Evaluation of thermal eあects on temperaturesensitive operating force of flow servo valve for fuel metering unit

Yng ZHANG, Shoping WANG, Jin SHI,*, Xi WANG

a School of Energy and Power Engineering, Beihang University, Beijing 100083, China

b School of Automation Science and Electrical Engineering, Beihang University, Beijing 100083, China

KEYWORDS Flow force;Jam fault;Servovalve;Spool deformation;Spool friction;Temperature effect

Abstract The temperature-induced variation in operating force of flow control valves may result in performance degradation or even jam faults of fuel metering unit(FMU),which significantly affects the safety of aircrafts. In this work, an analytical modeling approach of temperature-sensitive operating-force of servo valve is proposed to investigate the temperature characteristics in varying temperature conditions.Considering the temperature effects,a new extended model of flow force is built and an analytical model of valve friction is also derived theoretically based on the dynamic clearance induced by thermal effects. The extremum condition of friction is obtained to analyze the characteristic-temperature points where jam faults occur easily.The numerical results show that flow force increases firstly and then decreases as temperature increases under a constant valve opening. The maximum friction of flow servo valve can be uniquely determined when the structural parameters and ambient temperature are given. The worst situation just happens at the characteristic-temperature points, which are linearly related to the axial temperature gradients of valve spool. Such evaluations may give an explanation for the temperature-induced jam faults of vulnerable valves and provide a reference for designers to determine a suitable workingtemperature range of valves in practice.

1. Introduction

Flow control valves have been widely used in the fuel control systems of aircraft due to their advantages of high sensitivity,fast response and high accuracy.However,fuel control systems usually suffer different weather conditions in just one single flight, which will bring enormous challenges for control components.1-2Long-span temperature variation of ambient environment brings about hostile effects on fuel temperature.3Moreover,fuel is used as coolant in most aircraft systems and additional heat loads make it more difficult to maintain fuel temperature within established limits.4For the fuel metering unit (FMU) of fuel control system, its working temperature range can be from -40°C to 120°C. Therefore, it is quite urgent to investigate the temperature characteristics of vulnerable flow control valves to enhance the working reliability and reduce the probability of faults of key components in a wide temperature flight conditions.

As the most vulnerable components, servo control valves have a significant influence on the performance of flow-rate control system5-7, a great deal of research on this topic have been carried out during the past decades.These works concentrate on the numerical calculation8,9of flow forces on the valve spool or the optimum design10-12of orifice shape to reduce the flow forces and focus on the nonlinear dynamic friction compensation13,14to improve the control precision of servo valves.The force condition of valve directly determines the control performance. Hong and Kim15examined the lateral force and friction force of spool and suggested that it is the asymmetric pressure distribution in the clearance that makes the spool contact with the surface of the sleeve. Duan and Nielsen16derived the equations of motion of spool valves with considering the viscosity and the eccentric clearance that may have a significant influence on dynamical performances of spool valves. For the aerospace applications, however, these studies may be inadequate in tackling wide-temperature problems,because servo valves are susceptible to temperature variation, which may lead to the changes of fuel physical properties and the operating forces of subassemblies in FMU.

