葡萄物流及贮藏保鲜包装技术研究现状与展望

李宝庆,梁欣,韦婉琪,姚刚,李宇丞,阎瑞香*

农产品保鲜与食品包装

葡萄物流及贮藏保鲜包装技术研究现状与展望

李宝庆1,梁欣2,韦婉琪1,姚刚2,李宇丞1,阎瑞香1*

(1.天津科技大学 轻工科学与工程学院,天津 300222; 2.深圳顺丰泰森控股(集团)有限公司,广东 深圳 518000)

通过对葡萄物流运输、贮藏保鲜过程中使用的包装技术进行分类和系统介绍,分析其研究现状及存在问题,并展望未来发展前景,以促进葡萄贮运保鲜包装技术提升。针对贮运保鲜中葡萄果实容易出现的问题,介绍缓冲包装、气调包装、活性包装以及智能包装等包装技术的研究及应用现状,分析不同包装技术的优势,并讨论未来可能的发展方向。多种包装技术配合使用,提升运输包装缓冲减振效果,精确调控气调包装内部气氛,控制活性包装中药剂释放与分子迁移,提升智能指示标签的精确性,保证RFID智能包装系统的稳定性等,有利于葡萄贮运保鲜中品质的保持与货架寿命的延长。

葡萄;物流;贮藏;保鲜;包装技术

作为一种常见浆果类水果,葡萄在我国广受欢迎,其味道鲜美,果汁酸甜,具有丰富的营养价值,是我国五大水果之一[1]。葡萄一般在6月到9月成熟,此时正值高温多雨季节,采摘后的新鲜葡萄含糖量高、多汁,容易受到病菌侵染发生腐烂变质,并且果肉衰老速度快,在采收后2~3 d就会迅速变软,发生果实脱落等问题。据统计,葡萄采后从果园到消费者手中损失率达25%~30%,严重影响经济效益[2-3]。此外,“互联网+农业”的兴起,采用电商手段进行葡萄销售的模式越来越普遍,但葡萄本身汁多皮薄,果穗松软,在电商运输过程中,运输环境密闭且温度较高,颠簸震荡明显,再加上快递暴力分拣等因素,使得消费者收到的鲜食葡萄往往出现脱粒、果皮损伤、果梗褐变甚至发霉腐烂等情况,不仅降低了消费者的网购体验,而且限制了葡萄电商销售模式的发展[4-7]。

为解决葡萄在物流运输及贮藏过程中出现的脱粒、失水、腐烂等问题,国内外科研工作者围绕包装材料、包装结构、包装技术等进行了大量研究,但目前尚缺乏系统的分析与总结。因此,有必要对鲜食葡萄包装相关研究进行梳理分类,总结优势与要点,分析存在的问题,展望发展前景,以期促进葡萄产业的健康发展。

