Experimental analysis of ballistic trauma in a human body protected with 30 layer packages made of biaxial and triaxial Kevlar®29 fabrics

Justyn Pinkos , Zigniew Stempien , Ann Sme˛dr

a Institute of Textile Architecture, Lodz University of Technology, Lodz, Poland

b Chair and Department of Forensic Medicine, Medical University of Lodz, Lodz, Poland

Keywords:

ABSTRACT Behind armour blunt trauma (BABT) is a body injury resulting from the deformation of the back surface of armour as a result of a bullet impact.In the case of textile body armour,the severity of the injury may depend on the material of the fibres,but also on the geometric structure of the fabric.The article focuses on experimental research into injuries of the human body protected by ballistic packets made of biaxial and triaxial fabrics,during a non-penetrating impact from a Parabellum 9 mm×19 mm Full Metal Jacket(FMJ) bullet, at a speed of 406 ± 5 m/s. In experimental research, the fabrics had a comparable surface weight and were made of the same Kevlar® 29 yarn. The ballistic packages were made of 30 layers. As part of the work,a physical model of the human body was developed.The human body model consisted of a model of the heart,lungs,and skeletal and muscular systems.During the bullet impact,the pressure forces were recorded using sensors located at selected points of the human body. The bullets hit five selected places on the body that were considered critical, from the point of view of maintaining a human’s vital functions.It was found that,during firing,pressure increases both at the site of impact and in the internal organs,which can lead to multi-organ damage.As a result of the experimental analysis,it has been shown that the pressures exerted on specific organs are always lower in the case of body protection with a ballistic packet made of triaxial fabrics, compared to a packet made of biaxial fabrics.© 2022 China Ordnance Society. Publishing services by Elsevier B.V. on behalf of KeAi Communications

1. Introduction

Textile ballistic shields are designed to protect the wearer when struck by a low-energy bullet, usually fired from a handgun. It should be noted that, despite the retention of the bullet in the structure of the ballistic packages, potential 'behind armour blunt trauma' (BABT) injuries may occur due to excessive deformation and the possibility of the significant transmission of impact energy to the human body. BABT injuries involve the risk of external and internal injuries to the human body, causing disturbances in the functioning of the body,which,depending on the scale,may cause death or severe disability [1-3]. Studies in the field of bullet wounds[4-8]and animal injuries[9-12]show that the velocity of the bullet, the type of ballistic shield and the weight of the bulletproof vest wearer all have an impact on the scale of the ballistic impact. Numerical research mainly considers the evaluation of the physiological effects of a ballistic strike as a bullet hits the numerical model of a human body protected by a ballistic packet [13-16]. On the other hand, the development of numerical models of lungs,livers or cardiovascular systems,allow for a better understanding of the phenomenon of ballistic trauma in a specific organ [18-20]. Published studies on the BABT phenomenon show that a very important factor leading to bodily injuries is a sharp increase in pressure at the point of bullet impact (i.e. the stress wave and energy transmission to the human body [21]). It is claimed that, as a result of a rib rupture, the parenchyma of the lungs may tear and numerous bruises may appear [1]. Cases of blunt ballistic injuries, as a result of a non-penetrating shot,allowed the definition of the phenomenon of ballistic trauma as a clinical unit,the scale of which depends on the anatomical hit of the bullet[2].Taking into account the location of the bullet’s impact in the area protected by the armour,the greatest risk of death occurs when the strike affects the heart, lungs and liver; while the fat tissue, muscles and skin strongly suppress the shock wave [13,14].Due to these threats, there has been continuous research into obtaining textile ballistic packages that minimise lateral deformation during a non-penetrating impact, as well as the scale of BABT injuries [13-17].

Current developments in the field of material engineering (in terms of ballistic fabrics) consist of improving their strength properties. It should be noted, however, that the ballistic effectiveness of textile covers is also influenced by the geometric structure of individual layers [22-25]. A bullet impact into the textile-based ballistic material is associated with many complex penetration mechanisms, which depend on the properties of the fibre and ballistic materials,including the properties of fabrics,such as weave, fabric density or the type of fabric. On the other hand,they depend on the ballistic impact methodology, ballistic target arrangement and bullet parameters. From the point of view of the correct assessment of the dynamic deformation and failure mechanisms of ballistic materials,it is important to take into account all the parameters affecting ballistic resistance. Currently, in order to better understand the ballistic impact mechanism, apart from experimental research,research using the finite element method is very often used [26].

Multi-axial fabrics are promising textile structures for soft ballistic packages. Multi-axis textile structures result from the interweaving of at least three thread systems. This type of multi-axis structure is referred to as a fabric with a triaxial base weave. The triaxial fabric is characterised by two warp thread arrangements and one weft thread arrangement. Both warp thread systems are directed at an angle of ± 60°, with respect to the weft thread system.As a result of the bullet hitting the triaxial fabric with the base weave, the shock wave propagates radially along all the systems,making the area of the fabric absorbing the kinetic energy of the bullet much larger than the biaxial fabrics of the plain weave.This results in significantly lower transverse deformation of the packages made of triaxial fabrics, compared to the packages made of biaxial fabrics, while maintaining the same yarns constituting the structure of both fabrics and the surface weight of the bundle[22,23]. Therefore, when using triaxial fabrics in the layers of the ballistic packages, significantly less injury to the human body is expected from a non-penetrating bullet impact.

