Variations in dynamic recrystallization behavior and mechanical properties of AZ31 alloy with extrusion temperature

Jae Won Cha,Sung Hyuk Park

School of Materials Science and Engineering,Kyungpook National University,Daegu 41566,Republic of Korea

Abstract This study investigates the effects of extrusion temperature on the dynamic recrystallization (DRX) behavior of a Mg–3Al–1Zn–0.3Mn(AZ31,wt%) alloy during hot extrusion and on the microstructural characteristics and mechanical properties of materials extruded at 350 and 450 °C.An increase in the extrusion temperature causes a decrease in the amount of strain energy accumulated in the material during extrusion,because of promoted activation of pyramidal

Keywords: Mg–Al–Zn alloy;Extrusion;Dynamic recrystallization;Microstructure;Yield asymmetry.

1.Introduction

Extensive efforts have been made recently to reduce the carbon dioxide emissions of vehicles through reduction of their weight.Extruded Mg alloys have attracted considerable attention in the automobile industry because of their low density and high productivity.The microstructure of extruded Mg alloys varies with extrusion process variables such as the extrusion temperature,extrusion ratio,ram speed,extrusion type(e.g.,direct or indirect extrusion),and die angle[1–4].Among these process variables,extrusion temperature plays a decisive role in the grain size,developed texture,and resultant mechanical properties of extruded Mg alloys.An increase in the extrusion temperature promotes grain-boundary mobility during extrusion,which results in coarsening of dynamically recrystallized (DRXed) grains of the final extruded Mg alloy[5,6].Additionally,extrusion temperature influences the dominant dynamic recrystallization (DRX) mechanism and DRX behavior during extrusion,thereby affecting the sizes and area fractions of DRXed grains and unDRXed grains of extruded Mg alloys [7,8].The unDRXed grains of extruded Mg alloys have considerably different microstructural characteristics from their DRXed grains,such as a larger size,elongated morphology,stronger texture,and higher strain energy.Therefore,the unDRXed grains of extruded Mg alloys substantially affect the deformation and fracture behaviors during tension and compression [9–11].

Many studies have been conducted on extruded Mg–Al–Zn (AZ) alloys because commercial AZ-series alloys have excellent castability and well-balanced strength and ductility [12–14].Some studies have demonstrated that the extrusion temperature affects the average grain size,area fraction of DRXed grains,and basal texture of extruded AZ alloys [15–18].Kim et al.[19]reported that as the extrusion temperature increases from 250 to 350 °C,the DRXed grain size of an extruded AZ80 alloy increases from 12.0 to 21.9 μm owing to the stronger grain-boundary migration effect and weaker grain-boundary pinning effect resulting from the smaller number of Mg17Al12precipitates.Consequently,the tensile yield strength (TYS) of the extruded AZ80 alloy decreases from 241 to 194 MPa with increasing extrusion temperature.Accordingly,when the extrusion temperature of high-Al-containing AZ alloys (e.g.,AZ80 and AZ91)increases,the number of Mg17Al12precipitates formed during extrusion decreases and the size of DRXed grains increases,and consequently,the strength of the extruded alloys decreases[18,19].In contrast,some studies have reported that in the extrusion temperature range in which Mg17Al12precipitates are not formed during extrusion,an increase in the extrusion temperatures improves the strength of an extruded high-Al-containing AZ alloy owing to the intensification of texture [17,20].

Studies have also been conducted on the influence of extrusion temperature on the microstructure and mechanical properties of the low-Al-containing commercial AZ31 alloy[21–24].Regardless of the employed extrusion temperature,Mg17Al12precipitates are not formed in an AZ31 alloy during extrusion,because of its low Al content.Nevertheless,previous studies have obtained conflicting results on the effect of extrusion temperature on the mechanical properties of the extruded AZ31 alloy.Some studies have reported that the TYS of the extruded AZ31 alloy decreases with increasing extrusion temperature owing to the coarsening of DRXed grains [21,23].However,Park et al.[24]reported that the DRXed grain size of the extruded AZ31 alloy increases and its basal fiber texture strengthens with increases in the extrusion temperature and ram speed;consequently,the TYS of the extruded alloy remains almost unchanged.Therefore,extrusion temperature does not appear to have a consistent influence on the mechanical properties of the extruded AZ31 alloy.In the mass manufacturing of extruded products using an AZ31 alloy,hot extrusion is generally performed at temperatures higher than 350 °C via direct extrusion using a horizontal-type extrusion machine,in view of factors such as operation continuity,productivity,extrusion load,and equipment capacity.However,most of the previous studies on extruded AZ31 alloys have performed extrusion at relatively low temperatures (<350 °C),via the indirect extrusion process,or using a vertical-type extrusion machine (e.g.,a hydraulic press).Hence,the results of these studies are thought to be different from the results obtained in the mass-manufacturing process.Moreover,very few studies have examined the effects of extrusion temperature on the microstructural changes of the AZ31 alloy during extrusion,as opposed to the ample studies conducted on the microstructure of the fabricated extruded material.Therefore,in this study,direct extrusion is performed at 350 and 450 °C using a horizontal-type extrusion machine to produce extruded AZ31 materials similar to those obtained via the mass-manufacturing process.The effects of extrusion temperature on the DRX behavior and microstructural evolution of AZ31 materials during extrusion and on the tensile and compressive properties and yield asymmetry of the extruded AZ31 materials are systematically investigated.