1 葡萄包装技术分类

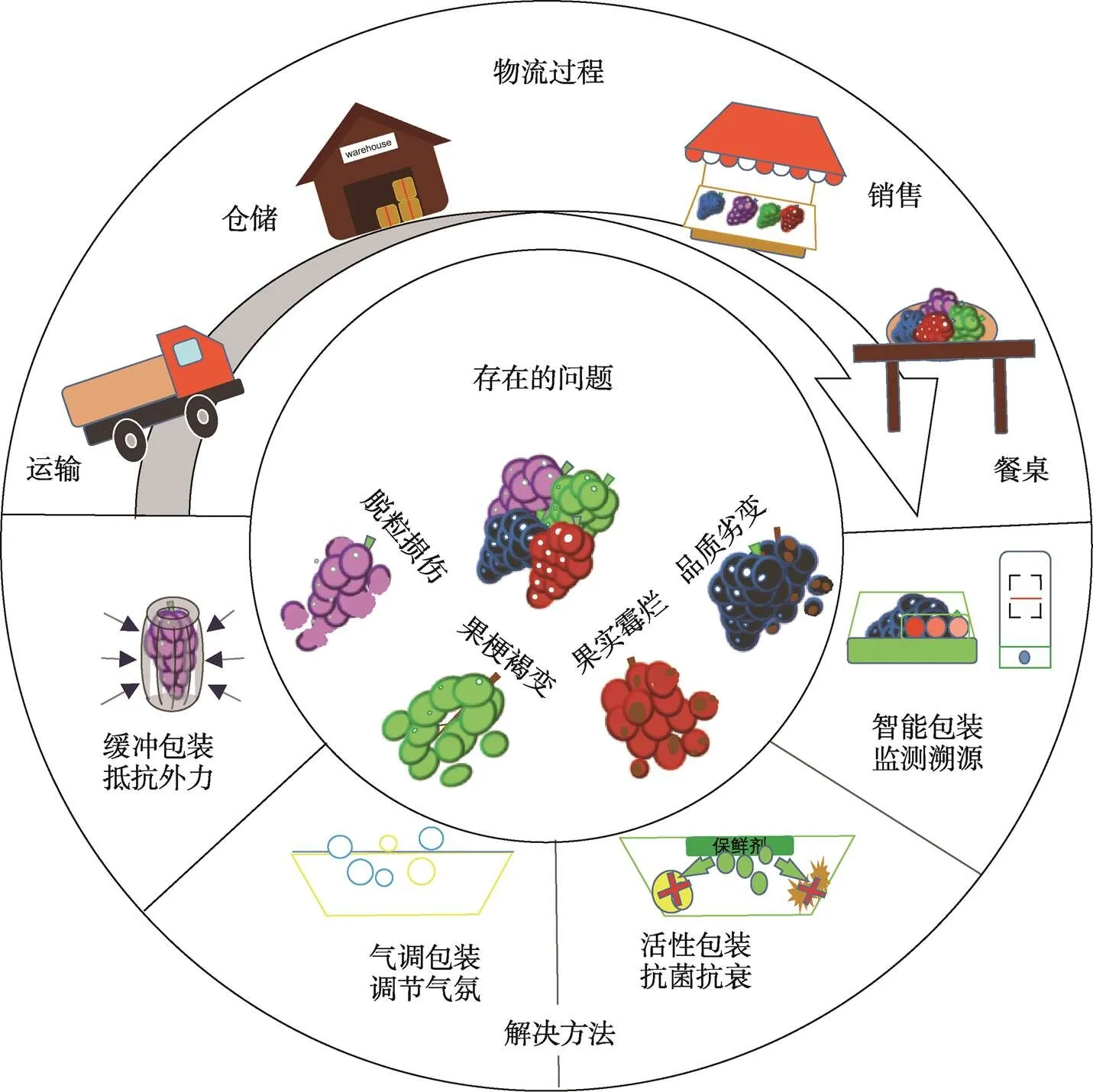

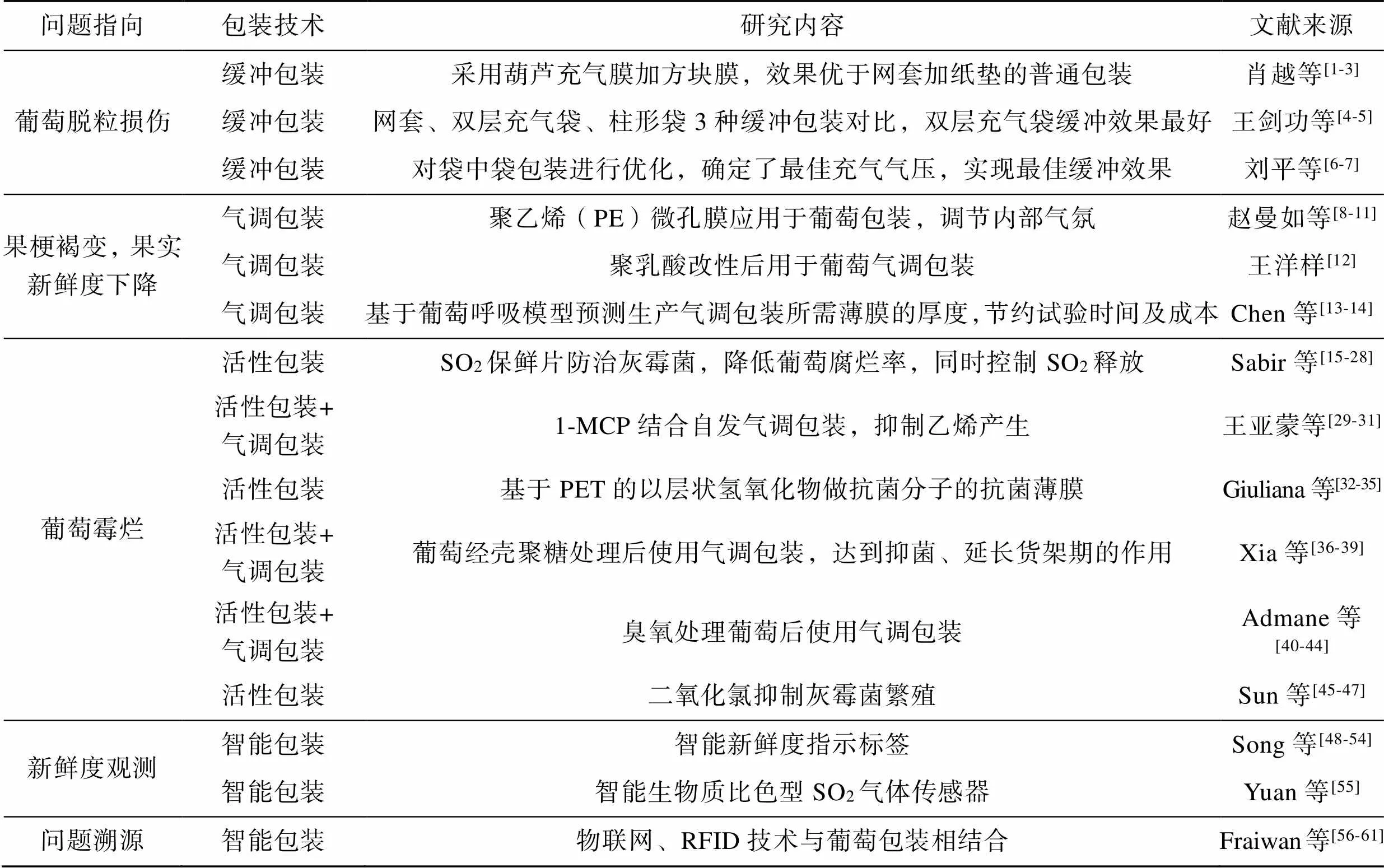

在鲜食葡萄的物流运输、贮藏过程中采用合适的包装技术,有利于在一定程度解决因葡萄自身特质、运输方式以及贮藏环境等因素导致的葡萄品质下降问题,提高经济效益。针对葡萄贮运保鲜过程中出现的问题不同,需采用不同的包装技术。按其功能可以分为4类,即:缓冲包装、气调包装、活性包装、智能包装。不同的包装方式,其原理不同,发挥的功能也各有差异,并且各有优劣,见表1。

以上4种包装方式作用于葡萄物流运输、贮藏保鲜的不同阶段,涵盖了从果园到餐桌的全过程,从保持葡萄外观色泽与营养品质到果品质量安全监测与问题追溯,大大提高了鲜食葡萄的商品价值与经济效益。本文对葡萄物流过程、存在问题以及解决方法的总结如图1所示,并对相关内容详细介绍。

2 包装技术研究现状

葡萄是典型的浆果类水果,在贮运保鲜过程中可能发生的脱粒、损伤、果梗褐变、果实软化、发霉腐烂等情况,需不同包装技术对其进行保护。目前相关研究主要从4个方面展开,包括缓冲包装、气调包装、活性包装以及智能包装等,已有的研究内容如表2所示。

2.1 缓冲包装

葡萄在物流运输中因车辆颠簸振动、搬运过程晃动跌落等因素容易出现果实脱落、挤压损伤等情况,从而影响外观品质,降低货架寿命,因此需要利用缓冲包装对葡萄在运输中进行保护。常见的包装材料有泡沫箱、泡沫网套、充气袋、柱形袋、瓦楞纸箱等。不同的缓冲包装形式对葡萄的保护效果不同,以夏黑葡萄为例,在网套、双层充气袋、柱形袋3种不同缓冲包装形式下的模拟运输试验显示,与另外2种包装下的葡萄相比,使用双层充气袋包装的夏黑葡萄外观及品质更佳,其质量损失率、脱粒率最低,硬度、可溶性固形物、总酸、色差值等最高,双层充气袋更有利于维持葡萄感官品质,保留营养物质[4-5]。目前,充气袋作为缓冲包装已经在实际生产中投入使用,并且缓冲减振效果较好,对鲜食葡萄的袋中袋充气包装进行进一步优化,试验测得最佳充气气压为4 kPa,该条件下能够最大程度避免损伤,平均损伤率仅为1.5%,平均脱粒率为0.2%[6-7]。

表1 葡萄包装技术分类

图1 葡萄物流过程、存在问题及解决方法

表2 葡萄贮运保鲜包装研究内容

Tab.2 Research content of grape storage, transportation and fresh-keeping packaging

