生物基包装材料的制备及其在果蔬保鲜中应用

潘洵,肖乃玉,胡心宽,仲芸芸,罗文翰,陈国健*,万小荣,肖更生

生物基包装材料的制备及其在果蔬保鲜中应用

潘洵1a,2,3,肖乃玉1a,2,3,胡心宽1a,2,3,仲芸芸1a,2,3,罗文翰1a,2,3,陈国健1a,2,3*,万小荣1b,肖更生1a,2,3

(1.仲恺农业工程学院 a.轻工食品学院 b.农业与生物学院,广州 510225; 2.广东省高校中央厨房绿色制造开发中心,广州 510225; 3.农业农村部岭南特色食品绿色加工与智能制造重点实验室,广州 510225)

近年来,随着消费水平及消费形态的发展,果蔬包装,尤其是鲜切果蔬包装的消费量迅速攀升。相较于传统石油基类包装材料,生物基包装材料拥有环境友好、可持续等特点,是未来果蔬包装材料发展的重要方向。本文拟综述国内外生物基包装材料的研究进展及其在果蔬保鲜中应用,为后续相关领域的研究与应用提供理论参考。首先介绍果蔬的保鲜机制及其包装需求,随后分类论述不同种类生物基材料的特性及制备方式,最后阐述相关生物基材料在果蔬包装中的应用。总结了生物基包装材料在果蔬包装领域的研究进展,并对其未来发展趋势进行展望。

生物基材料;包装材料;果蔬保鲜

中国是世界上最大的水果消费国,近年来水果消费量一直保持稳步增长[1]。随着消费水平及消费观念的提升,我国果蔬消费模式正从粗放式、低端化迈向精细化、个性化,这也推动着我国果蔬包装市场的快速增长。尤其是经过预先洗切等流程后包装销售的鲜切果蔬,极大提升了消费者食用的便利性,近年来销售量增长尤为迅速。

然而,主流的果蔬包装材料仍十分依赖于以化石资源为原料的传统塑料制品(如塑料薄膜、包装袋、盒、托盘等)。随着近年来人们对“能源危机”“白色污染”等问题的日渐关注,使用生物基包装材料替代化石类包装材料的呼声越来越多[2-3]。此外,通过改性、掺杂等手段,生物基材料可获得某些独特的保鲜性能,从而有效延长果蔬保质期,以减少果蔬在储运销售过程中的损耗[4-7]。

本文先对果蔬的保鲜机制及包装需求展开介绍,进而分类论述了不同种类生物基包装材料的特性及制备方式,并阐述了相关生物基材料在果蔬包装中的应用及研究进展。本文最后总结了生物基果蔬包装材料的研究进展,并展望了其未来趋势。

1 果蔬品质影响因素

市面销售的果蔬包装,可分为3类:蔬菜类(白菜、莴笋、茄子、土豆等),水果类(圣女果、荔枝、芒果等),食用菌类(蘑菇、香菇、木耳等)

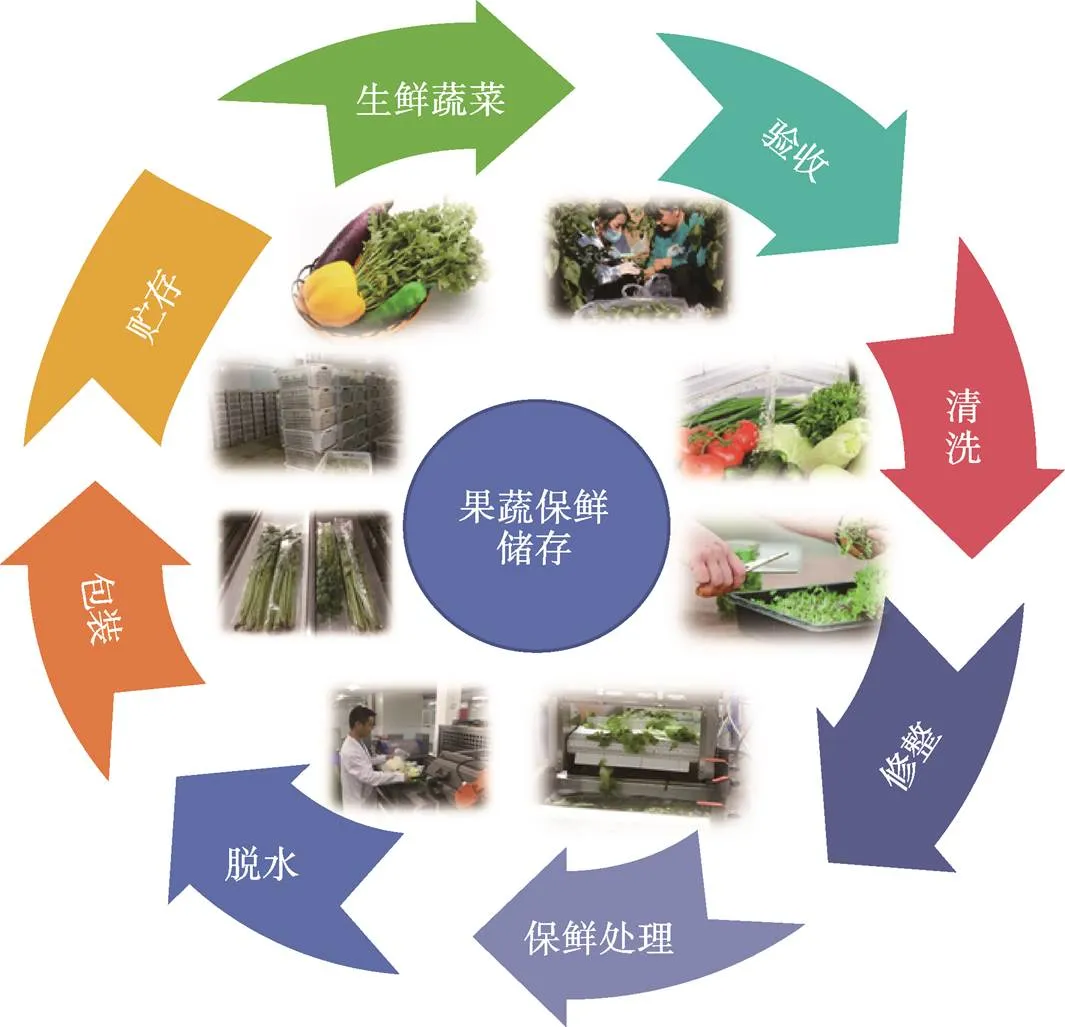

果蔬摘收后极易腐烂,即使是对其进行最低限度的加工,如切割和去皮,也会导致损伤点周围的细胞内容物泄漏,从而增加微生物感染的风险。蔬菜采后还会因衰老代谢及微生物的侵染引起软化褐变、脱帮失水[8],或者在采后运输、加工、贮藏过程会受到冲击、挤压、划伤等,致使商品的价值降低[8-9]。关于果蔬包装加工-储运-销售流程见图1所示。