Understanding the scale of injuries and the size of blunt BABT injuries resulting from a non-penetrating bullet hitting a human body protected by armour,is a difficult and complicated issue.From an ethical point of view, such research cannot be carried out with human subjects. Significant research into ballistic impacts on biological organisms, which occurs when they are hit by a nonpenetrating high-energy bullet, was carried out in Sweden [9,10].The aim of the research was to understand the effects and pathophysiological mechanisms of a non-penetrating NATO 7.62 mm×51 mm missile hitting a pig's body,at a speed of 800 m/s and protected by soft and hard ballistic packages.Non-penetrating impact tests confirmed the presence of apnoea for several minutes,leading to a severe drop in blood oxygen saturation, immediate hypotension, a decrease in cardiac output, an increase in mean pulmonary artery pressure, and a decrease in electroencephalogram (EEG) activity. Sometime after the injury, cardiovascular function returned to baseline levels but then slowly deteriorated,possibly due to oxygen deficiency. Soon after a lung injury, cell damage caused short-term hyperkalemia (increase in blood potassium) which, in some cases, resulted in fatal cardiac arrhythmias. Animals suffering from acute organ hypoxia for an extended period of time,died.The conducted research documented changes in the EEG graph after a ballistic impact.Research has documented changes in the EEG pattern following a ballistic impact.

During each non-penetrating bullet impact, the process of damaging the organs and tissues of the body took place,the scale of which depended on the place of impact, its parameters and the effectiveness of the ballistic shield. The resulting injuries and diseases, to which people are exposed to as a result of shelling, are numerous and varied[27-29].The classification of gunshot wound injuries, taking into account the wounded person's condition and the types of injuries suffered, was based on [30,31]. In practice,mechanical injuries are usually divided into 'penetrating open' or'penetrating'(in which the continuity of the body shell is damaged)and'non-penetrating'or'closed'injuries(in which the continuity of the body shell is not broken). However, the lack of a systemised criterion of the phenomenon of ballistic trauma for the thoracic and abdominal cavities contributed to the implementation of extensive scientific research,showing the scale of the problem.Due to the fact that experimental BABT research cannot be carried out with human participation or with the use of a human corpse,physical models of the human body are used for this purpose,which usually take into account the most important internal organs for vital functions, i.e.the heart, lungs, liver, skeletal and muscular systems [32,33]. The models are usually equipped with sensors, which record the pressure and allow the scale of the internal damage to be known during the non-penetrating impact of the bullet. 3D models of internal organs are made of thermoplastic plastics, the chemical composition of which varies depending on the organ.In physical models of the human body, the mapping of the muscular system is possible because of the use of silicone gel, which has strength parameters similar to the muscle tissues of the human body. The research conducted into the impact of a 9 mm bullet, moving at a speed of 430 m/s and hitting the chest (in line with the heart) covered in armour with a bullet resistance class III-A,showed that the highest pressure (0.85 MPa) occurred on the surface of the heart. In other organs, the pressure values were lower,e.g. for the left lobe of the liver it was 0.12 MPa.In the event of a bullet hitting the central area of the liver, a pressure of 1.64 MPa in the left lobe of the liver was recorded.Pressures of 0.74 MPa and 0.62 MPa were recorded in the right lobe of the liver and in the stomach.In turn,the sensor located in the heart recorded a value of 0.2 MPa.

In order to compare the effects of BABT during a nonpenetrating 9 mm Parabellum bullet hitting ballistic packages composed of biaxial and triaxial fabrics,experimental research was carried out using a physical model of the human body. The fabrics were made of the same Kevlar® 29 yarn. Such comparative research has not yet been carried out and published.

As part of this work, a physical model of the human body was developed. The model of the human body consisted of a model of the heart,lungs,and the skeletal and muscular systems.During the bullet impact,the pressure forces were recorded by sensors placed at selected points of the human body, which were then converted into pressures. During the firing, the bullet hit five selected places on the body,which were considered critical from the point of view of maintaining human vital functions. It was found that pressure increases both at the site of the impact and in the internal organs,which can lead to multi-organ damage. As a result of the experimental analysis, it has been shown that the pressures exerted on specific organs are always lower when the body is protected with ballistic packages made of triaxial fabrics. Based on the results obtained by experimental research, a medical analysis of possible injuries during a non-penetrating bullet hitting the human body,protected by a ballistic packet made of biaxial and triaxial fabrics,was carried out.

2. Ballistic fabrics

Two ballistic fabrics were used in this research: biaxial(Changzhou Utek Composite, China) and triaxial (Triaxial Structures, USA), both comprising identical Kevlar® 29 yarn. The detailed structural parameters of these fabrics are presented inTable 1.

