产香酵母筛选及其对葡萄酒香气成分的影响

摘要:【目的】从中条山野生毛葡萄中分离筛选出发酵性能优良、香气浓郁的产香酵母,并分析其对小芒森葡萄酒香气成分和品质的影响,为野生酵母资源开发利用及地域特色葡萄酒酿造提供理论基础。【方法】采集中条山野生毛葡萄果实并进行菌株分离,利用嗅闻法、杜氏管发酵法和电位滴定法筛选香气浓郁、起酵速度快且产酯量高的产香酵母,并对其进行分子生物学鉴定。分别采用单菌接种(酿酒酵母F15)和混菌接种(酿酒酵母F15和产香酵母菌株)发酵小芒森葡萄酒,测定2种酒样的基础理化指标,采用气相色谱—质谱法(GC-MS)分析香气成分并进行感官评价。【结果】共分离获得10株酵母菌,其中CL1菌株起酵速度快,产酯量达1.76 g/L,具有明显果香味和酒香味。基于26SrDNA序列相似性构建系统发育进化树,将CL1菌株鉴定为葡萄汁有孢汉逊酵母(Hanseniasporauvarum)。将产香酵母CL1与酿酒酵母F15混菌接种发酵小芒森葡萄酒,结果发现其总酚含量较单菌接种(酿酒酵母F15)增加7.60 mg/L。混菌接种酒样共检测出36种香气物质,比单菌接种增加12种,香气物质总含量增加39.83%,混菌接种酒样的2,3-丁二醇、苯乙醇、苯乙酸乙酯、乳酸乙酯、乙酸己酯和丁酸乙酯气味活性值(OAV)较高,对小芒森葡萄酒的香气贡献较大,赋予其奶油味、果香味和玫瑰香气等。感官评价结果表明,混菌接种小芒森葡萄酒的香气优雅度、芳香持续性和口感浓郁度均明显高于单菌接种。【结论】产香酵母菌株CL1具有良好的增香能力,与酿酒酵母混菌接种发酵对小芒森葡萄酒品质提升有明显作用,具有应用于酿造地域特色葡萄酒的潜力。

关键词:中条山野生毛葡萄;产香酵母;葡萄汁有孢汉逊酵母;混菌接种;香气成分

中图分类号:S663.109.9;TS261.1文献标志码:A文章编号:2095-1191(2024)08-2342-09

Aroma-producing yeast selection and its impact on aroma components in wine

CHENG Wen SHI Shou-guo2*,LI Xin 2*

(1College of Food Science and Engineering,Shanxi Agricultural University,Jinzhong,Shanxi 03080 China;2LifeSciences Department,Yuncheng University/Shanxi Key Laboratory of Yuncheng Salt Lake Ecological Protectionand Resource Utilization,Yuncheng,Shanxi 044000,China)

Abstract:【Objective】The aroma-producing yeast with excellent fermentation performance and strong aroma was iso-lated and screened from Zhongtiao Mountain wild Vitis quinquangularis,and its effects on the aroma components and quality of Petit Manseng wine were analyzed,which provided theoretical basis for the development and utilization of wild yeast resources and regional characteristic wine brewing.【Method】The Zhongtiao Mountain wild V.quinquangularis berries were collected and the strains were isolated.Based on olfactory method,Duchenne tube fermentation method and potentiometric titration,a yeast strain with strong aroma,fast fermentation speed,and high ester production was se-lected,and identified by molecular biology.Petit Manseng wine was fermented by single-strain inoculation(Saccharomy-ces cerevisiae F15)and mixed-strain inoculation(S.cerevisiae F15 and aroma-producing yeast strain)respectively.The basic physical and chemical indexes of the two wine samples were determined,and the aroma components were analyzedby gas chromatography-mass spectrometry(GC-MS)and sensory evaluation was carried out.【Result】A total of 10 yeast strains were isolated.Among them,the CL1 strain had a fast fermentation speed and an ester yield of 1.76 g/L,with ob-vious fruity and wine aroma.The CL1 strain was identified as Hanseniasporauvarum based on the phylogenetic tree con-structed by 26S rDNA sequence similarity.The aroma-producing yeast CL1 and S.cerevisiae F15 were inoculated to fer-ment Petit Manseng wine,and the results showed that the total phenol content was 7.60 mg/L higher than that of single strain inoculation(S.cerevisiae F15).A total of 36 aroma substances were detected in the wine samples inoculated with mixed strains,which was 12 more than that inoculated with single strain,and the total content of aroma substances in-creased by 39.83%.Among them,the odor activity values(OAV)of 2,3-butanediol,phenylethyl alcohol,ethylphace-tate,ethyl lactate,hexyl acetate and ethyl butyrate in wine sample inoculated with mixed strains were higher,which con-tributed more to the aroma of Petit Manseng wine,giving it creamy,fruity and rose aroma.The results of sensory evalua-tion showed that the aroma elegance,aroma persistence and taste intensity of the wine inoculated with mixed strains were greatly higher than those inoculated with single strain.【Conclusion】The aroma-producing yeast strain CL1 has good aroma-enhancing ability,and the mixed inoculation fermentation with S.cerevisiae has obvious effect on the quality im-provement of Petit Manseng wine,which has the potential to be applied to brewing regional characteristic wine.

Key words:Zhongtiao Mountain wild Vitis quinquangularis;aroma-producing yeast;Hanseniasporauvarum;mixed-strain inoculation;aroma components

Foundation items:National Natural Science Foundation of China(32300111);Shanxi Science and Technology Inno-vation Talent Team Project(202204051001035);Shanxi Basic Research Project(202203021211114);Yuncheng Basic Re-search Project(YCKJ-2021034)

