Formation and growth of precipitates in a Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy aged at 200 °C

Zhiwi Du ,Yonggang Png ,Hang Tng ,Zhong Cao ,Kui Zhang ,Minglong Ma ,Xiaoli Han,Ting Li,Cong Ch,Yongjun Li

a Guobiao (Beijing) Testing &Certification Co.,Ltd.,Beijing 100088,China

b China United Test &Certification Co.,Ltd.,Beijing 100088,China

cNanjing Yunhai Special Metal Co.,Ltd.,Nanjing 211212,China

d Shanghai Spaceflight Precision Machinery Institute,Shanghai 201600,China

e State Key Laboratory of Non-Ferrous Metals &Processes,GRIMAT Engineering Institute Co.,Ltd.,Beijing 101407,China

Abstract Crystal structures,growth characteristics,and transformation of the precipitates in a Mg-7Gd-5Y-1Nd-2Zn-0.5Zr (wt.%) alloy aged at 200 °C for various durations were investigated using transmission electron microscopy (TEM) and high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM).A detailed Mg-Gd type precipitation sequence for Mg-Gd-Y-Nd-Zn alloys was proposed as follows:supersaturated solid solution →solute clusters →zigzag GP zones+β′′(I)→β′→β′+protrusions/joints →pre-β1 →β1 →β.Solute clusters formed in the early stage of aging consisted of one or more rare-earth (RE)/Zn-rich atomic columns with different configurations.RE/Zn-rich solute clusters grew into zigzag GP zones and β′′(I) as aging time extending.The paired-zigzag GP zones might grow up to be β′ precipitates directly.In the peak-and plat-aging stages,the number of solute clusters in the matrix decreased until they disappeared,and most existed as zigzag arrays and super hexagons.Protrusions formed at the end of β′ at an angle of 120°,then grew into joints when two different β′ variants encountered together.Protrusions/joints comprise zigzag arrays,super-hexagons, β′F, β′′(II), βT,and hybrid structures rich in solute atoms,and act as catalysts for the growth of the β′ variants.Larger β′ grow by joints consumption while smaller β′ precipitates dissolve to form joints. β1 precipitates essentially evolve from pre-β1 precipitates,with four-point diamond structures formed by RE/Zn atomic substitution and atomic migration based on the original α-Mg structure.

Keywords: Magnesium alloys;Aging;Precipitates;Microstructures;HAADF-STEM.

1.Introduction

Magnesium alloys containing rare-earth (RE) elements have received increasing attention over the past two decades owing to their relatively high strength and excellent creep resistance [1–5].In our previous study [6,7],Mg-Gd-Y-Nd(-Zn)-Zr (wt.%) alloys was prepared based on Mg-7Gd-5Y-1Nd-0.5Zr (wt.%) (VW75) alloy by adding Zn element,to realize co-strengthening and toughening withβ′and long period stacking ordered (LPSO) phases.Microstructures of Mg-RE-Zn alloys have been previously reported [8–13].However,most studies on Mg-RE-Zn alloys have focused on the LPSO phases,composition adjustment,heat treatment,optimization of processing,and peaking aging microstructure analysis,while relatively less studies have been conducted on precipitation behavior,especially on Mg-Gd-Y-Nd-Zn complex multi-element alloy systems.In this study,the alloy underwent casting,homogenization,pre-precipitation and extrusion processes before aging.According to our previous study [13–15],the precipitation sequence of Mg-Gd-Y-Nd-Zn alloy during the entire process can be roughly summarized as Mg-Gd type (β-type) and LPSO type precipitation sequences.However,detailed aging precipitation behavior of this multi-element alloy under this specific process remains unclear.Based on many TEM observations,it was found that for this alloy after 0–2000 h aging,the metastable LPSO building-block clusters underwent almost no structural change and the main precipitates were theβ′phases.Therefore,this study focused on the formation and transformation behavior of the precipitates in the Mg-Gd type precipitation sequence.To master the formation and transformation of a series of metastable phases,a relatively low temperature (200 °C) was adopted to delay the aging process.

Previous researches suggested that the precipitation sequence in Mg-Gd(-Y) alloys with a four-stage sequence is supersaturated solid solution (SSSS) →β′′(D019) →β′(cbco) →β1(fcc) →β(fcc) [16,17].β′′has a D019crystal structure (a=0.64 nm andc=0.520 nm),and theβ′′phase possibly has a stoichiometric composition of Mg3X,as indicated by transmission electron microscopy (TEM) and three-dimensional atom probe studies [18].β′′phases were directly observed in the Mg-Gd-Y-Zr alloy using atomicresolution high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) [19].However,the role ofβ′′phase in the precipitation sequence is still controversial [15,20].Theβ′phase has a composition of Mg7Gd and an ordered orthorhombic structure (a=0.64 nm,b=2.28 nm andc=0.52 nm) in the Mg-5at%Gd alloy [21].Theβ1phase has an fcc structure (space group Fmm,a=0.74 nm) with Mg3X composition [22,23].The orientation relationship between theβ1phase andα-Mg is (12)β1//(100)αand [110]β1//[0001]α,equivalent to the Burgers orientation relationship [22].Theβphase has an fcc structure (space group F3 m,a=2.22 nm) and Mg5X composition [22,23].In recent years,with the development of electron microscopy,many detailed precipitation sequences have been reported [20,24,25],such as supersaturated solid solution →clusters →nucleationβ′(major)/βH(minor)→precipitateβ′(major)/βM,βT′(minor)→β1→β(equilibrium) in Mg-Gd-Y-Zr [20],supersaturated solid solution →ordered solute clusters →zigzag GP zones →β′→→β1→βin an Mg-Gd-Ag-Zr alloy [24],and supersaturated solid solution →ordered solute clusters →GP zones →β′→+tail-like hybrid structures →β1→βin Mg-Gd alloys [25],thus indicating that the Mg-Gd type precipitation sequence is not consistent in different alloy systems.