In fact, temperature changes may cause unexpected performance degradation of control valves and cause great changes in fuel viscosity, leakage and friction of power-stage valve spool, which in turn cause erratic operation or even prevent operation completely.Therefore,it is indispensable to incorporate temperature effect in the study of spool operating force.Zeng,et al.1developed the thermodynamic mathematical models for the high-temperature flow-rate valve based on the heat transfer methods and predicted the steady-state and transient temperature field distribution inside the valve. This work is of great significance for the investigations of thermal stress and thermal strain in valves. Wang, et al.2examined the temperature effect on the steady-state and dynamic characteristics of servo valve controlled FMU under the temperatures ranged from -10 to 60°C. Results show that the step response increases with the fuel temperature.Deng,et al.17revealed that the high temperature around the orifice may be a source of jam faults, because the allowable clearance between spool and sleeve is in the order of few microns and a very small thermal distortion of the spool may induce the jam fault. A study by Bordovsky and Murrenhoff18investigated the steady-state flow forces in spool valves of different geometries and at different oil temperatures.It was concluded that the oil temperature leads to quantitative deviations of the steady-state flow forces.Zhao,et al.19analyzed the spool deformation and fit clearance reduction of the spool and sleeve with oil temperature ranging from 40°C to 120°C.The mentioned or most of other relevant studies20,21have considered the temperature effects and obtain some valuable results, which improve the understanding of characteristics of control valves. However, less attention was paid to a specialized mechanism model of operating force that suits for wide-temperature working conditions and hence is the main motivation for this particular study. As a small distinct contribution to the relevant research, this paper provides a temperature-dependent model of operating force to investigate the temperature characteristics of operating force and possible effects on the jam fault in a theoretical way.The research conclusions may give an explanation for the jam faults of control valves in high-temperature conditions and also may contribute to the design of friction pairs with better robustness to wide temperature, reducing their tendency to jam in practice.

The paper is organized as follows: Section 1 presents the introduction to the work carried out in this paper. Section 2 gives the construction of FMU of fuel control system and also elaborates on the problem to be resolved and the fundamental assumptions to simplify the theoretical derivation in a subsequent section.In Section 3,the temperature-dependent mathematical models of flow forces and friction of valves are derived. Numerical simulation and analysis are conducted in Section 4. Section 5 provides the conclusive remarks.

2. Statement of problem

2.1.Configuration and working principle of FMU control system

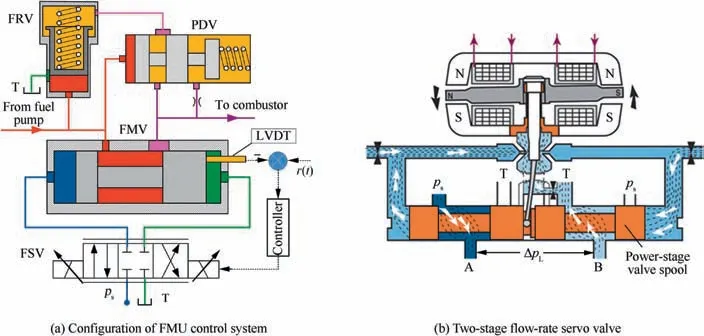

Consider a typical FMU control system in shown in Fig.1(a).It is a core part of fuel supply system in aircraft and it mainly consists of flow-rate servo valve (FSV), fuel metering valve(FMV),pressure differential valve(PDV)and fuel return valve(FRV). All of these control valves adopt a spool and a sleeve to control valve opening and in the operation process friction is inevitable. As electro-hydraulic flow-rate servo valve is the most sophisticated device and is very susceptible to the temperature, this study focuses on its power-stage valve, as shown in Fig. 1 (b). Its first stage (pilot stage) is electronically operated by a servo amplifier and the second stage (power stage) has a precision ground four-way control spool, which is hydraulically driven by the differential pressure between its left and right control chamber.

2.2. Statement of the problem

As an operating member of a control valve, the spool will be subjected to friction force,flow force,inertia force and viscosity force during its motion within the sleeve,as shown in Fig.2.

These forces may change the spool balance and directly affect the correct operation of valves. Thus, enough operating force is requisite for the motion of valve spool so that it can be controlled with a good dynamic performance. The operating force of valve spool is given by Eq. (1).

where Ffis the spool friction, Fsis the axial steady-state flow force,Fvis the viscous force and Fmis the inertia force of valve spool.

