考虑攻角范围的垂直轴风力机叶片翼型优化设计

汪 泉,甘 笛,杨书益,王环均

考虑攻角范围的垂直轴风力机叶片翼型优化设计

汪 泉,甘 笛,杨书益,王环均

(湖北工业大学机械工程学院,武汉 430068)

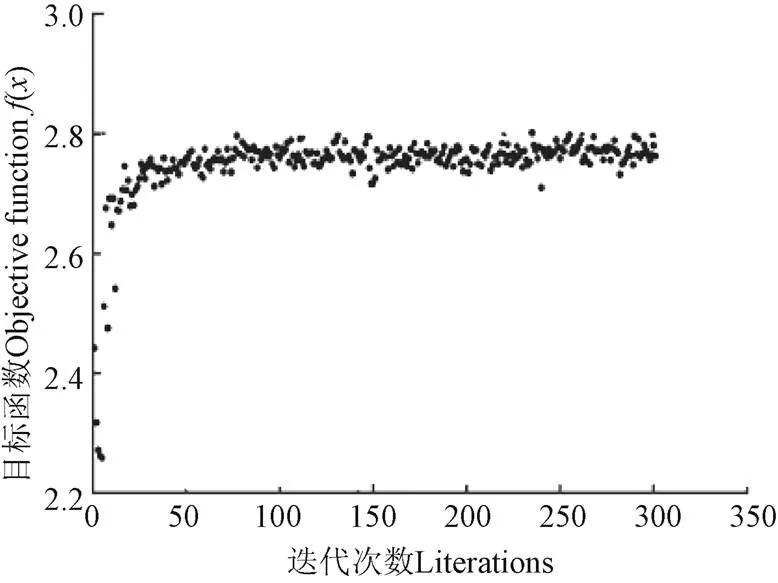

为解决目前垂直轴风力机叶片翼型都是在单一攻角下进行设计而忽略运行时叶片攻角变化范围大的问题,该研究提出一定攻角范围下垂直轴风力机叶片翼型廓线优化方法。首先采用类函数与B样条函数相结合的方法来表征翼型气动外形,以一定攻角范围下的切向力系数之和作为叶片翼型优化的目标函数。进一步利用粒子群算法和翼型气动性能预测软件RFOIL对H型垂直轴风力机叶片翼型气动外形进行优化设计。最后从功率系数、力矩系数、涡量分布和速度分布这4个方面讨论优化翼型较初始翼型的优越性。结果表明:相比原始垂直轴风力机,优化后的垂直轴风力机翼型能有效提高风力机的力矩系数及功率系数,其最大功率系数为0.362,提高了8.45%。研究结果对于设计高性能垂直轴风力机翼型具有很好的借鉴意义。

风力机,优化,叶片,类函数,功率系数,力矩系数

0 引 言

风能作为一种无污染、储量丰富、可再生的清洁能源越来越受到人们的关注和青睐。因此,提高风力机的产能输出一直是各国研究学者所关注的重点。由于H型垂直轴风力机(H-type Vertical Axis Wind Turbine,H-VAWT)具有结构简单,便于安装和维修,适应性高,无需偏航装置,叶片制造简单等优点,其研究近年成为风力发电领域的研究热点[1]。H-VAWT主要靠叶片捕捉风能,叶片的外形结构直接影响整个风力机产能输出,所以翼型气动外形优化设计显得至关重要。Ferreira等[2]研究了垂直轴风力机翼型表达方法,并应用了遗传算法耦合软件XFOIL对VAWT翼型进行优化设计,在不影响叶片气动性能的情况下有效减少了叶片重量。Lin等[3]将波浪状的叶片应用于VAWT叶片后缘,发现与直叶片相比,增大叶片尾缘的振幅和波长可使叶片最大推力提高2.31%,风力机功率系数提高16.4%。Peng等[4]提出了一种基于攻角-气动力系数的混合动力学模型,与现有的动力学模型相比,能更准确的预测作用在叶片上的气动力。Macphee等[5]研究探讨了柔性叶片的VAWT可行性,研究结果表明柔性叶片在提高风力机功率系数上更有优势,尤其在部分负载情况下,柔性叶片可提高风力机的自启动性能。Wang等[6]设计了一种可自动形成理想几何形状的新型VAWT叶片,并发现可变形叶片的低实度风力机能增幅最大功率系数约14.56%。Ferreira等[7-8]发现了叶片动态失速涡有顺时针旋向和逆时针旋向2种,叶片吸力面前缘产生顺时针失速涡,逆时针失速涡发生在吸力面与压力面的边界层中,并发现在叶片攻角较小时,失速涡在尾迹中产生,在叶片攻角较大时,动态失速涡在叶片内侧产生。Arab等[9]针对涡轮惯性对涡轮瞬态启动运动的影响,提出一种计算流体动力学(Computational Fluid Dynamics,CFD)方法来研究考虑涡轮转动惯量的VAWT自启动特性,发现随着转子转动惯量的增加,风力机达到最终转速需要较长时间,随着转动惯量的减小,风力机转速的振荡幅度增大。Abdolrahim等[10]研究了桨距角对垂直轴风力机性能的影响,研究表明当桨距角为-2°时,风力机功率系数能够提高6.6%。Li等[11]提出了垂直轴风力机叶片桨距角控制优化方法,发现在大范围叶尖速比情况下平均功率系数为0.177,并且能够有效抑制流体分离。Tavernier等[12]考虑垂直轴风力机叶片的气动性能与结构特性,利用遗传算法优化了在不同桨距角条件下翼型形状,性能较初始翼型有显著提高。在国内,杨秋萍等[13]研究了不同翼型、叶尖速比和实度组合状态下的垂直轴风力机性能影响,发现最佳安装角在1°~3°,并且可以通过改变翼型或增加翼型厚度来提高功率系数。张立军等[14]提出垂直轴风力机叶片分风区的方法来研究实时高效攻角调节规律,发现与原始风轮相比,调节攻角后的垂直轴风力机的风能利用率提高了11.03%。徐文浩等[15]提出双层反转构型的垂直轴风力机,发现与传统的垂直轴风力相比,新构型下的叶片时均扭矩系数提高了43.92%。向斌等[16]提出了叶片尾缘布置动态格尼襟翼的流动控制方法,该方法可有效提高风能利用率,当动态格栅保持在压力面时,整机最大风能利用率可提高27.9%。张旭等[17]提出了多种载荷作用下的H型垂直轴风力机叶片的结构优化。优化后风轮的质量、最大位移、最大应力、最大应变和强度比倒数最大值减少了7.51%、1.9%、8.5%、20.2%及16.1%。刘陈等[18]利用CFD方法计算分析了增强型垂直轴风力机和开放型垂直轴风力机的特性,发现与开放型VAWT相比,增强型VAWT的功率系数和扭矩系数有明显增加。李锦义[19]基于Joukowshi变形法和Trefftz构图法结合弦线迎合运动轨迹的思想,提出了一种VAWT叶片翼型设计的新方法,基于此设计出的一系列翼型具有良好的气动特性。张健宇[20]依据VAWT运行过程中叶片翼型的气动特性变化规律提出翼型尾缘高压面切开和弦线弯曲的优化方法,发现这2种翼型优化方法都可以提高风能利用率,且在低风速下切口翼型要优于弯曲翼型。甘洋[21]通过翼型改型的方法,分析了不同改型后的翼型的风力机的空气动力学性能。发现翼型采用3/2改型方法时,VAWT的空气动力学特性显著提高,最大风能利用率为0.384,较原翼型提高了16%。刘小红[22]对VAWT翼型进行动态分析,并根据多流管理论得出变桨距风力发电机的变桨规律,发现与定桨距风力机相比,变桨距风力机不仅具有良好的自启动性能,而且风能利用率更高。以上研究从不同的角度,研究了垂直轴风力机结构参数、翼型形状及流体特性等对VAWT的风能利用率的影响。然而,针对VAWT翼型优化设计,大多是基于单攻角或者较小攻角情况下设计而来。而垂直轴风力机运行攻角范围大,流场分布及湍流更复杂,使得单攻角情况下设计出来的翼型不能最大限度的提高风能利用率。