Atomic scale HAADF-STEM studies have also been conducted on solute clusters,protrusions at the end ofβ′,and connective structures between theβ′precipitates in the aging sequence of Mg-RE alloys [19,26,27].Both protrusion and joint are associated withβ′,and are essentially similar.However,with the extension of aging time,the distribution of the branch-shaped protrusions changed from being located at the end of theβ′phase to being between differentβ′variants.Polytype protrusion/joint structures have been observed in Mg-RE alloys [19,20,28,29].Among them,[28,29](also namedβ′T[20]andβ′S[30]),βT[19](also namedβM[20]),and super-hexagons [26,31,32](also namedβH[20]) are relatively common.Theβ′Fphase is composed of Mg7RE and has an ordered orthorhombic structure(a=0.64 nm,b=1.11 nm,c=0.52 nm) [29].TheβTphase has an orthorhombic crystal structure (a=0.64 nm,b=3.33 nm,andc=0.52 nm) is composed of Mg5X [19].According to the previous research,the structures and configurations of the protrusions/joints are sensitive to the alloy composition.Recently,our HAADF-STEM observations further demonstrated that the structures of the protrusions/joints of the Mg-Y-Nd alloy are mainlyβ′′[33],clearly different from those in this experimental alloy.Therefore,it is valuable to study the structures and configurations of the protrusions/joints in the experimental Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy.

In this study,atomic-resolution high-angle annular darkfield scanning transmission electron microscopy (HAADFSTEM) was used to obtain direct images of solute clusters,GP zones,protrusions/joints,β′,andβ1.This study focused on the structures and growth characteristics of solute clusters and protrusions/joints,and the role of these transition structures in the formation and growth ofβ′andβ1.The data obtained from the present study can contribute to a deeper understanding of the formation,growth,and transformation mechanisms of precipitates in the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy.

2.Materials and methods

The Mg-7Gd-5Y-1Nd-1Zn-0.5Zr (wt.%) alloy required for this study was prepared by melting pure Mg,Gd,Zn,and Mg-30 wt.% each of Y,Nd,and Zr intermediate alloys in an electric resistant furnace under the protection of an Ar and CH2FCF3atmosphere,and the final size of the ingot wasΦ120 mm × 300 mm.The as-cast alloy was homogenized at 515 °C for 48 h to realize the dissolution of eutectic structures and grain boundary LPSO phases as far as possible.After the homogenization treatment,the alloy was cooled in furnace to 480 °C and maintained 8 h (referred to as the preprecipitating),to realize the LPSO phases forming in{0001}αwith widths of tens to hundreds of nanometers.After the preprecipitation,the alloy was immediately extruded.The mold and extrusion temperatures were 480 and 450°C,respectively,and the extrusion ratio was 20:1.The as-extruded alloys were aged at 200 °C for various durations.

HAADF-STEM images of the precipitates in the aging stage were analyzed by using a Talos F200X transmission electron microscope operated at 200 kV and a camera length of 98–260 mm.The TEM foils were prepared by the conventional methods: grinding to 50 μm and two-jet thinning at-35 °C using 98 vol.% ethanol and 2 vol.% perchloric acid as the electrolytes.Hardness measurements were carried out using a Brinell hardness tester;the test load head and dwell time were 30 kgf and 25 s,respectively.

3.Results

3.1.Initial microstructure

In the as-cast alloy,eutectic structures ofα-Mg,(Mg,Zn)3RE,Mg5(RE,Zn) phases and blocky long-period stacking ordered (LPSO) structures exist widely at grain boundaries.RE and Zr-rich particles are diffusely distributed in the grain.After homogenized treatment at 515 °C/48 h,the microstructures are mainly composed ofα-Mg,residual blocky LPSO structures at grain boundary which were not dissolved completely,few single LPSO building blocks,different morphology Zn-Zr clusters,and RE/Zn-rich atomic columns,detailed results can be referred to our previous papers [34].After 515 °C/48 h,cooled in furnace to 480 °C,and maintained 8 h,a large number of lamellar 14H-LPSO structures were precipitated in {0001}α,referred to as the pre-precipitates.

Fig.1(a) shows the general microstructure of the LPSO structures,Mg5(RE,Zn),and Zn-Zr particles distributed in the as-extruded Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy,and the corresponding EDS maps are shown in Fig.1(b–g).In the extruded alloy,in addition to LPSO structures with various morphologies,irregularly shaped LPSO structure,broken preprecipitated LPSO structure and metastable LPSO building block clusters,and the submicron Mg5(RE,Zn)particles were uniformly distributed in the grain and grain boundaries,detailed results for which can be found in one of our previous reports [15].The LPSO structures and submicron Mg5(RE,Zn)particles attributed the as-extruded alloy with optimal mechanical properties,tensile strength,yield strength,and elongations of 365 MPa,276 MPa,and 17.5%,respectively [15].

Fig.1.General microstructure showing LPSO structures,Mg5(RE,Zn) and Zn-Zr particles distributed in the as-extruded Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy.(a) HAADF-STEM image;(b–g) corresponding EDS maps.

Fig.2(a) shows the selected area electron diffraction(SAED) pattern of the grain along the [0001]αzone axis,wherein no weak diffraction spots corresponding to the precipitates can be seen.The high-resolution HAADF-STEM image in Fig.2(b) shows almost no atomic clusters.The Mg atoms in various layers have been denoted by green and blue balls in Fig.2(c).Fig.2(d and e) show various types of thin LPSO plates in theα-Mg matrix and the corresponding SAED pattern viewed along the [110]αzone axis.These thin LPSO structures have also been called metastable LPSO building block clusters [35].The high-resolution HAADFSTEM images shown in Fig.2(f–h) further demonstrate that the LPSO thin-plate can consist of a single building block with an ABCA-type stacking sequence of its closely packed planes (also calledγ′[36]),two twin-related building blocks separated by three Mg layers constituting a complete 14HLPSO structure [37,38],and three building blocks separated by′′3+3′′Mg layers.The long-period atomic stacking sequence of the 14H-LPSO structures along the [0001]αdirection is ABABCACACACBABA,which is consistent with that in Mg-Y-Zn alloy [37,38].

