1-MCP 缓释水凝胶对采后草莓果实品质和抗病性的影响

罗自生,姜柔王,李贞彪,肖 韵,龚晓惠,侯东园,黄 静,陈彦培,林星宇,徐艳群,,3

(1.浙江大学生物系统工程与食品科学学院,浙江杭州 310058;2.浙江大学宁波科创中心,浙江宁波 315100;3.哈佛大学有机与进化生物学系,美国剑桥 MA 02138)

Strawberry (Fragaria×ananassaDuch.) is a popular fruit worldwide,known as the "Queen of fruit"due to its bright color,delicious flavor,and rich nutritional content[1].However,strawberry is soft and highly susceptible to biotic and abiotic stresses,leading to quality deterioration and spoilage after harvest,which affects the shelf life and market value[2].

Several factors contribute to the postharvest decay of strawberry,including senescence due to metabolism,rot caused by microbial infections such asBotrytis cinerea,and mechanical damage and water loss caused by inappropriate postharvest treatments[3-4].Therefore,postharvest preservation of strawberries has become a significant challenge,with several approaches being explored to improve postharvest quality and extend shelf life,such as packaging with modified atmospheres and UV-C irradiation[5-7].

Phytohormones partially regulate the postharvest decay process of strawberry fruit[7].Previous studies have shown that auxins (IAA) and abscisic acid(ABA) significantly contribute to postharvest quality.Jasmonates (JAs) have also been found to influence strawberry ripening,postharvest quality,and plant defense[8].While previous studies have reported higher ethylene release from the flowers and red ripe strawberry fruit[9],recent genetic evidence has suggested that ethylene plays a crucial role in strawberry ripening and postharvest senescence[10-11].However,as a non-climacteric fruit,the role of ethylene in the post-harvest preservation of strawberry still needs further exploration,especially compared to the abundant research already existing on climacteric fruits.

1-Methylcyclopropene (1-MCP) is an effective inhibitor of ethylene action[12].1-MCP can bind to ethylene receptors,preventing ethylene from binding to its receptors,thus slowing down the ripening and senescence process,and extending the shelf life of fruit[13].1-MCP has become a common preservative in fruit logistics,including strawberry,showing significant fresh-keeping effects in decreasing browning,chilling damage,aging,and diseases.Additionally,1-MCP treatment can also be used for postharvest lowtemperature resistance to reduce adverse environmental effects on crops[14-15].

Currently,1-MCP is commonly applied in a powder form by complexation withα-CD inclusion complexes.However,the variable impacts and complicated processing associated with this technology make it commercially viable only on a small scale.Fumigation of 1-MCP preservatives requires maintaining specific temperature conditions and is typically carried out using a 1-MCP tablet or powder fresh-keeping device under a hermetic environment[16].When used,1-MCP/cyclodextrin powder needs to be dissolved with a specific volume of solvent (such as pure water) to release the 1-MCP[17].Simultaneously,the fumigation of 1-MCP preservatives needs to maintain a specific range of temperature conditions,usually at 10~25 ℃[18].With the rapid development of the global food supply chain,controlled-release packaging has emerged as a kind of active packaging,aiming to reduce the loss of food quality[19].Novel packaging films and nano-packaging combined with 1-MCP have been investigated,which means that the sustained release of 1-MCP is crucial for long-lasting freshness in the fresh produce supply chain[20-21].

hydrogel is a hydrophilic polymer material with a network structure.The hydrophilic polymer chains are cross-linked to form a three-dimensional solid,and water serves as the dispersion medium[22].In addition,hydrogel materials have excellent biocompatibility and molecular transport capabilities,so they have the potential to be widely used in medical fields such as biomimetic materials and artificial tissues[23-24].hydrogel materials have extremely high retention,and their material textures are usually soft[20,25].

In this study,a copolymer hydrogel system for sustained release of 1-MCP,referred to as 1-MCP hydrogel,was created by utilizing the porous structure and molecular transfer characteristics of the hydrogel.The controlled release pattern of 1-MCP was measured and the effect of 1-MCP hydrogel on strawberry quality and shelf life was investigated.

