Nonlinear state estimation for fermentation process using cubature Kalman filter to incorporate delayed measurements☆

Liqiang Zhao,Jianlin Wang*,Tao Yu,Kunyun Chen,Tangjiang Liu

College of Information Science and Technology,Beijing University of Chemical Technology,Beijing 100029,China

Keywords:Nonlinear state estimation Fermentation process Cubature Kalman filter Delayed measurements Sample-state augmentation

ABSTRACT State estimation of biological process variables directly influences the performance of on-line monitoring and optimal control for fermentation process.A novel nonlinear state estimation method for fermentation process is proposed using cubature Kalman filter(CKF)to incorporate delayed measurements.The square-root version of CKF(SCKF)algorithm is given and the system with delayed measurements is described.On this basis,the sample-state augmentation method for the SCKF algorithm is provided and the implementation of the proposed algorithm is constructed.Then a nonlinear state space model for fermentation process is established and the SCKF algorithm incorporating delayed measurements based on fermentation process model is presented to implement the nonlinear state estimation.Finally,the proposed nonlinear state estimation methodology is applied to the state estimation for penicillin and industrial yeast fermentation processes.The simulation results show that the on-line state estimation for fermentation process can be achieved by the proposed method with higher estimation accuracy and better stability.

1.Introduction

Nonlinear state estimation is a highly active research area and plays a major role in many applications including the optimal control for fermentation process.Fermentation process is one of typical nonlinear processes,involving cell growth and reproduction.Various process parameters in a fermentation process can be divided into two categories:on-line measurements and off-line measurements.On-line measurements can be taken directly by hardware sensors without any time delay,including pH,temperature,culture volume,concentrations of carbon dioxide and dissolved oxygen,etc.Off-line measurements are mainly for biological variables,such as concentrations of biomass,substrate and product,generally obtained through laboratory analytical instruments and usually with uncertain time delays because of the limitation of operating conditions.The real-time monitoring of biological process variables is the key factor of the optimal control for fermentation process[1].However,the measurement of biological process variables is difficult due to the lack of hardware sensors.In the last two decades,soft sensors have been applied to fermentation process to solve this problem based on some easy-to-measure variables[2,3].Generally,soft sensors can be classified into two groups:model-driven and data driven[4].The focus of this work is the state estimation method by means of measurement data and suitable process model based on nonlinear filtering,which belongs to model-driven soft sensor.

As the nonlinear characteristic of fermentation model,nonlinear filters are the most popular state estimation technique used for bioprocess monitoring.The extended Kalman filter(EKF),based on a first-order linearization of process model,has been widely applied to on-line estimation of biological process states[5,6].It is generally known that the EKF has two main drawbacks:the linearized approximation makes the filter divergence if the assumption of local linearity is violated and calculation of Jacobian matrices may be very difficult or even infeasible for complex nonlinear systems.In order to overcome these drawbacks,the unscented Kalman filter(UKF)[7]is developed to solve nonlinear state estimation problems,which is better than the EKF in terms of robustness and speed of convergence[8].Wang et al.[9]has focused on the on-line estimation in fed-batch fermentation process using the UKF and their proposed method to improve estimation accuracy of biological process variables.Fermentation process model is highly nonlinear and usually considered as a high-dimensional nonlinear system,which is a challenge to nonlinear filters.Therefore,the performance of nonlinear filter is important to the accuracy and stability of state estimation for fermentation process.

The cubature Kalman filter(CKF)[10]is an emerging nonlinear state estimation method,especially for complex high-dimensional nonlinear system.The CKF algorithm can achieve at least second-order accuracy and does not need to calculate Jacobian matrices.Furthermore,the performance of the CKF is more stable and more accurate in high dimensional state estimation comparing with the UKF[11].As the CKF algorithm requires the square root operation of the state covariance matrix in the calculation,if the calculation conditions are not met,which will lead to the interruption of filter,it will affect the stability of the algorithm.Arasaratnam and Haykin[10]have also presented a squareroot version of cubature Kalman(SCKF)algorithm.The SCKF algorithm solves the problem of numerical stability and reduces the amount of computation,so it has better filtering performance.Consequently,the SCKF algorithm is introduced to solve the nonlinear state estimation for complex fermentation process in this paper.

Generally,off-line measurements in fermentation process belong to delayed measurements.They are usually considered as unsuitable for control and estimation purposes,because they are available with a time delay and usually infrequent and irregular[12].However,delayed measurements contain valuable information about biological process variables and if they can be utilized in appropriate ways,the accuracy of the estimation will be improved.The state estimation with delayed measurements for fermentation process has been studied using the multi-rate state estimation.Gudi et al.[13,14]and Soons et al.[15]implemented a multi-rate estimator using the EKF to estimate the key state variables based on delayed measurements for a bioreactor.Myers et al.[16]used a two-stage EKF to amalgamate on-line and time-delayed off-line measurements into a common estimate for state variables of a fed-batch biochemical reactor.To overcome the inadequacy of the EKF for severely nonlinear processes,Tatiraju et al.[17]presented a multi-rate state estimation method using nonlinear state observers to estimate state variables of a pilotscale biochemical reactor.Cao and Soh[18]designed a multi-rate nonlinear estimator based on Taylor series expansion and applied it to a class of biological systems to estimate unavailable state variables.The processing methods of delayed measurements in the multi-rate estimation are important to computational efficiency,accuracy and stability of the on-line estimation.It is therefore essential to further explore more effective methods to handle measurement delays in the multi-rate estimation to improve the performance of state estimation for fermentation process.