Fig.2.Precipitates distributed in grain for the as-extruded Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy.The electron beam is parallel to [0001]α in Fig.2(a–c),and parallel to [110]α in Fig.2(d–h).(a) SAED pattern;(b) high resolution HAADF-STEM image showing almost no atomic clusters appear;(c) Enlarged image corresponding to area A in Fig.2(b),Mg atoms at different layers are denoted with green and blue balls;(d) HAADF-STEM image showing LPSO building blocks;(e) corresponding SAED pattern of Fig.2(d);(f–h) high resolution HAADF-STEM images of γ′ and 14H-LPSO structure.

3.2.Hardness response

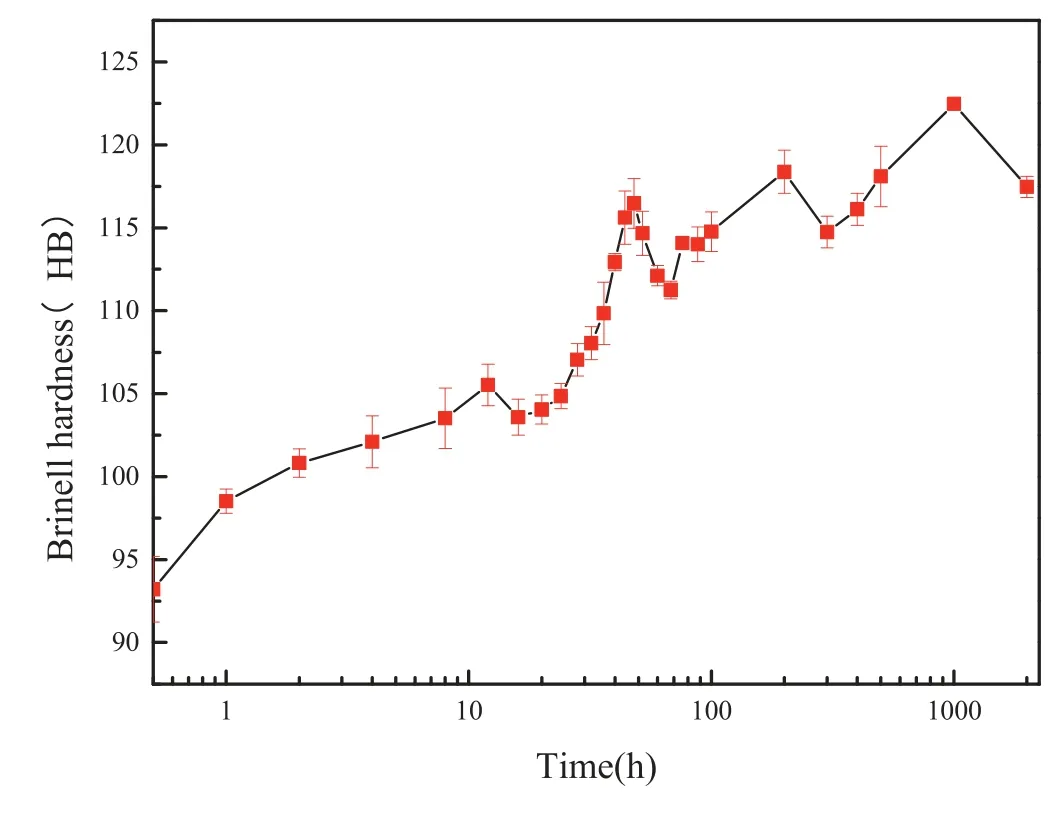

The extruded alloy was subjected to aging at 200 °C,and the age-hardness curve is shown in Fig.3.The alloy exhibited a remarkable hardening effect at 200 °C,and the peak hardness was obtained at 200 °C after 44 h of aging.A plateau in the aging response was observed between 44 and 2000 h.This long aging plateau suggests that the main strengthening phase precipitated in the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr extruded alloy had a good thermal stability.Based on many TEM observations,it was found that for 0–2000 h of aging,the metastable LPSO building-block clusters underwent almost no structural change and the main precipitates were theβ′phases.In the initial stage of aging,RE/Zn atoms desolvated from the supersaturated solid solution,and formed a large number of solute clusters,resulting in a slow increase in hardness.The hardness increased rapidly owing to the forming of a large number ofβ′.During 44–2000 h,the precipitates were mainlyβ′,and a small amount ofβ1appeared at 1000 h,indicating that the growth and transformation ofβ′are the reason for the plateau in the aging response.Therefore,the formation and growth of the precipitates belonging to the Mg-Gd type precipitation sequence in the as-extruded Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy aged at 200 °C were studied in detail;however,the LPSO structures were not investigated in this study.

Fig.3.Age-hardening curves of the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy at 473 K (200 °C).

3.3.Aging at 200 °C for 4 h

Fig.4(a and b) shows the general HAADF-STEM image and the corresponding SAED pattern viewed along the[0001]αzone axis for the alloy aged at 200 °C for 4 h.In the early stage of aging,a large number of high-contrast RE/Zn clusters with short-range-order structures were formed in the matrix.The analysis of a large number of atomicresolution HAADF-STEM images viewed along [0001]α,indicated that the short-range ordered structures were mainly composed of single,double,triple,quadruple,and other multiple RE/Zn-rich columns,as illustrated in Fig.4(c–m).For consistency,these will be referred to as solute atomic clusters,which have also been reported in binary Mg-RE alloys[26].

