改善Lyocell纤维原纤化的连续式无盐轧染工艺

唐奇 何奕 郑今欢 王成龙 王直成 柴丽琴

摘 要:为解决Lyocell织物活性染料染色无机盐用量大、纤维原纤化等问题,分析了Lyocell织物的连续式无盐轧染染色技术,探讨了焙烘温度、焙烘时间、浸轧次数、碱剂及尿素用量对染色性能的影响,并与传统浸染工艺进行了比较。结果表明:Lyocell织物活性染料轧-烘-焙最佳的染色配方和工艺为碱剂25 g/L,尿素60 g/L,二浸二轧,160 ℃下焙烘2 min。相比传统浸染工艺,连续式无盐轧染染色可获得更高的染色深度,且改善了原纤化程度。

关键词:Lyocell织物;活性染料;轧染;无盐;原纤化

中图分类号:TS190.6 文献标志码:A 文章编号:1009-265X(2023)06-0009-08

Lyocell纤维织物因其较高的干湿强度,优异的吸湿性,良好的光泽性、悬垂性和生物降解性广受消费者的喜爱[1-3]。然而,Lyocell纤维织物独特的原纤结构使其在湿态下,受到机械外力作用后会使织物表面起毛起球,即产生原纤化现象[4-5]。因此,如何使Lyocell织物在染整加工及服用过程中减少其原纤化程度是近年来的热点问题之一[6]。活性染料具有颜色鲜艳、色谱齐全、价格便宜等优点,在纤维素纤维的染色中广泛应用[7-8]。浸染是活性染料染色的常用方式,为促进活性染料染色,往往会在染液中加入大量无机盐,因此,染色存在能耗高、染色废水成分复杂多变、色度深、碱性大和处理成本昂贵等诸多弊端[9-11],研发适用于纤维素织物染色的低能耗、短流程染整加工技术,减少染色过程中的能源消耗和污染物排放,将会有利于纤维素纺织品清洁染色,促进整个印染加工行业的可持续发展。

本文拟系统研究Lyocell纤维织物活性染料连续式无盐轧染染色工艺,在提高染色性能、降低无机盐排放的同时,改善Lyocell纤维的原纤化程度,有效提升Lyocell纤维面料的品质。

1 实 验

1.1 材料和仪器

材料:Lyocell织物(30S/2,30S/2)、活性染料Br Red CA、Blue CA、Br Yellow CA(均为M型活性染料,湖州倍亨纺织有限公司),净洗剂209(武汉祥鼎达生物科技有限公司),硫酸钠、碳酸钠、冰醋酸(AR,杭州高晶化工有限公司),尿素(分析纯,天津市永大化学试剂有限公司),渗透剂JFC(工业级,上海文化化工颜料有限公司)。

仪器:M-6型连续式定型烘干机(上海际发仪器设备有限公司),P-A0型立式小轧车(宁波大禾仪器有限公司),DHS-6型水浴锅(绍兴鸿靖纺织机械设备有限公司),常温振荡试色机(佛山市华高自动化设备有限公司),PE型紫外分光光度计(美国PerkinElmer公司),SF600型电脑测色配色仪(美国Datacolor公司),Y571型耐摩擦色牢度测试仪(莱州元茂仪器有限公司),SW-12D型耐洗色牢度试验机(宁波纺织仪器厂),DHG-9070A型电热恒温鼓风干燥箱(上海精宏实验设备有限公司),OCA-20型接触角测量仪(德国Dataphsics公司)。

1.2 实验方法

1.2.1 轧染染色工艺

染色配方和工艺:活性染料20 g/L,渗透剂JFC 20 g/L,尿素0~120 g/L,碳酸钠10~30 g/L,轧液率70%,焙烘温度140~180 ℃,焙烘时间1~4 min。按上述配方配置染液,将经过前处理的Lyocell织物进行浸轧、预烘、焙烘和皂洗后熨平。皂洗配方和工艺为:碳酸钠1 g/L,净洗剂209 1 g/L,浴比1∶50,温度95 ℃,时间10 min。

1.2.2 浸染染色工藝

染色配方和工艺:活性染料X(o.w.f,%),碳酸钠20 g/L,硫酸钠50 g/L,染色温度60 ℃,染色时间90 min,浴比1∶50。通过染料用量归一化计算,将轧染所用染料浓度单位与浸染保持一致,按上述配方配置染液,40 ℃入染,15 min后加入硫酸钠,保温15 min后染浴以1 ℃/min升温至60 ℃,加入碳酸钠固色,继续保温60 min,染色结束后取出织物,经皂洗后熨干,皂洗配方和工艺同上。

