Improvement of machining accuracy in EDCM by enhanced electrochemical reaming based on a non-metallic backing layer

Chen WANG, Yan ZHANG, Lei JI, Wentao YANG, Jingjing WANG

School of Mechanical and Power Engineering, Nanjing Tech University, Nanjing 211800, China

KEYWORDS Backing layer;ECDM;Electrochemical reaming;Non-metallic

Abstract Electrochemical Discharge Machining(ECDM)is potentially applicable for the fabrication of film-cooling holes.However,It is extremely difficult for the holes to achieve higher precision and machining quality owing to the working liquid diminish in the lateral machining gap. In this study, a non-metallic backing layer was proposed to overcome the diminish of working liquid,and the electrochemical reaming, as a post-processing method for ECDM, was used to further improve the machining accuracy and quality of the holes.First,the three-dimensional morphology of the melted pit of a paraffin backing layer was scanned to obtain the geometric parameters.Then,simulation analysis and experimental verification of auxiliary flushing by using the non-metallic backing layer were performed. The machining performance of the holes machined with electrochemical reaming based on non-metallic backing layer was confirmed by the observations of the surface topography of the hole wall and orifice, measurement of the orifice precision, and analysis of the element composition on the surface of the orifice wall. Finally, an optimum combination of machining parameters for electrochemical reaming is obtained through a process parameter optimization experiment.

1. Introduction

The turbine blade,as a core component of an aero-engine with the largest thermal and mechanical load, is subjected to the impact of extremely high temperature and pressure gas.1,2To improve the heat-dissipation performance of turbine blades and ensure the engine reliability, a small-hole gas-filmcooling technology was introduced in.3-5The machining accuracy of these holes, including the roundness, taper, and consistency, directly determines the formation ability of the cooling gas film and the effect of thermal insulation.However,holes are small in size, large in number and variable in space angle.6And a variety of difficult materials such as casting superalloy, single crystal superalloy, and titanium alloy are increasingly used in the turbine blades.7Hence, it is overwhelmingly difficult for the gas-film-cooling holes to achieve higher precision.The high precision machining of these microholes has become a key challenge in the manufacturing of a high-performance aero-engine.

Electrochemical Discharge Machining(ECDM), which is a hybrid process of Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM) exploiting the advantages of these two processing technologies to achieve high machining efficiency, machining accuracy, and surface quality, can be potentially used for the fabrication of film-cooling holes.8By considering deionized water as the working fluid,an RC power supply circuit was reportedly used to realize the combination of EDM and ECM.9Yang et al.10presented a drilling method of electrochemical discharge with a spherical tool electrode.The machining efficiency is significantly improved by this method.However,during the drilling process using a tube electrode,the phenomenon of working fluid diminish in the lateral machining gap after penetration easily results in arc discharge and damage the machining accuracy. Meanwhile, the reduction of processing time for exit caused by the diminish of working fluid also allows the hole to easily produce a larger taper.

To obtain the holes with high machining accuracy, various innovative methods have been proposed in ECM/EDM by many scholars.11-13For example, double insulating layers comprising a TiO2ceramic coating and organic film were fabricated on the electrode sidewall and used for electrochemical machining.14Further,this electrode finally improves the accuracy of the precision of the hole shape.A dual pole tool with a metallic bush outside the insulated coating of a cathode tool has been utilized to improve machining accuracy in ECM.15An ultra-short voltage pulse combined with a high-speed rotating helical electrode was applied in an electrochemical drilling process.16Finally, micro-holes with diameters of 186 μm and without tapers were successfully obtained on a 500-μm-thick GH4169 plate. Tsui et al.17presented a method of ECM with a helical tool that significantly improves the shape accuracy of micro-hole hole in a simple and low-cost way. A helical electrode was introduced in micro electrical discharge machining to facilitate debris removal by Wang et al.18The experimental results show that the overcut and taper were greatly improved.Kim et al.19introduced a micro EDM using a variable capacitance method accompanied by ultrasonic vibration, and were thus able to greatly reduce taper and obtain a straight hole.Fang et al.20proposed an innovative approach to change the intensity of the electric field at the exit in ECM,thus improving the shape accuracy of holes. Yan et al.21developed a method that combines micro EDM and micro-ultrasonic vibration to produce micro-holes with high aspect ratios. The hole with high roundness precision and small taper was successfully machined by this method in borosilicate glass. Lee et al.22introduced a new ultrasonic-assisted micro EDM setup and analyzed the effect of ultrasonic parameters on the accuracy of a sinking hole. Ali et al.23explored different types of errors including cylindricity error, circularity error and diameter error of cylindrical holes machined with wire EDM in 2205 duplex stainless steel.

However,in addition to the above methods,the most effective one to improve the machining accuracy is to solve the problem of working fluid diminish in lateral machining gap.Therefore, some scholars have put forward methods of metal backing layer, such as metal sacrificial layer and filling with low melting point alloy, to form the a metal-layer block on the back of a workpiece to realize a reverse replenishment of working fluids in lateral machining gap. However, the metal sacrificial layer is not available when processing space is limited. And the alloy with low melting point alloys that adhere to metal surfaces are extremely difficult to remove completely.Thus the aforementioned methods cannot be used in the machining of film-cooling holes located in the turbine blade with complex hollow structures. Therefore, focusing on the diminish of working fluid, in this study, the authors innovatively propose a non-metallic backing layer for electrochemical discharge machining. Compared with metallic materials, the paraffin wax, as an non-metallic material with low melting point, has more wider applicability in the complex parts with inner cavities or flow channels. This material are not limited by the geometric shape and structural characteristics of the machining objects. Moreover, the paraffin wax is also a clean and safe material that can be easily removed by heating, so as to avoid any residue of material in micro-channels and cavities.At present,few studies have been conducted on the processing method of micro-holes with a non-metallic backing layer.

In this study,a non-metallic backing layer was proposed to overcome the diminish of working liquid,and the electrochemical reaming, as a post-processing method for EDCM, was used to further improve the machining accuracy and quality of the holes. Firstly, the three-dimensional morphology of the melted pit of a paraffin backing layer was scanned to obtain the geometric parameters.Secondly,simulation analysis and experimental verification of auxiliary flushing by using the non-metallic backing layer were performed. The machining performance of the holes machined with electrochemical reaming based on non-metallic backing layer was confirmed by the observations of the surface topography of the hole wall and orifice, measurement of the orifice precision, and analysis of the element composition on the surface of the orifice wall.Finally, an optimum combination of the main machining parameters for electrochemical reaming is obtained through a parameters optimization experiment.

2. Principle of electrochemical discharge machining using a non-metallic backing layer

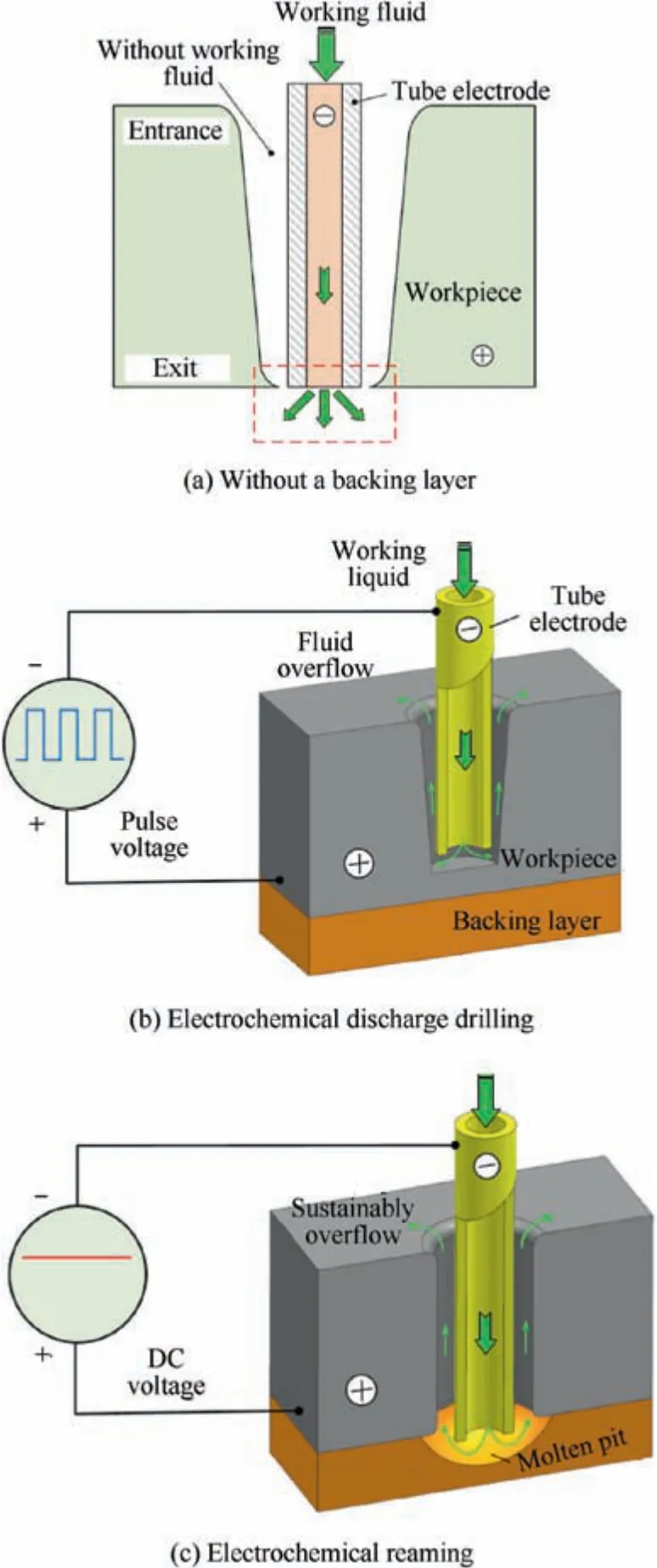

In previous studies about electrochemical discharge machining, the tube electrode was used as a tool electrode and the whole machining process was executed without a back layer.As such, after the workpiece is penetrated, the working fluid spurts from inside the tube electrode and then disperses rapidly, which can cause the working fluid in the lateral machining gap to diminish (Fig. 1(a)). The lack of liquid causes the reduction of the processing time for the exit, and the electrochemical reaction is not sufficient at the exit location; this results in a poor machining accuracy of the exit and produces a larger taper. Moreover, the diminish of working fluid in lateral machining gap easily results in arc discharge and damage to the exit roundness. Fig. 1(b) and (c) show the schematic of electrochemical discharge machining with a non-metallic backing layer. Before the drilling process, the low-melting-point non-metal is melted and filled at the bottom of the workpiece, and is then cooled to form a backing layer structure. The whole machining process can be divided into the following two stages.