3. Physical model of the human body

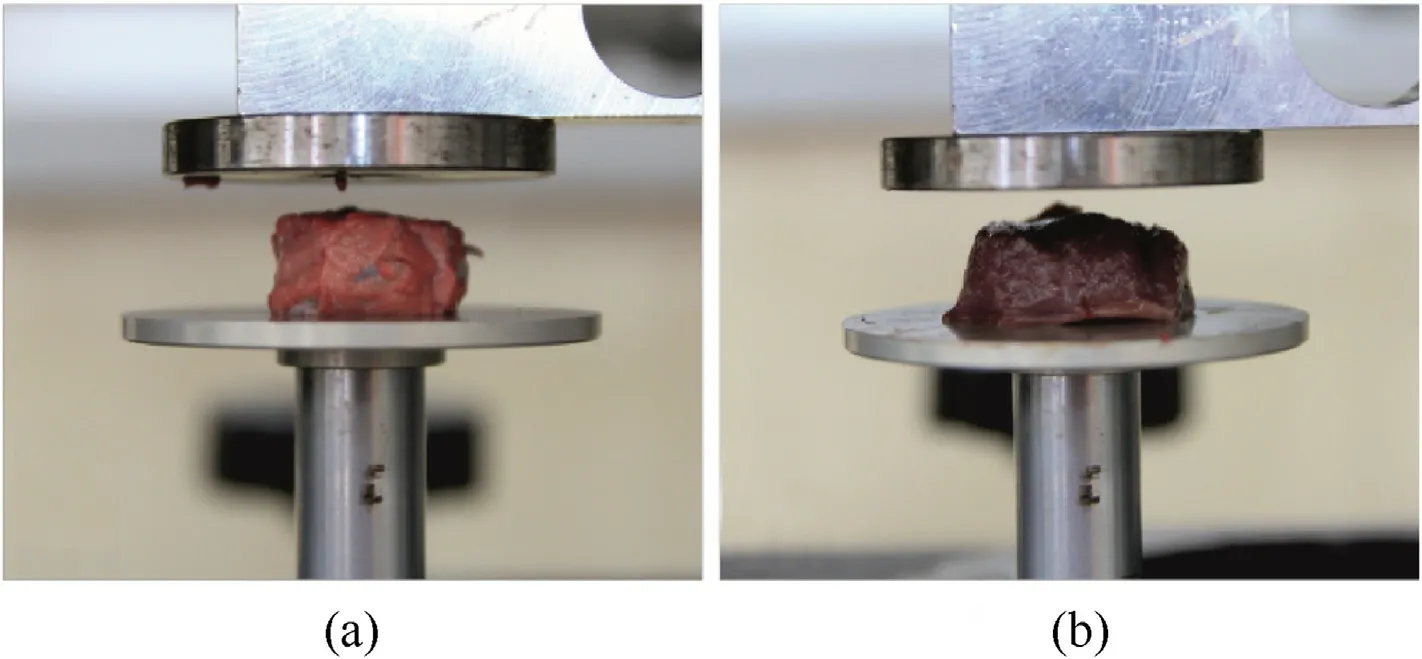

As part of this work, a physical model of the human body was developed, consisting of a model of the heart, lungs, and the skeletal and muscular systems.The lung and heart models were made of Gumosil S silicone (Silikony, Poland), which was obtained by combining polycondensation rubber,N catalyst and methyl silicone oil.In order to select the strength parameters of silicone similar to those of the biological heart and lungs, in the first stage of the uniaxial static compression study of samples prepared from the lung and heart organs from pigs,the characteristics of the stress as a function of material deformation were determined. In order to carry out these studies no pigs were killed specifically to provide organs but they were taken from a commercial slaughterhouse in which the slaugher is carried out for nutritional purposes in accordance with the standards in force in the European Union.Experimental static compression tests were carried out on prepared samples using a Hounsfield H10K-S testing machine(Hounsfield,USA),equipped with a force sensor and a displacement sensor.Ten cylindrical-shaped samples,with a diameter of 20 mm and a height of 10 mm, were taken from the collected animal organs (lungs and hearts). Each of the samples was placed between the movable and stationary plates and, during compression, the force was recorded as a function of the displacement of the movable plate moving at a constant speed of 2 mm/s. Fig. 1 shows the samples of the lung and heart organs placed on the testing machine before the compression process.

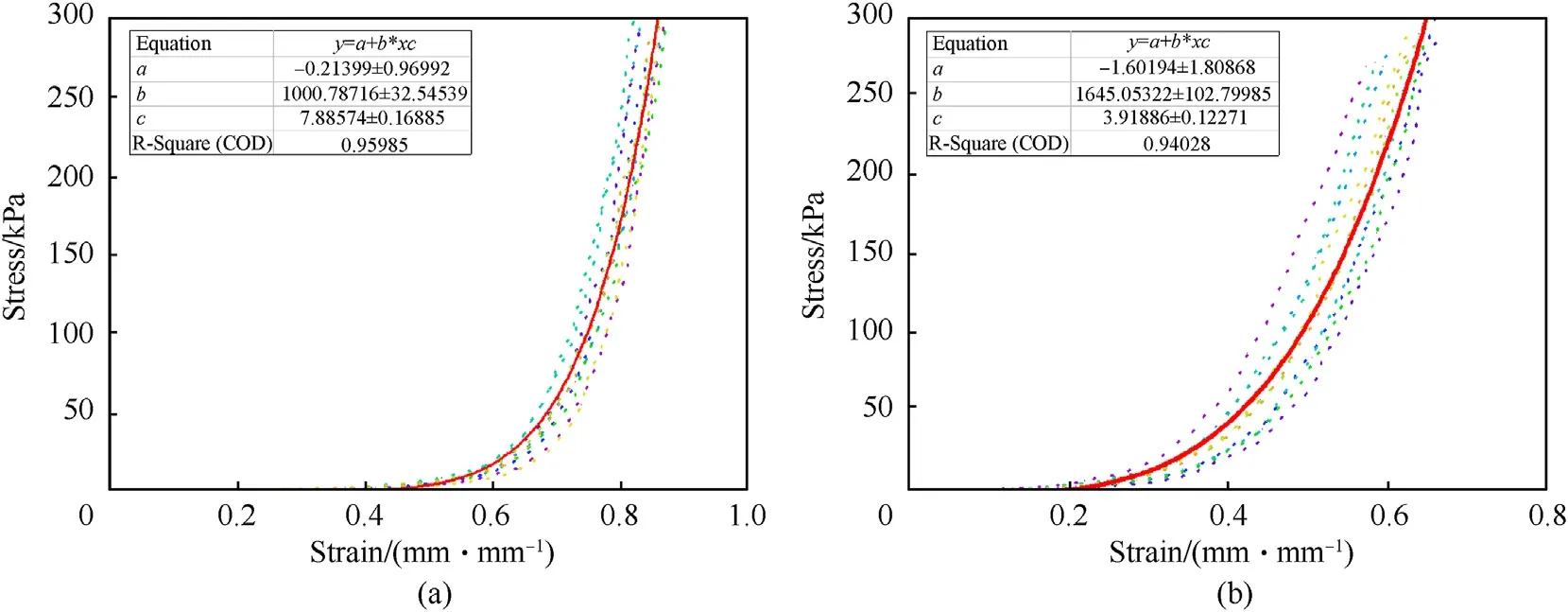

The characteristics of the stress-strain curves (Fig. 2) of the tested samples of the heart and lungs show the features of a nonlinear material. These types of curves are divided into several regions, the characteristics of which may be related to the structure and specific physiological function of the tissue [34,35]. There are three phases of the stress relationship with the soft tissue strain.An initial zone (with low pre-tension) is followed by a zone of practically flat compaction and then an exponential compaction zone.In the initial region,the soft tissue has stiffness,due to its strength.When the stiffness limit is exceeded,the forces associated with the compression of the elastin and collagen fibres in the heart and alveoli in the lungs, begin to act when the tissue is compressed further [34,36].