2.Experimental procedure

A commercial AZ31 alloy (Mg–3Al–1Zn–0.3Mn,wt%)was used in this study.Cast billets were fabricated by placing pure Mg ingots and pure Al,pure Zn,and pure Mn granules(purity: 99.99%) in an electric resistance furnace and melting them at 750 °C in an inert atmosphere of CO2–SF6(10:1)mixed gas.The molten metal was stabilized at 720 °C for 20 min and poured into a carbon steel mold preheated to 200 °C for 30 min using an electric furnace.The steel mold had a length of 210 mm,outer diameter of 100 mm,and inner diameter of 80 mm.The two resultant cast billets were homogenized at 400 °C for 10 h in an inert atmosphere of Ar–SF6mixed gas and then cooled by water quenching.The homogenized billets were machined into a cylindrical shape(length: 120 mm,diameter: 68 mm) for extrusion.Before the extrusion process,the machined billets were preheated to the extrusion temperature (either 350 or 450 °C) for 30 min;direct extrusion was then performed at an extrusion ratio of 25:1,a ram speed of 1 mm·s–1,and an extrusion temperature of 350 or 450 °C through a 300 ton horizontal-type hydraulic extrusion machine.After the extruded materials exited the single-hole (Ø13.6 mm) extrusion die,they were naturally air-cooled at 23 °C.The AZ31 materials extruded 350 and 450 °C are hereafter referred to as 350T and 450T,respectively.After extrusion,the extrusion butts remaining in the extrusion container and die were water-quenched.

The microstructures of the extruded materials and extrusion butts were analyzed using an optical microscope (OM)and an electron backscatter diffraction (EBSD) detector built into a field-emission scanning electron microscope(FE-SEM).For microstructural analysis,all the samples were first ground with progressively finer grades of sandpaper (#120–#2000 grit),then polished with 3 and 1 μm diamond pastes,and finally polished with 0.04 μm colloidal silica solution.EBSD measurements were performed using a Symmetry S2 detector(Oxford Instruments) at an accelerating voltage of 20 kV and a working distance of 17 mm.EBSD scans of the extruded materials and extrusion butts were performed with a step size of 1.8 μm using automated EBSD scan software (Aztec 5.0).Only those data that had a mean angular deviation smaller than 1.0 were used to analyze the average grain size,texture,Schmid factor(SF),and kernel average misorientation(KAM)by means of EBSD data analysis software (AztecCrystal 2.0).The average sizes of DRXed grains and unDRXed grains were measured via the equivalent circle diameter method.

For tension and compression tests,dogbone-shaped specimens (gauge length: 25 mm,gauge diameter: 6 mm) and cylindrical specimens (length: 12 mm,diameter: 8 mm),respectively,were used.All the specimens used in the tests were machined from the extruded materials,and their loading direction corresponded to the extrusion direction(ED).The tension and compression tests were performed thrice for each extruded material at RT (23 °C) at a strain rate of 1 × 10-3s-1using a Shimadzu AGS-100kNX universal testing machine;the average values and standard deviations of the tensile and compressive properties were presented.Fractured tensile specimens were observed along their longitudinal cross-sections using an OM and on the fracture surfaces using an FE-SEM.

3.Results

3.1.Microstructural characteristics of extruded materials

Fig.1 shows optical micrographs of the 350T and 450T at low and high magnifications.Both the extruded materials exhibit a bimodal grain structure comprising elongated un-DRXed and equiaxed DRXed grains.The area fraction of unDRXed grains of 450T is 11.7%,which is approximately 2.3 times that of 350T (5.0%) (Fig.1a and b).Several studies have reported that the area fraction of DRXed grains(i.e.,DRX fraction) of extruded Mg alloys increases with increasing extrusion temperature [19,25,26].However,in the present study,when the extrusion temperature increases from 350 to 450 °C,the DRX fraction of the extruded material decreases from 95.0% to 88.3%.This unusual variation in the DRX fraction is analyzed in detail in Section 4.1.A small number of Al–Mn phase particles is observed in both the extruded materials (blue arrows in Fig.1c and d).However,the extruded materials are devoid of Mg17Al12-phase particles owing to their low Al content (3 wt%).This presence of Al–Mn particles and absence of Mg17Al12particles are consistent with previously reported results for extruded AZ31 materials [27–29].

Fig.1.Microstructure of (a,c) 350T and (b,d) 450T: (a,b) low-magnification images and (c,d) high-magnification images and EDS results for Al–Mn phase. funDRXed and ED denote the area fraction of undynamically recrystallized (unDRXed) grains and the extrusion direction,respectively.