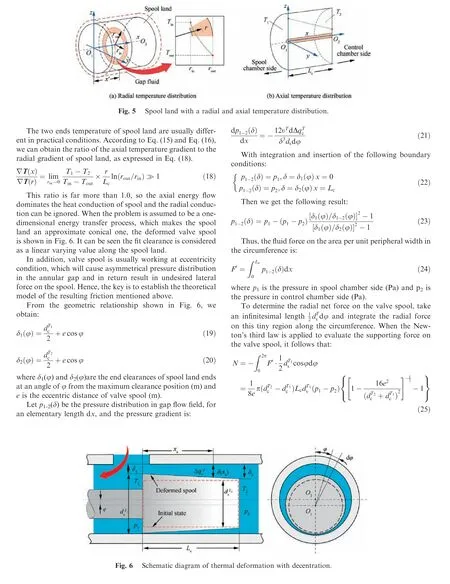

However, these forces are not always constant but contain temperature-sensitive variables.This paper focus on the effects of wide-range temperature on the operating force. On one hand,the properties of density and viscosity are related to temperature.22When the temperature rises, viscosity and density will decrease to some extent. This variations will cause the increasing leakage, excessive wear, and further cause raising temperature and clamping stagnation. In addition, the flow

Fig. 1 Schematic of FMU and flow-rate servo control valve of fuel control system.

Fig.2 Schematic of the axial load forces acting on a valve spool.coefficient is a function of Reynolds number,but the common practice in the scientific literature is to use a constant flow coefficient to calculate the flow rate of valves, orifices and other hydraulic elements23,24. Actually, Reynolds number is related to temperature,so the flow coefficient should also be expressed as a function of Reynolds number25for more accurate modeling.

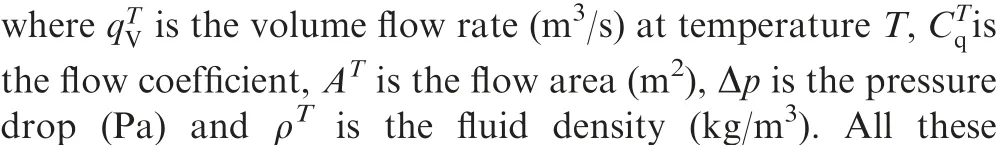

On the other hand, the thermal deformation of spool caused by temperature cannot be ignored.Due to the fact that the fit clearance between spool and sleeve is usually in the order of few microns26, and the spool deformation will lead to the uneven pressure distribution in the annular clearance,resulting in a lateral force of valve spool.This lateral force will cause an increase in friction or even clamping. Therefore, the temperature-dependent characteristics of operating force of valve spool should be researched. This paper concentrates on the dominating load forces, flow force and friction, as shown in Fig. 3.

2.3. Fundamental assumptions

For the convenience of theoretical derivation, the following basic assumptions are made:

(1) Strict cylindrical spool without taper.

(2) Negligible effects of valve spool gravity on friction force.

(3) Negligible thermal deformation of valve sleeve.17

(4) Negligible effects of oil pollution on the dynamic clearance and operating force of valve spool.

(5) Finite valve spool deformation that will not exceed the initial fit clearance.

(6) Laminar leakage flow in the annular clearance.27

3. Modeling and analysis of temperature-dependent operating force

As discussed in the previous section, friction force and flow forces dominate the valve spool operating force because the viscous shear force is usually negligibly small28and there is no relation between the inertial force and temperature. Thus,only the friction force and flow forces are modeled and analyzed in detail. For the sake of derivation, a new temperature variable is introduced and all the superscripts T in this paper denote the corresponding values at temperature T.