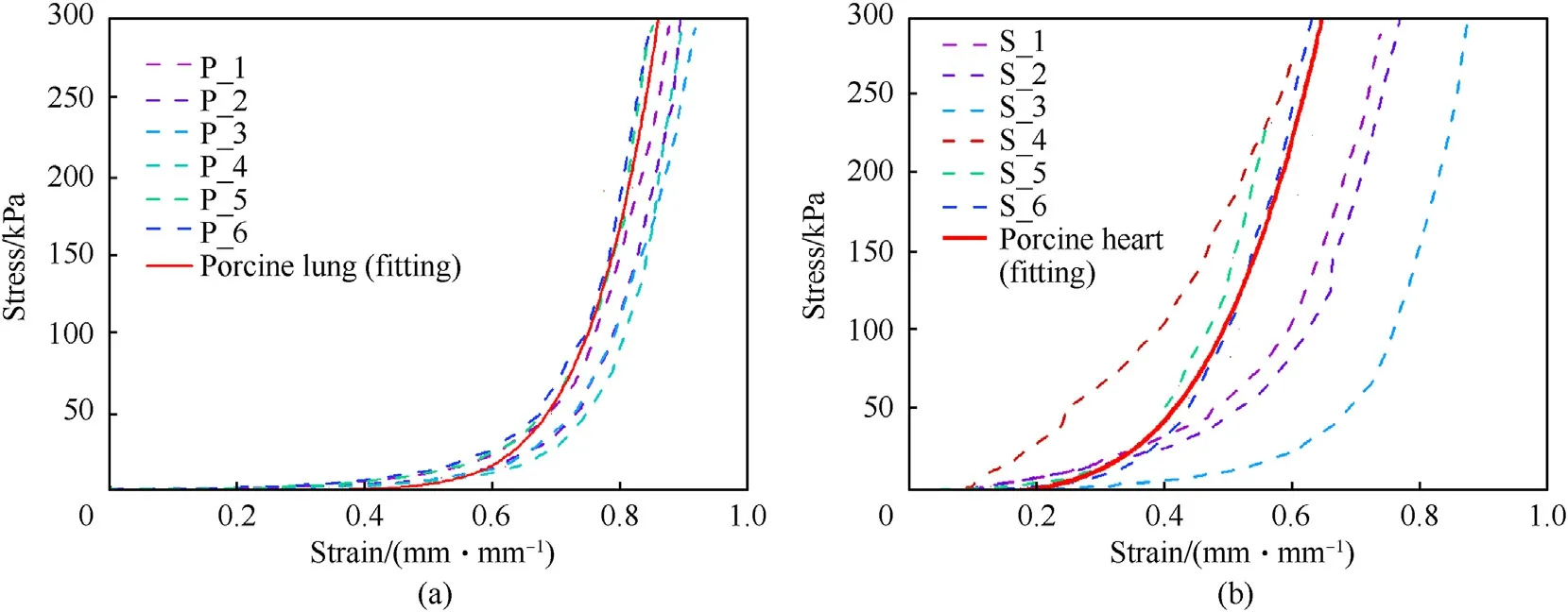

In order to select the materials forming the physical models of the heart and lungs, a series of uniaxial compression tests of samples made of a hardened mixture of polycondensation rubber, N catalyst and methyl silicone oil for various weight proportions were carried out. The obtained stress-elongation characteristics were compared with the approximate stress-elongation functions obtained from the compression of the biological samples.For each of the variants, cylinder-shaped samples, with a diameter of 20 mm and a height of 10 mm, were made. The weight proportions of polycondensation rubber, N catalyst and methyl silicone oil components in the mixture (in the case of lungs for the individual variants P_1 ÷ P_6) were 8.3/1/16.6 (P_1), 8.3/1/20.75 (P_2), 8.3/1/24.9(P_3),8.3/1/12.45(P_4),8.3/2.5/14.53(P_5)and 8.3/3.35/14.53(P_6),respectively.Fig.3 shows examples of the photographs of the sample made in the P_1 variant, from the uniaxial compression tests.

On the basis of the results obtained from the compression testing of silicone samples, the stress-elongation characteristics were determined. Fig. 4 presents a summary of the obtained characteristics for the adopted variants,which were then compared with the approximating curves from the experimental testing of biological samples of the lungs and the heart taken from a pig. It was noted that, by modelling the weight ratio between the components of the silicone mixture, one can obtain stress-elongation characteristics similar to those obtained for biological samples.On this basis, a variant of the mixture of silicone P_5 and S_6 was adopted for making physical models of the lungs and the heart.

Fig.1. Samples of organs from pigs before the compression process: (a) Lung; (b) Heart.

Fig. 2. Compression characteristics and approximation curves for: (a) Lungs; (b) Heart.

Fig. 3. Compression strength test of a silicone sample in variant P_1: (a) Before the compression process; (b) During the compression process.

Fig.4. The results of the compressive strength tests of silicone samples compared with the approximating function obtained from the testing of biological samples for:(a)Lungs;(b)Heart.