0引言

【研究意义】商业酿酒酵母(Saccharomyces cere-visiae)在葡萄酒酿造过程中应用极为广泛,导致葡萄酒口感、香气特征同质化现象严重,无突出特色。为打破过度依赖商业酿酒酵母的现状,利用非酿酒酵母进行葡萄酒发酵,分析其对葡萄酒品质和风味多样性提升作用的研究日益增加(Fenget al.,2021)。优质葡萄酒的酿造不仅取决于葡萄种类,也与酿酒葡萄中天然存在的各种微生物密切相关,其中的产香酵母更是葡萄酒发酵的核心微生物,对葡萄酒的口感、香气均有重要影响(吕枫等,2020;彭璐等,2020)。因此,筛选具有地域特色的优良产香酵母,对促进野生酵母资源的开发利用具有重要意义。【前人研究进展】产香酵母是在自身代谢过程中可产生芳香气味物质的重要微生物,又被称为产酯酵母(Hu etal.,2018)。目前,从葡萄汁中分离出来的产香酵母有40余种,常见的产香酵母属有假丝酵母属(Candida)、有孢圆酵母属(Torulaspora)、有孢汉逊酵母属(Hanseniaspora)、接合酵母属(Zygosaccharo-myces)、毕赤酵母属(Pichia)、裂殖酵母属(Schizo-saccharomyces)、梅奇酵母属(Metschnikowia)、类酵母属(Saccharomycodes)、德巴利酵母属(Debaryomyces)、克鲁维酵母属(Kluyveromyces)等(徐超等,2024)。产香酵母通过代谢产生糖苷a0b31a148e873f49a9699c423fc0e0d2酶和碳硫键裂解酶,增加萜烯类化合物,增加葡萄酒香气成分种类和含量,降低挥发性硫醇类化合物含量,增强葡萄酒的品种香气和发酵香气特征(汤晓宏等,2023)。在酒精发酵后期,产香酵母可通过自溶增加氨基酸、脂肪酸、甘露糖蛋白等物质含量,从而影响葡萄酒的口感(Gamero etal.,2016)。研究发现,产香酵母的酒精耐受性较差,酒精转化能力较低,而与酿酒酵母混合(同时接种或顺序接种)发酵葡萄酒,可明显改善葡萄酒的典型性和显著性香气,提高葡萄酒的香气特色和整体风味,混菌发酵逐渐成为葡萄酒酿造的发展趋势(Padilla et al.,2016)。Whitener等(2017)顺序接种产香酵母与酿酒酵母进行西拉葡萄酒混合发酵,发现泽普林假丝酵母(Candida zemplinina)、哈萨克斯坦酵母属Kazachstania aerobia、耐热克鲁维酵母(Lachanceathermotolerans)、美极梅奇酵母(M.pulcherrima)、戴尔有孢圆酵母(T.delbrueckii)、克鲁维毕赤酵母(P.kluyveri)等对葡萄酒香气成分种类和含量均有不同程度的贡献。Prior等(2019)将克鲁维毕赤酵母和酿酒酵母混合接种发酵,结果发现葡萄酒中高级醇和乙基酯含量显著提高,葡萄酒品质明显改善。我国葡萄酒产区众多且各具特色,酵母资源丰富,本土微生物菌群更适应当地的气候、土壤和微生态环境,应用本土酵母菌进行发酵有利于增强葡萄酒风味多样性和产区典型性(Zhang et al.,2022)。大量研究表明,本土产香酵母与酿酒酵母混菌发酵,有利于酯类、醇类及萜烯类化合物的生成,尤其是乙酸苯乙酯和苯乙醇,不仅可增强花香味和果香味,而且能使葡萄酒香气更浓郁(Hu et al.,2018;李毅丽等,2022;夏鸿川,2022;周桂珍,2022)。【本研究切入点】产香酵母在突出葡萄酒风味、提升葡萄酒品质等方面具有重要作用,发掘优良本土产香酵母有助于酿造地域特色葡萄酒。地处山西省南部的中条山,地理环境与气候条件独特,野生毛葡萄资源丰富,蕴藏着丰富多样的产香酵母资源,是获取产香酵母的重要新来源,亟需进一步发掘和研究。【拟解决的关键问题】从中条山野生毛葡萄果实中分离筛选发酵性能优良、香气浓郁的产香酵母,对其进行分子生物学鉴定,将筛选出的产香酵母与酿酒酵母混合发酵小芒森葡萄酒,分析其对葡萄酒香气成分和品质的影响,为野生酵母资源开发利用及地域特色葡萄酒酿造提供理论基础。

1材料与方法

1.1试验材料

1.1.1样品来源中条山野生毛葡萄采集自山西省运城市绛县,小芒森葡萄采集自山西省运城市夏县格瑞特酒庄;酿酒酵母F15购自法国LAFFORT公司。

1.1.2主要试剂酵母浸膏、蛋白胨、琼脂和麦芽浸粉均购自北京奥博星生物技术有限责任公司;葡萄糖购自天津市瑞金特化学品有限公司;无水硫酸钠、焦亚硫酸钾、二氯甲烷和2-辛醇均购自北京索莱宝科技有限公司;酵母菌DNA提取试剂盒购自广州飞扬生物工程有限公司。

1.1.3培养基YPD液体培养基:蛋白胨2 g、葡萄糖2 g、酵母浸膏1 g,蒸馏水100 mL,自然pH,121℃灭菌20min备用。

YPD固体培养基:琼脂2 g、蛋白胨2 g、葡萄糖2 g、酵母浸膏1 g,蒸馏水100 mL,自然pH,121℃灭菌20 min备用。

孟加拉红固体培养基:琼脂2 g、葡萄糖1 g、蛋白胨0.5 g、磷酸二氢钾0.1 g、硫酸镁0.05 g、氯霉素0.01 g、孟加拉红0.0033 g,蒸馏水100 mL,pH 7. 121℃灭菌20min备用。

产酯培养基:麦芽浸粉13 g、氯霉素0.01 g,蒸馏水100 mL,121℃灭菌20 min备用。

1.2试验方法

1.2.1菌株分离筛选将野生毛葡萄挤压破碎后,取1 mL葡萄汁,加入9 mL无菌水,混匀后接种于YPD液体培养基,28℃、150 r/min富集培养36 h(芦文娟等,2016)。将富集菌悬液梯度稀释10-5、10-6、10-7倍,分别吸取100μL接种于孟加拉红固体培养基,涂布均匀,28℃静置培养48h,通过嗅闻法筛选香气浓郁的菌株(李欢欢等,2022)。采用杜氏管发酵法测定菌株起酵速度,将待测筛选菌株接种至放有倒置杜氏小管的YPD液体培养基试管中,28℃静置培养,观察12、24、36和48 h的产气情况。参考GB/T 10345—2022《白酒分析方法》,将待测菌株接种于100 mL产酯培养基,28℃静置培养48h后蒸馏,取30 mL蒸馏液皂化回流1 h,采用电位滴定法测定菌株产酯量。综合菌株的香气、起酵速度和产酯量筛选产香酵母。

1.2.2菌株26S rDNA序列分析提取产香酵母菌株基因组DNA,采用正向引物NL1(5'-GCATATCA ATAAGCGGAGGAAAAG-3')和反向引物NL4(5'-G GTCCGTGTTTCAAGACGG-3'),对菌株26S rDNA的D1/D2区片段进行PCR扩增。PCR扩增产物经琼脂糖凝胶电泳检测后,委托北京三博远志生物技术有限责任公司进行测序。将测序结果在NCBI中进行同源序列比对,利用MEGA 7.0的邻接法(Neighbor-Joining,NJ)基于26S rDNA序列相似性构建系统发育进化树,Bootstrap设为1000次。