3.1.Temperature-dependent behavior of steady-state flow forces

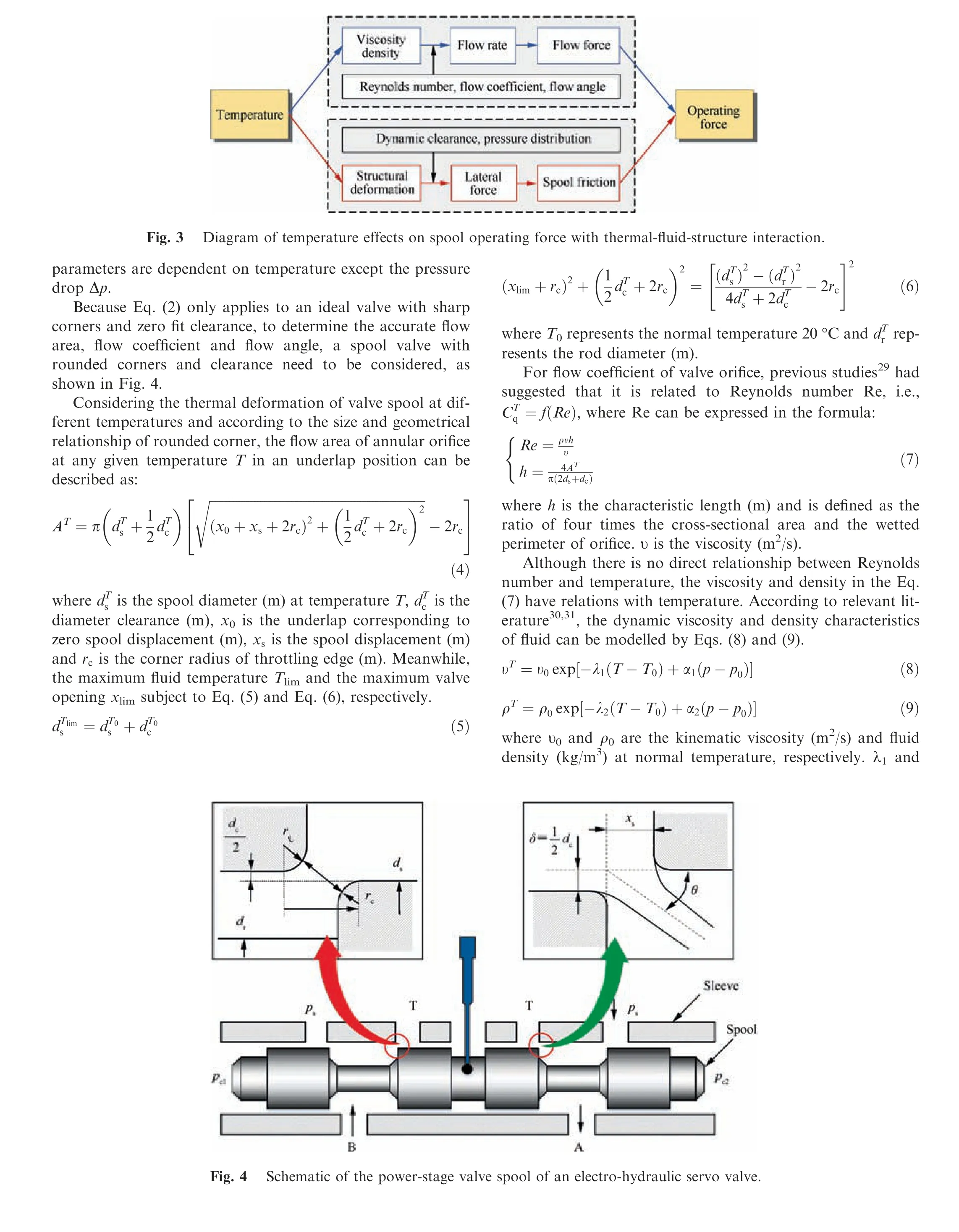

The steady-state flow force is one of the main forces on the valve spool and it varies greatly when flow rate and fluid parameters change. For steady state flow, the axial steadystate flow forces on spool is evaluated by Eq. (2).where qVis the volume flow rate (m3/s), ρ is the fluid density(kg/m3), v is the flow velocity (m/s), θ is the flow angle and the negative sign represents the closure direction of valve.

To study the temperature-dependent behavior of flow forces, all the parameters that related to temperature must be modeled first. The orifice flow rate can be expressed by Eq. (3).

