Mechanical properties of a clay soil reinforced with rice husk under drained and undrained conditions

Claudia Regina Bernardi Baldin, Maiky Yamato Kawanami, Weiner Gustavo Silva Costa,Vitor Reinaldo Bordignon, Cristhyano Cavali da Luz, Ronaldo Luis dos Santos Izzo

Federal University of Technology - Paraná, Curitiba, Brazil

Keywords:

ABSTRACT Fiber-reinforced soils have been increasingly used in geotechnical engineering.Over the years, research has sought to understand and investigate the influences of fibers as reinforcement in soil-fiber mixtures.This study assessed the behavior of clayey soil in the city of Curitiba (Paraná, Brazil), adding rice husk fiber (RHF), an industrial waste from Cooperativa Agroindustrial in Alegrete (Rio Grande do Sul, Brazil).To evaluate the effect of the presence of natural RHF on the mechanical behavior of compacted soil,aspects such as the influence of fiber content and the drained and undrained behaviors of the soil were evaluated through unconfined triaxial compression tests.The following tests were realized: soil granulometry,specific mass of solids and Atterberg limits.Specimens were produced in quadruplicate for the soil and mixtures using the RHF contents of 0.5%, 0.75%, 1% and 1.5% to determine the unconfined compressive strength(UCS).Triaxial tests were realized on a pure soil specimen and the specimens with 1% RHF under confining pressures of 50 kPa, 100 kPa, 200 kPa and 400 kPa.The interactions at the interface between husk surface and soil were analyzed using scanning electron microscopy(SEM).In UCS tests,specimens with RHF percentages of 1%and 1.5%presented the highest results,with an increment of 36%compared to the soil without RHF.The results of the consolidated drained triaxial compression tests show that in terms of effective stress,there was a small difference in the strength of the compacted pure soil and soil with the addition of RHF.For the undrained tests,the strength increased with the inclusion of husk, with a reduction of 50% in cohesion and an increment of 22% in friction angle for specimens containing RHF compared to the soil without RHF additions.

1.Introduction

Rice is one of the most produced and consumed grains in the world.For many people,it is considered the most important cereal.Among the residues generated by rice production are bran,broken rice, rice husk, and burnt husk ash.These by-products are generated in significant quantities and must be treated and disposed of properly (Lorenzett et al., 2012).Rice husk is generated in a considerable volume proportionally to the total mass of grain produced.According to Ali et al.(2016),1 ton of rice has 220 kg of husk.In keeping with this estimate, about 2.6 million tons of rice husk would be generated for the 11.75 million tons of Brazilian production in the 2019-2020 harvest (CONAB, 2021).

Much of the rice husk generated in Brazil is burnt after harvesting to reduce the impact on cultivated areas.However,burning this material can cause even more environmental problems such as air pollution and the waste of biological resources.Therefore, the proper and immediate disposal of rice husk is a crucial concern.Using this natural rice husk can help to reduce atmospheric pollution (Haider, 2013).Several authors have investigated rice husk ash in chemically stabilized soils (Basha et al., 2005;Muntohar, 2005; Rao et al., 2011; Kumar and Gupta, 2016; Jiang et al., 2019).Other researchers have used rice husks in composite materials (Canakci et al., 2015; Gowthaman et al., 2018; Pakravan et al., 2018; Mohamed et al., 2020).However, an alternative to this issue may be using natural rice husk in soil reinforcement studies to improve its mechanical properties, especially tensile strength.There is no information available on the use of rice husk to reinforce soil, requiring an experimental study.

Clay soils are highly sensitive to moisture variations and consequent changes in volume, while offering low shear strength,high compressibility and cracking tendencies when used in pavements, railway embankments, impervious blankets, sealing elements, and liners (Shourijeh et al., 2022).In this sense, short discrete fibers can be added and mixed randomly into the soil,which allows for an isotropic increase in the strength of the soil composite and the absence of planes of weakness (Maher, 1988;Gray et al., 1989; Chauhan et al., 2008; Estabragh et al., 2011;Gowthaman et al.,2018).The use of fibers as soil reinforcement can contribute to promoting an increase in the strength of the soilfiber mixture, as reported in the research by Estabragh et al.(2011), Qu and Sun (2016), Khatri et al.(2016), and Suffri et al.(2019).

Some work has been carried out to verify and analyze the reinforcement of soils with the use of fibers.According to Tang et al.(2007),when associated with the soils,the fibers can improve their mechanical properties and reduce deformation.In addition, for seeking sustainability,fiber-reinforced soils have been encouraged in geotechnics, including stabilizing paving bases and subbases,landfills, slope stabilization, retaining wall structures and improvements in hydraulic conductivity for waste containment(Shukla, 2017; Ammar et al., 2019; Ehrlich et al., 2019; Ghorbani et al., 2021).

Ibraim et al.(2012) studied the influence of the orientation of the fibers used to reinforce a sandy soil, using moist tamping and moist vibration techniques for specimen preparation.Three different discrete flexible polypropylene fibers have been used as reinforcing materials and the fiber orientation distribution was determined.An anisotropic behavior was verified in both specimen preparation methodologies and a gain in triaxial compressive strength.The marked anisotropic behavior supports the anisotropic distribution of the determined fiber orientation.

Sotomayor and Casagrande (2018) evaluated the loadsettlement behavior of unreinforced and reinforced sands with coconut fibers in either a random or a layered distribution in plate load tests.The authors observed that the most significant settlement reduction is obtained with fibers in the layered distribution and the random distribution of fibers provides some more ductility and,consequently,the mixture can resist the highest load than that with fibers of layered distribution.

Zhang et al.(2021) examined the performance of a micaceous soil reinforced with a combination of jute fibers, hydrated lime or slag-lime.On the unconfined compressive strength (UCS) tests,they observed that the material strength and stiffness were increased with the inclusion of up to 1% fiber and decreased if additional fibers were used.Moreover, the ductility was improved consistently with up to 1.5% fiber content.

Nezhad et al.(2021)investigated the influence of natural fibers,including basalt and bagasse as well as synthetic polyester fibers,on the strength behavior of clayey soil performing indirect tensile strength(ITS)and California bearing ratio(CBR)tests.The effects of various fiber contents(0.5%,1%and 2%)and lengths(2.5 mm,5 mm and 7.5 mm) were evaluated.It was found that increasing fiber content and length significantly influenced the CBR and ITS values.Moreover, the triaxial compression test results revealed that with the addition of basalt fibers,the internal friction angle increased by about 100%,and with the addition of polyester fibers,the cohesion increased by about 70%.

According to Correia et al.(2021), the fibers exert a strong influence on the mechanical properties of soil through the friction of the interface between the fibers and the soil particles, resulting in greater shear strength and improvement in soil ductility.These authors studied the behavior of a clayey soil mixed with polypropylene fibers(average diameter of 18 μm and average length of 12 mm)from drained and undrained triaxial compression tests.In the drained tests,the shear strength increased with the inclusion of the fiber for a particular average effective stress,represented by an increase in the apparent cohesion.The effect on the friction angle was smaller.From consolidated undrained (CU) triaxial compression tests,it was found that the positive excess pore water pressure observed in all tests was not sensitive to fiber reinforcement.The authors observed that the fiber strength is mobilized after plastification,which leads to an increase in strength.It was also observed that failure occurred at large strains in the drained tests, but at smaller strains in the undrained tests.