1.2.3 染料用量统一化

为了比较活性染料在不同的染色工艺下的染色效果,需要对所用的染料用量进行统一化处理,使轧染所用染料浓度单位与浸染保持一致[12]。

轧染时,当染料浓度1 g/L时,织物固色前布面的染料量为:

式中:Sλ代表在最大吸收波长下的标准偏差,n代表测试数量,计算出的Sλ越小,表明染色织物的匀染性越好。

1.3.3 色牢度的测定

耐摩擦色牢度参照GB/T 3920—2008《纺织品 色牢度试验 耐摩擦色牢度》,共5级,1级最差,5级最好;耐皂洗色牢度参照GB/T 3921—2008《纺织品 色牢度试验 耐皂洗色牢度》。

1.3.4 固色率的测定

染料的固色率采用尿素剥色法进行测定。将固色前后的染色试样在高浓度尿素溶液中进行剥色处理,收集剥色液,利用紫外分光光度计测试剥色液的吸光度值,即其染料量,测3次取平均值[14],固色率由式(5)计算得到:

式中:F为固色率,%;m0、m1分别为未固色试样、固色试样的干燥质量,g;A0、A1分别为未固色试样、固色试样的剥色液吸光度值。

1.3.5 Lyocell织物原纤化程度的测试

采用接触角测试仪拍摄Lyocell织物表观图片,根据织物表面毛羽分布,通过烧毛评定法评定Lyocell织物原纤化等级[15]。

2 结果与讨论

2.1 Lyocell织物活性染料的连续式无盐轧染工艺

2.1.1 焙烘温度对染色性能的影响

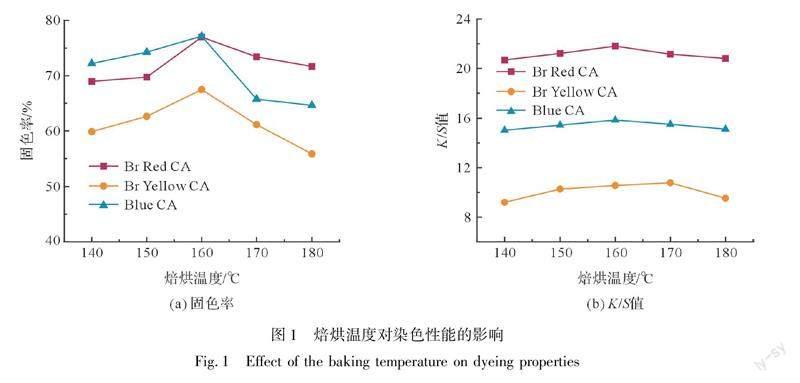

为探究焙烘温度对活性染料染色性能的影响,分别浸轧20 g/L的Br Red CA、Br Yellow CA、 Blue CA染液,经低温预烘一段时间后在140~180 ℃下进行焙烘固色,Lyocell织物的染色性能如图1所示。

由图1看出,3支染料的固色率和K/S值均随着焙烘温度的升高呈现出先增后减的趋势。当焙烘温度达到160 ℃左右时,染料的固色率最大,相应的染色K/S值也较大;当焙烘温度高于160 ℃,Lyocell织物的固色率显著下降,K/S值也有所下降。这是因为随着固色温度的升高,染料分子的热运动加快[16],在纤维内均匀扩散,织物的固色率和K/S值随之增加;而当固色温度过高时,活性染料水解速率逐渐大于染料与纤维的键合速率[17-18],同时,部分已与纤维结合的活性染料发生断键水解[19]。因此,3支染料在Lyocell织物上的焙烘温度选择160 ℃为宜。

2.1.2 焙烘时间对染色性能的影响

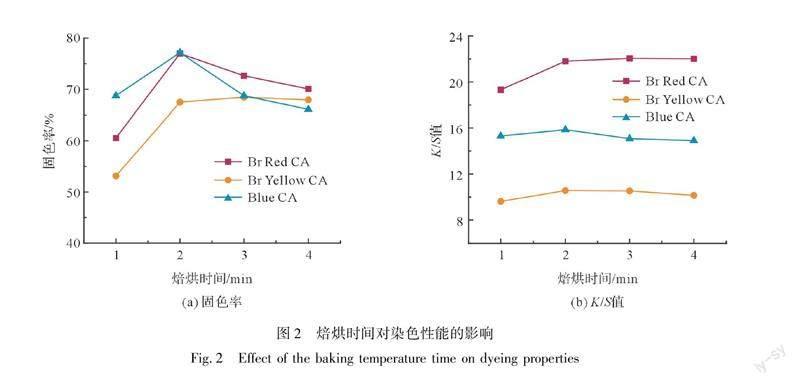

为探究焙烘时间对活性染料染色性能的影响,分别浸轧20 g/L的Br Red CA、Br Yellow CA、Blue CA染液,经低温预烘一段时间后在160 ℃焙烘固色1~4 min,Lyocell织物的染色性能如图2所示。

