Twin evolution in cast Mg-Gd-Y alloys and its dependence on aging heat treatment

Jingli Li ,Zhohui Dong ,Xin Yi,* ,Di Wu ,Rongshi Chen,*

a Department of Mechanics and Engineering Science,College of Engineering,Peking University,Beijing 100871,China

b Shi-Changxu Innovation Center for Advanced Materials,Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

Abstract Effects of rare-earth (RE) and precipitates on twin evolution in cast Mg-10Gd-3Y-0.5Zr (wt.%) (GW103) alloys of solid solution (T4)and aged (T6) states are investigated performing quasi-static room temperature compression tests and microstructural characterization.It is found that both {10–12} and {11–21} extension twins (ET1 and ET2) can appear in the T4 and T6 states but with different emergence sequences.As the aging heat treatment leads to consumption of RE solutes which could inhibit atomic shuffling required for nucleation of ET1 but not ET2,ET2 occurs prior to ET1 in the T4 state,and ET1 emerges before ET2 in the T6 state.The extension twins here mainly coordinate the plastic deformation through the non-Schmid effect.Our results shed light on the influence of RE elements on twin evolution in magnesium alloys and have implications in developing high-performance Mg-RE alloys.

Keywords: Mg-Gd-Y-Zr alloys;Rare-earth;Precipitates;Twinning;Compression.

1.Introduction

Rare-earth (RE) elements such as gadolinium (Gd) and yttrium (Y) have been used as alloying elements to adjust mechanical properties,corrosion resistance and heat resistance of metal alloys.Due to their high strength and good heat resistance,Mg-RE alloys are drawing wide attention in the fields of aerospace and automotive industries [1,2],and a series of high strength Mg-RE alloys such as Mg-Gd-Y-Zr and Mg-Gd-Y-Zn have been developed [3,4].An effective strengthening way to fabricate fine-and ultrafine-grained Mg alloys is the application of severe plastic deformation [5,6].In comparison with extensive studies on the effect of RE elements on the strengthening of Mg-RE alloys,less attention has been drawn on the plastic behaviors mediated by RE elements,and even fewer studies on twinning in particular.Recent studies show that RE elements could affect the plastic deformation of Mg-RE alloys significantly,for example,promoting

So far,the effects of RE elements on the mechanism of twinning in Mg-RE alloys remain unclear,and there even exist inconsistence in reported studies.It is shown that cerium solutes could reduce the critical stress for twinning[12],while Y solutes hinder twinning up to a certain concentration via characterizing the critical resolved shear stress (CRSS) of{10–12}extension twins(ET1)[13].Further investigations on the twinning behaviors of two single-phase binary alloys Mg-5Y and Mg-10Y(wt.%)show that the amount of ET1 twins is substantially reduced in alloys with higher amounts of Y[14].In Mg-10Y samples,{11–21} extension twins (ET2) with the a misorientation angle of 34°and misorientation axis of<10–10>are detected.It is demonstrated that the ET2 twins have a characteristic twinning shear of 0.64,significantly higher than that of the ET1 with 0.13,which is the reason that ET2 twins are rarely observed in Mg alloys.To the best of our knowledge,ET2 twins have only been observed in Mg-RE solid solution alloys so far,but ET2 twins do not occur in peak/overaged alloys such as WE54[15].Although aging heat treatment is commonly performed to improve the strength of Mg-RE alloys,the hardening effect of precipitates on ET1 twining is still under debate [16–18],whereas their effects on the rare ET2 twining are unknown.Generally speaking,there is lack of systematic investigation on twinning behaviors in Mg-RE alloys.Moreover,ET2 twins in Mg-RE alloys complicate their twinning and plastic deformation and give rise to richer mechanical behaviors in Mg-RE alloys compared to other Mg alloys.

As twinning could be significantly affected by texture due to polarity,here we investigate the twin evolution in cast Mg-RE alloys with random grain orientations to exclude the influence of texture.Interrupted compression experiments with microstructural observation at different strains are conducted on cast Mg-10Gd-3Y-0.5Zr (wt.%) (GW103) alloys to reveal the twinning behaviors in Mg-RE alloys,and the underlying mechanism is explored.The influence of the aging heat treatment on twinning behaviors is discussed via comparing the twin evolution in GW103 alloys of the solid solution (T4)and peak-aged (T6) states.It is found that ET2 emerges before ET1 in the T4 state,and ET1 emerges before ET2 in the T6 state,which together suggest that RE solutes could inhibit atomic shuffling required for nucleation of ET1 but not ET2.Our studies shed light on the influence of RE elements on twinning in Mg alloys.