The mechanical properties of a soil-fiber mixture are directly associated with the percentage of fiber addition and its length.For example,Wei et al.(2018)performed unconfined compression tests on a soil-fiber mixture to confirm the optimal fiber content and length of wheat straw, rice straw, jute, and polypropylene fiber.Triaxial compression tests were performed on fiber-lime-soil specimens to study their strength, stress-strain behavior, and failure pattern.The authors concluded that the four fiber types could improve the strength and stress-strain properties of the soil and soil-lime mixture.

Estabragh et al.(2011) investigated the effects of nylon fibers with small length (4 mm length, 2 mm width, and 0.4 mm thickness)as reinforcement in a clayey soil of low plasticity.CU triaxial tests were performed on unreinforced and reinforced soil specimens with different percentages of randomly distributed fibers.The results showed that the shear strength and internal friction angle of the natural soil significantly increased with the addition of the fiber.

Qu and Sun (2016) evaluated the effects of wheat straw fiber reinforcement in clayey soil.The dimensions of the straw fiber used in the study were approximately 10 mm in length.The results showed an increase in stiffness and shear strength with increasing fiber content.The internal friction angles in terms of total and effective stresses (φ and φ′, respectively) also increased with fiber content until it reached an optimal value, between 0.2% and 0.3%.

Khatri et al.(2016)performed a series of CU triaxial tests on coir fibers reinforced clay and reported an improvement in undrained shear strength with increased fiber content from 0.4% to 1.6%.

Suffri et al.(2019)also evaluated a clayey soil with coconut fiber contents of 0.5%-2% using CU triaxial tests and found that the inclusion of fibers increased the undrained shear strength.

According to Zhao et al.(2009),rice husk is an abundant waste,with low price and potential for biodegradability.However, relatively few published data are available on its performance as reinforcement to soil.In this sense,the present study puts focus on the effects of natural rice husk on improving the mechanical behavior of a clayey soil.Aspects such as the influence of fiber content and the presence of fiber on the drained and undrained behaviors of the soil were evaluated through unconfined triaxial compression tests.Clayey soil reinforced with rice husk can be a beneficial engineering material,as it is possible to use this fiber as a low-cost alternative material for soil reinforcement.

2.Materials and methods

2.1.Soil and rice husk

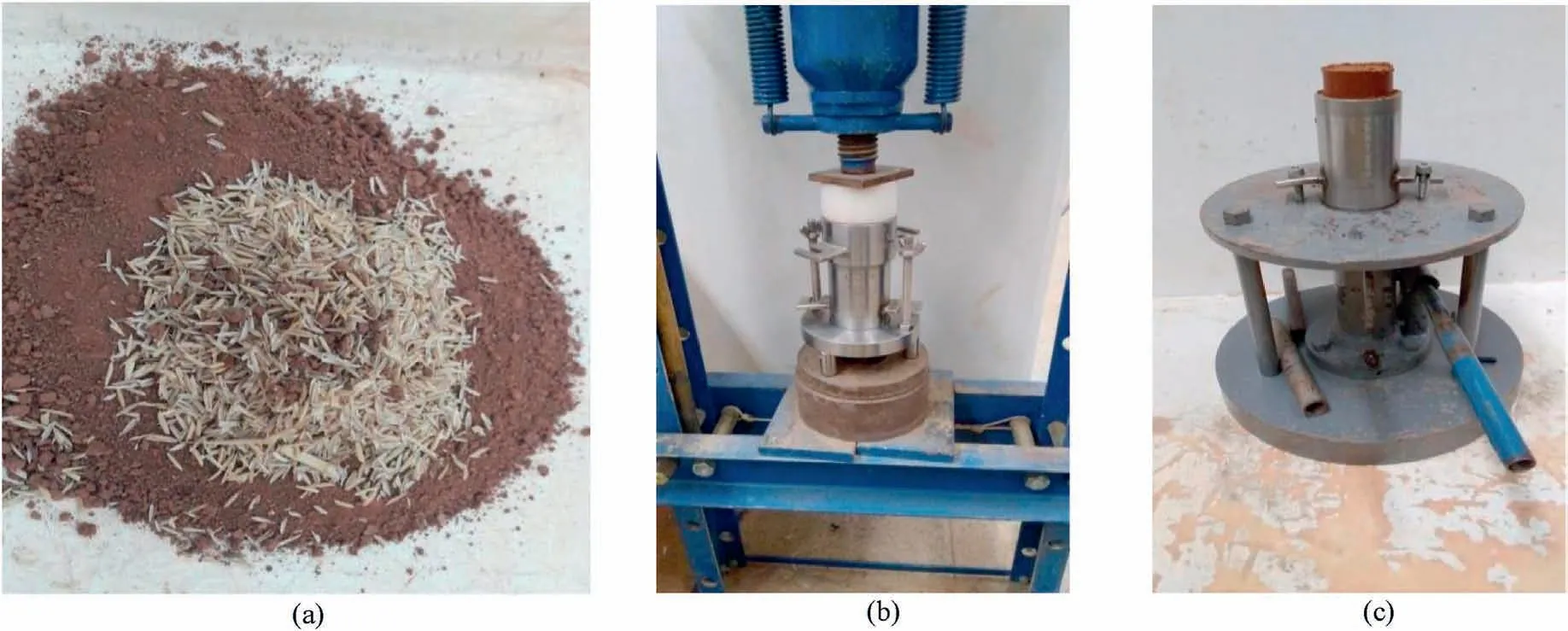

The material studied is a reddish-colored clay soil collected in a plot of land located in the vicinity of Cidade Industrial de Curitiba,near the Federal Technological University of Paraná at coordinates(-25°26′44.703′′, -49°21′14.613′′), in the city of Curitiba (Paraná,Brazil) (Fig.1).The natural rice husk, which is 8.92 mm long and 1.56 mm wide, was obtained directly from the rice processing industry in Alegrete(Rio Grande Sul, Brazil), and corresponds to the 2018 rice crop(Fig.2).

Fig.1.Profile of clay soil collected.

Fig.2.Rice husk fibers (RHFs).

