异双活性基三拼色染料在废烹饪油/水二元体系中的配伍性能

刘林云 董旭烨 刘芷钧 李锦冠 许嘉宁

摘要: 纺织印染工业中的纤维素活性染色面临的主要问题是高耗盐、高耗水和高排污等。在以废烹饪油为染色介质的研究中,考察了染色机理、烹饪油的去除效率及回用方法等。为扩展其应用范围,本文从固色时间对相对固色率的影响、染料投入量对固色效率的影响、拼色稳定性等方面研究了异双活性基三拼色染料在烹饪油/水二元体系中的配伍性能。结果表明,单个染料在棉布中某时刻的固色量差异较小;随着三拼色染料用量的增加,三拼色染料在棉布上的固色量的总和呈现线性增加;在二元体系中,三拼色染料具有良好的拼色稳定性,有色棉布的常规色牢度未明显发生下降。

关键词: 纤维素染色;应用范围;异双活性基三拼色染料;废烹饪油;二元体系;配伍性能

中图分类号: TS193.5

文献标志码: A

文章编号: 1001-7003(2023)04-0031-07

引用页码:

041105

DOI: 10.3969/j.issn.1001-7003.2023.04.005(篇序)

在当前的纺织原料印染加工中,纤维素的活性染料染色仍然是一种“三高(高耗水、高耗盐、高排污)”工艺,染色后的洗涤及污水处理的成本约占印染加工成本的50%[1]。从20世纪70年代至今,尤其是近20年内,众多的非水或少水染色体系被研发出来,如超临界流体(二氧化碳)[2]、二元有机溶剂体系(二甲亚砜/辛酸乙酯[3]、二甲亚砜/四氯乙烯[4-5])、少水体系(乙醇/水[6-7]、石蜡/水[8-10]、十甲基环五硅氧烷/水[11-14]等),这些新体系的主要优点有染料利用率高、无盐或低盐促染、皂洗用水少等。在这些染色媒介中,除二氧化碳外,基本上所有的非水溶剂都存在或大或小的生物毒性、闪爆风险、价格昂贵等不足。

在“非水介质染色关键技术研究与产业化示范”项目中,报道了以废烹饪油(Waste cooking oil,WCO)作为活性染料染色介质的染色技术。曾经WCO是一种令国人谈虎色变的城市餐饮废弃物,当前中国的WCO年产生量预计在560万t[15]。虽然,关于WCO的再利用有众多的途径,但是将WCO用于印染中的染色加工将是一条兼具环保、安全、经济等多方面特点的方案。在之前的研究中,分别考察了一氯均三嗪和乙烯砜型活性染料在WCO体系中的染色机理、染色后织物上WCO的去除效率、WCO的回用性能及回用方法等方面[16-18]。在当前纤维素类纺织品的活性染料染色加工中,很大一部分有色纺织品是通过染料之间的拼色实现的[19-21]。在活性染料的拼色染色中,所使用的三拼色染料对棉布具有接近的固色速率或固色率,随着织物颜色深度的增加,保持色光的一致性对于染色棉布具有重要意义,这也就是所谓的活性染料染色性能中的配伍性。而活性染料在WCO染色体系中的配伍性,还没有被报道。

本文选取了在纤维素染色中常用的异双活性基染料,对比研究三拼色染料在常规水介质和WCO介质中的配伍性能,分别考察了在不同固色时间的固色速率、在不同投入量时的固色效率、拼色稳定性及常规的色牢度(摩擦、日晒、洗涤)等,以期验证WCO染色体系替代传统水介质染色的可能性。

1 实 验

1.1 材 料

异双活性基三原色商品染料(菲诺染料化工(无锡)有限公司),其中C.I.活性红195、C.I.活性黄145、C.I.活性蓝222分别简写为R195、Y145和B222,所有染料在使用前都经过脱盐纯化处理。无水碳酸钠(Na2CO3)、浓硫酸(H2SO4)、无水硫酸钠(Na2SO4)、氢氧化钠(NaOH)(国药试剂有限公司)。废烹饪油(WCO)(厦门华亿宏进出口有限公司)。由于WCO中的脂肪酸和甘油等极性物质会对活性染料的染色结果有负面影响,所以在染色前WCO须经碱炼除杂处理。纱支为14.58×14.58 tex,密度为567×335根/10 cm,平方米质量为135 g/m2的100%棉平纹梭织漂白布(溢达纺织有限公司)。满足ISO 105-C10:2006的不含荧光增白剂的洗涤剂(上海米恩检测仪器有限公司)。

