crew cabin in which the cabin temperature and pressure can be controlled. Studies concerning this fields in China mainly laid emphasis on the ground-based ECS simulation system where experiment-based and CFD-based air distribution, temperature as well as human thermal comfort optimization were investigated. Experimentally, the bleed air was traditionally generated by compressor and furnace to obtain the desired temperature and pressure on the ground.Ma et al.66proposed an energy-saving method to produce the ram air flow in the ground through a turbo-compressor-assisted air cycle machine. The proposed method can obtain the ram air with desired low temperature and low pressure which simulates the environment of 0–10 km altitude while saving 35% power consumption compared with the traditional method.

Besides the ground-based realization of ECS,the optimized air distribution system which guarantees lower power consumption, high air quality, and healthier airflow was another research focus.As shown in Fig.13(a),the mixing air distribution system67where the fresh air flow is supplied from the top ceiling and taken away from the bottom was commonly applied to the commercial airplane in Boeing and Airbus in the early twenty-first century. Intensive efforts were paid towards air distribution improvement in China. Zhang et al.68proposed a novel air displacement where the air flow is supplied from the bottom and taken away from the top, which is illustrated in Fig. 13(b). The results infer that the proposed one can eliminate the contaminants more efficiently than the traditional one. Experimental research regarding the comparison among these three types was conducted to compare the displacement air distribution and mixing one using a novel set of evaluation system where the temperature uniformity and flow velocity uniformity, air mean age, and heat removal efficiency are considered. Experimental results show that the mean age of air for the displacement air distribution is significantly shorter than that for the mixing air system which indicates that the former one has higher ventilation efficiency. In addition, uniformities of the temperature and air flow are clearly better for the air displacement system. Zhang et al.69proposed a personalized air distribution system in which the conditioned air is supplied from personalized inlets installed in the seats or handrails so that the fresh air can be directly transported to the breathing area. This air system can reduce the CO2concentration by 30% compared with the traditional mixing air distribution system.Besides,Zhang et al.70adopted the Fluent to simulate the air flow patterns in a passenger cabin of three air distribution systems: traditional mixing air distribution system, under-floor displacement air distribution,and the proposed personalized air distribution system.Simulation results show that the proposed one creates the best cabin environment considering the combined effect of air velocity and temperature, airflow pattern, CO2concentration, and energy consumption. Based on the personalized air distribution system proposed in Zhang’s work,69Pang et al.71improved the personalized air distribution system in which the air is supplied from the under-floor and seatbacks and is absorbed from the ceiling and bottom of baggage hold. Using laser-based flow visualization technology, the proposed scheme was experimentally proved to be able to overcome stratification of the contaminated air above passengers’heads.Gao and Niu72developed a special air system which is placed right beneath the nose of the passenger as shown in Fig. 14 to ensure a highly efficient usage of the fresh air and a healthier air flow which can shield 60%of air pollutants.Past researches focused on the passive air distribution improvement to acquire a both healthy and economic air distribution system in the cabin. It suggests that the personalized air supply system is the relatively optimized air transport system in terms of the health issue, thermal comfort, and energy consumption.

Fig. 13 A traditional type of mixing air distribution system.