It is straightforward to deal with delayed measurements utilizing the filter recalculation method[19],which will recompute the estimates when delayed measurements are available from corresponding sampling time instant.The main drawback of this method is the huge storage cost and computational burden so it is not suitable for on-line nonlinear state estimation.Several state augmentation approaches have been explored in chemical and biochemical processes and discussed in detail by Gopalakrishnan et al.[20].There are mainly three schemes for assimilating the delayed measurements in recursive estimators: fixed-lag smoothing[21],measurement augmentation[22]and sample-state augmentation[23].The first two approaches require all the state information between sampled time instant and arrival time instant of the delayed measurements to obtain estimates when the state is updated to incorporate delayed measurements,leading to a heavy computational load.The samplestate augmentation method is a more efficient approach,only augmenting the state with the sample-state,which is the state at sampling time of the delayed measurements,and is applicable to the case with uncertain and time-varying delays[24].The sample-state augmentation based on EKF algorithm has been used to solve nonlinear state estimation problem of chemical process[20].In order to overcome the limitation of the EKF,it is promising to study the sample-state augmentation method in the SCKF algorithm frame to improve the state estimation considerably.

Hence,we focus on the nonlinear state estimation utilizing the SCKF algorithm and delayed measurements for fermentation process in this paper.The nonlinearstate estimation method using square-rootversion of SCKF algorithm to incorporate delayed measurements for fermentation process is explored.Two simulation examples are given for the state estimation of penicillin and industrial yeast fermentation processes,to demonstrate the validity and effectiveness of the proposed method.

2.Nonlinear State Estimation Methodology for Fermentation Process

2.1.Square-root version of CKF algorithm

Consider the following nonlinear discrete-time system

where xkand zkare the n-dimensional state vector and l-dimensional measurement vector of the system,respectively;wk-1and vkare the independent process and measurement Gaussian noise with zero means and covariances Qk-1and Rk,respectively;uk-1is the control input vector;fk-1(⋅)and hk(⋅)are the state function and measurement function of the nonlinear system.

The specific SCKF algorithm process based on the nonlinear system Eq.(1)is given as follows.

In the SCKF algorithm,m represents the number of cubature points,m=2n for a third degree spherical-radial cubature rule;the set of 2n cubature points is given by

where eidenotes the i th column of a n-dimensional unit matrix.

Initialization(k=0):

The initial state estimated value and its error covariance matrix are given by

The initial value S0|0of the square-root factor of error covariance matrix is computed by the Cholesky decomposition of P0|0

For k∈ {1,2,…,∞}:

Step 1:Time update procedure

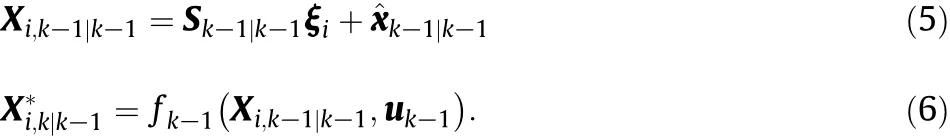

(1)Evaluate cubature points and propagate them through the state function

(2)Estimate the predicted state

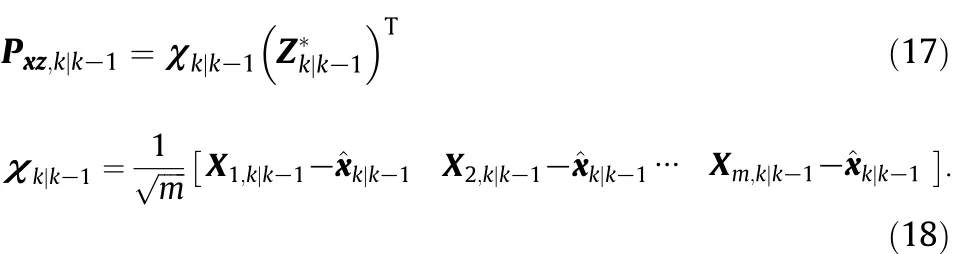

(3)Compute the square-root factor of predicted error covariance matrix

where SQ,k-1is a square-root factor of Qk-1,obtained by SQ,k-1=(chol(Qk-1))Tand

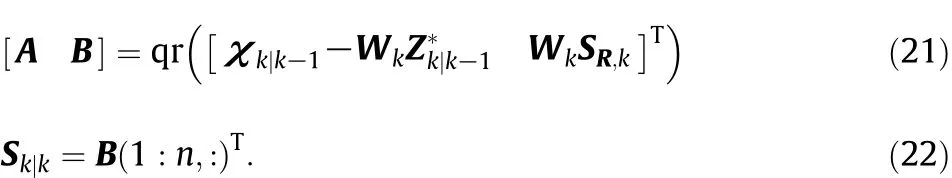

A and B are the unitary matrix and upper triangular matrix,respectively,through QR decomposition;B(1:n,:)Tdenotes the transpose operation of the n dimensional nonzero square matrix B(1:n,:),which is extracted from the matrix B.