1.2.3葡萄酒发酵将产香酵母菌株接种于YPD液体培养基,28℃、150 r/min培养24 h,8000 r/min离心5min,弃上清液,用无菌水洗涤2次后接入3 L发酵罐。选取颗粒完整、成熟度高的小芒森葡萄果实3kg,4℃冷浸渍24h,分别进行单菌接种(酿酒酵母F15)和混菌接种(酿酒酵母F15和产香酵母菌株)。发酵过程中实时监测发酵液比重和温度变化,比重在0.991~0.995时,视为发酵结束。分离皮渣后加入50 mg/L焦亚硫酸钾,静置澄清后装瓶。

1.2.4葡萄酒基础理化指标测定葡萄酒样品经0.45μm滤膜过滤,参考GB/T 15038—2006《葡萄酒、果酒通用分析方法》,测定酒样的酒精度、还原糖含量、游离二氧化硫含量和总二氧化硫含量;pH采用pH计测定;采用糖度计测定可溶性固形物含量;利用福林酚法测定酒样总酚含量(牛雪,2015;Aleixandre-Tudo et al.,2017),采用高效液相色谱法(HPLC)测定酒样有机酸含量(Hernández et al.,2009);以相同方法测定未接菌葡萄汁的基础理化指标;设3次重复。

1.2.5葡萄酒香气成分分析采用气相色谱—质谱法(GC-MS)测定酒样香气成分种类和含量,样品预处理、GC-MS条件及定性定量分析参考柴红等(2023)的方法并略作修改。色谱条件:色谱柱为DB-17ms(30 m×250μm×250μm);程序升温:40℃保持2 min,以3°C/min升至130°C,再以5°C/min升至230°C,保持2 min;进样口温度250℃;流速1 mL/min。质谱条件:离子源温度250℃;溶剂延迟2 min;质量扫描范围30~350 m/z。测定香气物质含量后计算气味活性值(Odor activity value,OAV),OAV=物质含量/气味阈值。

1.2.6葡萄酒感官评价由6名具有丰富品酒经验的评审人员对单菌接种和混菌接种发酵的酒样进行感官评价,在符合品酒要求的环境条件下(温度20~22℃,湿度60%~70%)(张志然等,2022),参考GB/T 15038—2006《葡萄酒、果酒通用分析方法》进行盲样品评。评价指标分别为澄清度、色泽、香气优雅度、口感浓郁度、芳香持续性、典型性、口感协调度、总体感觉、香气浓郁度和酒体结构,各评价指标分值均为10分。

1.3统计分析

试验数据采用SPSS 27.0进行差异显著性分析,利用Origin 2021绘图。

2结果与分析

2.1产香酵母的分离筛选结果

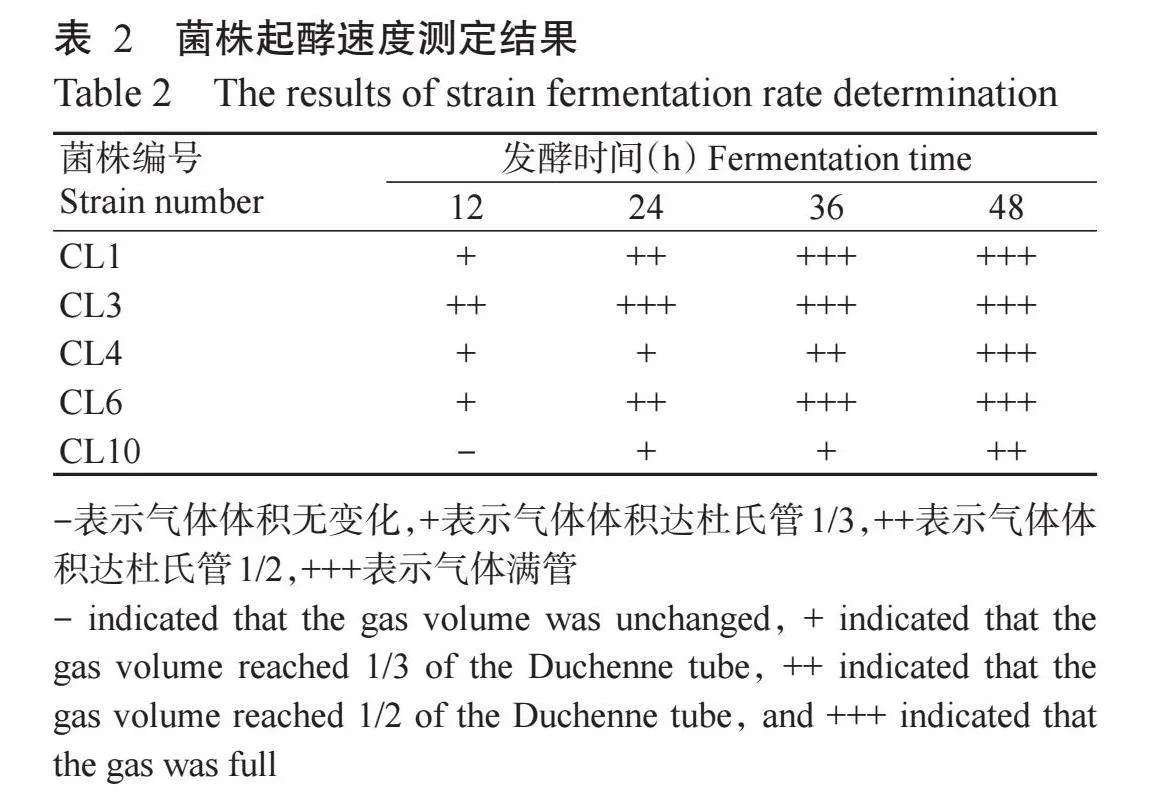

从中条山绛县产区的野生毛葡萄果实中分离获得10株酵母菌(表1)。通过嗅闻法初筛获得5株香气浓郁的菌株,分别为CL1、CL3、CL4、CL6、CL10。将5株菌株接种至放有倒置杜氏小管的YPD液体培养基试管中,28℃静置培养,观察产气情况,结果表明起酵速度快且产气多的菌株为CL1、CL3和CL6(表2)。将复筛获得的3株酵母菌CL1、CL3和CL6分别接种于产酯培养基静置培养48 h,测定其产酯量,结果分别为1.76、0.71和0.74 g/L。根据菌株的感官评价、起酵速度和产酯量测定结果,筛选出具有明显果香味和酒香味的产香酵母菌株CL1。