由图2可以看出,3支染料经轧-烘-焙工艺染色后,染色织物的固色率和K/S值随着焙烘时间的延长呈现先增后减的趋势。当焙烘时间在2 min时,染色织物的固色率和K/S值最大。这是由于固色时间过短,染料活性基与纤维素羟基阴离子间的反应不充分所导致;随着固色时间的延长,染料与纤维充分结合,固色率和K/S值随之增加;而固色时间过长,原本已与纤维结合的染料发生断键,固色率下降;同时织物在高温下处理时间过长,染料分解,织物表面黯淡,手感变差。因此,3支染料染色Lyocell织物的最适宜焙烘时间为2 min。

2.1.3 浸轧次数对染色性能的影响

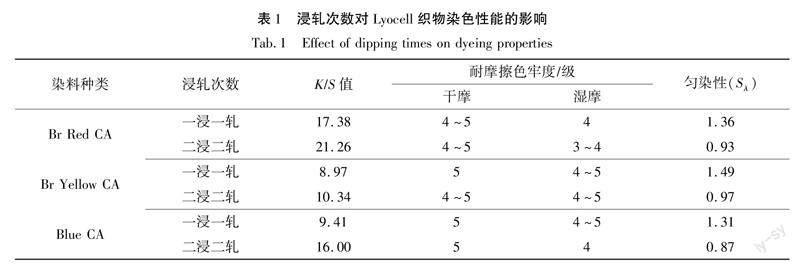

Lyocell织物采用1.2.1节染色工艺,焙烘温度160 ℃,焙烘时间2 min。考察浸轧次数对染色性能的影响,实验结果如表1所示。

由表1可知,与一浸一轧相比,3支染料二浸二轧染色织物的K/S值分别提高了18.25%、13.25%、41.19%,并且染色织物的匀染性有一定的提高。这是因为浸轧次数的增加,有利于去除纤维空隙间的空气使染料充分向纤维内部渗透并均匀分布在织物表面。采用不同的浸轧方式,对织物耐摩擦色牢度的影响较小,基本都在4级及以上,达到行业标准。因此,Lyocell织物轧染适宜采用二浸二轧工艺。

2.1.4 尿素用量对染色性能的影响

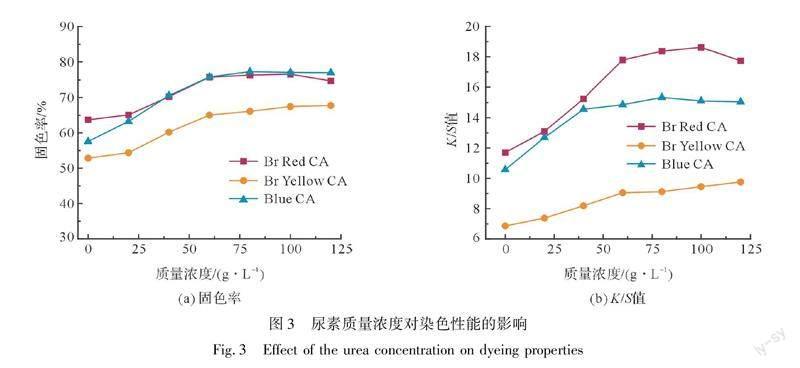

为探究尿素用量对活性染料染色性能的影响,分别浸轧20 g/L的Br Red CA、Br Yellow CA、Blue CA染液,焙烘固色160 ℃,2 min。Lyocell织物的染色性能如图3所示。

图3显示,当尿素用量低于60 g/L时,染色织物的固色率和K/S值随着尿素用量的增加逐渐增大;继续增加尿素用量,织物的固色率和K/S值增加不明显。尿素的加入对纤维起到溶胀作用,在带液率为70%的条件下,增加染料的水溶性,促进染料往纤维内部迁移扩散,染色织物的固色率和K/S值提高。高温时,尿素会与染料反应释放出氨气等有毒物质,并且影响染料的固色,因此,尿素的用量不宜过高,本实验后续采用的尿素质量浓度为60 g/L。