Fig. 14 A ventilation seat with a personalized air supply system.72

With the development of MEA/AEA, active measures to realize friendly environmental impact and efficient energy usage should be considered for the air cooling and organization design for the ECS. As mentioned above, the non-MEA/-AEA is designed to rely on the bleed air introduced from the aero-engine to maintain a comfort temperature and pressure. However, the air bled from the engine would reduce the operation efficiency, waste a large amount of energy, and cause a loss of thrust.73Therefore, a ‘‘no-bleed” ECS, which is shown in Fig. 15, was proposed by Sinnett.74The biggest innovation of this system is that the pressurized air is compressed by the compressor driven by the electrical motor in the electrical control module. Therefore, no air is bled from the engines which means that the ECS has no direct impact on the thermodynamic cycle of the engine where the efficiency of fuel consumption and energy management can be elevated.Moreover, the ‘‘no-bleed” ECS has been equipped in ‘‘787 Dreamliner” which is the latest aircraft of Boeing Company,manifesting the numerous economic advantages. Scholars in China did extensive research revolving this revolution of electrification of ECS. Jiang et al.75compared the engine performance of the ‘‘no-bleed” ECS and that of the traditional one from the aspect of exergy loss. The results indicate that the‘‘no-bleed” ECS would cause higher specific fuel consumption which is defined as the fuel consumption divided by thrust for extracting the same amount of exergy. However, the ‘‘nobleed” ECS is much more efficient as it requires less energy from engine. Such superiority can clearly emerge when the‘‘no-bleed”ECS is equipped in large-scale long-range airplanes as the total consumption of the fuel would be largely decreased.In order to solve the cabin humidification problem,Chen et al.76developed an integrated ECS where purified water is injected into the suction part of the turbine in the air cycle machine module without modifying the system structure. Experiment data agree with the established system analysis model in which the fuel penalty decreases by 1% under the proposed integrated system for the lower demand of ram air. It shows that the integrated system can increase the cabin smoothly to about 27.9%and the system operation is effective and economic. Yang et al.77promoted an active experimentverified energy-saving method for the ‘‘no-bleed” ECS. A turbocharger was integrated in the new ECS to transfer the energy from the cabin exhaust air into mechanical and pressure energy. A case study shows a 66.2% reduction in the input power compared with the ‘‘no-bleed” ECS since the energy recovery of the discharged air can effectively reduce the demand of engine power and the required pressure ratio of the compressor.

It can be concluded that research on the ‘‘no-bleed” ECS was confined into a sort of hardware optimization where various new components or elements were proposed to be integrated in the original ‘‘no-bleed” ECS. In contrast,investigation into a viable scheduling method to realize minimum power utilization of the ECS under different flight phases, which can maximize the superiority of the ‘‘nobleed”, is severely lacking. For the previous ECS, power is extracted from the engine bleed air in which the pressure and temperature of the bleed air are unchangeable, so the power optimization technique can only be designed in the ‘‘worst case” in which the power consumption is the largest under a certain flight phase. That is a primary reason for the low efficiency of the traditional ECS. For the ‘‘no-bleed” system, the power is generated from the electrical motor with adjustable speed, which can realize a variable temperature and pressure control of the ram air.It means that flexible power generation can be achieved. Current studies in China have not addressed the control of the power generation of the‘‘no-bleed”ECS and the dynamic optimized scheduling for the power generation under different flight phases. A minimum amount of power usage for the ECS is promised to be achieved with an optimized structural architecture, an optimized internal air distribution system, and an optimized scheduling of the power generation mechanism.

3.3. Non-fuel liquid cooling strategy

Capable of using both sensible and latent heat, the non-fuel liquid cooling strategy is adopted as the advanced heat transport method to dissipate the high heat flux from the object.Airborne avionics and space-based equipment will be subjected to various accelerations and gravitational fields with changes both in direction and magnitude, so an appropriate liquid cooling method can provide stable cooling capability in such complicated mechanical and gravitational environment.

Fig. 15 Schematic view of ‘‘no-bleed” air cooling system for ECS (adapted from Sinnett’s work74).

3.3.1. MPFL

As mentioned above,the MPFL has become a mature technology in which temperature control algorithm is critical to obtain the thermal control performance. Currently, the algorithm adopted in the China spacecraft is a look-up table one based on the experimental data. Such simple control method may have low robustness and low precision for temperature control.Much attention has been paid to the thermal control algorithm for the single-phase MPFL. Liu et al.78developed an agent-oriented intelligent control strategy for the nanosatellite MPFL.The bypass ratio λ and the radiator emissivity ε are the two controlled variables which can be realized by the actuation of the three-way valve and the louver-based radiator to stabilize the equipment temperature which is the controlled object.A combined expert system and fuzzy reasoning control system was employed. Simulation results show that the combined controlling mechanism of both the three-way valve and the radiator emissivity can achieve a nearly zero static error:when the heat load has a+160%step-disturbance,ε will be aggressively regulated; when the heat load has a -150%step-disturbance, λ will be primarily controlled; when normal step-disturbance is loaded, both ε and λ will be adjusted dynamically. Li and Lee79proposed the fuzzy coordination control strategy where ε and λ are still the controlled variables and the temperature of the downstream of the Microchannelbased Heat Exchanger(MHE)array θois the controlled object.Fig. 16 displays the overall fluid organization of the MPFL and the architecture of the control strategy. As shown in Fig. 16 (b), the fuzzy coordination control includes a fuzzy decision unit to derive a coordination factor β and two synergic PID controllers to adjust ε and λ. Simulation shows that the proposed control system is more reliable and robust by avoiding the frequent regulations of the three-way valve and radiator compared with the two separate PID controller.Besides, smaller overshoot in temperature and smoother adjustment in the two controlled variables can be obtained through the proposed scheme. Besides the three-way valve and radiator,the operation of the pump can also be controlled to obtain a flexible TMS. A PMW control strategy implemented on mechanical cycling pump was proposed by Liu et al.80The MFR G is directly adjusted by controlling the pressure difference between the pump outlet and inlet the pumping pressure ΔPpumpthrough Eq. (1). Ground prototype was established and an autonomous temperature control effect of±0.5°C was attained. It also suggests that the PMW-based control requires lower energy consumption in the control tasks.