2.2产香酵母菌株的鉴定结果

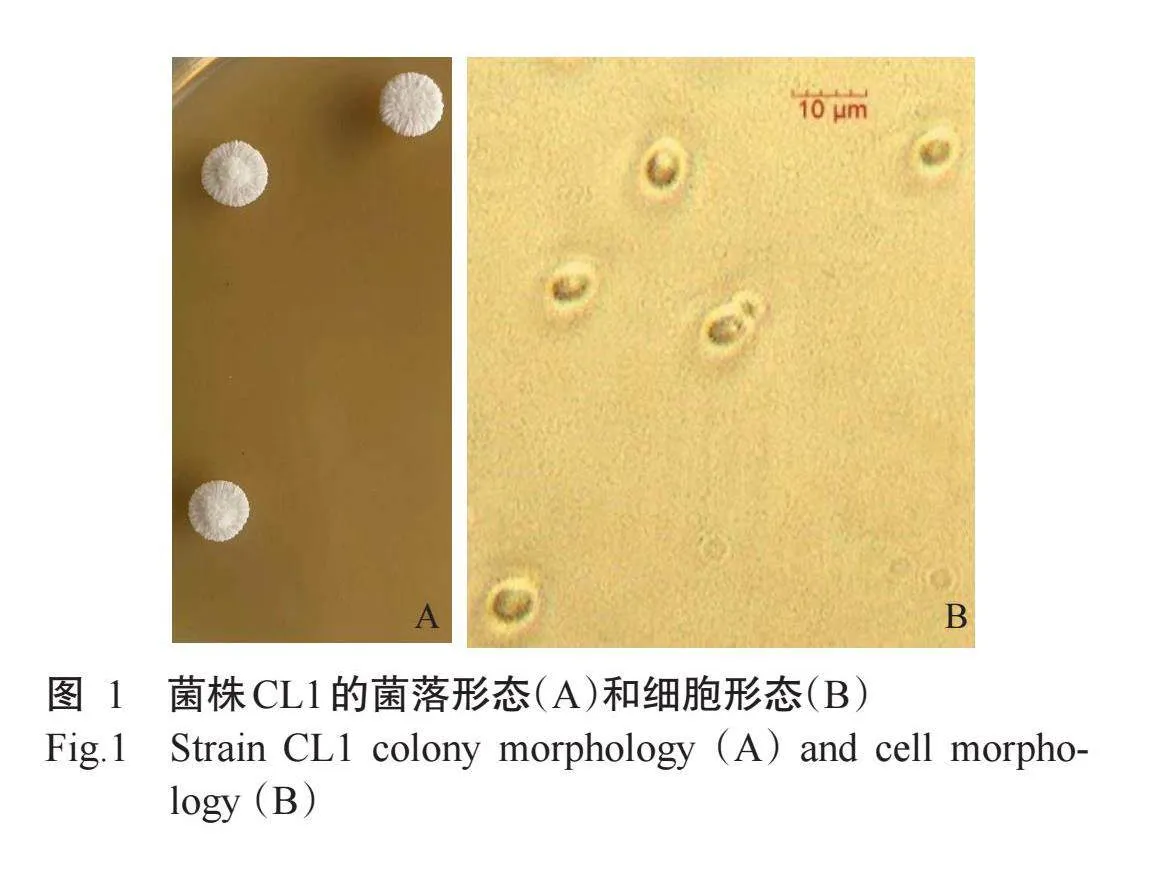

2.2.1形态学鉴定如图1-A所示,菌株CL1菌落形态大而厚,不黏稠,白色不透明,中间隆起,表面较粗糙,边缘呈不规则状。在显微镜下观察,发现菌株CL1的细胞形态呈椭圆形,无假菌丝,直径约5μm,为典型的酵母菌细胞形态(图1-B)。