Fig.1 Schematic of electrochemical discharge machining using a non-metallic backing layer.

Stage 1: Electrochemical discharge drilling process

During this stage,electrochemical dissolution and electrical discharge erosion were combined into a highly efficient synchronous hybrid process using low conductivity salt solution.Pulse voltages were applied to generate sparks between the interelectrode gap, thus high-precision entrance can be obtained with high machining efficiency, as shown in Fig. 1(b). Owing to the accompanying electrochemical dissolution,most of the surface defects generated by the spark on the hole wall were effectively removed.However,when the hole is close to penetration, the electrochemical dissolution reaction at the exit is insufficient owing to the poor reverse flushing of the working fluid. Therefore, the accuracy and surface quality,especially for the exit area, cannot meet the requirement.

Stage 2: Electrochemical reaming process

After penetration, the feed of the electrode is stopped, and the residual heat generated by the spark will cause partial melting of the non-metallic backing layer with a low melting point to form a pit. The formation of a molten pit on the nonmetallic baking layer is effective for maintaining reverse flushing in the lateral machining gap after penetration,as shown in Fig. 1(c). Therefore, for the machining gap, especially for the exit area, the working fluid can be supplied sufficiently, and an electrochemical dissolution reaction can occur continuously and stably. In this case, the machining accuracy of the exit is improved, while the taper and surface quality of the hole are further enhanced.

3. Simulation of flow field in electrochemical discharge machining with a non-metallic backing layer

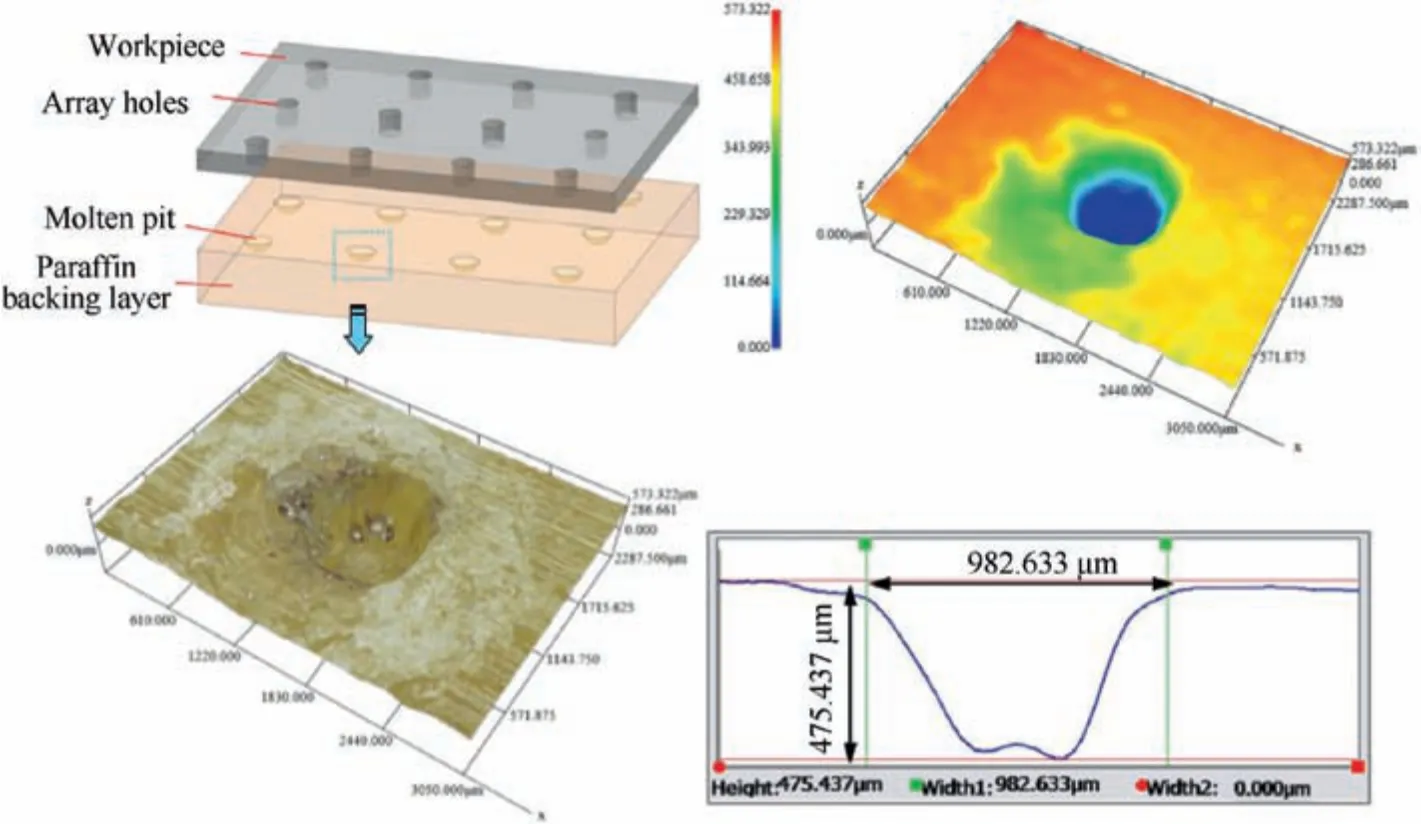

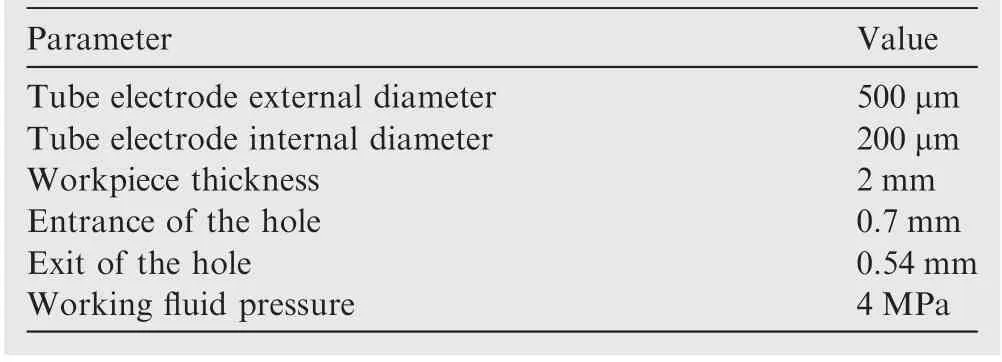

When the workpiece is penetrated, the residual heat of the high-temperature spark discharge is partially used to melt the paraffin backing layer and produce a pit, as shown in Fig. 2. The three-dimensional morphology and geometric dimensions of the melted paraffin pit were measured to establish a simulation model of the reverse flushing with a backing layer.Fig.2 shows the depth and diameter of the paraffin melting pit, which are 475.437 μm and 982.633 μm, respectively.Table 1 lists the parameters applied in the simulation.