1.1 生理生化因素

达到食用标准后进行采收的果蔬一般都到达了成熟期,随着其组织、器官的老化,进入衰老期,其机体免疫力下降,糖分、维生素C等营养物质被大量消耗,组织开始水解。果蔬往往还会发生酶促褐变,除了造成颜色变化、风味衰减和营养损失,甚至可能产生有害物质。一般,可通过低温、气调、添加抗氧化剂等手段延缓其生理生化衰变[10-11]。

1.2 机械损伤

果蔬的机械损伤(如刷洗、表面擦伤和割伤等)会加速其水分和维生素C的流失,从而增加对腐烂病原体的易感性。去皮、修整等步骤会不可避免地造成机体的机械损伤,破坏组织细胞的表皮保护层,诱导或加速生理生化变化,导致失水、代谢失调等现象,让病原微生物和化学污染物有机可乘[12]。因此,可采用缓冲包装,如纸箱、托盘、泡沫等,对易损果蔬进行保护,降低机械损伤的发生[13]。

图1 果蔬包装加工-储运-销售流程

1.3 微生物因素

微生物因素是影响果蔬品质的重要外界因素之一,导致食品变质或污染的主要微生物有大肠杆菌、酵母、李斯特菌群、霉菌、金黄色葡萄球菌、沙门氏菌等[14]。被微生物侵染后,果蔬细胞组织结构受到破坏,会导致果蔬变质发霉,甚至产生有毒代谢产物,使其商品价值急剧降低甚至丧失。控制措施除了传统的消毒剂、气调技术和储存条件调控技术以外,还可使用如高压处理、辐照、添加植物提取物等果蔬保鲜新技术,以满足其在市场上的需求[15]。也可采用精油等其他生物活性成分,抑制微生物的生长繁殖,以延长果蔬的保质期[16]。

1.4 氧气

往往鲜切后的果蔬中的酶依然保有活性,会存在有氧呼吸和无氧呼吸。氧气会影响呼吸作用,从而影响果蔬的腐变速率[10]。果蔬保鲜常采用降低O2浓度,增大CO2浓度的方式来减弱鲜切果蔬呼吸作用引起的发酵与腐烂,降低微生物的生长繁殖速度和乙烯的生成量,从而延长果蔬货架期。

1.5 温度

温度是影响果蔬贮藏品质的重要因素。低温有利于降低果蔬产品的呼吸速率和乙烯释放量,能够使微生物的活动受到抑制,因此低温是果蔬保鲜常用手段之一[17]。对于部分果蔬(例如柿子、柑橘、梨、苹果等),降低温度也能减少水分蒸腾作用,从而延长其货架期。

2 生物基包装材料的介绍与制备

生物基材料往往指利用可再生生物质(例如:谷物、秸秆、动物表壳或皮毛废弃物等),使用生物、化学、物理等处理方法制造出的新型材料。如图2所示,果蔬包装常用的生物基材料可分为以下几类。

图2 果蔬包装常用的生物基材料

2.1 多糖类

多糖在自然界中来源广泛,原料廉价且易得,并且具有良好的生物相容性,目前开发最为广泛。常用于果蔬保鲜的多糖有淀粉、纤维素、壳聚糖等。

植物源中淀粉是一种大量可用、廉价、可生物降解的天然多糖。纯淀粉基膜往往存在机械强度弱、阻隔性差、阻水性差等缺陷[18]。为此,在利用淀粉制备包装材料过程中,往往需要添加其他组分以改善其性能,如添加明胶等疏水性组分,增强薄膜阻水性[19],或通过加入甘油等塑化剂,改善所得薄膜的脆性[20]。

纤维素一般从木材、麦草、稻草、棉花、芦苇等原料中制取,其优点在于易降解、可再生和无毒性。纤维素广泛用于制备纸基包装材料。近年来,利用纤维素及其衍生物开发新型包装材料的工作层出不穷,但由于纤维素成膜性较差,结晶度较高,对气体的阻隔性差等特点,在开发新型纤维素包装材料的过程中,往往需要进行一定改性或复合。如将改性纤维素与聚己二酸/对苯二甲酸丁二醇酯(Poly (butyleneadipate-co-terephthalate),PBAT)共混后,通过模压法制成复合薄膜,以解决单一纤维素存在的缺陷[21]。

黄原胶一般是由玉米淀粉经过发酵生产出的一种多糖,因含有羟基和氨基等亲水基团,具有良好的成膜性能,且易分散在水中,可用作可食用涂层的聚合物基质[22]。黄原胶、氧化锌纳米颗粒、羧甲基纤维素、果胶与海藻酸钠共同制成可食性涂层,并应用于果蔬保鲜[23]。

壳聚糖一般从虾皮和蟹壳等虫类壳中提取,有良好的可降解性和成膜性能,且其本身就具有较好的抑菌性能[24]。单一壳聚糖制成的薄膜力学性能较差,常常与其他天然基质结合使用,如使用纤维素纳米晶作为增强材料,与壳聚糖共混制成生物基复合涂层,可有效提升薄膜的机械强度、氧阻隔性能、热稳定性、抗菌活性和疏水性[25]。

2.2 蛋白质类

常见的蛋白质来源有植物蛋白(大豆蛋白、花生蛋白、花玉米蛋白等)和动物蛋白(乳清蛋白、明胶、酪蛋白等)。因为蛋白质分子带有较多活性基团,可提升其与其他组分复合时的组分间相互作用及相容性[26],因此蛋白质也常与其他生物基材料复合使用。如在酰化大豆分离蛋白中添加木质素纳米颗粒作为增强组分,以提高包装材料的阻水性及机械强度[27]。

明胶是一种在动物(猪、牛、羊等)皮骨或软骨中提取的蛋白质,含有丰富的羟基、羧基等亲水性基团,具有较好的水溶性,易于通过溶液流延法制膜。如以鱼明胶、β-环糊精、TiO2为等材料共溶于水中,通过溶液流延法制备了具有乙烯清除、抑制微生物功能的复合薄膜,并用于西红柿的保鲜包装中[28]。

酪蛋白可以从牛乳蛋白中提取,具有较好的成膜性、阻水性、生物降解性、气体阻隔性,在作为包装薄膜或涂层时非常有优势[29]。常通过酪蛋白常与其他生物基材料复合,改善材料的气体阻隔性能[30]。

2.3 其他常用生物质高分子材料

聚乳酸(Polylactic Acid,PLA)是广泛使用的可降解塑料之一,可从小麦、水稻、玉米等天然的植物中利用其根茎或者叶片等有机废弃部分作为原料,通过发酵聚合获得[31]。PLA具有良好的硬度和热塑性,适用于吹塑、热塑等常规加工手段大规模制备,但热性能差、脆性大、阻隔性不高,往往需要改性或复合,才能在性能上达到传统石油基聚合物的水平。Mizielińska等[32]以溶液流延法制备了氧化锌纳米粒子掺杂的PLA复合薄膜,纳米粒子的加入能有效提升PLA薄膜的力学性能。

聚丁二酸丁二醇酯(Poly(Butylene Succinate),PBS)可以通过葡萄糖、乳糖、纤维素等发酵制备,有着耐热、柔软、可降解、兼容性好、可低温热封等优点,但透明度较低、撕裂强度不高[33]。为此,经常需要与其他聚合物共混改性,PBAT与PBS共混改性是其中常用的手段之一。PBS的加工性能好,常用的成型加工方法几乎都适用于PBS的加工。

