Modeling high-speed cutting of SiCp/Al composites using a semi-phenomenologically based damage model

Junfeng XIANG, Lijing XIE, Feinong GAO

a School of Civil Aviation, Northwestern Polytechnical University, Xi’an 710072, China

b Key Laboratory of Fundamental Science for Advanced Machining, Beijing Institute of Technology, Beijing 100081, China

KEYWORDS Chip morphology;Damage evolution;High-speed cutting;Semi-phenomenological plasticity;SiCp/Al composites

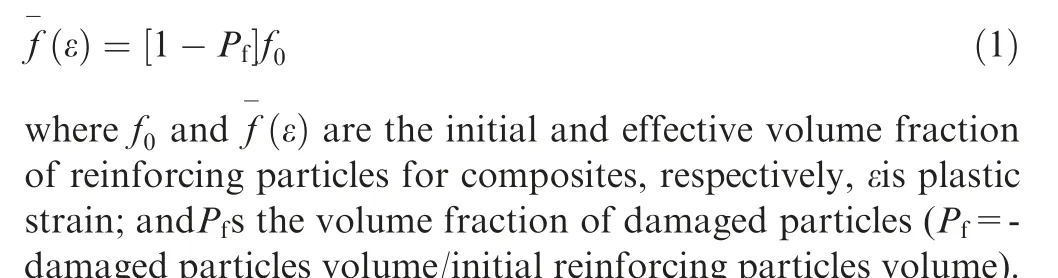

Abstract In this paper, we attempts to investigate cutting mechanisms in high-speed cutting of Al6061/SiCp/15p composites using a semi-phenomenologically based damage model in the equivalent homogeneous material (EHM) framework. By combining macroscale EHM modeling and underlying microscale physical mechanisms,a feasible semi-phenomenological plastic model is proposed for prediction of cutting forces and chip morphology during high-speed turning Al6061/SiCp/15p composites.This model incorporates the modified Weibull weakest-link effect to represent the strain-based damage evolution in large deformations. This proposed semi-phenomenological constitutive model is implemented by compiling material subroutines into cutting finite element(FE) codes. The effects of the critical shear stresses on chip formation that depend on the toolchip frictional coefficient are accounted for in the cutting FE model.The chip formation mechanism affecting material removal behaviors during high-speed turning is further investigated.The capabilities of the proposed constitutive model are evaluated by comparing cutting forces and chip morphologies between experiments and simulations at different cutting speeds associated with strain rates. The EHM-based and microstructure-based models are further compared in both computational efficiency and accuracy. The simulation results show that the developed semiphenomenological constitutive formalism and cutting model are promising and efficient tools for further investigation of dynamic mechanical and cutting behaviors of particle-reinforced composites with different volume fraction and particle size.

1. Introduction

Silicon carbide particle-reinforced aluminum matrix (SiCp/Al)composites possess high specific strength, high specific stiffness,low thermal expansion coefficients,and good damage tolerance. The thermophysical and mechanical properties of SiCp/Al composites can be further redesigned by altering the volume fraction of SiC reinforcing phase, the composition of aluminum matrix alloy, and preparation technologies.1Due to their excellent performance, SiCp/Al composites have been used in many fields including aerospace, automotive,electronics,medicine,and optics.However,during machining of SiCp/Al composites, irregularly shaped, high-hardness, highabrasiveness SiC particles in SiCp/Al composites cause material characteristics of non-uniformity, anisotropy, and low ductility that lead to problems encountered in the cutting process.2–5It is difficult and expensive to achieve the required machining quality with traditional cutting technologies, thus SiCp/Al composites are typical in difficult-to-cut materials.6–8

Generally, the physical phenomena that occur during cutting are difficult to understand through experimental observation alone. Numerical simulation has become an important supplementary tool for investigation of underlying physical mechanisms, and for optimization of cutting parameters and tool geometry to improve the machinability of difficult-to-cut materials. For the rapid development of high-speed, highprecision cutting technologies for new difficult-to-cut materials, research must incorporate experimental methods, theoretical analysis, and numerical simulation.9During machining of parts, significant and complex material deformation occurs at high strain-rate and elevated temperature; an in-depth understanding of material flow behaviors provides insight into the cutting mechanisms. Hence, mastering the material constitutive model, especially the dynamic mechanical behaviors at high strain-rate and elevated temperature is extremely important for high-speed precision machining research.10Due to differences in material fabrication technologies, processes and heat treatment often lead to significant variations in mechanical behaviors.11The practice of applying the constitutive model and data obtained from relevant literature to actual simulation studies without any modification is questionable.However, for the development of a dynamic constitutive model, many dynamic mechanical tests covering a wide range of strain rates and temperatures need to be conducted. Accurate expression of the constitutive model depends on the developer’s experience; uncertainty and non-uniformity are often inevitable in the development of material constitutive models.

Classical constitutive models cannot accurately describe the plastic flow behaviors of new materials for a wide range of strain,strain rate,and temperature.Faced with new challenges in modeling high-strain-rate plasticity, some researchers have modified the classical plastic constitutive models based on the intrinsic physical/mechanical parameters for such new materials, with a good coincidence between numerical and experimental results. Choi et al.12and Huang et al.13modified the O¨ zel material model by introducing an enhanced strainsoftening effect through dynamic recovery/recrystallization,and successfully predicted serrated chip formation in the machining of Ti-6Al-4 V alloy. Grissa et al.14combined the Johnson-Cook and kinetically isotropic hardening models to describe cyclic material deformation for predicting the residual stresses induced by orthogonal cutting. Zhu et al.15developed a thermo-plastic material model considering the phase transformation effect for WHT1300HF ultra-high strength steel.This model can reflect the plasticity induced by phase transformation and volume variations in hot deforming. Gurusamy and Rao16modified the Zerilli-Armstrong constitutive model on the basis of dislocation mechanics and achieved the same chip morphologies as those observed experimentally during the cutting of Inconel 718 super alloy.

Unlike simple but well-used phenomenological models,physics-based constitutive models are developed based on underlying physics mechanisms such as dislocation density evolution,dislocation interaction,thermal activation for dislocation slip, dynamic recrystallization, and phase transformation. Shen et al.17developed a physics-based material model by incorporating slip and twinning mechanisms to predict nanocrystalline microstructural evolution in cryogenic cutting.Imbrogno et al.18integrated thermal activation,forest dislocation, and Hall-Petch effects into their material model to capture the plastic deformation and microstructural evolution of serrated chips and machined surfaces. Demir and Mercan11presented a crystal plasticity constitutive model with physically-based dislocation dynamics and density evolution of statistically stored dislocations to account for crystal orientation and intrinsic length scale,eventually achieving high prediction accuracy of cutting force and shear angle in the turning of single crystal materials. To date, few physics-based models have been presented to discover the actual physics of cutting deformation over a wide range of high strain rates and cutting temperatures. Wide application of physics-based models is greatly limited, partly by difficulties in precisely controlled experiments required for identifying physical constants, and partly by the complexity reflected in a larger number of constitutive parameters than in phenomenological models.19Additionally, at macroscale, calculation based on physics constitutive models is often prohibited by high computational cost,unacceptable computation time, and difficulty in convergence.20As the number of model parameters increases,the difficulty and test cost of identifying a constitutive model significantly increases. For this reason, Xiang et al.21,22proposed a dependence-based material constitutive modeling methodology, together with a multi-objective parameter identification strategy,to create high-accuracy material models for predicting the high-speed cutting process. The combination of dependence-based material constitutive modeling methodology with a multi-objective parameter identification strategy offers flexibility; the introduction of observable or measured physical/mechanical properties into material models can be realized at low cost with high computational accuracy.21Phenomenological and physics-based constitutive models are suitable for characterizing homogenous materials such as ceramics, metals, alloys, and polymers, but not heterogeneous materials.

