Effect of curing condition on bonding quality of scarf-repaired composite laminates

Jie ZHANG, Xioqun CHENG, Jikui ZHANG, Xin GUO,Wenjun HUANG

a School of Aeronautic Science and Engineering, Beihang University, Beijing 100083, China

b Institute of Telecommunication Satellite, China Academy of Spacecraft Technology, Beijing 100094, China

c AVIC China Helicopter Research and Development Institute, Jingdezhen 333001, China

KEYWORDS Bonding quality;Curing condition;Finite element model;Moisture behavior;Scarf-repaired composite laminate

Abstract Both single-face vacuum bag curing (SVC) and double-face vacuum bag curing (DVC)can be used in scarf repair of composite structures. But different curing conditions caused by the sealing state may affect the bonding quality of scarf-repaired structures. In this paper, the effect of curing condition on bonding quality of scarf-repaired laminates was experimentally investigated in terms of surface profiles, moisture absorption curves and section profiles. In order to further explore the moisture absorption mechanism, finite element model of the repaired laminates using DVC was established with moisture diffusion of both the adhesive and composite laminates considered.This model was verified by experimental results.Based on the model of DVC case,the model of SVC case was built by changing moisture absorption parameters of the adhesive. Results show that SVC reduces the bonding quality,mainly reflecting in more adhesive inner voids and patch-toparent dislocation. And SVC increases moisture absorption rate and moisture equilibrium content of the adhesive, and its effect on the former is far greater than that on the latter.

1. Introduction

Composite materials have widely applied in aerospace field because of the superior mechanical performance over metal materials. The damage may occur during the service life of composite structures due to some causes such as complicated loading conditions.1-3To ensure structural integrity, the damaged parts need to be replaced or repaired,in which the repair solution is adopted in many cases for economic benefits.4,5Compared with other repair methods, scarf repair can keep the structure with smooth surface and consistent stiffness efficiently,so it is widely applied in engineering practice,especially in aircraft composite structure repair.6-8

The effect of scarf repairs can be characterized by the bonding quality which is mainly controlled by voids in the adhesive.There are some in-depth researches performed on formation mechanism of voids in the composite laminates,which are also appropriate to the voids in adhesive of scarf-repaired laminates. Ledru et al.9indicated that there are two main sources of voids in composite materials. One is artificially introduced during the lamination process. The other is from the gasification of some components in the matrix due to insufficient pressure during curing, which is inevitable. Shen10explained the growth process of voids in composite laminates and concluded it is closely related to the curing temperature and pressure. In addition,a few investigations have been conducted specially on the bonding quality of scarf-repaired composite laminates.Whittingham et al.11observed more voids in the scarfrepaired laminates cured in the oven than in the autoclave,and the voids are ellipse with the long axis in the adhesive thickness direction. Chong et al.12used double vacuum debulking (DVD) to perform in-situ soft patch repairs and found that this method decreases the void content of the adhesive in scarf-repaired laminates about 4%compared with standard vacuum bagging process.

Many researchers have found that voids in the composite laminates can cause the decrease of structural mechanical properties13-15and obviously increase the moisture absorption rate and moisture equilibrium content of composite structures.16-18Relatively fewer researches have been performed on the effect of adhesive inner void content on the mechanical properties of composite bonded joints and scarf-repaired laminates. Zhang et al.19used the finite element method to study the effects of adhesive inner void size, location and number on tensile properties of single-lap composite joints.The results show that the larger voids cause the lower tensile strength,the strength sharply reduces when the voids locate around the edges, and the void number has little effect on tensile strength with the same void area. Liu et al.20compared tensile properties of scarf-repaired laminates using autoclave with those using oven. The results show that the repaired laminate using autoclave curing has fewer adhesive inner voids and about 10%greater strength than that using oven curing.The strength difference would reduce with the increasing structural hygrothermal degree.21Chong et al.12investigated the effect of void contents in the adhesive from 0% to 4% on tensile strength of the 2D composite scarf joint and 3D scarfrepaired laminate. The results show that all the tensile strengths decrease within 5%, thus the adhesive inner voids with contents below 4%have little effect on tensile load carrying capacity of scarf-repaired structures.