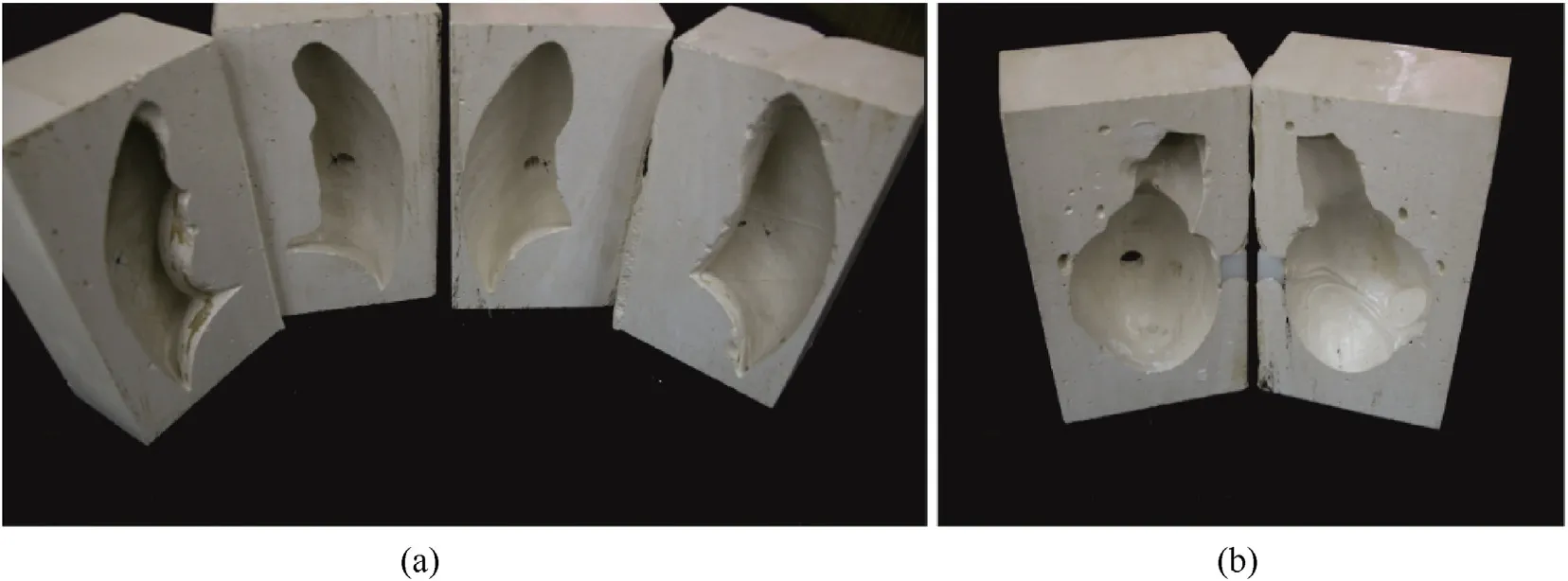

In order to make silicone models of the lungs and the heart,gypsum forms were made first, which were obtained by placing anatomical plastic models of the lungs and heart(with dimensions typical for a male)in a rectangular container,then filling the whole with gypsum.After hardening of the gypsum,the moulds obtained were cut into two parts and the remnants of the anatomical models of the heart and lungs were removed. Fig. 5 shows the gypsum moulds created.

Fig. 5. Gypsum moulds of: (a)The right and left lobe of the lung; (b) The heart.

Fig. 6. The silicone models of the right and left lung with sensors placed on the surface.

The silicone models of the lungs and the heart were made by filling gypsum moulds with a mixture of polycondensation rubber,N catalyst and methyl silicone oil, in the variant P_5 for the lungs and S_6 for the heart. Pressure force sensors CP18-151AS (IEE S.A.,Luxembourg), with a diameter of 12 mm and a measuring range from 0.2 N to 100.0 N, were used to measure the pressure exerted on the lungs and heart as a result of a ballistic strike after a bullet impact. Pressure force sensors were placed in the front part of the right and left lungs before filling the lung moulds with silicone.After both parts of the lung mould were filled with the silicone mixture,they were joined and allowed to cure for 24 h.Fig.6 shows the right and left lung models obtained, with sensors. A similar methodology was used for the production of a silicone heart model,in which pressure sensors were placed on the outer surface and in the centre of the heart. Fig. 7(a) shows a pressure sensor placed inside the heart after filling one part of the plaster with a silicone mixture. Fig. 7(b) shows a front view of the silicone heart model with the pressure sensor placed on the outer surface of the heart.

In the next stage of development of the physical model of the human body,a gypsum form of the human body was made,which had the actual dimensions of a man's chest. For this purpose, a clothing mannequin with the characteristic proportions of typical men aged 25-30 was used. In order to make a plaster mould, a clothing mannequin was placed in a wooden box with the dimensions taking into account the mould allowance, in relation to the external dimensions of the mannequin. In the next step, the whole structure was filled with gypsum and allowed to harden for about 14 days. The cured gypsum mould was then cut into two parts. Fig. 8 shows a view of a clothing mannequin adopted as a model of the human body(Fig.8(a)),a box filled with gypsum,left to harden(Fig. 8(b)), and the gypsum forms obtained after cutting the hardened casting (Fig. 8(c)).

In the next stage, a model of the skeletal system, consisting of the sternum,ribs and spine,was developed.The bridge model was made using a Bungard CCD numerical milling machine (Bungard,Germany) after making a numerical model of the bridge using the software. The shape and dimensions of the sternum were determined on the basis of computed tomography scans of the chest of a 30-year-old man. The bridge model was made of a 10 mm thick porous PVC plate.The front and back of the obtained model of the bridge,with the pressure force sensor attached,is shown in Fig.9(a)to Fig. 9(c).