1.2 方 法

1.2.1 废烹饪油(WCO)-水染色

染色方法基本按照本研究之前成果[17]:将2 g棉平纹梭织漂白布,在由无水碳酸钠配制的质量浓度40 g/L的溶液中预处理1 h左右,之后为控制棉布上碱的总量及保证碳酸钠的均匀性,按照印染加工中最常用的两浸两轧工艺,控制棉布的带液量为100%(相对布重),在90 ℃的R-3型定型烘干机(佛山精柯纺织印染设备有限公司)上处理约30 s后,将其置于恒温恒湿房(温度21 ℃,湿度65%)中回潮24 h。将回潮后的棉布,按照如图1所示的工艺曲线进行染色处理,浴比为1︰20(棉布︰水︰WCO=1︰1︰19)。染色结束后,棉布上的SHB-Ⅲ WCO按照真空抽液(广州华瑞化玻仪器有限公司)、P-AO型轧车轧液(佛山精柯纺织印染设备有限公司)和两浸两轧等一系列连续的工序进行回收。最后,后处理结束后的有色棉布,按照传统四步水洗法进行水洗以去除浮色。

1.2.2 传统水染色

将2 g棉平纹梭织漂白布,按照类似1.2.1的染色工艺曲线进行染色处理,浴比为1︰20。染色结束后的有色棉布,按照传统四步水洗法进行水洗以去除浮色。

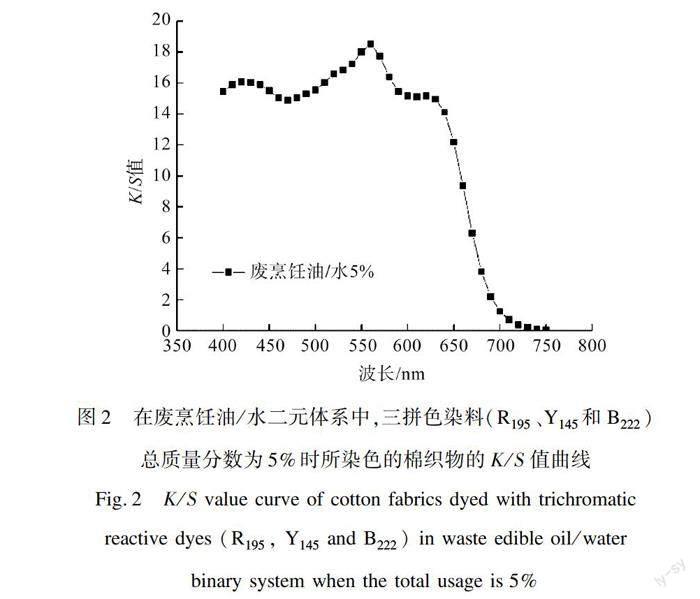

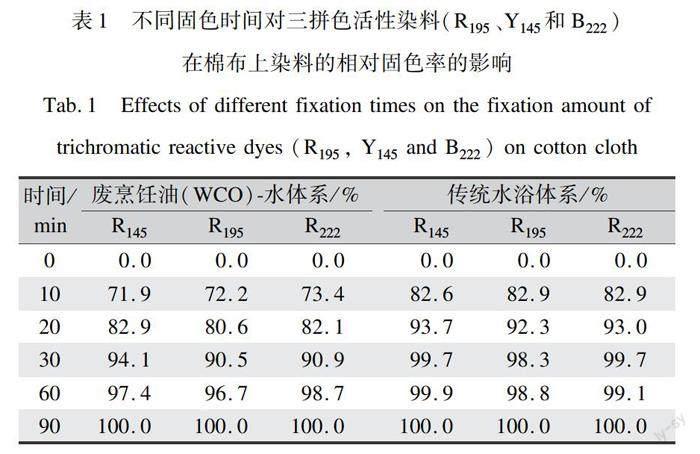

1.2.3 三拼色染料在不同固色时间的相对固色率

三拼色活性染料(R195、Y145和B222)的质量比为R195︰Y145︰B222=1︰1︰1,总质量分数为5%,固色时间为10~120 min,其他工艺条件同1.2.1和1.2.2。根据实际生产中的工艺,异双活性基染料的固色时间为30~60 min,所以将固色时间为90 min时的棉布上的染料量作为废烹饪油(WCO)-水体系和传统水体系固色达到平衡时的固色量。考查染色棉布上某一時刻(t)固着的某种活性染料的量(固色量),与达到固色平衡时棉布上固着的活性染料的量(∞),是否满足以下公式:

(Mt)1(M∞)1=(Mt)2(M∞)2=(Mt)3(M∞)3(1)