此外,其他类型的缓冲减振包装也有研究报道,例如,采用葫芦充气膜加方块膜的形式作为葡萄运输中的缓冲包装,与网套加纸垫的包装方式相比能够明显降低巨峰葡萄质量损失率和表面损伤系数,为葡萄提供有效的缓冲作用[1-3]。

2.2 气调包装

气调包装通过调节包装内部气体比例,控制被包装果蔬所处的气体环境,减缓其呼吸作用,抑制病菌生长,有利于延长内装产品货架寿命[8]。其中自发气调包装在果蔬保鲜中应用较多,该包装方法采用适宜的保鲜袋,可减少果蔬水分散失,并且依靠被包装产品的呼吸作用,一定程度上能够调节包装内部气氛。根据内装果蔬品种不同,需要采用不同材质和厚度的保鲜袋,使袋内形成保鲜所需的气体环境,保持产品新鲜度[9-10]。

生产中常用的葡萄气调包装多为聚乙烯膜(0.015 mm PE膜、PE微孔膜)。研究表明,透氧量为6 000 cm3/(m2·d)的微孔膜保鲜效果最佳,该材料通过膜上微孔调节包装内部氧气(O2)含量,使得O2体积分数保持在12%~14%,一定程度上避免了葡萄在运输和贮藏中无氧呼吸的发生,延缓果梗褐变,保持葡萄外观色泽和品质,延长其货架寿命[11]。

除微孔膜外,以聚乳酸(PLA)为基材,分别利用具有O2吸附性的聚三氟丙基甲基硅氧烷(PTFPMS)和二氧化碳(CO2)渗透性的聚乙二醇(PEG)对PLA进行改性,合成2种三嵌段共聚物,并以50∶50的质量比将其共混。得到的共混薄膜应用于巨峰葡萄保鲜,一定时间后,包装内部气体成分稳定在O2的体积分数为5%和CO2的体积分数为8.1%,在此气体含量下能够有效保持巨峰葡萄花色苷含量,维持外观色泽与新鲜度[12]。

针对不同品种、不同数量的葡萄,筛选不同厚度、不同种类的薄膜十分重要,直接关系到保鲜效果。此时,基于葡萄呼吸模型来对生产所需的气调包装用薄膜的厚度进行预测可以大大节省薄膜筛选过程的时间与成本,提高气调包装生产的经济效益,同时可以更好地对气调包装的保鲜效果进行调整[13-14]。将气调包装与活性包装结合使用,可以达到更好的保鲜效果。

2.3 活性包装

活性包装在果蔬保鲜中应用较多,并且取得了良好的效果。利用活性包装保存葡萄,有利于延缓果实衰老,抑制或者杀灭贮藏过程中滋生繁殖的灰霉菌等病菌,保持果实新鲜度、完整度和营养价值。

2.3.1 SO2杀菌包装

新鲜葡萄在贮藏过程中容易滋生灰霉菌等,导致果实发霉变质,因此葡萄的长期贮藏保鲜需要使用防腐保鲜剂[12]。国内外最广泛使用的防腐保鲜剂为二氧化硫(SO2),能够有效杀死灰霉菌,保持果梗鲜绿度,降低腐烂率、落粒率等[15-18]。但该方法仍然存在局限性,较为突出的是在保鲜过程中SO2浓度的控制问题。浓度不足时保鲜护绿效果不佳,浓度过高又会对葡萄造成漂白伤害,影响感官品质[19-20]。对SO2浓度的控制方法有利用脉冲式防腐设备对葡萄进行熏染,以及SO2气体精准熏蒸保鲜控制系统等[21-22]。

SO2葡萄保鲜片在市场上已有较多应用,常见的保鲜片制作方法是热熔制粒压片法,药效持续时间一般在6~7个月[23-25]。而将SO2保鲜片封装在带有打孔的塑料层压板中,则可以在起到防潮作用的同时控制SO2扩散到包装环境中的速率,降低初始的SO2浓度峰值,将保险片寿命延长3倍,该方法可以使得“红地球”葡萄货架期达到4个月甚至更长时间[26-28]。

2.3.2 1-MCP活性包装

1-甲基环丙烯(1-Methylcyclopropene,1-MCP)是一种乙烯受体抑制剂,常温下呈气态,可以通过与乙烯受体结合,抑制乙烯生理活动,因此1-MCP可以作为果蔬保鲜剂,延长果蔬贮藏时间[29-30]。将1-MCP气体熏蒸与自发气调包装相结合,低温下对葡萄保鲜效果良好。例如在夏黑葡萄保鲜应用中,结合0.18 mm厚度的聚乙烯制作的自发气调包装袋,在低温下(4±0.5)℃保鲜效果良好,能够减少腐烂率,维持较好的维生素C、可滴定酸和多酚含量等品质指标。需要注意的是,1-MCP熏蒸时对浓度的控制应适宜,过高或过低都无法达到良好的贮藏保鲜效果,该示例下,1.0 μL/L浓度的1-MCP进行熏蒸时效果最佳[31]。

实际操作中,依然应当结合不同品种葡萄的品质特性以及气调包装的选用、贮藏环境条件等控制不同的1-MCP浓度,从而保证包装成本,提高葡萄保鲜质量。

2.3.3 抗菌薄膜活性包装

为减少鲜食葡萄在采后贮藏中质量下降和发霉腐烂的问题,还可以采用抗菌薄膜来对其进行保鲜贮藏。例如以PET为基材添加2-乙酰氧基苯甲酸阴离子(水杨酸盐)的层状双氢氧化物作为抗菌分子,溶剂涂布后制得抗菌薄膜用于葡萄保鲜,具有优异的抗菌活性。该抗菌薄膜中水杨酸盐的迁移量符合迁移限度,因此用于葡萄贮藏保鲜也较为安全[32]。将抗菌材料与气调包装相结合,如包装内充入体积分数为20%的O2和体积分数为10%的CO2,在运输与冷藏期间可延长葡萄的货架期[32-34]。

此外,利用天然生物高聚物壳聚糖制作抗菌涂层,能够控制新鲜果蔬腐烂,增强采摘后的果蔬对包括灰霉在内的许多真菌的抵抗力[35-36]。经过质量分数分别为0.5%或1.0%的壳聚糖处理,能够有效改善鲜食葡萄的质量损失、损伤等情况,延缓浆果中总酚含量的下降。经过该处理后的葡萄装入高密度聚乙烯袋中,并充入10 kPa CO2和20 kPa O2,能够明显抑制灰霉菌等的繁殖,控制葡萄水分流失[37-39]。