2.Experimental procedures

GW103 alloy samples with a nominal chemical composition of Mg-10.0Gd-3.0Y-0.5Zr (wt.%) are fabricated using the sand casting approach.The alloy is prepared by melting pure Mg (99.95 wt.%),Gd (99.5 wt.%),Y (99.5 wt.%),and Mg-30Zr (wt.%) in an electric resistance furnace at about 780 °C with anti-oxidizing flux for oxidation protection.The cast plate has dimensions of 200 mm × 90 mm × 20 mm.The risers and cold irons are used to eliminate casting defects.The specimen chemical composition is Mg-9.44Gd-2.89Y-0.36Zr(wt.%)using inductively coupled plasma atomic emission spectroscopy.T4 specimens are obtained by treating as-cast alloys at 510 °C for 8 h and cooling in air,and T6 specimens are fabricated with aging at 250 °C for 12 h after solid solution treatment.

Room temperature uniaxial compression experiments are performedon a Shimadzuuniversaltestingmachine (AGI500 kN) at an initialstrain rate of 1 ×10–3s–1.The dimensions of the gage cut from the cast plate areΦ8 mm × 12 mm.Each compression test is repeated at least three times.The compression experiments are interrupted at different strain levels to study microstructural evolution of specimens.For optical microstructure observation,samples are etched in acetic-picric acid solution (25 mL ethanol+2 g picric acid+5 mL acetic acid+5 mL water).Electron back-scattered diffraction (EBSD) measurements are carried out for microstructure and twin analyses using a JEOL-JSM-7001F field emission scanning electron microscope equipped with an automated orientation acquisition system (Oxford Instruments HKL Chanel 5).Since the cast alloys have a coarse grain structure but fine twin lamella,an EBSD scanning step size of 3 μm is chosen for initial scan,and a fine step size of 1 μm is for more elaborate investigation of twins.An FEI-Tecnai G2 30 transmission electron microscope (TEM)is used to observe fine precipitates in aged samples and twins in both solid solution and peak-aged states.Thin foil specimens for TEM are prepared by punching 3 mm diameter discs,followed by dimple grinding and Ar ion milling in a precision ion polishing system (Leica EM RES101).

The misorientation angle and misorientation axis of TBs are obtained using Channel 5 post processing software to analyze the types of twin variants.To further verify the activated twin variant type,euler angles of twin variants of ET1 and ET2 are calculated using MATLAB and compared with these of actual twin variants from EBSD measurements.Then the Schmid factors of different twin variants are determined.The activated twins are characterized by twinning plane and misorientation axis and denoted by,where subscripts 1 and 2 are used to identify quantities associated ET1 and ET2,respectively,and superscripts I to VI correspond to six types of twin variants (Table 1).

Table 1Six variants of ET1 and ET2.

3.Results and discussion

3.1.Observation of ET1 and ET2

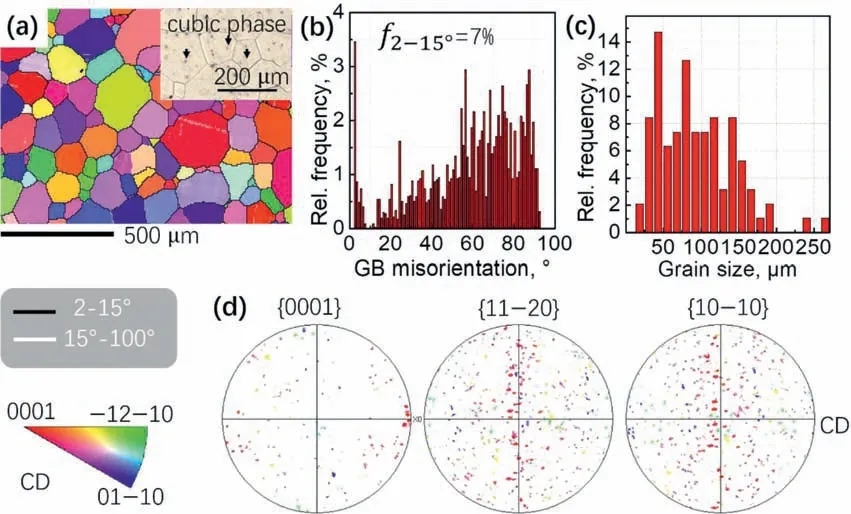

Fig.1 displays the initial microstructure of the cast GW103 alloys.One can see that the T4 state mainly consists of anα-Mg solid solution and a small number of cubic phases(Fig.1a).Fig.1a,b shows that there exist no twins and only few low angle grain boundaries (GBs),indicating that the T4 sample has a uniform microstructure with no internal stress.The average size of the equiaxed grains is around 162 μm (Fig.1c).Pole figures in Fig.1d indicate that the cast alloys do not exhibit evident preferred orientation.This is in agreement with reported results that most cast metals do have a nearly random texture [19].TEM images obtained along [0002]α-Mgand [11–20]α-Mgof a T6 sample demonstrate that abundant fine lens-shaped precipitates are formed and evenly distributed in the matrix after aging heat treatment.The projection of the prismatic precipitates onto(0002)α-Mgshows a triangular pattern (Fig.2a) and the projection along [0001]α-Mgshows a pattern of parallel needles(Fig.2b),consistent with the well-describedβ’ precipitate morphology in Mg-RE alloys [20,21].The existence ofβ’(c-axis base-centered orthorhombic) phase is identified by the selected area electron diffraction characterization in Fig.2c,d with features of diffuse spots at 1/4,1/2 and 3/4 {1–100}α-Mgreflections [22–24].