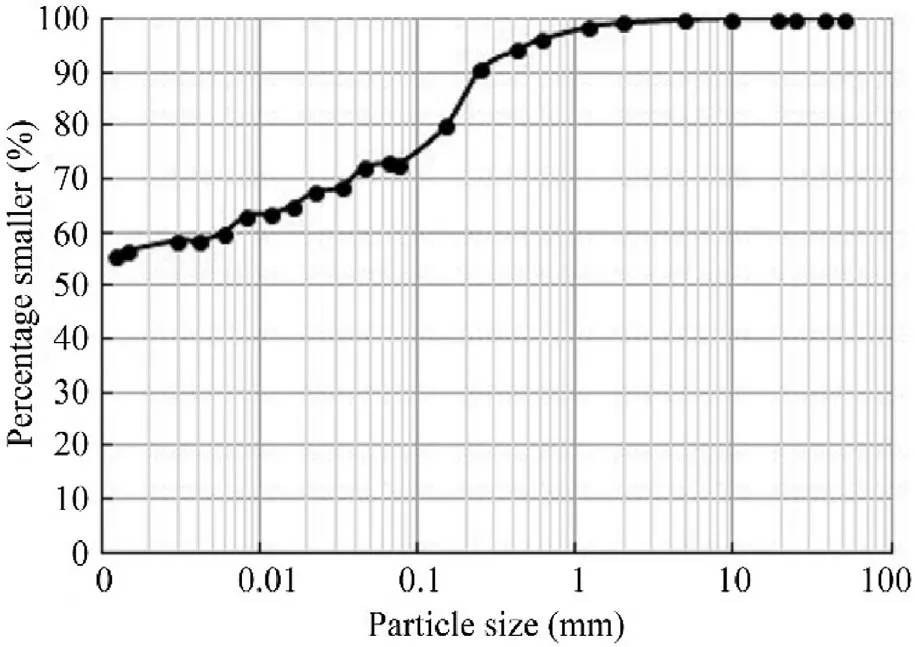

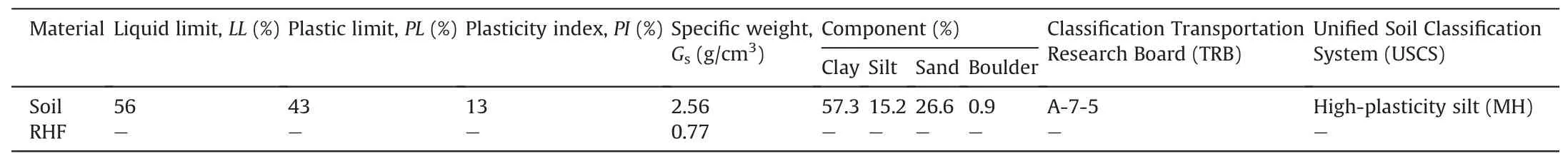

The soil characteristics are presented in Table 1 and Fig.3.The soil classification follows ASTM D2487-17 (2017), and the particle size distribution is measured following NBR 7181 (2016).The specific mass of the soil solids is determined according to the procedures of ASTM D854-14 (2014), and the consistency limits, i.e.the liquidity and plasticity limits, are obtained based on the recommendations of NBR 6459 (2016) and NBR 7180 (2016),respectively.

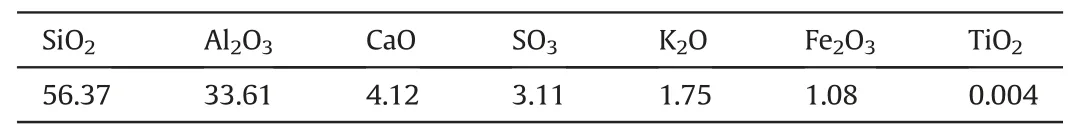

The quantitative chemical composition of the soil specimen surveyed by X-ray fluorescence (XRF) is presented in Table 2.

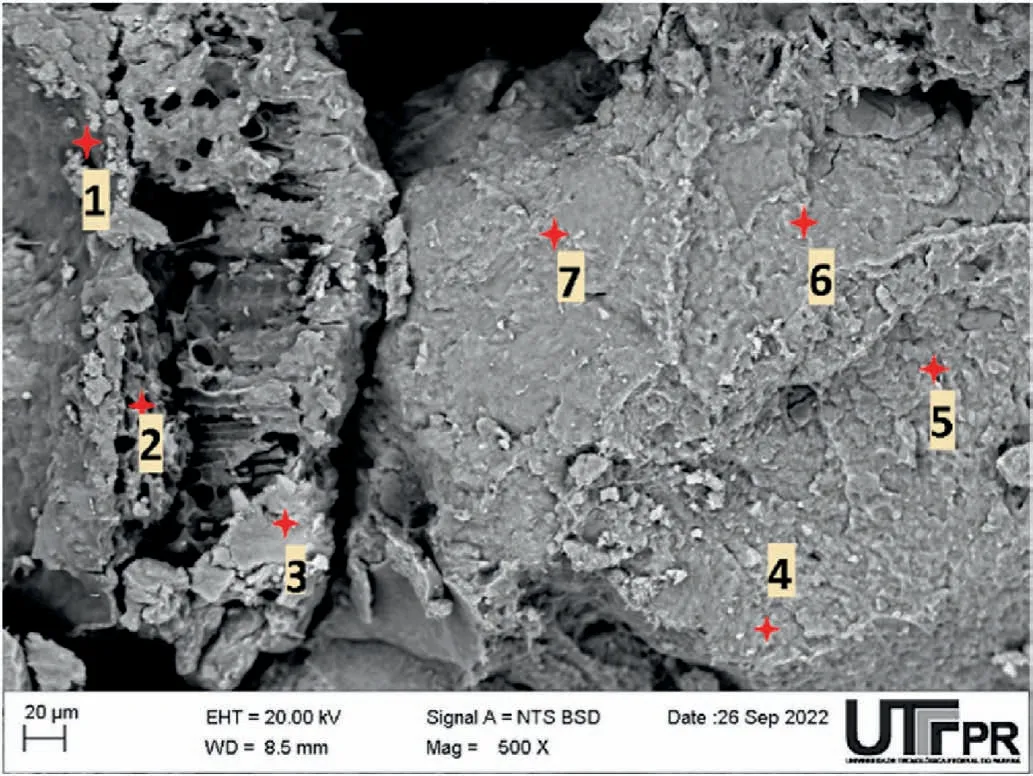

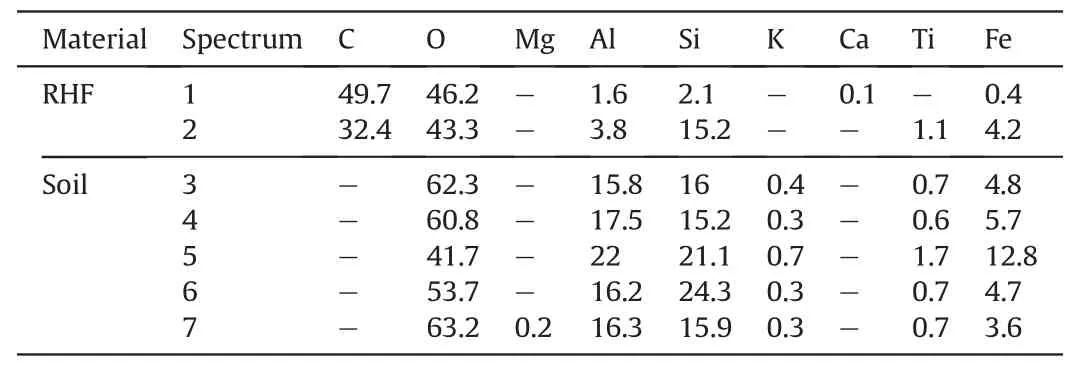

Fig.4 shows the microphotographs for soil-RHF mixture using scanning electron microscope (SEM) with a magnification of 500 times.Energy dispersive X-ray spectroscopy (EDX) analysis of microanalysis points shown in Fig.4 are presented in Table 3.These results agree with those obtained in the XRF analysis where silicon,aluminum and oxygen were observed mainly in the soil.In RHF,carbon, oxygen and silicon predominate.