2.3.4 其他活性包装

臭氧(O3)被美国食品药品监督管理局(US Food and Drug Administration,US FDA)宣布为一般公认安全(Generally Recognized as Safe,GRAS)的物质后,在食品工业中被广泛应用。研究表明持续低浓度的O3可以抑制鲜食葡萄存储过程中灰霉菌的繁殖,延长葡萄的储存时间。因此,在葡萄保鲜包装中O3可以作为抗菌剂。将体积分数为20 μL/L的O3与空气混合后,对葡萄进行30 min熏蒸预处理,并将处理后的葡萄装入由聚酰胺/聚乙烯(PA/PE)制成的包装袋中,充入体积分数为2%的O2和体积分数为5%的CO2,在该气调包装下进行密封储存。该处理对霉烂的抑制作用明显,能够更好地保持葡萄的外观色泽、感官品质和营养成分[40-44]。

二氧化氯(ClO2)由于具有广泛的杀菌谱,也常作为葡萄保鲜剂,具有良好的保鲜效果。该方法能够有效杀灭葡萄表面的灰霉菌、青霉、交链孢霉等。使用过程中ClO2最低质量浓度应为12 mg/m3,否则保鲜效果不理想[45-47]。

2.4 智能包装

2.4.1 智能指示标签

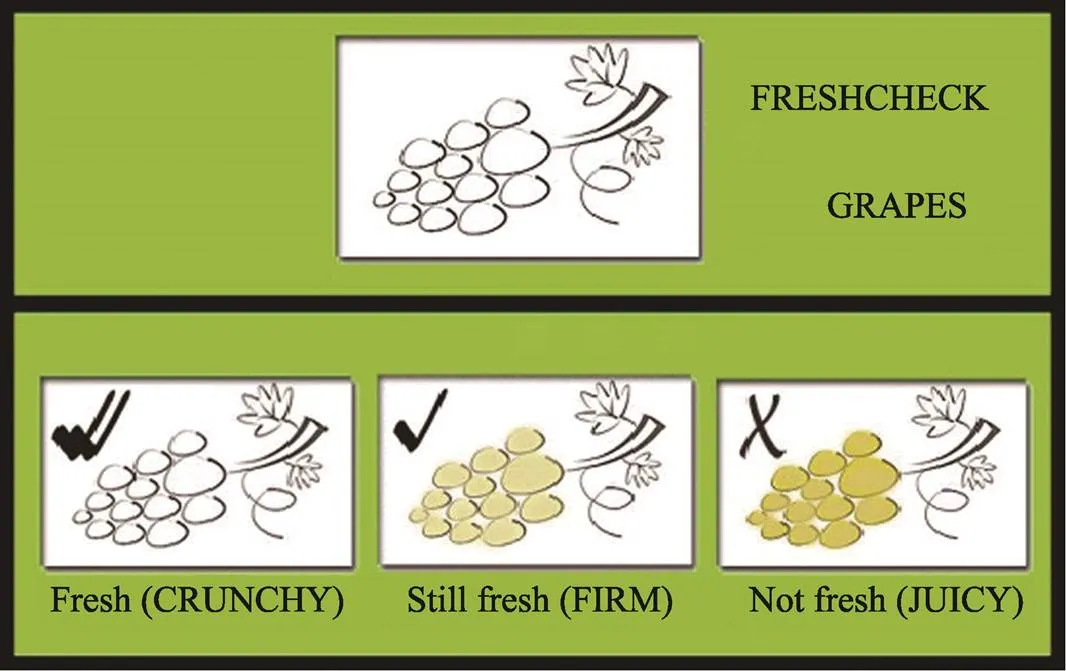

葡萄在收获后成熟过程中,产生各种挥发性化合物,比较典型的有乙烯、有机酸等。但在葡萄成熟过程中,乙烯产量只略有增加,没有典型的呼吸峰值出现[33]。相比之下,有机酸(马来酸和酒石酸)的产量较多,更易被监测到。可以利用该特性进行智能标签的制作,监测葡萄果实新鲜度[48-53]。例如,一种基于氯酚红(Chlorophenol Red,CPR)的葡萄新鲜度智能指示标签,与包装顶空的挥发性有机酸反应后,标签颜色变化指示葡萄新鲜程度。随着葡萄逐渐成熟,包装顶空挥发性有机酸增加,CPR与挥发性有机酸反应后,指示标签由白色变成米色,最后变成黄色。如图2所示[54]。