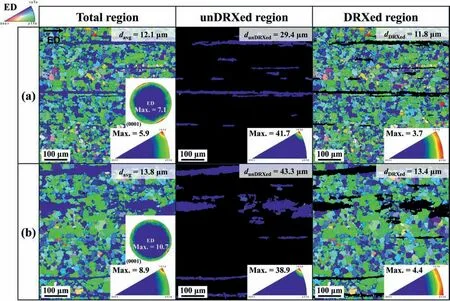

Fig.2a and b shows the inverse pole figure(IPF)maps and ED IPFs of the total (unDRXed+DRXed),unDRXed,and DRXed regions of 350T and 450T,respectively.As the extrusion temperature increases from 350 to 450 °C,the average size of the unDRXed grains increases from 29.4 to 43.3 μm and that of the DRXed grains increases from 11.8 to 13.4 μm;consequently,the average grain size of the extruded material(i.e.,the total region) increases from 12.1 to 13.8 μm.This result of increasing grain size with increasing extrusion temperature has been widely reported for various Mg alloy systems such as Mg–Al-[30],Mg–Zn-[31],Mg–Sn-[32],and Mg–Bi-based alloys [33].Because grain growth at elevated temperatures occurs through the diffusion of atoms at and near grain boundaries,a temperature rise accelerates atomic diffusion at the grain boundaries and consequently coarsens grains [34].

Fig.2.IPF maps and ED IPFs of total,unDRXed,and DRXed regions of (a) 350T and (b) 450T. davg, dunDRXed,and dDRXed denote the average grain sizes of the total,unDRXed,and DRXed regions,respectively.

Both the extruded materials have a basal fiber texture in which most basal planes are oriented parallel to the ED;such a texture is typical of extruded Mg materials devoid of Ca and rare-earth elements [35–37].The maximum texture intensities of 350T and 450T are 5.9 and 8.9,respectively,which indicates that the basal texture of the extruded material intensifies significantly with increasing extrusion temperature.In both the extruded materials,the maximum texture intensities of the unDRXed grains (41.7 and 38.9 for 350T and 450T,respectively) are approximately 10 times those of the DRXed grains (3.7 and 4.4 for 350T and 450T,respectively).Furthermore,the unDRXed grains have a considerably strong<10-10>//ED texture because basalslip and prismaticslip occur continuously in them during the entire extrusion process,without the occurrence of DRX [38].The maximum texture intensities of the DRXed and unDRXed grains of 450T (4.4 and 38.9) are similar to those of the DRXed and unDRXed grains of 350T (3.7 and 41.7).However,the area fraction of the unDRXed grains,which have a strong texture,is larger in 450T than in 350T(11.7%and 5.0%,respectively).Therefore,the decrease in the DRX fraction with increasing extrusion temperature is responsible for the increase in the maximum texture intensity of the extruded material.

3.2.Tensile and compressive properties of extruded materials

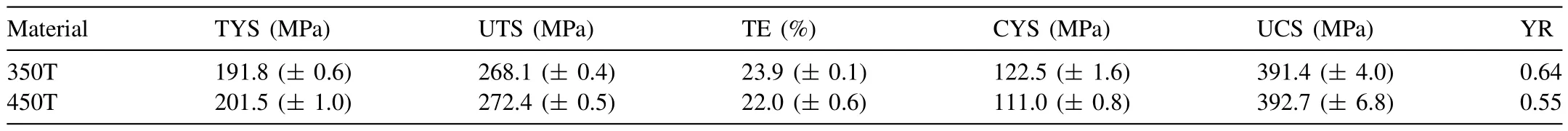

Fig.3 shows the engineering tensile and compressive stress–strain curves of 350T and 450T,and Table 1 lists their corresponding tensile and compressive properties.The TYSs of 350T and 450T are 191.8 and 201.5 MPa,respectively,and their compressive yield strengths (CYSs) are 122.5 and 111.0 MPa,respectively.The yield strength of a polycrystalline material is inversely proportional to its average grain size according to the Hall–Petch equation,and this relation is expressed as follows [39]:

Table 1Tensile and compressive properties of extruded materials.

Fig.3.Engineering tensile and compressive stress–strain curves of 350T and 450T.

whereσ0,k,anddare the frictional stress,Hall–Petch coefficient,and average grain size,respectively.In a rolled AZ31 alloy with a bimodal grain structure,thekvalue and frication TYS,UTS,TE,CYS,UCS,and YR denote the tensile yield strength,ultimate tensile strength,tensile elongation,compressive yield strength,ultimate compressive strength,and tension–compression yield stress ratio (=CYS/TYS),respectively.stress for fine grains of~17 μm (kfandσf) under tension along the rolling direction are 290 MPa·μm-1/2and 131 MPa,respectively,whereas those for coarse grains of~42 μm (kcandσc) are 507 MPa μm-1/2and 78 MPa,respectively [40].Therefore,the Hall–Petch relationship for the bimodal-grained AZ31 alloy can be expressed as follows [40]:

wheredf,ff,dc,andfcare the size of fine grains,area fraction of fine grains,size of coarse grains,and area fraction of coarse grains,respectively.By substituting the Hall–Petch coefficients,average grain sizes,and area fractions of fine DRXed grains and coarse unDRXed grains into Eq.(2),the TYSs of 350T and 450T based on the above Hall–Petch relationship are calculated as 212.8 and 204.9 MPa,respectively.This result indicates that when only the grain-boundary strengthening effect is considered,the TYS of 450T will be 7.9 MPa lower than that of 350T owing to the coarser grain size of the former.However,the tension test results reveal that the TYS of 450T is 9.7 MPa higher than that of 350T.Therefore,it can be assumed that 450T has additional hardening mechanisms that are stronger than those of 350T and that these additional hardening mechanisms cause the TYS of 450T to be 17.6 MPa (=7.9 MPa+9.7 MPa) higher than that of 350T.The differences between the hardening mechanisms of the extruded materials are discussed in detail in Section 4.2.