Generally,RE/Zn-rich atomic columns are located at the vertices of the minimum Mg-hexagon ring,and multi-columns are arranged consecutively at opposite angles of the adjacent Mg-hexagon rings,tending to form a as super-hexagon reported in Refs.[26,31,32](as shown in Fig.4(i)) or zigzag structures,also called zigzag GP zones reported in Ref.[24](as shown in Fig.4(g)).The zigzag arrays and superhexagons,as solute clusters in a broad sense,are different from the others and can be seen as two types of structural units with better periodicity among the early solute clusters.In three dimensions,the zigzag arrays are plate-like and the super-hexagons are rod-shaped.

According to the arrangement rules of the RE/Zn-rich columns,the four atomic columns usually appear in three forms: Fig.4(f and g) show two of them,and the structural models are shown in Fig.4(n),marked as numbers 4-6.The components with the four RE/Zn-rich atomic columns would transform into two structures: RE/Zn-rich super-hexagons(Fig.4(i and k)) and zigzag GP zones (Fig.4(g and l)).The spacing of adjacent RE/Zn-rich columns for the cluster is 3.7(see Fig.4(n-2)) along the<100>αdirection,twice of those of adjacent Mg atomic columns in the minimum Mghexagon ring,that is √3/2*2/3*aMg=1.85(aMg=3.21),viewed along<0001>α(Fig.4n).And the spacing of the next-nearest RE/Zn-rich columns is 6.4(see Fig.4(n-3)).In essence,RE/Zn occupied the second-nearest position ofα-Mg,with a spacing of 4.5.

The arrangements of the RE/Zn-rich and Mg columns in the super-hexagons were consistent with those in the Ni3Sntype D019structure (Fig.4i) [19].The super-hexagons grew to a larger size by continuous stacking (Fig.4(n-9) and (n-10)) and formed a new long-range ordered structure (Fig.4k)similar to theβ′′reported in Ref.[19].In this study,to distinguish theβ′′precipitate at 200 °C/500 h,it will be henceforth referred to asβ′′(I).The lattice parameters of theβ′′(I) phase werea=2aMgandc=cMg,and its composition was Mg3(RE,Zn).

The zigzag GP zone is usually present as a monolayer(Fig.4(g))or paired((Fig.4(l))zigzag RE/Zn-rich column arrangement.In the paired-zigzag structure,the atomic columns were arranged in a mirror symmetry with respect to the{100}αplane,and the spacing between the zigzag arrays was 1.11 nm (6*√3/2 × 2/3*aMg=11.12) (as marked in Fig.4(n-11)).Moreover,the spacing between the two top and two down RE/Zn-rich columns in the zigzag arrays was 0.93 nm (5*√3/2 × 2/3*a=9.27) and 1.30 nm(7*√3/2 × 2/3*a=12.97),respectively,along<100>α,as marked in Fig.4(n-11).In certain regions,the RE/Znrich columns occupied the adjacent positions of the minimum magnesium hexagonal ring,as shown in Fig.4(m).The compact arrangement of the RE/Zn-rich atomic columns is believed to have resulted from two monolayer zigzag structures(marked by red and yellow circles,respectively)growing together.

3.4.Aging at 200 °C for 44 h

Upon further aging of the alloy,in addition to the solute clusters,super-hexagons,and zigzag GP zones,β′precipitates were widely observed (Fig.5(a)).Branch-shaped protrusions,also called tail-like hybrid structures [25],appeared at the end of certainβ′precipitates.The number of solute clusters decreased,and their structures were almost identical to those desolvated from the matrix in the initial stage of aging.Some solute clusters grew further and evolved into zigzag arrays,super-hexagons,β′structures,or hybrid structures made up of them.Theβ′phase had three orientation variants,related by a 120° rotation with respect to each other around<0001>α.And most variants with different orientations were not connected to each other at this stage.

Fig.5. β′ precipitates exhibiting in the alloy aging at 200 °C for 44 h The electron beam is parallel to [0001]α in Fig.5(a–c),and parallel to [110]α in Fig.5(d,e).(a,d) HAADF-STEM images showing the general distribution,the inset is corresponding SAED pattern;(b) high resolution HAADF-STEM image showing β′ precipitates with protrusions,superimposed unit cell exhibiting the atomic arrangements;(c) high resolution HAADF-STEM image showing two β′ overlapped at different heights;(e) high resolution HAADF-STEM image with superimposed unit cell of β′ precipitates;(h) structural model of β′precipitates,red,yellow,green and blue ball representing RE/Zn (Z=0),RE/Zn (Z=0.5),Mg (Z=0) and Mg (Z=0.5),respectively.

The analysis of a large number of high-resolution HAADFSTEM images indicated that theβ′phase was formed when a third zigzag was linked to the original paired-zigzag structure.This indicates that theβ′precipitates can be formed from paired-zigzag arrays directly withoutβ′′,as reported in Refs.[15,20].With the formation and growth of theβ′precipitates,the size of theβ′ranged from 3 to 6 nm and contained 3–6 zigzag arrays along<100>α.Viewed along<0001>ɑ,the RE/Zn-rich columns in the zigzag arrays were arranged in opposite directions.The zigzag arrays were separated by three{100}Mg layers.Based on the analysis of atomic resolution HAADF-STEM images (Fig.5b and e),the actual lattice parameters ofβ′were found to bea=0.66 nm (a≈ 2aMg=0.64 nm),b=2.35 nm(b≈√3/2*2/3*12aMg=2.22 nm),andc=0.53 nm (c≈cMg=0.52 nm).The results indicated that theβ′phase had a certain lattice distortion compared with theα-Mg matrix,and the strain field around theβ′phase may have promoted the formation of the protrusions.And the structural model for theβ′was shown in Fig.5(f),which is consistent with the structure ofβ′reported in Refs.[21,37].