where G is the mass flow rate, and Rfis the flow resistance.

It is acknowledged that the controlling section does consume energy in the electrical-driven actuation component. In order to reduce the energy consumption of the operation of the MPFL, Wang et al.81proposed a novel wax-driven selfadaptive three-way valve to substitute traditional electricdriven three-way valve as shown in Fig. 4 for the purpose of enhancing systematic reliability and reducing energy consumption. Traditional three-way valve utilized electrical power to adjust the opening degree to regulate the MFR of the CP based on a set of algorithms where the adaptability is acquired by a high energy consumption. The proposed self-adaptive valve is a wax-driven component in which wax was inserted into to directly sense the fluid’s temperature. When the temperature is higher than the reference temperature, the wax would be melted and expanded to trigger the actuator to enlarge the opening degree, and when the temperature decreases below the reference temperature, the wax would be solidified and shrunk to reduce the opening degree. The reference temperature is determined by the thermophysical parameter of the selected wax. Mathematic modelling of the MPFL with the proposed self-adaptive valve, radiator, and heat source was established to predict temperature dynamic performance.Simulation results show that the proposed scheme can be utilized as an energy-saving and effective thermal control method where a tighter phase-change temperature range can attain a more precise temperature control result. In their following research, a self-adaptive CP where a paraffin-driven thermal control valve is installed in the front part of it was invented by Wang et al.82The largest innovation lies in the paraffindriven thermal control valve which is shown in Fig. 17 (a)and (b). Fig. 17 (c) and (d) illustrate typical positions of the valve and the operating mechanism of it. Experiment shows that a ±2°C precision was obtained with current prototype in which the selected paraffin’s phase-change range was between 40°C and 44.4°C. Thermal control performance comparison using two species of paraffin was investigated experimentally in their later study.83It shows that the practical range of the controlled temperature corresponds to the paraffin’s phase-change temperature range. A tight phase-change temperature range can enhance the precision of the thermal control performance but will deteriorate the stability of the system where the settling time is not satisfied compared with the system using the paraffin with relatively wide phasechange temperature range.Instead of the paraffin,Guo et al.84utilized shape memory alloy to act as the actuator of the thermal control valve which locates in the inlet of each CP to realize MFR adjustment. Such method can avoid the potential danger of paraffin leak and relatively large temperature fluctuation. Literature in this paragraph exhibits approaches to a self-driven flexible MPFL without any energy consumption in temperature control. Thermal capacity flexibility obtained by material’s thermo-physical parameters with reduced energy consumption and high reliability will be one of the focuses of the future MPFL for the energy-optimized aerospace vehicle.

Employing the Green’s function, Su et al. simulated the steady-state85and transient86temperature map within the CP using Green’s Function. Their analytical results were verified by the experiment where the relative error was within ±3%.In order to decrease the temperature non-uniformity within the CP, Wang et al.87proposed a hybrid cooling method integrating CP and forced gas to maintain the temperature of a space-based battery pack as shown in Fig.18.A fan is installed in the lower side wall of the battery package with the fins attached to the bottom surface of the CP which could be expected to improve the battery temperature distribution.CFD simulation illustrates that the maximum temperature can be reduced by 3.54°C. Xu et al.88utilized a thermoelectric-cooler to balance the temperature distribution within the CP where the thermoelectric-cooler can transport the heat from CP’s high temperature area to its low temperature region to improve the temperature uniformity of the cooling object. Electric current of the thermoelectric-cooler can be adjusted by fuzzy-PID controller or BP-PID one to acquire a relatively depressed temperature overshoot and steady state error, as well as short response time. Recently, the CP employed in the fluid loop has been becoming the microchannel one for the enhanced heat transfer. Please refer to Section 3.3.4 for the detailed development of the microchannel cooling.