Fig.1.Initial microstructure of the cast GW103 alloys.(a) Inverse pole figure map,(b) grain boundary misorientation distribution,(c) grain size distribution,and (d) pole figures of an T4 sample.

Fig.2.TEM images obtained along [0002]α-Mg and [11–20]α-Mg of a T6 sample.Bright-field micrographs along [0001](a) and [11–20](b) zone axes and corresponding selected area electron diffraction patterns (c,d).B in (c,d) denoting the incident beam direction.

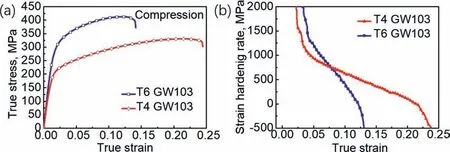

Fig.3a shows the curves of compressive true stress versus strain (σversusε) in the T4 and T6 GW103 samples.It is known that slip deformation is regarded as the dominant mechanism for the concave feature ofσ-εcurves,whileσεrelationship dominated by twinning deformation displays convexity,especially ET1 twinning [25].Therefore,slip shall be the dominant deformation mechanism during compression of the cast GW103 alloys in both T4 and T6 states.The strain hardening rate is defined asΘ=dσ/dε,and its gradual reduction is associated with dynamic recovery [26].Fig.3b shows that the gradual reduction ofΘhere starts at a small strain around 0.04,indicating that the dynamic recovery can be easily activated in the Mg-RE alloys here.

Fig.3.(a) True stress σ versus true strain ε and (b) the corresponding strain hardening rate Θ versus true strain ε for the T4 and T6 GW103 alloys compressed at room temperature at 1 × 10–3 s–1.

Inverse pole figure (IPF) maps and various TBs of the T4 GW103 alloys at different compressive plastic strains of 2%,8% and 16% are shown in Fig.4a–c and d–f.Combined with Fig.4g,h on distributions of GB misorientation and misorientation axis,one can see that abundant twins in the T4 state are evident in room temperature compression.At plastic strain 2%,only several thin twins are observed in three out of around 50 grains (Fig.4a,d).As the plastic strain increases to 8%,more twins appear in more grains.As the plastic strain further increases from 8% to 16%,the twin lamella thickness increases but the twin number decreases (Fig.4b,c and e,f).One can conclude that twin nucleation mainly occurs at small and medium true strains and the twin growth or coalescence prevails in the late stage of plastic compression.Note that the main twin type in the T4 state during the compression is ET2,whose TBs are marked by yellow lines (Fig.4d–f).The characteristic twin misorientation axis and twin misorientation angle are<10–10>and 34°,respectively (Fig.4g).ET1 and few{10–11}compression twins(CT1)also appear at medium and large strains,where the corresponding TBs are denoted by red and blue lines,respectively (Fig.4e,f).Two peaks at 86.3° (±5°) about<–12–10>and at 34° (±5°) about<10–10>shown in Fig.4h correspond to the conventional ET1 and relatively unusual ET2,respectively.Our results on the observation of ET2 at small and medium stains are consistent with reported results on compression of cast magnesium alloy WE54 [14,15].Since the magnitude of the compression strain in refs.[14,15]is only limited to 8%,only ET2 are observed there.Present results indicate a novel phenomenon that ET2 and ET1 emerge in succession and locate in the same grains.Further detailed analysis on the twin evolution is discussed in the following section.

Fig.4.EBSD analysis of the T4 GW103 alloys at plastic strain of 2% (a,d,g),8% (b,e,h) and 16% (failure,c,f) with initial scanning step size of 3 μm.(a–c)IPF maps,(d–f) band contrast superimposed with various TBs,and (g,h) corresponding GB misorientation distribution superimposed with the misorientation axis distribution.Solid arrows in (g,h),intermediate and high angle misorientation peaks.

Fig.5 demonstrates the microstructure evolution of the T6 GW103 alloys at different plastic strains (2%,4% and 8%).Comparing Figs.3 and 4 clearly indicates that the twinning behavior of the T6 alloys is significantly different from that of the T4 alloys.At small plastic strain (2% here),abundant ET1 but no ET2 are observed.In contrast to the T4 state,with increasing plastic strain,the twin lamella thickness increases but the twin number does not increase significantly.At failure plastic strain (8% here),several thin ET2 lamella accompanying ET1 are observed (Fig.5f).For the cast GW103 alloys interested here,ET2 occurs prior to ET1 in the T4 state,and ET1 emerges before ET2 in the T6 state.

Fig.5.EBSD analysis of the T6 GW103 alloys at plastic strain of 2% (a,d),4% (b,e) and 8% (failure,c,f) with initial scanning step size of 3 μm.(a–c) IPF maps,(d–f) band contrast superimposed with various TBs.