The next task in the implementation of the skeletal system was the preparation of rib models.Ribs material was selected based on the reports of human rib strength testing. Stein and Granik [37]reported that the relationships between human age ahand flexural strength σflexas well as breaking load P for human ribs during three-point bending of them can be determined by the experimental Eq. (1) and Eq. (2)

where the σflexand P are given in MPa and N, respectively. According to these equations, the value of flexural strength and breaking load for the 30-year-old man ribs can be calculated as 100.1 MPa and 153.8 N, respectively. Yoganandan and Pintar [38]experimentally determined the flexural modulus of human ribs at a level of 2.08 ± 0.45 GPa, while three-point bending the 120 postmortem ribs taken from individuals aged between 29 and 81. The breaking load of ribs from 137 to 162 N was noted, depending on the rib number. Pezowicz and Głowacki [39] under similar test conditions determined the flexural modulus of human ribs in young adults at a level of 4.71 ± 1.67 GPa.While analysing the reported strength parameters of human ribs a similar performance of the poly(methyl methacrylate) PMMA was found out. Al-Dwairi et al. [40] reported the flexural modulus and strength of conventional heat-cured PMMA equal to 2.1172 GPa and 93.33 MPa,respectively. Kurguzov and Demeshkin [41] reported the flexural strength of PMMA at a level of 102.827 MPa during three-point bending. Di Carlo et al. [42] reported the flexural modulus and strength of conventional PMMA of 2.88 GPa and 96.32 MPa,respectively.It can be compared that the values of flexural modulus and strength for human ribs are similar to the reported values for conventional PMMA. On the base of this comparison, the conventional PMMA was selected as ribs material in developed human model.To fabricate the physical model of ribs a 4 mm thick PMMA plexiglass plate was purchased from Akces Co.(Poland).In order to determine the strength parameters of this plexiglass plate,6 bars of size of 4×20×160 mm3were cut and subjected to a three-point bending test on an Instron 3366 testing machine with a span length of 100 mm. It was determined that the flexural modulus and strength for this PMMA plexiglass were 2.7 ± 0.23 GPa and 98.0±8.2 MPa,respectively.Assuming the value of breaking load P calculated from Eq. (2) for the 30-year-old man ribs equal to 153.8 N, finally the width b of PMMA plexiglass bars, which modelled the ribs in a physical model of the human body was calculated from Eq. (3)

Fig.8. Photos from the stages of developing a physical model of the human body:(a)Stage one-a view of the adopted clothing mannequin;(b)Stage two-a gypsum block with a clothing mannequin; (c) Stage three - gypsum forms of the front and back of the body after cutting.

where L is the span length,σPMMAis the flexural strength of PMMA plexiglass and a is the thickness of PMMA plexiglass plate. For the span length,flexural strength and thickness of PMMA plexiglass of 100 mm, 98.0 MPa and 4 mm, respectively, the width of bars of 14.7 mm was calculated.In order to reproduce the shape of the rib,each flat bar was plasticised by annealing at a temperature of 90-100°C for approximately 10 min and then formed to the assumed rib curvature. The rib pairs were attached to a sternum and spine, constructed from an aluminium profile with a crosssection of 4 × 4 cm2and screws(Fig. 9(a) and Fig. 9(b)).