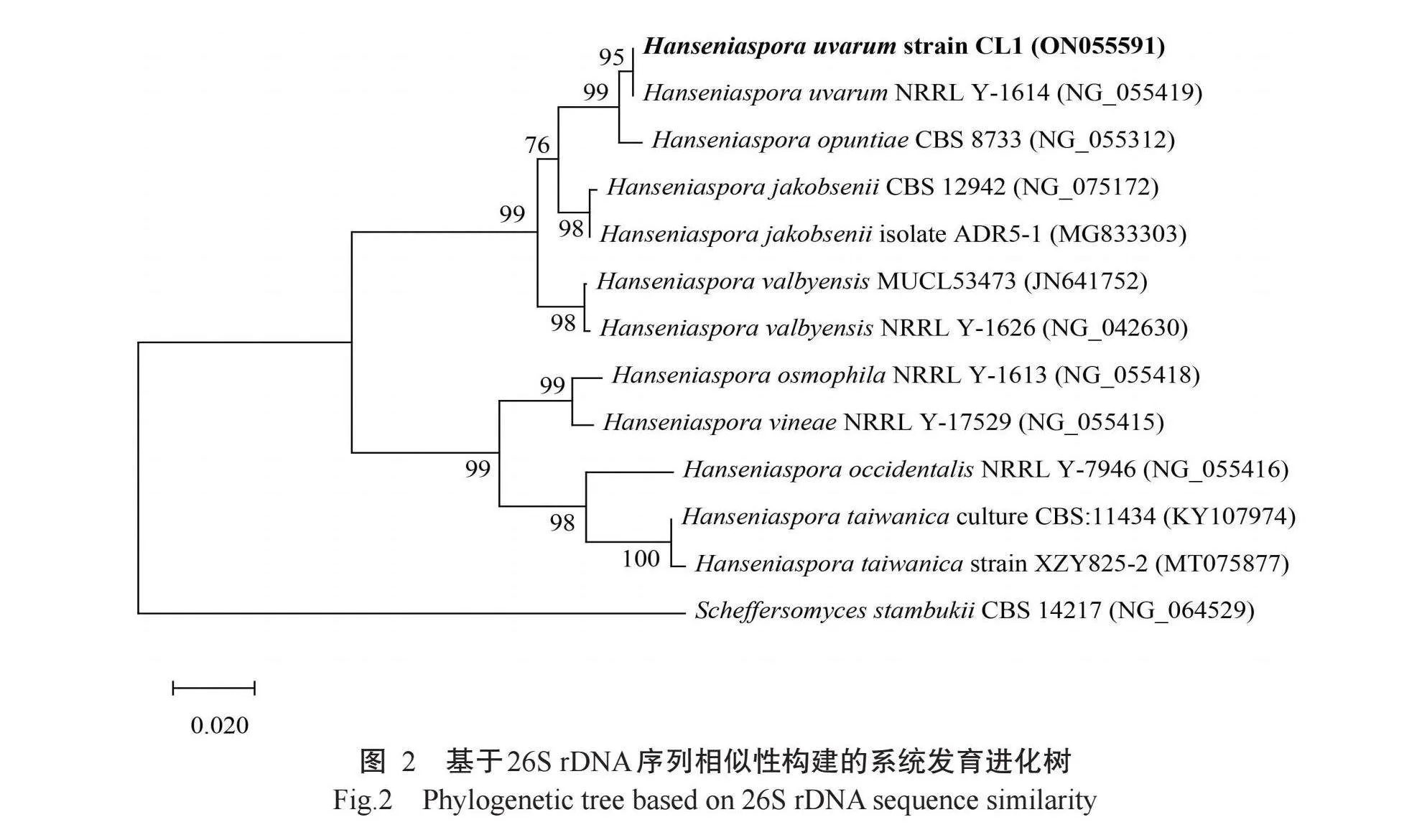

2.2.2分子生物学鉴定将菌株CL1的26S rDNA测序结果提交NCBI(登录号ON055591),基于测序结果进行同源性比对,结果发现菌株CL1与葡萄汁有孢汉逊酵母(H.uvarum)NRRL Y-1614相似度最高,达99%以上。系统发育分析结果表明,菌株CL1与葡萄汁有孢汉逊酵母NRRL Y-1614聚为同一分支,确定CL1菌株为葡萄汁有孢汉逊酵母,命名为H.uvarumstrain CL1(图2)。

2.3小芒森葡萄酒理化指标测定结果

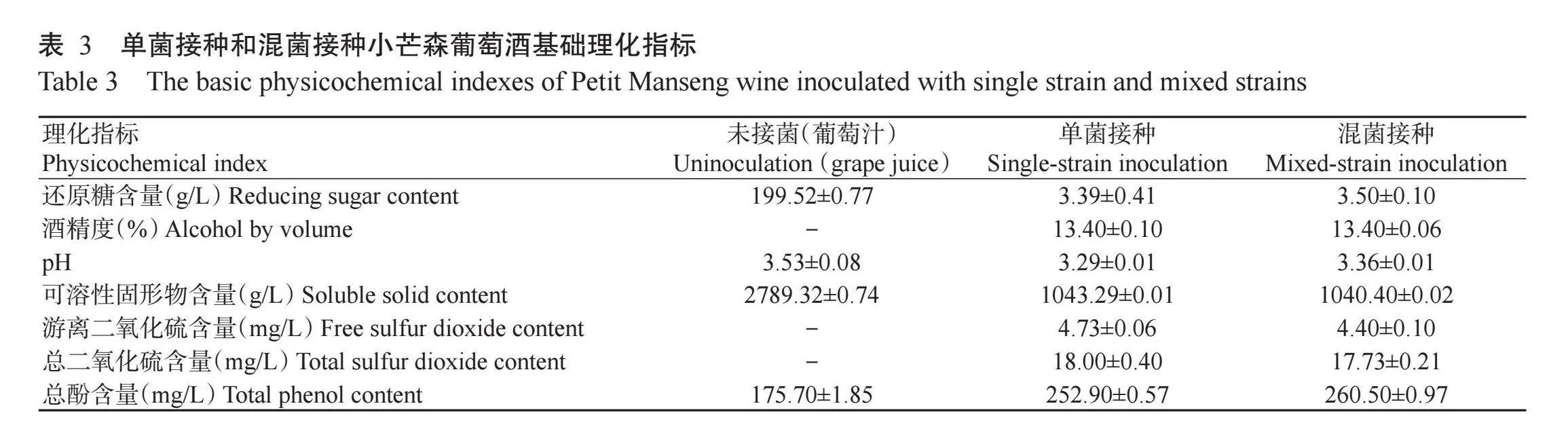

2.3.1基础理化指标如表3所示,2种发酵酒样的残留还原糖含量均小于4.00 g/L,符合GB/T 15037—2006《葡萄酒》中的干型葡萄酒标准。酒精度均为13.40%,符合GB/T 15037—2006《葡萄酒》中的酒精度要求(≥7.0%)。pH对葡萄酒的稳定性和口感均有重要作用,单菌、混菌接种酒样pH分别为3.29和3.36。混菌接种酒样的可溶性固形物含量为1040.40 g/L,较葡萄汁和单菌接种酒样分别降低62.70%和0.28%。经测定发现,单菌、混菌接种酒样的总酚含量分别为252.90和260.50 mg/L,较葡萄汁的总酚含量分别增加43.94%和48.26%,其中混菌接种酒样较单菌接种酒样增加7.60 mg/L。

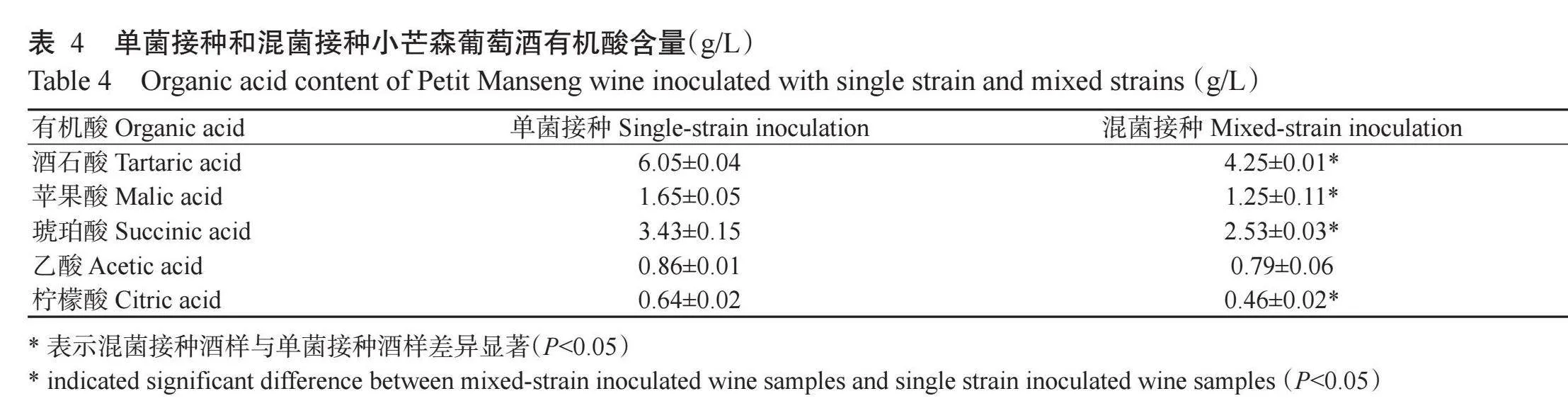

2.3.2有机酸含量如表4所示,单菌和混菌接种酒样的各有机酸含量由高到低均依次为酒石酸>琥珀酸>苹果酸>乙酸>柠檬酸,其中酒石酸含量最高,是酒样主体酸。混菌接种酒样中,酒石酸、琥珀酸和柠檬酸含量分别为4.25、2.53和0.46 g/L,分别较单菌接种显著降低29.75%、26.24%和28.13%(r<0.05,下同),同时苹果酸含量也显著降低,乙酸含量降低但无显著差异(r>0.05)。