Fig. 16 Fluidic organization of MPFL and proposed control strategy (adapted from Li’s work79).

Fig. 17 Structure of self-adaptive CP.82

Fig. 18 Hybrid cooling scheme of space battery (adapted from Wang’s work87).

Radiator optimization of the MPFL should be emphasized as well.A MPFL for cooling the lunar surface nuclear reactor power system was proposed by Fan et al.89It showed that the optimized surface temperature of the radiator can be between 480 K and 520 K for an optimized radiator size and mass for a given situation in which the total required heat rejection,outer space temperature, and surface emissivity are fixed to be 400 kWt,300 K,and 0.9 respectively.This optimization might have an engineering value in a certain thermal environment on the lunar surface but would be a failure considering the significant temperature difference between the lunar day and night time. A flexible radiator would be a preferred option for this situation.Li et al.90adopted fuzzy control strategy to establish a ground equivalent radiator. Their purpose was to simulate the space radiative heat transfer under the convective heat transfer in the ground using a thermoelectric-cooler, a platefin HE,and a forced cooling fan.Through controlling the electric current of the thermoelectric-cooler and the electric current of the fan, the cooling capacity of thermoelectric-cooler and the thermal resistance of the equivalent radiator can be regulated dynamically. This research can enhance the feasibility of the ground-based thermal experiment of MPFL economically while not harm the test precision.

Facing the increasingly heat load of the on-board equipment, Two-Phase MPFL (TPMPFL) is more recommended by thermal scientists. A ground-based TPMPFL thermal experiment in which a 20 m evaporator was installed in this system was tested by Liu et al.91CO2was selected as the coolant due to its low liquid/vapor density ratio which facilitates a smaller volume expansion in the evaporator. Strategies to determine and control the coolant temperature in evaporator were developed to guarantee a liquid phase before the coolant enters the cycling pump, which is a crucial factor to a reliable and durable operation of the TPMPFL. In their following research, both ground test and space verification were conducted with the assistance of the Chinese Tianzhou-1 Cargo Spaceship (TZ1).92Since it is the first on-board test for the proposed TPMPFL, the maximum dissipated heat was set to be 80 W. Different operation modes in the preliminary experiments were organized to show the system’s high reliability as the coolant in the inlet of the pump can be remained to be liquid phase.Another TPMPFL where the ammonia was selected as the coolant as shown in Fig.19 was fabricated by Yu et al.93The evaporator was a diamond-made microchannel type prepared for a high heat flux impact, and the condenser was fabricated by the phase change material to absorb the heat from the evaporator. Both ground and on-orbit experiment could achieve a high heat-flux dissipation up to 271 W/cm2which manifests the superiority of the two-phase heat transfer.