聚羟基脂肪酸酯(Polyhydroxyalkanoates,PHA)存在于细菌细胞等微生物细胞中,也可以从烟草、马铃薯、棉花、油菜、玉米、苜蓿等植物中提取,具有较好的力学性能、加工性能、阻隔性、生物降解性、生物相容性[6]。PHA缺点在于结晶度高达80%、热敏感性差、

力学性能较差、耐溶剂性差、降解期长等,需要复合改性以扩大其应用领域。如与PLA等其他聚合物共混,可改善其力学性能[34];或加入果胶以及废弃咖啡渣提取物等其他生物基组分,缩短其降解时长[35]。

3 生物基材料在果蔬包装中的应用

在果蔬包装领域,生物基材料的应用形式主要有薄膜、可食用涂层、纸类、智能包装等,具体进展见表1。

表1 果蔬包装中生物基材料的包装形态选用和功能

3.1 生物基包装薄膜

3.1.1 气调包装膜

果蔬在采后一段时间内仍保有新陈代谢及呼吸活性,通过调节包装微环境内的气体种类、浓度和湿度等环境因素,并对氧气、CO2和乙烯等关键气体调控,可减缓包装果蔬代谢速率,抑制包装内微生物生长,从而延长其保质期[52]。Wu等[10]采用PLA和本征微孔聚合物(Polymer of Intrinsic Microporosity-1,PIM-1)制备了PIM-1/PLA平衡气调包装膜,通过对材料的透湿和透气性能进行调控,在保鲜过程中抑制了芒果的呼吸速率,延缓了其品质的变化。此外,在壳聚糖薄膜中加入具有光催化特性的纳米TiO2颗粒,高效分解了包装微环境中乙烯气体,也可减缓果蔬成熟过程,以延长保质期[53]。

3.1.2 抗菌抗氧化薄膜

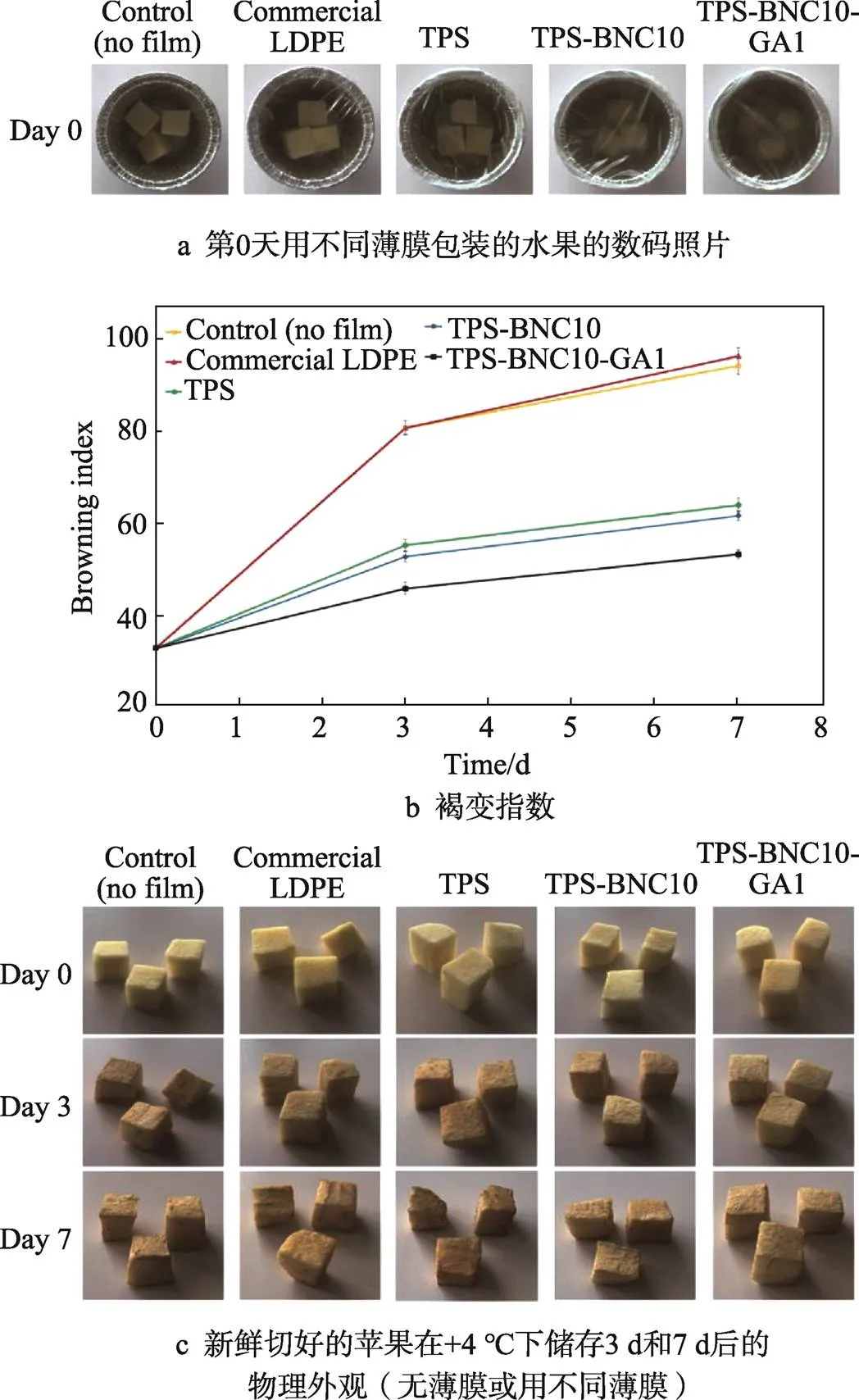

如上文所述,因外界微生物、氧气等导致的生理生化反应,严重威胁着果蔬的品质稳定。基于生物基材料本征或外加的抗菌抗氧化特性,可降低储运过程中包装果蔬的腐败变质。如壳聚糖材料具有本征抗菌特性,与具备光催化活性的氧化锌纳米颗粒复合后,进一步提升了其对大肠杆菌和金黄色葡萄菌的抗性[3];类似的,在PBAT/PBS包装薄膜中添加二氧化钛纳米颗粒,可实现对微生物生长的显著抑制作用,从而延缓了香蕉果实的成熟[33]。茶多酚是具有抗菌抗氧化特性的天然分子,Chen等[11]将其掺入黄原胶/羟丙基甲基维素复合薄膜中,由于茶多酚优秀的抗氧化活性和抗菌性能,可延长鲜切青椒的保质期,且降低保存期内营养成分的下降速率。利用ε-聚赖氨酸的抗菌活性,Zhao等[26]使用静电纺丝的方法制备了掺有聚乙烯醇(Polyvinyl Alcohol,PVA)、ε-聚赖氨酸修饰的大豆分离蛋白纳米纤维膜,对金黄色葡萄球菌等5种微生物有明显的抑制作用,延长了蓝莓在4 °C下的保质期。在细菌纳米纤维素和淀粉制成的薄膜中添加3,4,5-三羟基苯甲酸,可提升薄膜的抗氧化、抗菌和紫外线阻隔性能,对革兰氏阳性金黄色葡萄球菌具有较强抗性,如图3所示,可应用于鲜切苹果保鲜[18]。Zhang等[54]将辣椒素添加至海藻酸钠/普鲁兰多糖复合薄膜中,对大肠杆菌和金黄色葡萄球菌表现出良好的抗菌活性,能够延长果蔬的保质期、抑制细菌的生长。褐藻核叶提取物具有抗菌和抗氧化性,将其添加到明胶与酪蛋白薄膜中,有望用于果蔬保鲜中[55]。金属有机骨架化合物(Metal organic Frameworks,MOFs)是近年来的研究热点,在明胶基底中加入Zn-MOF纳米结构,使薄膜获得优异的抗氧化活性、紫外线吸收和抗菌性能,显示出对微生物具有生长预防的作用[56]。