式中:(Mt)i,是在固色时间t min时,第i种三原色染料在棉布上的固着量;(M∞)i,是在固色达到平衡时,第i种三原色染料在棉布上的固着量。

1.2.4 三拼色染料在不同投入量时的固色量的变化

三拼色活性染料(R195、Y145和B222)的质量比为红︰黄︰蓝=1︰1︰1,总质量分数为3%~7%,固色时间为60 min,其他工艺条件同1.2.1和1.2.2。考查在不同的三拼色活性染料投入量时,棉布上三拼色活性染料的总固色量和颜色深度的变化情况。

1.2.5 三拼色染料的拼色稳定性

依据1.2.1的操作方法进行重复染色,三拼色活性染料的总质量分数同1.2.3,其中下一次所使用的染色介质,是将上一次的染色残液和经过回收的废烹饪油合并,将其经过重新脱酸处理后用于下一次染色,其中染色介质的酸值保持在0.1 mg/g以下。

1.3 測试与表征

1.3.1 染料固色量的测定

将做过净洗并晾干的有色棉布,经105 ℃的高温预烘2 h左右以去除结合水,之后被转移至室温下的干燥器中冷却至温度不发生变化。用分析天平精确称取0.1 g有色棉布于70%的硫酸溶液中至未观察到溶液中有固体后,在TU-1901型分光光度计(北京普析通用仪器有限责任公司)上测试有色硫酸溶液的吸光度值。由于多组分体系中吸光度值具有可加和的特点[22-23],所以可根据分光光度法中标准曲线的变形公式计算硫酸溶液中的三拼色染料的质量浓度,并计算棉布上的染料固着量。

(At)i=K195×b×C195+K145×b×C145+K222×b×C222(2)

式中:(At)i为三拼色活性染料(R195、Y145和B222)在时间为t时R195、Y145或B222的最大吸收波长下的吸光度值。b为常数,是TU-1901型分光光度计所用比色皿的宽度;K195、K145、K222为三拼活性染料的吸光参数,这两项参数可分别根据配制的硫酸溶液中已知浓度的R195、Y145和B222的标准曲线来进行计算。C195、C145、C222为溶解有三拼色染料染色后的棉布的有色硫酸溶液中三拼活性染料(R195、Y145和B222)的质量浓度。