1 Materials and methods

1.1 Materials and instruments

Strawberry (Fragaria×ananassaDuch.Beinhoppe) picked from a local orchard in Hangzhou(Zhejiang,China),with a maturity of 70%~80%.The harvested fruit had no mechanical damage or diseases,and the shape,color,and size were basically the same;Acrylic acid (AA),2-hydroxyethyl methacrylate(HEA),poly (ethylene glycol) diacrylate (PEGDA),diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide(TPO),and 1-methylcyclopropene (1-MCP) powder Aladdin Co.,Ltd.(Shanghai,China);All the other chemicals used were of analytical grade.

Gas chromatograph Agilent 7890A USA Agilent Technologies Inc;CR-400 automatic colorimeter Japan Konica Minolta Co.,Ltd.;Texture analyzer TA-XT2i UK Stable Micro Systems Ltd.;Sugar meter PAL-BX/ACID F5 Japan Atago Co.,Ltd.

1.2 Experimental methods

1.2.1 Preparation of the 1-MCP hydrogel Firstly,1.5 g monomer A (2-hydroxyethyl methacrylate,HEA),0.5 g monomer B (Acrylic acid,AA),0.05 g crosslinking agent (poly (ethylene glycol) diacrylate,PEDGA),and 2 mL distilled water were successively added into the beaker to form a hydrogel system.Subsequently,dissolved 0.02 g 1-MCP powder and 0.02 g photosensitive initiator (diphenyl (2,4,6-trimethylbenzoyl)phosphine oxide,TPO) in hydrogel systems.Finally,exposed the liquid mixture to ultraviolet light for 20 min until it became solid 1-MCP hydrogel.All the experiments were conducted three times.

1.2.2 Determination of the controlled release of 1-MCP The preservatives including 4 g 1-MCP hydrogel (containing 0.5% 1-MCP powder),0.02 g 1-MCP powder,and 1-MCP powder solution (0.02 g 1-MCP powder mixed with 4 mL distilled water) were placed on different petri dishes,separately.Each was placed in a 400 mL reagent bottle containing 4 mL of saturated potassium nitrate solution (keeping 95% relative humidity) and sealed quickly at room temperature.Extracted 1 mL of headspace gas at 0,12,24,48,72,and 96 h and injected into a gas chromatograph.

A gas chromatograph combined with a hydrogen flame ionization detector (FID) was used to detect 1-MCP release content.HP-5ms capillary column(30 m×250 μm×0.25 μm) was used.The temperature of the column was 100 ℃,the carrier gas was nitrogen,the pressure was 120 kPa,the injector temperature was 130 ℃,the detector temperature was 150 ℃,and the injection volume was 2 mL[26].Based on the similar FID response factor of 1-MCP and isobutene,the amount of 1-MCP was determined with 48.8 μL/L isobutene as the external standard[27].

1.2.3 Fruit treatments Immersed the strawberry in 0.5% sodium hypochlorite for 5 min,followed by washing with sterile water to remove residues,and dried at room temperature.Randomly divided the fruit into two groups.4 g 1-MCP hydrogel prepared was put into a fresh-keeping box lined with a tray,covered with fresh-keeping packaging.Each box contained ten strawberries.Stored the fruit at 20 ℃ and kept the relative humidity at 95% for 6 d.The control group was set in the same packaging box without 1-MCP hydrogel.Samples were taken every 2 d during storage to observe the effects.The fruit treatment experiments were conducted three times,thus in the results each group contained 180 strawberries with three biological replicates totally.

1.2.4 Determination of weight loss and decay rate The fruit was weighed at each sampling point,and six of them were randomly selected for experiments.Weight loss was expressed as a percentage of total weight lost.The following equation was used to calculate the weight loss of the samples[28].

Note: m1represents the initial fruit weight,g;m2represents the fruit weight after storage,g.