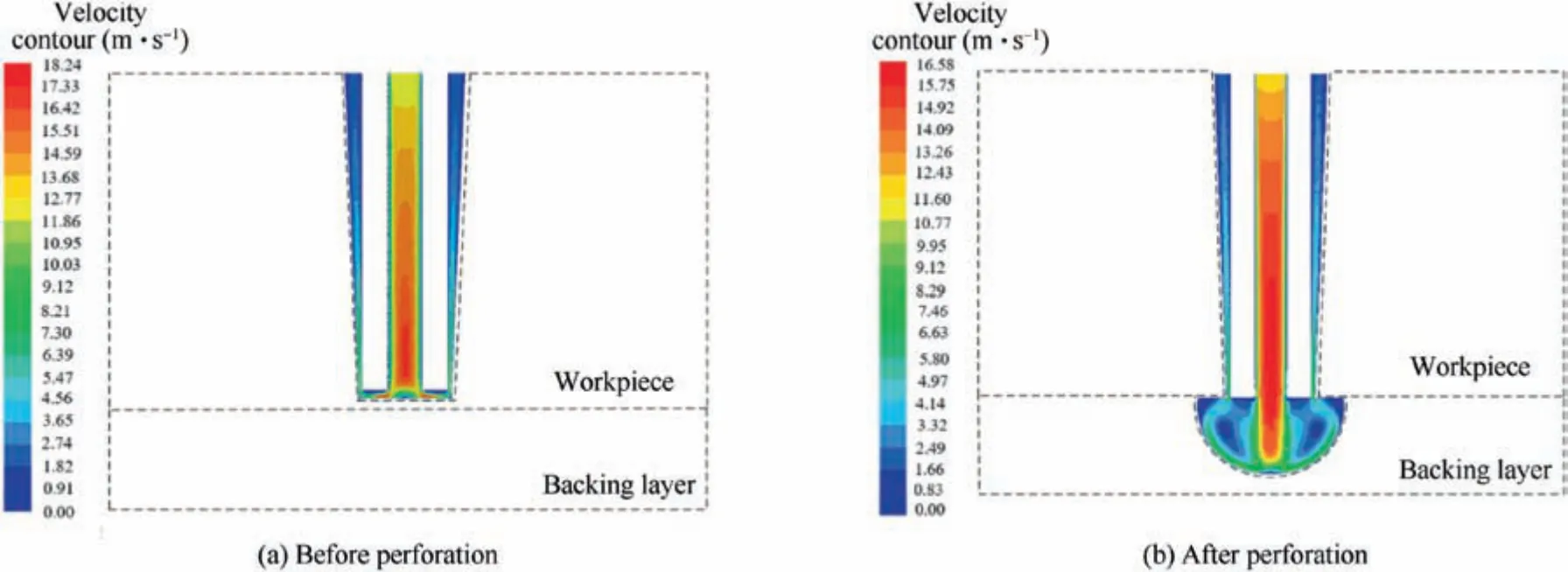

Fig. 3 presents the compared results of electrolyte velocity contours in the machining gap between different processing stages.When the workpiece is not penetrated by the tube electrode, the working fluid flows into the machining area rapidly from the inside of the tube electrode, and then flows out through the side of the machining gap from the entrance, as show in Fig. 3(a). In this process, the machining products are rapidly removed from the micro-machining gap to achieve the cleanliness for flow-field environment in the machining area. The continuous, clean and stable fluid flushing process maintains the normal spark discharge and electrochemical reaction.

Fig. 3(b)shows the flow velocity distribution after perforation. As shown, there is an excellent reverse replenishment of the working fluid owing to the presence of the backing layer.A whirlpool is formed owing to the special shape of the pit formed at the bottom, and the working fluid is accelerated to overflow from the machining gap via the exit. Therefore, it is illustrated that with the assistance of the paraffin backing layer,the problem of working fluid diminish in lateral machining gap can be effectively solved, especially when the workpiece is penetrated.

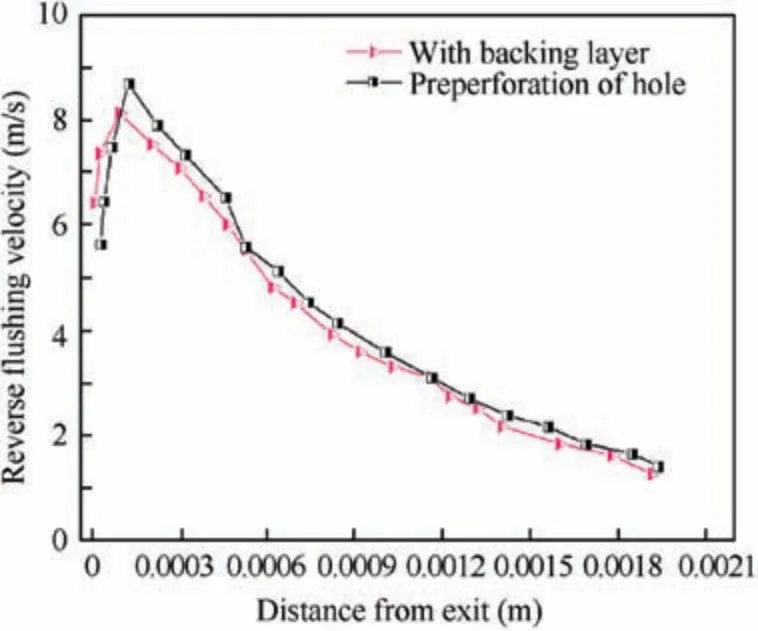

Fig. 4 reflects the change of the reverse-flow axial velocity of working fluid in the lateral machining gap under two conditions.As shown,owing to the presence of the paraffin backing layer,the axial velocity distribution of the working fluid in the lateral gap after the perforation is consistent with the velocity distribution when the workpiece is not penetrated.In addition,the figure shows that in both cases,the reverse flushing velocity in the lateral machining gap first increases and then decreases.Although the reverse flushing velocity in lateral machining gap is slightly higher when it is not penetrated on the whole, the maximum velocity difference between the two curves is only 0.54 m/s.Therefore,such result means that the effect of reverse flushing in the machining gap after penetration is similar to that before penetration. It is further proved that the method of non-metallic backing layer is feasible and effective in solving the problem of working fluid to diminish from the lateral machining gap after hole penetration.In particular,compared with the machining method without a backing layer, a back layer can achieve an increased reverse flow rate of working fluid in machining gap near the exit from 0 m/s to a velocity of 8 m/s.The working fluid replenishment in lateral machining gap with a baking layer can effectively avoid the abnormal discharge phenomenon, thereby improving the machining accuracy of the exit. Continuous and sufficient working fluid replenishment provides a good flow field environment for the follow-up electrochemical reaming, thus further improving the machining accuracy and surface quality of the hole with electrochemical dissolution.

Fig. 2 Three-dimensional morphology and geometric dimensions of paraffin pit.

Table 1 Parameters applied in simulation.

4. Experimental setup

4.1. Machine tool

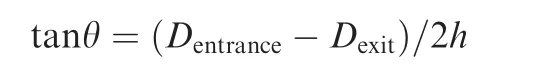

Fig. 5 presents the experimental apparatus of the hybrid machining, which is designed to verify the enhanced effect of a backing layer on machining accuracy. This apparatus contains an X-Y-Z motion stage, a working-fluid recycle system,a power supply system,a tool electrode,a self-designed fixture,etc. The self-designed fixture is used for clamping the workpiece, the inner cavity of which is used to hold the melted paraffin, and it serves as a backing layer at the back of the workpiece after the melted paraffin cools and solidifies. The tube electrode driven by a servo motor is fed in a direction perpendicular to the X-Y plane.The rotation of the tube electrode is accomplished via a motor installed on the Z axis. A power system can provide pulse and DC voltages, which can be switched according to machining requirements.

Fig. 3 Comparison of electrolyte velocity contours in machining gap between different processing stages.

Fig. 4 Comparison of reverse-flow axial velocity of working fluid in lateral machining gap under two conditions.

4.2. Material

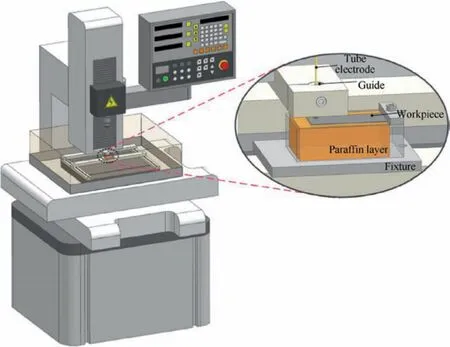

The backing layer material is a kind of paraffin wax with lower softening temperature and melting point and larger viscosity.The softening temperature and melting temperature of such paraffin are respectively about 68 ℃and 90 ℃.Thus,the backing layer material can be rapidly melted by residual heat from spark discharge when the tube electrode penetrates through the workpiece;simultaneously,a stable pit shape can be formed in a short time.Therefore,this kind of backing material can realize a timely reverse fluid replenishment in lateral machining gap after penetration, thus effectively avoiding the diminish of working fluid. A cobalt-based superalloy was used in this experiment.The elemental composition of cobalt-based superalloy is given in Table 2.The superalloy has a high initial melting temperature, stable microstructure, excellent resistance to cold and hot fatigue, oxidation and heat corrosion resistance,as well as good comprehensive properties such as creep resistance,durability,and fatigue resistance.Cobalt-based superalloys have been widely used to fabricate complex cavity-cooled turbine guide blades for aerospace, naval, and land gas turbines.Moreover,the material of the tool electrode was copper,and sodium nitrate solution was used as the working fluid.

4.3. Processing parameters

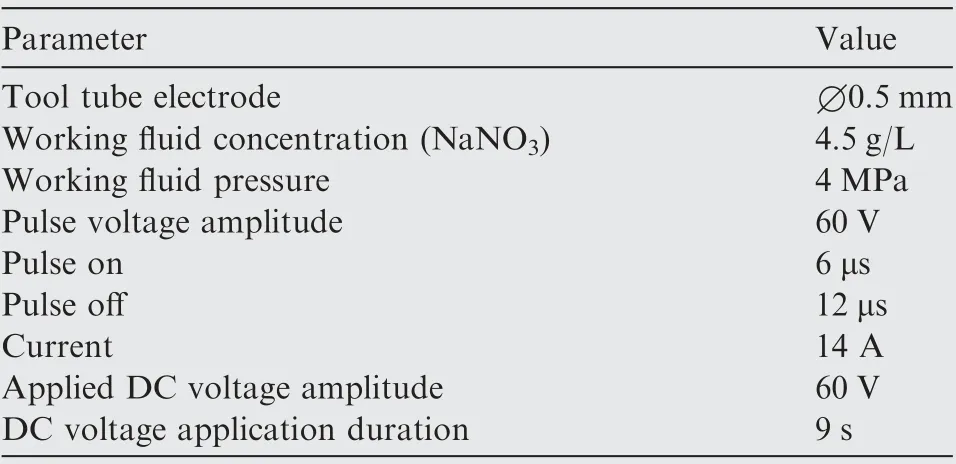

To verify the simulation results,comparison experiments were carried out under two conditions, namely with and without a backing layer; the experimental parameters are listed in Table 3.