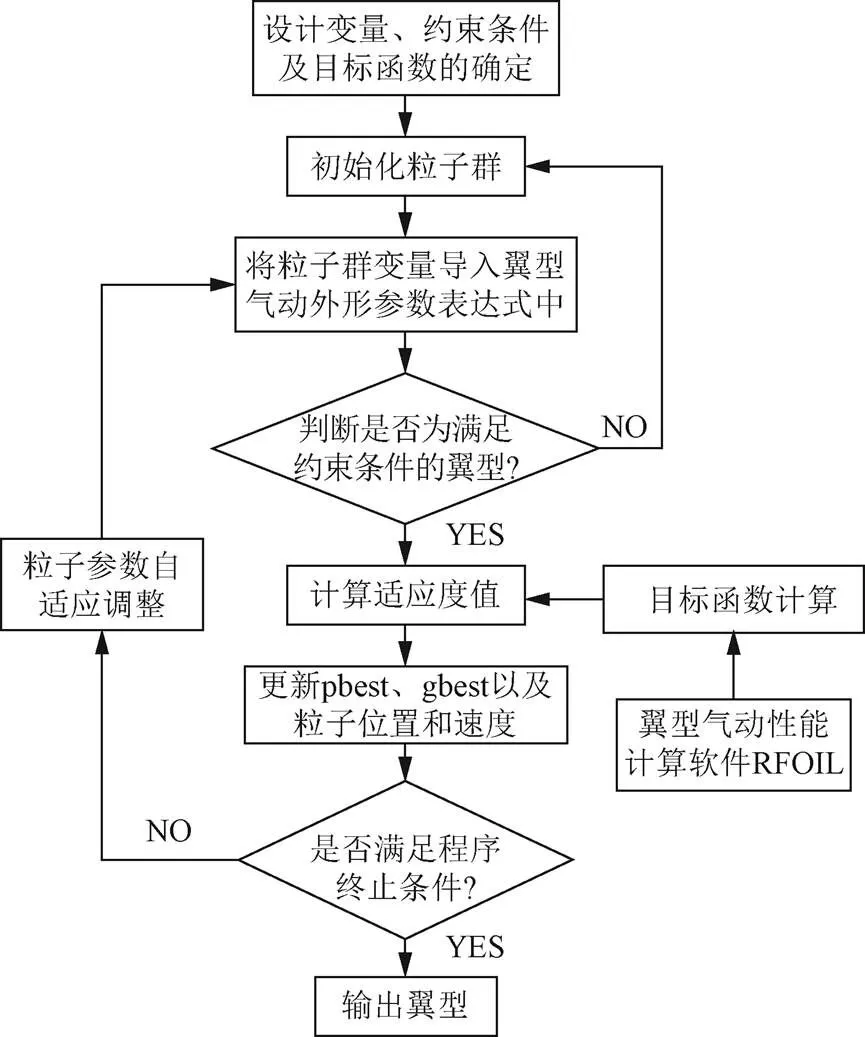

因此,本文提出大攻角范围内垂直轴风力机叶片翼型气动形状优化方法,采用一种类函数与B样条结合的方法表征翼型气动外形,选用NACA0015对称翼型作为原始翼型,考虑3组攻角范围,分别建立以力矩系数极大作为目标函数的风力机翼型优化数学模型,编制粒子群算法优化程序并耦合RFOIL软件对垂直轴风力机翼型进行优化设计,从风力功率系数、力矩系数及涡量分别对优化结果进行评价。