The decay of the fruit was observed at each sampling point.Six strawberries were randomly selected for the experiment.The decay rate was evaluated as the account of decayed fruit relative to the total number of fruit and was expressed as a percentage.The following equation was used to calculate the decay rate of the samples[29].

Note: n1represents the number of diseased fruit;n2represents the total number of fruit.

1.2.5 Determination of fruit color The skin color of the fruit was measured using a CR-400 automatic colorimeter.Six strawberries were randomly selected,and the peel color,including Luminance (L*),redgreen deviation (a*),and blue-yellow deviation (b*),was measured at two symmetrical equatorial points of the fruit surface[30].

1.2.6 Determination of fruit firmness A texture analyzer was used to measure firmness.Six strawberries were randomly selected from each group.Each was tested twice around the center with a 5 mm diameter probe.The penetration distance was 15 mm,and the test speed was 5 mm/s.The maximum force was considered firmness read off and expressed in newtons(N).

1.2.7 Determination of total soluble solids (TSS) and total acid (TA) TSS and TA of the fruit were determined using a sugar meter,and six fruits were randomly selected for determination according to the reference of Yan et al[31].

1.3 Statistical analysis

All experiments were carried out with three biological replicates,and data were presented as the means±standard deviation (SD).SPSS 21.0 (SPSS Inc.,Chicago,IL,USA) with one-way analysis of variance(ANOVA) was used for statistical analyses.Use Duncan's multiple range tests to analyze the statistical significance at the level ofP<0.05.

2 Result and discussion

2.1 Morphology and characterization of 1-MCP hydrogel

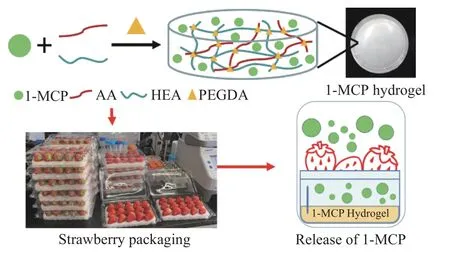

Recent research has shown that the development of sustained-release 1-MCP products is essential for fruit preservation,but there is still a lack of such products,particularly for non-climacteric fruits,such as berries[32-33].In this study,a copolymer hydrogel,referred to as 1-MCP hydrogel,was successfully created.The 1-MCP hydrogel exhibited good elasticity and performed positive sustained-release performance as shown in Fig.1.The hydrogel system's plasticity enabled the shape and thickness of the product to be adjusted as needed.For this study,the 1-MCP hydrogel was made into a round sheet with a thickness of 0.3 cm to serve as a buffer spacer for strawberry fruit.

Fig.1 Schematic diagram of 1-MCP hydrogel

2.2 Release characteristic of 1-MCP hydrogel

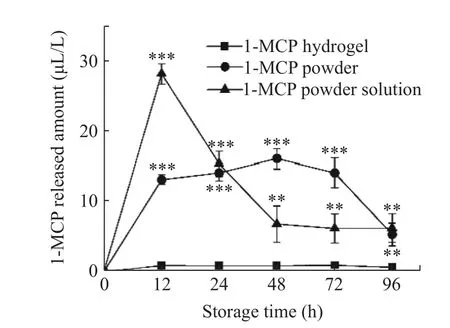

As shown in Fig.2,the 1-MCP hydrogel showed the lowest value of 1-MCP release,which was 7%and 3% of the 1-MCP powder group and 1-MCP powder solution group at 12 h.This result indicated that the porous hydrogel system used in this study had an excellent throttling effect on 1-MCP gas,so its volatilization amount will not rush to a high level instantly.Although the peak value of 1-MCP hydrogel was smaller than the other two products,its concentration remained above the concentration required for the fruit[27,34-35],and the release of 1-MCP hydrogel remained relatively stable throughout the study.