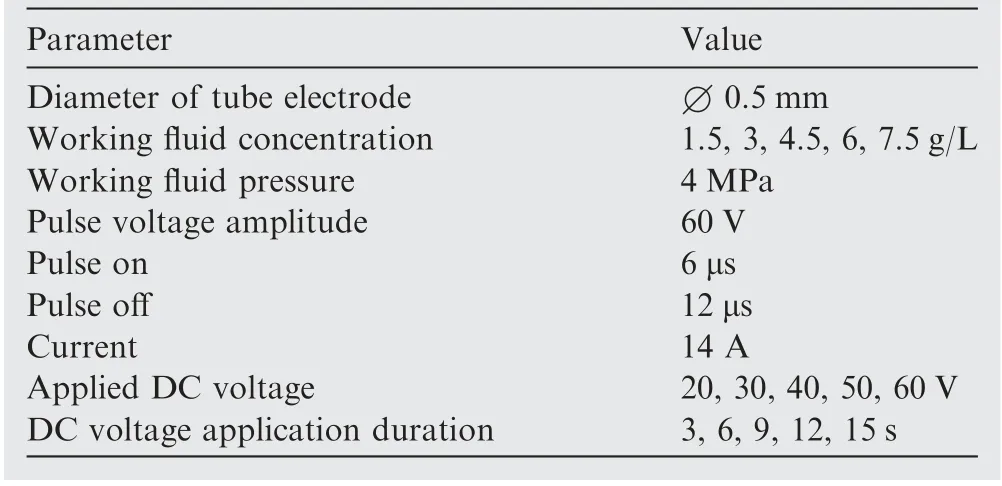

To further improve the machining performance of holes machined by ECM reaming with a paraffin backing layer,the effects of concentration of working fluid,applied DC voltage and electrochemical reaming duration on the machining accuracy were studied by a single factor experiment, finally,determining the optimum combination of these parameters.It is a strategy to study the effect of any parameter on machining accuracy by fixing other two parameters.The experimental parameters are listed in the Table 4.

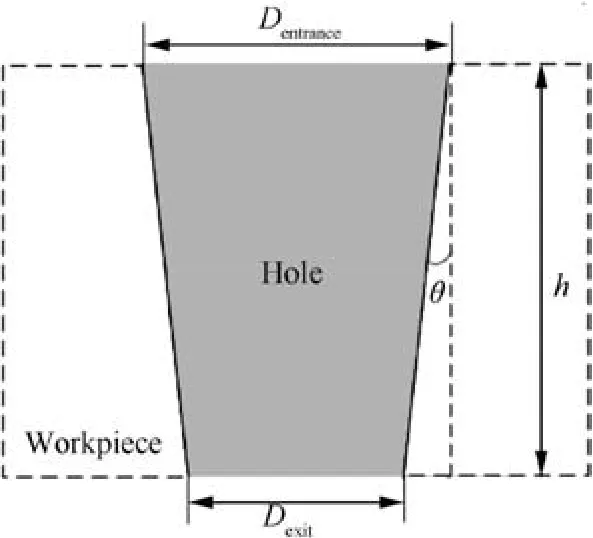

The geometric parameters of the hole were measured using a scanning electron microscope and optical microscope according to Fig. 6. The final taper value is an average value of three holes machined with the same processing parameters.The taper angle θ of the micro-holes is given by the following equation:

where Dentranceis the entrance diameter and Dexitis the exit diameter of the hole, h is the thickness of the workpiece.

Fig. 5 Experimental apparatus of hybrid machining.

Table 2 Elemental composition of cobalt-based superalloy.

Table 3 Machining parameters used in comparison experiments.

Table 4 Experimental parameters of ECM reaming.

Fig. 6 Calculation method of taper of hole.

5. Results and discussion

5.1.Verification of performance improvement in electrochemical discharge machining by using a non-metallic backing layer

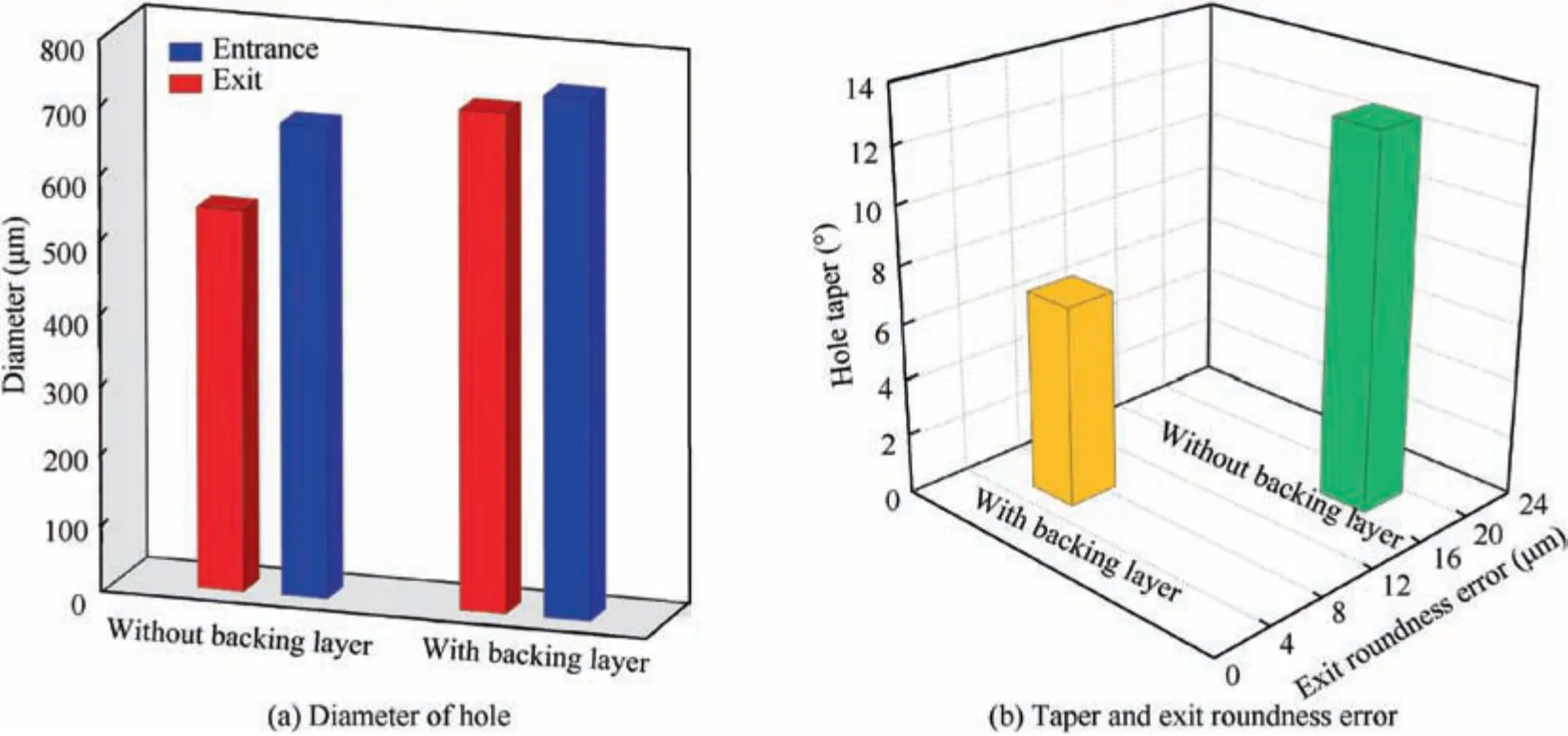

To verify the improvement in machining performance during EDM using a non-metallic backing layer,a comparison experiment involving machining with and without a paraffin backing layer was carried out.

Fig. 7 shows the comparison of machining accuracy of the holes obtained with and without a backing layer,including the taper, exit roundness error, and diameters. As observed in Fig. 7(a), the diameters of both the entrance and exit holes when machined with the backing layer are obviously larger than those machined without the backing layer. Meanwhile,a significant diameter difference of up to 130 μm was observed between the entrance and exit holes without the backing layer.However,it can be observed that the diameter difference of the hole machined with the backing layer was only 30 μm.In addition,it is observed from Fig.7(a)that the increase of diameter at the outlet is more than that at the inlet. This can be explained by the following fact.The hole machined by EDCM has a certain taper,which leads to the initial machining gap of electrochemical reaming at the outlet is larger than that at the inlet. Hence, the higher electric field intensity at the outlet causes the electrochemical dissolution volume at the outlet to be greater than at the inlet.