图2 基于CPR的葡萄新鲜度指示标签

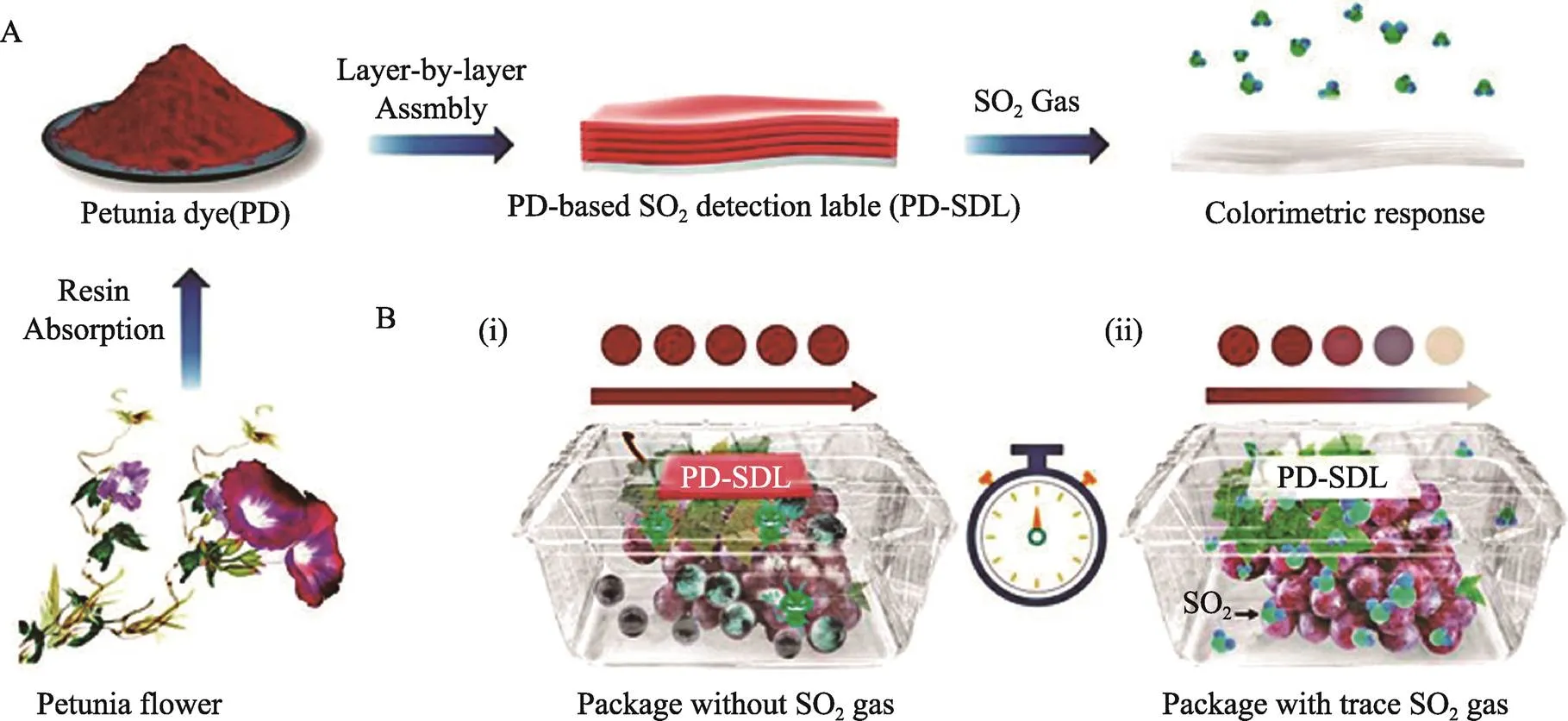

由于葡萄保鲜包装广泛使用SO2保鲜剂,因此针对包装内部SO2含量进行检测,同样能够对葡萄质量进行实时预测。例如,从天然矮牵牛花中提取的矮牵牛染料能够与SO2反应,染料中牵牛花色素与SO2溶于水产生的亚硫酸氢根反应,染料颜色由鲜红色逐渐褪变为无色,比色响应高度敏感,色差可达74.8,容易被肉眼观测。若包装内部仍存在SO2,则标签发生褪色,葡萄较长时间保持新鲜;而包装内部不存在SO2时,标签保持红色,葡萄会在短时间发生变质。因此,该指示标签可用于检测SO2含量,进而预测葡萄的新鲜度[55]。

图3 牵牛花基SO2检测标签示意图

注:A过程为牵牛花基SO2检测标签制备工艺及其对SO2气体的比色响应; B过程为SO2气体不存在(i)与微量存在(ii)时,葡萄新鲜度和指示标签颜色变化。

2.4.2 RFID智能包装

无线射频(Radio Frequency Identification,RFID)技术能够实现非接触性数据自动识别和交换,且操作简单,无须人工,目前在产品包装上已有应用[55-59]。例如一种葡萄生产-销售全过程追溯系统,通过对葡萄生产厂家、产地、产品种类、采摘日期、包装日期等信息,对电子产品编码、全球贸易项目代码、业务批次编码和追溯码等进行设计,以二维码形式在产品外包装上进行印刷。通过手机客户端扫描二维码,链接到溯源系统中可以查询生产信息、仓储管理、运输管理、销售管理、质量安全等内容,有利于消费者、生产厂家、销售企业以及监管部门等对产品进行实时追溯,对偶发性事故进行溯源调查,提高葡萄质量安全性,节约时间、降低成本[55-60]。消费者同样可以利用手机,电脑等设备,扫描识别葡萄外包装二维码,追踪检测质量安全性能,而优质葡萄的农产品有机认证等信息也存放于条码中心数据库中。通过条码查询可以获得农产品化验报告和参数,利于消费者进行购买选择[61]。

3 前景展望

围绕鲜食葡萄进行的包装技术研究日渐成熟,包括充气袋缓冲包装、SO2保鲜剂、无线射频智能包装在内的多种技术已投入实际生产中,且效果良好。

未来葡萄贮运保鲜包装技术需围绕现存问题进行改进:对缓冲包装进一步优化,提高减振缓冲效果,减少难降解塑料的使用;气调包装与活性包装有机结合,针对葡萄的不同品种、不同特性,细化包装材料和保鲜剂的选择与使用,并避免包装材料和所用试剂的分子迁移影响葡萄品质;智能包装则需要进一步提升对市场的适应性,保证智能标签的准确性、葡萄生产信息系统的稳定性等。

葡萄贮藏与运输全过程所使用的4类包装技术,在未来发展中仍需通过开发新材料、新结构、新方法来提升包装效果,解决葡萄脱粒、损伤、果梗褐变、果实霉烂等问题,进一步延长葡萄货架寿命,提升经济效益。

4 结语

葡萄物流运输和贮藏保鲜过程中采用的4类包装技术:缓冲包装、气调包装、活性包装、智能包装,在解决葡萄的脱粒、损伤、果梗褐变、霉烂等问题上能够起到较为理想的效果,并且部分包装方法已经投入市场。这些方法作用于葡萄运输、仓储、销售的全过程,大大提升了葡萄的商品价值。目前,不断地涌现出性能更好、成本更低、更加实用的新技术,在经过市场检验后,能够更加适应葡萄的仓储营运,保证了产品品质,并给消费者带来更好的消费体验。

[1] 肖越, 武佩, 王顺喜, 等. 葡萄贮运过程中跌落与振动损伤的试验分析[J]. 包装工程, 2019, 40(5): 9-18.

XIAO Yue, WU Pei, WANG Shun-xi, et al. Experimental Analysis of Grape Falling and Vibration Damage during Storage and Transportation[J]. Packaging Engineering, 2019, 40(5): 9-18.

[2] 徐垚, 张哲, 董丽玮, 等. 贮藏过程中葡萄保鲜方法研究进展[J]. 冷藏技术, 2017, 40(4): 56-59.

XU Yao, ZHANG Zhe, DONG Li-wei, et al. Research Progress of Preservation of Grapes in Store[J]. Cold Storage Technic, 2017, 40(4): 56-59.

[3] 程杨, 唐谦, 刁源, 等. 智能包装模式对电商配送“夏黑”葡萄贮运保鲜效果的影响[J]. 西南大学学报(自然科学版), 2020, 42(10): 88-95.

CHENG Yang, TANG Qian, DIAO Yuan, et al. Effect of Intelligent Packaging Mode on Storage and Storage of "Xiahei" Grape[J]. Journal of Southwest University (Natural Science), 2020, 42(10): 88-95.

[4] 王剑功, 褚伟雄, 吴剑. 葡萄电商运输工艺关键技术研究[J]. 食品科技, 2020(1): 62-68.

WANG Jian-gong, CHU Wei-xiong, WU Jian. Research on Key Technologies of Grape E-Commerce Transportation Technology[J]. Food Science and Technology, 2020(1): 62-68.

[5] 张玉. 生鲜电商物流效率评价体系研究[D]. 北京: 首都经济贸易大学, 2017: 14-16.

ZHANG Yu. Research on the Evaluation System Of Fresh E-commerce Logistics Efficiency[D]. Capital University of Economics and Business, 2017: 14-16.