The tensile elongations(TEs)of 350T and 450T are 23.9%and 22.0%,respectively (Fig.3 and Table 1).When extruded Mg materials with a basal fiber texture are subjected to tensile loading in a direction parallel to the ED,{10-11} contraction twins and {10-11}-{10-12} double twins are formed in the late stage of deformation [41].Once these twins are formed,they become regions of high strain concentration because their crystallographic orientations are favorable for the activation of basalslip;subsequently,microcracks are initiated along the twins[41,42].Because the critical stress for the activation of deformation twinning (i.e.,twinning stress)is inversely proportional to the grain size of a material,the twinning stresses of{10-11}contraction and{10-11}-{10-12}double twins decrease with an increase in the average grain size of an extruded Mg material [43,44].Consequently,extruded Mg materials with coarser grain sizes have lower TEs than their counterparts with finer grain sizes [45,46].Fig.4a and b shows optical micrographs obtained along longitudinal cross-sections of the fractured tensile specimens of 350T and 450T,respectively.In the specimens of both 350T and 450T,numerous twins are observed near the fracture surface.In particular,numerous twins are formed in the unDRXed grains of the specimens (blue arrows in Fig.4a and b) because the coarseness of these grains facilitates twin formation during tension.Furthermore,microcracking occurs along the twins formed in the unDRXed grains (red arrows in Fig.4a and b).Fig.4c and d shows SEM fractographs of the fractured tensile specimens of 350T and 450T,respectively.Several cleavage planes are observed on the fracture surfaces of both the specimens (yellow dotted regions in Fig.4c and d),and the maximum sizes of these planes in the 350T and 450T specimens are 28.2 and 42.7 μm,respectively.These sizes correspond to the average sizes of the unDRXed grains (29.4 and 43.3 μm in 350T and 450T,respectively),which indicates that the coarse twins formed in the unDRXed grains act as crack initiation sites.Fig.5 shows the IPF maps of the fractured tensile specimens of the extruded materials and the crystallographic orientations of twins formed in them;the EBSD measurements were performed on the longitudinal cross-sections near the fracture surface.In Mg alloys,{10-11} contraction twin and {10-11}-{10-12} double twin have misorientation angles of approximately 56° and 38° with their parent grains,respectively [47].The misorientation angle relationships between the parent grains and the twinned regions reveal that the twins formed in the fractured tensile specimens are {10-11} contraction or {10-11}-{10-12} double twins (Fig.5),which are consistent with previous results in other extruded Mg materials [41,42].In the IPF maps of the fractured tensile specimens,black-colored regions,which are not indexed by the EBSD scan,are present,unlike in the IPF maps of the extruded materials and extrusion butts because the high dislocation density in the contraction and double twins makes EBSD indexing difficult [41].Therefore,because the area fraction and size of the unDRXed grains are larger in 450T than in 350T,the formation of contraction and double twins under tension is more pronounced in 450T,which is subsequently responsible for its lower tensile ductility.

Fig.5.EBSD results measured on longitudinal cross-sections of fractured tensile specimens of (a) 350T and (b) 450T: IPF maps and crystallographic orientations of twins.P,CT,and DT denote the parent grain,{10–11} contraction twin,and {10–11}-{10–12} double twin,respectively.

4.Discussion

4.1.Variation in DRX behavior with extrusion temperature

The microstructures of the extrusion butts of 350T and 450T are analyzed to investigate the change in the DRX behavior during extrusion with the extrusion temperature(Fig.6).Fig.6a shows a schematic illustration of the longitudinal cross-section of the extrusion butt as well as EBSD measurement positions A and B,which are located at distances of 5 and 10 mm,respectively,from the exit of the extrusion die along the centerline of the butt.At position A,both materials have an obvious bimodal grain structure comprising fine DRXed grains and coarse unDRXed grains.The DRX fractions at position A in the extrusion butts of 350T and 450T are similar (39.9% and 36.1%,respectively),and the average sizes of the DRXed grains at this position are also similar in both the materials (16.1 and 17.0 μm for the 350T and 450T extrusion butts,respectively) (Fig.6b).This microstructural similarity indicates that the increase in the extrusion temperature from 350 to 450 °C has little influence on the DRX behavior in the early stage of extrusion (position A).In contrast,at position B,the DRX fraction of the 350T extrusion butt (69.4%) is larger than that of the 450T extrusion butt (54.1%) (Fig.6c),which indicates that the DRX behavior in the intermediate stage of extrusion (position B) is suppressed by the higher extrusion temperature.In general,at deformation temperatures higher than 300 °C,the main DRX mechanism of Mg alloys is discontinuous DRX (DDRX),in which DRXed grains are formed by grain-boundary bulging and subgrain formation through dislocation climb near the initial grain boundaries[48,49].Because grain-boundary bulging and dislocation climb are more pronounced at higher deformation temperatures,DDRX generally occurs more vigorously as the deformation temperature increases,and this consequently results in the formation of a greater number of DRXed grains.However,in this study,the DRX behavior during extrusion weakens as the extrusion temperature increases from 350 to 450 °C,which can be attributed to the change in the driving force for DRX with the extrusion temperature.