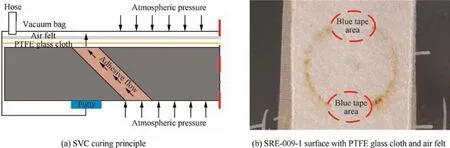

Until now, all the investigations on scarf-repaired composite laminates have focused on DVC with little attention to SVC because DVC is widely used in engineering practice.The difference of DVC and SVC is shown in Fig.1.However,SVC may be used in some scarf repair of penetration damage due to the low accessibility of composite structures,such as integral tails.SVC can also be used in some fast repair of composite structures.In the early period of SVC,the vacuum pressure cannot be reached due to air leakage through the bondline. With the temperature increasing, the adhesive melts and blocks the bondline, making the pressure in the vacuum bag increase.SVC may cause more adhesive inner voids and other uncertain defects, resulting in the decrease of mechanical properties of scarf-repaired composite laminates. Therefore, bonding quality of scarf-repaired composite laminates using SVC deserves to be investigated.

In this paper, scarf-repaired specimens were firstly manufactured using DVC and SVC, and the effects of scarf angle,adhesive thickness and small-hole diameter were considered in SVC specimens.Then,surface profiles,moisture absorption curves and section profiles of DVC and SVC were compared.Finally, moisture diffusion finite element (FE) models of scarf-repaired laminates using DVC and SVC were established to explore the effect of curing condition on the moisture absorption behaviors of the adhesive.

2. Specimen design and manufacturing

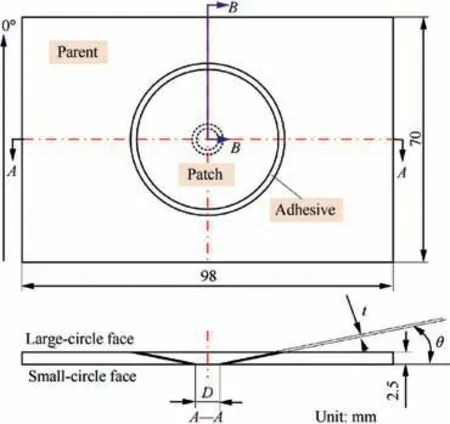

The scarf-repaired composite laminate consists of the adherends (i.e. parent and patch) and adhesive. Both of the adherends were made of CCF300/5228A (carbon fiber/epoxy) with the stacking sequence of [45/02/-45/90/45/02/-45/0]s. A layer of adhesive film SY-14M with a nominal thickness of 0.13 mm was used. Detailed specimen configuration and arrangement are shown in Fig. 2 and Table 1, respectively.For comparison, two corresponding intact specimens named DIN-1 and DIN-2 were manufactured.

The manufacturing processes of scarf-repaired specimens are as following.

Firstly, pregregs were laid and cured in an autoclave at 180°C with a pressure of 0.6 MPa for 2 h to manufacture composite laminates.

Secondly,parents and patches were cut from the laminates.The patches were assembled to the parents by a layer of adhesive film and fixed by blue tapes.

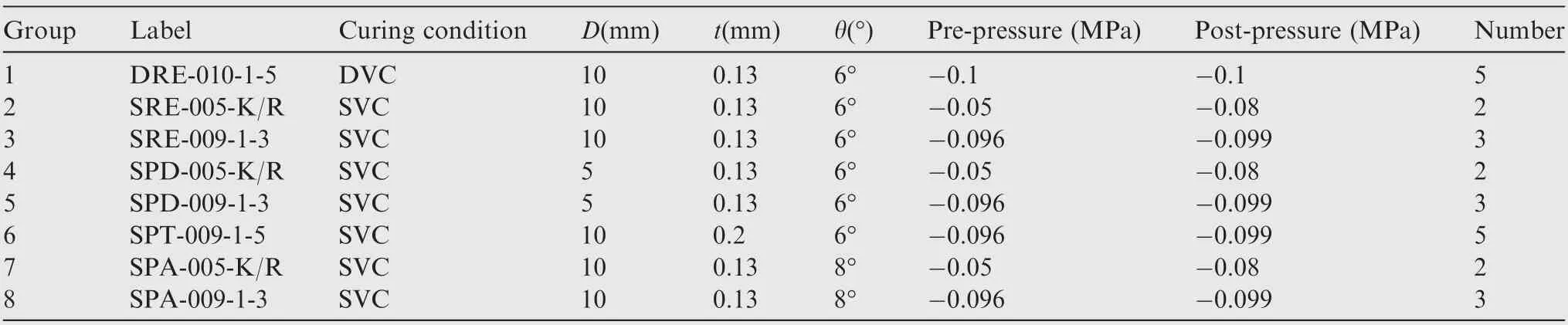

Thirdly, scarf-repaired laminates were put into vacuum bags as shown in Fig. 1. The DVC laminates were vacuumed to -0.1 MPa during curing (see Fig. 3(a)). Vacuum pressure was hardly exerted for the SVC laminates due to the air leakage along bondline at first, and the pressure decreased about half an hour after curing and then kept constant. There were two SVC cases. One was vacuumed with the small-circle faces free during curing, while the other was vacuumed with the small-circle holes covered by blue tapes (see Fig. 3(b)) which were removed before curing.Detailed pressure variation of the two cases are shown in Table 1.All the repaired laminates were cured in ovens at 180°C for 2 h. Detailed temperature and pressure versus time curves are shown in Fig. 3(c), in which SVC-005 and SVC-009 denote SVC with pre-pressure of-0.05 MPa and -0.096 MPa respectively.