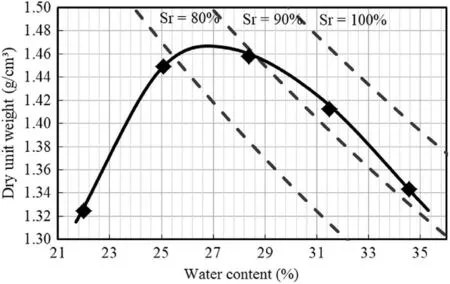

The optimum soil compaction parameters were determined by the standard Proctor test using material reuse (NBR 7182, 2016).The material has 27%optimum moisture and 1.47 g/cm3maximum dry density.The soil compaction curve is shown in Fig.5.The preconsolidation stress of this compacted soil is 260 kPa,according to the Pacheco Silva method.

Fig.3.Grain size distribution curve of the soil studied.

Table 2 Chemical composition (%) of the soil used.

Fig.4.SEM image of soil-RHF mixture with a magnification of 500 (1-7 are the EDS points).

Table 3 EDX results of soil and RHF (in weight%).

Table 1 Properties of the materials used.

Fig.5.Soil compaction curve without the addition of RHF.

2.2.UCS test procedures

Soil specimens were prepared for characterization and compaction tests according to NBR 6457 (2016) with oven drying due to high atmospheric humidity.

At the optimum compaction parameters, specimens were molded in quadruplicate with the homogeneous pure soil to determine the UCS.

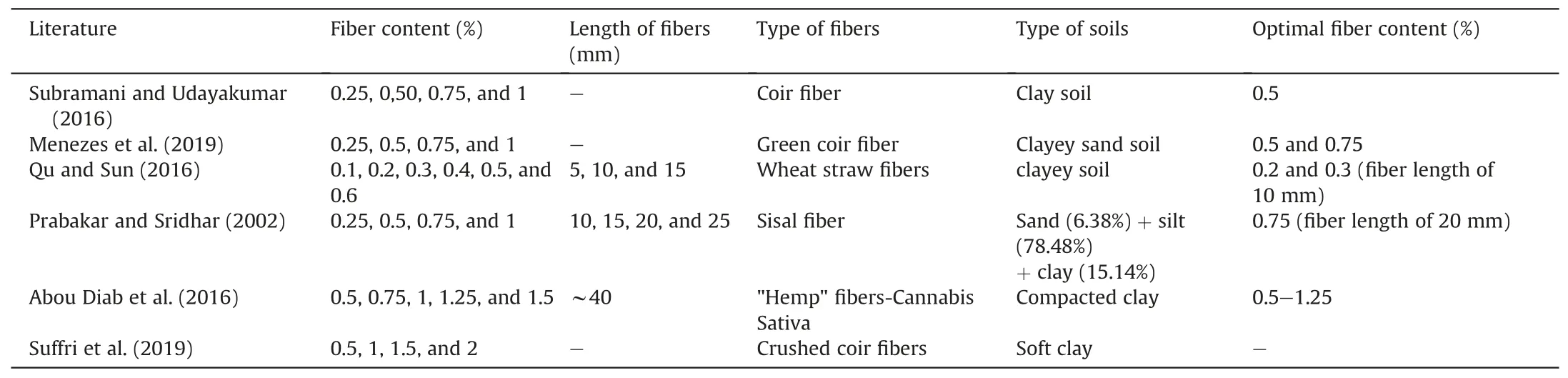

For evaluating the effect of fiber addition on the UCS, the soil was mixed with fibers at 0.5%, 0.75%,1% and 1.5% in terms of dry mass, under the same compaction conditions as the soil without fibers.Water was added to reach the optimum moisture content(wot).The mixing of the composite with distilled water was carried out as quickly as possible, trying to minimize moisture losses during the molding process of the specimens.The fiber contents were chosen based on studies that used natural fibers as reinforcement in clayey soil, as shown in Table 4.

The specimens were statically compacted in three layers with a stainless-steel mold with an internal diameter of 50 mm,100 mm height and 5 mm thick at the optimal compaction parameters.The molding was done with the help of a manual hydraulic press(Fig.6a-c).The specimens were compacted to achieve a minimum degree of compaction of 95% at the optimum moisture content of the fiber-free soil.

The UCS test procedures were performed according to NBR 12025 (1990) after molding.The test speed was 1 mm/min.The UCS is the maximum breaking load of the material divided by the cross-sectional area of the specimen (Fig.7).

2.3.Triaxial test procedures

For the triaxial shear tests, specimens were molded under the same conditions for the unconfined compression tests.Consolidated drained (CD) and CU triaxial shear tests were performed according to ASTM D7181-20 (2020) and ASTM D4767-11(2020) (2020), respectively, to evaluate the difference between the drained and undrained behaviors of the soil without and with the addition of natural rice husk.

Table 4 Studies that used natural fibers as reinforcement in clayey soil.

Fig.6.Preparation and molding of specimens: (a) Mixing; (b) Compaction; and (c) Extraction.

Fig.7.UCS test press.

Specimens were saturated using water percolation and backpressure until a minimum B parameter of 0.95 (Skempton,1954).Subsequently, the specimens were consolidated with average effective stresses of 50 kPa,100 kPa,200 kPa,and 400 kPa.The test speed was 1 mm/min for both the CD and CU tests.Information about the specimens is described in Table 5.

A semiautomatic press was used for the triaxial shear tests,consisting of three components: the press, the volume control module,and the pore pressure control module,as shown in Fig.8.

2.4.SEM

SEM and chemical microanalyses of natural and fiber-reinforced soils were determined by EDX analysis using an Oxford (Penta FET125 Precision)laser micro-mass analyzer(LAMMA-1000,model X-ACT).

3.Results and discussion

3.1.UCS

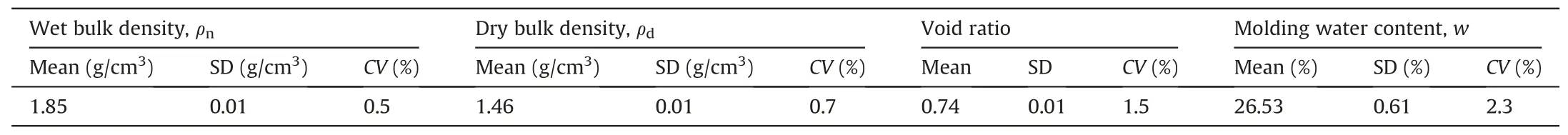

Results of the compression tests on the pure and RHF-reinforced soils are presented in Table 6 and Fig.9.The mean, SD, and CV values for each mixture are presented according to statistical criteria.

From the average results obtained,the gain in UCS was evident when the added RHF content was above 1%.For the soil with 1%and 1.5% fiber addition, the strength values were 324.9 kPa and 323.2 kPa,respectively, approximately 36%higher than that of thepure soil (238.6 kPa) (Table 6).These tests were performed at the optimum moisture content,i.e.under unsaturation conditions.The results obtained here were possibly influenced by the higher volume of solids in the mixtures with a higher amount of fiber,given the lower density of the fiber and that the specimens were compacted under the same dry specific mass.This may have led to greater compaction in the molding process.