Fig.5(c) shows a different structure associated with theβ′phase viewed along [0001]α,which is composed of two groups of zigzag arrays belonging to the twoβ′precipitates,the adjacent zigzag arrays have equal spacing.Fig.5(d)shows HAADF-STEM images viewed along[110]α;the twoβ′precipitates marked by the red arrows (β′-1 andβ′-2) almost overlapped once imaging along<0001>α,further indicating that this structure was an overlapping image formed byβ′at different Z-heights.

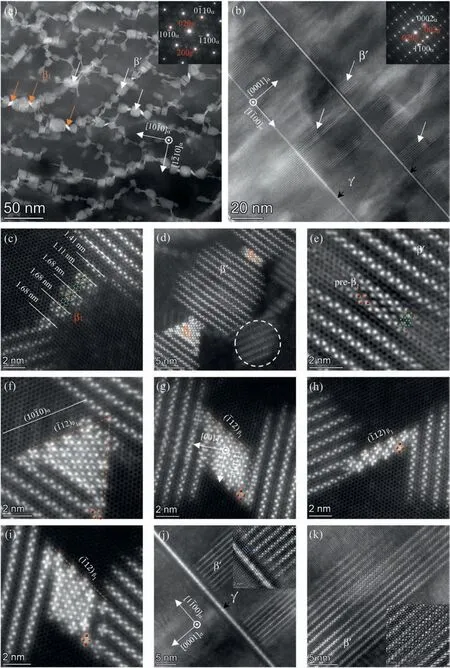

3.5.Aging at 200 °C for 500 h

Fig.6(a and b) and their insets show the HAADF-STEM images and the corresponding SAED patterns viewed along the [0001]αand [110]αzone axes for the alloy aged at 200 °C for 500 h Upon further aging,isolated short-rangeordered solute clusters and zigzag GP zones almost disappeared andβ′further grew with protrusions elongating along<100>α,as shown in Fig.6(a).

Fig.6. β′ precipitates and protrusions/joints exhibiting in the alloy aging at 200 °C for 500 h The electron beam is parallel to [0001]α in Fig.6(a,c–j),and parallel to [110]α in Fig.6(b).(a,b) HAADF-STEM image showing the general distribution of precipitates,the insets are corresponding SAED patterns;(c–j) high resolution HAADF-STEM images showing protrusions/joints with different configurations of RE/Zn rich columns;(k) typical structural model corresponding to the experimental images.

Most of theβ′precipitates were linked via protrusions with complicated structures.The protrusions as connected structures between the precipitates will be referred to as joints in this study.The metastable LPSO building block clusters did not grow significantly and still had a single building block structure (γ′) as shown in Fig.6(b).

Through extensive atomic-resolution HAADF-STEM images analysis,it was concluded that the joints between the twoβ′phases were mainly composed of two types of structural units: (I) zigzag array and (II) super-hexagon.Fig.6(c–j) show the connective structures stacked by two structural units with different configurations.When the zigzag arrays were aligned with<100>α,and the spacing between them was 1.10–1.12 nm,as shown in Fig.6(c and d),the crystal structures of some of the joints were consistent with that of thephase as reported in Refs.[28,29].Thephase had an orthogonal structure with lattice parametersa=0.64 nm(a=2aMg),b=1.1 nm (b=6*√3/2 × 2/3*aMg=1.11 nm),andc=0.52 nm (c=cMg),and a Mg7RE composition.Certain joints stacked by super-hexagons located at the ends of theβ′phases possessed a D019structure similar to that of theβ′′(I) phase mentioned in Section 3.3,and were namedβ′′(II) because they existed at different aging stage,as shown in Fig.6(f and g).β′′has only been reported in the early stage of aging [23];however,in this study,it also appears in the peak-aging plateau stage.In addition to the joints composed of continuously stacked super-hexagons,some were composed of super-hexagons arranged in rows along<110>αand elongated along<100>αwith a spacing of 1.68–1.69 nm (≈9*√3/2 × 2/3*aMg=1.67 nm),as shown in Fig.6(h and i),which have structures identical toβTas reported in Ref.[19].According to the arrangement characteristics of the atoms in theβTconnected structure,the growth direction order can be inferred as<0001>α(//<001>βT),<100>α(//<010>βT),and<110>α(//<100>βT),which is different from that ofβ′.The structural models of,β′′(II),andβT,projected along [0001]α,are shown in Fig.6(k).To sum up,the structures of joints at this aging stage include,β′′(II),andβTand some hybrid structures stacked by super-hexagons and zigzag arrays.

3.6.Aging at 200 °C for 1000 h

Fig.7(a and b) and their insets show the HAADF-STEM images and corresponding SAED patterns viewed along the[0001]αand [110]αzone axes for the alloy aged at 200 °C for 1000 h The HAADF-STEM images and the corresponding SAED patterns show that most of the precipitates areβ′(white arrows,(Fig.7(a and b)),which grew further and almost connected to form a closed chain.

Fig.7. β′ precipitates,joints and β1 exhibiting in the alloy aging at 200 °C for 1000 h.The electron beam is parallel to [0001]α in Fig.7(a,c–i),and parallel to [110]α in Fig.7(b,j,k).(a,b) HAADF-STEM image showing the general distribution of precipitates,the insets are corresponding SAED patterns;(c)high resolution HAADF-STEM images showing joint having βT structure;(d) high resolution HAADF-STEM images showing β1 precipitates formed between β′;(e) enlarged image corresponding to β1 in the top right of Fig.7(d);(f–i) high resolution HAADF-STEM images showing interfaces between β1 and adjacent ɑ-Mg or β′;(j) high resolution HAADF-STEM images showing the interface between LPSO structure and β′;(k) high resolution HAADF-STEM image showing two β′ overlapped at different heights along observation direction.

The joints existed in the long-aging state,and their structures were almost similar to those of the structures aged at 200 °C for 500 h The structures ofβTwere more common;therefore,it was deduced that other joints eventually would tend to transform intoβT.Fig.7(c) illustrates a joint with the structure ofβT.At the end of this joint,close to another nearbyβ′,the structure was a zigzag array.It was misaligned withβ′by shifting 1/2aMgalong [110]αand had a distance of~1.41 nm along [100]αwithβ′,which is consistent with the structures shown in Fig.6(k).