4. Numerical simulation and analysis

To further investigate the theoretical model of operating force of valve spool derived in the previous section and explore the temperature-related characteristics of flow force and friction,several relevant numerical simulation have been carried out based on a specific valve spool and the relevant results are analyzed in this section.

4.1. Parameters in numerical simulation

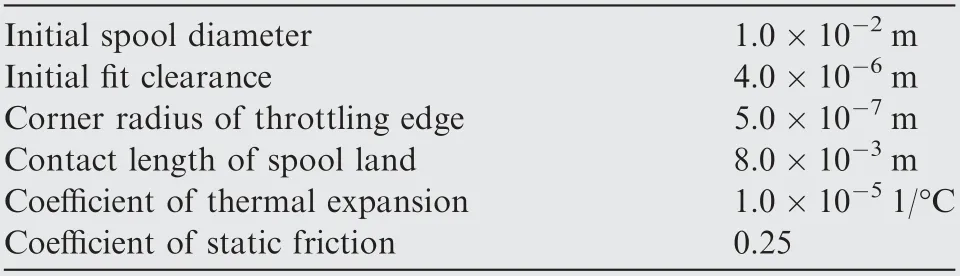

The parameters of a certain type mineral oil are utilized to explore the effects of temperature on the flow force of valve spool and actual spool parameters are also used to study the temperature-related behavior of spool friction with the spool material being 15CrMo. The main parameters and values are shown in Table 1.

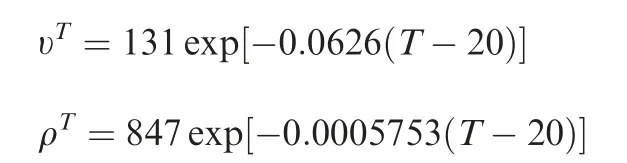

The specific relationships between fluid parameters and temperature must be investigated first, but compared with the pressure effects,the temperature affects the fluid properties more dramatically. Therefore, only take temperature into account in this study, ignoring the pressure effects in Eqs. (8)and (9).

To get the temperature characteristics of fluid viscosity and density, the nonlinear least square method based on the trust region algorithm is employed to fit the existing the oil property data and the temperature coefficient can be easily obtained,they are -0.0626 (1/°C) and -0.0005753 (1/°C), respectively.

The variation trend of fitting viscosity and density is illustrated in Fig. 8. It is clear that when fluid temperature increases from 0°C to 100°C, the fluid viscosity decreases exponentially and the fluid density decreases almost linearly.

Parameter Value

Table 1 Main parameters of valve spool used in the numerical simulation.

Fig. 8 Variation in viscosity and density with temperatures.

The fitting results in Fig.8 also makes it clear that temperature has a greater impact on viscosity than on density. More specifically,when fluid temperature varies from 0°C to 100°C,the viscosity dramatically drops by nearly 97.8%, while the density descends to 809 kg/m3from 858 kg/m3with a reduction of only 5.7%.

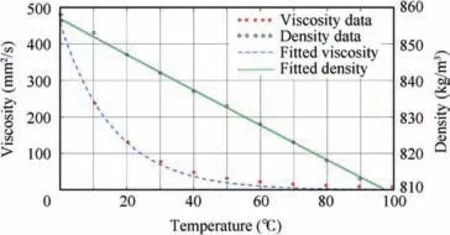

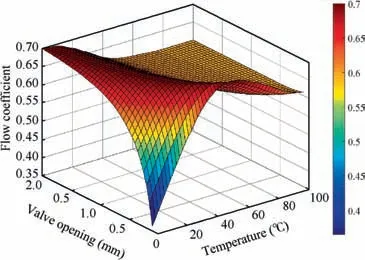

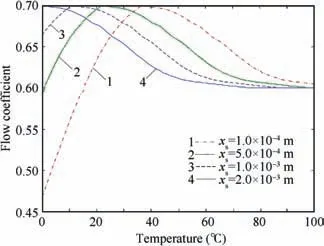

Fig. 9 Numerical results of relationship between temperature and flow coefficient.