Fig. 1 Configurations of DVC and SVC.

Fig. 2 Scarf-repaired specimen configuration.

Fourthly,the laminates were cooled within the closed oven naturally and then cut into specimens according to the configuration in Fig. 2.

3. Experimental procedures

In theoretical analysis of SVC case, the air and adhesive flow along bondline due to pressure difference between the largecircle and small-circle faces. This will cause more adhesive inner voids and non-uniform void contents.After manufacturing, the bonding quality of specimen surfaces was visually observed. Then, moisture absorption, moisture desorption and section observation experiments were conducted sequentially, in which the front two are to characterize the void contents and the last one is to study void distribution along the bondline.

Moisture absorption experiment was performed based on ASTM standard D5229.22Specimens were immersed in a deionized water tank with the temperature of 95°C.Specimen weights were regularly measured by an analytical balance with the accuracy of 1 mg. The specimens were cleaned by the absorbent cloth and then weighed in 5 min. Moisture absorption equilibrium reached when the following equation was met.

where M=(W - Wb)/Wb, Wbis initial oven-dry specimen mass,W is current specimen mass,M is moisture content,subscript i denotes values at current time and subscript i-1 denotes values at previous time.

Moisture desorption experiment was also performed based on ASTM standard D5229.22The specimens were put into an 95°C oven after moisture absorption equilibrium. Specimens were also regularly weighed as before. Moisture desorption equilibrium reached when Eq.(1)was met,but Wbis specimen mass at moisture absorption equilibrium here.

With regards to section observation, strips with a length of 35 mm and a width of 10 mm were cut out at the specimen central sections through thickness. The observation sections B-B(see Fig. 2) were polished by P-2T metallographic polishing machine, and the Leica S6D microscope with 32 times magnifications was used to observe.

4. Experimental results and analysis

4.1. Surface profile

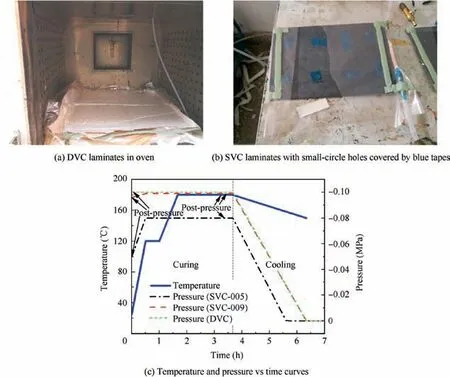

Surface profiles of DVC and SVC scarf-repaired specimens are shown in Fig. 4. Each of SRE-005, SPD-005 and SPA-005 specimens has two samples and their adhesive flows out of small holes. In order to explore the moisture behavior of the adhesive along bondline,the rich adhesive zones around small holes were removed from some samples marked by -R. The other samples are marked by -K to distinguish from -R.

It can be found that there are no obvious differences between surface profiles of specimens with different repair parameters.The adhesive in the DVC specimens is white,while the adhesive in the SVC specimens shows quite yellow and it is more yellow in specimens cured by SVC-005 than in those by SVC-009. This is because the adhesive is oxidized and turns yellow if cured in a hot oxygen environment, and the contentof oxygen is greater for SVC-005 specimens than for SVC-009 specimens.

Table 1 Scarf-repaired specimen arrangement.

Fig. 3 Curing processes of DVC and SVC scarf-repaired laminates.

Both surfaces of the DVC specimens are smooth, while the SVC-005 specimens have rich adhesive and SVC-009 specimens have lean adhesive on both faces. Fig. 5 shows the SVC curing principle. The pressures at small-circle and largecircle faces of SVC specimens (see Fig. 2) are not same with the small-circle holes out of vacuum bags.Thus,with the temperature rising,the adhesive flows in a viscous flow state to the air felt through the PTFE glass cloth.The effect of the pressure on adhesive flow along the bondlines is related to the prepressure. When the pre-pressure is low, the adhesive hardly flows into air felts at large-circle faces and flows out of small-circle holes due to gravity. When the pre-pressure is large, the adhesive flows into air felts at large-circle faces and hardly flows out of small-circle holes. In addition, for lower the pre-pressure, the components in the adhesive more easily gasify, resulting in more inner voids. Thus, SVC-005 specimens have rich adhesive and SVC-009 specimens have lean adhesive on both faces. And the adhesive in SVC-005 specimens have more voids at the two faces than that in SVC-009 specimens.