The joints with a brighter contrast betweenβ′are shown in Fig.7(a),marked by yellow arrows.Typical high-resolution HAADF-STEM images corresponding to the brighter contrast region are shown in Fig.7(d–i).These precipitates were indexed toβ1through serial high-resolution HAADFSTEM image analysis.Theβ1phase had a face-centered cubic structure (a=0.74 nm) and a Mg3(RE,Zn) composition [22,23].From Fig.7(f–i),it can be determined that the orientation relationship between theβ1phase andα-Mg is(12)β1//(100)αand [110]β1//[0001]α,and its habit plane is parallel to {100}α,which is equivalent to the Burgers orientation relationship in other Mg-RE alloys [22,23].β1precipitates almost appeared at the necks of the chains.As shown in Fig.7(d–i),a large number of four-point diamonds (named pre-β1in this study) were observed,which had a structure similar to,but not exactly the same asβ1.The pre-β1structure at the neck of the precipitate chain acts as a precursor duringβ1formation.Fig.7(d) shows twoβ1precipitates formed betweenβ′with the same orientation,and their locally enlarged images are shown in Fig.7(e and f).Pre-β1evolved from theβ′Fphase (Fig.7(e)) and then transformed intoβ1.As pre-β1grew toβ1,it attached to one side of theβ′variant,and gradually consumedβ′.And thenβ′gradually transformed intoβ1from outside to inside,starting at the edges.Fig.7(h) shows that the structure was composed of two pre-β1rows between twoβ′rows with different orientations.Fig.7(i) shows the structure composed of pre-β1at the edge andβ1in the core between twoβ′with different orientations.

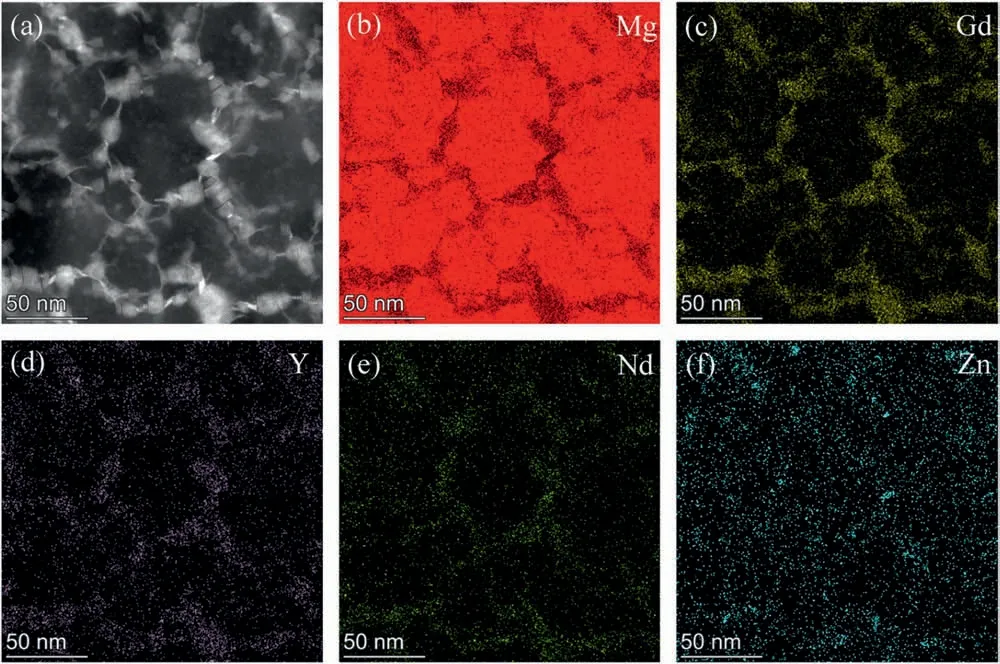

Fig.7(j) shows theβ′precipitates and the LPSO structure encounter,and they had a gap with threeα-Mg layers(marked by blue lines) along [0001]α.Fig.7(k) shows an overlapped structure composed of twoβ′precipitates viewed along [110]α,which is similar to that shown in Fig.5(c) but viewed along different directions.Fig.8 shows the HAADFSTEM image and EDS elemental maps of the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr (wt.%) alloy aged at 200 °C for 1000 h viewed along the<0001>ɑ.Zn was clearly enriched in theβ1phase and participated in the formation of precipitates in the Mg-Gd type precipitation sequence,which is consistent with that in Ref.[8].

Fig.8.Enrichment of solute atoms of β1 precipitates in the chains in the alloy aging at 200 °C for 1000 h.The electron beam is parallel to [0001]α.(a)HAADF-STEM image;(b–f) corresponding EDS maps.

4.Discussion

4.1.Characteristics of protrusions/joints

Branch-shaped protrusions,also called tail-like hybrid structures [25],appeared at the ends of certainβ′precipitates at an angle of 120° to the third-order characteristic growth direction (<100>α) of theβ′parent (Fig.5(b)),matched the orientation angles of the differentβ′variants.Upon further aging of the alloy,most of the protrusions connected differentβ′variants together as joints.Therefore,both protrusion and joint actually fall into one category,and coexist in the prolonged aging stage as shown in Figs.6(a) and 7(a).At the initial stage of protrusion formation,they exhibit the structures of zigzag array,super-hexagon,and some hybrid structures stacked by them.Upon further aging,the protrusions almost being located between twoβ′variants,become joints,which consist of zigzag arrays,super-hexagons,′′(II),βT,and some hybrid structures,and eventually tend to change toβT.The evolution for the protrusions/joints at different aging stage can be attributed to the aging time.Protrusions/joints with various structures have also been observed in the Mg-RE alloy [19,20,28,29].The joints hadβ′S(also calledor+tail-like hybrid structures in Mg-Gd(-Y) alloys [25,30,28],while hadβ′′(II) structure in Mg-7Y-1Nd alloy [33].Obviously,the more abundant structures of the protrusions/joints exist in this experimental alloy,which can be attributed to the multiple alloying element in Mg-Gd-Y-Nd-Zn alloy.