Fig.2 Release behavior of 1-MCP hydrogel,1-MCP powder,and 1-MCP powder solution under 95% relative humidity and room temperature

2.3 Effect of 1-MCP hydrogel on fruit weight loss

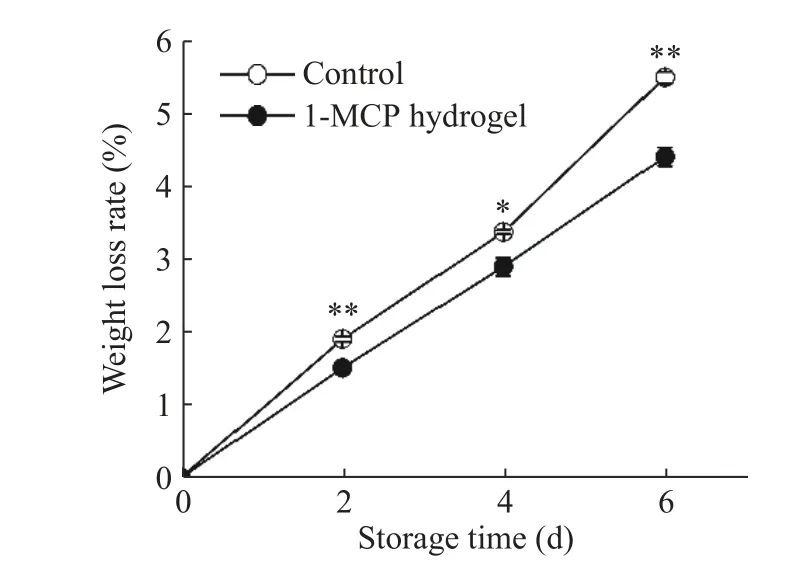

Fruit weight loss is closely linked to packaging[36].As shown in Fig.3,the weight loss rate increased with storage time.However,the weight loss rate in the 1-MCP hydrogel group was significantly (P<0.05) lower than that of the control group,decreasing by 21%,14%,and 20%,respectively,after 2,4,and 6 d of storage.These results indicated that the product could effectively reduce water evaporation and thus effectively reduce postharvest loss,possibly by maintaining better humidity,and effectively inhibited fruit metabolism respiration.

Fig.3 Effects of 1-MCP hydrogel on weight loss rate of strawberry during storage

2.4 Effects of 1-MCP hydrogel on the decay rate of strawberry

As shown in Fig.4,the decay rate of the fruit gradually increased during storage,but the 1-MCP hydrogel significantly reduced the fruit decay rate compared to the control group.After 2,4,and 6 d of storage,the decay rate of the 1-MCP hydrogel group was 75%,35%,and 21% lower (P<0.05) than the control group.These results demonstrate that 1-MCP hydrogel can effectively reduce the incidence of fruit decay and maintain the commercial value of strawberry fruit during storage.