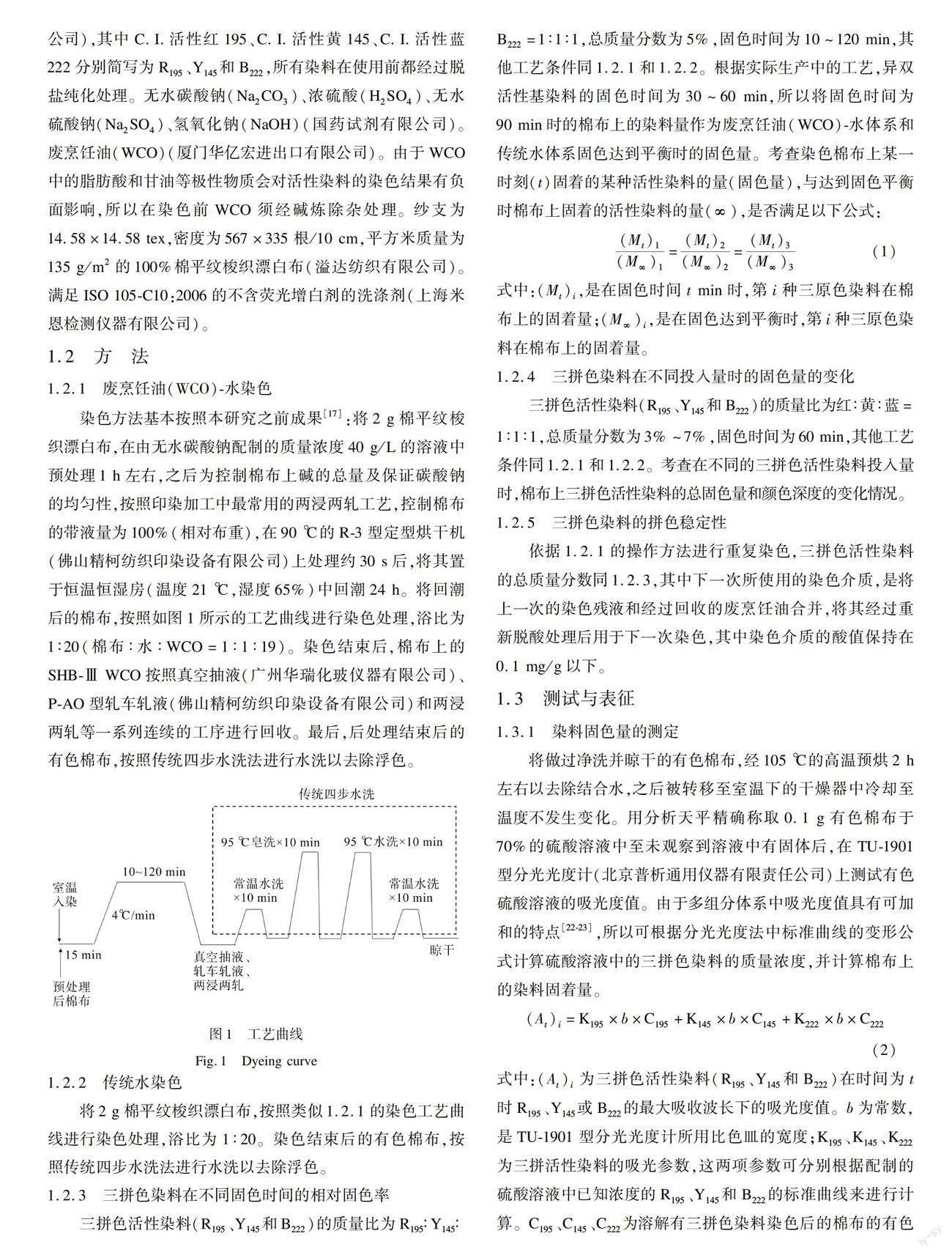

1.3.2 染色棉布颜色参数的测定

将做过净洗并晾干的有色棉布置于恒温恒湿房(温度21 ℃,湿度65%)中回潮24 h后,通过Ci7800型分光光度计(爱色丽有限公司)表征有色棉布的颜色深度(K/S值)和色差(ΔE)等方面的数值,其中ΔE主要用于评价染色有色棉布之间的颜色差异,而基于Kubelka-Munk理论的K/S值,主要用于评价染色有色棉布的颜色深度。对于单一活性染料染色的棉布,主要用可见光范围内最大吸收波长下的K/S值来表示染色棉布的颜色深度,而对于本研究所选用的三拼色染料(R195、Y145和B222)染色后的棉布,由于其在最大吸收波长560 nm处仍具有最大的K/S值(在废烹饪油/水二元体系中,三拼色染料总质量分数为5%时所染色的棉织物的K/S值曲线如图2所示,其中R195、Y145和B222=1︰1︰1),所以仍然可用最大吸收波长下的K/S值来反应拼色染色棉布的颜色深度。

1.3.3 色牢度的测定

分别测试经净洗并晾干的有色棉布的三种色牢度,即耐皂洗色牢度(AATCC TM61-2013e(2020) 2A《耐洗色牢度:加速》)、耐日晒色牢度(AATCC TM16.3-2020 Option3《耐光色牢度:氙弧法》)、耐摩擦色牢度(AATCC TM8-2016e《摩擦色牢度测试》)。