Fig.6.(a) Schematic illustration of longitudinal cross-section of extrusion butt and EBSD measurement positions A and B.(b,c) IPF maps of extrusion butts of 350T and 450T at (b) position A and (c) position B. fDRXed and davg denote the area fraction of DRXed grains and the average grain size of the total region,respectively.

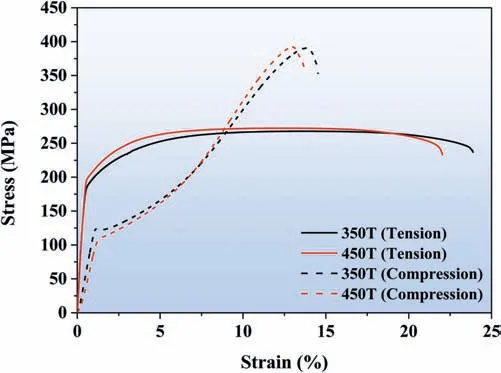

Fig.7a and 7b shows the KAM maps of the unDRXed regions at positions A and B in the 350T and 450T extrusion butts,respectively.The KAM map represents the amount of strain accumulated in a material,and the KAM is a measure of the local misorientation at a measurement point with respect to its neighboring points [50,51].Blue grains (strainfree) formed by grain-boundary bulging are observed in both the extrusion butts (red arrows in Fig.7),which indicates that DRXed grains are formed by DDRX during extrusion at 350 and 450 °C.DDRX is a softening mechanism that reduces the strain energy of a material by inducing the formation of new strain-free grains,and the strain energy accumulated in the material acts as a driving force for recrystallization [34].As the extrusion temperature increases from 350 to 450 °C,the average KAM values of the unDRXed grains at positions A and B decrease from 1.81 to 1.43 and from 2.10 to 1.86,respectively.These decreases imply that the increase in the extrusion temperature causes a decrease in the amount of strain energy accumulated in the unDRXed grains during extrusion,thereby reducing the driving force for DRX.An increase in the deformation temperature of Mg alloys can cause activation of pyramidal

Fig.7.Kernel average misorientation (KAM) maps of unDRXed regions of extrusion butts of 350T and 450T at (a) position A and (b) position B. KAMavg denotes the average KAM value.

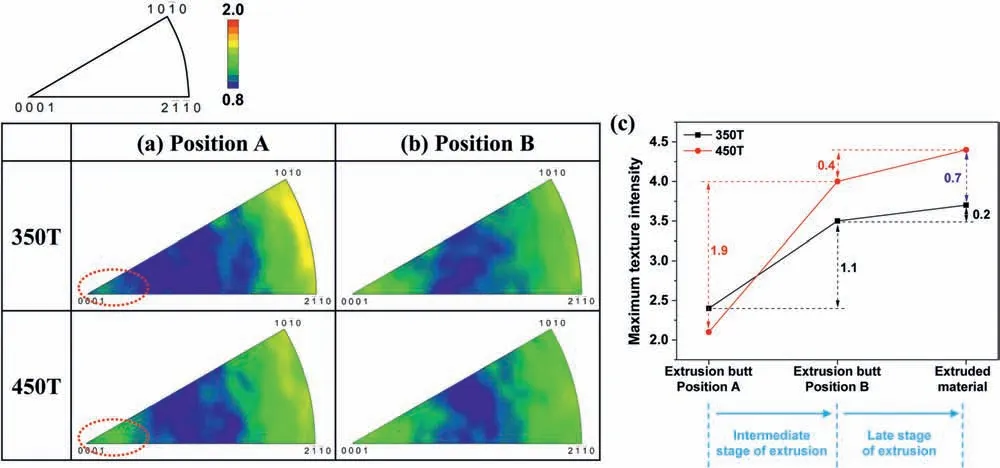

Fig.8 shows the IPF maps and ED IPFs of the DRXed regions at positions A and B in the 350T and 450T extrusion butts.When extrusion proceeds from position A to position B,the average size of the DRXed grains of the 350T extrusion butt decreases from 13.5 to 12.9 μm and their maximum texture intensity increases from 2.4 to 3.5,whereas the average size of the DRXed grains of the 450T extrusion butt remains almost unchanged(from 14.4 to 14.1 μm)and their maximum texture intensity increases considerably from 2.1 to 4.0.At position A,the DRXed grains of both the extrusion butts have low maximum texture intensities and relatively broad orientation distributions (Fig.8a) because DRXed grains formed via DDRX have more random crystallographic orientations than do those formed via CDRX [49,60,61].These DRXed grains formed in the early stage of extrusion undergo lattice rotation by further deformation during extrusion.The basal plane of a DRXed grain is aligned parallel to the ED because of the activation of basalslip,and one of its prismatic planes is aligned perpendicular to the ED owing to the activation of prismaticslip.As a result,at position B,the DRXed grains of both the extrusion butts have a strong<10-10>//ED texture (Fig.8b).Further,the maximum texture intensity at position B in the 450T extrusion butt is higher than that in the 350T extrusion butt.As the deformation temperature of Mg alloys increases,the CRSS of basalslip remains almost unchanged whereas that of prismaticslip gradually decreases [62,63].Therefore,more vigorous activation of prismaticslip at 450 °C leads to the formation of a stronger<10-10>//ED texture at position B in the 450T extrusion butt.