3.2.Twin evolution in T4 GW103 alloys

Owing to the relatively large scanning step size of 3 μm in Fig.4,no twins are detected at some positions with morphological characteristics of twin lamellaes.To further explore the twin evolution in the T4 state,selected regions containing twins in Fig.4 (marked by blue rectangles) are analyzed using finer EBSD scanning step size of 1 μm (see Fig.6).Thin ET2 twin lamellas span across the entire grain prior to ET1 occurrence during compression.Although the absence of ET1 with low characteristic twinning shear strain might be attributed to the inhibition effect of RE on ET1 twinning[14],it remains unclear whether the RE elements inhibit the nucleation or growth of ET1.Our results in Fig.6 show that in the T4 GW103 alloys ET1 can grow and coalesce rapidly(Fig.6c,f) after nucleation at ET2 boundaries at an intermediate plastic strain of 8% (Fig.6b,e),consistent with the invasive growth capability of ET1 in Mg and RE-free Mg alloys[27].As the growth of ET1 is not affected by RE elements,one can conclude that RE elements mainly inhibit twin nucleation.Atomistic simulations and topological analyses suggest that twin nucleation requires not only high local stress but also defect structures [28].Since both GBs and TBs are local stress concentration positions and ET1 twins in the T4 GW103 alloys here originate from ET2 boundaries instead of GBs,ET2 boundaries might provide defects required for stable twin nucleus formation thus facilitate nucleation of ET1 in the T4 GW103 alloys here.As a consequence,one can observe amounts of dislocations exist in and nearby ET2 in the T4 GW103 alloys at 2% plastic strain (Fig.7).These dislocations might dissociate and produce twinning dislocations with increasing plastic strain.Therefore,one can conclude that RE elements suppress the nucleation of ET1,while ET2 boundaries facilitate the heterogeneous nucleation of ET1 by providing defects structure such as dislocations.

Fig.6.Detailed microstructure of the regions indicated by dashed squares in Fig.4 at different plastic strains.Compression direction is horizontal.G1–G10,parent grains 1–10.

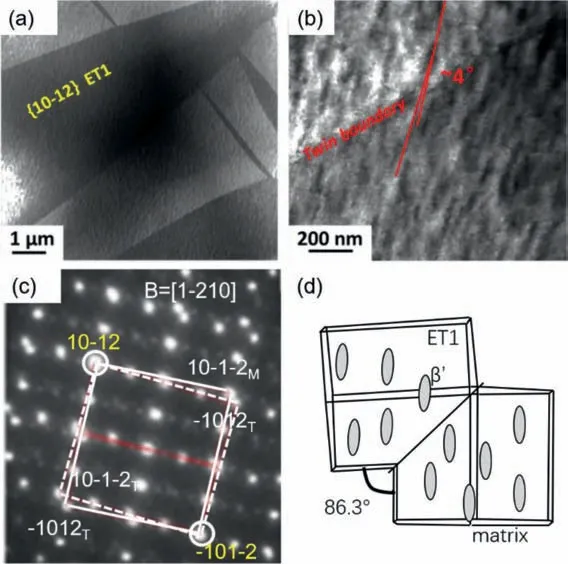

Fig.7.Identification of ET2 in the T4 sample at 2% plastic strain under compression.TEM images of ET2 identified by diffraction patterns of twins (dashed boxes) and matrices (box) at incident beam directions parallel to zone axes [1–213](a,c) and [–1100](b,d).

Twins of thickness around 500 nm shown in Fig.7a,b could be identified as ET2 ({11–21} twins) from diffraction patterns along [1–213]and [–1100]zone axes parallel to (11–21) plane (Fig.7c,d).It is shown that the twin and matrix share (11–21) diffraction spots and their diffraction patterns are of mirror symmetry about a row of (11–21) diffraction spots,indicating the presence of ET2.In the current case,(11–21) planes have bright spots (circled) at the beam incident directionB=[1–213](Fig.7c) but these spots are invisible atB=[–1100](Fig.7d).Therefore,the diffraction pattern atB=[1–213]here is relatively direct in confirming the presence of ET2 in Fig.7a,b.One advantage of performing selected area electron diffraction along [–1100]zone axes is that the 34°<10–10>misorientation of ET2 can be obtained from its diffraction pattern (Fig.7d).