Fig.4 Effects of 1-MCP hydrogel on the decay rate of strawberry during storage

2.5 Effects of 1-MCP hydrogel on the color of strawberry

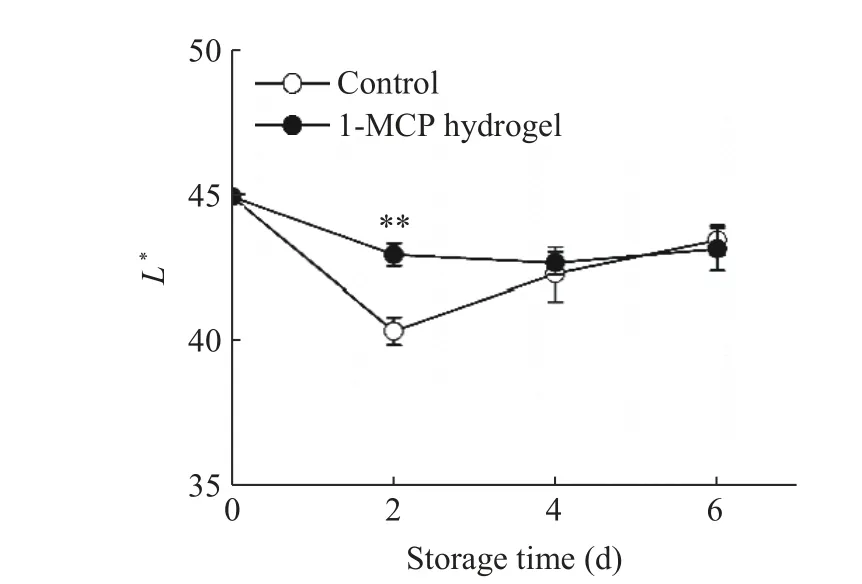

The color of the fruit surface directly affects its commodity value.Thea*value indicates the color change from green to red during fruit ripening and senescence,and theb*value indicates the color change from blue to yellow.TheL*value reflects the peel glossiness of the strawberry.To investigate the effects of the 1-MCP hydrogel on the color quality of strawberry,thea*,b*andL*values were measured.As shown in Fig.5,thea*value in the 1-MCP hydrogel group showed a trend of increasing first and then decreasing,but was always higher than that in the control group,especially on the 2 d of storage,the value was 11% significantly higher than that in the control group (P<0.05).b*value in the strawberry treated with 1-MCP hydrogel increased gradually during storage and reached its maximum value on day 4,which was 11% higher than that in the control group (Fig.6).L*value in the control group decreased significantly(P<0.05) on the 2 d of storage,and then increased gradually at the later stage of storage.However,L*value in 1-MCP hydrogel group remained at a stable level during storage and was higher than that in the control group,which was 6% higher than that in the control group on day 2.These results suggest that the 1-MCP hydrogel effectively maintained the fruit color quality (Fig.7).Ethylene treatment has been reported to inhibit anthocyanin biosynthesis and down-regulate anthocyanin biosynthesis genes during the ripening of strawberry fruit[10],which might explain the brighter color of the study,as 1-MCP inhibits ethylene work.

Fig.5 Effects of 1-MCP hydrogel on the a* value of strawberry during storage

Fig.7 Effects of 1-MCP hydrogel on the L* value of strawberry during storage

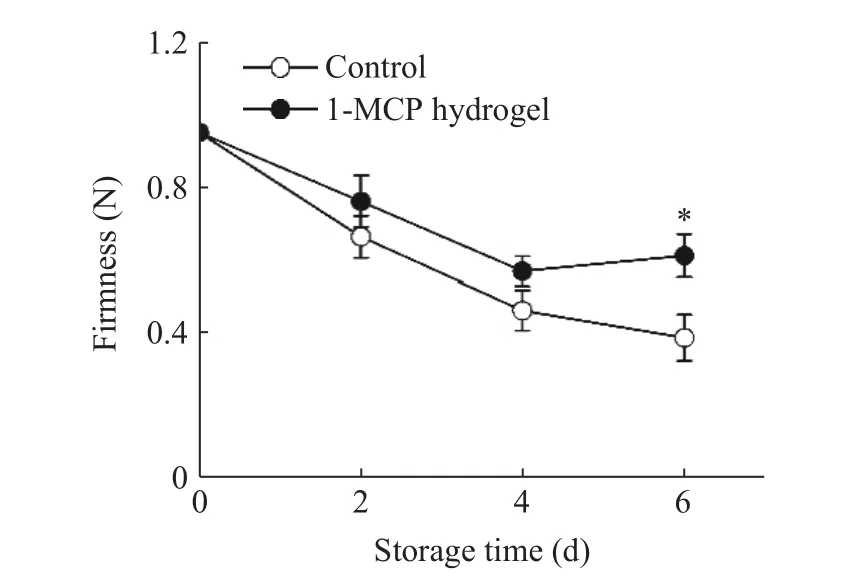

2.6 Effects of 1-MCP hydrogel on the firmness of strawberry

As shown in Fig.8,the firmness of strawberry decreased gradually with the extension of storage time,but 1-MCP hydrogel treatment delayed the declining trend,especially on the 6 d of storage,when the firmness of strawberries treated with 1-MCP hydrogel was 21% higher than that of the control group (P<0.05).These findings are consistent with previous studies that reported 1-MCP delayed the loss of firmness and prevented or delayed softening of strawberry[36-37].