According to Fig.7(b),the roundness error of the exit holes with the backing layer is also smaller, and its taper is 40%lower than the hole machined without the backing layer.Therefore, it can be concluded that owing to the reverse replenishment of working fluids in lateral machining gap with the backing layer, electrochemical reaming could be further enhanced after penetration, especially for the exit area.Therefore,the diameter of the hole could be enlarged,the roundness of the exit could be improved,and the diameter difference and taper of the hole could be reduced.

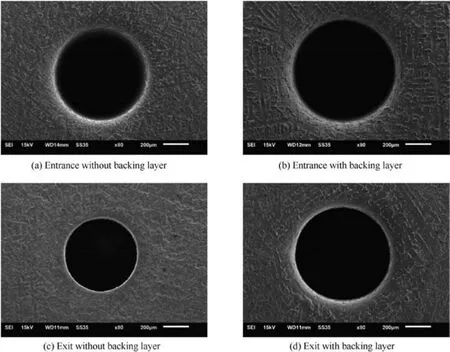

The orifice morphologies of the entrances and exits machined with and without a backing layer are shown in Fig. 8. The entrances shown in Fig. 8(a) and (b) have obvious rounded corners owing to electrochemical dissolution; however, the exit shown in Fig. 8(d), machined with the backing layer, shows better rounded corner and has a larger diameter than the exit of hole machined without the backing layer as shown in Fig.8(c).It also can be seen that the diameter difference between the entrance and exit is significantly reduced with the backing layer compared to the hole machined without the backing layer. These results, in accordance with Fig. 7, also indicate that the reverse replenishment of working fluids in lateral machining gap with a non-metallic backing layer can effectively enhance electrochemical reactions and significantly improve machining accuracy, especially for the exit.

Fig. 7 Comparison of machining accuracy of holes machined under two conditions.

Fig. 8 Orifice morphologies of holes machined under different processing conditions.

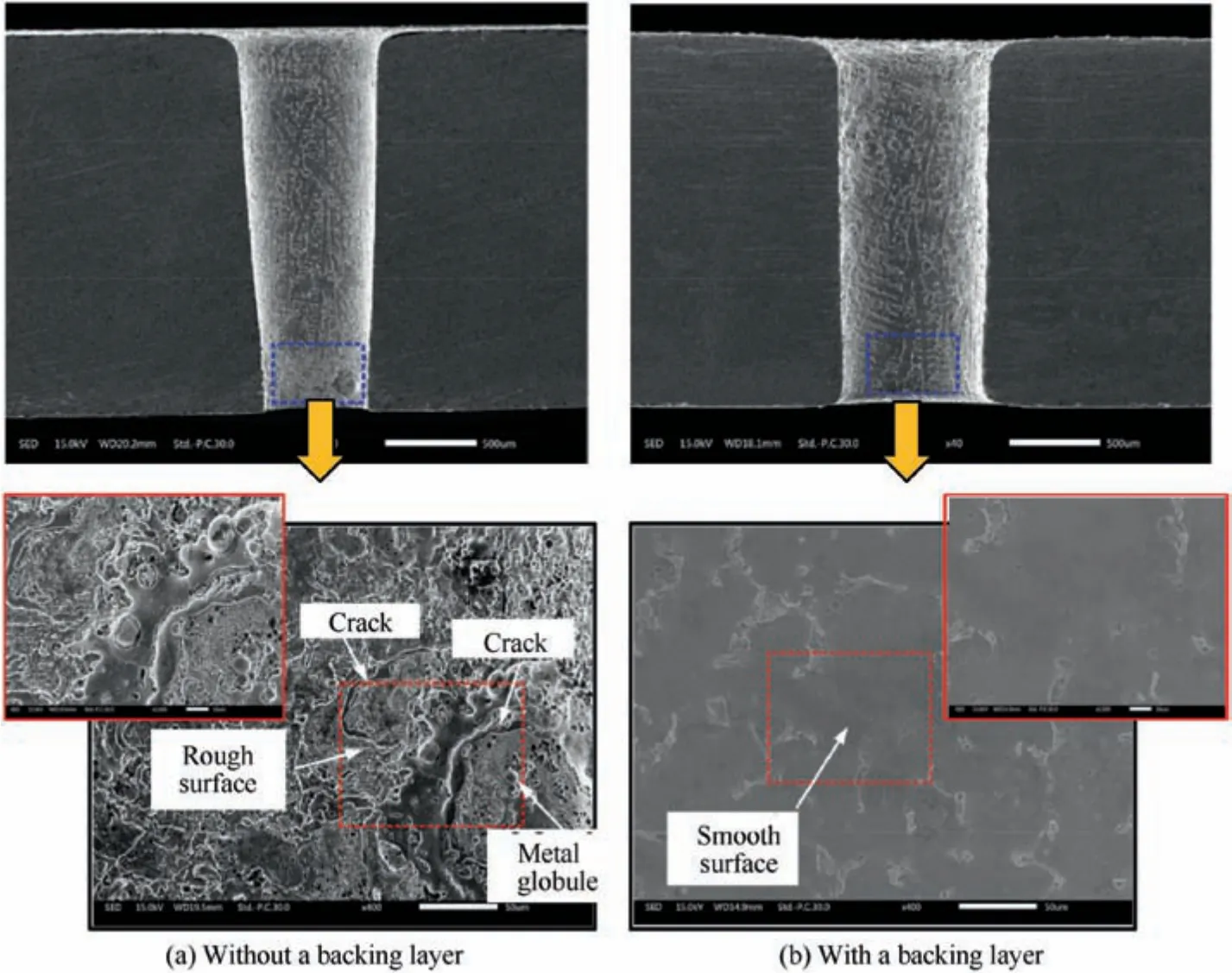

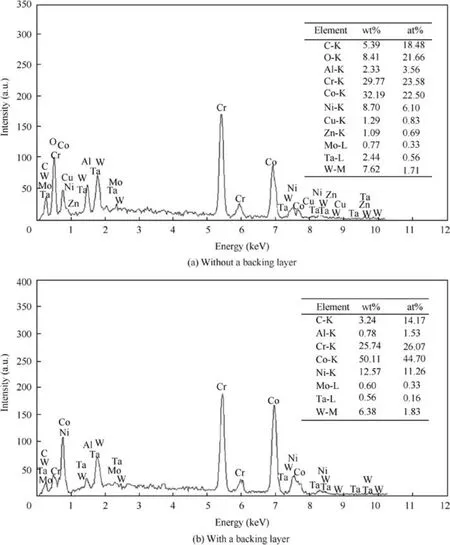

Fig. 9 shows the section views of the hole and enlarged views of the hole wall to compare the taper and surface of the hole. When no non-metallic backing layer is applied at the exit, short circuit discharge will occur at hole wall due to the diminish of working fluid in the lateral machining gap. It can be observed in Fig. 9(a) that the surface of hole near the exit machined without the backing layer is extremely rough with a large number of defects caused by the spark discharge,such as microcracks, metal globules, and pores. However,when the non-metallic backing layer is applied to the exit,thus effectively avoiding the problem of short circuit discharge, the continuous working fluid supply in the lateral machining gap can be obtained. Therefore, the entire surface of the hole machined with the backing layer is smooth with a desired roughness level, as observed in Fig. 9(b). Further, the elemental compositions of these two surfaces were analyzed by EDS,and the results are presented in Fig. 10. It can be seen that there is more oxygen on the exit hole wall machined without the backing layer than on that machined with the backing layer. This is because machining without backing layer makes the time of electrochemical dissolution shorter,and the surface defects generated by EDM cannot be entirely removed,explained by Fig. 10(a). While it can be inferred from Fig.10(b)that this problem can be solved by using the backing layer. It can be concluded that owing to the continuous and sufficient reverse flushing of working fluid in lateral machining gap with a backing layer,the electrochemical dissolution reaction occurring at the exit becomes adequate, so as to improve the machining accuracy of the hole and surface quality.

In brief, it can be inferred from the simulation and experimental results that using a backing layer,the problem of working fluid diminish in lateral machining gap can be effectively solved. Thus, a steady and continuous supply of the working fluid further enhances the electrochemical reaction. Additionally, the lateral machining gap, especially near the exit, will expand continuously to improve the machining accuracy and surface quality of the hole.

Fig. 9 SEM images of tapers and surfaces of holes obtained using two processing conditions.