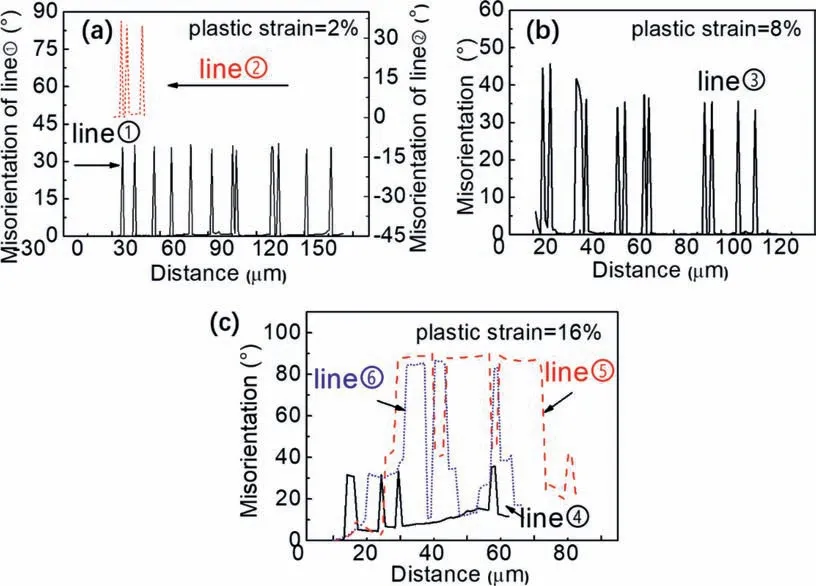

As shown in Fig.8,the thickness evolution of ET2 is evaluated from the misorientation variation versus position distance with respect to starting points of lines ○1–○ 6in Fig.6.It is indicated that ET2 thickness does not vary significantly,and the average ET2 thicknesses are around 1 μm,3 μm,and 3 μm at under plastic strain 2%,8%,and 16%,respectively.The growth of ET2 mainly occurs in the early stage of plastic deformation (from 1 μm to 3 μm as plastic strain varying from 2% to 8%).After 8% plastic strain,the growth of ET2 is inhibited.Compared to the invasive growth capability of ET1,the propagation of ET2 is very limited.

Fig.8.Misorientation angle profiles of lines 1○– 6○in Fig.6 versus position distance with respect to starting points.

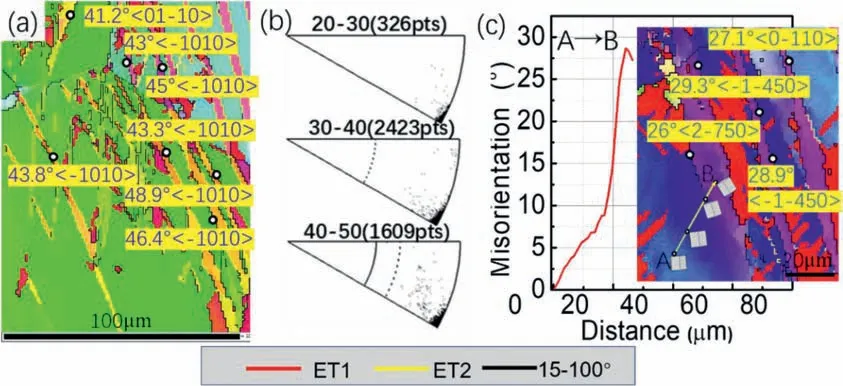

The growth of ET2 is inhibited probably due to the transformation of the TBs into high-angle (>15°) GBs.Fig.9a,b contains an IPF map with the misorientation angle and misorientation axis distribution of grains 4–6 (G4–G6) in Fig.6b,e.Though the misorientation axis of<10–10>is maintained as plastic strain increases to 8%,misorientation angles in G4–G6 deviate away from 34°,indicating the loss of crystallographic characteristics of ET2.Further increase of the strain eventually leads to the vanish of the characteristic misorientation axis (see inset of Fig.9c).The growth of the ET1 at some positions also stops with increasing strain turning TBs into common GBs (see G10 grain in Fig.6f),similar mechanism to that for the TB-GB transition of ET2 discussed above.

Fig.9.IPF map with misorientation (a) and misorientation axis distribution of G8 (b) of grains 4–6 (G4–G6) in Fig.6.Misorientation angle profile of line AB with respect to point A (inset,G8 in Fig.6).

So far ET2 twinning mechanism in Mg-RE alloys remains unclear.For ET2 in pure titanium,it is found that ET2 boundaries can evolve from the kink band boundaries through the accumulative slip of single basal-dislocations [29].Detailed EBSD analysis of microstructural evolution in Fig.9c suggests that ET2 in Mg-RE alloys might share the same twinning mechanism as ET2 in pure titanium.For example,one displayed ET2 lamella in grain 8 emerges in the parent grain through crystal rotation (line AB in Fig.9c).A similar rotation can be observed in grain 9 (Fig.6h).This indicates that the formation of ET2 boundaries is different from the known mechanism of deformation twinning in metals that the TB misorientation can be achieved once twins nucleate.

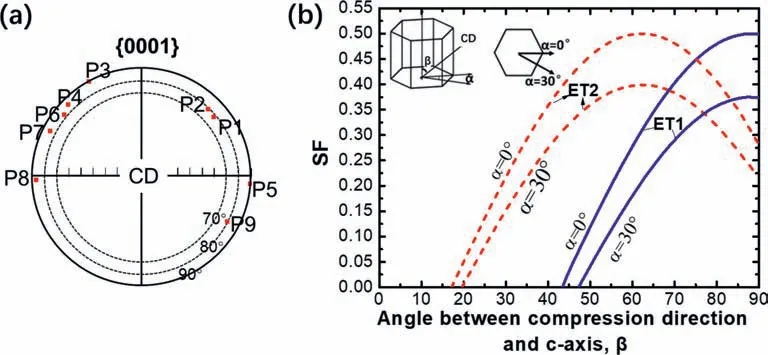

The polarity of twins refers to the phenomenon that twins can only be activated as the sample is stretched along the caxis or compressed perpendicular to the c-axis [8].For ET1,the polarity happens to be consistent with the angle between the c-axis and loading direction based on Schmid’s law.For ET2,the {0001} planes of all their parent grains have angles around 80° to 90° with respect to the compression direction(Fig.10a),significantly different from an angle around 63°according to Schmid’s law (Fig.10b).The observation suggests that ET2 could exhibit polarity and the optimal orientation for both ET1 and ET2 twinning is dominated by polarity instead of Schmid’s law.