Two-phase processes are expected to occur in the evaporator of the TPMPFL, which means that only the radiative heat transfer in the radiator is not adequate to reject the equivalent heat to the outer space. One solution is to add a two-phase heat sink in the TPMPFL which can enhance both heat dissipation capability and flexibility. Guo et al.94proposed a MPFL with a radiator-sublimator dual heat sink system which is demonstrated in Fig. 20. The dual heat sink system consists of a radiator and a sublimator component which can be collaboratively operated to dissipate the heat ∑ni=1Qiwith a desired controlled temperature Tcon. Upstream of both the radiator and sublimator component is installed with three-way valves for controlling Tconby adjusting the opening degree of the valves between 0 and 100%. A CP and a sublimator form the sublimator component where the heat is transferred from the coolant flowing through the CP to the sublimator. Based on the mathematic models of the radiator and water sublimator, the authors performed ground-based experiments using the method of hardware-in-loop, in which thermal behaviour of the dual heat sink system was simulated by a valvecontrolled cooling loop. The results show that the proposed system can provide a wide range of heat dissipation capability(400–1600 W), suggesting a strong thermal flexibility suitable for the low earth orbit satellites. In their following study,Zhong et al.95made a slight structural modification of the proposed MPFL,as shown in Fig.21,with the dual heat sink system in which the sublimator resides in the upstream of flow direction compared with the radiator. The operation mechanism of the dual heat sink system is described as follows: In most cases,the three-way valve 1 will short out the sublimator to let the coolant go through the bypass line, so the radiator will be operated as the only heat sink, and thus Tconwill be only adjusted by the PID-controlled three-way valve 2 in this case. When the heat load increases rapidly and exceeds the maximum heat dissipating capability, the three-way valve 1 switches and the sublimator will function as the supplementary heat sink.Dynamic in-loop performance of the sublimator and the optimal control strategies in terms of temperature control efficiency of the proposed system were investigated numerically.Adding another heat sink may enhance the cooling capability of the system but increase the systematic complexity as well.What’s worse,the failure of the sublimator will also deteriorate the reliability and such integration has not been verified by the on-orbit test. There are several researchers who are looking for another solution which involves the improvement of the radiator itself.

Fig. 19 A TPMPFL proposed by Yu et al (adapted from Yu’s work93).

Fig. 20 An MPFL with dual heat sinks proposed by Guo et al.94

Fig. 21 An MPFL with dual heat sinks proposed by Zhong et al.95

As mentioned in Section 2.2.3, the liquid-droplet radiator and heat-pipe radiator are highly recommended. As shown in Fig. 22,96the liquid-droplet radiator consists of a droplet generator and a droplet collector, in which an originally passive heat dissipation type becomes an active one. The heated coolant accumulates in the droplet generator where the coolant is atomized into numerous droplets to form a droplet sheet where the radiation occurs,and then the droplets will be collected in the droplet collector.The radiative heat transfer can be significantly augmented because the atomized droplets can increase the radiation surface area for a given MFR.One shortcoming of this radiator is that evaporation will occur during the flight of the droplets,which leads to a constant mass loss during operation. Therefore, the system should overload more coolant to guarantee a longer operation time as when the overloaded coolant is evaporated,the liquid-droplet radiator will fail to be operated.A combined radiation-evaporation model of the silicon oil droplet sheet was established by Ye and Ma.97Evaporation transfer equation and radiation heat transfer model were built to investigate the influence of droplet exit temperature,and width of the droplet sheet on the temperature distribution, evaporation rate, and system lifetime. It shows that the main contribution to the evaporation rate is from the high temperature of droplet at the exit of the droplet generator. Thus, this temperature also affects the system lifetime significantly. Simulation shows that if the droplet exit temperature decreases from 320 K to 320 K, the system lifetime would increase by nearly nineteen times. Yin and Liu98modelled radiative heat transfer in a two-dimensional droplet sheet with phase-change droplets. The authors utilized the Mie theory to calculate the radiative properties of the droplet sheet and the discrete ordinates to solve the distribution of the radiation field. Calculations manifest that the size distribution has a strong effect on the radiative heat flux when the droplet velocity is above 100 m/s. An enhanced radiative heat flux results from an increase in the droplet velocity for a given volume fraction of droplets in the sheet. Numerical solutions of the radiative energy conservation and evaporative characteristics of the silicon oil droplet are proposed by Qin et al.99Grid independence analysis of the temperature distribution of the droplet sheet was conducted where the temperature distribution and evaporation loss were obtained. Numerical results show that the grid number of the thickness direction is recommended to be 100 times larger than that of the optical thickness to obtain a reliable temperature distribution. Both high droplet exit temperature and high velocity contribute to a high evaporation loss rate which is unfavourable for the durable operation of the liquid-droplet radiator. In order to prolong its lifetime, one popular method is to enlarge the MFR of the droplet to minimize the exit temperature.

Fig. 22 Structure of MPFL with a liquid-droplet radiator(adapted from Zeng’s work96).

Fig. 23 Schematic view of heat-pipe radiator.