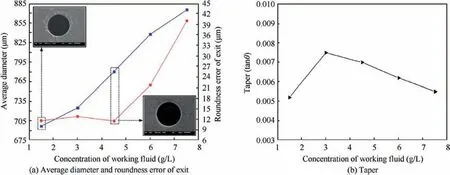

5.2. Effect of the concentration of the working fluid on machining accuracy of holes

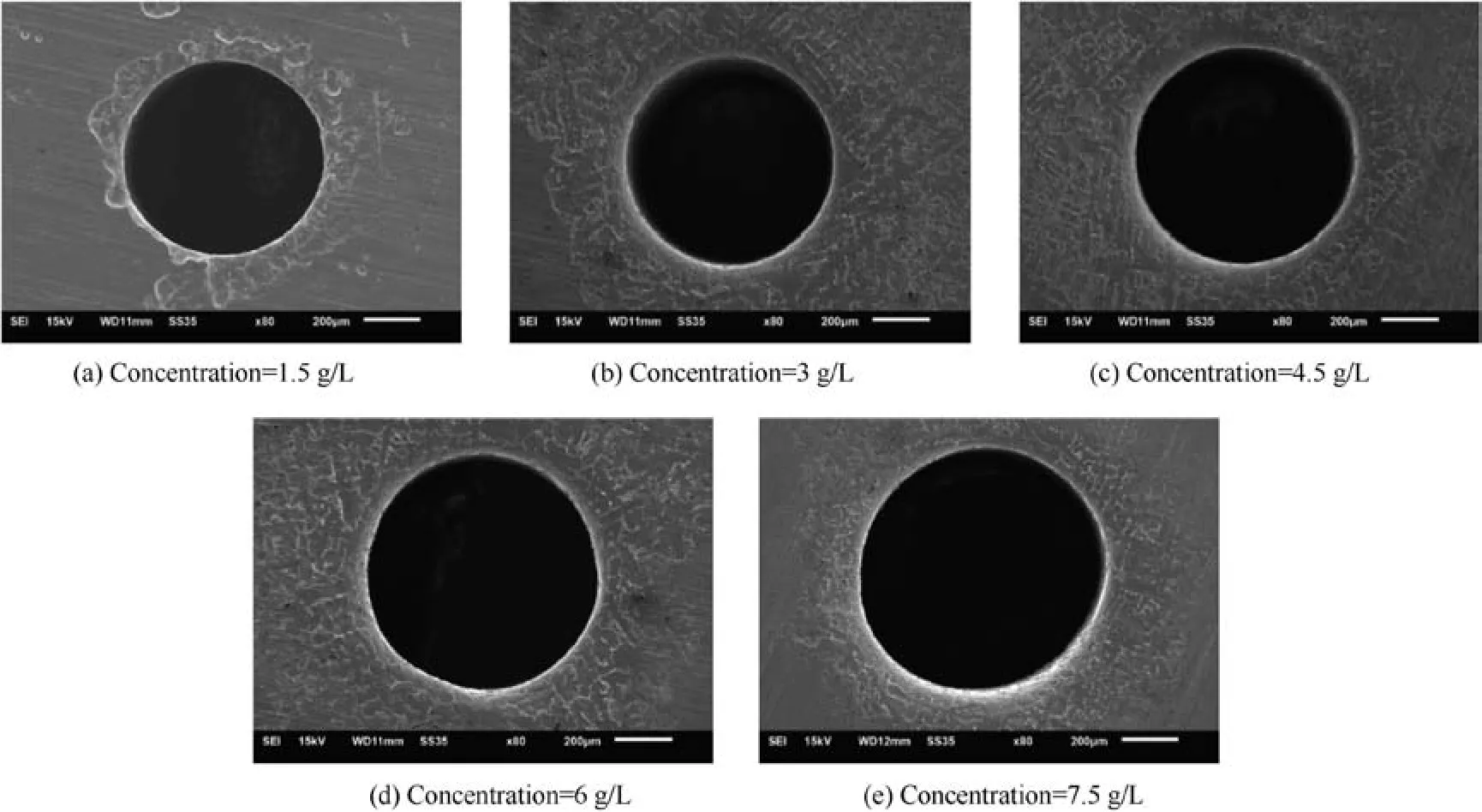

When studying the effect of the concentration of working fluid,the fixed values of Applied DC voltage and electrochemical reaming duration were 60 V and 9 s, respectively. The effect of the working fluid concentration on machining accuracy is shown in Fig. 11. It can be observed in Fig. 11(a) that when the concentration increases, the average diameter increases gradually; however, the roundness error of the exit tends to decrease slightly and then increase steadily.The average diameter increases because as the working fluid concentration increases, the higher conductivity will enhance the electrochemical reaction; this accelerates the dissolution and expansion of the side machining gap. As for the roundness of the exit, when working fluid concentration is low (1.5-4.5 g/L),the weak electrochemical reaction improves the localization of ECM, so the roundness error of the exit is smaller. However, when the concentration of the working fluid exceeds 4.5 g/L, several reaction products like hydroxide precipitates and bubbles will promote unsteady electrochemical reactions and deteriorate the exit roundness. The exit morphology of holes machined with different concentration of the working fluid is shown in Fig. 12, which further reflects the variation in the average diameter and roundness error of the exits.

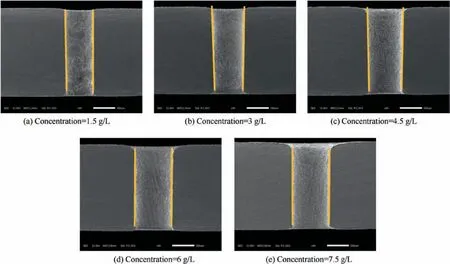

Fig.11(b)shows the variation of taper with increasing concentration of the working fluid. It can be observed that the taper of the hole rises firstly and then decreases steadily with the increase of working fluid concentration. Increasing the working fluid concentration will affect the taper in two ways.On the one hand,during the electrochemical discharge drilling process,owing to the difference in the duration of electrochemical reactions between the entrance and exit, a higher concentration of working fluid will result in a larger taper. On the other hand, during electrochemical reaming, owing to the higher rate of electrochemical dissolution at the exit than at the entrance,the taper decreases with the increasing concentration of the working fluid. When the concentration is higher than 3 g/L,due to the less generation of electrochemical products including hydrogen bubbles and other insoluble products,thus the electrochemical reaction rate during electrochemical discharge machining is higher than that during electrochemical reaming.Therefore,the taper increases with the increasing the working fluid concentration.However,when the concentration is higher than 3 g/L, the effect of the electrochemical dissolution during electrochemical reaming on the taper is higher;hence, the taper decreases when the concentration increases.The cross sections of holes processed using different concentrations of the working fluid are shown in Fig. 13, and the taper variations are consistent with the results shown in Fig. 11(b).

Precision indicators of a hole include the taper, roundness of the exit, and average diameter. The following should be determined for optimizing the process parameters. In terms of the priority level, the taper precedes the roundness of the exit, and the roundness of the exit precedes the average diameter. The average diameter should be smaller when the other two indicators are the same. Hence, according to Fig. 11(b),the minimum taper can be obtained when the working fluid concentration is 1.5 g/L. Fig. 11(a) indicates that the value of the exit roundness error when using a working fluid concentration of 1.5 g/L is very close to its minimum at 4.5 g/L. The minimum average diameter can also be obtained when using a concentration of 1.5 g/L. Therefore, the optimal working fluid concentration is 1.5 g/L.

Fig. 10 EDS analysis results of hole surface using two processing conditions.

Fig. 11 Effect working fluid concentration on machining accuracy of holes.

Fig. 12 Exit morphology of holes processed using different concentration of working fluid.

Fig. 13 Cross sections of holes machined using different concentration of working fluid.

5.3.Effect of applied voltage during electrochemical reaming on machining accuracy of holes

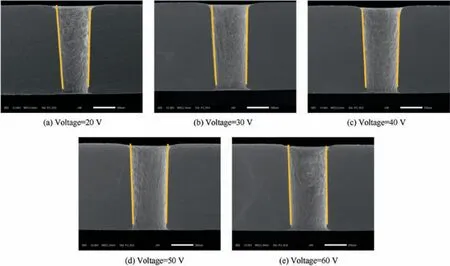

Fig. 14 Effect of applied voltage during electrochemical reaming on machining accuracy of holes.

Fig. 15 Exit morphology of holes processed using different voltage during ECM.