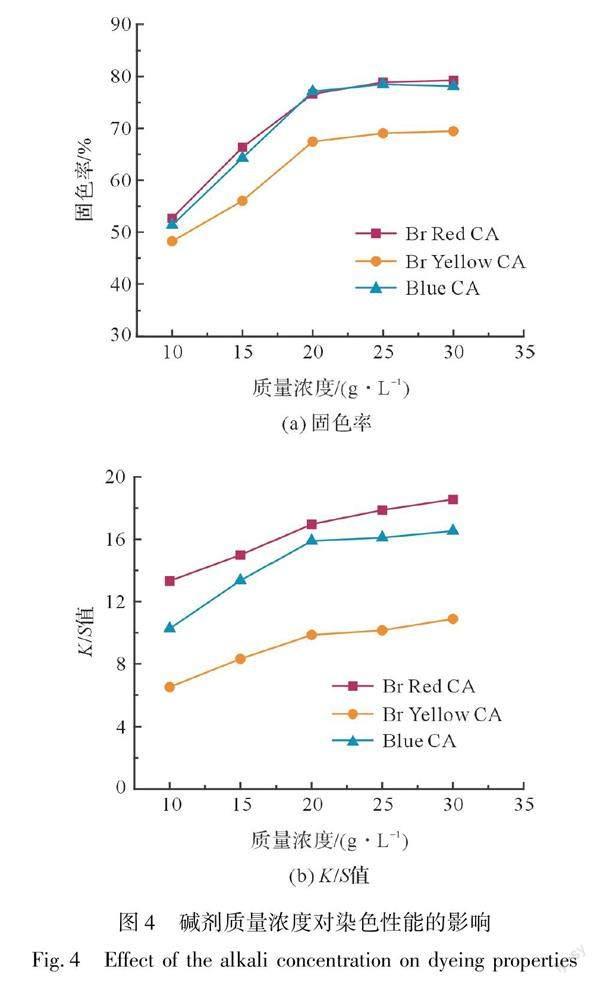

2.1.5 碱剂用量对染色性能的影响

为探究碱剂用量对活性染料染色性能的影响,分别浸轧20 g/L的Br Red CA、Br Yellow CA、Blue CA染液,焙烘固色160 ℃,2 min。Lyocell织物的染色性能如图4所示。

由图4可以看出,随着碳酸钠用量的增加,染料的固色率和染色织物的K/S值逐渐增大,当碳酸钠用量超过20 g/L后,染料固色率基本趋于平衡,相应K/S值的增速也趋缓。这主要是因为在碱性条件下,纤维素羟基电离生成纤维素羟基阴离子,随着碱性的增加,生成的羟基阴离子增加,与染料活性基的反应速度加快,对应染料的固色率和染色织物的K/S值逐渐增加。但若染液碱性过强,染料与纤维反应速率加快的同时,活性染料的水解速率也同样加剧,真正能与纤维发生反应的染料量可能没有显著增加,对应的固色率和染色K/S值提高不明显。综合分析,本实验后续采用的碱剂质量浓度为20 g/L。