3.1.3 紫外线阻隔

果蔬在分销和包装的过程中,可能因暴露在紫外线等光照作用下,导致营养成分下降和颜色变化。因此,提升生物基包装材料的紫外阻隔性能,也是实现果蔬有效保鲜的路径。如在PLA/PBS薄膜中,通过添加木薯淀粉可以改善紫外光的阻隔性能,降低薄膜的生产成本,并提高薄膜的降解率[19];利用木质素的紫外吸收特性,对结冷胶、2-羟乙基纤维素(Hetastarch,HEC)复合薄膜进行掺杂,获得近100%的UVB(280~320 nm)防护和90%的UVA(320~400 nm)防护的紫外阻隔薄膜[57]。

图3 不同薄膜之间保鲜效果对比[18]

3.1.4 抗拉伸高阻隔薄膜

常规生物基包装材料的阻隔性能、力学性能并不高,难以有效保护其包装的果蔬产品,通过添加功能组分,提升其拉伸、阻隔等性能,是目前生物基果蔬包装材料应用的研究热点。如通过在PBAT/PBS复合薄膜中加入SiO2、TiO2等纳米颗粒,通过纳米颗粒与聚合物基体间相互作用,显著提升薄膜产品的水蒸气透过率、氧气透过率、拉伸强度和伸长率[33, 58]。此外,添加较低成本的滑石粉,也可显著提升PBAT薄膜的弹性模量与水蒸气阻隔性[59]。

3.2 可食用涂层类

可食用涂层是一种新型的果蔬包装保鲜形式。涂层材料在控制包装内气体成分、微生物繁殖、保障食品品质、延长食品货架期中起到关键性作用。可食用包装涂层的基材有很多,大体可分为4种:多糖基、蛋白质基、脂质基和复合基。

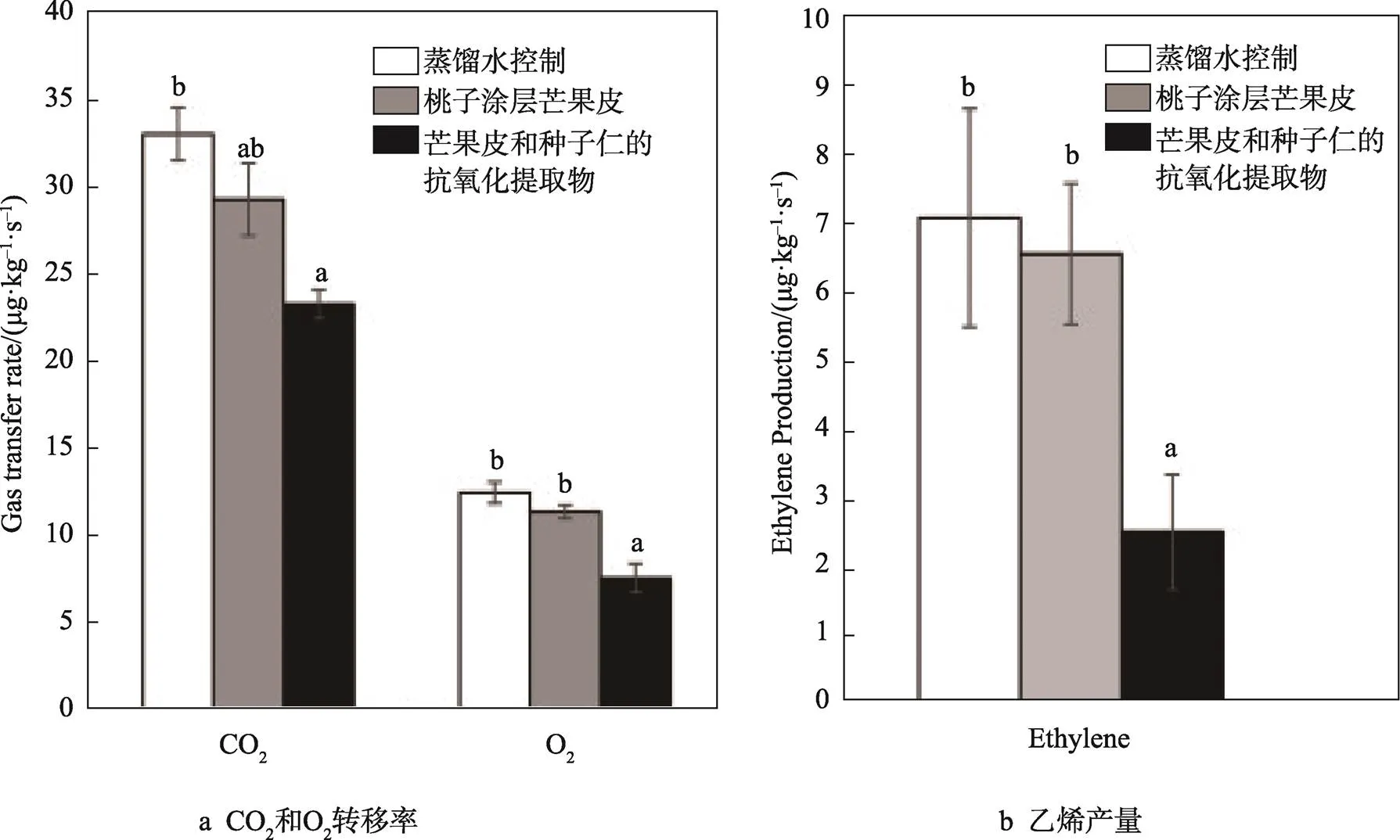

Tabassum等[4]制作了掺杂植物精油的海藻酸盐基食用涂层,用于鲜切木瓜的气调包装,能有效改善质量损失、减缓pH值变化、延迟食用期限等。如图4所示,基于芒果皮和种子仁的抗氧化提取物制备的生物基可食性涂层,可降低桃子的呼吸速率,从而延长桃子的保质期[17]。Kumar等[60-61]用石榴皮提取物与壳聚糖、普鲁兰多糖复合,制备了复合食用涂层,提取物的抗氧化特性能有效减少了果蔬的质量损失及褐变,应用于番茄及甜椒保鲜上,显著提高了其采后的质地、营养物数量和活性。