Fig.10.(a) Positions of parent grains for ET2 in a {0001} pole figure,and (b) the variation of Schmid factor (SF) of basal slip,ET1 and ET2 with the angle β between c-axis and loading direction in randomly textured Mg alloys.CD,compression direction;angle α here,the angle between the reflection of CD on(0001) plane and the <11–20> direction.

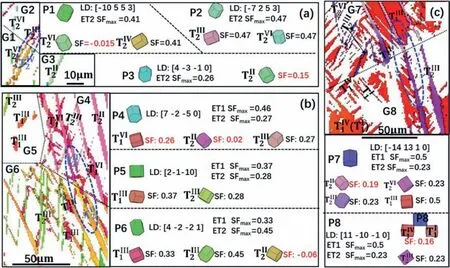

Theoretically twins may occur in specific twinning directions in six equivalent twinning planes for HCP metals,that is,there exist six twin variants.The selection of twin variants depends on whether the cumulative local stress reaches the corresponding CRSS.Although primary twinning follows the Schmid’s law in many cases [30,31],the selection of twin variants in practice is a complex process and is affected by various aspects such as strain coordination between grains[32]and strain path [33],and multiple twin variants could be even activated in one grain [31,34].Fig.11 shows a selection of twin variants and the Schmid factor (SF) analysis of the T4 samples at different strains.It is shown that only one pair of ET1 twin variants appears in one parent grain,but multiple ET2 variant pairs can appear during compression of the T4 GW103 alloys at room temperature.The non-Schmid effect exists in selecting twin variants of both ET1 and ET2.In ET1,the non-Schmid effect might be related to the variant types of ET2.

Fig.11.Selection of twin variants and SF analysis of T4 GW103 samples at different plastic strains of 2% (a),8% (b) and 16% (c,failure).The boundaries of neighboring grains are roughly denoted by dotted lines.Orientations of parent grains 1–8 (G1–G8) are denoted by P1–P8,respectively.

The non-Schmid behavior could occur during secondary twinning in polycrystalline magnesium alloys,because it provides the closest match between the primary and secondary twinning planes [35].It is demonstrated that ET2 occurrence with low SF (such asin grain 1 in Fig.11a,in grains 4 and 6 in Fig.11b,and grain 7 in Fig.11c) is always accompanied by twin transmission across GBs (blue loops in Fig.11),that is,the non-Schmid effect occurs in the form of twin transmission.As the twin transmission behavior is a consequence of local strain accommodation at GBs [36],the non-Schmid effect in ET2 accommodates shear strain,making contribution to plastic deformation.

3.3.Precipitation effect on twinning behaviors of cast Mg-Gd-Y-Zr alloys

Fig.12 shows the selected regions containing twins in Fig.5 (marked by yellow rectangles) using finer EBSD scanning step size of 1 μm.One can see that ET1 twins with an average thickness of 5.2 μm appear at small plastic strain(2% here) and their number does not increase significantly as the strain increases.Relatively few ET2 twins exist and only appear in a few grains at the end of the compression(8%).As mentioned above,ET1 emerges before ET2 in the T6 GW103 alloys,opposite to the emergence sequence of ET2 and ET1 in the T4 GW103 alloys.

Fig.12.Detailed microstructure of regions indicated by dashed squares in Fig.5 at different plastic strains.

This observation indicates that the CRSS of ET1 is higher than that of ET2 in the T4 state,and precipitation strengthening induced by aging heat treatment leads to more significant increment of CRSS of ET2 against ET1.The strengthening effect of precipitates on ET1 twining can be quantitatively analyzed according to a hardening model [37]characterizing the precipitate-twin interaction based on an assumption that precipitates are neither twinned nor sheared but undergo small rotation,consistent with our observation in Fig.13.In addition to the formation of new precipitates,aging heat treatment can also lead to the consumption of RE solutes.As RE solutes strongly hinder ET1 twinning as reported in ref.[14],aging treatment facilitates ET1 twinning.In contrast,the mechanism of precipitate-induced strengthening and effect of RE solutes on ET2 so far have not been revealed,and the lack of either qualitatively or quantitatively relevant studies severely hinders our understanding on the variation of twining behaviors in the T4 and T6 states.