2 结果与分析

2.1 固色时间对三拼色染料相对固色率的影响

在废烹饪油(WCO)-水体系和传统水体系中,不同固色时间对三拼色活性染料(R195、Y145和B222)在棉布上固色量的影响见表1。从表1可见,在传统工艺中,当固色时间达到30 min时,三拼色活性染料(R195、Y145和B222)的相对固色率基本达到了最大,延长固色时间基本不会进一步提高棉布上三拼色染料的固色量;而在废烹饪油(WCO)-水体系中,固色时间达到60 min时棉布上三拼色染料的相对固色率和固色量才达到最大。实验结果与之前报道的活性染料在油/水二元溶剂染色体系中随着单一染料投入量的增加,染色棉布上染料的总固着量呈现增加的趋势基本保持一致。这是由于在上述二元溶剂的染色体系中,初始分散在废烹饪油中的三拼色染料纳米液滴在染色的过程中需要完成液滴的聚集、液滴在棉布中的扩散、染料在棉布中的固着等过程[24]。同时还可发现,虽然三拼色活性染料(R195、Y145和B222)在油/水二元溶剂体系中的固色速率下降了,但是单个活性染料(R195、Y145和B222)在棉布中某一时刻(10、20、30 min等)的固色量基本保持了同步增加,其间差异在5%以内[25]。从固色时间的角度可见,三拼色活性染料(R195、Y145和B222)在油/水二元溶剂体系中也具有良好的配伍性。

2.2 三拼色染料投入量对棉布上染料总固着量的影响

三拼色染料(R195、Y145和B222)总质量分数对棉布上染料总固着量的影响如图3所示。由图3可知,由于不改变三拼色染料(R195、Y145和B222)的质量比(R195︰Y145︰B222=1︰1︰1),随着三拼色染料(R195、Y145和B222)总质量分数的增加,有色棉织物上三拼色染料(R195、Y145和B222)的总固着的染料量呈线性增加。其中三拼色染料(R195、Y145和B222)在废烹饪油/水体系中的线性相关系数R2为0.996 0,而在传统水体系中的线性相关系数R2为0.986 5。随着染料投入量的增加,异双活性基染料在传统水相中对棉布的染色需要添加大量的中性盐,但是仍然存在大量的未固着或水解染料残留在水中;而在油/水两相染色中,染色前通过高速剪切所制备的纳米级染料液滴在染色过程中会聚集并几乎100%上染棉布,并进一步发生固着反应。所以,异双活性基染料在油/水两相染色中,在棉布上的固着效率具有更好的线性相关系数。

2.3 三拼色染料在油/水二元与传统水相中颜色的差异

三拼色染料(R195︰Y145︰B222)在油/水两相和传统水相中上染棉布后的颜色差异见表2。从表2可见,在油/水二元体系和传统水体系的3组对比实验中,油水二元体系中染色的棉布与传统水体系中染色的棉布的色差值(ΔE)均不超过0.5,满足当前纺织印染企业对有色纺织品一次成功的基本要求。而且,在所选择的油/水二元体系和传统水体系的3组对比实验中,相比于传统水体系,油/水二元体系可节省约20%~30%异双活性基染料的用量。

2.4 三拼色染料在油/水二元体系中的拼色稳定性

三拼色染料在油/水二元体系中的拼色稳定性如图4所示。由图4可见,在染色循环次数为1~5时,染色棉布与初次染色的棉布的色差值(ΔE)小于均0.4,染色棉布的颜色深度(K/S值)基本在18.5左右。这是由于废烹饪油在脱酸预处理的过程中已经将会影响染色质量的油脂降解产物(如脂肪酸和甘油等)基本去除掉了,虽然在染色过程中废烹饪油仍然有微弱的降解,但是在废烹饪油回用前,降解产物依旧可以通过之前开发的碱炼、离心和水洗等工艺去除。这说明了从拼色稳定性的角度出发,非极性(油)/极性(水)二元体系是有望替代传统水相体系用以纤维素活性染色的。