Fig.8.IPF maps and ED IPFs of DRXed regions of extrusion butts of 350T and 450T at (a) position A and (b) position B.

In-grain migration axis (IGMA) analysis is performed to confirm the promoted activation of prismaticslip during extrusion at 450 °C.IGMA analysis is an effective method for confirming the dominant active slip system in a deformed single crystal through matching of the measured IGMA with the Taylor axis [63].Fig.9 shows the IGMA distributions of the DRXed grains at positions A and B in the 350T and 450T extrusion butts,which are analyzed in the misorientation angle range of 0.5°–2°.An IGMA distribution in the<0001>direction indicates predominant activation of prismaticslip,whereas an IGMA distribution from the<10-10>to the<2-1-10>direction indicates predominant activation of basalslip or pyramidal

Fig.9.IGMA analyses of DRXed grains of extrusion butts of 350T and 450T at (a) position A and (b) position B.(c) Variation in maximum texture intensity of DRXed grains of extrusion butts and extruded materials with progress of extrusion.

Fig.9c shows the variation in the maximum texture intensity of the DRXed grains during the extrusion process.In the early stage of extrusion (position A),350T has a higher maximum texture intensity than 450T because the lattice rotation of basal planes of the DRXed grains is more pronounced in the former owing to the predominant activation of basalslip at 350 °C.In contrast,450T has a higher maximum texture intensity than 350T at position B because the continuous activation of prismaticslip at 450 °C causes vigorousa-axis rotation of the DRXed grains and consequently results in the formation of a stronger<10-10>//ED texture in the intermediate stage of extrusion (between positions A and B).These results can be reconfirmed from the IPFs of the DRXed grains in Fig.8.In the late stage of extrusion (from position B to the extruded material),the degree of increase in the maximum texture intensity of 450T (0.4) is greater than that of 350T (0.2) (Fig.9c) because of the promoted activation of prismaticslip in the former.Therefore,prismaticslip is activated more easily during extrusion at higher temperatures,and this behavior consequently results in a stronger texture of the DRXed grains of the extruded material.

4.2.Variations in yield strengths and yield stress ratio with extrusion temperature

As discussed in Section 3.2,as the extrusion temperature increases,the TYS of the extruded material increases despite the increase in its average grain size.The TYS of extruded Mg materials is a combined outcome of several hardening mechanisms: grain-boundary hardening,second-phaseparticle hardening,solid-solution hardening,texture hardening,and strain hardening [64].In this study,350T and 450T have the same alloying compositions and are almost completely devoid of second-phase particles (e.g.,they do not contain any Mg17Al12precipitates and contain only a few Al–Mn particles).Accordingly,both the materials have the same solid-solution and second-phase-particle hardening effects.Therefore,the higher TYS of 450T,which has a weaker grain-boundary hardening effect than 350T,can be attributed to the stronger texture hardening and strain hardening effects of the former.Unlike the TYS of cast Mg materials,which have a random texture,that of wrought Mg materials strongly depends on their texture because the dominant deformation mechanism changes with a change in the relationship between the crystallographic orientations and the loading direction [65,66].When an extruded Mg material with a basal fiber texture is subjected to tension along the ED at RT,the dominant deformation mechanism is basalslip [66];hence,the SF for basalslip should be considered for analyzing the texture hardening effect of the extruded Mg material.Fig.10 shows SF maps and SF distributions for basalslip under tension along the ED for the DRXed and unDRXed regions of 350T and 450T.It can be observed from the SF maps of the DRXed regions that the number of DRXed grains with high SF values,which appear reddish in color,is higher in 350T than in 450T (Fig.10a and b).In contrast,the SF distributions of the DRXed regions reveal that the area fraction of DRXed grains with low SF values (<0.1) is larger in 450T than in 350T (Fig.10c).Consequently,the average SF value of the DRXed region of 450T (0.15) is lower than that of 350T (0.17),which means that the crystallographic orientations of the DRXed grains of 450T are less favorable for basalslip under tension than are those of 350T.Therefore,the texture hardening effect of the DRXed grains is more pronounced in 450T than in 350T.In the SF maps,the unDRXed regions of 350T and 450T are blue in color (Fig.10e and f),which indicates that they have considerably low SF values for basalslip under tension.The unDRXed regions of the two materials have the same average SF value of 0.04,and this low SF value is attributed to the substantially strong basal texture of the unDRXed grains.Although the unDRXed regions of both the materials have the same average SF value,their area fraction in 450T (11.7%) is larger than that in 350T(5.0%).Therefore,it can be observed from the SF distributions of the total regions of the two materials that the area fraction of grains with significantly low SF values (<0.05)is larger in 450T (25.8%) than in 350T (19.6%) (Fig.10g).Because of the lower SF value of the DRXed grains and larger area fraction of the unDRXed grains of 450T,the average SF value for basalslip under tension for 450T(0.13) is lower than that for 350T (0.16).Consequently,the texture hardening effect of the extruded material becomes stronger with increasing extrusion temperature,and subsequently,its TYS increases with increasing extrusion temperature.