Fig. 10 Comparison of flow coefficient under four different valve openings.

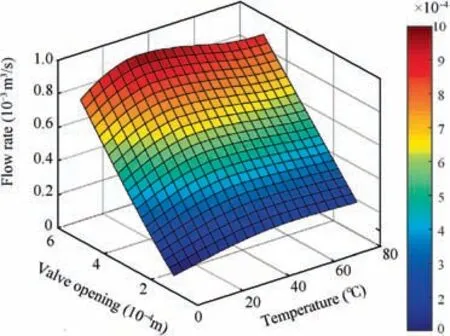

Fig. 11 Three-dimensional variation in flow rate with different valve openings and temperatures.

4.2. Temperature characteristics of steady-state flow force

In the theoretical modeling section, the temperature-related parameters have been modeled at any temperature T, such as the flow coefficient, flow rate and flow force. In this part, the influence of temperature on these parameters will be analyzed in a quantitative way. The principal results of temperaturedependent flow coefficient are collected in Fig. 9 and Fig. 10,where flow coefficients for four valve openings are plotted against temperature.

It can be seen from Fig.9 that the flow coefficient not only depends on temperature but also but also has close relation with the valve opening. In general, it is greatly affected in the small opening and low temperature conditions but is slightly affected in large opening and high temperature.Specifically,the flow coefficients are at first rising gradually,but later bend over to reach a maximum with the increase of temperature. Beyond the maximum they begin to descend with a decreasing rapidity and eventually reach a steady value of 0.6. Fig. 10 also depicts that the temperatures corresponding to the peak values of flow coefficients decrease from 40°C to 0°C with an increasing in opening from 1.0×10-4m to 2.0×10-3m.

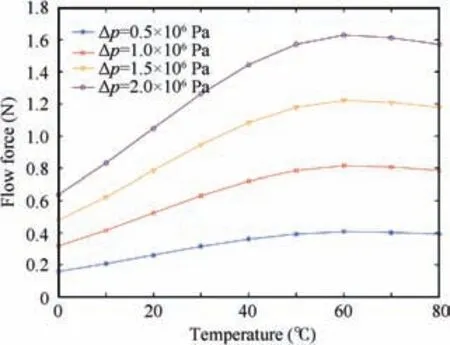

Fig. 12 Variation in flow force at different pressure drops and temperatures.

The variations in flow coefficient have a direct impact on the flow rate and flow force. So that is the reason why there will be some errors in the flow rate when a constant flow coefficient is adopted. Fig. 11 represents the temperature-related flow rate of valve port under a constant pressure drop of 3.5×106Pa.

From Fig.11,it can be seen that:(1)the flow rate is almost proportional to valve opening and it simultaneously fluctuates with temperature in certain degree, and (2) the magnitude of flow fluctuation in large opening is higher than that in small opening. That means it is important to consider the effects of temperature on flow rate, especially in large valve openings application,and in this way,it may avoid large errors in calculating the volume flow rate.

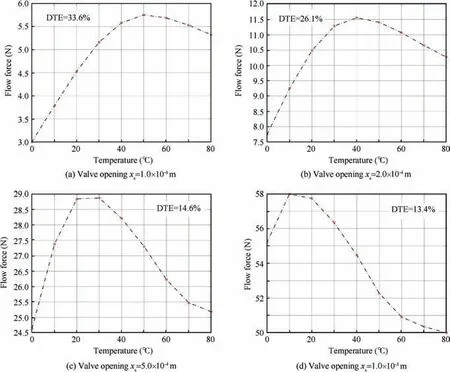

Fig. 13 Comparison of flow forces under four different valve openings.

Fig. 14 Friction forces between valve spool and sleeve under different temperatures.