[6] 刘平, 高德政, 王春颖, 等. 鲜食葡萄袋中袋包装装置设计与试验[J]. 农业机械学报, 2023, 54(1): 376-384.

LIU Ping, GAO De-zheng, WANG Chun-ying, et al. Design and Experiment of Bag-in-Bag Packaging Device for Fresh Grapes[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(1): 376-384.

[7] HEJAZI Z, NAWAKHT N A, HEDAYAT Y M, et al. Styrofoam Packaging as Alternative of the Afghan Traditional "Gangina" Container to Extend Quality of 'Taifi' Grapes in Room Temperature Storage[J]. Journal of Packaging Technology and Research, 2023, 7: 35-41.

[8] 赵曼如, 胡文忠, 于皎雪, 等. 气调包装在鲜切果蔬保鲜方面的应用进展[C]// 中国食品科学技术学会. 中国食品科学技术学会第十六届年会暨第十届中美食品业高层论坛论文摘要集, 2019: 2.

ZHAO Man-ru, HU Wen-zhong, YU Jiao-xue, et al. The Application Progress of Modified Atmosphere Packaging In the Preservation of Fresh-cut Fruits and Vegetables[C]// Abstracts of the 16th Annual Conference of the Chinese Society of Food Science and Technology and the 10th Sino-US Food Industry High-level Forum, 2019: 2.

[9] 张雪丹, 杨娟侠, 木志杰, 等. 温度对自发气调包装贮藏“美早”樱桃品质的影响[J]. 山东农业科学, 2018, 50(11): 143-147.

ZHANG Xue-dan, YANG Juan-xia, MU Zhi-jie, et al. Effect of Temperature on Quality of Meizao Cherry Fruit Stored with MAP[J]. Shandong Agricultural Sciences, 2018, 50(11): 143-147.

[10] 梁洁玉, 朱丹实, 冯叙桥, 等. 果蔬气调贮藏保鲜技术研究现状与展望[J]. 食品安全质量检测学报, 2013, 4(6): 1617-1625.

LIANG Jie-yu, ZHU Dan-shi, FENG Xu-qiao, et al. Status and Prospects on Modified Atmosphere Storage Technology of Fruits and Vegetables[J]. Journal of Food Safety & Quality, 2013, 4(6): 1617-1625.

[11] 张昭, 田全明, 魏佳, 等. 气调微孔膜包装技术在鲜食葡萄贮运中的应用[J]. 包装工程, 2021, 42(17): 76-87.

ZHANG Zhao, TIAN Quan-ming, WEI Jia, et al. Application of Modified Air Microporous Film Packaging Technology in Storage and Transportation of Fresh Table Grapes[J]. Packaging Engineering, 2021, 42(17): 76-87.

[12] 王洋样. 聚乳酸呼吸包装膜对巨峰葡萄花色苷的保护及葡萄保鲜效果的研究[D]. 内蒙古: 内蒙古农业大学, 2022: 20-56.

WANG Yang-yang. Study on the Protection of Anthocyanin in Kyoho Grapes by Poly(L-lactic acid) Breathable Packaging Film and Its Preservation Effect on Grape Freshness[D]. Inner Mongolia: Inner Mongolia Agricultural University, 2022: 20-56.

[13] CHEN S J, WANG H O, FU Q Q, et al. Prediction of Plastic Film Thickness Based on gas Permeability and Validation with 'Kyoho' Table Grapes for Optimal Modified Atmosphere Packaging[J]. Packaging Technology and Science, 2018, 31(7): 491-497.

[14] 关文强, 张华云, 刘兴华, 等. 葡萄贮藏保鲜技术研究进展[J]. 果树学报, 2002, 19(5): 326-329.

GUAN Wen-qiang, ZHANG Hua-yun, LIU Xing-hua, et al. Advances in Research on the Storage of Table Grapes[J]. Journal of Fruit Science, 2002, 19(5): 326-329.

[15] SABIR F K, UNAL S, SABIR A. Postharvest Aloe vera Gel Coatings Delay the Physiological Senescence of 'Alphonse Lavallée' and 'Red Globe' Grapes During Cold Storage as an Alternative to SO2[J]. Erwerbs-Obstbau, 2022, 11(1): 1-10.

[16] CHEN Yan-pei, LI Zhen-biao, ETTOUMI F E, et al. The Detoxification of Cellular Sulfite in Table Grape under SO2Exposure: Quantitative Evidence of Sulfur Absorption and Assimilation Patterns[J]. Journal of Hazardous Materials, 2022, 439: 129685.

[17] 田静, 薛美昭, 仪慧兰. SO2保鲜剂对玫瑰香葡萄灰霉菌的抑制作用[J]. 食品工业科技, 2018, 39(10): 298-302.

TIAN Jing, XUE Mei-zhao, YI Hui-lan. Inhibitory Activity of Sulfur Dioxide Preservative on Botrytis Cinerea of Muscat Hamburg Table Grapes[J]. Science and Technology of Food Industry, 2018, 39(10): 298-302.

[18] 王世军. 二氧化硫类防腐杀菌剂在葡萄保鲜中的应用[J]. 保鲜与加工, 2015, 15(2): 1-6.

WANG Shi-jun. Application of Sulfur Dioxide Antiseptic and Bactericide in Grape Preservation[J]. Storage and Process, 2015, 15(2): 1-6.

[19] YUAN Y, WEI J, XING S, et al. Sulfur Dioxide (SO2) Accumulation in Postharvest Grape: The Role of Pedicels of Four Different Varieties[J]. Postharvest Biology and Technology, 2022, 190: 111953.

[20] 王凤超. 二氧化硫处理对鲜食葡萄贮藏病害及生理的影响[D]. 乌鲁木齐: 新疆农业大学, 2013: 20-58.

WANG Feng-chao. Effects of Sulfur Dioxide Treatment on Storage Diseases and Physiology of Table Grapes[D]. Urumqi: Xinjiang Agricultural University, 2013: 20-58.

[21] 贾晓昱, 杨维巧, 潘艳芳, 等. 红提葡萄SO2脉冲式防腐保鲜技术[J]. 包装工程, 2019, 40(9): 22-27.

JIA Xiao-yu, YANG Wei-qiao, PAN Yan-fang, et al. SO2Pulse Preservative and Fresh-Keeping Technology for Red Grape[J]. Packaging Engineering, 2019, 40(9): 22-27.

[22] 魏佳, 张政, 赵芳芳, 等. 鲜食葡萄SO2气体精准熏蒸保鲜控制系统设计[J]. 农业工程学报, 2019, 35(1): 260-268.

WEI Jia, ZHANG Zheng, ZHAO Fang-fang, et al. Design of Sulfur Dioxide Automatic Control Fumigation System for Table Grape Preservation[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(1): 260-268.