1 H型垂直轴风力机建模及验证

1.1 H型垂直轴风力机建模

1.1.1 CFD模型建立

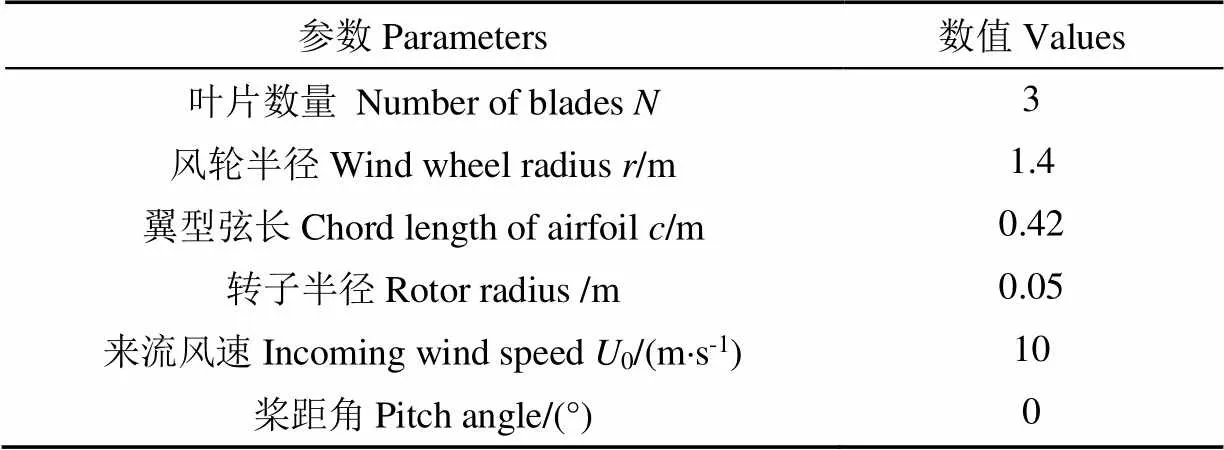

本文参照McLaren[23]风洞试验的试验模型建立H-VAWT二维数模型,使用的翼型为NACA0015对称翼型,模型的详细参数如表1所示。

表1 垂直轴风力机模型参数

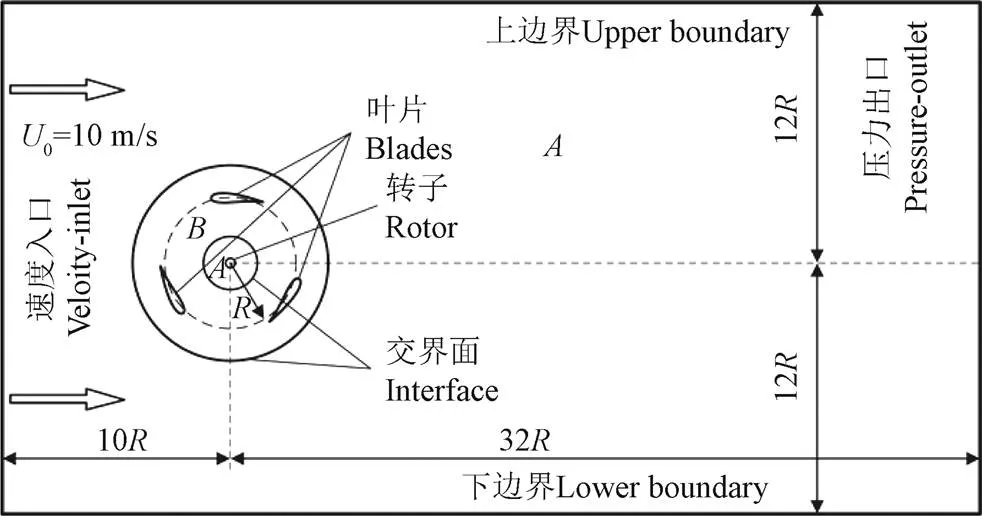

注:A为固定区域;B为旋转区域;R为风力机旋转半径。

1.1.2 网格划分

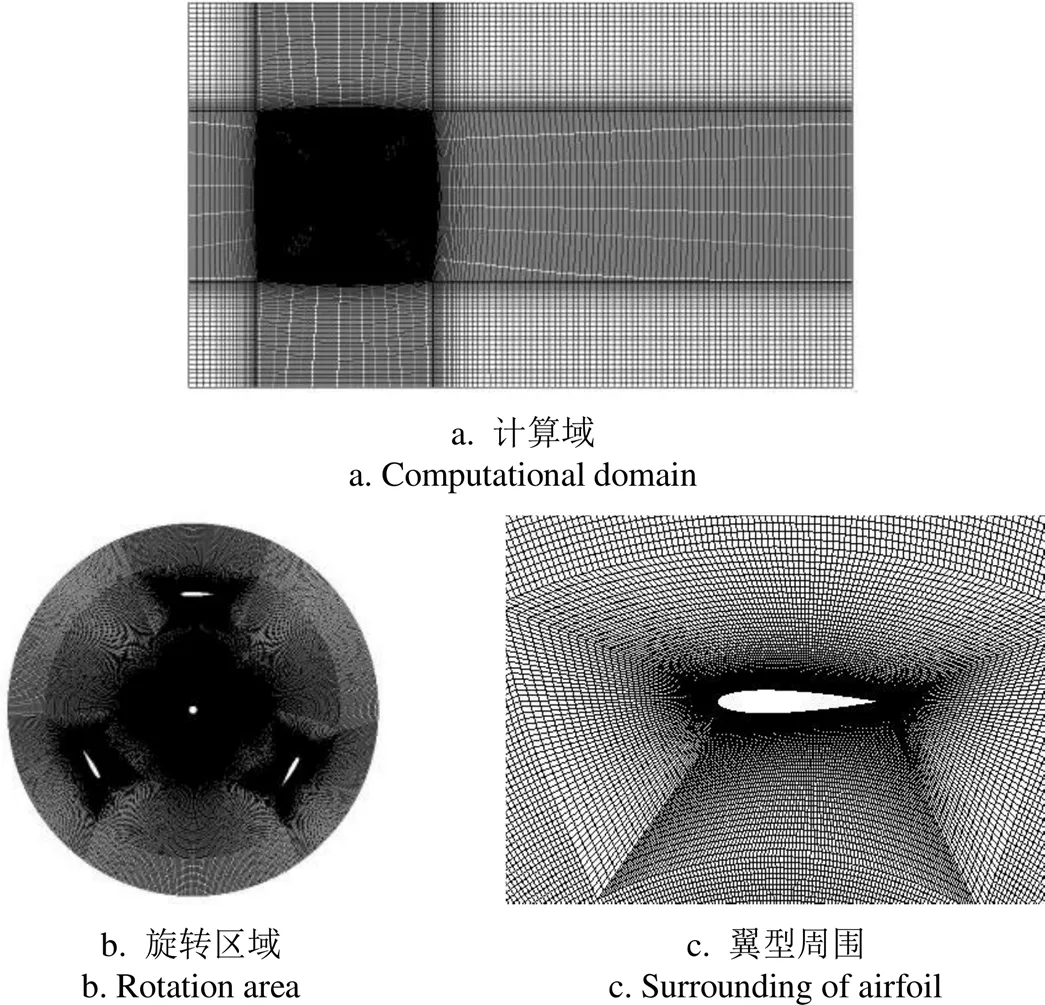

本文采用结构化网格对H-VAWT进行网格划分,整个计算域网格如图2a所示。固定区域与旋转区域之间的交界面的节点网格增长率设为1.05,翼型近壁面处网格增长率为1.05,旋转区域网格划分如图2b,翼型附近网格划分如图2c。网格数量约为50万,通过网格无关解研究,满足计算精度要求。

图2 计算域网格

1.1.3 湍流模型与求解器设置

1.1.4 计算模型边界条件设置