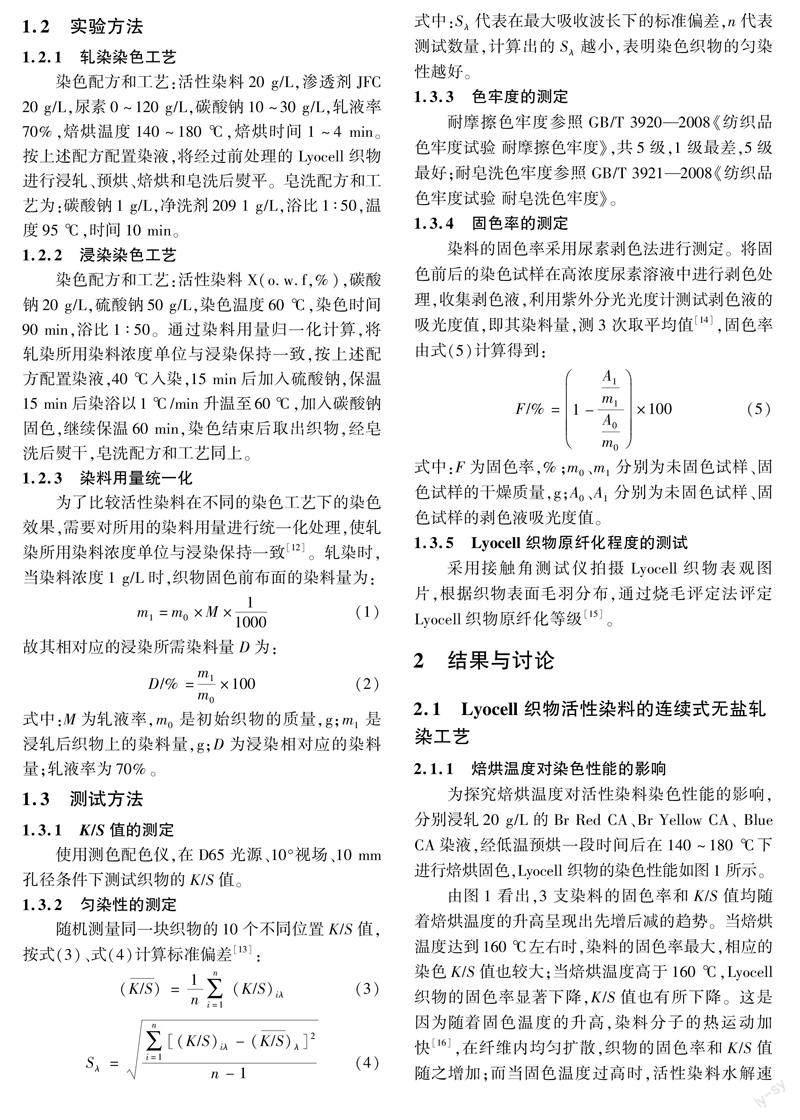

2.2 连续式无盐轧染与传统浸染的染色效果比较

2.2.1 染深性和匀染性对比

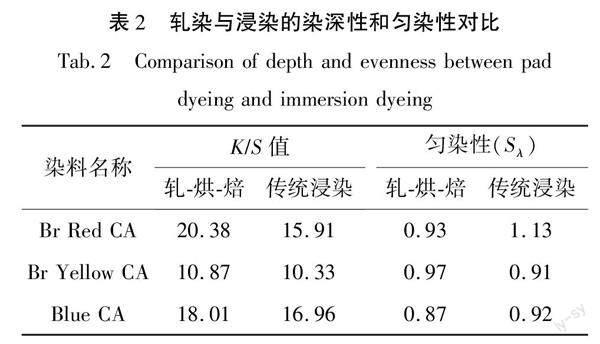

采用优化后的工艺对Lyocell织物进行轧-烘-焙染色,并与传统的浸染工艺进行了K/S值和匀染性的对比。轧-烘-焙工艺选用的染料浓度为20 g/L,通过式(1)和式(2)计算得到传统浸染所对应的染料用量为1.4% (o.w.f),两者的染深性和匀染性效果如表2—表4和图5所示。

由表2可以看出,在染料用量相同的情况下,采用轧-烘-焙染色工艺所染织物的K/S值均优于传统浸染,说明染得相同色深前者所需的染料量较少。

这可能是由于轧染温度较高,染料更容易与纤维发生共价结合,并且染色流程短,织物上染料水解较少。而浸染染色时间长,活性染料在此过程中易水解,导致K/S值较低;另外,轧-烘-焙工艺染色织物的匀染性与浸染差别不大,Sλ均较小。

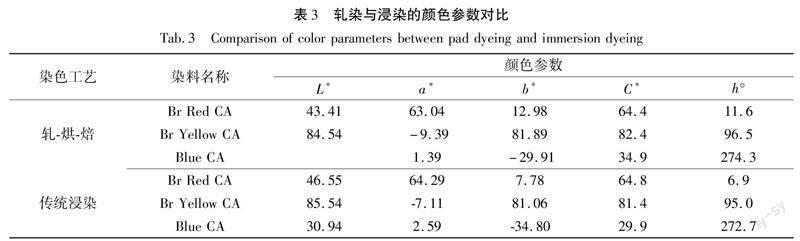

2.2.2 颜色参数对比

由图5所示,同一支染料轧染与浸染的最大吸收波长相同,说明轧染没有改变染色织物的色光。由表3可知,轧染织物的L*值普遍小于浸染工艺染色织物的L*值,说明在染料量相同的情况下,前者所染Lyocell织物的颜色会更深;轧染织物a*值绝对值小于浸染,说明浸染更偏红光,而b*值绝对值大于浸染,说明轧染更偏蓝光;轧染织物C*值普遍比浸染高,即前者的鮮艳度较高。