Step 2:Measurement update procedure

(1)Evaluate cubature points and update the propagated cubature points through the measurement function

(2)Estimate the predicted measurement

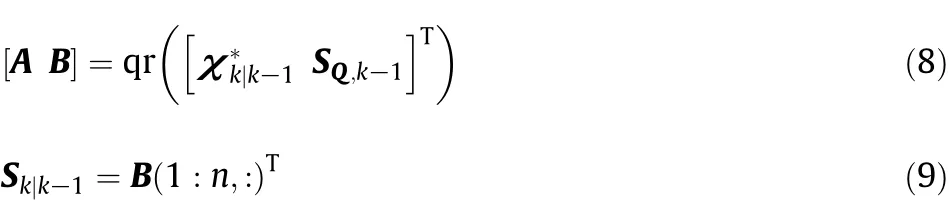

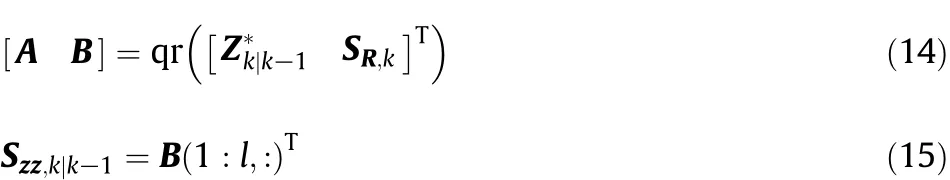

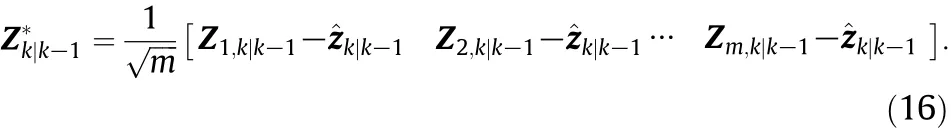

(3)Compute the square-root factor of the innovation covariance matrix

where SR,kis a square-root factor of Rkand

(4)Compute the cross-covariance matrix

(5)Calculate the SCKF gain

(6)Estimate the updated state

(7)Evaluate corresponding square-root factor of the error covariance matrix

Step 3:Repeat Steps 1 to 2 for the next time instant until arriving the terminal time.

Compared with the EKF and UKF,the accuracy and stability of the SCKF are better,especially for high-dimensional nonlinear systems.The mathematical model for fermentation process is generally complex with the features of high dimension and strong nonlinearity,so it is suitable to handle with the nonlinear state estimation using the SCKF algorithm.However,the delayed measurements in fermentation process,with the potential to improve the accuracy of nonlinear state estimation,cannot be utilized directly in the SCKF algorithm frame.The model description for nonlinear system Eq.(1)is no longer appropriate and the strategy for processing delayed measurements must be studied further if using SCKF algorithm for nonlinear state estimation to incorporate delayed measurements.

2.2.Sample-state augmentation method in the SCKF algorithm

2.2.1.System model description

The measurements of standard SCKF algorithm do not have delay for data processing at each sampling instant.When a system contains delayed measurements,the system model and filtering process method change.Some measurements of the key process variables(referred to as primary measurements)may be achieved after a certain unknown time delay when they are sampled.Other measurements for nonlinear state estimation can arrive at data processing unit instantaneously(called secondary measurements).The time instant at which only secondary measurements arrive is known as minor instance,and when both secondary and primary measurements arrive it is known as major instance.

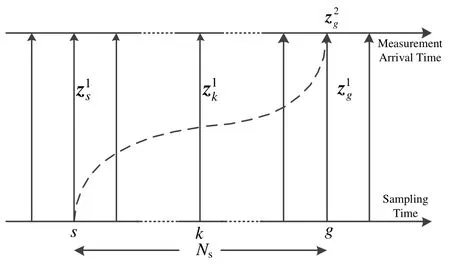

Fig.1 shows the system diagram with delayed measurements,with one major instance only and without other primary measurements sampled in the delay period.Here,the upper horizontal arrow denotes the measurement arrival time and lower one means the actual sampling time,vertical arrows represent secondary measurements and dashed arrow represents primary measurements,k is the current measurement instant,s is the actual sampling time of primary measurements,g is the major instance at which primary measurements arrive at data processing unit,Nsis the delay interval from sampling time instant s to major instance g,,andrepresent secondary measurements at corresponding time instants,andrepresents primary measurements at major instance.Secondary measurements can be achieved instantaneously when they are sampled at minor instance.However,for primary measurements sampled at time instant s,they will not be available until time instant g after waiting for a time-lag Ns.Consequently,primary and secondary measurements arrive at the data processing unit simultaneously at time instant g,but primary measurementsonly contain the system information of time instant s.The improved SCKF algorithm incorporating delayed measurements is to increase the accuracy of nonlinear state estimation at time instant g by fully exploiting associated primary and secondary measurements.It is noteworthy that primary measurements can be sampled at any minor instance and measurement delay time interval Nsis also time varying.

Fig.1.System diagram with delayed measurements.