For composite materials, material models are categorized as EHM-based models (macroscopically isotropic materials)and multiphase microstructure-based models.Microstructure-based models can accurately describe the microstructure of the matrix (grain, texture), reinforcement(volume fraction, shape, size, and spatial distribution), and more detailed microstructure information(such as phase interface), which are necessary in the investigation of local deformation and failure behaviors. However, the applicability of such models is considerably limited by their high calculation costs.23EHM material models can considerably reduce the computational complexity in simulation, simplify the complicated process of geometric modeling for the distribution,shape, and size of the reinforcing phase, and avoid the laborintensive definition of the reinforcement-matrix contact and interfacial phase. However, EHM-based material modeling ignores the fundamental characteristics of the microstructure and phase interface of composite materials, leading to an inability to adequately describe local mechanical behaviors.Because composite materials are microscopically sensitive,the micro-damage initiated during cutting depends on the size,shape, and spatial distribution of the reinforcing phases, and the bonding strength at the reinforcement-matrix interface.More material parameters should be introduced for establishing a material model of composite materials than for the corresponding matrix or reinforcement. Thus, the material modeling of composite materials based on realistic microstructures is complicated.

To date, only a few phenomenological material models of SiCp/Al composites have been presented for simulating the high-speed cutting process. Li et al.24studied the dynamic mechanical response of 20 vol.% SiCp/A359 composites for strain rates in the range of 10-5–105s-1. The coupling effect of strain-rate hardening and volume fraction of reinforcement phase was established, which can reflect the compression deformation behaviors under high strain rates and small strain.Based on the research of Li et al.24,Dandekar and Shin25constructed an EHM-based model by introducing temperaturedependence to simulate the turning process of A359/SiC/20p composites, and obtained the stress and temperature distribution in the machined subsurface. Xiang et al.26combined the generalized Johnson-Cook plastic constitutive model and the Cockroft and Latham failure model to reproduce the material removal process when drilling SiCp/Al6063 composites; they successfully predicted the thrust forces, temperature distribution, and built-up edge positions. On this basis, through numerical simulation and experiments of ultra-precision turning of SiCp/Al composites, the machined surface formation mechanism, brittle-ductile transition, and tool wear mechanisms at different depths of cut were studied.27However, due to the lack of microscopic physical mechanisms such as particle damage evolution,these models cannot accurately describe the strain-softening behavior at high strains.

Establishing an accurate and reliable constitutive model of SiCp/Al composites is the key to predicting cutting forces,cutting temperature, chip morphology, and surface integrity.Hence, in the modeling and simulation of cutting of SiCp/Al composites, the effects of microscopic SiC particles, including particle damage evolution, on the cutting forces and chip formation should be considered. This study focuses on modeling high-strain-rate plasticity and its application in modeling highspeed cutting of 15vol% SiC reinforced Al6061 matrix(Al6061/SiCp/15p) composites, considering that high strain in the narrow primary shear zone induces the damage softening effect.

2. High strain-rate plastic modeling

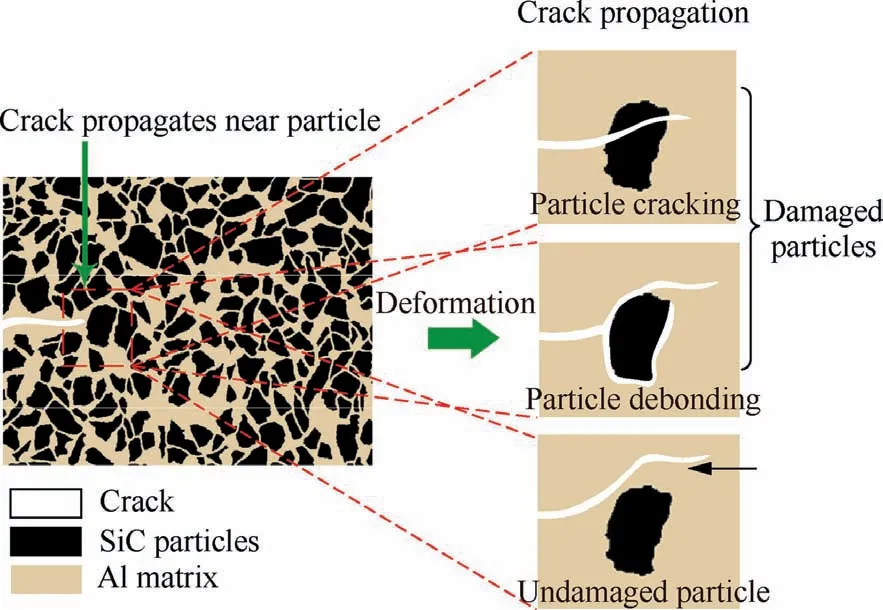

As shown in Fig. 1, SiC particles subjected to debonding and cracking do not constrain the plastic flow of the matrix, but still bear load. Li et al.28studied the viscoplastic deformation and compressive damage of A356/SiCpcomposites,and found that damage evolution is related to the macroscopic deformation behaviors. Once SiC particles are damaged, they cannot effectively restrain the plastic flow of the Al matrix, or strengthen the matrix; they act only as a filling medium that still can transmit load.Once SiCp/Al composites are plastically deformed,cracks at micro-defects or weakly bonded interfaces initiate, promoting the formation of secondary cracks in the surrounding matrix as deformation proceeds.With continuous accumulation of secondary cracks,the strain hardening behavior is gradually weakened.The volume fraction of undamaged particles gradually decreases with damage evolution;the effective volume fraction of reinforcing particles during compressive deformation can be determined by Eq. (1).

Fig. 1 Damage modes of SiC particles in SiCp/Al composites during dynamic deformation.

Lloyd29found that particle cracking is the main failure mode of particle-reinforced metal matrix composites with good interface bonding when the particle size is greater than 20 μm. This is also confirmed by the high-speed milling study of Wang et al.30on the defect formation mechanism of SiCp/Al composites. Under high strain-rate compression, as plastic deformation increases, more SiC particle cracking occurs and less interface debonding appears. The failure modes of PRMMCs are closely related to the interfacial bonding strength and reinforcing particle size.31With high local stress,larger particles have more defects, and a higher probability of fracture by shearing.Al6061/SiCp/15p composites prepared by the pressure infiltration method have good interfacial bonding strength.Thus,the plastic flow of Al6061/SiCp/15p composites is generally affected by damage to the reinforcing SiC particles.The damage probability of SiC particles is determined according to the modified Weibull weakest-link model.32

where σ0is the material constant; d is the particle diameter,with the average particle size being approximately 5.09 μm;dNis the regularized particle parameter;q is the Weibull inhomogeneity factor; σpis the flow stress of reinforcing particle.The flow stress σpcan be represented as a power function of plastic strain σp=kεn, and Eq. (2) can be further simplified as Eq. (3).