2.4不同接种方式对小芒森葡萄酒香气成分的影响

采用GC-MS测定单菌接种和混菌接种的葡萄酒香气成分种类和含量,在2种酒样中共鉴定出46种香气物质,包括醇类物质6种、酯类物质14种、酸类物质4种、醛酮类物质4种、芳香类物质5种、烯萜类物质5种和其他BJ2i9Vp98TPZ6CS0JYNER8UWbKY5XaltcHgDFznMbDo=物质8种(表5)。

混菌接种使葡萄酒香气物质种类和含量明显增加,混菌接种酒样共检测出36种香气物质,比单菌接种多12种,混菌接种酒样的香气物质总含量为93.87 mg/L,较单菌接种增加39.83%。酯类物质是酒精发酵产生的典型副产物之一,混菌接种酒样具有7种单菌接种酒样所没有的酯类物质,其中丁酸乙酯、苯乙酸乙酯、乳酸乙酯、乙酸己酯OAV均高于0.10(表6),增强了葡萄酒的果香味,提升了香气复杂性。单菌接种和混菌接种酒样的醇类物质总含量分别为49.16和74.24 mg/L,其中苯乙醇含量在2种酒样中均为最高,且混菌接种酒样的苯乙醇含量较单菌接种提高77.55%,其OAV高于1.00,是对葡萄酒香气贡献最大的醇类物质,赋予葡萄酒玫瑰香气;2,3-丁二醇具有奶油味和水果香味,在混菌接种酒样中含量较高,其OAV高于0.10,在葡萄酒中起协同增香作用;此外,醇类物质中含量较高的1-壬醇和1-庚醇均对葡萄酒有辅助增香作用。酸类和醛酮类物质则在浓度较低时可调节酒体香气平衡,使葡萄酒呈淡淡的脂肪气味。将产香酵母CL1与酿酒酵母F15混合发酵,可明显降低酒样的辛酸和癸酸含量,同时增加己酸等单菌接种酒样没有的酸类物质,且其OAV高于0.10,是葡萄酒中潜在的增香物质。混菌接种酒样含有麝香酮和2H-吡喃-2,6(3H)-二酮,二者在单菌接种酒样中均未检测到;2种酒样的苯甲醛含量差异不明显。

2.5小芒森葡萄酒感官评价结果

对单菌接种和混菌接种的小芒森葡萄酒进行感官评价,各评价指标得分结果如图3所示。混菌接种小芒森葡萄酒的各评价指标得分均高于单菌接种。在外观方面,2种小芒森葡萄酒均有较好的澄清度和色泽,且无明显差异。在香气方面,混菌接种小芒森葡萄酒的香气优雅度和芳香持续性明显高于单菌接种。在口感方面,混菌接种小芒森葡萄酒的口感浓郁度较单菌接种明显提高。

3讨论

葡萄酒酿造过程中多种微生物相互作用,其中产香酵母是葡萄酒酿造的关键微生物,其代谢产物为葡萄酒提供多种风味物质,赋予葡萄酒复杂的口感及香气。本研究从中条山野生毛葡萄中分离筛选出1株起酵速度快、产酯量高且香气浓郁的优良产香酵母菌株CL 系统发育分析结果表明其为葡萄汁有孢汉逊酵母。作为典型的半发酵型非酿酒酵母,葡萄汁有孢汉逊酵母的生长代谢在改善葡萄酒风味方面具有重要作用(张晴雯等,2024)。

葡萄酒发酵是一个复杂的过程,为保证葡萄酒品质,本研究对单菌接种(酿酒酵母F15)和混菌接种(酿酒酵母F15和产香酵母菌株CL1)酒样进行基础理化指标检测,结果表明均符合我国葡萄酒国家标准要求。总酚对葡萄酒口感、复杂性和抗氧化性能等具有重要影响,是评价葡萄酒品质的主要指标之一(Gutiérrez-Escobar et al.,2021)。本研究中混菌接种较单菌接种酒样的总酚含量明显增加,可能是混菌接种过程中某些代谢产物或失活菌体有助于提升葡萄酒总酚含量,与李俊娥等(2017)、刘晓燕(2022)关于混菌接种对干红葡萄酒酚类物质含量影响的研究结果一致。有机酸是葡萄酒的重要成分,其含量及种类组成比例对葡萄酒的口感品质及稳定性会产生较大影响(Chidi et al.,2018)。本研究中,2种酒样中酒石酸含量均为最高,其次是琥珀酸,柠檬酸含量最低,与庞敏等(2019)研究结果一致。添加产香酵母菌株CL1进行混菌接种能不同程度降低葡萄酒的酒石酸、苹果酸、琥珀酸、乙酸和柠檬酸含量,使葡萄酒口感更加醇厚丰富,与卫春会等(2021)研究结果相似。葡萄酒香气成分种类和含量的增加对葡萄酒品质有积极影响,本研究发现,混菌接种酒样中香气物质种类及含量均有增加,与赵书田等(2023)研究结果一致。高级醇是酵母糖代谢的副产物,当其总含量低于300 mg/L时,能使葡萄酒的香气更为复杂、浓郁,但当其总含量超过400 mg/L时,会产生强烈的刺鼻味并给人带来不悦感(李毅丽等,2022)。本研究中,2种酒样的高级醇物质总含量均低于300 mg/L,其中苯乙醇对葡萄酒香气提升具有重要作用,混菌接种较单菌接种酒样的苯乙醇含量提高77.55%,苯乙醇能使葡萄酒增加清甜的玫瑰香气,提升酒体香气的复杂性(Cordenteetal.,2021;张春芝等,2024)。酯类物质是葡萄酒的典型性香气成分,主要形成于酒精发酵过程和葡萄酒陈酿过程(李红玉等,2023)。本研究发现,相较于酿酒酵母F15单菌接种,产香酵母CL1与酿酒酵母F15混菌接种酒样独有的酯类物质为7种,其中丁酸乙酯、苯乙酸乙酯、乳酸乙酯和乙酸己酯对葡萄酒香气贡献较大,可能是产香酵母在发酵过程中,产生β-葡萄糖苷酶使果实中糖苷结合态香气成分释放,增加了葡萄酒的果香味,提升了香气复杂度。

4结论

产香酵母菌株CL1具有良好的增香能力,与酿酒酵母混菌接种发酵对小芒森葡萄酒品质提升有明显作用,具有应用于酿造地域特色葡萄酒的潜力。

参考文献(References):

柴红,师守国,李善菊,李新.2023.中条山野生葡萄产香酵母的筛选及其混菌发酵对葡萄酒香气成分的影响[J].微生物学通报,50(1):262-272.[Chai H,Shi S G,Li S J,Li X.2023.Mixed fermentation with an aroma-producing yeast strain screened from the wild grape on Zhongtiao Mountain affects aromatic components of the wine[J].Microbiology China,50(1):262-272.]doi:10.13344/j.mi-crobiol.china.220369.