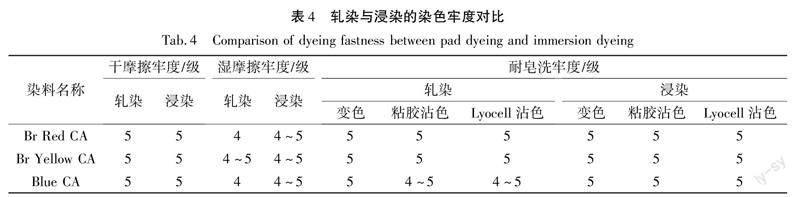

2.2.3 染色牢度对比

從表4可以看出,3支染料在两种工艺下,均有较好的耐摩擦色牢度和耐皂洗色牢度,分别可以达到4级和4~5级以上。

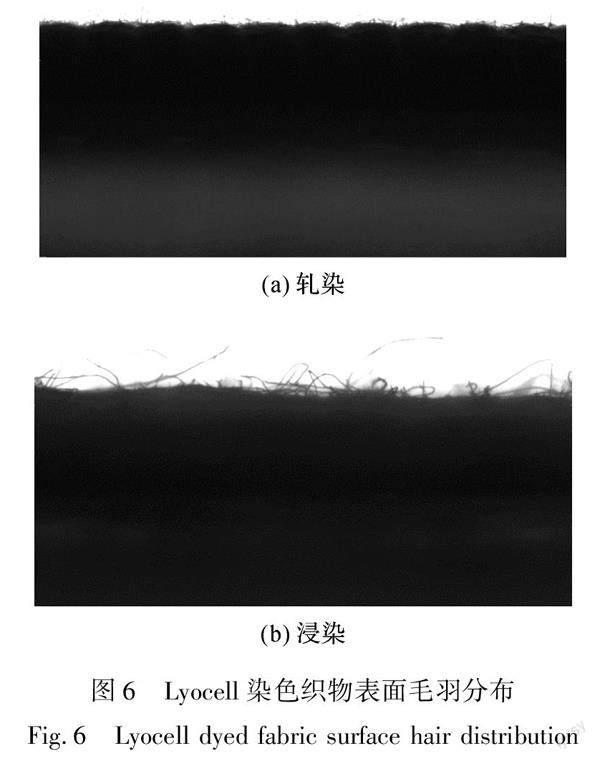

2.2.4 原纤化程度对比

利用接触角测试仪测试经轧染和浸染Lyocell织物的表面毛羽情况,来表征Lyocell织物的原纤化程度,具体效果如图6所示。

由图6可以看出,轧染染色后的织物表面较浸染织物更为平整,原纤化程度有所改善,这可能是因为Lyocell织物在浸染染色时,纤维与纤维之间的相互摩擦剧烈,且织物在染液中停留的时间较长,导致Lyocell纤维表面沿着纤维轴向分裂出很多细小的微纤。而采用平幅轧染染色工艺时,纤维之间几乎不会产生相互摩擦,在染液中停留时间短,织物的原纤化程度减弱,因而可使染色织物表面较为平滑。

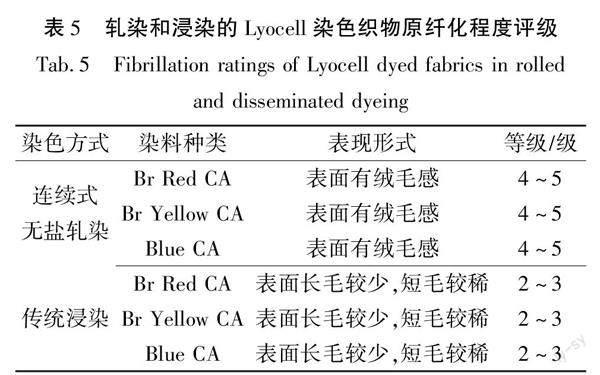

根据织物表面的毛羽情况,采用纤维素纤维的烧毛评级法,对Lyocell织物的原纤化程度进行评级,结果如表5所示。级数越小,原纤化越严重,另则反之。

3 结 论

本文研究了Lyocell织物的连续式无盐轧染工艺,并将优化后的染色结果与浸染相比,得到了以下的结论:

a)采用Br Red CA、Blue CA、Br Yellow CA3支染料对Lyocell织物进行轧-烘-焙染色时,最适宜的工艺条件为:二浸二轧,焙烘固色温度160 ℃,固色时间2 min。

b)在相同染料用量下,相较于传统浸染染色,轧-烘-焙染色工艺具有较高的染深性和匀染性;两种工艺所染织物均具有较好的耐摩擦色牢度和耐皂洗色牢度,分别可达4级和4~5级以上。

c)采用轧-烘-焙染色工艺可以降低Lyocell织物的原纤化程度,相较于浸染工艺,织物表面更平整光滑,原纤化程度可改善2个等级。

参考文献:

[1]黄伟,张嘉煜,张东,等.Lyocell纤维性能表征及其对比分析[J].纺织学报,2023,44(3):42-48.