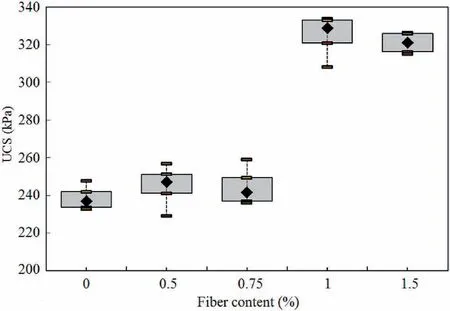

Table 5 Information on the compacted specimens for performing the unconfined and triaxial compression tests.

Fig.8.Triaxial test press.

Table 6 UCS of mixtures,and the mean value,SD and CV values for all mixtures according to RHF addition levels.

Fig.9.UCS results.

Studies indicate that the UCS increases with fiber content up to a threshold (Maliakal and Thiyyakkandi, 2013; Najjar et al., 2014),beyond which the improvement in strength reaches an asymptotic upper limit,and thereafter begins to decline(Prabakar and Sridhar,2002;Anagnostopoulos et al.,2014).Abou Diab et al.(2016)pointed out that high fiber contents result in a poor mixture, preventing contact between soil particles and weakening the fiber/soil bond.Thus, it can be argued that 1% and 1.5% levels of RHF significantly improve the UCS,with a tendency of decrease in strength when the added RHF is beyond 1.5%.

Kumar et al.(2006)assessed a clay soil in UCS test with 0%,0.5%,1%,1.5% and 2% flat and crimped polyester fibers.Three lengths of 3 mm,6 mm and 12 mm were chosen for flat fibers,while crimped fibers were cut to 3 mm long.The results indicated that as the fiber length and/or fiber content increases, the UCS value improves.

Canakci et al.(2015) analyzed the expansive soil specimens treated with lignin,rice husk powder(RHP)ranging from 0%to 20%,and rice husk ash(RHA)from 0%to 10%by weight in the laboratory.The treated specimens were submitted to UCS tests.The results indicated that an RHP content of 15% was ideal in relation to UCS.

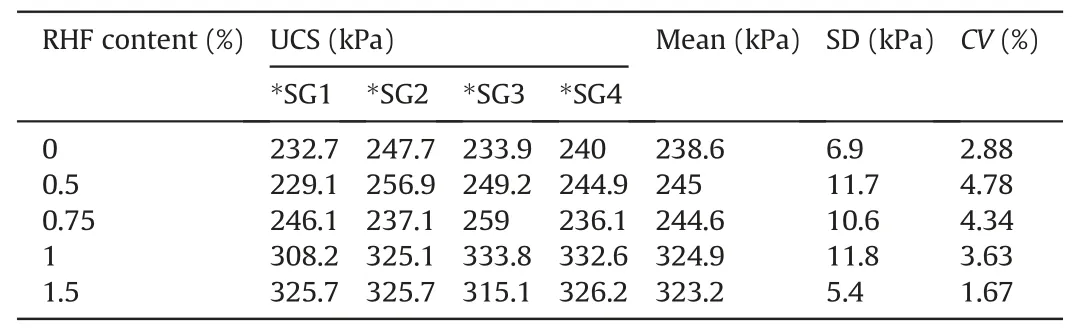

Fig.10.Failure envelopes in terms of effective stresses.

Wei et al.(2018) found that soil reinforcement with wheat straw, rice straw, jute and polypropylene fiber brought improvements concerning UCS at different fiber contents and lengths.The best results were observed at fiber contents between 0.2% and 0.25%, and the ideal fiber length was 30% or 40% of the specimen diameter(61.8 mm).It was observed that lower fiber contents were necessary to obtain better behavior in this test for this length,which is much longer than that of rice husk.

3.2.Triaxial compression tests

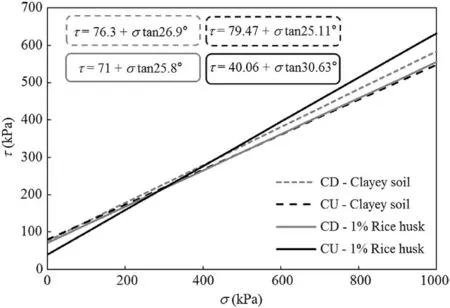

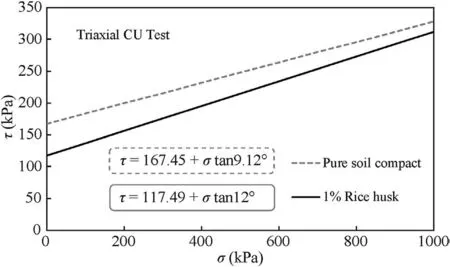

In Fig.10, the failure envelopes are presented in terms of effective stresses.It is noteworthy that in the CD test,compared to the pure compacted soil,the cohesion of the soil with the addition of 1%RHF reduced by 5 kPa and the internal friction angle reduced by 1%.For the CU triaxial test,there was a greater difference in both parameters when comparing the soils with and without fiber reinforcement, showing a possible influence of the fibers on the undrained behavior.

Regarding the effect of the fibers on the effective stress parameters, the results of the undrained triaxial compression tests showed a notable increase of internal friction angle (φ) and a reduction of cohesion (c).Shen et al.(2021) explained that the presence of fibers can modify the internal friction angle and cohesion of clayey soil.This result indicated an interaction between the soil and RHF strongly influenced by the friction in undrained conditions.

Fig.12.Excessive pore pressure versus axial strain obtained from CU tests.

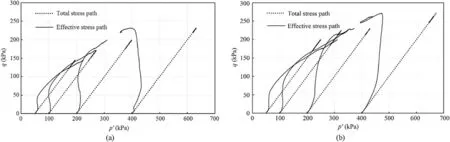

Fig.11.Stress paths in the CU triaxial test: (a) RHF-soil mixture; and (b) Compacted pure soil.q is the deviatoric stress, and p′ is the mean effective stress.

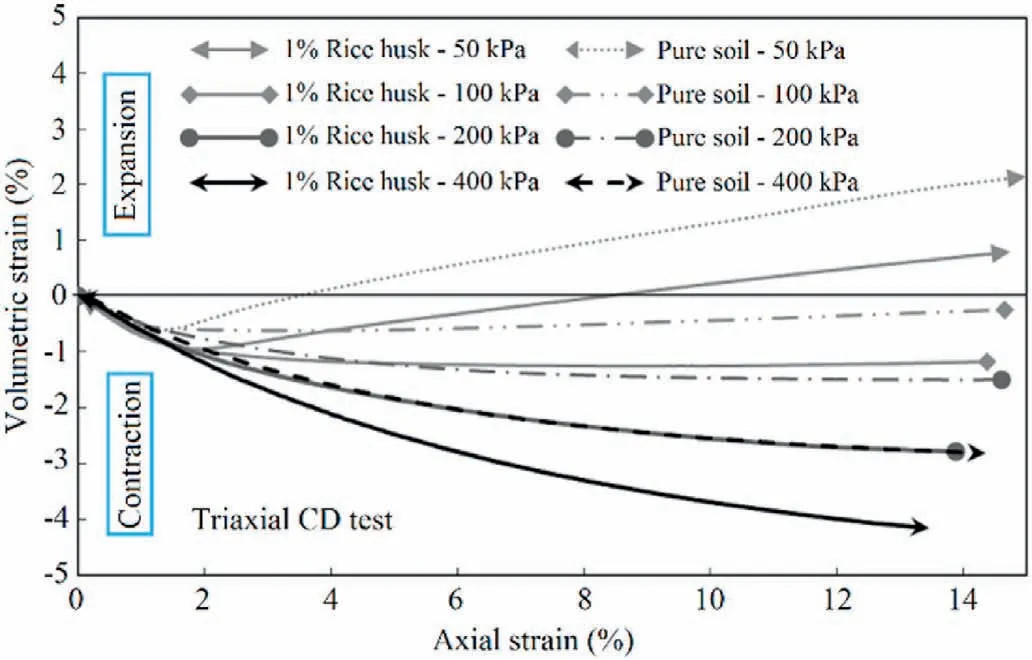

Fig.13.Volumetric strain versus axial strain obtained from CD tests.