Fig.13.Interaction between precipitates and ET1 twinning in the GW103K-T6 alloys at plastic strain 2%.(a) The TEM images of β’ precipitates and a thick ET1.(b) Enlargement of a region near an ET1 boundary in (a),showing the long axes of β’ precipitates on two sides of the twin boundary have an intersection angle around 4°.(c) Along [1–210]zone axis,selected area electron diffraction patterns of ET1 (dashed square) and matrix (square) show that they share (10–12) diffraction spots.(d) Schematic of the interaction between the β’ precipitates and ET1,illustrating that precipitates are neither twinned nor sheared.

Here we intend to provide a self-consistent qualitative explanation for the different emergence sequence of extension twins in the T4 and T6 GW103 alloys.ET1 and ET2 here appear at the same orientations with the c-axis nearly perpendicular to the compression direction (Fig.10a).Therefore,they might compete with each other during deformation.In the T4 state,ET2 occurs prior to ET1,which implies that the CRSS of ET2 is lower than that of ET1.It is well known that in pure Mg and non-RE Mg alloys,ET1 has a relatively low CRSS value and is always activated simultaneously with basal slip to accommodate c-axis deformation [27]while ET2 is rarely observed in pure Mg and non-RE Mg alloys [14].Therefore,it is probable that CRSS changes caused by RE solutes for ET1 and ET2 are different.Investigating the influence of yttrium contents on the twinning behavior in Mg-Y alloys,Stanford et al.in ref.[12]claim that Y solutes have a stronger hardening effect on ET1 than on ET2.With the increase of RE concentration,CRSS of ET2 could become lower than that of ET1.This is probably the mechanism underlying our observation that ET2 occurs prior to ET1 in the high-RE-containing GW103 solid solution from the viewpoint of CRSS change.

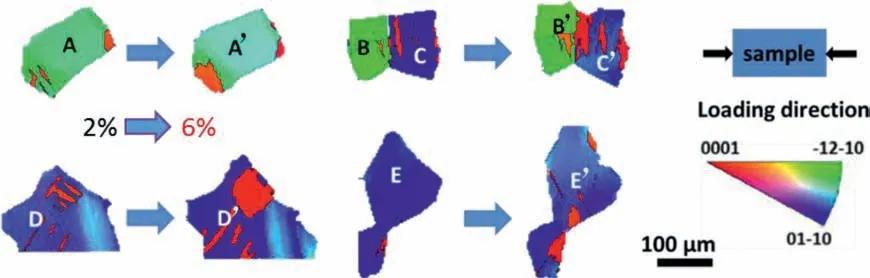

It is well known that atomic shearing and shuffling usually accompany the formation of twins.According to the theory of the crystallography of deformation twinning [38],the mirror symmetry between the matrix and ET2 can be realized by shearing without additional atomic shuffling.In contrast,ET1 is mainly formed by atomic shuffling [39].Experimental studies indicate that solutes affect atomic shuffling to a greater extent in comparison with shearing [40].Recalling the CRSS change of ET2 is smaller than that of ET1,RE solutes in the Mg matrix might inhibit atomic shuffling.Requiring more atomic shuffling,ET1 nucleation is prohibited by the RE solutes,responsible for the emergence sequence of ET2 prior to ET1 in the T4 state.According to Fig.6,RE solutes inhibit nucleation and have minor influence on the growth and propagation of ET1.As the formation of ET1 requires atomic shuffling and is difficult in the T4 GW103 alloys,it is anticipated that RE hinders the twin nucleation by inhibiting atomic shuffling.Unlike some RE solutes mainly affecting twin nucleation,precipitates here are suggested to mainly affect twin growth [16–18].Consequently,ET1 could be observed earlier in GW103 alloy after aging heat treatment,and the twin length is generally short(Fig.12).As the strain increases,ET1 twins in the T6 alloys undergo lateral propagation and coalescence,as indicated from the insitu twin evolution in grains A–E of the T6 GW103 alloys as the plastic strain increases from 2% to 6% (Fig.14).

Fig.14.Twin evolution in grains A–E of the T6 GW103 alloys as plastic strain increases from 2% to 6%.

3.4.Role of twins in room temperature compression of cast GW103 alloys

As there are abundant ET1 and ET2 in the cast GW103 alloys(Figs.4-6 and 12),it is necessary to discuss the influence of twins on the mechanical behaviors of the cast GW103 alloys during room temperature compression.It is reported that twins contribute to the strength via grain partitioning by TBs[41].Therefore,the raise of flow stress due to twin formation can be roughly evaluated from the Hall–Petch hardening stressΔσH–Pcalculated as [30]

wheredinitial,deffandkrepresents the initial grain size,the effective grain size ata given strain,and the Hall–Petchcoefficient (240 MPa·μm1/2for Mg-10Gd alloys[42]),respectively.dinitialanddeffat different strains are calculated based on Figs.1,4 and 5 using ImageJ software and the correspondingdeff-εandΔσH–P-εcurves are shown in Fig.15.It shows that with increasing strain the effective grain size decreases,and thus the Hall–Petch hardening increases for the GW103 alloys in both T4 and T6 states.The maximumΔσH–Pobtained at failure strains are around 21 MPa and 4 MPa for the T4 and T6 GW103 alloys,respectively,which account for 6% and 0.1% of the corresponding compressive stress.This indicates that the contribution of twin-induced Hall–Petch strengthening is limited for the cast GW103 alloys,consistent with the concave feature ofσ-εcurves in Fig.4.