李红玉,贺艳楠,李毅丽.2023.混菌发酵对两个品种葡萄酒香气的影响[J].中外葡萄与葡萄酒,(6):99-106.[Li H Y,He Y N,Li Y L.2023.Effect of mixed yeasts fermenta-tion on aroma of wine from two grape varieties[J].Sino-Overseas Grapevine&Wine,(6):99-106.]doi:10.13414/j.cnki.zwpp.2023.06.014.

李欢欢,曾雪莹,谢娟,刘玲,徐学锋.2022.产香酵母的筛选鉴定及产酯条件优化[J].中国酿造,41(6):87-92.[Li H H,Zeng X Y,Xie J,Liu L,Xu X F.2022.Screening and identification of aroma-producing yeasts and optimization of ester production conditions[J].China Brewing,41(6):87-92.]doi:10.11882/j.issn.0254-5jKjyO3f4JeNfh1Jh+bJE31bByk6GrEsRq4T2UiCtye4=071.2022.06.015.

李俊娥,张金宏,吴正,樊明涛,魏新元.2017.灭活酵母对干红葡萄酒酚类物质及其抗氧化活性的影响[J].食品研究与开发,38(5):143-147.[Li J E,Zhang J H,Wu Z,Fan M T,Wei X Y.2017.Influence of inactivated yeast on phe-nolic compounds and antioxidation of red wine[J].Food Research and Development,38(5):143-147.]doi:10.3969/j.issn.1005-6521.2017.05.030.

李毅丽,李红玉,贺艳楠,高山.2022.混菌发酵对昌黎赤霞珠葡萄酒品质的影响[J].食品与发酵工业,48(21):54-60.[Li Y L,Li HY,He YN,Gao S.2022.Effect of mixed fer-mentation on quality of Cabernet Sauvignon wine in Chang-li region[J].Food and Fermentation Industries,48(21):54-60.]doi:10.13995/j.cnki.11-1802/ts.032629.

吕枫,赵兴秀,李仕鲁,刘苑皓,何义国,方春玉,邹伟,赵长青,艾小满.2020.酱香型白酒窖醅中耐高温产香酵母的筛选及性能研究[J].中国酿造,39(11):43-47.[LüF,Zhao X X,Li S L,Liu Y H,He Y G,Fang C Y,Zou W,Zhao C Q,Ai X M.2020.Screening of thermotolerant aroma-producing yeast from fermented grains of sauce-flavor Baijiu and its fermentation performance[J].China Brewing,39(11):43-47.]doi:10.11882/j.issn.0254-5071.2020.11.009.

芦文娟,李宝坤,卢士玲.2016.新疆塔城地区哈萨克族传统奶酪中酵母菌的分离鉴定[J].中国酿造,35(7):24-29.[Lu W J,Li B K,Lu S L.2016.Isolation and identifica-tion of yeast from traditional cheese of Kazak in Tachengregion of Xinjiang[J].China Brewing,35(7):24-29.]doi:10.11882/j.issn.0254-5071.2016.07.006.

刘晓燕.2022.混菌发酵、酒泥陈酿对赤霞珠干红葡萄酒品质的影响[D].乌鲁木齐:新疆农业大学.[Liu X Y.2022.Effects of mixed fermentation,lees aging on the quality of Cabernet Sauvignon dry red wine[D].Urumqi:Xinjiang Agricultural University.]doi:10.27431/d.cnki.gxnyu.2022.000220.

牛雪.2015.福林酚法测定葡萄酒总酚的优化研究[D].银川:宁夏大学.[Niu X.2015.The research on optimized total wine phenols determination by Folin Ciocalteu assay[D].Yinchuan:Ningxia University.]doi:10.7666/d.Y2860624.

庞敏,蔡松铃,刘茜.2019.葡萄酒中有机酸及其分析方法的研究进展[J].食品安全质量检测学报,10(6):1588-1593.[Pang M,Cai S L,Liu Q.2019.Research progress on the analysis methods of organic acids in wine[J].Journal of Food Safety and Quality,10(6):1588-1593.]doi:10.3969/j.issn.2095-0381.2019.06.029.

彭璐,明红梅,陶敏,任清,熊堂语,王轩,俞飞.2020.樱桃酒酿造用产香酵母的筛选及其特征香气成分分析[J].中国酿造,39(11):36-42.[Peng L,Ming H M,Tao M,Ren Q,Xiong T Y,Wang X,Yu F.2020.Screening of aroma-producing yeast for cherry wine brewing and analysis ofits characteristic aroma components[J].China Brewing,39(11):36-42.]doi:10.11882/j.issn.0254-5071.2020.11.008.

汤晓宏,丁燕,钟轲,荆晓姝,韩晓梅,李志宇,杨阳,孙玉霞.2023.一株拜耳接合酵母菌的基本性能及发酵香气研究[J].中外葡萄与葡萄酒,(6):70-77.[Tang X H,Ding Y,Zhong K,Jing X S,Han X M,Li Z Y,Yang Y,Sun Y X.2023.Study on basic properties and fermentation aroma of Zygosaccharomyces bailii[J].Sino-Overseas Grapevine&Wine,(6):70-77.]doi:10.13414/j.cnki.zwpp.2023.06.010.

卫春会,黄亮,姚亚林,吴树坤,黄治国.2021.山葡萄酒发酵过程中活性物质、抗氧化能力及有机酸的变化[J].食品工业科技,42(6):9-14.[Wei C H,Huang L,Yao Y L,Wu S K,Huang Z G.2021.Changes of active substances,anti-oxidant capacity and organic acids during the fermentation of Vitis amurensis wine[J].Science and Technology of Food Industry,42(6):9-14.]doi:10.13386/j.issn 1002-0306.2020050307.

夏鸿川.2022.宁夏贺兰山东麓产区葡萄酒的混菌发酵研究[D].银川:宁夏大学.[Xia H C.2022.Study on mixed fermentation of wine from Eastern Foothill of Helan Mountain in Ningxia[D].Yinchuan:Ningxia University.]doi:10.27257/d.cnki.gnxhc.2022.001148.