2.5 三拼色染料在油/水二元体系中的色牢度

表3为三拼色染料在油/水二元体系中的色牢度。在油/水二元体系与传统水相体系所染色的有色棉布的颜色深度基本相当的前提下,染色棉织物的常规色牢度(耐摩擦、耐洗涤和耐日晒)基本一致,可以满足消费者对有色纺织品的色牢度需要。

3 结 论

本文对比研究了异双活性基三拼色染料(R195︰Y145︰B222)在常规水介质和废烹饪油/水介质体系中的配伍性能。主要结论如下:

1) 相比传统水体系,在废烹饪油/水体系中三拼色染料的固色速率稍慢,但是单个活性染料(R195、Y145和B222)在棉布中某一时刻(10~60 min等)的固色量,相互之间的差异在5%以内。

2) 当三拼色染料的投入量改变时,棉织物上三拼色染料固色量的总和呈现一定线性增加。其中,染料在废烹饪油/水体系中的线性相关系数(R2为0.996 0)要好于传统水体系(R2为0.986 5)。

3) 在废烹饪油/水体系中,当染色循环次数为1~5时,染色棉布与初次染色的棉布的色差(ΔE)小于0.6。与传统水介质相比,废烹饪油/水体系所染色的棉布的常规色牢度(耐摩擦、耐洗涤和耐日晒)基本没有发生下降。

参考文献:

[1]KHATRI A, PEERZADA M H, MOHSIN M, et al. A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution[J]. Journal of Cleaner Production, 2015, 87: 50-57.

[2]ZHOU T B, WANG Y X, ZHENG H D, et al. Sustainable and eco-friendly strategies for polyester-cotton blends dyeing in supercritical CO2[J]. Journal of CO2 Utilization, 2022, 55: 101816.

[3]ZHAO J B, AGABA A, SUI X F, et al. A heterogeneous binary solvent system for recyclable reactive dyeing of cotton fabrics[J]. Cellulose, 2018, 25(12): 7381-7392.

[4]DENG Y, XU M, ZHANG Y G, et al. Non-water dyeing process of reactive dyes in two organic solvents with temperature-dependent miscibility[J]. Textile Research Journal, 2019, 89(18): 3882-3889.

[5]柯鋼强, 江立文, 董霞, 等. 棉织物含水率对DMSO/PCE体系活性染色性能的影响[J]. 印染, 2018, 44(22): 1-6.

KE Gangqiang, JIANG Liwen, DONG Xia, et al. Effects of water content of cotton on reactive dyeing behaviors in DMSO/PCE miscible system[J]. China Dyeing & Finishing, 2018, 44(22): 1-6.

[6]DONG X, GU Z J, HANG C Y, et al. Study on the salt-free low-alkaline reactive cotton dyeing in high concentration of ethanol in volume[J]. Journal of Cleaner Production, 2019, 226: 316-323.

[7]谷智杰, 柯钢强, 姚金龙, 等. 乙醇/水染色体系中棉纤维的溶胀性能[J]. 印染, 2018, 44(3): 1-4.

GU Zhijie, KE Gangqiang, YAO Jinlong, et al. Swelling behaviors of cotton fibers in ethanol/water dyeing system[J]. China Dyeing & Finishing, 2018, 44(3): 1-4.

[8]FAN J, SHAO M, MIAO J H, et al. Thermodynamic properties of cotton dyeing with indigo dyes in non-aqueous media of liquid paraffin and D5[J]. Textile Research Journal, 2021, 91(21/22): 2692-2704.

[9]朱振旭, 周嵐, 黄益, 等. 棉织物的活性染料/液体石蜡体系无盐节水染色[J]. 染整技术, 2017, 39(3): 52-57.

ZHU Zhenxu, ZHOU Lan, HUANG Yi, et al. A water-saving and salt-free dyeing of cotton fabrics with reactive dye/liquid paraffin system[J]. Textile Dyeing and Finishing Journal, 2017, 39(3): 52-57.

[10]AN Y, MA J R, ZHU Z X, et al. Study on a water-saving and salt-free reactive dyeing of cotton fabrics in non-aqueous medium of liquid paraffin system[J]. The Journal of The Textile Institute, 2020, 111(10): 1538-1545.