4.2. Moisture absorption curve

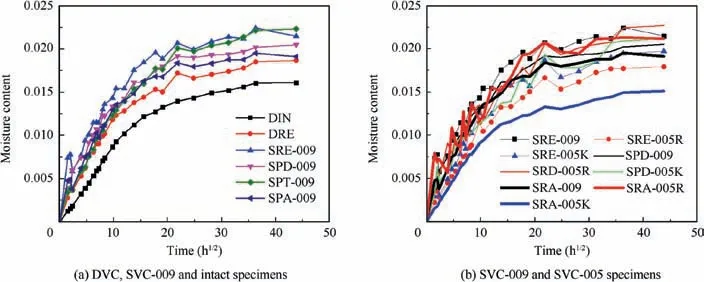

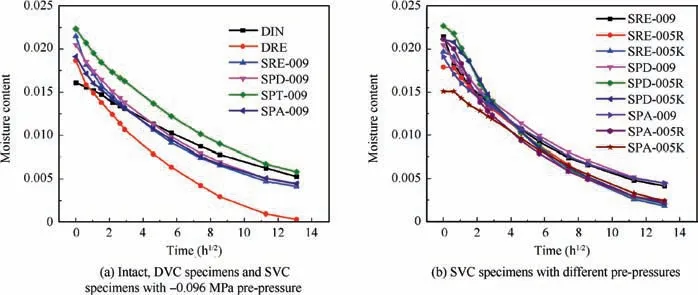

Moisture absorption curves of intact and scarf-repaired specimens are shown in Fig. 6, in which the moisture contents are the average values of the corresponding specimens.

From Fig. 6(a), it is found that all the specimens reach the moisture absorption equilibrium after 1918 h (80 days), and the sequence of moisture equilibrium content is SPT-009 >SRE-009 >SPD-009 >SPA-009 >DRE, which are obviously greater than that of the intact laminate. Therefore, the introduction of the adhesive contributes to the obvious increase of the moisture equilibrium content of specimens and the content is related to the adhesive volume and curing conditions.

From Fig. 6(b), the sequences of moisture equilibrium contents of SVC specimens with different pre-pressures are SRE-009 >SRE-005-K >SRE-005-R, SPD-005-R >SPD-005-K >SPD-009, SPD-005-R >SPD-009 >SPD-005-K.Thus, the pre-pressure has no obvious effect on moisture absorption behavior of specimens.

Moisture desorption curves of scarf-repaired and intact specimens are shown in Fig. 7, in which the moisture contents are also the average values. Compared with the moisture absorption curves, the moisture desorption speed is significantly faster, and the curves of the DVC and SVC specimens are smoother without obvious initial linear stages. In addition, the desorption of DRE and SPT-009 specimens is fastest and slowest respectively. Times of DRE, SVC-005, SVC-009 and intact specimens corresponding to moisture content of 0.005 are approximately 46.2 h,73.0 h, 127.0 h and 171.3 h respectively. That means that the introduction of the adhesive may accelerate the moisture desorption speed (as tDINis largest), the voids inside adhesive may delay desorption (tSVC-005, tSVC-009>tDRE),and rich adhesive at both faces may hinder desorption(tSVC-005<tSVC-009).

In summary,the moisture absorption-desorption behaviors of scarf-repaired laminates have nothing to do with the repair parameters but are affected by curing condition.

Fig. 4 Surface profiles of DVC and SVC scarf-repaired specimens.