In addition, pressure drop and valve openings of valve spool also play an important role in determining the spool flow force. Fig. 12 shows the variation in flow force at different pressure drops and different temperatures while valve opening is a constant value of 5.0×10-5m. It is obvious that flow forces are approximately proportional to the pressure drops of valve port when both valve opening and fluid temperature are constant, but they all consistently reach their maximums at about 60°C. Because it is the oil viscosity, density, temperature, flow velocity, valve opening and pressure drop synthetically determines the maximum flow force. In addition, the higher the pressure drop of valve port, the steeper the curve of flow force will be.It also means that the larger the flow rate is, the more significant the temperature effect under a fixed valve opening will be.

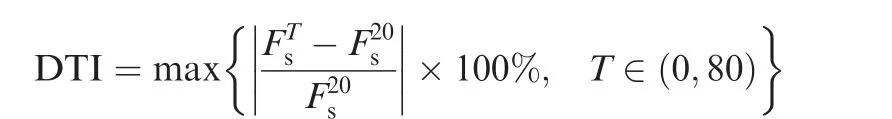

A comparison of flow forces under different temperatures and openings is shown in Fig. 13. In order to quantitatively evaluate the degree of temperature influence (DTI) in a widetemperature range, we adopted the following assessment criteria:

It can be seen from the above figures that there is a similar trend that the flow force is first increasing and then decreasing,while the temperature corresponding to the peak value is getting lower with an increase of valve opening. The maximum flow force increases from 5.7 N to 57.9 N gradually corresponding to the increasing valve opening from 1.0×10-4m to 1.0×10-3m,moreover,the maximal fluctuating magnitude of flow force caused by temperature variation is only 8.0 N,which accounts for nearly 13.4%of the flow force that at normal temperature.

According to the defined assessment criteria,the four corresponding DTI values (33.6%, 26.1%, 14.6% and 13.4%)under four different openings are calculated and also shown in Fig. 13. Therefore, the flow force gets more influence by valve opening than fluid temperature in general, but it may be necessary to model the effects of temperature-dependent flow force if accurate model of operating force is expected for servo control system, although its effects may well be of secondary significance.

4.3. Temperature characteristics of friction

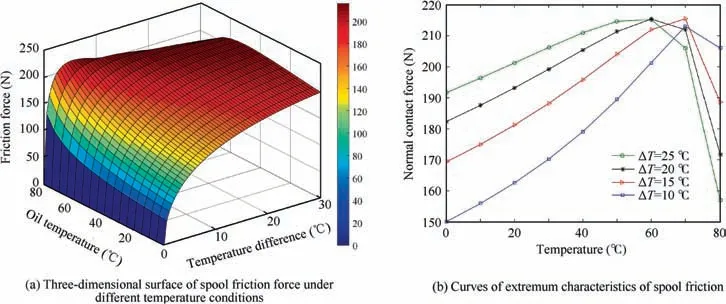

Compared with the flow force, friction force is more susceptible to temperature variation. Due to the limited flow rate of servo valves,the effects of temperature on the tiny fitting clearance are more noticeable. Considering different fluid temperatures and different temperature differences of spool ends, the obtained results are shown in Fig. 14.

It can be seen from Fig. 14(a) that fluid temperature and temperature difference are two different affecting factors and that the friction force gets more influence by temperature difference. Fig. 14(b) shows the similar varying tendency of friction force, i.e., it increases in a linear trend at first, up to the maximal value, but later begin to fall precipitously. This is mainly because the gap-sensitive oil pressure in the annular clearance sharply decreases when the spool deformation is too large and thus the lateral force on the spool decreases.