We assume that primary measurements are sampled at time instant s and there is no more appearance of primary measurements during the period of delay.Hence,the nonlinear system model incorporating delayed measurements can be described as

It is noticed that the primary measurements in Eq.(25)arrive at time instant g,but they are related to the state and noise at sampling time instant s.Comparing with the nonlinear system described by Eq.(1),the system with delayed measurements described by Eqs.(23)-(25)has one more primary measurement equation,added to express off-line delayed measurements.The problem is how to make full use of primary measurements to promote the accuracy of state estimation for the SCKF algorithm.

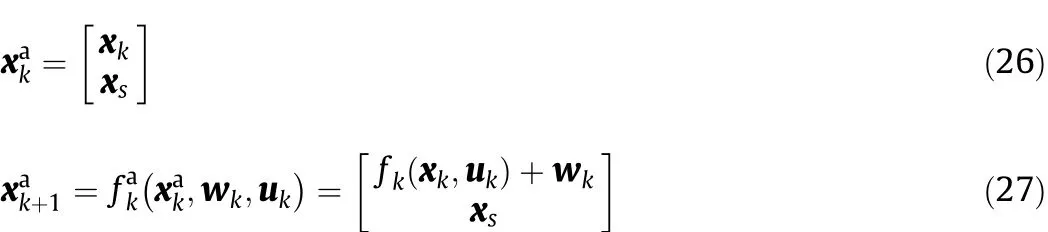

2.2.2.Sample-state augmentation method

State augmentation based methods are usually adopted to deal with delayed measurements for nonlinear state estimation,and the sample-state augmentation method is one of the promising methods with the best tradeoff between estimation accuracy and computational time[20].The state vector is augmented between the period of sampling time and arrival time of primary measurements.The goal here is to preserve the sample-state and its covariance during the delay through the state augmentation and redefinition of system model.The augmented state and state equation are defined as

where xkis the original state vector and xsis the system state vector at time instant s(s≤k)at which primary measurements are sampled,is the augmented state;fk(⋅)represents the original state function before state augmentation and(⋅)represents the augmented state function,wkis the original process noise at time instant k.By using this approach,the information of sample-state xscan be kept when the augmented system state variables are updated.

Assuming that the primary measurement is sampled at time instant s with k=s,the augmented state estimation at current time instant k can be expressed as

The error covariance matrix of stateis given as

Similar to the derivation of,the square-root factor of the covariance of process noise for augmented state is

And then we can evaluate the predicted augmented state and corresponding prediction error covariance matrix through the time update procedure in the SCKF algorithm frame

For the next measurement update procedure in the SCKF algorithm frame,one difficult problem is how to ensure that the specific states remain unchanged when secondary measurements arrive in the delay period.The Joseph form of the measurement update equations is adopted to deal with this difficulty[23],which has the property that certain states are marked as“ancillary”and their values are not updated.Thus the modified SCKF gain is given by

where M is the indicator matrix,indicating the updated and reserved sections of the states.If the partitioned matrix of matrix M is an identity matrix,corresponding states can be updated.On the contrary,the states cannot be updated if the partitioned matrix is a zero matrix.The values of M for the sample-state augmentation method is

where I is the identity matrix.

Eq.(19)in the measurement update procedure of the SCKF algorithm is replaced with Eq.(34).The equation of secondary measurements for augmented stateduring the delay period is

For the covariance matrix of Eq.(38),the bottom right sub-block maintains the error covariance of the state at time instant s,and the top left sub-block is the error covariance matrix for updated state,which has the same value with the covariance evaluated by the SCKF algorithm for the original state.The estimated cross covariancesandwhich contain the information of the state at sampled time s,is very important to fuse delayed measurements when primary measurements arrive,and it will improve the estimation accuracy of the nonlinear system.is used for the next time instant update for the augmented state until k=s+Ns-1.

When primary measurements arrive at time instant g,the equation for delayed measurements can be given by

It is noteworthy that the primary and secondary measurements arrive at time instant g synchronously.Thus Eqs.(36)and(39)should be merged together as the measurement equations with the augmented measurements and noises.

For the time update procedure at time instant g,the augmented state is still propagated using the time update procedure of the SCKF algorithm discussed above.For the measurement update procedure in the SCKF algorithm frame,the augmented state will be updated using Eq.(20)with primary and secondary measurements,which can fuse delayed measurements to the upper half of the updated augmented state.After these procedures,the estimation accuracy of the updated state is improved through incorporating the delayed measurements at time instant g.

Finally,after the measurement update procedures at time instant g,stateand its associated covariance no longer need to be kept.The updated state can be obtained by removing statefrom the augmented state and its corresponding error covariance matrix for the next time instant of g can be obtained by extracting the top left sub-block of the error covariance for the updated augmented state at time instant g,which is also waiting for the next sampling time of the primary measurements.

2.3.Implementation of the SCKF algorithm incorporating delayed measurements

The implementation of the SCK algorithm incorporating delayed measurements is given as follows.

Initialization:give initial conditions and parameters setting,including initial state valueand its covariance P0|0,noise statistics Q,R1and R2,and compute S0|0by Eq.(4).

For time sequences k∈{1,2,…,L},where L is the expected maximum time instant,s and g represent sampling time and arrival time of primary measurements,respectively,the sampling time interval of primary measurements is Msand the delay time interval between s and g is N s.