[11]AN Y, MIAO J H, FAN J, et al. High-efficiency dispersant-free polyester dyeing using D5 non-aqueous medium[J]. Dyes and Pigments, 2021, 190: 109303.

[12]SALEEM M A, PEI L J, SALEEM M F, et al. Sustainable dyeing of nylon fabric with acid dyes in decamethylcyclopentasiloxane (D5) solvent for improving dye uptake and reducing raw material consumption[J]. Journal of Cleaner Production, 2021, 279: 123480.

[13]PEI L J, GU X M, WANG J P. Sustainable dyeing of cotton fabric with reactive dye in silicone oil emulsion for improving dye uptake and reducing wastewater[J]. Cellulose, 2021, 28(4): 2537-2550.

[14]PEI L J, LUO Y N, SALEEM M A, et al. Sustainable pilot scale reactive dyeing based on silicone oil for improving dye fixation and reducing discharges[J]. Journal of Cleaner Production, 2021, 279: 123831.

[15]TEIXEIRA M R, NOGUEIRA R, NUNES L M. Quantitative assessment of the valorisation of used cooking oils in 23 countries[J]. Waste Management, 2018, 78: 611-620.

[16]LIU L Y, MU B N, LI W, et al. Cost-effective reactive dyeing using spent cooking oil for minimal discharge of dyes and salts[J]. Journal of Cleaner Production, 2019, 227: 1023-1034.

[17]LIU L Y, MU B N, LI W, et al. Semistable emulsion system based on spent cooking oil for pilot-scale reactive dyeing with minimal discharges[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(16): 13698-13707.

[18]LIU L Y, MU B N, LI W, et al. Clean cotton dyeing in circulated dyebath of waste cooking oil: A feasible industrialization strategy for pollution minimization[J]. Journal of Cleaner Production, 2021, 278: 123799.

[19]WANG Y M, TANG Y L, LEE C H, et al. A computer color-matching study of reverse micellar dyeing of wool with reactive dyes[J]. Polymers, 2019, 11(1): 132.

[20]ZHANG H J, YANG H, XIE K L, et al. Novel reactive dyes with intramolecular color matching combination containing different chromophores[J]. Dyes and Pigments, 2018, 159: 576-583.

[21]TANG A Y L, WANG Y M, LEE C H, et al. Comparison of computer colour matching of water-based and solvent-based reverse micellar dyeing of cotton fibre[J]. Coloration Technology, 2018, 134(4): 258-265.

[22]王先鋒, 赵涛, 郑建范, 等. 小浴比染色用活性染料的配伍性能[J]. 印染, 2013, 39(12): 11-15.

WANG Xianfeng, ZHAO Tao, ZHENG Jianfan, et al. Compatibility of reactive dyes for low liquor ratio dyeing[J]. China Dyeing & Finishing, 2013, 39(12): 11-15.

[23]HUANG G, DAI J J, DONG F C, et al. Compatibility of a disperse dye mixture in supercritical carbon dioxide dyeing[J]. Coloration Technology, 2013, 129(4): 305-311.

[24]MU B N, LIU L Y, LI W, et al. A water/cottonseed oil bath with controllable dye sorption for high dyeing quality and minimum discharges[J]. Journal of Cleaner Production, 2019, 236: 117566.

[25]MU B N, LIU L Y, LI W, et al. High sorption of reactive dyes onto cotton controlled by chemical potential gradient for reduction of dyeing effluents[J]. Journal of Environmental Management, 2019, 239: 271-278.