Fig.8 Effects of 1-MCP hydrogel on the firmness of strawberry during storage

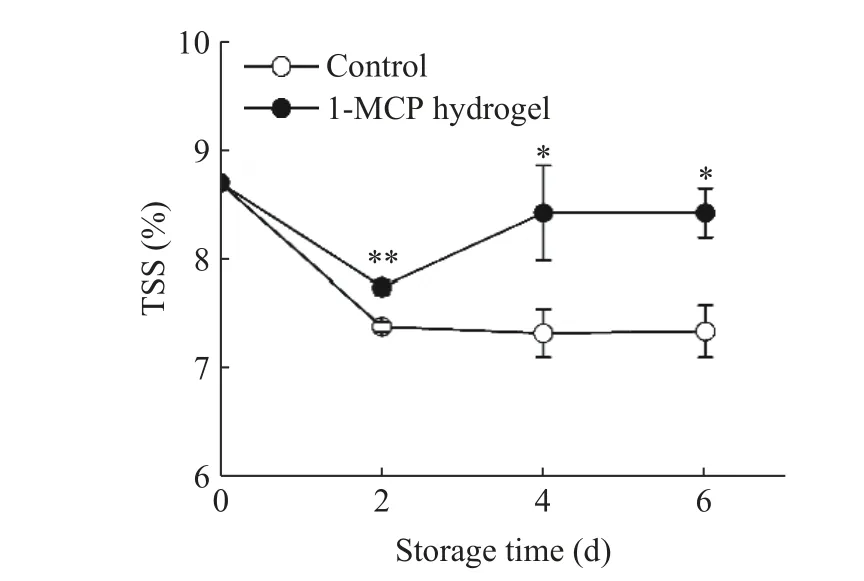

2.7 Effects of 1-MCP hydrogel on TSS of strawberry

Total soluble solid (TSS) is an important parameter to characterize fruit flavor and nutritional quality.As shown in Fig.9,the TSS content performance indicated that the 1-MCP hydrogel group had significantly higher TSS content (P<0.05) than the control group during the entire storage period.On the 6 d of the storage time,the 1-MCP hydrogel group was 15%higher than the control.

Fig.9 Effects of 1-MCP hydrogel on the total soluble solids(TSS) content of strawberry during storage

2.8 Effects of 1-MCP hydrogel on TA of strawberry

Titratable acid (TA) is an important index of fruit flavor quality and has an important effect on the taste and flavor of strawberry.As shown in Fig.10,the TA content of the control group generally decreased throughout the storage period,while the TA content of the 1-MCP hydrogel group started to decrease on the second day of storage and then gradually increased over time.After 6 d of storage,the TA content of the 1-MCP hydrogel group was 18% higher than that of the control group.Overall,the results of Fig.9 and Fig.10 showed that the 1-MCP hydrogel effectively inhibited TSS and TA degradation,contributing to the preservation of fruit flavor quality.

Fig.10 Effects of 1-MCP hydrogel on the titratable acid (TA)content of strawberry during storage

3 Conclusion

In conclusion,the 1-MCP hydrogel developed in this study demonstrated excellent sustained release of 1-MCP.Compared to 1-MCP powder and 1-MCP powder solution,the 1-MCP hydrogel exhibited a better-sustained release effect.For the preservation of postharvest strawberries,1-MCP hydrogel reduced fruit weight loss and the decay rate,and maintained highera*,b*,L*values and firmness.Meanwhile,the results also showed that the strawberry treated with 1-MCP hydrogel maintained higher TSS and TA contents.Thus,the copolymer hydrogel with sustained release of 1-MCP has multiple functions,including sustained and controlled release of 1-MCP and fruit quality enhancement.Moreover,it has the potential to be widely used in postharvest preservation due to its convenient preparation.