Rossi-márquez等[62]研究制作了一种基于蛋白质和碳水化合物的多层可食用涂层,其能保持鲜切毛叶番荔枝的总酚醛含量、pH值和糖度值的同时减少了水分损失。Xing等[63]研究发现,将金属NPs掺入食用涂层和薄膜中,然后将其涂在水果和蔬菜上,由于阳离子聚合物或游离金属离子与微生物细胞膜之间的静电相互作用、NPs的光催化反应、游离金属离子作用等,能有效灭杀致腐微生物,从而延长水果和蔬菜的保质期并提高储存质量。

3.3 纸包装类

相较于上述新型生物基包装材料,纸包装材料的应用历史更为悠久,近年来也有不少学者进一步挖掘其在果蔬保鲜中的潜力。常规纸包装材料的耐水性较差,在包装含水量较高的果蔬时,容易因吸水导致力学性能急剧下降。因此,开发出高度疏水的表面对维持纸包装材料结构和防止食材变质是至关重要的。常规解决手段是在纸包装的内表面施加生物基材料作为防水层。如将纳米纤维素(Nanocellulose,NC)[64]、二氧化硅[65-66]、改性木质纤维素[67]、矿物填料[68]等与生物基材料复配获得疏水涂层,对纸质材料进行涂布后,水接触角能达到150°以上,使纸包装材料获得优异的疏水性。此外,通过涂层分子内部的分子间相互作用(如氢键作用、交联作用等),改善涂层的紧密性与韧性,也可进一步提高涂层对水的阻隔性,从而提升涂布后纸包装材料的耐水性[66]。

3.4 果蔬新鲜度指示智能包装材料

果蔬新鲜度指示材料,能对储运销售过程中果蔬的新鲜度实行可视化监控,对果蔬质量变化进行指示预警。天然植物中提取的花青素、姜黄素等分子能对果蔬代谢产生的气体进行响应,从而改变其颜色,实现果蔬新鲜度指示。因生物基材料与上述天然色素分子具有较好的相容性,且无毒安全,常被用于制作新鲜度指示材料的基材。如以蓝莓花青素提取物、果胶、海藻酸钠、黄原胶复合制成一种对pH敏感的生物基薄膜材料,可用于监测蓝莓的新鲜度,进行合理销售安排,以减少蓝莓的浪费[69];将紫薯花青素提取物添加到淀粉/明胶薄膜中,制备的金针菇新鲜度指示标签,能随着金针菇的储存变质,产生绿-紫灰-黄的一系列颜色变化,实现对金针菇新鲜度的指示[70]。

图4 在20 ℃下存储8 d时各类气体的变化[17]

3.5 其他

温度是影响果蔬储运过程质量的关键因素之一,而机械损伤也严重威胁着果蔬的质量安全。发泡材料具有较好的隔热保温与缓冲作用,在果蔬包装中应用广泛。然而常规发泡材料,如聚苯乙烯、聚丙烯、聚氨酯等均是非生物基的,生物基隔热缓冲材料目前研究空间还很大。如以魔芋葡甘聚糖与淀粉制作的气凝胶,因其多孔结构,使其获得了优异的保温、缓冲性能[13];聚丙烯酰胺/聚乙烯醇纳米颗粒水凝胶,通过实现辐射和蒸发冷却的结合效果,保护果实品质免受太阳辐射和高温伤害[71];具有吸湿、隔热、快干以及缓冲功能的3D发泡材料,能提供稳定的水吸附能力和包装保护性,用于水果保鲜包装具有显著效果[72]。

4 结语

随着对能源危机和环境污染的关注度的逐步提高,在包装行业中,以生物基包装材料逐步替代传统石油基包装材料,是更符合“双碳”目标的发展方向。针对果蔬保质期间的质量变化机制与保鲜需求,近年来,基于多糖类、蛋白质类等生物基材料,以及一系列保鲜包装材料被开发并应用。通过掺杂、复合改性等手段,使这些传统生物基材料获得了气调、抗菌抗氧化、高阻隔、高疏水、新鲜度指示等一系列独特且优异的性能,在多种果蔬产品保鲜中获得了显著效果,为该领域的发展提供了重要的参考与指导意义。

美中不足的是,现阶段生物基材料具有成本较高、制备过程较复杂、大规模加工成型手段不足等缺点,这制约着其大规模生产。此外,生物基材料在力学性能、阻隔性能、耐水性能、耐热性能等方面,与传统包装材料仍有较大差距,限制了其应用场合。因此,在生物基材料未来发展上,仍有大量研究工作需要展开。不断改善生物基包装材料的性能(尤其是力学性能及阻隔性能),通过与多种生物质材料复合、材料改性等手段,显著提升其性能,使其能接近乃至超过现有的传统包装材料,以获得更广泛的应用;进一步改进生物质材料的大规模制备工艺,进一步提升其产量并降低制备成本;完善生物质材料回收、后处理工艺,真正实现生物质包装材料全生命周期绿色化;根据生物质包装材料性能特质,开发新型包装形式及包装结构,最大限度扬长避短,发挥生物质材料的应用潜力。

[1] 周应恒, 李娜. “大食物观” 与我国食物安全保障新思路[J]. 中国农业大学学报(社会科学版), 2023, 40(4): 147-158.

ZHOU Ying-heng, LI Na. All-Encompassing Approach to Food and New Thinking of Food Security[J]. Journal of China Agricultural University Social Sciences, 2023, 40(4): 147-158.

[2] YANG R, LIU B, YU F, et al. Superhydrophobic Cellulose Paper with Sustained Antib-acterial Activity Prepared by In-situ Growth of Carvacrol-loaded Zinc-based Metal Orga-nic Framework Nanorods for Food Packaging Application[J]. Int J Biol Macromol, 2023, 234: 123712.

[3] KUMAR S, MUDAI A, ROY B, et al. Biodegradable Hybrid Nanocomposite of Chitosan/Gelatin and Green Synthesized Zinc Oxide Nanoparticles for Food Packaging[J]. Foods, 2020, 9(9): 1143.

[4] TABASSUM N, KHAN M A. Modified Atmosphere Packaging of Fresh-Cut Papaya Using Alginate Based Edible Coating: Quality Evaluation and Shelf Life Study[J]. Scientia Horticulturae, 2020, 259: 108853.

[5] KIM H, LEE C, YOON K, et al. Synergistic Effect of UV-C LED Irradiation and PLA/PBAT-Based Antimicrobial Packaging Film on Fresh-Cut Vegetables[J]. Food Control, 2022,138: 109027.

[6] VOSTREJS P, ADAMCOVA D, VAVERKOVA M D, et al. Active Biodegradable Packaging Films Modified with Grape Seeds Lignin[J]. RSC Adv, 2020, 10(49): 29202-29213.

[7] TRIPATHI A D, MISHRA P K, DARANI K K, et al. Hydrothermal Treatment of Lignocellulose Waste for the Production of Polyhydroxyalkanoates Copolymer with Potential Application in Food Packaging[J]. Trends in Food Science & Technology, 2022, 123: 233-250.