4.3. Section profile

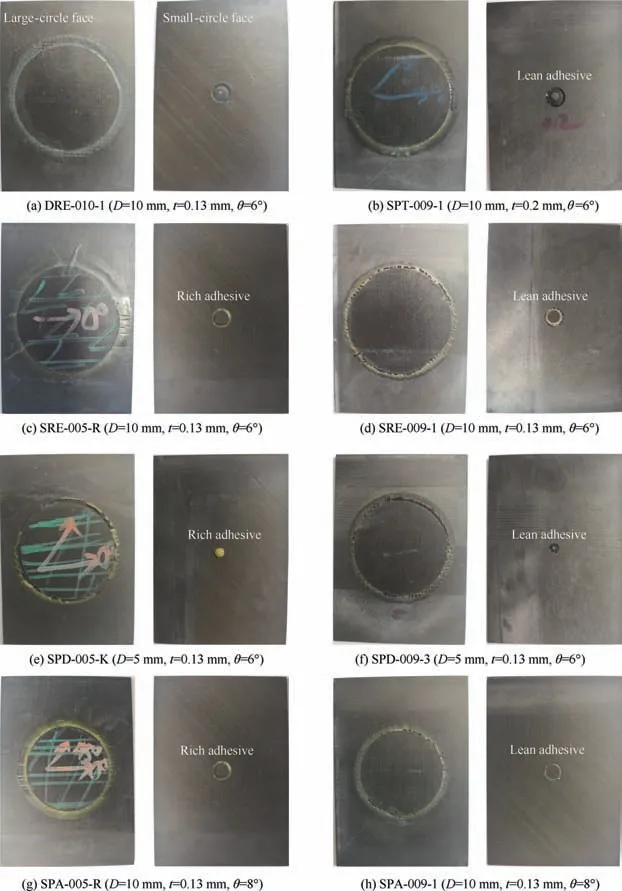

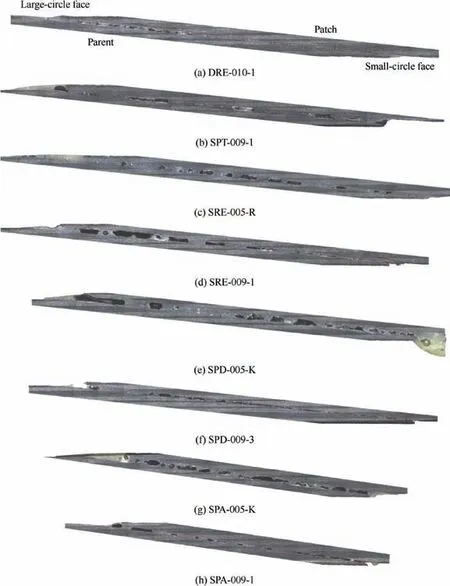

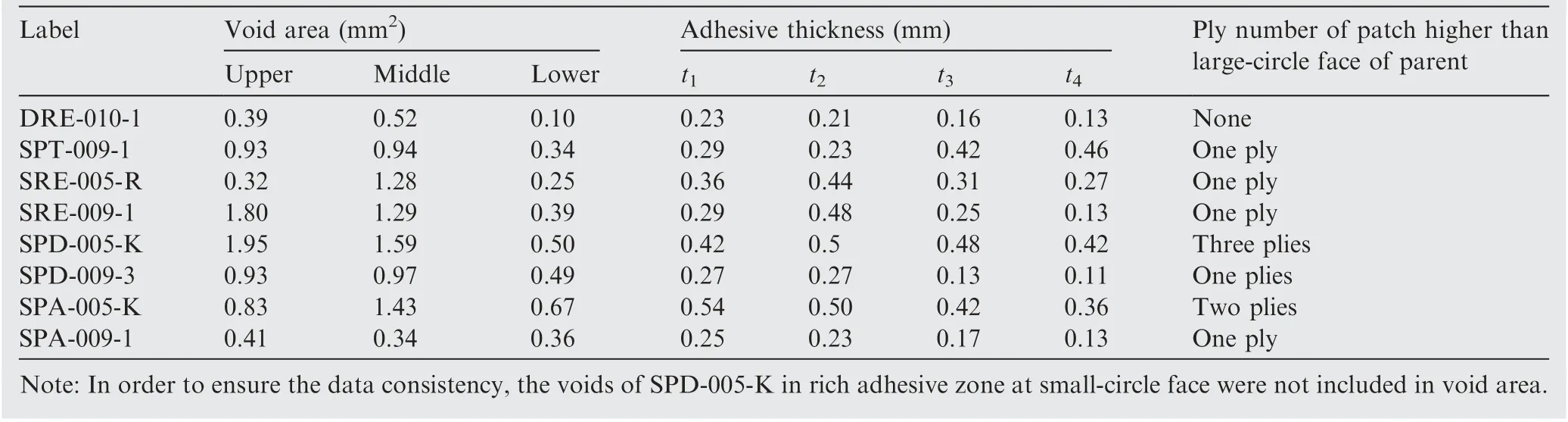

Central section profiles of scarf-repaired specimens are shown in Fig.8. Detailed void area, adhesive thickness and patch-toparent dislocation situation in the thickness direction are shown in Table 2 and Fig. 9.

With regards to patch-to-parent dislocation situation,there is no dislocation for DVC specimens, while the patches are at least one ply higher than the parents for SVC specimens with severer dislocation situations of SVC-005 specimens than those of SVC-009 specimens. Therefore, in terms of ply-to-ply matching between the patch and the parent, DVC is better than SVC and SVC-009 is better than SVC-005.

Fig. 5 Curing principle of SVC specimens.