As can be observed from the stress paths and the behavior of volumetric variation and generated pore pressure (Figs.11-13),during failure in the CD and CU tests, respectively, there is a difference in the behavior of compacted pure soil and soil with the addition of RHF.A behavior of more contraction and more significant excess pore pressure can be observed in the specimens with fiber, possibly due to the strain behavior of the RHF.For lower stresses (50 kPa and 100 kPa), the tendency of dilation was more accentuated in the soil without the fiber, since there was a more significant generation of negative pore pressure in undrained conditions.This behavior is typical of overconsolidated clays(Craig,2004).

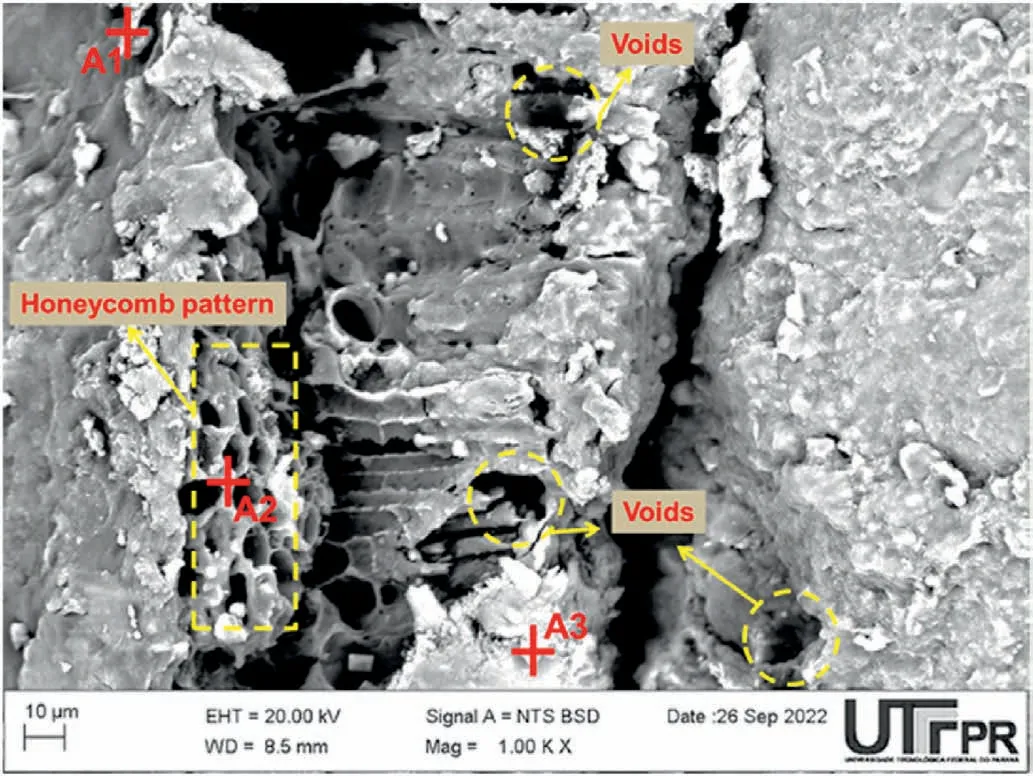

At the drained condition (CD test), the reduction in the shear strength parameters was influenced by the presence of RHF,possibly by the lower RHF-soil shear strength.Factors such as the shape, lubrication, length and honeycomb pattern of the RHF can contribute to this behavior.

At the undrained condition (CU test),as observed,the negative pore pressures occur in the soil in a more accentuated way than that in the RHF-soil mixture at lower confining stresses (Fig.12).Furthermore, the lower excess pore pressure in the pure soil at higher confining stresses influences frictional resistance.Therefore,the strength is influenced by the lower effective stresses in the mixture with a reduction in the cohesion and an increase in the internal friction angle under the undrained condition (Fig.10).

As the analysis was done in terms of effective stress, the pore pressure generated in the CU test modified the stress paths,as can be seen in Fig.11.The development of pore pressure was greater in the soil specimen reinforced with RHF.This behavior probably due to the honeycomb pattern of the fibers.

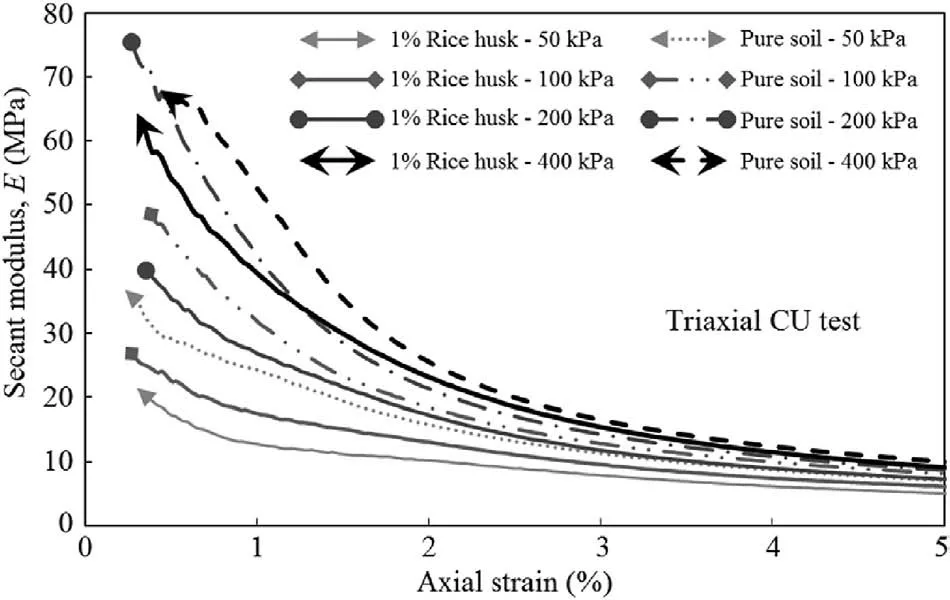

Fig.14.Secant modulus versus axial strain obtained from CU tests.

Due to the positive excess pore pressure, it is possible to verify that the effective stress envelope moves away from the total stress at confining stresses of 200 kPa and 400 kPa.It is also possible to verify that the soils with and without fiber present a similar behavior.However, it is important to consider that the shear strength decreases at the soil-fiber interface due to the low resistance generated between them.

Regarding the volumetric strain in the CD triaxial tests(Fig.13),the RHF-soil mixture shows more significant contraction than the pure soil.This is in agreement with the behavior under undrained conditions with a tendency to swelling,typical of overconsolidated clays.Studies conducted by Abou Diab et al.(2018), Louzada et al.(2019), and Correia et al.(2021) also observed more significant contraction during shear tests on the fiber-reinforced soil compared with unreinforced soil.