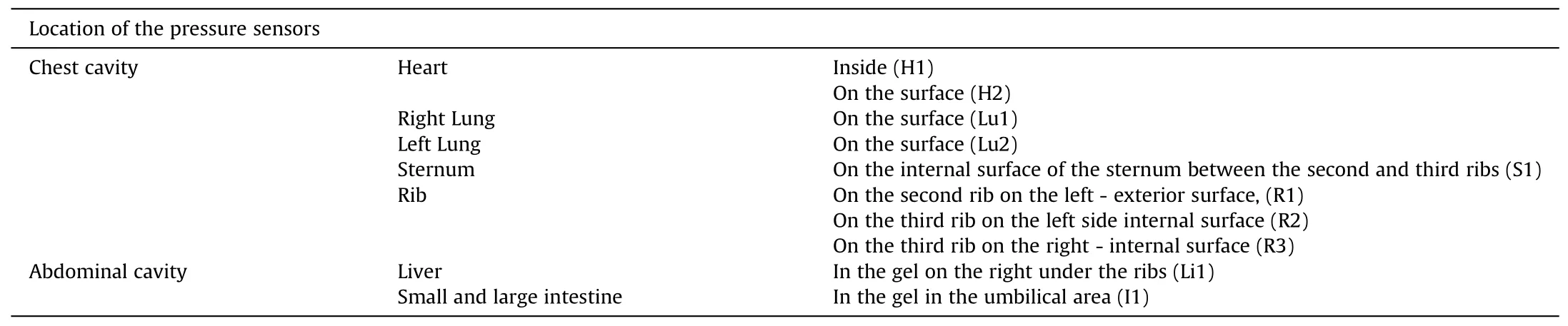

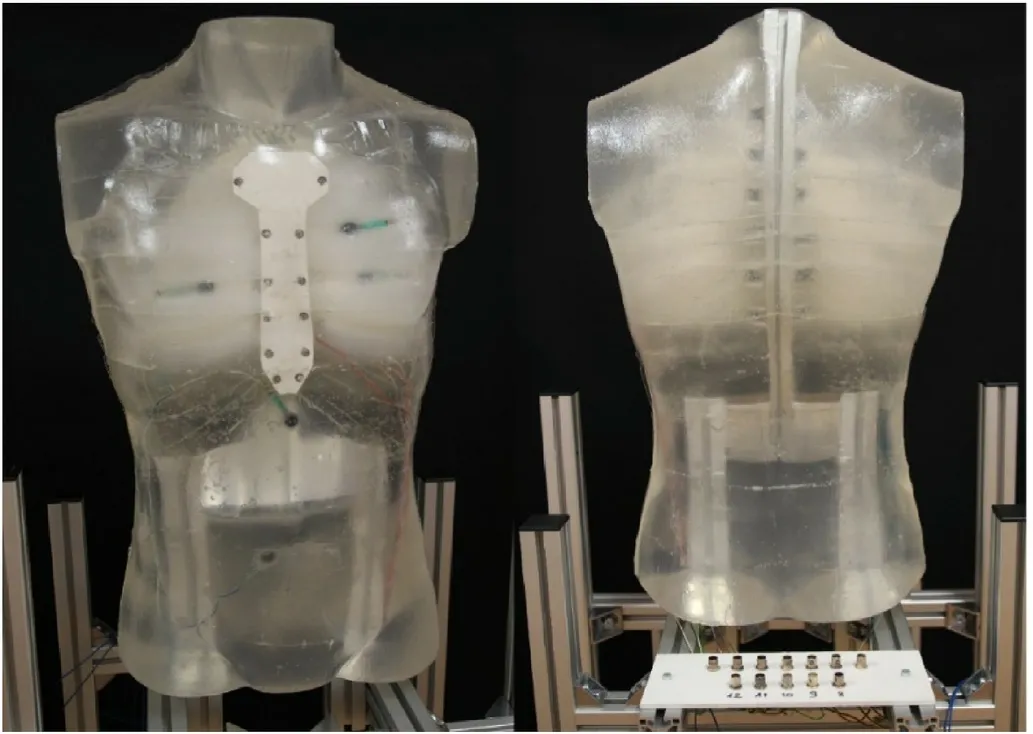

The developed models of the lungs,heart and skeletal system,as well as the pressure force sensors located in accordance with Table 2,were placed in plaster moulds of the human body model.In the next step, 20% Synthetic Ballistic Gelatin (Clear Ballistics, USA)was melted at a temperature of 126°C and filled into gypsum moulds of the human body.The whole was left to fully harden the ballistic gel for 48 h and then the finished model was removed from the gypsum mould.For the ballistic tests,two identical human body models were made(one for the biaxial fabric packet and the other for the triaxial fabric packet).Fig.10 shows the front and back views of the model of the human body.

Table 2 Location of pressure sensors in the human body model.

The physical model of the human body in the ballistic studies did not include the liver model or the small and large intestine model.The pressure force sensors were embedded in ballistic gel in the anatomical location of the centre of the liver, at a depth of 22-24 mm and, in the case of the small and large intestines, at a depth of 18-19 mm.