[8] AL-TAYYAR N A, YOUSSEF A M, AL-HINDI R R. Edible Coatings and Antimicrobial Nanoemulsions for Enhancing Shelf Life and Reducing Foodborne Pathogens of Fruits and Vegetables: A Review[J]. Sustainable Materials and Technologies, 2020, 26: 215.

[9] AGRIOPOULOU S, STAMATELOPOULOU E, SACHADYN-KRÓL M, et al. Lactic Acid Bacteria as Antibacterial Agents to Extend the Shelf Life of Fresh and Minimally Processed Fruits and Vegetables: Quality and Safety Aspects[J]. Microorganisms, 2020, 8(6): 952.

[10] WU Y, XIAO K, ZHU L, et al. Preparation and Application of Equilibrium Modified at-Mosphere Packaging Membranes with Polylactic Acid and Polymers of Intrinsic Microporeosity[J]. Food Packaging and Shelf Life, 2023, 37: 101063.

[11] CHEN Jian-fu, ZHENG Mei-xia, TAN K B, et al. Development of Xanthan Gum/Hydroxypropyl Methyl Cellulose Composite Films Incorporating Tea Polyphenol and Its Application on Fresh-Cut Green Bell Peppers Preservation[J]. International Journal of Biological Macromolecules, 2022, 211: 198-206.

[12] 张学杰, 刘宜生, 孙润峰. 切割果蔬的质量控制及改善货架期的途径[J]. 中国农业科学, 1999, 32(3): 72-77.

ZHANG Xue-jie, LIU Yi-sheng, SUN Run-feng. Quality Control and Measures Taken for Improving Shelf Life of Minimally Processed Fruits and Vegetables[J]. Scientia Agricultura Sinica, 1999, 32(3): 72-77.

[13] WU K, WU H, WANG R, et al. The Use of Cellulose Fiber from Office Waste Paper to Improve The thermal insulation-related Property of Konjac Glucomannan/Starch Aerogel[J]. Industrial Crops and Products, 2022, 177: 114424.

[14] LORENZO J M, MUNEKATA P E, DOMINGUEZ R, et al. Chapter 3-Main Groups of Microorganisms of Relevance for Food Safety and Stability: General Aspects and Overall Description[M].New York: Innovative Technologies for Food Preservation. Academic Press, 2018: 53-107.

[15] MIR S A, SHAH M A, MIR M M, et al. Microbiological Contamination of Ready-to-Eat Vegetable Salads in Developing Countries and Potential Solutions in the Supply Chain to Control Microbial Pathogens[J]. Food Control, 2018, 85: 235-244.

[16] TIWARI S, DUBEY N K. Nanoencapsulated Essential Oils as Novel Green Preservatives Against Fungal and Mycotoxin Contamination of Food Commodities[J]. Current Opinion in Food Science, 2022, 45: 100831.

[17] TORRES-LEÓN C, VICENTE A A, FLORES-LÓPEZ M L, et al. Edible Films and Coatings Based on Mango (var. Ataulfo) by-Products to Improve Gas Transfer Rate of Peach[J]. LWT, 2018, 97: 624-631.

[18] ALMEIDA T, KARAMYSHEVA A, VALENTE B F A, et al. Biobased Ternary Films of Thermopl-astic Starch, Bacterial Nanocellulose and Gallic Acid for Active Food Packaging[J]. Food Hydrocolloids, 2023, 144: 108934.

[19] GHOSHAL G, CHOPRA H. Impact of Apricot Oil Incorporation in Tamarind Starch/Gelatin Based Edible Coating on Shelf Life of Grape Fruit[J]. Journal of Food Measurement & C-haracterization, 2022, 16(2): 1274-1290.

[20] FRANCIS D V, THALIYAKATTIL S, CHERIAN L, et al. Metallic Nanoparticle Integrated Ternary Polymer Blend of PVA/Starch/Glycerol: A Promising Antimicrobial Food Packaging Material[J]. Polymers, 2022, 14(7): 1379.

[21] 吕瑶. 改性纤维素/PBAT复合薄膜的制备及性能研究[D]. 贵阳: 贵州师范大学, 2023.

LYU Yao. Preparation and Properties of Modified Ccellulose /PBAT Composite Films[D]. Guiyang: Guizhou Normal University, 2023.

[22] JOSHY K S, JOSE J, LI T, et al. Application of Novel Zinc Oxide Reinforced Xanthan Gum Hybrid System for Edible Coatings[J]. International Journal of Biological Macromolecules, 2020, 151: 806-813.

[23] FAN Y, YANG J, DUAN A, et al. Pectin/Sodium Alginate/Xanthan Gum Edible Composite Films as The fresh-cut Package[J]. Int J Biol Macromol, 2021, 181: 1003-1009.

[24] ZAM W. Effect of Alginate and Chitosan Edible Coating Enriched with Olive LeavesExtract on the Shelf Life of Sweet Cherries (Prunus avium L.)[J]. Journal of Food Quality, 2019, 2019: 8192964.

[25] DU Y, SHI B, LUAN X, et al. Chitosan/Cellulose Nanocrystal Biocomposite Coating For Fruit Postharvest Preservation[J]. Industrial Crops And Products, 2023, 205: 117543.

[26] ZHAO X, HAN Z, ZHANG S, Et Al. Preparation of Pva/Tremella Polysaccharide and Soy- Protein Isolate Complex/ε-Polylysine Active Membrane and Its Application in Blueberry Preservation[J]. Food Packaging and Shelf Life, 2023, 40: 101163.

[27] ZOU Z, ISMAIL B B, ZHANG X, Et Al. Improving Barrier and Antibacterial Properties of Chitosan Composite Films by Incorporating Lignin Nanoparticles and Acylated Soy Protein Isolate Nanogel[J]. Food Hydrocolloids, 2023, 134: 108091.

[28] DU H, MIN T, SUN X, Et Al. Multifunctional Film Based on Gelatin With Titanium D-ioxide and Thymol@β-Cyclodextrins for Fresh-Keeping Packaging[J]. Food Bioscience, 2022, 50: 102168.

[29] SOOD A, SAINI C S. Red Pomelo Peel Pectin Based Edible Composite Films: Effect of Pectin Incorporation on Mechanical, Structural, Morphological and Thermal Properties of Composite Films[J]. Food Hydrocolloids, 2022, 123: 107135.

[30] SOOD A, SAINI C S. Utilization of Peel of White Pomelo For The Development of Pectin Based Biodegradable Composite Films Blended With Casein And Egg Albumen[J]. Food Chemistry Advances, 2022, 1: 100054.

[31] SUCINDA E F, ABDUL MAJID M S, RIDZUAN M J M, et al. Development and Cha-racterisation of Packaging Film from Napier Cellulose Nanowhisker Reinforced Polylactic Ac-id (PLA) Bionanocomposites[J]. International Journal of Biological Macromolecules, 2021, 187: 43-53.

[32] MIZIELIŃSKA M, KOWALSKA U, JAROSZ M, Et Al. The Effect of Uv Aging on Antimicrobial and Mechanical Properties of Pla Films With Incorporated Zinc Oxide Nanoparticles[J]. International Journal of Environmental Research and Public Health, 2018, 15(4): 794.