These differences are in line with the study by Bordoloi et al.(2017), where infiltration rate was investigated in a compacted composite of soil reinforced with natural fibers (jute, coir, and water hyacinth), using the same aspect ratio to reinforce the soil using three different fiber percentages and different densities.The authors observed that percolation increased for all fiber-soil mixtures compared to pure soil.This increase was attributed to the preferential flow along the fibers in the case of compounds.It was also observed that the surface morphology and the type of filament arrangement also influenced the infiltration of these composites.The same results were obtained for a soil-fiber mixture by Ehrlich et al.(2019) and Miller and Rifai (2004).The preferential pathways for the flow of water within the specimen and the resulting increase in hydraulic conductivity contribute to facilitating water percolation and the volumetric contraction behavior.

Abou Diab et al.(2018) evaluated the volumetric deformation versus axial deformation for clay specimens and specimens reinforced with 40 mm long hemp fibers,with fiber contents of 1%and 1.5%.They found that the measured volumetric strains show additional shrinkage in reinforced specimens.This effect increases as the fiber content increases.

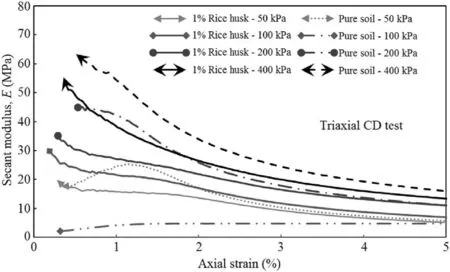

The relations between the secant modulus and axial strain for the CU and CD tests with pure soil and the addition of RHF are shown in Figs.14 and 15, respectively.In the undrained triaxial tests, a higher modulus was observed for the pure soil.This tendency was also found in the drained triaxial tests.Notably, the presence of fibers reduced the secant modulus and showed a lower cohesion value between soil particles, causing a change in the structure of the fiber-compacted material.This is probably a consequence of the limitation related to the anchorage length of the fiber, in addition to its honeycomb form structure, which may have contributed to the reduction of material ductility.Casagrande and Consoli (2002) studied the behavior of soil reinforced with polypropylene fibers.They observed that the addition of fibers to the soil caused a reduction of the soil secant modulus by approximately 20%.The authors explained that changes in the material structure due to the incorporation of fibers can have consequences of reduced secant modulus.According to Wang et al.(2019), it is probably due to the change in the soil fabric generated by the presence of flexible fibers.

Fig.15.Secant modulus versus axial strain obtained from CD tests.

The idea of ductility is presented here and used to determine the action of rice husk.Bekhiti et al.(2019)defined the ductility by the aptitude of a material or structural system to sustain inelastic deformation prior to collapse without significant loss of strength.The authors observed the contribution of tire rubber fibers to the increase of ductility of a fiber-reinforced soil specimen in comparison with cement-reinforced specimens.Bordoloi et al.(2015)affirmed that the inclusion of water hyacinth fiber changed the brittle behavior of the soil to a ductile behavior of the soil-fiber composite.

Wang et al.(2019) investigated the effect of wheat straw fiber reinforcement on the mechanical behavior of clayey soil, and analyzed the secant modulus at 1.2%axial strain level for untreated soil and fiber-reinforced soil.The authors observed that there was a reduction in the secant modulus with reinforcement.Despite this,the effect of fiber reinforcement on the shear strength was beneficial, with the addition of 0.4% fibers.

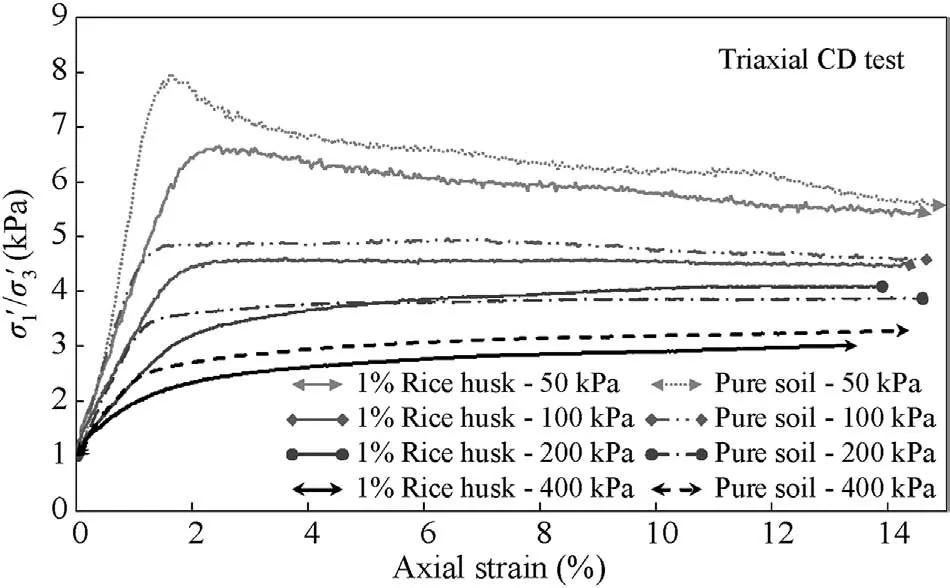

Fig.16 presents the relation between the main effectives stress ratio(σ′1/σ′3)and the axial strain under CD conditions for pure soil and soi-RHF mixture.The figure indicates that the increase in stresses makes the behavior of the soil with and without fiber become less uneven.It is observed that the magnitudes of variability of the stress ratio curves under higher and lower confining stresses are different between soil and RHF-soil mixture.The typical behavior of overconsolidated clays is also observed at the peak of the effective stress versus axial strain curves at lower confining stresses.This is less pronounced in the RHF-soil mixture.The previously presented factors on the fiber probably attenuate the overconsolidated behavior of the mixture.It is also observed from Fig.16 that the material undergoes greater deformation until the maximum stress is reached, when RHF is added.

Mirzababaei et al.(2020) found that the improvement in shear strength of fiber-reinforced clay decreased with confining stress due to the fiber breakage effect.Correia et al.(2021)observed that the efficiency of polypropylene fibers on a clay soil seems not to increase with the increase of confining stresses,which is expected since it improves the soil-fiber interaction.The authors attributed this to a potential fiber breakage effect at the highest mean effective stress levels.

Fig.16.Principal effective stress ratio for CD tests.

Fig.17 presents the strength envelopes in terms of total stresses.It is noted that in undrained conditions, the greatest difference occurs in cohesion, with a greater value for pure soil.This result may be related to the contact between the soil grains, which may cause gaps between the particles and reduce the cohesion value of the soil-RHF mixture in relation to the pure soil.

Although a slight increase of the internal friction angle may be related to the increase in soil-fiber roughness,cohesion is notably affected by the presence of fibers, with the reduction of bonds between soil particles,which may explain the drop in the cohesion value shown in Fig.17.The typical behavior of overconsolidated clays less pronounced in the soil-RHF mixture also justified this difference.

Wang et al.(2017)investigated the strategies for improving the strength characteristics of expansive soil through the insertion of jute fibers into soil mass.They observed that a further increase in fiber content (above 0.6%) decreases the cohesion.This decrease was attributed to the replacement of soil particles by many fibers.