Step 1:Check whether k is equal to s.If so,augment the state using Eq.(28)and acquire the square root factor of the error covariance of augmented state using Eq.(30),and then propagate the augmented state forward using the time update procedure of the SCKF algorithm to get predicted augmented state Eq.(32)and its corresponding predicted error covariance matrix Eq.(33),and execute specific measurement update procedure for the augmented state using the modified SCKF gain Eq.(34).If not,the state will remain unchanged.

Step 2:Check whether s<k<g is satisfied.If so,continue the time update procedure and measurement update procedure for the augmented state;if not,update the original state and its error covariance using Eqs.(5)-(22)in the standard SCKF algorithm.

Step 3:Check whether k is equal to g.If so,merge the primary and secondary measurements together as the measurement equations and then update the augmented state and reduce the dimension of the updated state and its covariance.Afterwards,redefine the sampling time and arrival time of primary measurements,and we have s=s+Ms,g=s+Ms+Ns.If not,move to the next step.

Step 4:Check whether the end condition k=L is satisfied.If not,repeat Steps 1-3 for the next time instant k=k+1;If the expected time instant arrives,the algorithm will be end.

The whole flow chart of the SCKF algorithm based on the samplestate augmentation method incorporating delayed measurements is shown in Fig.2.Compared with the standard SCKF algorithm,this algorithm integrating the sample-state augmentation method to handle with the primary measurements has less increase in the complexity and it is well-organized to distinctly improve the state estimation accuracy of the nonlinear system with delayed information.

Fig.2.Flow chart of the SCKF algorithm incorporating delayed measurements.

2.4.Establishment of the state space model for fermentation process

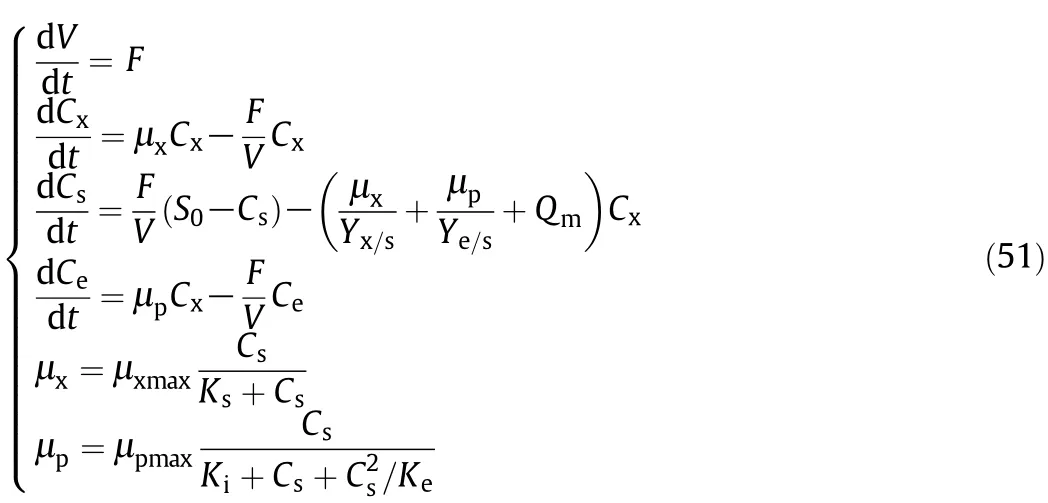

Normally,process model is the basis for the state estimation method utilizing filtering procedure.Fermentation processes can be classified into three categories:batch,fed-batch and continuous fermentation.Fed-batch fermentation combines the advantages of batch and continuous fermentation and is the most commonly used one.Its mechanism model can be expressed as[25]

where ζ is the state vector of component concentrations,r(ζ)is the reaction rate vector of components,Kmis the transfer matrix of stoichiometric calculation,Kmr(ζ)indicates the dynamic change of the biochemical reaction for fermentation process,and u is the in put control vector of the fermenter,including all the rates of incoming and outgoing materials.Therefore,the mechanism model offermentation process can be presented by a set of constant differential equations.With the measurements of fermentation process as the measurement equation,a fed-batch fermentation process can be described in a state space model[16].

Eq.(41)is for continuous time systems while Eq.(1)represents discrete time systems.The parameter values of the state space model can be obtained through the parameter identification algorithm.

The fermentation process is complex,time-varying,and highly nonlinear,so its mechanism model is usually simplified,with the mutual relation ship among the key process variables only[26].The state variables in the kinematic equations for fermentation are usually unmeasurable,and the functional relationship between on-line measurements and state variables is few and rare.Thus the support vector machines(SVM)method is adopted to supplement the measurement equations of Eq.(41)[9]

where SVM(·)denotes the nonlinear formulation established using SVM method.

Based on the nonlinear state space model established for fermentation process,we adopt the SCKF algorithm incorporating delayed measurements to achieve nonlinear state estimation of process variables.The on-line measurement equations such as Eq.(42)can be treated as secondary measurement equations in the nonlinear filter procedure.The off-line measurements are delayed measurements of biological process variables,which can be taken as primary measurement equations directly.It can effectively remove the interference of noises and improve the estimation accuracy of the state for fermentation process using the proposed nonlinear filtering scheme.