According the structural model (see Fig.6(k)),the characteristic spacing is respectively 1.11 and 1.67 nm between adjacent zigzag arrays,and adjacent super-hexagons in the same protrusion/joint along<100>α.The measured spacing(see Figs.5–7) along<100>α,in the inner of the joints,is~1.11 nm between adjacent zigzag arrays,while~1.67 nm between adjacent super-hexagons,which is consistent with the theoretical value (see Fig.6k).However,at the interface between the joints and theβ′precipitates,there are two different values of the spacing between adjacent zigzag arrays,which are~1.11 and~1.39 nm,respectively.When the spacing between adjacent zigzag arrays is~1.39 nm at the interface,it does not belong to any metastable structure and the corresponding structural model is shown in Fig.6(k).It is due to the protrusion growing at one end of certainβ′precipitate,the original distance between the twoβ′precipitates determines the spacing of the zigzag arrays when the protrusion meets anotherβ′precipitate at the other end.Therefore,based on the characteristic spacing,it can be deduced that whichβ′the protrusions/joints grow on.Fig.6(j) shows a special case where the distance between the joint and theβ′precipitates at both ends is the characteristic distance of 1.11 nm.However,the distance between the two zigzag arrays inside the joint is~0.80 nm.Therefore,this joint was composed by two protrusions which grew together,which further confirms that protrusions/joints actually fall into one category.

4.2.Formation and growth of β′

In the early aging,RE/Zn-rich solute clusters consist of one or more RE/Zn-rich ordered atomic columns with different configurations.RE/Zn-rich solute clusters grow into zigzag GP zones andβ′′(I) as aging time extending.Zigzag GP zones contains a monolayer or paired zigzag RE/Zn-rich column arrangement.In the paired zigzag GP zones,two monolayer zigzag arrays have a constant spacing (~1.11 nm)and are arranged in a mirror symmetry with respect to the{100}αplane.The spacing and arrangement of two zigzag arrays are same as those inβ′.Therefore,the paired-zigzag GP zones might grow up to beβ′precipitates directly as in Mg-Gd alloys [24,25].From their evolution from the RE/Znrich solute clusters to the zigzag GP zones toβ′phases,it was deduced that the sequence of the growth direction ofβ′was<0001>α(//<001>β′),<110>α(//<100>β′>),and<100>α(//<010>β′),while the morphology of the precipitates evolved from 1-D (1-dimensional) linear to a 2-D plate,and then to a 3-D lath.β′′(I) was observed aging at 200 °C for 4 h,while disappeared aging at 200 °C for 44 h In this process,β′grows via Ostwald ripening [25,39].It can be inferred thatβ′′(I) are transformed intoβ′by dissolving.

β′phase has a certain lattice distortion compared withα-Mg matrix asβ′grows.The stress and strain around theβ′precipitates are believed to have gradually increased with their coarsening,especially at their ends [25].Whenβ′grew to a certain extent,protrusions were formed at the end ofβ′,and grew along<100>α.Taking an example ofβT,the growth direction order can be inferred as<0001>α(//<001>βT),<100>α(//<010>βT),and<110>α(//<100>βT),which is different with that ofβ′,and<100>αis the second priority growth direction.Comparing withβ′,the aspect ratio of protrusion/joint is larger,that is,the length along<100>αis larger than that along<110>α.Comparing Fig.5(a),Fig.6(a) and Fig.7(a),theβ′precipitates and the closed precipitate chains grew as aging time extending.During the coarsening process,the joints were metastable,and acted as catalysts for the growth of theβ′variants.Largerβ′precipitates grew by the consumption of joint while smallerβ′precipitates dissolved to form joints.By this means,β′variants are further coarsened,and change the orientations to that of some coarse variants by consuming the relatively small precipitates with different orientations on the chains,and the joints.Fig.7(d) shows that the precipitate (marked by white circle),which no longer has the perfect zigzag structural characteristic of theβ′phase,is almost completely consumed.This direct experimental observation further confirms thatβ′grows via Ostwald ripening.Joints act as the RE/Zn atomic migration channel,and promote the coarsening ofβ′.

4.3.Formation and growth of β1

Precipitateβ1,as a metastable precipitate after prolonged aging,has been focused on the crystal structure,orientation relationship with the matrix and the precipitation sequence in different alloy systems.However,previous studies have shown that the transition sequence toβ1is inconsistent and which structure is the precursor remains unclear.The precipitation sequence of Mg-Gd(-Y) alloys was traditionally considered to be SSSS →β′′→β′→β1→β[16,17].The transformation fromβ′toβ1was suggested to be the consequence of shear strain energy accommodation in Mg-Y-Nd alloy[20].In recent years,with the development of electron microscopy,many transition models fromβ′toβ1have been proposed in Mg-RE alloys,such asβ′→β′F→β1in Mg-Gd-Ag alloy [24]andβ′→+tail-like hybrid structures →β1in Mg-Gd alloy [25].In this paper,a large number of highresolution HAADF-STEM images located at joints between twoβ′variants were acquired,and the structure ofβ1phase and its precursor (pre-β1) having nearlyβ1structure were deeply analyzed,and the formation and growth mechanism ofβ1was proposed.