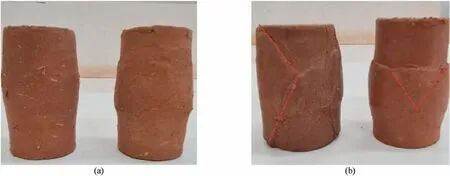

As shown in Fig.18,one of the main advantages of using fibers is the absence of potential planes of weakness.The soil-RHF specimens exhibited “bulging” behavior after the maximum deviatoric stress was reached, and unreinforced soil specimens exhibited partial development of a shear plane.Correia et al.(2021) also observed this behavior in drained tests, and Xu et al.(2018) noted the same rupture in CU tests with bulging located in the middle of the specimens.Mirzababaei et al.(2020) found that bulging could occur in different vertical locations of the specimen if the fibers are not uniformly distributed.

According to Ghavami et al.(1999), the main variables that generally control the strength and performance of a fiber-soil composite are tensile strength, water absorption by the fibers and their adhesion to the soil.The authors illustrated that the adhesion at the fiber-matrix interface is determined by three factors:(i)the soil shear strength due to the surface shape and fiber roughness;(ii)friction forces on the fiber surface due to soil contraction in case of drying;and(iii)the cohesive properties of the soil.In addition,each of these three factors, affected by dimensional changes in the natural fiber, can occur due to changes in humidity and temperature.

Several researchers have noted that fiber slip resistance is strongly dependent on the fiber surface roughness (Tang et al.,2010; Hejazi et al., 2012; Jamsawang et al., 2018) and length(Jamsawang et al.,2018).Jamsawang et al.(2018)explained that as the shear force is applied to a soil-fiber matrix,the adhesion force decreases due to the decrease in embedded fiber length.Thus,failure occurs when the shear force exceeds the binding force along the length of the fiber embedded in the soil.

Fig.17.Failure envelopes in terms of total stresses for CU tests.

Fig.18.Specimens after rupture: (a) Soil-RHF mixture; and (b) Compacted pure soil.

Fig.19.SEM image of soil-fiber surface.

3.3.SEM

SEM micrographs of the soil-RHF surface (Fig.19) show a honeycomb pattern of the fiber and the experimental evidence of friction between fibers and soil due to undulations presented on the soil surface and the breakage or pulling out of the fibers.Through SEM micrographs of wheat straw fiber-reinforced and unreinforced soils, Wang et al.(2019) observed that the mobilization of the fiber reinforcement effect was driven by friction developed during physical contact between soil particles and the fiber surface.In addition, they also observed the honeycomb pattern by analyzing the surface of wheat straw fibers.

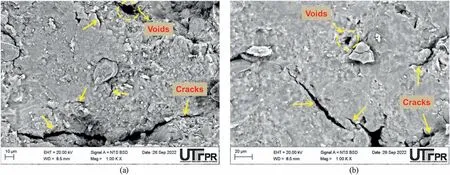

SEM images of fiber-reinforced and unreinforced soils are shown in Fig.20.Fig.20b shows that the surface presented by the soil reinforced with 1% fiber is more compacted compared to soil without fibers (Fig.20a).However, the presence of cracks and porous space is observed on the two surfaces analyzed(Fig.20).By observing these images, it can be concluded that the voids in the soil-fiber contact may have influenced the stress-strain behavior of the mixture.This more compacted structure may have contributed to the increase in the UCS (Table 6).However, a significant increase in the soil shear strength was not observed.The limited length of the fiber and its shape may have influenced this performance.

The soil treatment with fibers is considered one of the best ways to prevent cracks.Although fiber has been shown to boost hydraulic conductivity in clayey soils,where its effectiveness has been shown to be limited, fiber also strengthens the soil (Firoozi et al.,2017).

Tang et al.(2007) analyzed by SEM the interactions at the interface between the surface of polypropylene short fibers and a clayey soil matrix.It was found that bond strength and friction at the soil-fiber interface can be influenced by several factors,such as bonding materials in the soil,normal stress around the fiber body,effective interface contact area,and surface roughness of the fiber.Both fiber length and fiber shape contribute to the interfacial bond strength of soil-fiber matrix (Jamsawang et al., 2018).

Fig.20.SEM images of clayey soil (a) before and (b) after modifying with 1% fiber.

4.Conclusions

This paper has presented the behavior of clayey soil mixed with rice husk, using the results of UCS tests, drained and undrained triaxial shear tests and SEM analysis.The specimens for UCS tests were prepared with 0.5%,0.75%,1%and 1.5%RHF.For triaxial shear tests, specimens were prepared only with 1% RHF.They were isotropically consolidated under confining pressures of 50 kPa,100 kPa, 200 kPa and 400 kPa.The microstructural mechanisms involved in the soil-fiber effect were analyzed using SEM micrographs.The main results obtained in the present study are as follows:

(1) The experimental results of the UCS tests showed an improvement in the soil strength with RHF addition at levels higher than 1%.The mixtures of pure soil and RHF of 0.5%and 0.75% remained similar resistance values.

(2) The results of CD triaxial shear tests showed that in terms of the effective stress, there was no improvement in the strength of the compacted pure soil reinforced with rice husk.For undrained tests, the strength increased with the inclusion of fibers, with differences in the cohesion and internal friction angle.With the addition of fibers,there was an increase in the internal friction angle and a decrease in the cohesion.

(3) Pore pressure in specimens with RHF was higher than that in the compacted pure soil.This behavior was observed at all confining stresses.

(4) The addition of fibers increased the soil compressibility and reduced dilation, with greater influence at lower confining stresses between 50 kPa and 100 kPa.

(5) In both drained and undrained tests, the secant modulus grew with increasing confining stresses for compacted pure soil and fiber-reinforced soil.However, the addition of RHF caused a reduction in the secant modulus of the mixture.

(6) The results showed that in undrained conditions, the strength of compacted pure soil was higher than that of fiberreinforced soil.

In general,the behavior of reinforced soil with the addition of 1%rice husk showed promising results for the UCS tests and the fibers had a low influence on the strength parameters with the saturation of the specimens.Obviously, the use of the rice husk studied here could occur in temporary geotechnical structures.As a natural material, the long-term behavior of the rice husk has not been evaluated in an open exposure field condition which includes abrasiveness, temperature fluctuations, lubrication due to water,erosion, and chemical and biological degradation.Therefore, more research should be conducted to check parameters related to the fiber additions in other soils or field conditions.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors acknowledge the Laboratory of Geotechnics of the Federal University of Technology- Paraná(UTFPR).

Journal of Rock Mechanics and Geotechnical Engineering2023年10期

Journal of Rock Mechanics and Geotechnical Engineering2023年10期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Analytical solutions for the restraint effect of isolation piles against tunneling-induced vertical ground displacements

- Characterizing large-scale weak interlayer shear zones using conditional random field theory

- Displacement-based back analysis of mitigating the effects of displacement loss in underground engineering

- Investigation of long-wavelength elastic wave propagation through wet bentonite-filled rock joints

- Evaluation of soil fabric using elastic waves during load-unload

- Effects of non-liquefiable crust layer and superstructure mass on the response of 2 × 2 pile groups to liquefaction-induced lateral spreading