Fig. 6 Moisture absorption curves of scarf-repaired and intact specimens.

Fig. 7 Moisture desorption curves of intact and scarf-repaired specimens.

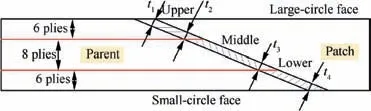

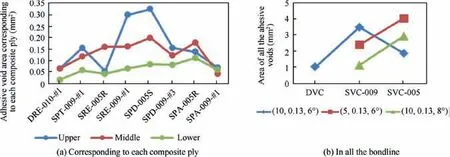

In order to further study the distribution of voids inside the adhesive, three regions (upper, middle and lower regions as shown in Fig.9 and Table 2)were divided.Then,the adhesive inner void areas in the three regions were divided by the corresponding composite ply numbers to obtain void areas corresponding to each composite ply at the central section which are shown in Fig.10(a).It can be found that all the specimens have apparently more voids around large-circle faces than around small-circle faces. This is because vacuuming hoses are at the sides of large-circle faces, so the air channels more easily form there. In addition, areas of all the voids inside the adhesive of scarf-repaired specimens at the central section are shown in Fig.10(b). It can be found that the void areas of DVC specimens are smaller than those of SVC specimens,and the void areas of SVC-009 specimens are generally smaller than those of SVC-005 specimens except SRE specimen(possibly due to the randomness of the observation section). This is because during curing, there is no external air introduced in DVC specimens, while the air flows into the bondline through small-circle holes in SVC specimens which is more easily for SVC-005 specimens than for SVC-009 specimens. And the sequence of the pre-pressure is DVC >SVC-009 >SVC-005, thus the components in the adhesive most easily gasify in SVC-005 specimens.

Fig. 8 Central section profiles of scarf-repaired specimens.

Table 2 Central section analysis of scarf-repaired specimens.

Fig. 9 Parameter meanings in Table 2.

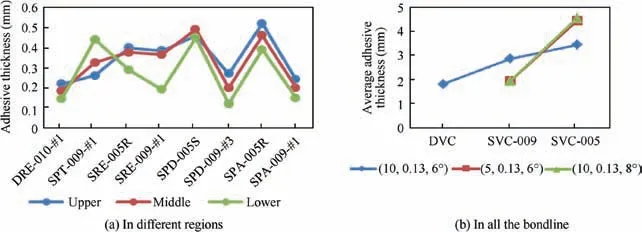

In order to further study the distribution of adhesive thicknesses along bondlines,four adhesive thicknesses(t1,t2,t3and t4as shown in Fig.9 and Table 2)at the ends of upper,middle and lower regions were obtained by measuring the corresponding distances between the parents and patches.Then,the average adhesive thicknesses in the three regions were calculated by hupper=(t1+t2)/2, hmiddle=(t2+t3)/2, hlower=(t3+t4)/2,which are shown in Fig. 11(a). It can be found that the adhesive thicknesses do not show linearly variation along bondline for some specimens, which is possibly due to the manufacturing error of scarf bonded surfaces. Adhesive thicknesses of every specimen in all regions are greater than the adhesive nominal thickness due to adhesive inner voids and even four times of the nominal thickness. The variation of adhesive thicknesses of DVC specimens is the smallest (t1/t4=1.8 for DRE-010#1).The average adhesive thicknesses in the all bondline (hAVE=(t1+t2+t3+t4)/2) are shown in Fig. 11(b). It indicates that adhesive thicknesses of SVC-009 specimens are closer to nominal thickness than those of SVC-005 specimens,which correspond to more voids in SVC-005 specimens than those in SVC-009 specimens. Therefore, in terms of keeping adhesive thickness consistency, DVC is better than SVC, and SVC-009 is better than SVC-005.

5. Moisture absorption mechanism analysis

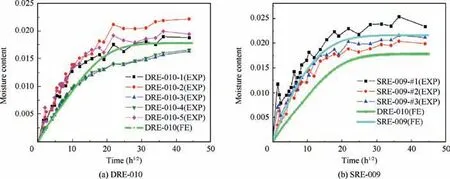

Since SVC-009 specimens generally have the fewer voids than SVC-005 specimens, curing condition of SVC-009 is recommended in practical SVC repair.Thus,only the moisture diffusion of DRE-010 and SRE-009 specimens was studied here,in order to further investigate the effect of curing condition on moisture absorption mechanism of scarf-repaired laminates.