如图1所示,将计算域左边设为速度入口(Velocity-intlet),来流风速大小为10 m/s,方向从左到右,湍流强度为1%。右边设为压力出口(Pressure-outlet)。上边界和下边界设为对称边界(Symmetry)。旋转区域与固定区域设置为交界面(Interface),便于数值模拟时旋转区域与固定区域之间的数据传递。翼型边界设置为移动壁面(Moving-wall,no-slip)。

1.2 模型修正

1.2.1 H型垂直轴风力机功率计算方法

在FLUENT数值计算中,监测的对象为风力机旋转过程中力矩系数曲线。在数值计算的前几个周期中由于风力机处于非稳定状态,其力矩系数曲线变化不规律。待垂直轴风力机稳定过后,力矩系数呈现周期性变化。为保证计算结果的准确性,待垂直轴风力机处于稳定状态过后,取最后一个周期的力矩系数数据进行分析计算,本文取叶片旋转10圈后的力矩系数作为分析计算值。

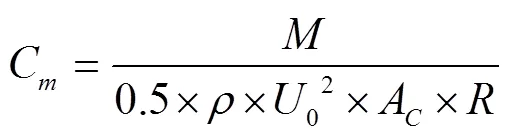

需要注意的是,监测到的力矩系数和弯矩系数之间必须有一个转换,转化后的弯矩系数用来计算风力机的功率系数,其计算公式如下:

1.2.2 气动力系数修正模型

由于数值计算所得的功率系数随叶尖速比变化比风洞实验值大,如图3所示。因此,需进行理论模型修正,借鉴McLaren[23]的修正模型:

图3 功率修正后数值模拟与风洞试验结果对比

2 翼型优化设计

2.1 翼型气动外形参数化表达

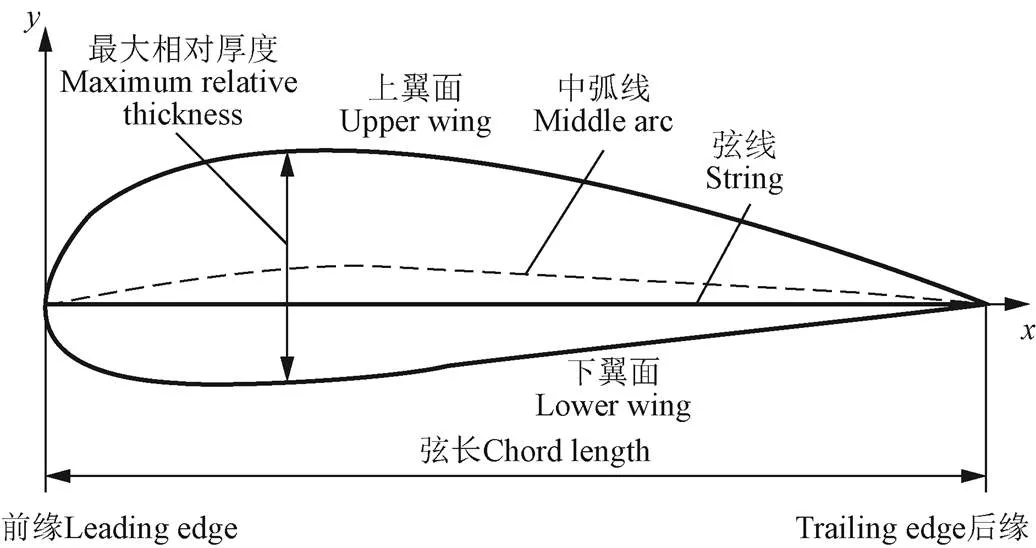

翼型是叶片重要的组成部分,其气动特性直接影响整个风力机的空气动力学特性。从某种意义上来讲,翼型可以理解成一个封闭的曲面,当来流绕过曲面,翼型的上下翼面因风速大小的不同而产生压力差,故而产生气动力。翼型主要几何参数有前缘、尾缘、弦长、弦线、翼型上下翼面和翼型最大厚度等,如图4所示。

图4 NAVA0015翼型几何参数示意图

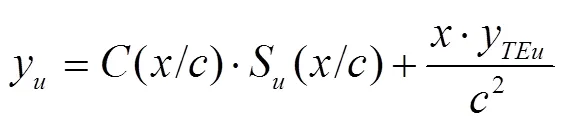

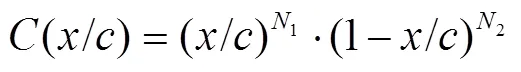

常用的翼型气动外形参数化表达方法有解析函数线性叠加法(Hicks-Henne参数化方法等)和样条拟合法(如B样条法和三次样条插值方法等)。在翼型的优化设计中,翼型气动外形参数化表达方法对优化结果有直接的影响,简单的插值方法对优化设计过程中翼型曲线变化缺乏调控能力。而且由于H-VAWT翼型尾缘处都较为平滑,影响了翼型的气动特性。而B样条曲线能较好的实现翼型曲线的局部调控。考虑到翼型尾缘处轮廓线比较平滑以及尾缘结构特征对翼型气动特性的影响,为更好地实现一定攻角情况下风力机翼型廓线优化,以获取更好性能的H-VAWT叶片,本文提出类函数与B样条结合的翼型气动外形参数化表达方法。翼型的上翼面和下翼面参数化表达式为

2.2 H-VAWT叶片翼型优化设计

2.2.1 设计变量

表2 设计变量控制范围

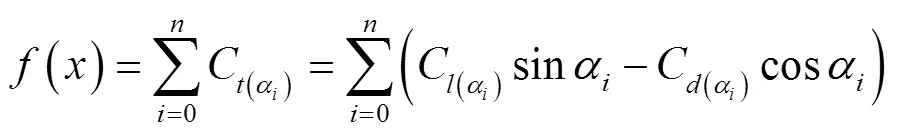

2.2.2 目标函数

2.2.3 约束条件

翼型最大相对厚度对翼型结构特性和气动特性有至关重要的影响[26],翼型最大相对厚度约束范围为

翼型相对弯度约束条件为

2.2.4 优化流程

注:pbest为个体最优;gbest为全局最优。

3 翼型优化结果及性能分析

3.1 优化结果

3.2 翼型优化性能分析

3.2.1 功率系数

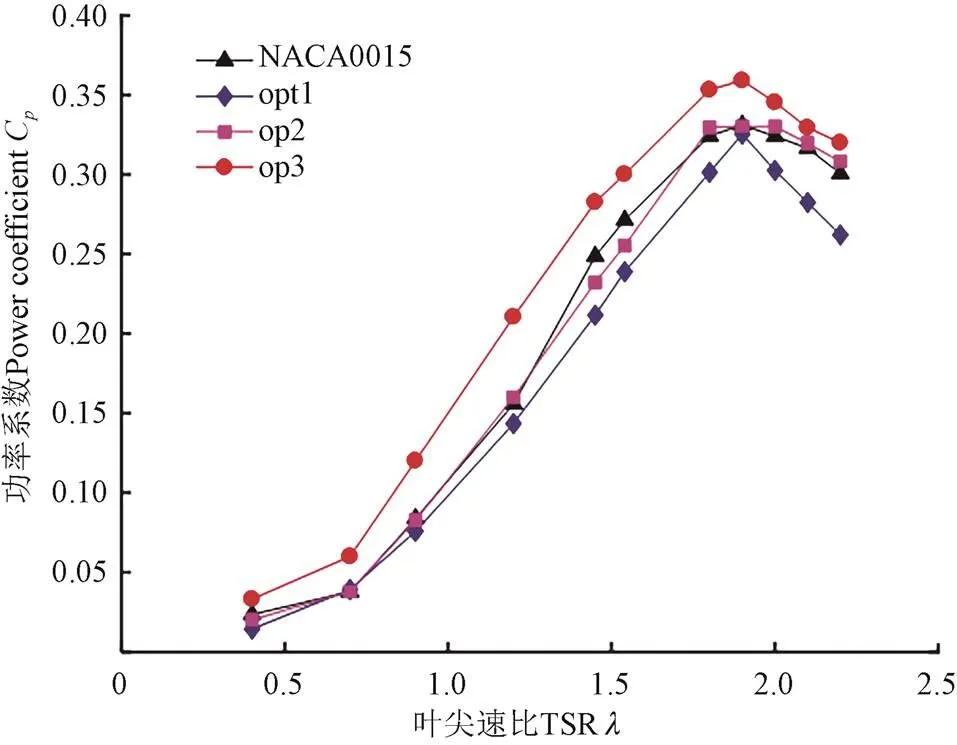

图6 翼型优化过程迭代图()