In the precipitate chains,β1with higher solute concentration almost appeared at the necks of the precipitate chains,where the stress and strain were concentrated.The orientation relationship between theβ1phase andα-Mg is(12)β1//(100)αand [110]β1//[0001]α,and its habit plane is parallel to {100}α,which is consistent with the results reported in Refs.[22,23].The high-resolution HAADF-STEM images shown in Fig.7 exhibit various structural configurations during the formation ofβ1.Eitherβ′or joints (zigzag arrays,super-hexagons,β′F,β′′(II),βT,and hybrid structures)at the necks are involved in the formation ofβ1.Regardless of element type,in essence,β′and joints are consistent with the HCP arrangement,except that RE/Zn atoms partly replace magnesium atoms.Similary,regardless of element type,althoughβ1has an fcc structure (Fig.9a),β1exhibits a bcc sub-lattice structure (Fig.9b).Therefore,without considering differences in element types,the transition fromβ′toβ1is hcp/bcc,i.e.Burgers orientation relationship betweenβ1andα-Mg,not hcp/fcc [22].

Fig.9.Atomic structure model and formation mechanism of β1 phase.(a) unit cell of β1 phase;(b) body-centered cubic sub-unit cell extracted from β1 unit cell;(c) atomic structure model exhibiting the transition from zigzag structure (in β′ or protrusions/joints) →pre-β1 →β1.

Considering differences in element types,β′and joints can be considered to be composed of a single structural unit,that is,a solute cluster consisting of three RE/Zn-rich columns(see Fig.4e and n-4).When a zigzag structure contains three RE/Zn-rich columns,if another RE/Zn atom moves to the opposite position on the top of the zigzag array (i.e.,the second-nearest position ofα-Mg) via diffusion,the RE/Zn columns form a new quadrangle (pre-β1).The RE/Zn-rich atomic columns of pre-β1are elongated,indicating that the atomic projection along<0001>αis not consistent with that ofα-Mg,possibly because of the movement of the atoms during the phase transformation.This process is consistent with the transformation of→β1in Mg-Gd-Ag alloy [24].In thez=0.5cMglayer,atoms movealong<100>α,and the pre-β1form.To reach a new equilibrium and form the newβ1phase,the atoms migrated a small distance via diffusion.During this transition,the lattices expanded by~15.6%along<110>αand compressed~5.7% along<0001>α,as deduced from the variation of the characteristic spacing marked in Fig.9(c and d).

This transition mechanism determines that three RE/Znrich columns tends to preferentially undergo pre-β1transition of four-point diamond structures in the position with relatively concentrated stress,such as the joints and the end ofβ′.To sum up,the formation ofβ1followed the rules ofβ′/joints →pre-β1→β1.At the neck of the precipitate chain,due to the presence of large stress and strain,any zigzag structural unit with three RE/Zn-rich atom columns may form pre-β1with four-point diamonds structure through the diffusion of RE/Zn atoms,and then form the early prototype ofβ1through the short-range diffusion adjustment of local atoms.In other words,both theβ′phase and the joints can be used as the nucleation position ofβ1phase.With the further coarsening ofβ1,the pre-β1structure will be preferentially formed at the edge of the ajacentβ′and surround the initialβ′,finally theβ′transform toβ1from outside to inside.

To sum up,a detailed Mg-Gd type precipitation sequence for Mg-Gd-Y-Nd-Zn alloys was proposed as follows:supersaturated solid solution →solute clusters →zigzag GP zone +β′′(I) →β′→β′+protrusions/joints →preβ1→β1→β.

5.Conclusions

(1) A detailed Mg-Gd type precipitation sequence for Mg-Gd-Y-Nd-Zn alloys aging 200 °C was proposed as follows: supersaturated solid solution →solute clusters →zigzag GP zones +β′′(I) →β′→β′+protrusions/joints →pre-β1→β1→β.

(2) RE/Zn-rich solute clusters form in the early stage of aging and consist of one or more RE/Zn-rich ordered atomic columns with different configurations.RE/Znrich solute clusters grow into zigzag GP zones andβ′′(I)as aging time extending.

(3)β′can be formed directly from the growth of zigzag GP zones,without the formation of other transition phases.The sequence of growth ofβ′is along<0001>α(//<001>β′),<110>α(//<100>β′>),and<100>α(//<010>β′),while the morphology of the precipitates evolves from 1-D linear →2-D plate →3-D lath.

(4) Protrusions form at the end ofβ′at an angle of 120°,then grow into joints when two differentβ′variants encounter together.Protrusions/joints comprise zigzag arrays,super-hexagons,β′F,β′′(II),βT,and hybrid structures rich in solute atoms,and act as catalysts for the growth of theβ′variants.Largerβ′precipitates grow by joints consumption while smallerβ′precipitates dissolve to form joints.

(5)β1precipitates essentially evolve from pre-β1,with four-point diamond structures formed by RE/Zn atomic substitution and atomic migration based on the originalα-Mg structure.The formation and growth ofβ1follow the following rules: zigzag structure (inβ′or protrusions/joints) →pre-β1→β1→β′consumption →β1coarsening.

Foundation item

Project (51871195) supported by the National Natural Science Foundation of China;Youth Fund Project of GRINM(G12620213129038);Henan Provincial Department of Science and Technology Research Project (No.222102230113).

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The work was supported by the National Natural Science Foundation of China (51871195),Youth Fund Project of GRINM (G12620213129038) and Henan Provincial Department of Science and Technology Research Project (No.222102230113).

Journal of Magnesium and Alloys2023年7期

Journal of Magnesium and Alloys2023年7期

- Journal of Magnesium and Alloys的其它文章

- Recent progress in MgB2 superconducting joint technology

- “Smart” micro/nano container-based self-healing coatings on magnesium alloys: A review

- Recent advances using equal-channel angular pressing to improve the properties of biodegradable Mg–Zn alloys

- Twin evolution in cast Mg-Gd-Y alloys and its dependence on aging heat treatment

- Effects of Ce content on the modification of Mg2Si phase in Mg-5Al-2Si alloy

- Solute drag-controlled grain growth in magnesium investigated by quasi in-situ orientation mapping and level-set simulations