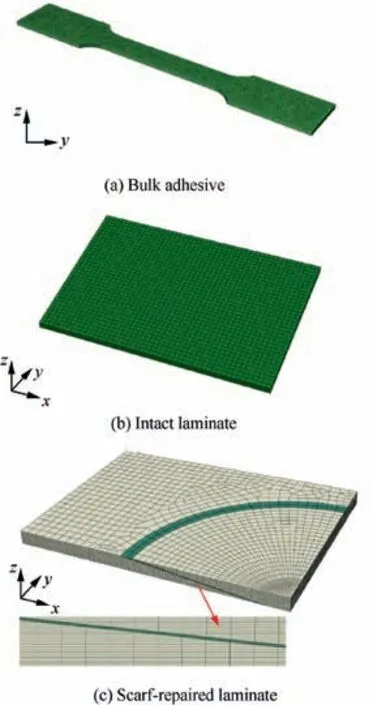

In this section, the finite element models of bulk adhesive,intact laminate and scarf-repaired laminate (DRE-010 and SRE-009) were established with ABAQUS software. The first model was based on the experiment of Ref. 23 and the latter two models were based on the experiments here. There were 4 plies in the thickness direction of the bulk adhesive model,while there were 20 plies in model thickness direction of the intact and scarf-repaired laminates to simulate each composite ply.In the scarf-repaired model, the adhesive was modelled as one ply in adhesive thickness direction, and 1/4 model was adopted to reduce the amount of calculation. The detailed meshing is shown in Fig. 12. The stacking sequence of intact laminate and adherends in scarf-repaired model is same as that of specimens introduced in Section 2,i.e.[45/02/-45/90/45/02/-45/0]s.

5.1. Moisture diffusion FE model

Moisture diffusion models of bulk adhesive and intact laminate were established firstly to validate moisture absorption parameters and simulation method, then diffusion model of DRE-010 was built using the same parameters and method.Finally diffusion model of SRE-009 was built by changing moisture equilibrium content and moisture absorption rate of the adhesive.

Moisture diffusion was analyzed by using‘‘Mass Diffusion/Transient” module based on Fick’s law24in ABAQUS. The mass diffusion element has only one degree of freedom,namely the normalized concentration φ, which is defined as follows:

Fig. 10 Adhesive inner void areas of scarf-repaired specimens at the central section ((D, t, θ) in the legends).

Fig. 11 Average adhesive thicknesses of scarf-repaired specimens at the central section ((D, t, θ) in the legends).

Fig. 12 Finite element models of bulk adhesive, intact laminate and scarf-repaired laminate.

where c is the mass concentration of the diffusing material,and s is the solubility of the diffusing material in the reference material. The mass diffusion process follows the law of mass conservation, as follows:

where V is the volume, S is the surface area, n is the normal vector of S, and J is the moisture diffusion flux.

Moisture absorption rate(C)and solubility(s)of the water in the composite CCF300/5228A and adhesive SY14M should be given in the moisture diffusion modeling. For adhesive SY14M, C=0.0226 mm2/h and s=0.0635.23For composite CCF300/5228A, s=0.0161, and the longitudinal, transverse and through-thickness moisture diffusivity constants (C11,C22, C33) were 0.012 mm2/h, 3.38×10-3mm2/h and 3.38×10-3mm2/h, respectively.25

In addition,the boundary condition was the moisture saturation situation(φ=1)on the structural outer surfaces which element type is DC3D8.

5.2. Numerical results and analysis

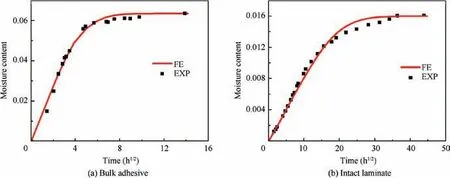

Experimental and FE moisture absorption results of bulk adhesive and intact laminate are shown in Fig. 13. It can be found that the finite element results are in good agreement with experimental results, so the moisture absorption parameters and simulation method are effective.

Experimental and finite element moisture absorption curves of DRE-010 and SRE-009 scarf-repaired laminates are shown in Fig.14.It can be found the finite element results are in good agreement with experimental results, thus adhesive moisture absorption parameters ‘‘C=0.0226 mm2/h, s=0.0635” and‘‘C=2.26 mm2/h, s=0.165” are efficient for DRE-010 and SRE-009 scarf-repaired laminates respectively.

As mentioned in Section 4, compared with DVC, SVC causes more adhesive inner voids, larger and less uniform adhesive thickness along bondline and patch-to-parent dislocation in the thickness direction, in which voids result in the latter phenomena.It was called void combined effect here.It can be found that the void combined effect causes the increase of moisture equilibrium content and moisture absorption rate by 2.6 and 100 times respectively, which means that the combined effect has far greater influence on moisture absorption rate than on moisture equilibrium content.