图7 不同攻角范围优化翼型与初始翼型对比

3.2.2 力矩系数

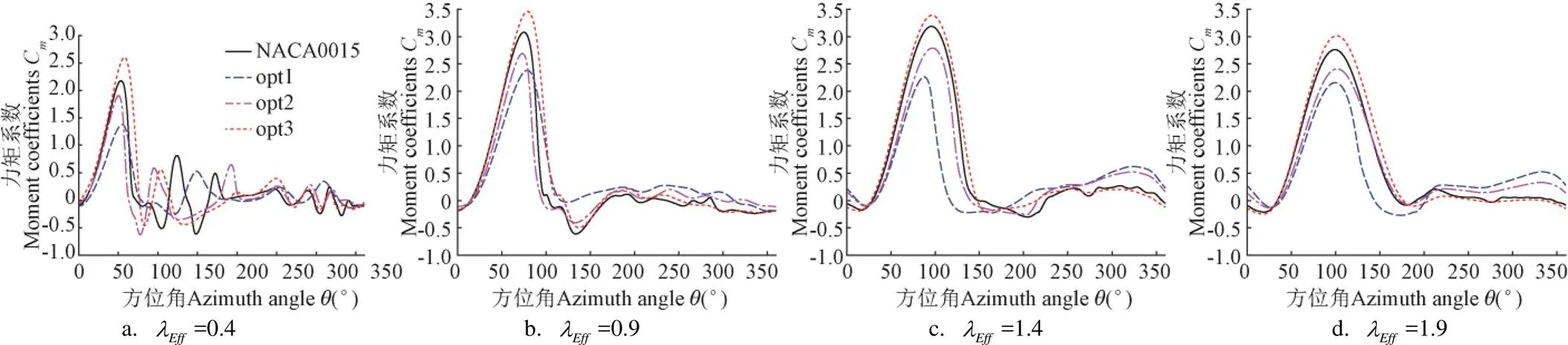

根据式(1)~(4)可知翼型力矩系数决定了风力机功率系数的大小。选取有效叶尖速比为0.4、0.7、1.4和1.9工况下,优化的3个翼型在一个旋转周期内的力矩系数进行对比分析。修正后的力矩系数曲线如图9所示。从力矩系数曲线波动的幅值来分析,叶尖速比较小时,4条力矩系数曲线波动较大,尤其是下风区,如图9a所示。这是由于风力机在低速下运行时,叶片攻角变化范围大,风力机叶片处于失速状态,从而预测的力矩系数曲线变化杂乱无章。但随着风力机转速增加,可以看出力矩系数曲线渐渐趋于平稳。从图9b、9c、9d可以看出,翼型在下风区的力矩系数曲线趋于水平。

此外,在比较不同叶尖速比下的力矩系数变化时,发现2个变化规律:一方面,力矩系数的峰值位置随叶尖速比的增加而向右移动;另一方面,H-VAWT产生功率的工作方位角在上风区,叶片在下风区时几乎不做功。当风力机叶片在上风区时,在大攻角范围下优化翼型opt3所产生的力矩系数整体较大,且在上风区的开口角度较也较宽。而对于下风区而言,力矩系数曲线均在零线上下波动,对风力机气动性能的影响较小。综上所述,相比于优化翼型opt1和opt2,优化翼型opt3对于提高垂直轴风力机气动性能具有一定的优越性。

注:NACA0015为初始翼型;opt1、opt2、opt3分别表示攻角范围在、、下的优化翼型。下同。

图9 优化翼型不同叶尖速比下的单个叶片力矩系数曲线

图10中展示了初始翼型与优化翼型opt3在一个周期内的合力矩系数变化情况。可以明显看出:在一个周期内,优化叶片力矩系数曲线明显高于初始翼型,这意味着H型垂直轴风力机在运行过程中,每秒钟的功率系数都能得到提高。在一个旋转周期内,配备3个优化叶片的垂直轴风力机力矩系数峰值出现的方位角分别在101°、221°和341°。即当单个叶片的力矩系数达到峰值时的同时,3个叶片的合力矩系数同样达到峰值。

图10 = 1.9时叶片合力矩系数曲线(3叶片)

3.2.3 涡量及速度分布

风力机叶片周围的速度分布分析有助于进一步分析风力机叶片动态失速的特性。图12为叶尖速比为1.9时的风力机叶片附近速度分布,图12a所示,叶片方位角在0°时,初始叶片前缘出现脱落涡,而优化叶片前缘出现脱落涡的程度较小;从30°开始,翼型前缘和尾缘速度不断增大,直到方位角为120°时,前缘速度开始逐渐减小;当叶片方位角在240°时,初始叶片尾流处出现较大的漩涡,优化叶片尾流出也相应出现漩涡,但其程度明显较初始叶片小。这些分离涡会导致叶片出现动态失速,使叶片丧失部分力矩。优化叶片虽然不能完全抑制叶片动态失速的现象,但能改善叶片动态失速的程度,这样叶片的气动特性也得到了有效的提高。从速度流场的梯度变化范围上看,优化叶片附近速度分布梯度在下风区明显较初始叶片弱。由动量守恒定理来判断,来流风经过上风区一部分能量被风力机吸收,另一部分流向下风区。由此可推出,优化叶片的风力机在上风区吸收的能量较初始叶片多。综上所述,优化叶片在提高风力机空气动力学性能上更有优势。

图11 优化翼型与初始翼型不同方位角下的涡量分布

图12 优化翼型与初始翼型不同方位角下的速度分布

4 结 论

在H-VAWT叶片翼型的设计中,考虑到其运行状态下叶片攻角变化大这一特性,提出大攻角范围下的叶片翼型优化设计方法。将新型H-VAWT与初始H-VAWT气动性能进行对比分析,主要结论如下:

2)新型H-VAWT叶片尾迹得到有效改善,并且优化的叶片翼型有效的抑制了叶片表面的涡脱落现象。

[1]Ma N, Lei H, Han Z, et al. Airfoil optimization to improve power performance of a high-solidity vertical axis wind turbine at a moderate tip speed ratio[J]. Energy, 2018, 150: 236-252.