Admittedly, the mass loss of the liquid-droplet radiator restricts its extensive space applications. Able to perform a durable enhanced radiative heat dissipation task, the heatpipe radiator, which is planned to be deployed in the future space unclear power system where the waste heat is huge and can be up to an order of 103 kW,has been paid more attention to recently. As shown in Fig. 23, the heated coolant transfers the heat to the evaporation end of the heat pipe, and then the heat is transferred into the condensation end of the heat pipe where the heat is rejected to the radiation surface. Usually, the radiation surface is composed of fins or areaexpanded structure where the heat can be dissipated into the space via radiation. Zhang et al.100uncovered the thermal design of a heat-pipe radiator in terms of working fluid,capillary structure, and container for the space TOPAZ-II power system where approximately 110 kW waste heat should be rejected by the radiator. The authors also analysed the steady state of the thermal performance of the proposed potassiumbased heat-pipe radiator and compared it with that of the traditional convection-based radiator.The radiator with 200 heat pipes was selected considering the lower mass and higher operational limit. The comparison shows that the heat-pipe radiator has better isothermal performance due to the almost constant vapor temperature. The maximum temperature difference of a single fin for the heat-pipe radiator is only 30 K while that for traditional one is about 100 K,which means that the heat-pipe one will suffer less from the thermal stress.Transient characteristics and heat transport limits of the potassiumbased heat-pipe radiator for a space nuclear power reactor in the space environment were analysed by Wang et al.101Numerical results show that it spends 5 min for the heat pipe starting up from frozen state to fully active state where an excellent isothermal process would occur inside the heat pipe.During the start-up process, the sonic limit would be encountered with higher possibility compared with other limits which means that more attention should be paid to the sonic limit in the design stage of the heat pipe.In general,the proposed heatpipe radiator has a fast response under the start-up and transient conditions due to an equivalent thermal conductivity of up to 82255 W·m-1·K-1.Possessing the overall understanding of steady-state and transient thermal performance of the heatpipe radiator, Zhang et al.102established a thermal–hydraulic model of the whole space thermionic reactor TOPAZ-II, integrating core reactor’s thermal–hydraulic and neutron kinetics model, radiator model, and MPFL model. The authors examined the steady state of the full power operation and two accidental transient performances(partial loss of flow accident and overpower condition)of the on-orbit space reactor.The calculated steady-state parameters of the reactor demonstrate a good agreement with those of the designed one,which can validate the feasibility of the established model. It also indicates that the two selected transient accidental conditions have no serious problem to the TOPAZ-II where the fuel component and other critical materials are all below their temperature limits since the coolant has a sufficient boiling margin. Instead of the fin-based surface for radiation as shown in Fig. 24 (a), Xu et al.103proposed metal-foam-based radiation surface which is illustrated in Fig.24(b).Experimental results demonstrate that the metal-foam-based surface has better heat dissipation performance compared to the traditional fin-based one. And the thermal resistance between the condensation end and the ambient air can reduce by 10% when the metal foam with the pore density of 5 PPI is adopted.It also shows that the primary fraction of the thermal resistance of the proposed scheme comes from the poor soldering technique which limits the cooling performance of the proposed heat-pipe radiator.

This section introduces the domestic progress of the MPFL,which has been extensively applied to the aerospace vehicles.In general, the currently adopted MPFL is a single-phase one where the fluid management in the complicated environment of space and high-altitude area is reliable. Although the fundamental research on the space-oriented two-phase heat transfer has been explored intensively,104,105the two-phase MPFL is still very rare as there is no guarantee for the cycling of the two-phase system under multiple-gravity. For example,the liquid–vapor separation under the microgravity is extremely difficult. Therefore, investigation involving the system cycling of the two-phase MPFL under the space and air conditions should be the focus in the future.