[33] VARGHESE S A, PHOTHISARATTANA D, SRISA A, Et Al. Novel Eco-Friendly Anti-microbial Uv-Blocking Pbat/Pbs/Tio2Nanocomposite Films for Improved Shelf-Life of Bananas[J]. Food Bioscience, 2023, 55: 102993.

[34] 沈春华, 李立, 杜云飞. PLA/PHA活性抗菌薄膜对蓝莓低温保鲜效果的影响[J]. 食品与机械, 2018, 34(7): 121-126.

SHEN Chun-hua, LI Li, DU Yun-fei. Effect of PLA/PHA Active Films on Preservation of Blueberries during Cold Storage[J]. Food & Machinery, 2018, 34(7): 121-126.

[35] MIRPOOR S F, CORRADO I, DI GIROLAMO R, et al. Manufacture of Active Multilayer Films Made of Functionalized Pectin Coated by Polyhydroxyalkanoates: A Fully Renewable Approach to Active Food Packaging[J]. Polymer (Guilford), 2023, 281: 126136.

[36] NGUYEN T T, THI DAO U T, THI BUI Q P, et al. Enhanced Antimicrobial Activities and Physiochemical Properties of Edible Film based on Chitosan Incorporated with Sonneratia Caseolaris (L.) Engl. Leaf Extract[J]. Progress in Organic Coatings, 2020, 140: 105487.

[37] SHIVANGI S, DORAIRAJ D, NEGI P S, et al. Development and Characterisation of a Pectin-Based Edible Film That Contains Mulberry Leaf Extract and Its Bio-Active Components[J]. Food Hydrocolloids, 2021, 121: 107046.

[38] AKHTER R, MASOODI F A, WANI T A, et al. Functional Characterization of Biopolymer Based Composite Film: Incorporation of Natural Essential Oils and Antimicrobial Agents[J]. Int J Biol Macromol, 2019, 137: 1245-1255.

[39] CHEN J, ZHANG J, LIU D, et al. Preparation, Characterization, and Application of Edible Antibacterial Three-Layer Films Based on Gelatin-Chitosan-Corn Starch-Incorporated Nisin[J]. Food Packaging And Shelf Life, 2022, 34:100980.

[40] LEI Y, WU H, JIAO C, et al. Investigation of The Structural And Physical Properties, Antioxidant and Antimicrobial Activity of Pectin-Konjac Glucomannan Composite Edible Films Incorporated with Tea Polyphenol[J]. Food Hydrocolloids, 2019,94:128-135.

[41] LALNUNTHARI C, DEVI L M, BADWAIK L S. Extraction of Protein and Pectin From Pumpkin Industry by-Products and Their Utilization for Developing Edible Film[J]. J Food Sci Technol, 2020, 57(5): 1807-1816.

[42] RUX G, LABUDE C, HERPPICH W B, et al. Investigation on The Potential of Applying Bio-Based Edible Coatings for Horticultural Products Exemplified with Cucumbers[J]. Curr Res Food Sci, 2023, 6: 100407.

[43] GHOSH T, MONDAL K, GIRI B S, et al. Silk Nanodisc based Edible Chitosan Nanoc-omposite Coating for Fresh Produces: A Candidate with Superior Thermal, Hydrophobic,Optical, Mechanical and Food Properties[J]. Food Chem, 2021, 360: 130048.

[44] BUENDÍA MORENO L, SOTO JOVER S, ROS CHUMILLAS M, et al. Innovative Cardboard Active Packaging with a Coating Including Encapsulated Essential Oils to Extend Cherry Tomato Shelf Life[J]. LWT, 2019, 116: 108584.

[45] 关玥彤, 常善丰, 鄂玉萍. 葡甘聚糖涂布纸箱对芒果保鲜效果的研究[J]. 包装世界, 2016(1): 33-36.

GUAN Yue-tong, CHANG Shan-feng, E Yu-ping. Study on Fresh-Keeping Effect of Glucomannan Coated Carton on Mango[J]. Packaging World, 2016(1): 33-36.

[46] LI Sheng-hai, ZHANG Suo-bo, WANG Xian-hong. Fabrication of Superhydrophobic Cellulose-Based Materials through a Solution-Immersion Process[J]. Langmuir, 2008, 24(10): 5585-5590.

[47] CHEN H, WANG B, LI J, et al. High-Strength and Super-Hydrophobic Multilayered Paper based on Nano-Silica Coating and Micro-Fibrillated Cellulose[J]. Carbohydr Pol-ym, 2022, 288: 119371.

[48] YU F, SHI H, WANG K, et al. Preparation of Robust and Fully Bio-Based Modified P-aper Via Mussel-inspired Layer-by-Layer Assembly of Chitosan and Carboxymethyl Cel-lulose for Food Packaging[J]. Int J Biol Macromol, 2022, 222: 1238-1249.

[49] BUENDÍA MORENO L, SOTO JOVER S, ROS CHUMILLAS M, et al. An Innovative Active Cardboard Box for Bulk Packaging of Fresh Bell Pepper[J]. Postharvest Biology and Technology, 2020, 164: 111171.

[50] 沈祖广, 俞朝晖, 郭蕊, 等. 基于纳米微球技术的香蕉/猕猴桃保鲜纸箱[J]. 包装工程, 2018, 39(3): 7-11.

SHEN Zu-Guang, YU Chao-hui, GUO Rui, et al. Banana/Kiwi Fresh-Keeping Carton Based on Nano-Microsphere Technology[J]. Packaging Engineering, 2018, 39(3): 7-11.

[51] ZHOU Wei, WU Zheng-guo, XIE Feng-wei, et al. 3D Printed Nanocellulose-Based Label for Fruit Freshness Keeping and Visual Monitoring[J]. Carbohydrate Polymers, 2021, 273: 118545.

[52] 李小丽, 赵萦. 气调包装技术在鲜切果蔬中的应用及研究进展[J]. 现代食品, 2020(18): 145-147.

LI Xiao-li, ZHAO Ying. Application and Research Progress of Modified Atmosphere Packaging Technology in Fresh-Cut Fruits and Vegetables[J]. Modern Food, 2020(18): 145-147.

[53] SIRIPATRAWAN U, KAEWKLIN P. Fabrication and Characterization of Chitosan-Titani-um Dioxide Nanocomposite Film as Ethylene Scavenging and Antimicrobial Active Foo-d Packaging[J]. Food Hydrocolloids, 2018, 84: 125-134.

[54] ZHANG Shen, WEI Feng, HAN Xiao-jun. An Edible Film of Sodium Alginate/Pullulan Incorporated with Capsaicin[J]. New Journal of Chemistry, 2018, 42(21): 17756-17761.

[55] KADAM S U, PANKAJ S K, TIWARI B K, et al. Development of Biopolymer-Based Gelatin and Casein Films Incorporating Brown Seaweed Ascophyllum Nodosum Extract[J]. Food Packaging and Shelf Life, 2015, 6: 68-74.