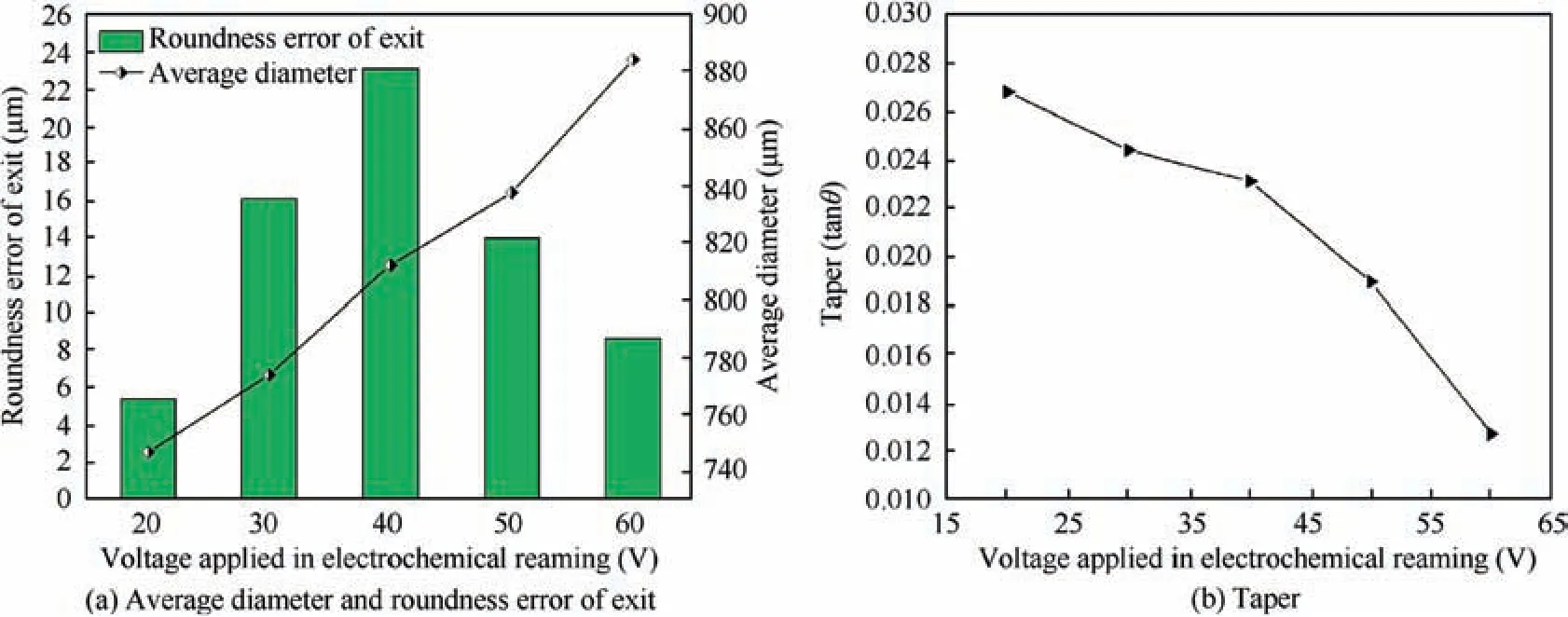

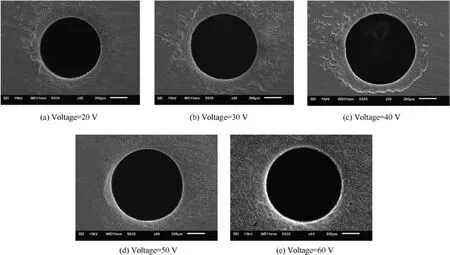

When studying the effect of voltage,the fixed values of concentration of working fluid and electrochemical reaming duration were 4 g/L and 20 s,respectively.Fig.14 illustrates the effect of the applied voltage during electrochemical reaming on machining accuracy. As observed in Fig. 14(a), the average diameter increases gradually with the increase of voltage. Based on the same current efficiency and volume electrochemical equivalent,a higher voltage can provide a higher current density. Hence,the electrochemical dissolution rate in the machining gap increases with an increasing voltage. Moreover, Fig. 14(a)shows that the exit roundness error first increases and then decreases with an increasing voltage. With an increasing voltage (20-40 V), strong electrochemical reaction causes a increasing accumulation of machining products such as numerous hydrogen bubbles and other electrochemical insoluble products. The machining accuracy of holes will decrease owing to a deteriorating flow field environment.As the voltage continues to increase (40-60 V), the large machining gap resulting from the enhanced electrochemical reaming is sufficient to remove these machining products, thus the roundness error of the exit decreases. The exit morphologies of the holes machined by electrochemical reaming with different voltages are shown in Fig. 15, which clearly reflects the variation in the average diameter and exits roundness error in shown in Fig. 14(a). The taper decreases steadily as the voltage increases,as shown in Fig.14(b).This may be explained as follows: As the initial machining gap at the exit is smaller than that at the entrance, the rate of electrochemical dissolution is faster at the exit when using same voltage, which allows for a continuously decreasing taper. The variation trend can also be verified by observing the cross sections of holes in Fig. 16.

In summary, Fig. 14(b) shows that the minimum taper can be obtained at 60 V. For the roundness error, there is not much difference between the value at 60 V and the minimum value at 20 V according to Fig. 14(a). The large value of the average diameter at 60 V is acceptable because it is not the most important indicator of machining accuracy. Hence, the optimal processing voltage applied in electrochemical reaming is 60 V.

5.4. Effect of electrochemical reaming duration on the accuracy of holes

Fig. 16 Cross sections of holes processes using different voltages during ECM.

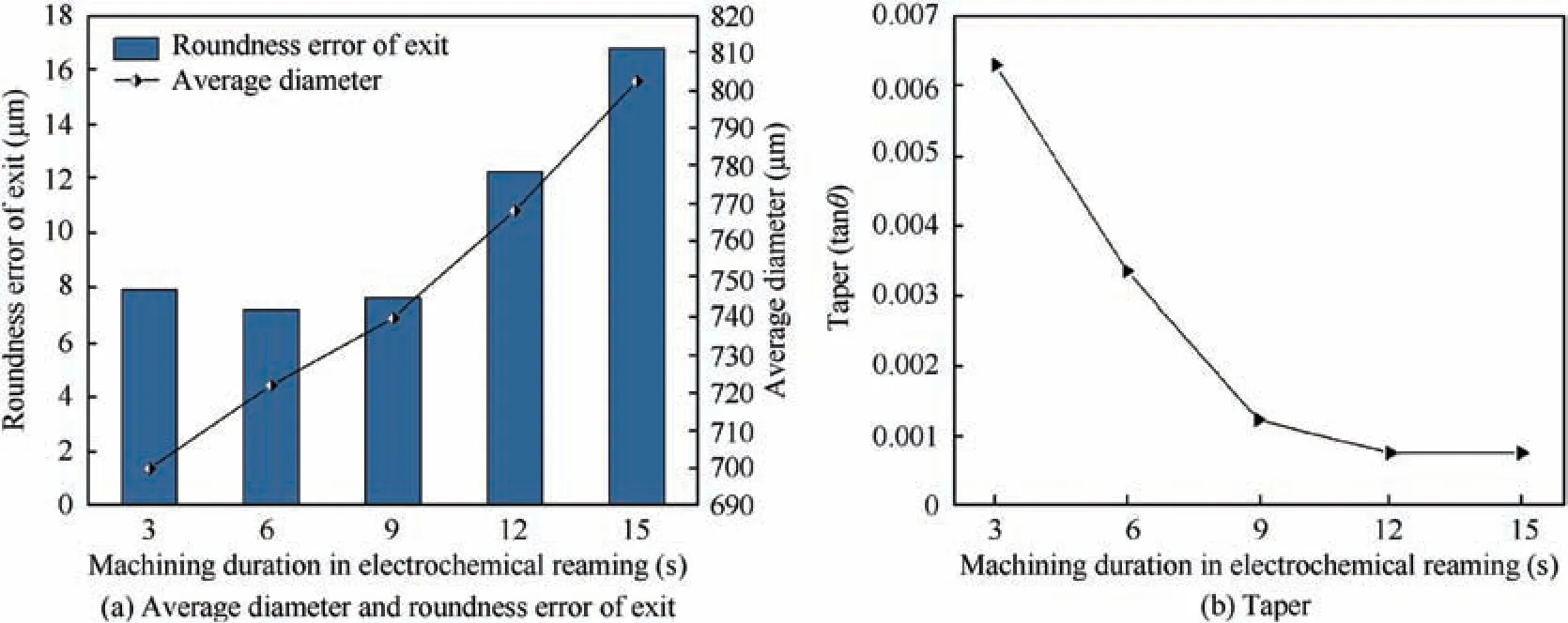

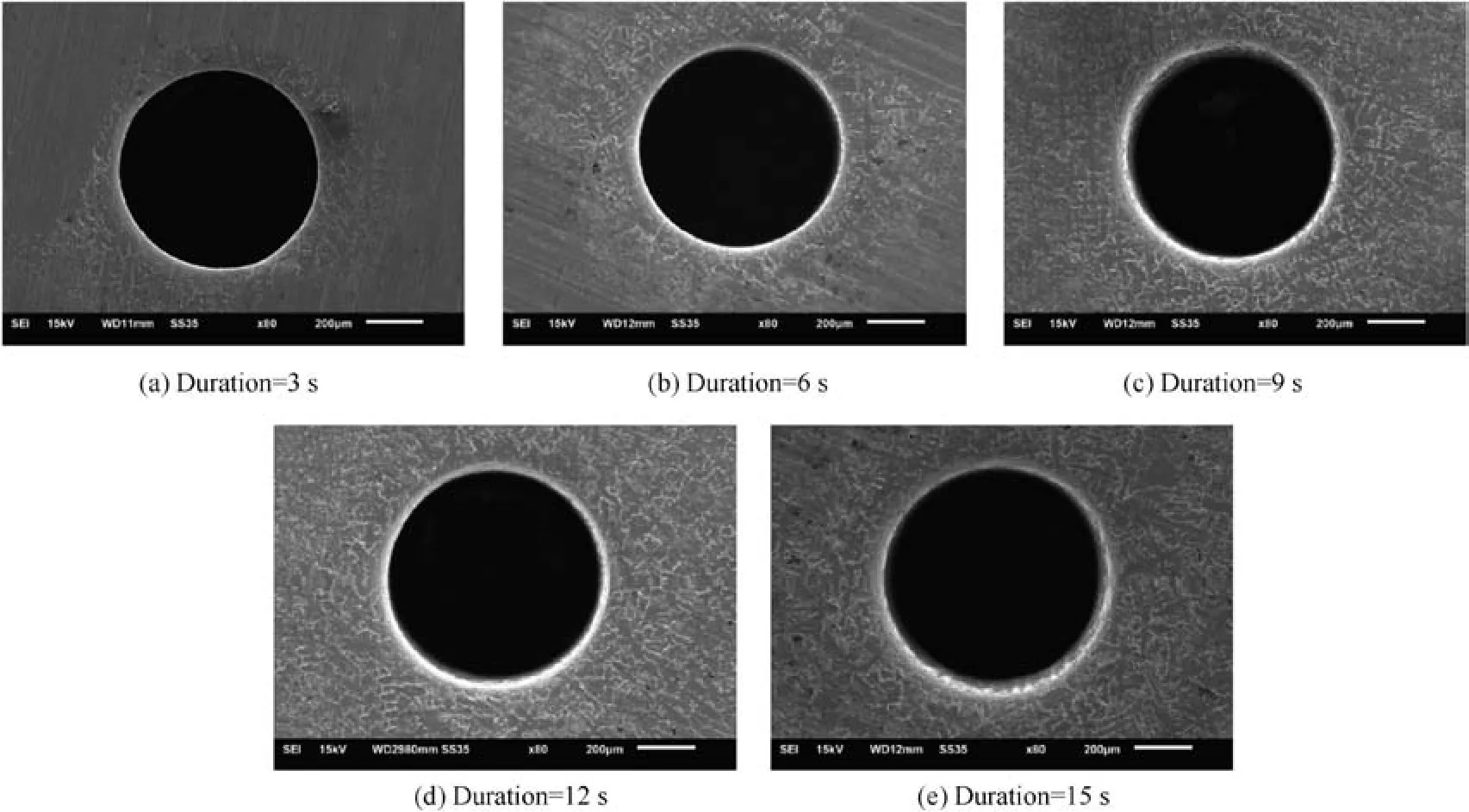

Fig. 17 Effect of electrochemical reaming duration the accuracy of holes.