Fig.15.Effective grain size and corresponding Hall–Petch hardening stress versus compressive strain.Here an effective grain has boundaries with misorientation angle larger than 15°.

The twinning strain is calculated as [30,43]

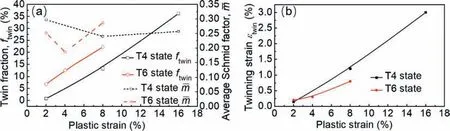

whereεtwin,ftwin,,andγtwindenote the twinning strain,volume fraction of twins,average SF of twin variants,and characteristic twinning shear strain,respectively.At plastic strain of 8% and 16%,the T4 samples have two types of twins,and the contributions of ET1 and ET2 are not separated for simplicity,and the averageγtwinof 0.375 is used as the characteristic shear strain.According to the volume fraction and the average SF of twins (Fig.16a),the twinning strain at different plastic strains are calculated (Fig.16b).It is found that the twinning strain in both T4 and T6 states gradually increases during the compression and the maximum values are 0.03 and 0.008,respectively,only accounting for 18.7%and 10% of the total plastic strain.It indicates that extension twins do not contribute directly to the strength and plasticity of the Mg-Gd-Y alloys in both states.

Fig.16.The volume fraction and average SF of twins (a) and twinning strain εtwin (b) versus plastic strain.

In the T4 state,non-Schmid effect has been observed(Fig.11).For the T6 GW103 alloys,the SF analysis of the twin variant selection is conducted and the results are shown in Fig.17.Comparing the SFs of the activated twin variants to the maximum SF (SFmax) for six variants,one can see that in the T6 GW103 alloys many of the SFs of the activated twin variants are much lower than SFmax,displaying the non-Schmid effect.Therefore,ET1 and ET2 mainly contribute to the strength and plasticity by coordinating plastic deformation.

Fig.17.Selection of twin variants and SF analysis of the T6 GW103 samples at different values of plastic strain of (a) 2%,(b) 4% and (c) 8% (failure).Adjacent grains are simply distinguished by dotted lines.Orientations of parent grains 1–14 (G1–G14) are represented by P1–P14,respectively.

4.Conclusions

In this work,the twin evolution and twin interaction of cast Mg-10Gd-3Y-0.5Zr(GW103)alloys are characterized by conducting compression tests.The influences of rare-earth (RE)solutes and precipitates on twinning behaviors are analyzed comparing the microstructure of GW103 alloys in the solid solution (T4) and aged (T6) states at different plastic strains.Roles of twins in the plastic deformation of the GW103 alloys are discussed based on EBSD analysis and Schmid factor analysis of twins.Main conclusions are as follows.

1.Under room temperature compression both {10–12} and{11–21} extension twins (ET1 and ET2) could occur in cast Mg-Gd-Y-Zr alloys of T4 and T6 states.Intriguingly,the sequences of the twin appearance are different in these two states.

2.Most ET1 twins occur in the grains containing ET2 in the T4 alloys,and the c-axis of the favorable parent grain orientation for twinning is nearly perpendicular to the compression direction.ET2 twins exhibit polarity that can only be activated as the sample is compressed nearly perpendicular to the c-axis.

3.The uncommon phenomenon that ET2 occurs prior to ET1 in the T4 state is attributed to the different CRSS change caused by RE solutes.Since solutes mainly inhibit atomic shuffling which is the dominant for ET1 nucleation but inessential for ET2 nucleation,RE solutes have a stronger hardening effect on ET1 than on ET2.With consumption of RE solutes after precipitation,the strong hardening effect of RE solutes on ET1 can be significantly reduced and the emergence sequence is ET1 prior to ET2 in the T6 state.

4.Although extension twins do not contribute directly to the strength and plasticity of the Mg-Gd-Y alloys in the T4 and T6 states,they can coordinate the plastic deformation during compression through non-Schmid factor effect.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (grants U1830121,51301173,51531002,51601193,and 52171055),the National Science and Technology Major Project (2017-VI-0003-0073),the National Key Research and Development Program of China (2016YFB0301104) and China Postdoctoral Science Foundation (grant 8206300226).

Journal of Magnesium and Alloys2023年7期

Journal of Magnesium and Alloys2023年7期

- Journal of Magnesium and Alloys的其它文章

- Recent progress in MgB2 superconducting joint technology

- “Smart” micro/nano container-based self-healing coatings on magnesium alloys: A review

- Recent advances using equal-channel angular pressing to improve the properties of biodegradable Mg–Zn alloys

- Effects of Ce content on the modification of Mg2Si phase in Mg-5Al-2Si alloy

- Solute drag-controlled grain growth in magnesium investigated by quasi in-situ orientation mapping and level-set simulations

- Formation and growth of precipitates in a Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy aged at 200 °C