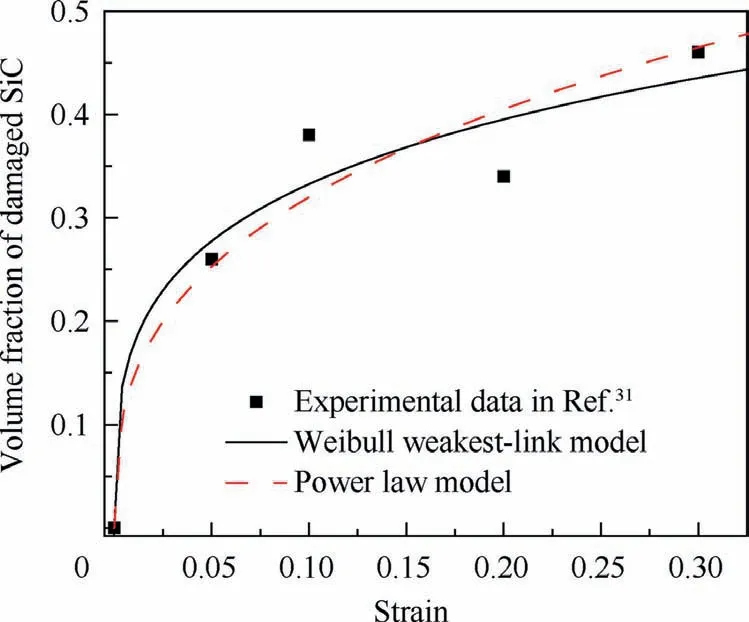

The damage probability model of SiC particles formulated in Eq. (3) can be well-fitted to the experimental data in Ref.[31], and is better able to predict the damage volume fraction of SiC particles varying with strain,as shown in Fig.2.Hence,the damage evolution of SiC particles in Al6061/SiCp/15p composites can be characterized by the effective volume fraction of reinforcing SiC particles.

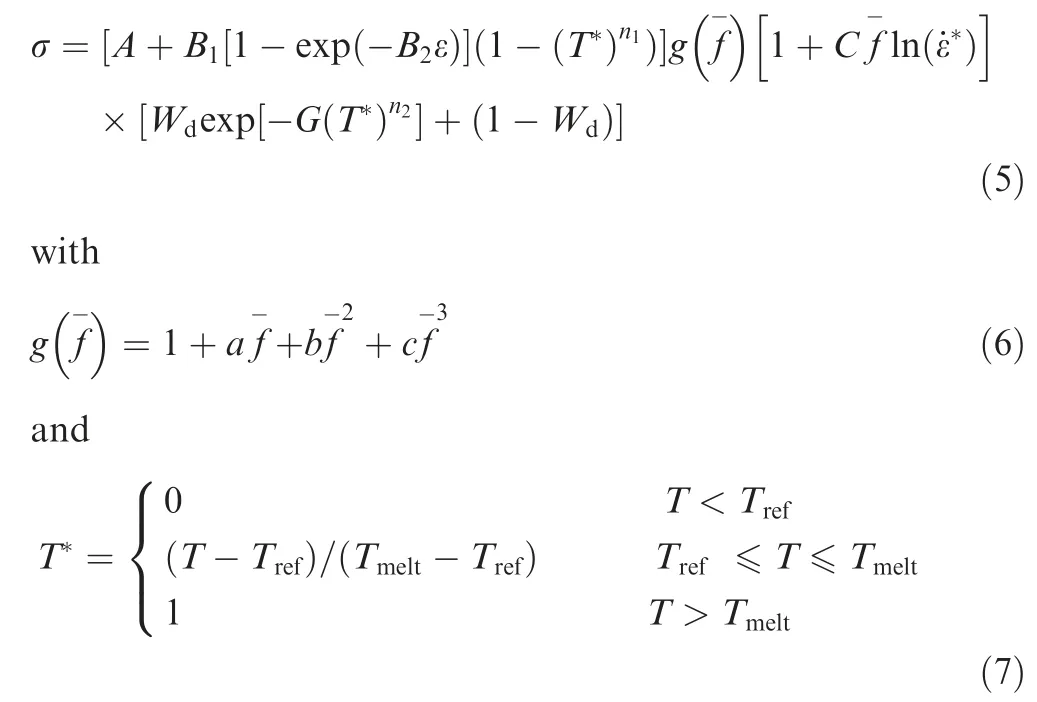

To consider the damage effect of SiCp/Al6061 composites during compressive deformation, through dependence-based integrated modeling methodology, a modified semiphenomenological material model of Al6061/SiCp/15p composites containing the damage evolution of SiC particles is proposed,based on the fit quality of the model to the test data in Ref. [21].

Fig. 2 Comparison of modified Weibull weakest-link model prediction and test data for damage evolution of SiC particles with strain.

Fig. 3 Fitting of proposed material model to experimental flow stress from Ref. [21] under different loading modes.

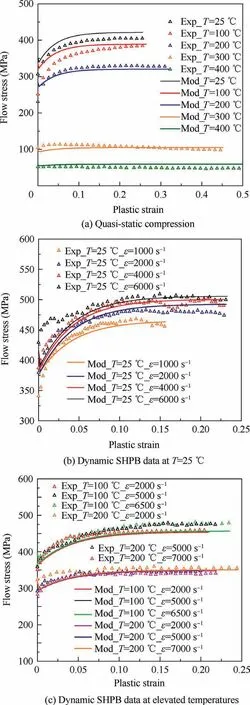

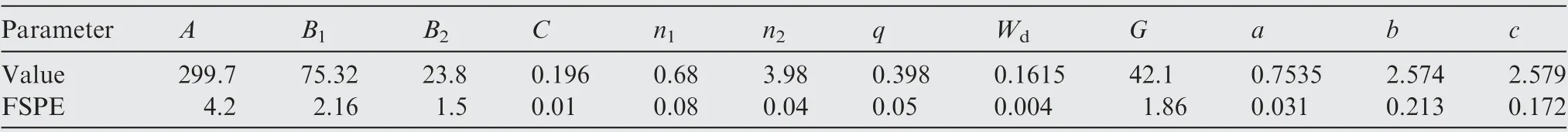

According to the weighted multi-objective optimization method for identifying model parameters proposed in Ref.[22], the form of the proposed constitutive model for Al6061/SiCp/15p composites is identified through a multi-curve fit to the test data in different quasi-static and dynamic loading modes. The results of the prediction and test data obtained using the proposed model under quasi-static and dynamic deformation conditions are compared in Fig. 3. The fitted material parameters of the developed constitutive model are summarized in Table 1, which lists the specific model formalism of Al6061/SiCp/15p composites,with a coefficient of determination (R2), average absolute relative error (AARE), and asymptotic fit standard error (AFSE) of 99.09%, 4.63%, and 14.0 MPa, respectively. The fit standard parameter errors(FSPE)is used to measure the effects of changed experimental data on fitting parameters variability.

The results demonstrate the satisfactory prediction accuracy of the developed model for the plastic behaviors of Al6061/SiCp/15p composites. By combining macroscale EHM phenomenological modeling and the underlying physical mechanism of micro-deformation, a semi-phenomenological constitutive model of Al6061/SiCp/15p composites for high strain-rate deformation is established based on Split Hopkinson Pressure Bar tests with different strain rates and elevated temperatures. The presented semi-phenomenological material model reduces the difficulty and complexity of material modeling compared with multiphase microstructure-based and physics-based models, and has a higher constitutive modeling accuracy than a phenomenological model does.