[2]Ferreira C S , Geurts B . Aerofoil optimization for vertical‐axis wind turbines[J]. Wind Energy, 2015, 18(8):1371-1385.

[3]Lin S Y , Lin Y Y , Bai C J , et al. Performance analysis of vertical-axis-wind-turbine blade with modified trailing edge through computational fluid dynamics[J]. Renewable Energy, 2016, 99: 654-662.

[4]Peng Y X , Xu Y L , Zhan S . A hybrid DMST model for pitch optimization and performance assessment of high-solidity straight-bladed vertical axis wind turbines[J]. Applied Energy, 2019, 250: 215-228.

[5]Macphee D W , Beyene A . Fluid–structure interaction analysis of a morphing vertical axis wind turbine[J]. Journal of Fluids & Structures, 2016, 60:143-159.

[6]Wang Ying, Sun Xiaojing, Dong Xiaohua, et al. Numerical investigation on aerodynamic performance of a novel vertical axis wind turbine with adaptive blades[J]. Energy Conversion and Management, 2016, 108: 275-286.

[7]Ferreira C J S , Bussel G J W V , Kuik G A M V , et al. On the use of velocity data for load estimation of a VAWT in dynamic stall[J]. Journal of Solar Energy Engineering, 2011, 133(1):169-175.

[8]Ferreira C J S, Hofemann C, Dixon K, et al. 3D Wake Dynamics of the VAWT[C]. Orlando: 48th AIAA Aerospace Science Meeting, 2010: 1-33.

[9]Arab A , Javadi M , Anbarsooz M , et al. A numerical study on the aerodynamic performance and the self-starting characteristics of a Darrieus wind turbine considering its moment of inertia[J]. Renewable Energy, 2017, 107(7): 298-311.

[10]Abdolrahim R, Ivo K, Bert B. et al Effect of pitch angle on power performance and aerodynamics of a vertical axis wind turbine[J]. Applied Energy, 2017(197): 132-150.

[11]Li C , Xiao Y , Xu Y L , et al. Optimization of blade pitch in H-rotor vertical axis wind turbines through computational fluid dynamics simulations[J]. Applied Energy, 2018, 212:1107-1125.

[12]Tavernier D , Ferreira C , Van Bussel G . Airfoil optimisation for vertical-axis wind turbines with variable pitch[J]. Wind Energy, 2019, 22(4):547-562.

[13]杨秋萍,席德科. 叶片安装角对H型垂直轴风力机气动性能的影响研究[J]. 太阳能学报,2017,38(9):2544-2551. Yang Qiuping, Xi Deke. Study on the influence of blade installation angle on the aerodynamic performance of H-type vertical axis wind turbine[J]. Acta Solar Energy, 2017, 38(9): 2544-2551. (in Chinese with English abstract)

[14]张立军,赵昕辉,王旱祥,等. H型垂直轴风力机实时高效攻角调节方法研究[J]. 机械工程学报,2018,54(10):173-181. Zhang Lijun, Zhao Xinhui, Wang Hanxiang, et al. Research on real-time and efficient angle of attack adjustment method of H-type vertical axis wind turbine[J]. Journal of Mechanical Engineering, 2018, 54(10): 173-181. (in Chinese with English abstract)

[15]徐文浩,邱展,喻伯平,等. 双层反转垂直轴风力机的流场特性数值模拟[J]. 浙江大学学报:工学版,2019,53(11):2223-2230. Xu Wenhao, Qiu Zhan, Yu Boping. Numerical simulation of flow field characteristics of double-layer reverse vertical axis wind turbine[J]. Journal of Zhejiang University: Engineering Edition, 2019, 53 (11): 2223-2230. (in Chinese with English abstract)

[16]向斌,缪维跑,李春,等. 动态格尼襟翼对垂直轴风力机性能影响研究[J].中国机械工程,[2020-01-20] http:// kns.cnki.net/kcms/detail/42.1294.th.20200119.1650.006.html. Xiang bin, Miao weipao, Li Chun, et al. Study on the influence of dynamic gurney flap on the performance of vertical axis wind turbine[J]. China Mechanical Engineering, [2020-01-20] http://kns.cnki.net/kcms/detail/42.1294.th.20200119. 1650.006.html. (in Chinese with English abstract)

[17]张旭,李召暄,李伟. 多种载荷作用下H 型垂直轴风力机叶片的结构优化[J]. 农业工程学报,2020,36(7):83-91. Zhang Xu, Li Zhaoxuan, Li Wei. Structural optimization of H-type vertical axis wind turbine blade under various loads[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(7): 83-91. (in Chinese with English abstract)

[18]刘陈,运洪禄,吕续舰. 基于CFD的二维垂直轴风力机性能计算[J]. 太阳能学报,2020,41(2):144-151. Liu Chen, Yun Honglu, Lu Xujian. Performance calculation of two-dimensional vertical axis wind turbine based on CFD[J]. Acta Solar Energy Sinica, 2020, 41 (2): 144-151. (in Chinese with English abstract)