3.Simulation Results

Two case studies for fermentation process are used to validate the efficacy of the nonlinear state estimation method presented in this paper.The first case is the state estimation of a penicillin fed-batch fermentation process,which is a benchmark simulation model for monitoring and fault diagnosis of fermentation process.The second case focuses on the state estimation of an industrial yeast fermentation process,which is often used for the test of optimization control methods for fermentation process.

3.1.Case study I:state estimation for penicillin fermentation process

3.1.1.Model description

The mechanism model of the penicillin fed-batch fermentation process has been fully studied and the most representative one is the simulator PenSim v2.0 developed by the monitoring and control group at Illinois Institute Technology[27].This complex simulation model contains 9 process variables as the initial conditions and it is impracticable for nonlinear state estimation.Based on the simulation data generated by above model,a simplified dynamic mechanistic model for the penicillin fermentation process is developed as follows.

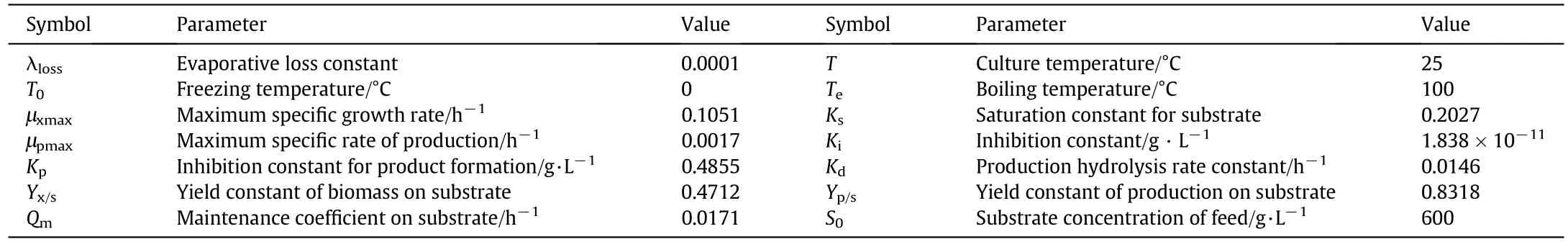

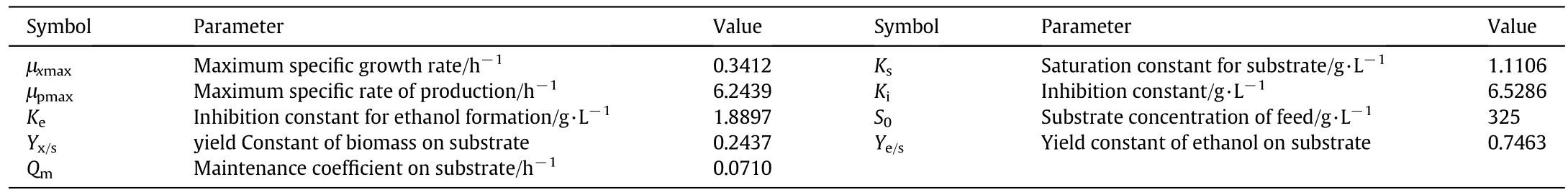

where V is the culture volume of fermenter;Cx,Csand Cpare the concentrations of biomass,substrate and penicillin,respectively,which are the key biological process variables but usually cannot be measured on-line;F is the substrate feed flow rate,which is the control input vector and the data of feeding strategy are also generated by the PenSim simulator;μxis the specific growth rate and μpis the specific rate of penicillin production.Other parameters can be obtained through the optimal parameter identification algorithm and their values are listed in Table 1.

For the state variables of above model,only V is the real-time measurable process variable,so the secondary measurement equation is

Three key biological process variables are the primary off-line measurements,so the delayed measurements equation can be given by

The simulation time for penicillin fermentation process is 400 h and the discrete time interval is set to 0.25 h,so the discrete time system model can be obtained through the forward Euler discretization of Eq.(43).The nonlinear state estimation method can be applied to the estimation of key biological variables.

3.1.2.Experiment and analysis

It is not easy to obtain true initial state conditions for penicillin fermentation process.Biomass,substrate and penicillin concentrations are the key biological process variables for on-line monitoring and optimal control of penicillin fermentation process,unfortunately,they are all off-line measurements and must be obtained by analytical instruments,resulting in long measurement cycle period and large measurement delay.Therefore,on-line state estimation for the biological process variables is achieved utilizing the proposed SCKF algorithm to incorporate delayed measurements.The first sampling time for primary measurements is at the 15th hour with the sampling interval of 5 h,and the delayed time period is 3 h.The initial values of the state are set to

which are different from the true initial values of the state[0.1 15 0 100]T.Other tuning parameters for the SCKF algorithm are as follows.

Table 1 Parameters of the simplified mechanism model for penicillin fermentation process

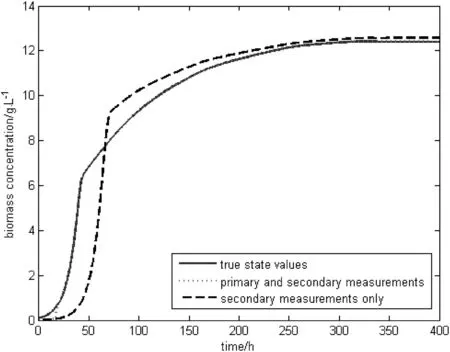

Fig.3.Estimation of biomass concentration for penicillin fermentation process.