3. High-speed turning modeling and experimental set-up

3.1. Modeling of high-speed turning

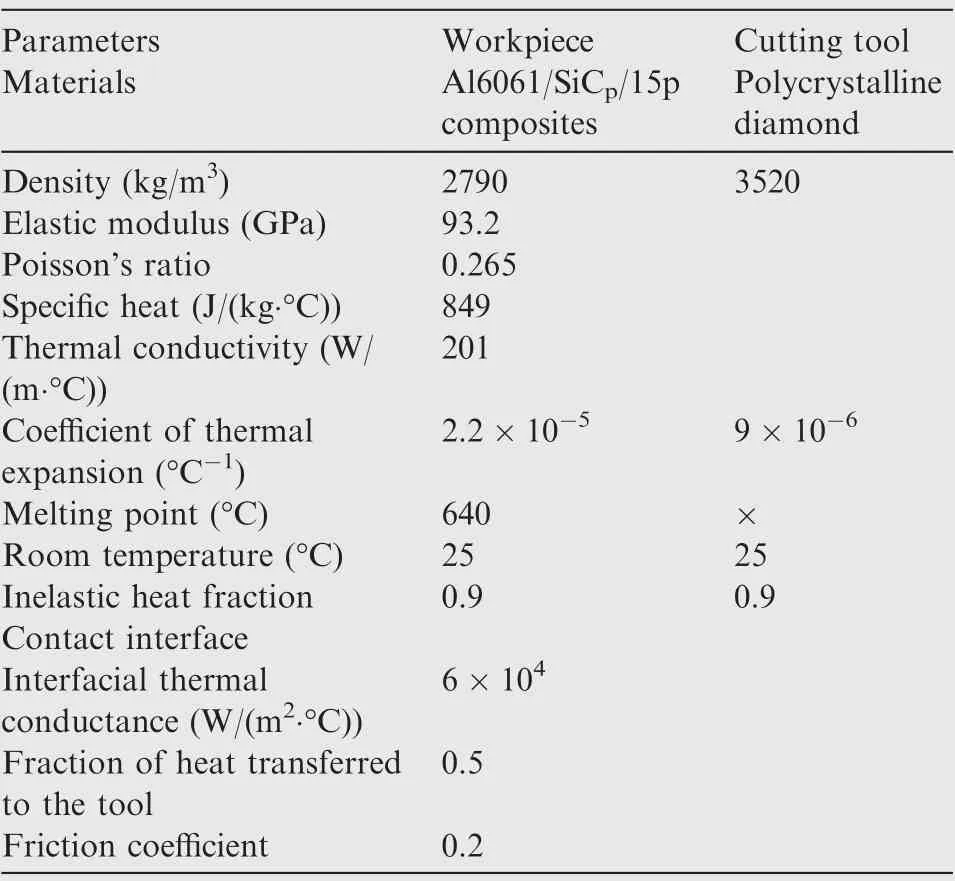

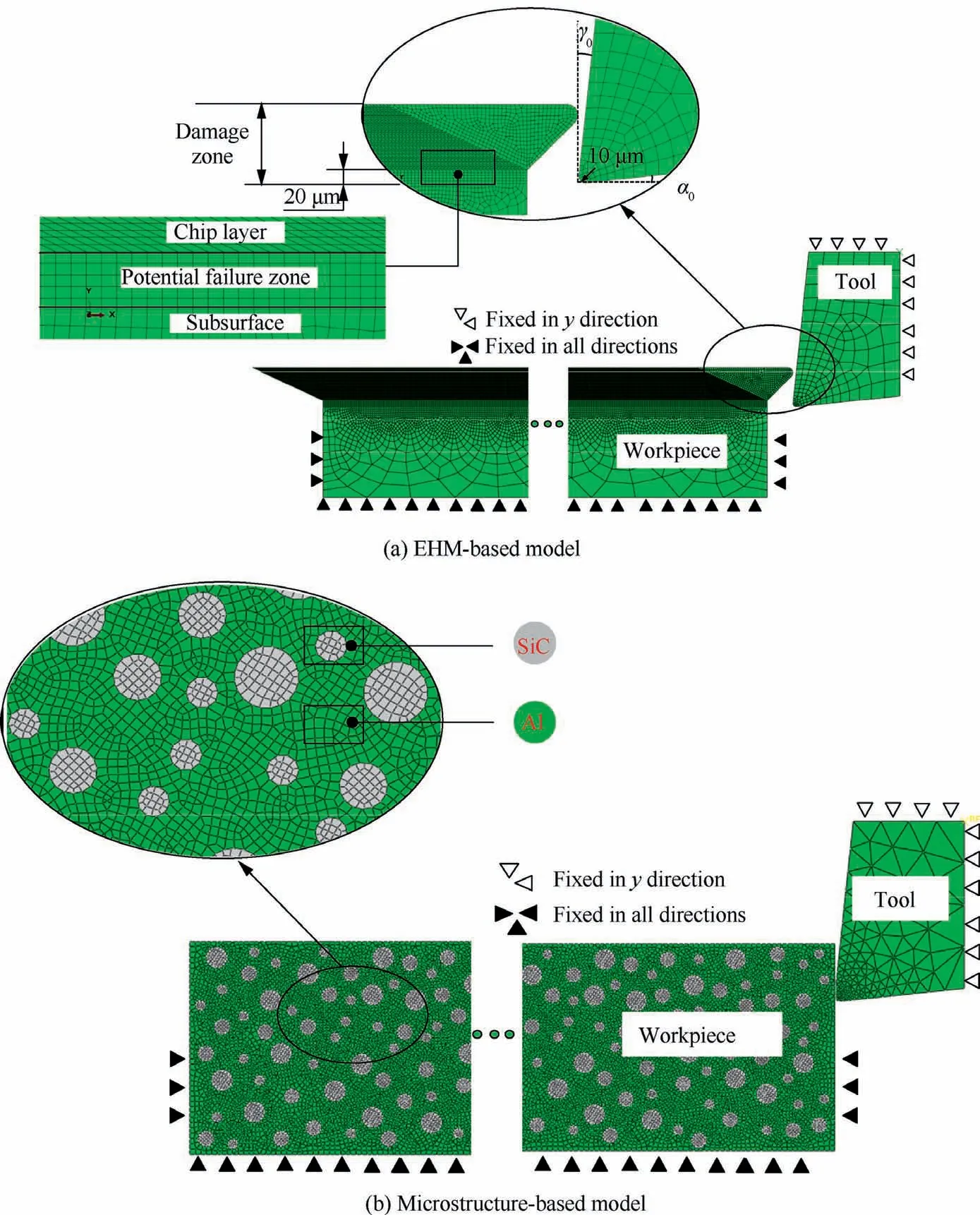

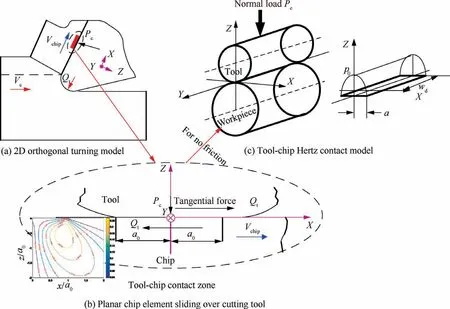

The constitutive formalism determined in Eq. (5) is described in a mathematical form suited to finite element codes, for describing the mechanical behaviors of a material during high-speed cutting. The developed constitutive model of Al6061/SiCp/15p composites is operated through user material subroutines invoked by finite element codes. Secondary development of material subroutines for the proposed constitutive model is conducted to model high-strain-rate plasticity of Al6061/SiCp/15p composites containing damage evolution.The maximum degradation of Johnson-Cook and shear damage criteria are employed to evaluate the damage initiation of chips; the damage evolution of chips is simulated using the Hillerborg fracture energy criterion.Table 2 lists the material parameters of the workpiece,the tool,and contact properties. A phenomenologically based finite element model is developed for free orthogonal cutting of Al6061/SiCp/15p composites. A four-node thermally coupled quadrilateral element, CPE4RT, with reduced integration and hourglass control, is used for meshing Al6061/SiCp/15p composites. A plane-strain-based thermomechanical analysis is performed using Lagrangian algorithms in the ABAQUS Explicit dynamic solver. The modeling of the cutting tool adopts geometric parameters consistent with the actual turning tool. To optimize the tool-workpiece contact conditions and improve the convergence of a nonlinear solution, a modeling methodsimilar to the method used in Ref.[33]is employed to establish a 2-D free orthogonal turning model of Al6061/SiCp/15p composites, as shown in Fig. 4(a). To further evaluate the reliability and effectiveness of the semi-phenomenological EHMbased model, a microstructure-based model of the Al matrix and SiC particles is established according to a realistic volume fraction and statistical particle size.

Table 2 Material parameters and contact properties.

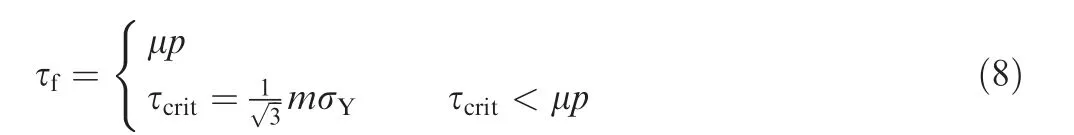