Fig. 13 Experimental and finite element moisture absorption curves of bulk adhesive and intact laminate.

Fig. 14 Experimental and FE moisture absorption curves of DRE-010 and SRE-009 scarf-repaired laminates.

Fig. 15 MFL vectors of the adhesive in DRE-010 and SRE-009 scarf-repaired laminates at 24 h.

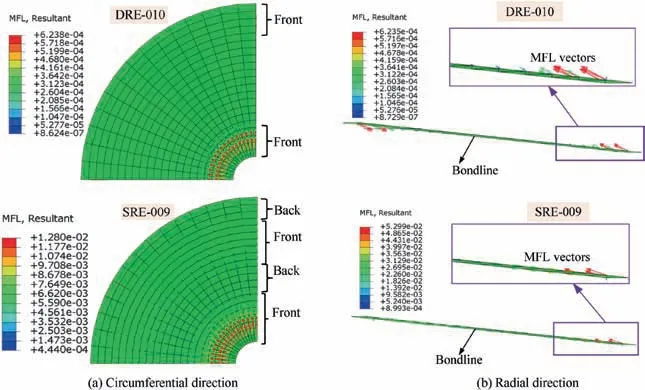

There are two moisture absorption paths in the adhesive of the scarf-repaired laminate. One is along bondline, and the other is along structural thickness which consists of the parent,adhesive and patch.The two moisture absorption components combine into the moisture mass flow, namely MFL vector.MFL vectors of the adhesive in DRE-010 and SRE-009 scarf-repaired laminates at 24 h are shown in Fig.15.In order to show the MFL distribution at circumferential direction more clearly, ‘‘Front” and ‘‘Back” were marked in Fig. 15(a), in which ‘‘Front” means the regions MFL distributes at the side you see,and‘‘Back”means at the side you cannot see.It can be found that the angles between MFL vectors and the bondline for the SRE-009 case are smaller than those for DRE-010 case, which means that there is more proportion of the former path in the SRE-009 case than that in DRE-010 case.In addition,MFL vectors of SRE-009 case have the maximum value of 5.299×10-2and the moisture has diffused across all the bondline, while those of DRE-010 case are limited around two ends of the bondline with the maximum value of 6.235×10-4at 24 h. So there is larger moisture diffusion rate of the former path in the SRE-009 case than that in DRE-010 case.

6. Conclusions

In this paper,the effect of curing condition on bonding quality of scarf-repaired composite laminates was experimentally investigated in terms of surface profiles, moisture absorption curves and section profiles.FE models were established to simulate the moisture diffusion of scarf-repaired laminates using DVC and SVC,and moisture absorption mechanism was analyzed. The following conclusions have been obtained:

(1) The adhesive in the DVC specimens are white, while it shows quite yellow in the SVC specimens and more yellow in SVC-005 specimens than in SVC-009 specimens.At both small-circle and large-circle faces, the DVC specimens have smooth adhesive, while SVC-005 specimens have rich adhesive and SVC-009 specimens have lean adhesive.

(2) Compared with DVC, SVC causes more adhesive inner voids, larger and less uniform adhesive thickness along bondline and patch-to-parent dislocation in the thickness direction, in which the former two is more serious around the large-circle face than around the smallcircle face.And SVC-005 generally results in the severer phenomena than SVC-009.

(3) Curing condition has obvious effect on moisture absorption-desorption curves of scarf-repaired laminates.Compared with DVC, SVC results in greater adhesive moisture equilibrium content, greater absorption rate and less adhesive desorption rate. And the effect is far greater on adhesive moisture absorption rate than on adhesive moisture equilibrium content.

(4) There are two moisture absorption paths in the adhesive of the scarf-repaired laminate. One is along bondline,and the other is along structural thickness which consists of the parent, adhesive and patch. The former path in SVC scarf-repaired laminate has more proportion and greater moisture diffusion rate than those in DVC laminate.

Acknowledgement

We would like to thank the National Natural Science Foundation of China (No. 11472024) for financial support.

CHINESE JOURNAL OF AERONAUTICS2020年8期

CHINESE JOURNAL OF AERONAUTICS2020年8期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Structural dynamic responses of a stripped solar sail subjected to solar radiation pressure

- Dynamic coefficients and stability analysis of a water-lubricated hydrostatic bearing by solving the uncoupled Reynolds equation

- Rotor airfoil aerodynamic design method and wind tunnel test verification

- A heuristic cabin-type component alignment method based on multi-source data fusion

- Influence of uniaxial tensile pre-strain on forming limit curve by using biaxial tensile test

- Influence of non-equilibrium reactions on the optimization of aerothrust aeroassisted maneuver with orbital change