Fig.10.Results of analysis of Schmid factor (SF) for basal 〈a〉 slip (SFbasal) under tension along ED for 350T and 450T: (a,b) SF maps and (c) SF distributions of DRXed regions of (a) 350T,(b) 450T,and (c) 350T and 450T;(e,f) SF maps of unDRXed regions of (e) 350T and (f) 450T;and (g) SF distributions of total regions of 350T and 450T. SFavg denotes the average SF value.

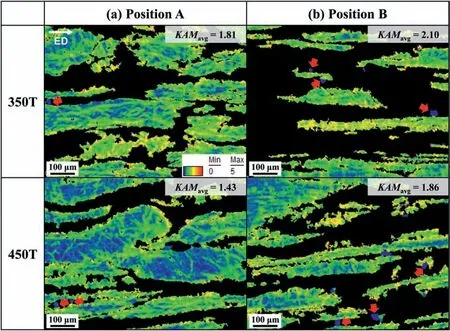

The difference between the strain hardening effects of the two extruded materials can also contribute to the higher TYS of 450T.Generally,the degree of strain hardening of a material is proportional to the square root of its dislocation density[64,67].Fig.11 shows KAM maps of the unDRXed,DRXed,and total regions of 350T and 450T.The average KAM values of the unDRXed regions (2.18 and 1.94 for 350T and 450T,respectively) are approximately 4.7 times those of the DRXed regions (0.42 and 0.45 for 350T and 450T,respectively) (Fig.11a and b).Because the KAM value is directly proportional to the density of geometrically necessary dislocations (GNDs),the aforementioned result implies that the unDRXed regions have a considerably higher GND density than the DRXed regions [68,69].The average KAM values of the DRXed and unDRXed regions of 350T are comparable to those of 450T.However,because 450T has a larger area fraction of unDRXed grains than 350T,the average KAM value of the former(0.67)is 24%higher than that of the latter(0.54)(Fig.11c).From the mathematical relationship between the KAM value and the GND density[68],the GND densities of 350T and 450T are calculated as 4.0 × 1013and 5.0 ×1013m–2,respectively.The higher GND density of 450T is attributed mainly to the larger area fraction of unDRXed grains,which have a high dislocation density.The higher the initial dislocation density of a material,the more impeded is the movement of the dislocations during plastic deformation owing to their intersection and entanglement;therefore,the material strength is directly proportional to the initial dislocation density [64,67].Therefore,in addition to the texture hardening effect,the strain hardening effect is stronger in 450T than in 350T.Consequently,although the grain-boundary hardening effect is stronger in 350T than in 450T,the texture hardening and strain hardening effects are stronger in the latter.From these results,it can be inferred that the stronger texture hardening and strain hardening effects of 450T outweigh its weaker grain-boundary hardening effect,and therefore,the TYS of 450T is 9.7 MPa higher than that of 350T.

Fig.11.KAM maps of (a) unDRXed,(b) DRXed,and (c) total regions of 350T and 450T.

Unlike the TYS,the CYS of the extruded material decreases from 122.5 to 111.0 MPa as the extrusion temperature increases from 350 to 450 °C (Fig.3 and Table 1).The CYSs of both 350T and 450T are closely related to {10-12}extension twinning,and according to the Hall–Petch relation,the minimum stress required to activate {10-12} extension twinning (i.e.,twinning stress) also decreases with increasing grain size [43].In Mg alloys,the Hall–Petch coefficient for{10-12} twining is higher than that for basal slip [70];hence,as the grain size decreases,the twinning stress more rapidly increases than the stress required to activating basal slip [71].Therefore,in extruded Mg materials,the Hall–Petch coefficient under compression along the ED is higher than that under tension along the ED.For instance,Chang et al.[72]reported that the Hall–Petch coefficient of an extruded AZ31 material is 390 MPa·μm-1/2under compression along the ED (i.e.,twining-dominant condition),which is higher than 303 MPa·μm-1/2under tension along the ED (i.e.,basal-slipdominant condition).Consequently,the degree of decrease in CYS caused by the coarser grain size of 450T than that of 350T is more pronounced than the degree of decrease in TYS.Further,the maximum intensity of the basal texture of 450T(8.9) is significantly higher than that of 350T (5.9) (Fig.2),which means that the crystallographic orientations of 450T are more favorable than those of 350T for {10-12} extension twinning under compression along the ED [66,73];consequently,the twinning stress of the former is lower.Therefore,because of the coarser grain size and stronger basal texture of 450T,its CYS is 11.5 MPa lower than that of 350T.