The contact mechanics between the tool and chips is represented by the Zorev sticking/sliding contact model in Eq. (8).The shear stress τfof the near tool-tip sticking zone is equal to the workpiece shear yield stress τcrit. In the sliding zone away from the tool tip, the frictional stress is lower than the shear yield stress, following Coulomb’s friction law.26

where σYand τfare the yield stresses in tensile and shear modes; μ is frictional coefficient; m is Taylor factor; p is the chip-tool interface pressure.

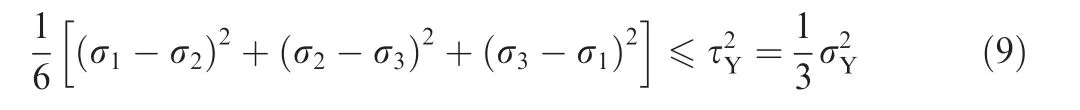

The upper limit of the shear yield stress is calculated using the von Mises criterion.

where σi(i=1, 2, 3) is the principal stress.

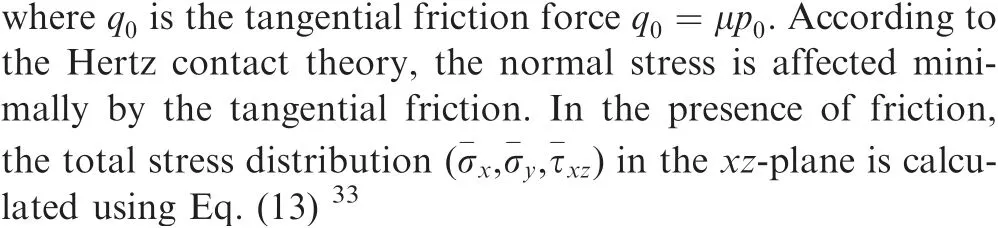

When the tool-chip friction coefficient is relatively small,the maximum shear stress may be below the tool-chip contact surface. If the critical shear stress is assumed to be the maximum shear stress, the workpiece material below the tool-chip contact surfaces will have already failed before the materialnear the tool tip reaches the critical shear stress.Thus,a proper definition of the critical shear stress can help accurately simulate the formation of chips.

Table 1 Material parameters of the developed constitutive model for Al6061/SiCp/15p composites.

Fig. 4 Geometry, boundary conditions and meshing in 2D free orthogonal turning model of Al6061/SiCp/15p composites.

Fig.5(a)shows the tool-chip contact conditions.The workpiece is fixed, and the cutting tool performs a cutting motion from right to left at a cutting speed of Vc. A micro-element of the tool-chip contact interface with a relative sliding speed of Vchipbetween the chip and the tool, and a normal force per unit length Pcare selected to study the tool-chip contact mechanics. For ease of understanding and modeling, the tool-chip contact model is reasonably simplified, as shown in Fig. 5(b). In the contact model, a planar chip element moves along the curved profiles of the tool at a constant speed Vchip.For elastic contact without any friction,as the size of the toolworkpiece contact zone is small relative to that of the tool or workpiece itself, the tool-workpiece contact problem can be solved based on the Hertz contact theories.34The tool-chip contact problem in the plane-strain case is simplified as an interaction between two cylinders, as shown in Fig. 5(c); here,a0is half the contact width of the two cylinders, and p0is the maximum contact pressure.