[56] RIAHI Z, HONG S J, RHIM J, et al. High-performance Multifunctional Gelatin-based Films Engineered with Metal-Organic Frameworks for Active Food Packaging Applications[J]. Food Hydrocolloids, 2023, 144: 108984.

[57] RUKMANIKRISHNAN B, RAMALINGAM S, RAJASEKHARAN S K, et al. Binary and Ternary Sustainable Composites of Gellan Gum, Hydroxyethyl Cellulose and Lignin for Food Packaging Applications: Biocompatibility, Antioxidant Activity, Uv and Water Barrier Properties[J]. International Journal of Biological Macromolecules, 2020, 153: 55-62.

[58] PULIKKALPARAMBIL H, PHOTHISARATTANA D, PROMHUAD K, et al. Effect of Silicon Dioxide Nanoparticle on Microstructure, Mechanical and Barrier Properties of B-iodegradable Pbat/Pbs Food Packaging[J]. Food Bioscience, 2023, 55: 103023.

[59] ITABANA B E, PAL A K, MOHANTY A K, et al. Biodegradable Blown Film Compos-ite from Poly (Butylene Adipate-Co-Terephthalate) and Talc: Effect of Uniaxial Stretchingon Mechanical and Barrier Properties[J]. Food Packaging and Shelf Life, 2023, 39: 101147.

[60] KUMAR N, NEERAJ, PRATIBHA, et al. Improved Shelf Life and Quality of Tomato-(Solanum Lycopersicum L.) by Using Chitosan-Pullulan Composite Edible CoatingEnriched with Pomegranate Peel Extract[J]. ACS Food Science & Technology, 2021, 1(4): 500-510.

[61] KUMAR N, PRATIBHA, NEERAJ, et al. Effect of Active Chitosan-pullulan Composite Edible Coating Enrich with Pomegranate Peel Extract on The Storage quality of Green Bell Pepper[J]. LWT, 2021,138:110435.

[62] ROSSI-MÁRQUEZ G, DÁVALOS-SAUCEDO C A, MAYEK-PÉREZ N, et al. Multilayered Edible Coatings to Enhance Some Quality Attributes of Ready-to-Eat Cherimoya (Annona- Cherimola)[J]. Coatings, 2023, 13(1): 41.

[63] XING Y, LI W, WANG Q, et al. Antimicrobial Nanoparticles Incorporated in Edible Coatings and Films for the Preservation of Fruits and Vegetables[J]. Molecules, 2019, 24(9): 1695

[64] PIROZZI A, FERRARI G, DONSÌ F. The Use of Nanocellulose in Edible Coatings for the Preservation of Perishable Fruits and Vegetables[J]. Coatings (Basel), 2021, 11(8): 990.

[65] LIU J, LI P, CHEN L, et al. Superhydrophilic and Underwater Superoleophobic Modifi-ed Chitosancoated Mesh for Oil/Water Separation[J]. Surface and Coatings Technology, 2016, 307: 171-176.

[66] ZHU R, FU X, JIN S, et al. Water and Oil-Resistant Paper Materials Based on Sodium Alginate/Hydroxypropyl Methylcellulose/Polyvinyl Butyral/Nano-Silica with Biodegradab-le And High Barrier Properties[J]. International Journal of Biological Macromolecules, 2023, 225: 162-171.

[67] ZHONG Y, GU L, WANG S, et al. Green and Superhydrophobic Coatings Based on Tailor-Modified Lignocellulose Nanofibrils for Self-Cleaning Surfaces[J]. Industrial & Engineering Chemistry Research, 2019, 58(44): 20323-20330.

[68] MIRVAKILI M N, HATZIKIRIAKOS S G, ENGLEZOS P. Superhydrophobic Lignocell-Ulosic Wood Fiber/ Mineral Networks[J]. ACS Appl Mater Interfaces, 2013, 5(18): 9057-9066.

[69] LI Yang, HU Ze-xi, HUO Ruo-bing, et al. Preparation of an Indicator Film Based on Pectin, Sodium Alginate, and Xanthan Gum Containing Blueberry Anthocyanin Extract and Its Application in Blueberry Freshness Monitoring[J]. Heliyon, 2023, 9(3): 14421.

[70] ZONG Z, LIU M, CHEN H, et al. Preparation and Characterization Of a Novel Intelligent-Starch/Gelatin Binary Film Containing Purple Sweet Potato Anthocyanins for Flamm-ulina Velutipes Mushroom Freshness Monitoring[J]. Food Chem, 2023, 405: 134839.

[71] XU Liang, SUN Da-wen, TIAN You, et al. Combined Effects of Radiative and Evaporative Cooling on Fruit Preservation under Solar Radiation: Sunburn Resistance and Temperature Stabilization[J]. ACS Applied Materials & Interfaces, 2022, 14(40): 45788-45799.

[72] LIN Yu-xuan, SHAO Ke, LI Shuai, et al. Hygroscopic and Photothermal All-Polymer Foams for Efficient Atmospheric Water Harvesting, Passive Humidity Management, and Protective Packaging[J]. ACS Applied Materials & Interfaces, 2023, 15(7): 10084-10097.

Preparation of Bio-based Packaging Materials and Their Application in Fruit and Vegetable Preservation

PAN Xun1a,2,3,XIAO Nai-yu1a,2,3, HU Xin-kuan1a,2,3,ZHONG Yun-yun1a,2,3,LUO Wen-han1a,2,3,CHEN Guo-jian1a,2,3*,WAN Xiao-rong1b,XIAO Geng-sheng1a,2,3

(1. a. College of Agriculture and Biology, b. College of Light Industry and Food Science, Zhongkai University of Agriculture and Engineering, Guangzhou 510225, China; 2. Guangdong Provincial Green Manufacturing Development Center of Central Kitchens in Universities, Guangzhou 510225, China; 3. Key Laboratory for Green Process and Intelligent Manufacturing of Lingnan Special Food, Ministry of Agriculture and Rural Affairs, Guangzhou 510225, China)

In recent years, the consumption of packaged fruits and vegetables, especially packaged fresh-cut fruits and vegetables, has risen rapidly. Compared with traditional petroleum-based packaging materials, bio-based packaging materials have the characteristics of environmental friendliness and sustainability, making them promising in the future. The work aims to summarize the research progress of bio-based packaging materials in China and abroad and their application in fruit and vegetable preservation, so as to provide theoretical reference for research and application in relevant fields. Firstly, the preservation mechanism of fruit and vegetable, and their packaging requirements were analyzed. Then, the characteristics and preparation methods of different kinds of bio-based materials were classified and discussed, and finally the application of such bio-based materials in fruit and vegetable packaging was studied. The progress of bio-based packaging materials in the field of fruit and vegetable packaging is summarized, and its future development trend is prospected.

bio-based materials; packaging materials; fruit and vegetable preservation

TB484

A

1001-3563(2023)23-0084-10

10.19554/j.cnki.1001-3563.2023.23.010

2023-10-16

广东省基础与应用基础研究基金联合基金项目(2022A1515110363);广东省教育厅青年创新人才项目(2021KQNCX030);广东丹青印务有限公司横向项目(D122222G909)

责任编辑:曾钰婵