徐超,胡文效,陈明光,朱明宣,邱磊,赵先炎.2024.葡萄酒发酵香气物质调控研究进展[J].中外葡萄与葡萄酒,(1):81-93.[Xu C,Hu W X,Chen M G,Zhu M X,Qiu L,Zhao X Y.2024.Advances on regulation of aroma substances in wi37789de1727b52c27b718d4919ac961fe8f425de0ac732fec714bbd05e9f1faane fermentation[J].Sino-Overseas Grapevine&Wine,(1):81-93.]doi:10.13414/j.cnki.zwpp.2024.01.011.

张春芝,江志国,莫寅斌,吴立国,谢惠芳.2024.本土酵母与商业酵母混菌发酵对“马瑟兰”干红葡萄酒品质的影响[J].安徽农业科学,52(2):152-155.[Zhang C Z,Jiang Z G,Mo Y B,Wu L G,Xie H F.2024.Effect of indigenous and commercial Saccharomyces cerevisiae mixed fermen‐tation on the quality of Marselan dry red wine[J].Journal of Anhui Agricultural Sciences,52(2):152-155.]doi:10.3969/j.issn.0517-6611.2024.02.034.

张晴雯,邓杰,杨易坤,卫春会,任志强,黄治国.2024.非酿酒酵母对葡萄酒风味影响的研究进展[J].中国酿造,43(3):13-20.[Zhang Q W,Deng J,Yang Y K,Wei C H,Ren Z Q,Huang Z G.2024.Research progress on the effect of non-Saccharomyces yeasts on wine flavor[J].China Brewing,43(3):13-20.]doi:10.11882/j.issn.0254-5071.2024.03.003.

张志然,王恩辉,李兴元,许程,夏磊.2022.葡萄酒感官质量评价及其理化因子分析[J].现代食品,28(7):202-206.[Zhang Z R,Wang E H,Li X Y,Xu C,Xia L.2022.Sen‐sory quality evaluation and physicochemical factor analy‐sis of wines[J].Modern Food,28(7):202-206.]doi:10.16736/j.cnki.cn41-1434/ts.2022.07.052.

赵书田,丁波,熊灵,林颖,吴浪,童隆浩,张文学.2023.产香酵母的筛选及桑葚酒发酵特性分析[J].食品科技,48(12):9-15.[Zhao S T,Ding B,Xiong L,Lin Y,Wu L,Tong L H,Zhang W X.2023.Screening of fragrant yeast and analysis of fermentation characteristics of mulberry wine[J].Food Science and Technology,48(12):9-15.]doi:10.13684/j.cnki.spkj.2023.12.004.

周桂珍.2022.宁夏贺兰山东麓葡萄酒酵母菌的筛选及混菌发酵研究[D].银川:宁夏大学.[Zhou G Z.2022.Scree-ning and mixed fermentation of wine yeasts in the castern part of Ningxia Helan Mountains[D].Yinchuan:Ningxia University.]doi:10.27257/d.cnki.gnxhc.2022.001675.

Aleixandre-Tudo J L,Buica A,Nieuwoudt H,Aleixandre J L,du 634687a25da7cf63c049ef020da62c0fToit W.2017.Spectrophotometric analysis of phenolic compounds in grapes and wines[J].Journal of Agricultural and Food Chemistry,65(20):4009-4026.doi:10.1021/acs.jafc.7b01724.

Baffi M A,dos Santos Bezerra C,Arévalo-Villena M,Briones-Pérez A I,Gomes E,da Silva R.2011.Isolation and molecular identification of wine yeasts from a Brazilian vineyard[J].Annals of Microbiology,61:75-78.doi:10.1007/s 13213-010-0099-z.

Chidi B S,Bauer F F,Rossouw D.2018.Organic acid metabo‐lism and the impact of fermentation practices on wine aci-dity-A review[J].South African Journal of Enology and Viticulture,39(2):315-329.doi:10.21548/39-2-3172.

Cordente A G,EspinaseNandorfy D,Solomon M,Schulkin A,Kolouchova R,Francis I L,Schmidt S A.2021.Aromatic higher alcohols in wine:Implication on aroma and palate attributes during chardonnay aging[J].Molecules,26(16):4979.doi:10.3390/molecules26164979.

Feng C T,Du X,Wee J.2021.Microbial and chemical analysis of non-Saccharomyces yeasts from Chambourcin hybrid grapes for potential use in winemaking[J].Fermentation,7(1):15.doi:10.3390/fermentation7010015.

Gamero A,Quintilla R,Groenewald M,Alkema W,Boekhout T,Hazelwood L.2016.High-throughput screening of a large collection of non-conventional yeasts reveals their potential for aroma formation in food fermentation[J].Food Microbiology,60:147-159.doi:10.1016/j.fm.2016.07.006.

Gutiérrez-Escobar R,Aliaño-González M J,Cantos-Villar E.2021.Wine polyphenol content and its influence on wine quality and properties:A review[J].Molecules,26(3):718.doi:10.3390/molecules26030718.

Hernández Y,Lobo M G,González M.2009.Factors affecting sample extraction in the liquid chromatographic determina‐tion of organic acids in papaya and pineapple[J].Food Chemistry,114(2):734-741.doi:10.1016/j.foodchem.2008.10.021.

Hu K,Jin G J,Xu Y H,Tao Y S.2018.Wine aroma response to different participation of selected Hanseniasporauvarum in mixed fermentation with Saccharomyces cerevisiae[J].Food Research International,108:119-127.doi:10.1016/j.foodres.2018.03.037.

Padilla B,Gil J V,Manzanares P.2016.Past and future of non-Saccharomyces yeasts:From spoilage microorganisms to biotechnological tools for improving wine aroma comple-xity[J].Frontiers in Microbiology,7:411.doi:10.3389/fmicb.2016.00411.

Prior K J,Bauer F F,Divol B.2019.The utilisation of nitro-genous compounds by commercial non-Saccharomyces yeasts associated with wine[J].Food Microbiology,79:75-84.doi:10.1016/j.fm.2018.12.002.

Whitener M E B,Stanstrup J,Carlin S,Divol B,Du Toit M,Vrhovsek U.2017.Effect of non‐Saccharomyces yeasts on the volatile chemical profile of Shiraz wine[J].Australian Journal of Grape and Wine Research,23(2):179-192.doi:10.1111/ajgw.12269.

Zhang B Q,Tang C,Yang D Q,Liu H,Xue J,Duan C Q,Yan G L.2022.Effects of three indigenous non-Saccharomyces yeasts and their pairwise combinations in co-fermentation with Saccharomyces cerevisiae on volatile compounds of Petit Manseng wines[J].Food Chemistry,368:130807.doi:10.1016/j.foodchem.2021.130807.

(责任编辑刘可丹)