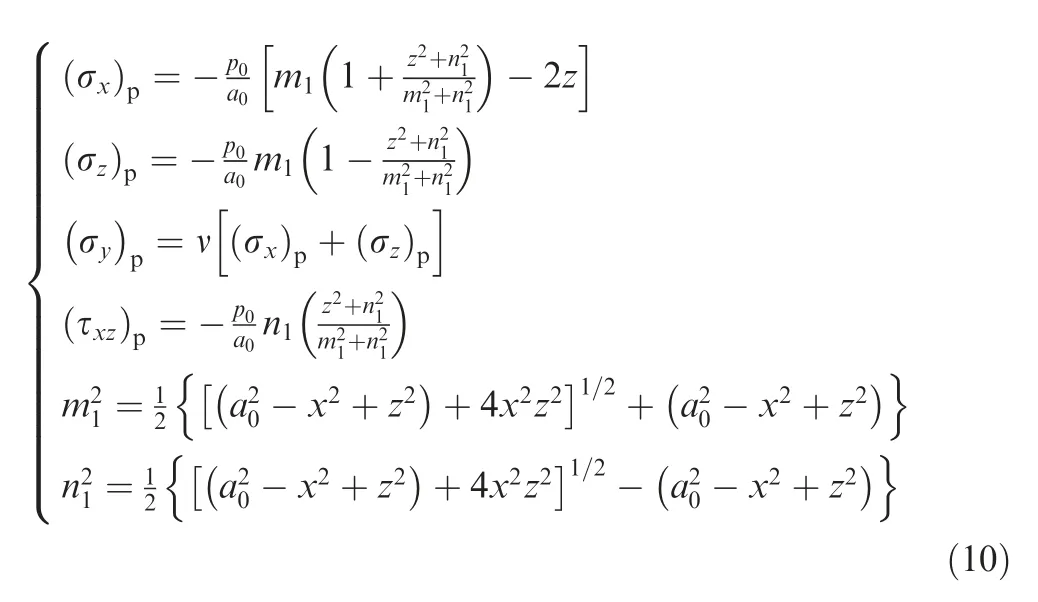

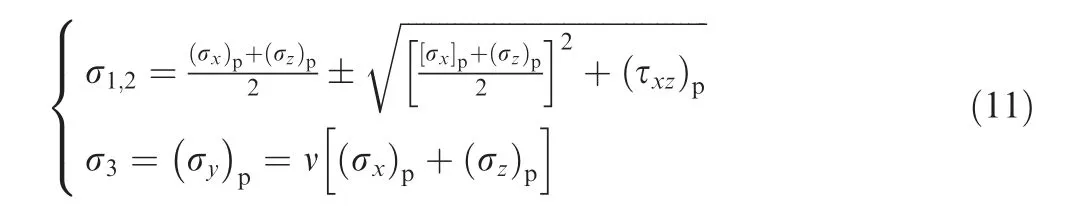

According to the theories of contact mechanics, with a small friction coefficient or no friction between the chip and the tool,under the action of the normal load Pc,the stress distribution in the chips is expressed as34

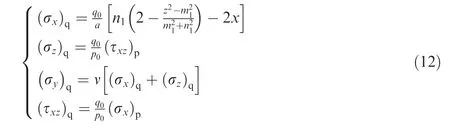

where σi(i=x, y, z) is the normal stress in the ith direction;τxzis the shear stress in xz-plane; ν is Poisson’s ratio; m1and n1are intermediate variables.The subscripts p and q represent the stress components caused by normal load and tangential friction, respectively.

Fig. 5 Simplified tool-chip contact model based on the Hertz contact theories.

Under plane strain, the principal stress of the chip contact zone can be expressed as

Considering friction, the chip stress distribution resulting from the tangential force Qtis described as

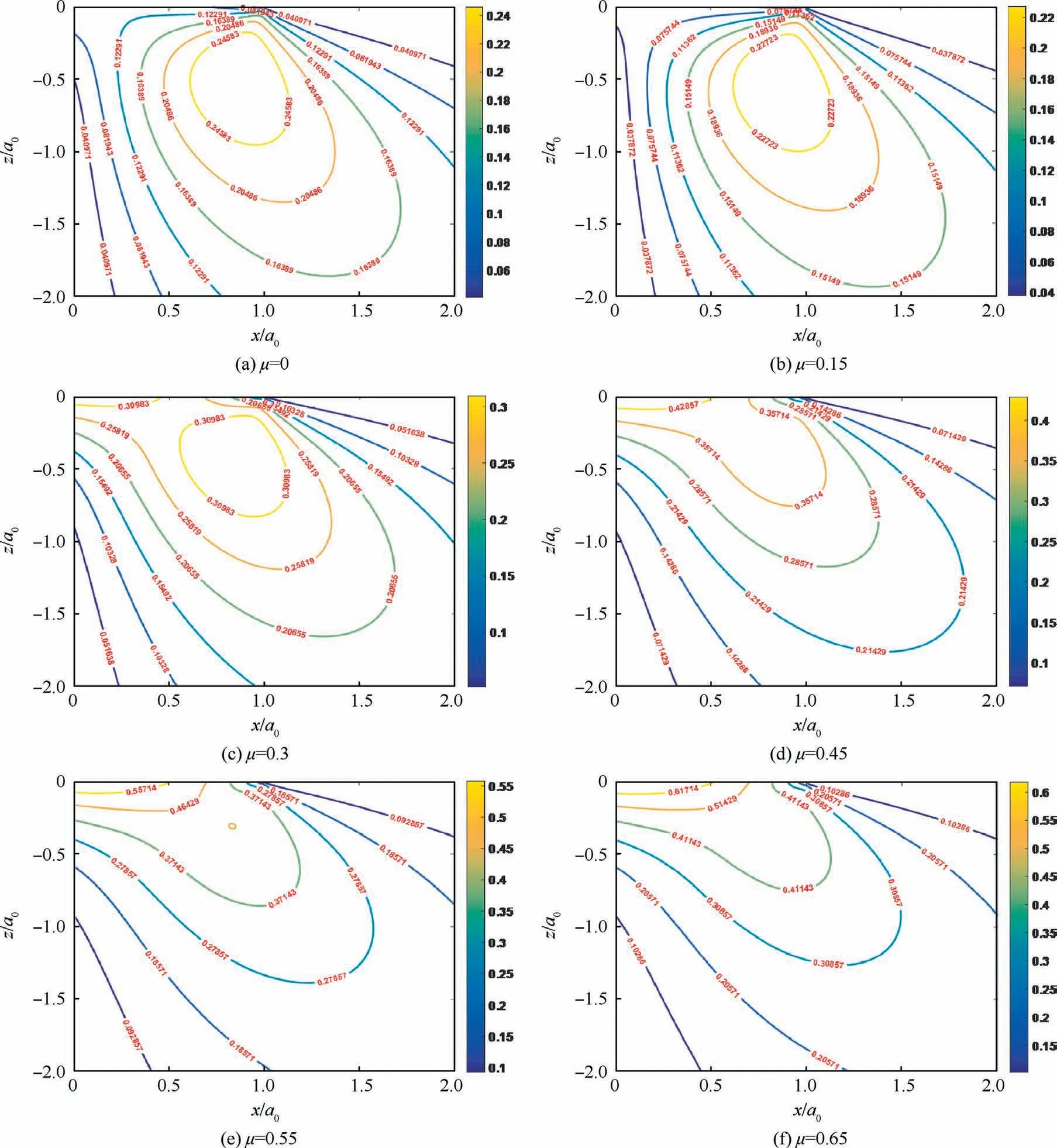

Fig.6 shows the shear stress distribution of the chip contact zone as the tool-chip friction coefficient increases. Under frictionless conditions,the maximum shear stress is below the chip contact surface. As the friction coefficient continues to increase, the maximum shear stress amplitude increases, and the position of the maximum shear stress gradually moves toward the chip contact surface. When the friction coefficient reaches 0.55,the maximum shear stress positions will have just moved to the chip contact surface, and the maximum contact stress on the chip surface is 0.577p0. In this case, the shear stress on the chip contact surface is at the maximum and is equal to the material yield stress of 1/√---3. When the friction coefficient further increases to 0.65, the positions of the maximum shear stress no longer change,and are still located on the chip contact surface. When the tool-chip friction coefficient is less than 0.55, the shear stress on the chip contact surface is defined as the critical shear stress.

3.2. Experimental set-up

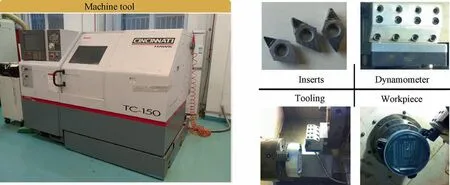

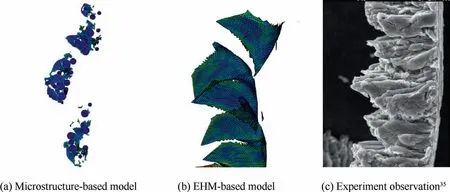

Before the turning experiment, 3-mm-wide ring-shaped ridges are prefabricated on the cylindrical workpiece. To satisfy the free orthogonal cutting requirements,the turning of the raised ring portion is performed with a single-side edge of the polycrystalline diamond (PCD) tip part on the carbide inserts, as shown in Fig. 7. The cutting force is measured using a Kistler 9257B dynamometer installed on the HAWK TC-150 CNC lathe. The cutting parameters and experimental set-up for the turning of Al6061/SiCp/15p composites are listed in Table 3.