Fig.4.Estimation of substrate concentration for penicillin fermentation process.

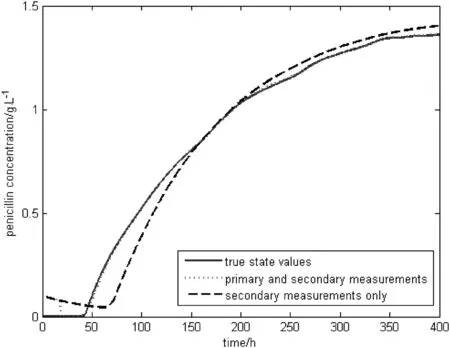

Fig.5.Estimation of penicillin concentration for penicillin fermentation process.

To validate the performance of nonlinear state estimation using delayed measurements,the SCKF algorithm employing only the secondary measurement equation is adopted for comparison.Figs.3-5 show the results for state estimation of biomass,substrate and penicillin concentrations using the SCKF algorithm to incorporate delayed measurements(“primary and secondary measurements”)and the SCKF algorithm with the measurements of culture volume(“secondary measurements only”),where“true state values”are the output of the practical state generated by the simulated penicillin model.The estimates with secondary measurements only cannot track the true state values lacking of sufficient measurement information under incorrect initial conditions,while the estimation of the SCKF algorithm incorporating delayed measurements converges to the true process state much faster after the first time arrival of primary measurements.The estimation accuracy of the key biological process variables is improved greatly with the SCKF algorithm incorporating delayed measurements,which modifies the state estimation values with the rational use of the off-line measurements.

3.2.Case study II:state estimation for industrial yeast fermentation process

3.2.1.Model description

Industrial yeast fermentation is a fed-batch process and the optimization of feed flow rate is the main method to achieve the optimal control of process.It is necessary to monitor the key biological process variables on-line,such as concentrations of yeast,glucose and ethanol,to ensure proper condition for biomass growth.Traditional filtering method of model-based approach uses on-line measurements only for state estimation,while off-line measurements of yeast and glucose concentrations,with potential to improve the accuracy of estimation,are not employed.

The simulation system of industrial yeast fermentation process is established based on mass balance equations described by volume and concentrations,such as biomass,ethanol,glucose,oxygen and carbon dioxide concentrations[28,29].The complex simulation model is based on the bottleneck hypothesis[30]and governed by 6 differential equations.The simplified model with 4 process variables is constructed based the generated data by the complex simulation system

where Cx,Csand Ceare the concentrations of yeast,substrate and ethanol,respectively,which are key biological process variables;μxis the specific growth rate and μpis the specific rate of ethanol production.Substrate feed flow rate F is the control input vector and its data are from a nonlinear exponential feeding strategy

where F0is the initial feed flow rate,500 L·h-1for the simulation.Other parameters are obtained by the parameter identification algorithm and their values are listed in Table 2.

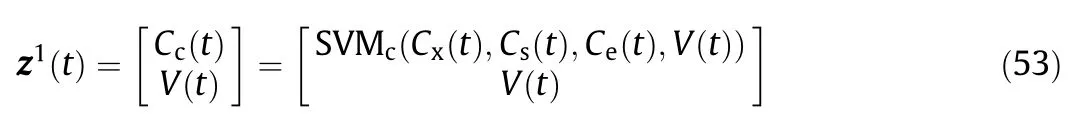

The concentration of carbon dioxide is measured on-line in the process and related to the growth of yeast and consumption of glucose.Without specific formula between on-line measurements and key state variables,we adopt SVM model as the supplement.With the addition of culture volume V,the secondary measurement equations for the simplified state space model are

where SVMcindicates the SVM model between the concentration of carbon dioxide,concentrations of yeast,glucose,and ethanol,and culture volume,which is constructed using the ε-SVR(support vector regression)in the LIBSVM software library[31].The batch data from the simulation system of industrial yeast fermentation are taken as the training sample set and the optimum parameters[C,γ,ε]for the training of SVM model are[4,2,0.001],where C is the penalty parameter for the error term,γ is the kernel parameter,and ε is the precision parameter in loss function of the ε-SVR.

The acquisition of delayed measurements is time-consuming and money-expending,with operators and expensive analytical instruments.Thus we choose the concentrations of yeast and glucose in the primary measurement equation

The simulation time for the process is 16.5 h and the discrete time interval is set to 10 min,so the discrete time system model can be obtained through the forward Euler discretization of Eq.(51).The SCKFalgorithm incorporating delayed measurements is applied to the state estimation with uncertain measurement delay.

Table 2 Parameters of the simplified mechanism model for yeast fermentation process

3.2.2.Experiment and analysis

The simulation for the process provides the true state values and both primary and secondary measurements.The white Gaussian noises are also added to the measurements to account for the actual environment.The first sampling time for primary measurements is at the 1st hour with sampling interval 2 h,and measurements are available after uncertain delay of 30-90 min.The initial values of the state are set to

which are close to the true initial values of the state[0.5 7 0 50000]T.Other tuning parameters for the SCKF algorithm are as follows.