Fig. 24 Surfaces for radiation.103

3.3.2. Microchannel cooling

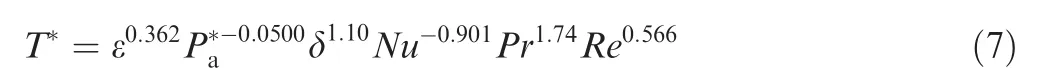

As shown in Fig. 8(a), microchannel cooling is an efficient cooling method for the aerospace application as the confined effect acquired from the micro-scaled channel can possess a decent gravity-immunity.106The coolant can be confined in the channels, which facilitates the flow management under complex gravitational fields. Several studies concerning the liquid-based single-phase and two-phase heat transfer in microscale channels under accelerations were performed in China.Xi et al.107studied the flow and heat transfer characteristics of the swirl microchannels.Unlike the flow in the straight channels,swirl flow motion will produce the centrifugal forces upon the coolant itself. Comparative study indicates that the heat transfer in curved microchannels improves by 50% compared with that in straight microchannels,which can be attributed to the secondary flows inside the swirl microchannels caused by the centrifugal force. Yang et al.108focused on the flow characteristics of the curved microchannels. They found that the friction factor calculated from the traditional Darcy Equation is much smaller than the experimentally measured one. For the purpose of explaining such divergence, a roughness-viscosity model was introduced into the classical one to match the experimental data. Experimental study on the two-phase heat transfer in a narrow straight rectangular channel in rotating state was conducted by Zhang et al.109.Experimental data illustrate that the CHF is enhanced due to the effect of the acceleration since it facilitates two-phase mixing up and bubble separation.Besides,a fitting correlation for the CHF considering the acceleration, velocity, inlet temperature,heating position,and channel structure was proposed as shown in Eq.(2)where the Weber number is defined by Eq.(3)and the dynamic load Gxis calculated by Eq.(4).Effects of rotational acceleration on the heat transfer in both straight and swirl microchannels were investigated by Xie et al.110with the assistance of a rotating table shown in Fig.25 in which a1is the centrifugal acceleration, a2is the acceleration caused by curvature of the microchannels, and acis the Coriolis acceleration. The results show that the influence of the acceleration upon the swirl microchannel is reduced, compared with that upon the straight one. Therefore, it can be concluded that the swirl microchannel has a larger resistance against acceleration in terms of the Nusselt number and friction factor. In addition, a higher MFR can also reinforce the acceleration resistance.

where qCHFis the critical heat flux,cpis the sensible heat of the coolant, ΔTsubis the inlet coolant subcooling degree, hfgis the latent heat,ρgis the saturated vapor density,ρlis the saturated liquid density,L is the length of the channel,Gxis the dynamic load,H is the height of the microchannel,W is the width of the microchannel, γ is the heating orientation, We is the Weber number, σ is the surface tension force, lais the distance from the test section center to the rotating center, n is the rotation rate, and g is the gravitational acceleration.

For the research above,traditional coolant such as distilled water, water-based alcohol solution, and freon was adopted.However, the microchannel using traditional coolant is reaching its heat transfer limitation, and much attention has been paid to the nanofluid as a novel functional fluid for the enhancement of heat transfer111.Xu et al.112did a comparative study on the heat transfer performance using distilled water and Al2O3-water nanofluid (0.2 wt%) in a single rectangular microchannel. It was found that the heat transfer coefficient of the nanofluid is significantly larger than that of the water(17% enhancement). One primary reason could account for this enhancement:compared with the purified water,the nanofluid has a smaller bubble departure size and a higher bubble departure frequency which is originally from the decreased surface tension force acting on the bubble. In addition, the common problem of deposition for the proposed nanofluid was not observed after weeks’operation,suggesting a high feasibility of using the nanofluid as coolant in the microchannel cooling area.Dong et al.113studied the boiling heat transfer characteristics of Al2O3-water nanofluid in microchannel under an acceleration force. The results show that the effect of acceleration has a negative impact on the boiling heat transfer in the swirl microchannel. The heat transfer coefficient reduces with an increase of the acceleration magnitude. This phenomenon contradicts that observed by Zhang et al.109where a straight microchannel was the object and water was adopted as the coolant.They also gave the reason for the deterioration of the heat transfer: a high pressure would be generated upon the fluid,resulting in an increase in the saturated temperature.That will lead to an increase in the temperature of both coolant and channel wall which manifests degraded heat transfer performance.It can be concluded from the above literature review that the acceleration effect can,on one hand,disturb the internal flow pattern which is a favorable element for the enhanced heat transfer, but the elevated internal pressure will, on the other hand, deteriorate the cooling performance. There is a sort of trade-off existing in such acceleration-exerted flow heat transfer in microchannel.