4. Validation of plastic constitutive and cutting models

4.1. Chip morphologies

Fig. 6 Stress distribution in the chip contact zone when tool-chip friction coefficient is 0, 0.15, 0.3, 0.45, 0.55, and 0.7.

Fig. 7 Experimental set-up of free orthogonal turning of Al6061/SiCp/15p composites.

Table 3 Process parameters and experimental set-up during turning of Al6061/SiCp/15p composites.

The chip formation mechanism has been one of the most studied scientific problems in automated production processes.Chip formation during the cutting of Al6061/SiCp/15p composites is investigated under different cutting speeds and feed rates. Fig. 8 shows the chip formation process during turning of SiCp/Al6061 composites at a cutting speed of 200 m/min.The chip shape during the turning of SiCp/Al6061 composites is assumed to include mixed morphologies of serrated chips and segmental chips. Such mixed chips cannot be explained using the adiabatic shear theory for severe plastic deformation along the shear plane. SiCp/Al6061 composites exhibit high hardness, brittle and poor plasticity, and under the extrusion action of the tool nose,the difference in flow ability on the free and back surfaces of the chips leads to periodic cracking on the free surface due to incompatible deformation between free and back surfaces. High shear stress in the primary deformation zone also promotes further crack initiation from the free surface. Along with void coalescence within the primary shear zone, the micro-cracks grow and continue to propagate from the free surfaces to the back surfaces of the chip. High shear strain in the primary deformation zone induces damage and failure of SiCp/Al6061 composites, and adiabatic shear localization promotes instabilities of plastic deformation and damage.Under the combined action of these two mechanisms, the mixed chip morphologies are formed.

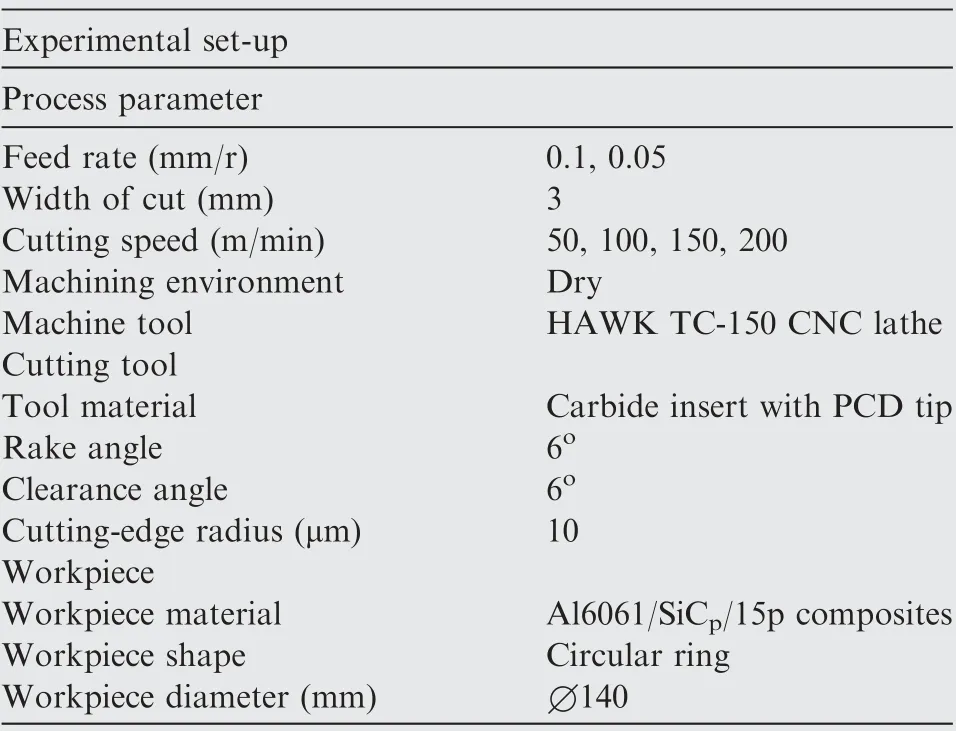

Due to the heterogeneity and discontinuity inside SiCp/Al6061 composites, the experimentally obtained chip during turning of SiCp/Al6061 composites is irregularly serrated, as shown in Fig. 9. As experimentally observed, and shown in Fig. 9(c), many small voids appear owing to the debonding of weakly bonded interfaces or particle cracking within a newly formed chip under high stress concentration around SiC particle corners.Some voids grow into micro-cracks,eventually evolving into lamellar structure. The lamellar structure in the serrated chips can be predicted using a microstructurebased model,as shown in Fig.9(b).The numerically simulated chip morphologies in the developed free orthogonal cutting model agree with experimentally observed morphologies in Ref. [35]. It can be inferred that a 2-D orthogonal model for the turning of Al6061/SiCp/15p composites based on the proposed semi-phenomenological material model for high-speed cutting can successfully predict chip formation and chip morphologies.

Fig. 8 Chip formation process during turning of Al6061/SiCp/15p composites at a cutting speed of 200 m/min.

Fig.9 Chip morphologies obtained from microstructure-based model,EHM-based model and experimental observation during cutting of SiCp/Al6061 composites.

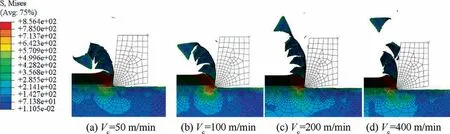

As the cutting speed increases from 50 m/min to 400 m/min, the transition of chip morphologies from serrated chips to more discontinuous debris is observed, as shown in Fig. 10. The chip shear angle increases with cutting speed,and the resulting shear localization yields strain induced damage softening according to the proposed constitutive model.Therefore, with increasing the cutting speed, the chip serrated degree increases until the chip becomes fractured. In addition,a decrease in chip pitch with cutting speed suggests that chip formation mechanisms during turning of SiCp/Al6061 composites are not pure shearing, but involve periodic crack initiation and shear localization associated with strain rate, and instabilities of plastic deformation and damage caused by heterogeneity and discontinuity of SiCp/Al6061 composites.

4.2. Cutting forces

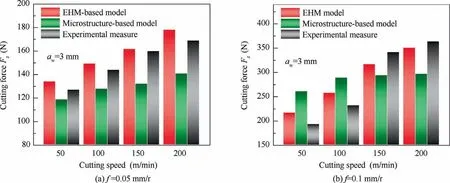

Under different cutting conditions,a comparison of the cutting force components (Fz) along the z-direction predicted by the semi-phenomenological EHM-based model and the microstructure-based model,with the experimentally measured Fzis illustrated in Fig.11. The EHM-based model can predict the experimentally measured cutting forces at feed rates of 0.05 mm/r and 0.1 mm/r more accurately than the microstructure-based model can.

Fig. 10 Evolution of chip morphologies during turning of SiCp/Al6061 composites at different cutting speeds.