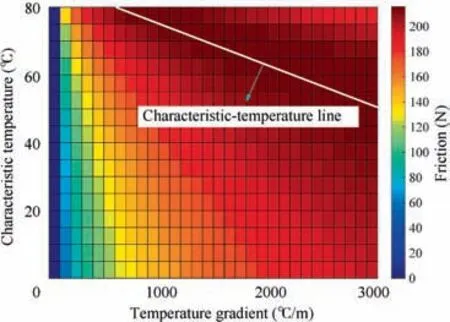

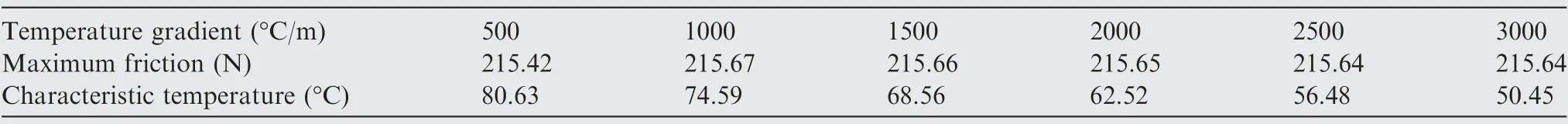

Fig. 15 Relationship between characteristic temperature and temperature gradient.

Table 2 Characteristic temperatures and maximal friction at different temperature gradients.

In addition, the greater the temperature difference is, the greater the friction force will be at a certain temperature below the characteristic temperature.Meanwhile,it is also interesting to see that under different temperature differences,the friction forces have the same maximum value, despite the different characteristic temperatures corresponding to these maximum values. To clarify this point further, the characteristictemperature line is drawn by connecting all the darkest points in the projection drawing of Fig. 14(a), as shown in Fig. 15.

Obviously, the characteristic-temperature line is linearly related to the axial temperature gradient of spool.It decreases with the linear increase of temperature gradient. The detailed numerical results are shown in Table 2.

It is also observed that from Table 2, the maximal friction forces remain unchanged at around 215 N although the temperature gradient ranges from 500°C/m to 3000°C/m. As a result, it is concluded that the characteristic temperature is directly determined by the axial temperature gradient of spool and the spool friction reaches its maximum at this temperature point.Hence,this conclusion suggests a proper operating temperature is one of the indispensable conditions for achieving high performance.

5. Conclusions Aiming at evaluating the control performance and avoiding jam faults of FMU within a wide-temperature range, the temperature characteristics of operating force of flow-rate servo valve are investigated in this study. The main conclusions can be drawn as follows:

(1) The flow force gets more influence by valve opening than temperature. Moreover, it increases first and then decreases as fuel temperature increases when valve opening is constant.The temperature effect becomes particularly critical when valve opening is small and the maximal fluctuating magnitude of flow force reaches to 33.6 % compared with that at normal temperature.

(2) The maximal friction appears when the fuel temperature reaches the characteristic-temperature point, where the derived extremum conditions of the friction just holds.At a certain fuel temperature below the characteristic temperature,there is a positive correlation between friction and temperature gradient,but the situation changes when at a certain fuel temperature above the characteristic temperature. In addition, the maximal friction can be determined once the structure parameters of valve spool and temperature are given.

(3) The characteristic temperature at which point the maximum friction occurs is not directly related to the fuel temperature,but depends essentially upon the axial temperature gradient of valve spool. There is a linear relation between the axial temperature gradient and the characteristic temperature.The greater the axial temperature gradient, the lower the characteristic temperature is.

Acknowledgements

This study was co-supported by the National Science and Technology Major Project of China (Nos. 2017-V-0011-0062,2017-V-0010-0060), National Natural Science Foundation of China (Nos. 51620105010, 51875014 and 51575019), Natural Science Foundation of Beijing Municipality of China (No.L171003) and Program 111 of China.

CHINESE JOURNAL OF AERONAUTICS2020年6期

CHINESE JOURNAL OF AERONAUTICS2020年6期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- A novel variable structure multi-model approach based on error-ambiguity decomposition

- Multi-block SSD based on small object detection for UAV railway scene surveillance

- A new online modelling method for aircraft engine state space model

- Cross-sectional deformation of H96 brass double-ridged rectangular tube in rotary draw bending process with diあerent yield criteria

- Application of a PCA-DBN-based surrogate model to robust aerodynamic design optimization

- Numerical exploration on the thermal invasion characteristics of two typical gap-cavity structures subjected to hypersonic airflow