Compatibility of a hetero-bifunctional dye mixture in the waste cooking oil/water binary system

LIU Linyun1, DONG Xuye1, LIU Zhijun1, LI Jinguan2, XU Jianing2

(1.School of Textile, Guangdong Polytechnic, Foshan 528000, China; 2.Prosperity Textiles Co., Ltd., Shaoguan 512000, China)

Abstract:

Up to now, the cotton fiber is still an important textile fiber, and it accounts for about 80% of the global annual output of natural fibers. The main problems of the reactive dyeing technology for cotton fibers in the processes of dyeing and finishing are high salt consumption, high water consumption, high sewage discharge, etc. The relevant costs from the removal of hydrolyzed reactive dyes from the dyed cotton fiber and degradation of hydrolyzed reactive dyes from the dyeing wastewater account for about 50% of the total cost of cotton fiber processing. During the past two decades of the 21st century, many improvement schemes, including cationic modification technology for cellulose, supercritical carbon dioxide dyeing technology, low-water foam dyeing technology, non-aqueous solvent dyeing technology, low-water solvent dyeing technology, etc. of the reactive dyeing technology for cotton fibers have been proposed. However, the new cotton fiber dyeing technology reported above is difficult to meet the requirements of the dyeing quality, production safety, and processing cost simultaneously. A low-water dyeing technology for cotton fibers with waste cooking oil as the dyeing medium was proposed in our previous research, and the dyeing mechanism, removal efficiency of waste cooking oil and recycling methods of waste cooking oil were investigated.

To expand the application scope of the low-water reactive technology with waste cooking oil as the dyeing medium, it is especially necessary to study the compatibility of commonly used hetero-bifunctional trichromatic dye mixture in the waste cooking oil/water binary dyeing system. In the waste cooking oil/water binary dyeing system, almost all the hetero-bifunctional trichromatic reactive dye droplets will enter the surface of cotton cloth from the waste cooking oil phase during the dyeing process. Firstly, the trichromatic reactive dye samples were taken at different fixation times during the cotton fibre dyeing process, and the effects of the fixation time on the relative rate of hetero-bifunctional trichromatic reactive dyes on cotton cloth were analyzed. On this basis, the input of hetero-bifunctional trichromatic reactive dyes in the waste cooking oil/water binary dyeing system was increased, and the impact of the hetero-bifunctional trichromatic reactive dye input on the fixation of hetero-bifunctional trichromatic reactive dyes on cotton cloth was investigated. The waste cooking oil in the dyeing residue was reused as the dyeing medium after deacidification, and the color matching stability of hetero-bifunctional trichromatic reactive dyes in the waste cooking oil/water binary dyeing system was studied. The traditional method of checking the compatibility of hetero-bifunctional trichromatic reactive dyes is mainly to test the dye uptake rate of a single hetero-bifunctional trichromatic reactive dye on cotton cloth. The dyeing compatibility of hetero-bifunctional trichromatic reactive dyes in the waste cooking oil/water binary dyeing system was characterized by testing the relative fixation rate and fixation amount of hetero-bifunctional trichromatic reactive dyes in the dyeing process of cotton cloth. The results show that there are few differences in the fixation of a single hetero-bifunctional trichromatic reactive dye in cotton cloth at a certain time; the total fixation of hetero-bifunctional trichromatic reactive dyes on cotton cloth increases linearly with the increase of the amount of hetero-bifunctional trichromatic reactive dyes; hetero-bifunctional trichromatic reactive dyes have good color matching stability in the waste cooking oil/water binary dyeing system; in the waste cooking oil/water binary dyeing system, the conventional color fastness of colored cotton cloth basically does not decrease.

For the reactive dye dyeing technology of cotton fibers, the products dyed with waste cooking oil as the dyeing medium could meet the requirements of dyeing quality, production safety, and processing cost simultaneously. The compatibility of hetero-bifunctional trichromatic reactive dyes, which are commonly used in the aqueous dyeing medium, will be of great significance for the industrial prospect of the waste cooking oil/water binary dyeing system.

Key words:

cellulose dyeing; application scope; hetero-bifunctional trichromatic dye mixture; waste cooking oil; binary dyeing system; compatibility

收稿日期:

2022-07-25;

修回日期:

2023-03-06

基金項目:

广东省普通高校特色创新类项目(2021KTSCX210);广东职业技术学院校级科研项目(ZXKY2022054);佛山市先进纺织技术工程技术研发中心项目(2120001009566);广东职业技术学院校级科研项目(XJKY2021010);广东职业技术学院高层次人才科研专项项目(GZGC202208)

作者简介:

刘林云(1985),男,讲师,主要从事生物质材料的清洁生产的研究。