[19]李锦义. 垂直轴风力机翼型与叶片空气动力稳定性分析与优化[D]. 南通:南通大学,2018. Li Jinyi. Aerodynamic Stability Analysis and Optimization of Vertical Axis Wind Turbine Airfoil and Blade[D]. Nantong: Nantong University, 2018. (in Chinese with English abstract)

[20]张健宇. H型垂直轴风力机数值模拟及叶型优化[D]. 武汉:华中科技大学,2011. Zhang Jianyu. Numerical Simulation and Blade Profile Optimization of H-type Vertical Axis Wind Turbine[D]. Wuhan: Huazhong University of Science and Technology, 2011. (in Chinese with English abstract)

[21]甘洋. H型垂直轴风力发电机气动性能优化研究[D]. 重庆:重庆大学,2017. Gan Yang. Aerodynamic Performance Optimization of H-type Vertical Axis Wind Turbine[D]. Chongqing: Chongqing University, 2017. (in Chinese with English abstract)

[22]刘小红. 变桨距垂直轴风力机气动性能分析[D]. 哈尔滨:哈尔滨工程大学,2012. Liu Xiaohong. Aerodynamic Performance Analysis of Variable Pitch Vertical Axis Wind Turbine[D]. Harbin: Harbin Engineering University, 2012. (in Chinese with English abstract)

[23]McLaren K W. A Numerical and Experimental Study of Unsteady Loading of High Solidity Vertical Axis Wind Turbines[D]. Hamilton: McMaster University, 2011.

[24]Bedon G ,Betta S D, Benini E. Performance-optimized airfoil for darrieus wind turbines[J]. Renewable Energy, 2016, 94(aug.):328-340.

[25]施法中. NURBS插值曲线(一)[J]. 计算机工程,1994(S1):522-527. Shi Fazhong. NURBS interpolation curve(1)[J]. Computer Engineering, 1994(S1): 522-527. (in Chinese with English abstract)

[26]Wang Q , Wang J , Sun J , et al. Optimal design of wind turbine airfoils based on functional integral and curvature smooth continuous theory[J]. Aerospace Ence & Technology, 2016, 55(aug.):34-42.

Optimized design of H-VAWT blade airfoils profile considering range of angle of attack

Wang Quan, Gan Di, Yang Shuyi, Wang Huanjun

(,,430068)

Wind energy, as a green and renewable energy, has attracted increasing attention from all over the world. Currently, rapidly developed wind turbine can transfer wind energy into electricity power. A H-type vertical axis wind turbine (VAWT) has become a research focus to design new types of VAWT with high aerodynamic performance, due to its simple structure, easy installation, high adaptability, no need of yaw device, and feasible blade manufacturing. Therefore, H-type VAWT has become a focus on how to design new VAWT with high aerodynamic performance. The aerodynamic performance design of VAWT has very important influence on the power characteristics of wind station. Most previous studies on VAWTs were reported to predict accurately the energy efficiency and the effects of parameters, such as the number of blades, solidity, chord length, and pitch angle, on power coefficients using CFD simulation. As to the airfoil optimization design of H-type VAWT blade, most airfoils profile were designed based on an angle of attack or narrow range of angles of attack when determining the optimal angle of attack. In order to solve the problem that the airfoil profile of vertical axis wind turbine is designed under a single angle of attack, without considering the condition of large variation range of blade angle of attacks when the vertical axis wind turbine is working. In this study, an optimization design was proposed for the airfoil profile of VAWT blade under a certain angle of attacks. Firstly, the aerodynamic shape of blade airfoil in a VAWT was expressed in the combination of class function and B-spline function. As such, the optimal objective function of blade airfoil was set to the sum of tangential force coefficients under a certain angle of attacks. a NACA-0015 symmetric airfoil was chosen as the original airfoil when considering three ranges of angles of attack. Furthermore, the particle swarm optimization (PSO) and the aerodynamic performance prediction RFOIL software were used to optimize the aerodynamic shape of H-type VAWT blade. Finally, the optimized VAWT blade airfoil was addressed over the initial airfoil, particularly on the performance for utilization ratio of wind energy, torque coefficient, and vorticity distribution. The results showed that compared with the original vertical axis wind turbine, the new vertical axis wind turbine blade can effectively improve the torque coefficient and power coefficient of the vertical axis wind turbine. To be exactly, when the tip speed ratio is 1.9, the power coefficient reaches the peak which the maximum power coefficient of the new vertical axis wind turbine was 0.362 increased by 8.45% comparing to the original vertical axis wind turbine. In addition, the wake of the new H-type VAWT was effectively improved, which attributed to the new airfoil that could effectively suppressed the vortex shedding on the blade surface. This study has a good reference for how to the design the vertical axis wind turbine blade airfoil profile with high performance.

wind turbine; optimization; blade; integrated function; power coefficient; moment coefficient.

汪泉,甘笛,杨书益,等. 考虑攻角范围的垂直轴风力机叶片翼型优化设计[J]. 农业工程学报,2020,36(24):38-45.doi:10.11975/j.issn.1002-6819.2020.24.005 http://www.tcsae.org

Wang Quan, Gan Di, Yang Shuyi, et al. Optimized design of H-VAWT blade airfoils profile considering range of angle of attack[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(24): 38-45. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.24.005 http://www.tcsae.org

2020-09-09

2020-12-09

国家自然科学基金项目(51975190)

汪泉,博士,副教授,主要研究方向:机械系统优化设计、风力发电机叶片关键技术和机器人技术。Emaile:quan_wang2003@163.com

10.11975/j.issn.1002-6819.2020.24.005

TM315

A

1002-6819(2020)-24-0038-08