HUANG Wei, ZHANG Jiayu, ZHANG Dong, et al. Property characterization and comparative analysis of Lyocell fibers[J].Journal of Textile Research, 2023, 44(3): 42-48.

[2]朱雪琪,彭康,张慧慧,等.功能化Lyocell纤维的研究进展[J].功能材料,2021,52(1):1078-1085,1201.

ZHU Xueqi, PENG Kang, ZHANG Huihui, et al. Progress in functionalized Lyocell fibers[J]. Journal of Functional Materials, 2021, 52(1): 1078-1085,1201.

[3]SIROKA B, NOISTERNIG M, GRIESSEr U J, et al. Characterization of cellulosic fibers and fabrics by sorption/desorption[J]. Carbohydrate Research, 2008, 343(12): 2194-2199.

[4]元伟,王铁晗,张玉梅,等.Lyocell纤维的原纤化现象及测试方法综述[J].人造纤维,2019,49(6):11-15.

YUAN Wei, WANG Tiehan, ZHANG Yumei, et al. A review of Lyocell fiber fibrination phenomena and testing methods[J].Artificial Fibre, 2019, 49(6): 11-15.

[5]黄伟,程春祖,张嘉煜,等.Lyocell纤维的低原纤化控制方法研究进展[J].纤维素科学与技术,2021,29(2):78-84.

HUANG Wei, CHENG Chunzu, ZHANG Jiayu, et al. Research progress and control methods of low fibrillar Lyocell fiber[J]. Journal of Cellulose Science and Technology, 2021, 29(2): 78-84.

[6]崔世强,元伟,王铁晗,等.Lyocell纤维的抗原纤化研究进展[J].人造纤维,2020,50(6):17-27.

CUI Shiqiang, YUAN Wei, WANG Tiehan, et al. Research progress of Lyocell fiber antigenic fibrination[J].Artificial Fibre, 2020, 50(6): 17-27.

[7]樊杰,苗俊华,安源,等.棉织物的活性染料浸轧/非水介质固着工艺[J].印染助剂,2021,38(5):38-42.

FAN Jie, MIAO Junhua, AN Yuan, et al. Padding/non-aqueous medium fixation process of cotton fabrics with reactive dyes[J]. Textile Auxiliaries, 2021, 38(5): 38-42.

[8]朱振旭,周岚,黄益,等.棉织物的活性染料/液体石蜡体系无盐节水染色[J].染整技术,2017,39(3):52-57.

ZHU Zhenxu, ZHOU Lan, HUANG Yi, et al. A water-saving and salt-free dyeing of cotton fabrics with reactive dye/liquid paraffin system[J].Textile Dyeing and Finishing Journal, 2017, 39(3): 52-57.

[9]WANG A M, XIA L J, ZHOU S J, et al. Solvent assisted reactive dyeing of cotton with high exhaustion in the absence of salt[J]. Journal of Cleaner Production, 2020, 267: 122062.

[10]LIM C L, MORAD N, TENG T T,et al. Chemical Oxygen Demand (COD) reduction of a reactive dye wastewater using H2O2/pyridine/Cu (Ⅱ) system[J]. Desalination, 2011, 278(1/2/3): 26-30.

[11]SAKKAYAWRONG N, THIRAVETYAN P, NAKBANPOTE W. Adsorption mechanism of synthetic reactive dye wastewater by chitosan[J]. Journal of Colloid and Interface Science, 2005, 286(1): 36-42.

[12]王菊.棉針织物活性染料冷轧堆染色[D].上海:东华大学,2014.

WANG Ju. Cold Pad-batch Dyeing of Cotton Knitted Fabric with Reactive Dyes[D]. Shanghai: Donghua University, 2014.

[13]WANG M Y, LIU M, ZHAO H J, et al. Reactive modified curcumin for high-fastness nonaqueous SC-CO2 dyeing of cotton fabric[J]. Cellulose, 2020, 27(17): 10541-10551.

[14]陈林,王建庆.活性染料固色率的酸溶解法和尿素剥色法测定[J].印染,2015,41(1):9-12.

CHEN Lin, WANG Jianqing. Determination of fixation of reactive dyes by acid dissolution method and urea stripping method[J].China Dyeing & Finishing, 2015, 41(1): 9-12.

[15]毛军,陈红霞.Lyocell纤维家纺面料的原纤化控制方法及评价标准[J].染整技术,2022,44(3):23-27,51.

MAO Jun, CHEN Hongxia. Fibrillation control method and evaluation standard of home textile made of Lyocell fiber[J].Textile Dyeing and Finishing Journal, 2022, 44(3): 23-27, 51.