When studying the effect of electrochemical reaming duration,the fixed values of voltage applied DC voltage and concentration of working fluid were 60 V and 4 g/L respectively.Fig.17 reveals the effect of the electrochemical reaming duration on the accuracy of holes. It can be observed in Fig. 17(a) that the average diameter increases linearly with the increase of the electrochemical reaming duration. The longer duration of electrochemical dissolution causes a larger expansion of the machining gap, which leads to a continuous increase in the average diameter.Fig.17(a)also shows that with an increasing electrochemical reaming duration, the roundness error of the exit decreases first and then increases, and the smallest roundness error occurs when using a duration of 6 s.This is because with such elecetrochemical reaming duration, the roundness can be improved steadily by increasing the electrochemical reaction time. However, when the processing time exceeds 6 s, more electrochemical dissolution products are produced,and they block the paraffin pit, which affects the performance of ECM and leads to poor roundness of the exit.The exit morphologies of holes processed using different machining times are shown in Fig. 18. With an increasing machining time, the smooth area and radius of the orifice steadily increase owing to the electrochemical dissolution. This accurately reflects the variation in the average diameter and roundness error of the exit in shown in Fig. 17(a).

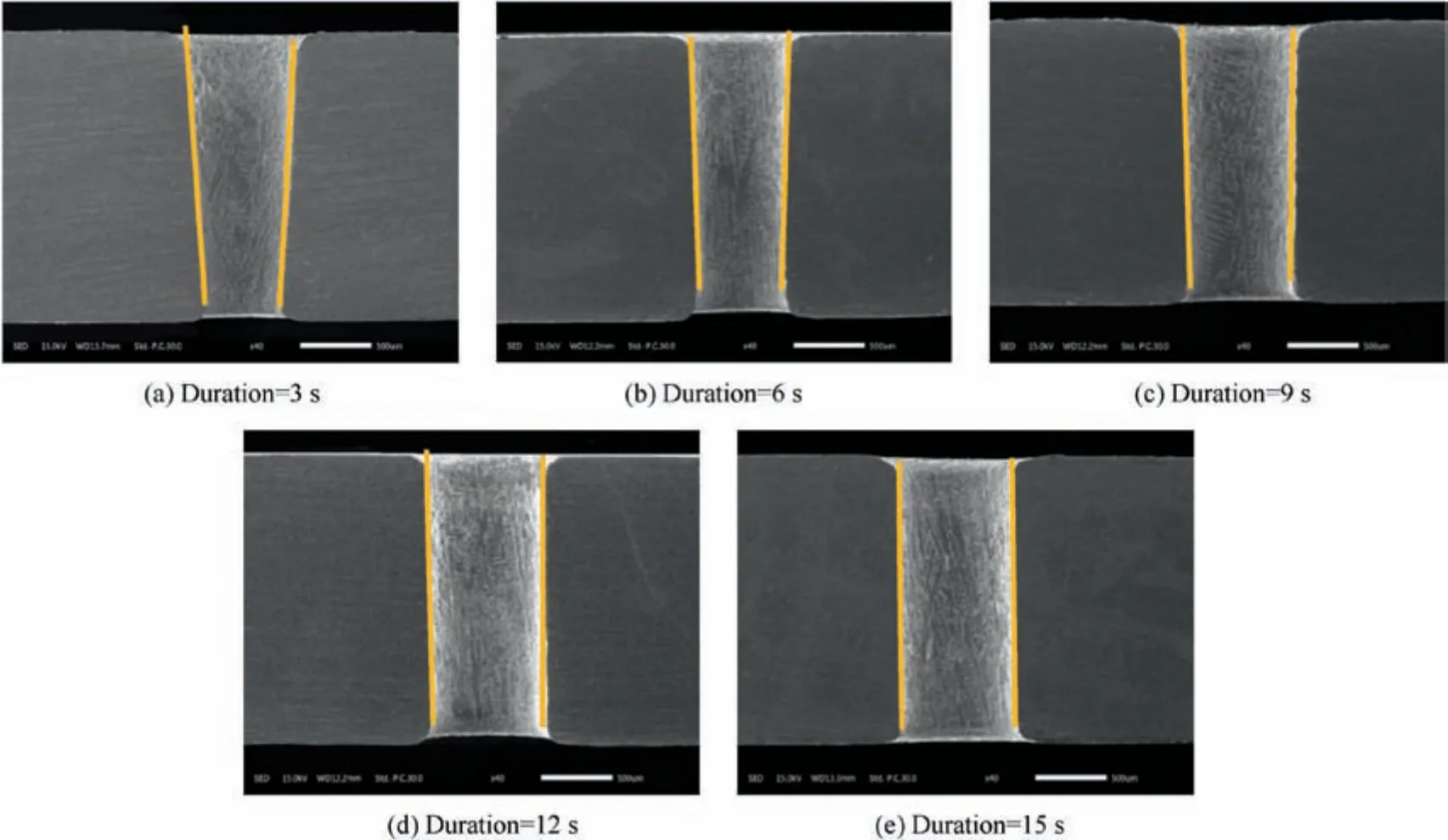

According to Fig.17(b), the taper gradually decreases with an increasing electrochemical reaming duration. It is observed that owing to the smaller initial machining gap, the rate of electrochemical reaction at the exit is much higher than that at the entrance; therefore, the diameter difference decreases sharply in a short time (3-9 s), and the taper decreases correspondingly.However,as the electrochemical reaming duration exceeds 9 s, the smaller machining gap difference makes the dissolution rates at the exit and entrance almost equal, so the taper of holes decreases slowly. Fig. 19 shows the cross sections of holes processed by different electrochemical reaming duration, which verifies the variation of taper shown in Fig. 17(b).

Fig. 18 Exit morphologies of holes processed by different electrochemical reaming duration.

Fig. 19 Cross sections of holes processed by different electrochemical reaming duration.

Fig.17(b)indicates that the minimum taper is obtained by a electrochemical reaming duration of 12 s.Even if the values of the average diameter and exit roundness error are both greater than those obtained when using a electrochemical reaming duration of 6 s, according to Fig. 17(a), the taper is still a top priority so the electrochemical reaming duration of 12 s will be choosed as the optimal value.

Based on the results presented in Figs. 11-19, to obtain holes with better machining accuracy,the optimized combination of machining parameters for electrochemical reaming is a working fluid concentration of 1.5 g/L, machining voltage of 60 V and electrochemical reaming of 12 s.

6. Conclusions

Electrochemical discharge machining using a non-metallic backing layer was studied to improve the machining accuracy of holes.The main conclusions of the study can be summarized as follows:

1) Simulation results of the flow field in the gap of the paraffin backing layer show that by using the nonmetallic backing layer method, a sufficient and continuous supply of working fluid for reverse flushing could be provided to the machining gap after the workpiece is penetrated by the tube electrode. Performing reverse flushing in the non-metallic backing method is as good as that during normal flushing before perforation.

2) Comparative experiment results show that with auxiliary flushing using the paraffin backing layer, the shape precision of the exit is obviously improved,and the taper of the small hole is significantly reduced. Moreover, the entire wall of the hole is machined to be smooth and machining precision is obviously improved.

3) The optimal process parameters of electrochemical reaming were obtained through optimization experiments, and the optimized combination of machining parameters for electrochemical reaming is a working fluid concentration of 1.5 g/L, machining voltage of 60 V and electrochemical reaming of 12 s.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This project is supported by the National Natural Science Foundation of China (No. 51705239).

CHINESE JOURNAL OF AERONAUTICS2021年12期

CHINESE JOURNAL OF AERONAUTICS2021年12期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Entropy based inverse design of aircraft mission success space in system-of-systems confrontation

- Nonlinear resonance characteristics of a dual-rotor system with a local defect on the inner ring of the inter-shaft bearing

- Failure mechanisms of bolted flanges in aero-engine casings subjected to impact loading

- Synchronized perturbation elimination and DOA estimation via signal selection mechanism and parallel deep capsule networks in multipath environment

- Improving seeking precision by utilizing ghost imaging in a semi-active quadrant detection seeker

- A high dynamics algorithm based on steepest ascent method for GNSS receiver