[23] 申继增, 吐尔地, 靳涛. 葡萄保鲜片:中国, 1091354C[P]. 2002-09-25.

SHEN Ji-Zeng, TU Er-di, JIN Tao. Long Acting Antistaling Tablet for Grapes: China, 1091354C[P]. 2002-09-25.

[24] 吕昌文. 葡萄保鲜剂和生产方法: 中国, 1099833C[P]. 2003-01-29.

LYU Chang-wen. Fresh-Keeping Agent for Grape and Its Production Method: China, 1099833C[P]. 2003-01-29..

[25] SUN C, CAO J, WANG Y, et al. Ultrasound-Mediated Molecular Self-Assemble of Thymol with 2-Hydroxypropyl- β-Cyclodextrin for Fruit Preservation[J]. Food Chemistry, 2021, 363: 130327.

[26] 焦旋, 高振峰, 冯志宏, 等. 二氧化硫精准释放葡萄保鲜片的研制与应用[J]. 食品工业科技, 2021, 42(6): 297-303.

JIAO Xuan, GAO Zhen-feng, FENG Zhi-hong, et al. Development and Evaluation of Grape Preservative Tablets with Precise Sulfur Dioxide Release[J]. Science and Technology of Food Industry, 2021, 42(6): 297-303.

[27] YOHANAN Z, AMNON L, TATIANA K, et al. Extended Storage of 'Red Globe' Grapes in Modified SO2Generating Pads[J]. Postharvest Biology and Technology, 2008, 50: 12-17.

[28] LUO J, GU Y, YUAN Y, et al. Lignin-Induced Sacrificial Conjoined-Network Enabled Strong and Tough Chitosan Membrane for Food Preservation[J]. Carbohydrate Polymers, 2023, 33: 120876.

[29] 王亚蒙, 赵霞, 唐彬, 等. 1-MCP熏蒸对甘薯茎尖的保鲜效果[J]. 食品与机械, 2019, 35(6): 139-144.

WANG Ya-meng, ZHAO Xia, TANG Bin, et al. Effect of 1-MCP on the Quality of Sweet Potato Leaves[J]. Food & Machinery, 2019, 35(6): 139-144.

[30] 徐方旭. 1-MCP结构相似物调节香蕉和草莓采后成熟和衰老的分子生理机制[D]. 沈阳: 沈阳农业大学, 2014: 20-65.

XU Fang-xu. Molecular and Physiological Mechanism of Structural Analogues of 1-MCP to Regulate Postharvest Ripening and Senescence of Banana and Strawberry Fruits[J]. Shenyang Agricultural University, 2014: 20-65.

[31] 孙思胜, 张晓娟, 马传贵, 等. 1-MCP结合自发气调包装对夏黑葡萄保鲜效果[J]. 食品研究与开发, 2020, 41(22): 93-99.

SUN Si-sheng, ZHANG Xiao-juan, MA Chuan-gui, et al. Effects of 1-MCP Coupling with Modified Atmosphere Package Treatment on Storage of Summer Black Grape[J]. Food Research and Development, 2020, 41(22): 93-99.

[32] GIULIANA G, VALERIA B, LUIGI V, et al. Active Packaging for Table Grapes: Evaluation of Antimicrobial Performances of Packaging for Shelf Life of the Grapes under Thermal Stress[J]. Food Packaging and Shelf Life, 2020, 25: 100545.

[33] FATIMA S, MIR M I, KHAN M R, et al. The Optimization of Gelatin Extraction from Chicken Feet and the Development of Gelatin Based Active Packaging for the Shelf-Life Extension of Fresh Grapes[J]. Sustainability, 2022, 14(13): 7881.

[34] DOPAZO V, LUZ C, QUILES J M, et al. Potential Application of Lactic Acid Bacteria in the Biopreservation of Red Grape from Mycotoxigenic Fungi[J]. Journal of the Science of Food and Agriculture, 2022, 102(3): 898-907.

[35] NIU X, DUAN X, LYU S, et al. Antifungal Activity of Ginsenoside CK Against Botrytis Cinerea by Targeting Sterol 14α-Demethylase Cytochrome P450 (CYP51) and the Application on Cherry Tomato Preservation[J]. Postharvest Biology and Technology, 2023, 199: 112294.

[36] XIA K, ZHANG C, ZHANG X, et al. Control of Grey Mould by Sodium Diacetate Treatments and Its Effects on Postharvest Quality of 'Red Globe' Grapes[J]. Physiological and Molecular Plant Pathology, 2023: 102014.

[37] ZHENG Y, JIA X, ZHAO Z, et al. Innovative Natural Antimicrobial Natamycin Incorporated Titanium Dioxide (Nano-TiO2)/Poly (Butylene Adipate-co-Terephthalate) (PBAT)/Poly (Lactic Acid)(PLA) Biodegradable Active Film (NTP@ PLA) and Application in Grape Preservation[J]. Food Chemistry, 2023, 400: 134100.

[38] JIANG L L, WANG J B, WANG W H, et al. Effects of Three Essential Oil Fumigation Treatments on the Postharvest Control ofand Their Efficacy as Preservatives of Cherry Tomatoes[J]. Plant Dis, 2023, 107(6): 1874-1882.

[39] LIGUORI G, SORTINO G, GULLO G, et al. Effects of Modified Atmosphere Packaging and Chitosan Treatment on Quality and Sensorial Parameters of Minimally Processed cv. 'Italia'table Grapes[J]. Agronomy, 2021, 11(2): 328.

[40] ADMANE N, GENOVESE F, ALTIERI G, et al. Effect of Ozone or Carbon Dioxide Pre-Treatment during Long-Term Storage of Organic Table Grapes with Modified Atmosphere Packaging[J]. LWT-- Food Science and Technology, 2018, 98: 170-178.

[41] HUANG X, HONG M, WANG L, et al. Bioadhesive and Antibacterial Edible Coating of EGCG-Grafted Pectin for Improving the Quality of Grapes During Storage[J]. Food Hydrocolloids, 2023, 136: 108255.

[42] MOHAMMED A E, ABDALHALIM L R, ATALLA K M, et al. Chitosan and Sodium Alginate Nanoparticles Synthesis and Its Application in Food Preservation[J]. Rendiconti Lincei. Scienze Fisiche e Naturali, 2023, 34: 415-425.

[43] HUANG L, SUN D W, PU H, et al. Nanocellulose-Based Polymeric Nanozyme as Bioinspired Spray Coating for Fruit Preservation[J]. Food Hydrocolloids, 2023, 135: 108138.