Microchannel cooling under microgravity was investigated by Yu et al.93with the assistance of the TZ1 which was launched on 20 April, 2017 from Wenchang Space Launch Center, Hainan Province, China. The diamond-made microchannel-based evaporator, whose channel width is 0.2 mm and height is 1 mm, was integrated in the TPMPFL shown in Fig.19.Deviation between the ground-based thermal performance and the on-orbit one is within 10% which suggests that the gravity effect in the two-phase heat transfer is limited. Specifically, the heat transfer performance of the microgravity experiment is slightly better than the groundbased one due to the rapid bubble movement in the on-orbit microgravity environment.

The microchannel cooling technology can be regarded as a critical component of the MPFL where the heat is from the cooling object to the fluid loop. The microchannel can boost the contact area of the coolant to enhance the coolant efficiency and it can facilitate the management of the two-phase flow within the microchannel because of its confined space.Such technology would achieve a big development on the condition that the breakthrough of the two-phase MPFL is obtained, which has been elaborated in the above section.

3.3.3. Spray cooling technology

Spray cooling is regarded as the next-generation high heat flux dissipation measure. Investigation on the aerospace-oriented spray cooling is the hotspot not only in China but all over the world as there are several critical problems on the aerospace application. One is that droplet heat transfer and flow pattern can be affected significantly by gravity greatly as shown in Fig. 9 where the unknowns related with the change in behavior in various gravitational fields could impede the deployment of the spray cooling system aboard;another is that the cycling and management of gas–liquid two-phase flows are difficult to be controlled in various gravitational fields, which restrains the application of the closed-loop spray cooling system aboard, as Silk EA, a NASA researcher specializing in space thermal technology, commented that more attention should be paid to liquid management and phase separation techniques in future research concerning aerospace spray cooling system.114Researchers in the USA and Japan mainly focused on the droplet heat transfer and spray flow pattern under microgravity, which contributes to the solution of the former problem, while scientists in China laid more emphases on the systematic fluidic organization and optimization of the closed-loop spray cooling system aboard. Wang et al.115utilized Metal Porous Materials (MPMs) to manage the twophase gas–liquid delivery across the spray cooling system. In the spray chamber, the target surface is covered by the MPM where the high permeability of the MPM ensures an efficient capture of the droplet and the superhydrophilicity of it ensures a high-efficiency vapor–liquid separation even under microgravity. The operation of the proposed system can be described as the atomized droplets are jetted to a land of sand,so the droplets can be captured in various gravitational field.A four-node thermal network model and thermal control strategies for the purpose of predicting the temperature trend and maintaining the temperature range under different heat load levels were established. Simulation shows that compared with the PID,the fuzzy-PID control scheme is more feasible to control the pump voltage in order to realize the temperature control. As shown in Fig. 26, experimental study of the MPMinvolved spray cooling system was conducted by their follow-up research.116MPM selection criteria based on its functioning were covered. Besides the function of droplet capture and liquid–gas separation, the MPM, on one hand, provides a strong effect of the surface tension in the cooling region which means that the experimental data from the normal gravity could be comparable with that from the microgravity because the surface tension forces instead of gravity govern the flow and heat transfer in microgravity as shown in Fig. 9. It, on the other hand, offers a self-sufficient cycling power – capillary forces – for the delivery of the coolant as the function of the porous wick in heat pipes. Using the proposed scheme, the two functions mentioned above can be relatively maximized. It suggests that the selected MPM with the pore diameter of 0.16 mm, porosity of 98%, and permeability of 4×10-7m2can have a Bond number of 0.003 which means that the effect of surface tension forces is about three hundred times that of gravity and a fluidic COP of 65 which means that the effect of capillary forces is sixty-five times that of fluidic resistance forces. However, a layer of MPM covered upon the surface will increase the thermal resistance that deteriorates the heat transfer absolutely. Wang et al. proposed a surface semi-covered by the MPM in their investigation.117Experimental data show a maximum enhancement of 125.3% in terms of the heat flux compared with the surface fully covered by the MPM. In addition, experimental empirical equations for thermal prediction of the semi-covered and fully-covered surfaces were obtained as displayed in Eq. (5) and Eq. (6)respectively.

Fig. 26 Ground-based apparatus of MPM-involved spray cooling system.116

where Nu is the Nusselt number,χ is the dimensionless temperature, and η is the spray effectiveness.