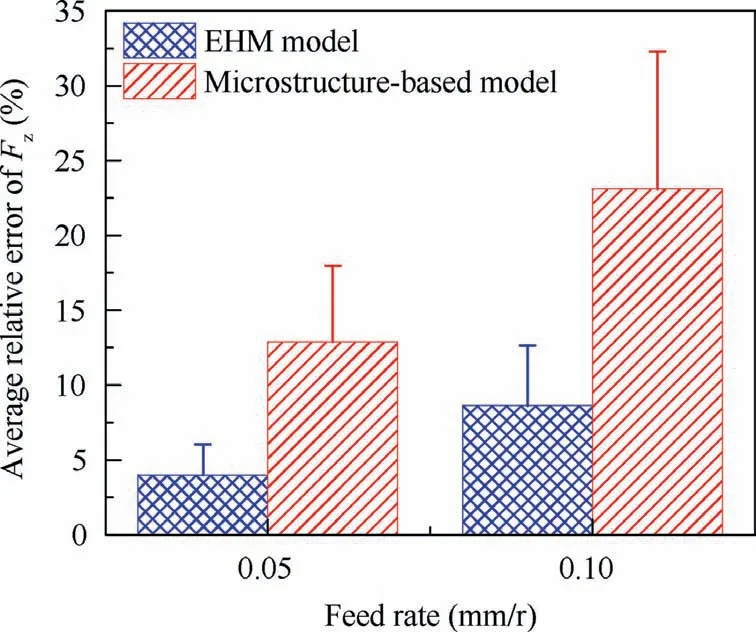

At the feed of 0.1 mm/r, with increasing cutting speed, the relative errors for EHM-based model show a gradual decrease tendency ranging from 11.06% to 3.07%, while at 0.05 mm/r,no monotonic decrease tendency of the relative error is observed, as shown in Fig. 12. The EHM-based model is observed to overestimate cutting forces particularly at low cutting speeds,and the largest relative error is 11.0%at 50 m/min cutting speed and 0.1 mm/r feed.Fig.13 shows the average relative errors of the predicted cutting forces Fzin the EHMbased and microstructure-based models. The average prediction error of the cutting forces by the EHM model based on the proposed semi-phenomenological constitutive model is within 10%. The relative error of the predicted cutting forces by the microstructure-based model at a feed rate of 0.1 mm/r is greater than 20%, but still within the acceptable range for engineering.

Fig. 11 Comparison of cutting forces component Fz predicted by EHM-based and microstructure-based models with experimental measurement.

Fig.12 Relative errors of cutting forces Fz between EHM-based model and experimental data.

Fig. 13 Average relative errors of predicted cutting forces Fz from EHM-based and microstructure-based models.

Compared to pure Al6061 alloy, geometrically necessary dislocations inside the Al6061 matrix significantly increase due to the mismatch in coefficient of thermal expansion when cooling to room temperatures from processing temperatures,and the mismatch in elastic modulus when plastically deforming.Eventually,this leads to material flow strengthening of the Al6061 matrix in Al6061/SiCp/15p composites. Lower prediction accuracy of cutting forces by the microstructure-based model is partly due to the enhanced flow stress of the Al6061 matrix,and partly due to the absence of plastic strain gradient originating from geometrical mismatch between the soft Al6061 matrix and hard SiC particles. These aspects of flow strengthening of the composite matrix cannot be quantified by mechanical tests, a main difficulty in establishing the microstructure-based model where flow behavior of the composite matrix cannot be accurately described by a proper material model.

All numerical models were carried out on a ThinkPad 480 desktop PC with an Intel(R) Core(TM) I7-10510U Quadcore processor, 16 GB RAM and Windows10 64-bit operating system. At the cutting speed of 50 m/min, the microstructurebased model (17 min) requires 24 times as much time as the EHM model based on the homogenization framework (6 h 44 min).Additionally,when the cutting simulations at the cutting speed higher than 150 m/min are performed, the convergence issues occur, indicating that the ratio of deformation speed to wave speed exceeds 1.

Hence,the EHM-based model based on the proposed semiphenomenological constitutive model can accurately predict the cutting forces at macroscale,and the chip formation mechanism at microscale during turning of Al6061/SiCp/15p composites. The EHM-based model also offers superior computational time and capabilities, and a fast but accuracy numerical solution for practical cutting applications.

5. Conclusions

A semi-phenomenological constitutive model of Al6061/SiCp/15p composites for high-speed cutting that considers the evolution law of compression damage during high-speed cutting is developed by combining dependence-based integrated constitutive modeling methodology and a multiobjective material parameter identification strategy with high fitting accuracy (R2=99.09%, AARE=4.63%,AFSE=14.0 MPa) to experimentally obtained flow stress under different loading modes. The failure probability of SiC particles based on the evolution law of compression damage is calculated based on the modified Weibull weakest-link model, to determine the effective volume fraction of undamaged reinforcing particles.

A plane-strain-based explicit dynamic FE model is developed for the high-speed cutting of Al6061/SiCp/15p composites. The free orthogonal turning model considers the critical shear stress effects on chip formation with regard to the tool-chip frictional coefficient. The proposed semiphenomenological constitutive model is implemented by compiling material subroutines into FE cutting codes. The numerically and experimentally obtained chip morphologies illustrate that the combined actions of these mechanisms involving the damage and failure induced by high shear strain in the primary deformation zone,the difference in flowability of free and back surfaces of the chip,and the instabilities of plastic deformation and damage promoted by adiabatic shear localization, lead to the formation of mixed serrated chip morphologies.As the cutting speed increases from 50 m/min to 400 m/min, the chip morphologies evolve from serrated chips to more discontinuous debris. Additionally, a decrease in chip pitch with cutting speed further indicates that chip formation mechanisms during turning of SiCp/Al6061 composites involve shear localization associated with strain rate, periodic crack initiation, and plastically deformed instability.

By comparing the cutting forces and chip morphologies between experiment and simulation at different cutting speeds associated with different strain rates, the reliability and accuracy of the free orthogonal turning model based on the proposed semi-phenomenological constitutive model is confirmed.The developed semi-phenomenological constitutive formalism and high-speed cutting model of Al6061/SiCp/15p composites are promising and efficient tools for further investigation of dynamic mechanical responses in cutting behaviors of particle-reinforced metal matrix composites with different volume fractions and particle size.Future research will attempt to develop a multiscale model that incorporates interfacial debonding and particle cracking to describe material removal behavior of particle-reinforced metal matrix composites at microscale, with low computational cost and high prediction accuracy.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This study was co-supported by the National Natural Science Foundation of China (No. 51575051) and Fundamental Research Funds for the Central Universities (No.G2020KY0501).

CHINESE JOURNAL OF AERONAUTICS2021年8期

CHINESE JOURNAL OF AERONAUTICS2021年8期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- A novel virtual material layer model for predicting natural frequencies of composite bolted joints

- Multi-layered plate finite element models with node-dependent kinematics for smart structures with piezoelectric components

- Modeling bending behavior of shape memory alloy wire-reinforced composites: Semi-analytical model and finite element analysis

- Sequential ensemble optimization based on general surrogate model prediction variance and its application on engine acceleration schedule design

- Transition prediction and sensitivity analysis for a natural laminar flow wing glove flight experiment

- Modeling on mechanical behavior and damage evolution of single-lap bolted composite interference-fit joints under thermal effects