[44] LIU W, KANG S, ZHANG Q, et al. Self-Assembly Fabrication of Chitosan-Tannic Acid/MXene Composite Film with Excellent Antibacterial and Antioxidant Properties for Fruit Preservation[J]. Food Chemistry, 2023, 1: 135405.

[45] NIU X, LIU L, WANG H, et al. Discovery of Novel Photosensitized Nanoparticles as a Preservative for the Storage of Strawberries and Their Activity Against Botrytis Cinerea[J]. LWT, 2021, 145: 111359.

[46] SUN X, ZHOU B, LUO Y, et al. Effect of Controlled-Release Chlorine Dioxide on the Quality and Safety of Cherry/Grape Tomatoes[J]. Food Control, 2017, 82: 26-30.

[47] LIU J, WANG T, HU C, et al. Hydrophobic Chitosan/Salicylic Acid Blends Film with Excellent Tensile Properties for Degradable Food Packaging Plastic Materials[J]. Journal of Applied Polymer Science, 2022, 139(43): 53042.

[48] SONG Z, PANG Q, LU S, et al. Transcriptomic and Metabolmic Approaches to Counter the Effect of Botrytis Cinerea in Grape Berry with the Application of Nitric Oxide[J]. Scientia Horticulturae, 2022, 296: 110901.

[49] WU P, XIN F, XU H, et al. Chitosan Inhibits Postharvest Berry Abscission of 'Kyoho' Table Grapes by Affecting the Structure of Abscission Zone, Cell Wall Degrading Enzymes and SO2Permeation[J]. Postharvest Biology and Technology, 2021, 176: 111507.

[50] CHETIA J, ADHIKARY P, DEVI L M, et al. Extraction of Essential Oil from Assam Lemon Peels and Its Incorporation in Chitosan Based Coating for Maintaining Grape Quality[J]. Sustainable Chemistry and Pharmacy, 2023, 32: 101034.

[51] XIE Y, ZHU J, LIU H, et al. In Vitro Antifungal Activity of Essential Oils Against Botrytis Cinerea of Postharvest Grapes[J]. IOP Conference Series: Earth and Environmental Science, 2022, 1035(1): 012008.

[52] CHOUDHARY S, SHARMA K, MISHRA P K, et al. Development and Characterization of Biodegradable Agarose/Gum Neem/Nanohydroxyapatite/Polyoxyethylene Sorbitan Monooleate Based Edible Bio-Film for Applications Towards a circular economy[J]. Environmental Technology & Innovation, 2023, 29: 103023.

[53] RUAN X, LI P, WANG C, et al. Synergistic Antibacterial Activity of Chitosan Modified by Double Antibacterial Agents as Coating Material for Fruits Preservation[J]. International Journal of Biological Macromolecules, 2022, 222: 3100-3107.

[54] KUSWANDI B, MURDYANINGSIH E A. Simple on Package Indicator Label for Monitoring of Grape Ripening Process Using Colorimetric pH Sensor[J]. Journal of Food Measurement and Characterization, 2017(11): 2180-2194.

[55] YUAN Liu-bo, GAO Meng, XIANG Hu-bing, et al. A Biomass-Based Colorimetric Sulfur Dioxide Gas Sensor for Smart Packaging[J]. ACS Nano, 2023, 17(7): 6849-6856.

[56] FRAIWAN M, FAOURI E, KHASAWNEH N. Multiclass Classification of Grape Diseases Using Deep Artificial Intelligence[J]. Agriculture, 2022, 12(10): 1542.

[57] WANG Y, WEI C, SUN H, et al. Design of Intelligent Detection Platform for Wine Grape Pests and Diseases in Ningxia[J]. Plants, 2022, 12(1): 106.

[58] 彭哲. 面向物联网的RFID与条形码混合应用的蔬菜生产管理与追溯系统[D]. 广州: 华南理工大学, 2012: 25-55.

PENG Zhe. Vegetables Production Management and Tracing System Using RFID and Barcode technology for the Internet of Things[D]. Guangzhou: South China University of Technology, 2012: 25-55.

[59] 边吉荣, 宋丽亚, 蔺金元. 基于RFID的危险品运输安全管理系统设计[J]. 宁夏工程技术, 2010, 9(3): 242-245.

BIAN Ji-rong, SONG Li-ya, LIN Jin-yuan. Design of Transportation Safety Management System for Dangerous Goods Based on RFID[J]. Ningxia Engingeering Technology, 2010, 9(3): 242-245.

[60] 陈宏君. 基于RFID的衡阳市珠晖葡萄质量安全溯源系统研究[D]. 长沙: 中南林业科技大学, 2019: 20-59.

CHEN Hong-jun. Research on Quality and Safety Traceability System of Zhuhui Grape in Hengyang City Based on RFID[D].Changsha: Central South University of Forestry & Technology, 2019: 20-59.

[61] 李万富. 物联网技术在葡萄生产管理中的应用研究[D]. 武汉: 华中师范大学, 2018: 31-42.

LI Wan-fu. Research on the Application of Internet of Things Technology in Grape Production Management[D]. Wuhan: Central China Normal University, 2018: 31-42.

Research Status and Prospect of Grape Logistics, Storage and Preservation Packaging Technology

LI Bao-qing1, LIANG Xin2, WEI Wan-qi1, YAO Gang2, LI Yu-cheng1, YAN Rui-xiang1*

(1. College of Light Industry Science and Engineering, Tianjin University of Science & Technology, Tianjin 300222, China; 2. Shenzhen SF Taisen Holding (Group) Co., Ltd., Guangdong Shenzhen 518000, China)

The work aims to classify and systematically introduce packaging technologies used in logistics transportation, storage and preservation of grapes, analyze their research application and packaging effect, and promote the improvement of storage, transportation and preservation packaging technology of grapes. In view of the problems prone to occur in storage, transportation and preservation of grapes, this paper introduced the research and application status of packaging technologies such as buffer packaging, modified atmosphere packaging, active packaging and intelligent packaging, analyzed the advantages of different packaging technologies, and discussed possible development directions in the future. By improving the cushioning and vibration reduction effect of transportation packaging, accurately regulating the internal atmosphere of modified atmosphere packaging, controlling the release of pharmaceuticals and molecular migration in active packaging, improving the accuracy of intelligent indication tags, and ensuring the stability of the RFID intelligent packaging system, the combination of various packaging technologies can effectively maintain the quality of grapes in storage and transportation and prolong their shelf life.

grapes; logistics; storage; preservation; packaging technology

S609+.3

A

1001-3563(2023)23-0094-09

10.19554/j.cnki.1001-3563.2023.23.011

2023-04-29

顺丰横向合作项目(90202205240357);大学生创新创业项目(202310057021)

责任编辑:曾钰婵