[16]XIA J Y,WERF W, RABBINGE R. Influence of tempe-rature on bionomics of cotton aphid, Aphis gossypii, on cotton[J]. Entomologia Experimentalis et Applicata, 1999, 90(1): 25-35.

[17]舒大武,房宽峻,刘秀明,等.织物升温速率对活性染料轧-蒸无盐染色的影响[J].纺织学报,2018,39(2):106-111.

SHU Dawu, FANG Guangjun, LIU Xiuming, et al. Influence of fabric heating rate on salt-free pad-steam dyeing of reactive dye[J]. Journal of Textile Research, 2018, 39(2): 106-111.

[18]SHU D W, FANG K J, LIU X M, et al. Cleaner coloration of cotton fabric with reactive dyes using a pad-batch-steam dyeing process[J]. Journal of Cleaner Production, 2018, 196: 935-942.

[19]KLANCINK M. The influence of temperature on the kinetics of concurrent hydrolysis and methanolysis reactions of a monochlorotriazine reactive dye[J]. Dyes and Pigments, 2000, 46(1): 9-15.

Continuous salt-free pad dyeing process to improve the fibrillation of Lyocell fibers

TANG Qi1, HE Yi1, ZHENG Jinhuan1, WANG Chenglong1, WANG Zhicheng2, CHAI Liqin1

Abstract: Lyocell fibers are regenerated cellulose fibers. In addition to the advantages of hygroscopic property, good luster and comfortable wearing, Lyocell fibers also have better wet and dry strength than other regenerated cellulose fibers. However, Lyocell fibers are prone to fibrination, which limits their application in textile applications. The reactive dye is one of the most commonly used dyes for cellulose fiber dyeing, with advantages of simple application, cheap price and bright color, but in the process of immersion dyeing, to promote reactive dye dyeing, a large number of inorganic salts are often added in the dyeing solution. Therefore, there are high energy consumption, complex and variable dyeing wastewater composition, deep color, alkaline and expensive treatment costs and many other drawbacks. In this paper, the continuous salt-free rolling dyeing process of Lyocell fiber fabrics with reactive dyes was systematically studied, which not only improved the dyeing property and reduced the emission of inorganic salts, but also improved the fibrillation degree of Lyocell fibers and effectively improved the quality of Tencel fabrics.

The effects of dyeing and fixing process and formula (baking temperature, baking time, dipping times, dosage of alkali and urea) on dyeing properties (K/S value and fixing rate) of fabrics were discussed. The dyeing properties and fibrination degree of fabrics were compared with those of traditional dyeing process. The results show that the optimized rolling, baking and dyeing formula and process of the Lyocell fabric require alkali of 25 g/L, urea of 60 g/L, and a baking time of 2 min at 160 ℃ after twice dipping and twice padding. The three dyes of Br Red CA, Br Yellow CA and Blue CA have good dyeing effect, and the color fixing rates are 76.98%, 67.48%, 77.15%, and K/S values are 21.87, 10.87, 15.85, respectively. Compared with the traditional immersion dyeing process, the continuous salt-free rolling dyeing can obtain higher dyeing depth , and the K/S values of the three dyes are increased by 28.10%, 5.23% and 6.20%, respectively. The maximum absorption wavelength of the same dye is the same under rolling, baking and immersion dyeing, indicating that pad dyeing does not change the color light of the fabric. The L* value of the pad dyeing fabric is generally lower than that of the immersion dyeing fabric, indicating that the color of the Lyocell fabric dyed by the former will be darker under the condition of the same amount of dyes. The dry rubbing fastness of the three dyes is higher than that of the wet rubbing fastness, reaching grade 5, while the wet rubbing fastness is one or two grades lower. Both of them have good soap color fastness, generally at grade 4-5 or above. The surface fibril of Lyocell fibers after continuous salt-free rolling dyeing is less than that of immersion dyed fabrics, and the fibrillarization degree of the fabric is weaker and the surface is smoother.

Continuous salt-free rolling dyeing of Lyocell fibers can obtain good dyeing effect, reduce energy consumption and pollutant emission in the dyeing process, which will be conducive to clean dyeing of cellulose textiles, and promote the sustainable development of the whole dyeing process.

Keywords: Lyocell fabric; reactive dye; pad dyeing; salt-free; fibrination

收稿日期:20230327 網络出版日期:20230510

基金项目:浙江省基础公益研究计划项目(LGC20E030001,LGF21E030004)

作者简介:唐奇(1998—),女,杭州人,硕士研究生,主要从事生态染整技术方面的研究。

通信作者:柴丽琴,E-mail: chailiqin0101@163.com