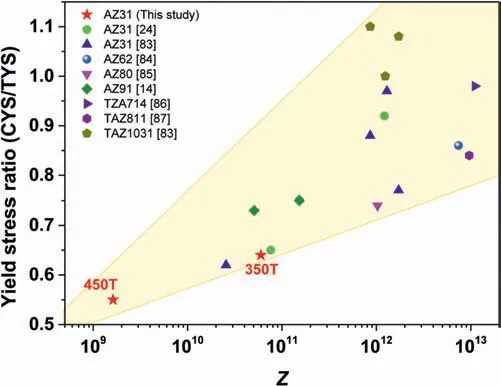

As the extrusion temperature increases from 350 to 450°C,the TYS of the extruded material increases by 9.7 MPa,whereas its CYS decreases by 11.5 MPa.Consequently,the difference between the TYS and the CYS of 450T(90.5 MPa)is greater than that of 350T (69.3 MPa),and the tension–compression yield stress ratio (=CYS/TYS) of the former(0.55) is lower than that of the latter (0.64).These results indicate that the tension–compression yield asymmetry of the extruded material increases with increasing extrusion temperature.The tension–compression yield stress ratios of extruded Mg materials are strongly dependent on their grain size and texture [74–76],and the grain size and texture,in turn,vary with extrusion process parameters,particularly the extrusion temperature and strain rate [48,74,77].The effects of temperature and strain rate during hot deformation on the DRXed grain size and mechanical properties of the deformed material can be expressed as a single value in the form of the Zener–Hollomon parameter(Z)[78].In theZequation(Z=´εexp(Q/RT)),´εis the strain rate,Qis the activation energy for diffusion,Tis the deformation temperature,andRis the gas constant [78].Qis related to the atomistic mechanisms of a material,which vary with the crystal structure and melting point of the material [79];theQfor the lattice self-diffusion of Mg is 135 kJ·mol-1[80,81].The strain rate (´ε) applied to a material during extrusion can be calculated as follows [82]:

whereDBandDEare the diameters of the initial billet and extruded material,respectively;VRis the ram speed,andERis the extrusion ratio.In this study,because only the extrusion temperature is varied,the same strain rate is applied during the extrusion of both 350T and 450T,which is calculated to be 0.286 by Eq.(3).The calculatedZvalues for 350T and 450T are 5.9 × 1010and 1.6 × 109,respectively;that is,the increase in the extrusion temperature from 350 to 450 °C leads to a significant decrease inZ.Fig.12 shows the tension–compression yield stress ratios of various extruded Mg materials as a function ofZ[14,24,83–87].This figure reveals that the tension–compression yield stress ratio is linearly proportional to the logarithm ofZirrespective of the alloying composition,and both the extruded materials examined in this study (350T and 450T) also follow this relation.In various hot-deformed metallic materials,the size of DRXed grains decreases with increasing Z (i.e.,with decreasing deformation temperature or increasing strain rate)[88].Extruded Mg materials also follow this tendency,which consequently increases tension-compression yield stress ratio with increasing Z owing to the suppressed {10-12} twinning behavior under compression [83,89].Therefore,extrusion process conditions with highZ(i.e.,a high strain rate and low extrusion temperature) are required to improve the yield symmetry of extruded Mg materials.This study demonstrates that the increase in the extrusion temperature from 350 to 450 °C alters the microstructural characteristics of the extruded AZ31 material (the DRX fraction,grain size,texture,and dislocation density),which consequently causes an increase in the TYS,a decrease in the CYS,and a reduction in the yield symmetry ratio of the extruded material.

Fig.12.Relationship between tension–compression yield stress ratio and Zener–Hollomon parameter (Z) for various extruded Mg materials,including extruded AZ31 materials investigated in this study.

5.Conclusions

This study investigates the effects of extrusion temperature on the DRX behavior of a commercial AZ31 alloy during extrusion and on its mechanical properties by comparing the microstructural evolutions during extrusion at 350 and 450 °C and the microstructural characteristics and mechanical properties of the extruded materials.As the extrusion temperature increases,the strain energy accumulated in the material during extrusion decreases owing to the promoted activation of pyramidal

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

CRediT authorship contribution statement

Jae Won Cha:Methodology,Data curation,Formal analysis,Writing– original draft.Sung Hyuk Park:Conceptualization,Writing– review &editing,Supervision,Project administration.

Acknowledgments

This research was supported by the National Research Foundation of Korea (NRF) grant (No.2019R1A2C1085272)funded by the Ministry of Science,ICT and Future Planning(MSIP,South Korea).

Journal of Magnesium and Alloys2023年7期

Journal of Magnesium and Alloys2023年7期

- Journal of Magnesium and Alloys的其它文章

- Recent progress in MgB2 superconducting joint technology

- “Smart” micro/nano container-based self-healing coatings on magnesium alloys: A review

- Recent advances using equal-channel angular pressing to improve the properties of biodegradable Mg–Zn alloys

- Twin evolution in cast Mg-Gd-Y alloys and its dependence on aging heat treatment

- Effects of Ce content on the modification of Mg2Si phase in Mg-5Al-2Si alloy

- Solute drag-controlled grain growth in magnesium investigated by quasi in-situ orientation mapping and level-set simulations