For the process,yeast biomass is the desired product and ethanol is accumulated as by-product with glucose consumption.The results for state estimation of yeast,glucose and ethanol concentrations using the SCKF algorithm incorporating delayed measurements and that with secondary measurements only are shown in Figs.6-8,where sampling time is the instant for primary measurements and arrival time is the time with primary measurements available.The SCKF algorithm incorporating delayed measurements can rectify the wrong estimation of SCKF algorithm with the secondary measurements only immediately when the primary measurements arrive after their first sample.Although ethanol concentration is not taken as the primary or secondary measurement,its estimation is also improved with the help of other measurement information.Thus the proposed nonlinear state estimation method shows better accuracy and stability than the traditional state estimation method without the use of delayed measurements.

Fig.6.Estimation of yeast concentration for industrial yeast fermentation process.

Fig.7.Estimation of glucose concentration for industrial yeast fermentation process.

Fig.8.Estimation of ethanol concentration for industrial yeast fermentation process.

4.Conclusions

The key motivation for this paper is to introduce a novel nonlinear state estimation methodology for fermentation processes,which can make full use of the benefits of the SCKF algorithm and delayed measurements of biological process variables.The SCKF is a promising nonlinear filter,especially for high-dimensional nonlinear systems,which has potential to improve the performance of state estimation for complex fermentation process.We design a nonlinear state estimation methodology using the SCKF and sample-state augmentation method to incorporate the delayed measurements,so the delayed primary measurements can be utilized in a more effective way with considerable improvement in estimation results.The simulation studies demonstrate the effectiveness of the proposed estimation method for fermentation processes.In conclusion,the proposed nonlinear estimation method incorporating delayed measurements expands the application range of the SCKF for the nonlinear state estimation and will have large applicability to biological and chemical processes.

Nomenclature

A unitary matrix obtained through QR decomposition

B upper triangular matrix obtained through QR decomposition

C penalty parameter for error term in SVM model

Ciconcentration of component i,g·L-1

eii th column of a n-dimensional unit matrix

F feed flow rate,L·h-1

F0initial value of feed flow rate(=500 L·h-1)

f(⋅) state function of nonlinear system

fa(⋅) augmented state function of nonlinear system

g major instance at which the primary measurements arrive

h(⋅) measurement function of nonlinear system

hk1(⋅) secondary measurement function

hs2(⋅) primary measurement function

I identity matrix

Kdproduction hydrolysis rate constant,h-1

Keinhibition constant for ethanol formation,g⋅L-1

Kiinhibition constant,g·L-1

Kmtransfer matrix of stoichiometric calculation

Kpinhibition constant for product formation,g·L-1

Kssaturation constant for substrate(glucose)

k time instant of secondary measurements

L expected maximum time instant

M indicator matrix

Mssampling time interval of primary measurements

m number of cubature points

Nsdelay interval from sampling time instant to major instance

n dimension of state vector

P covariance of state vector

Q covariance of process noise

Qmglucose consumption rate for maintenance energy,h-1

R covariance of measurement noise

r reaction rate vector of components

S square-root factor of covariance matrix

S0substrate concentration of feed,g·L-1

s actual sampling time of primary measurements

T culture temperature(=25°C)

Teboiling temperature(=100°C)

T0freezing temperature(=0°C)

t time,h

u control input vector

V volume,L

v measurement Gaussian noise

W Kalman gain matrix

w process Gaussian noise

Xii th element of cubature points of state vector

x state vector

^x estimation of state vector

xaaugmented state vector

Yi/jyield of component i on j

Zii th element of cubature points of measurement vector

Z* weighted centered matrix in SCKF algorithm

z measurement vector

γ kernel parameter of RBF for SVM model

ε precision parameter in loss function for SVM model

ζ state vector of component concentrations

λlossconstant in Floss

μpspecific rate of production,h-1

μpmaxmaximum specific rate of production,h-1

μxspecific growth rate,h-1

μxmaxmaximum specific growth rate,h-1

ξii th element of cubature points

χ weighted centered matrix in SCKF algorithm

Subscripts

c carbon dioxide

e ethanol

k time instant

p product

s substrate(glucose)

x biomass

Chinese Journal of Chemical Engineering2015年11期

Chinese Journal of Chemical Engineering2015年11期

- Chinese Journal of Chemical Engineering的其它文章

- N-methyl-2-(2-nitrobenzylidene)hydrazine carbothioamide—A new corrosion inhibitor for mild steel in 1 mol·L-1 hydrochloric acid

- A dual-scale turbulence model for gas-liquid bubbly flows☆

- Gas-liquid hydrodynamics in a vessel stirred by dual dislocated-blade Rushton impellers☆

- Convective mass transfer enhancement in a membrane channel by delta winglets and their comparison with rectangular winglets☆

- Cobalt-free gadolinium-doped perovskite Gd x Ba1-x FeO3-δas high-performance materials for oxygen separation☆

- Synthesis and adsorption property of zeolite FAU/LTA from lithium slag with utilization of mother liquid☆