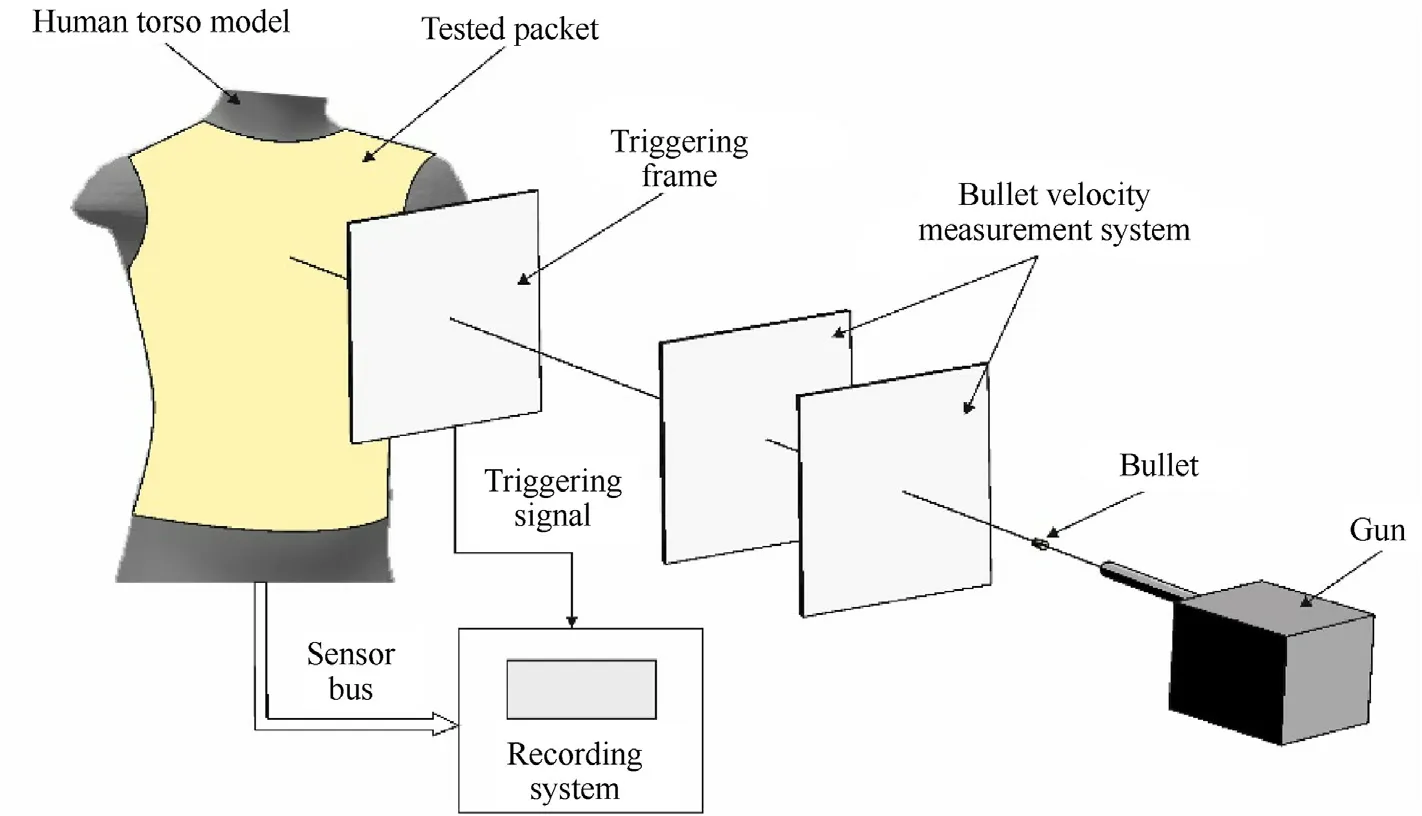

Experimental research was carried out in a ballistics laboratory.The diagram of the ballistic stand is shown in Fig.11.The stand was equipped with a ballistic test barrel to launch bullets, a system of gates for measuring the velocity of impact, a frame generating a signal for triggering the signal registration system from the sensors and a human body model with ballistic packages. In the experimental research,Winchester 9×19 mm FMJ Parabellum bullet was used,with a lead core and a shell made of ballistic brass.The weight of the bullet was 8 g. The signal recording system comprised Textronics digital multi-channel oscilloscopes.

Fig.11. Diagram of the ballistic stand.

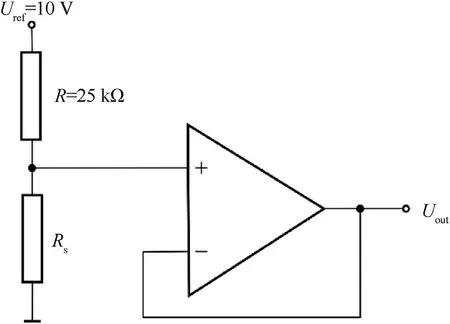

Each pressure force sensor was connected to the measuring system and contained a voltage divider and a voltage follower(Fig.12). The measured output voltage was equal to

Prior to the placement of the sensors in the human body model,they were calibrated by placing each sensor between the 12 mm diameter pneumatic actuator stem and the force measuring head.During the calibration,the air pressure values were adjusted so that the pressure force was at a set level, and then the output voltage Uoutwas measured.

The experiments were carried out for each of the pressure force sensors used in the human body model.The calibration process was carried out three times for each of the sensors and, based on the recorded values, the equation of the calibration curve was determined

Fig.10. Front and back view of the human body model with the heart, lungs, skeletal and muscular systems and pressure sensors.

where

F - given force,

Uout- measured voltage in the measuring system,

F0, A1, A2, Uout0, t1, t2- parameters of the approximating function.

An exemplary graph of the dependence of the pressure force as a function of voltage is shown in Fig.13.

The calibration of the sensors allowed further experimental research to calculate the pressure force, based on the recorded voltage values. Knowing the values of the pressure force and the sensor surface, the pressure exerted at the sensor location was calculated from the quotient of these values.

4. Ballistic packages for experimental research

Before starting the experimental research in the ballistic tunnel,packages consisting of 30 layers were prepared from the tested ballistic fabrics. For this purpose, a design for the front of the armour was constructed based on the dimensions of the human body model.The layers were then cut from the ballistic fabrics and joined with a double lock-stitch, using 100% Twaron NM 50/2 aramid threads.Several point stitches,at a distance of approximately 1 cm from the edge of the packages, were carried out with a stitching length of about 5 cm.Fig.14 shows a view of two identical modelsof the human body, with applied ballistic packages made from biaxial and triaxial fabrics, before firing.

Fig. 12. Diagram of the connection of a pressure force sensor with the measuring system.

Fig.14. View of human body models before the firing with applied ballistic packages made of fabrics: (a) Biaxial, (b) Triaxial.

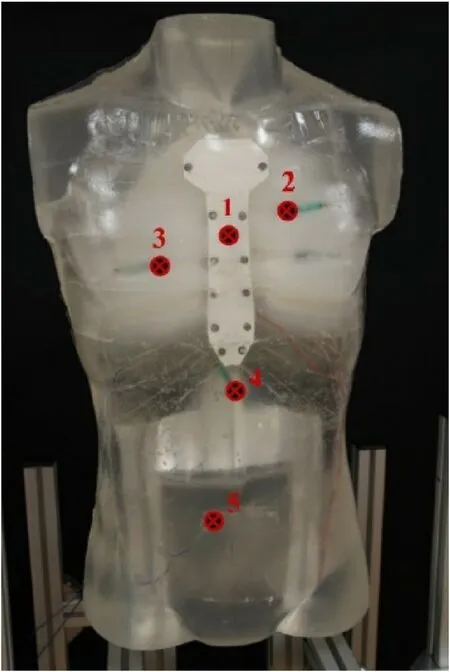

At a later stage, the sensors recording the pressure forces were connected to multichannel digital oscilloscopes and each of the ballistic packages received five hits from Winchester 9 mm × 19 mm FMJ Parabellum bullets,in accordance with the selected firing points (Fig. 15). These were considered critical, from the point of view of maintaining a functioning person's life. Firing point 1 corresponds to the bullet where the sternum is located,behind which is the heart and large blood vessels.Firing point 2 is the site of one of the ribs, behind which is the pleural cavity with a lung. Firing point 3 was located in the projection of one of the intercostal spaces, under which there is also the pleural cavity with a lung.Firing point 4 is projected onto the medial epigastric region,beneath which the liver is located,and firing point 5 corresponds to the medial epigastric projection of the intestines.The listed organs are important from the point of view of maintaining vital functions and their damage, directly or indirectly, may be life-threatening.

Fig. 15. Selected places of bullet impact on the physical model of the human body,where:1-sternum in line with the heart position,2-rib II,3-intercostal space in line with the lungs, 4 - liver, 5 - small and large intestine.

5. Results of experimental research depending on the location of the bullet impact

5.1. Bullet hitting the sternum on the heart position line

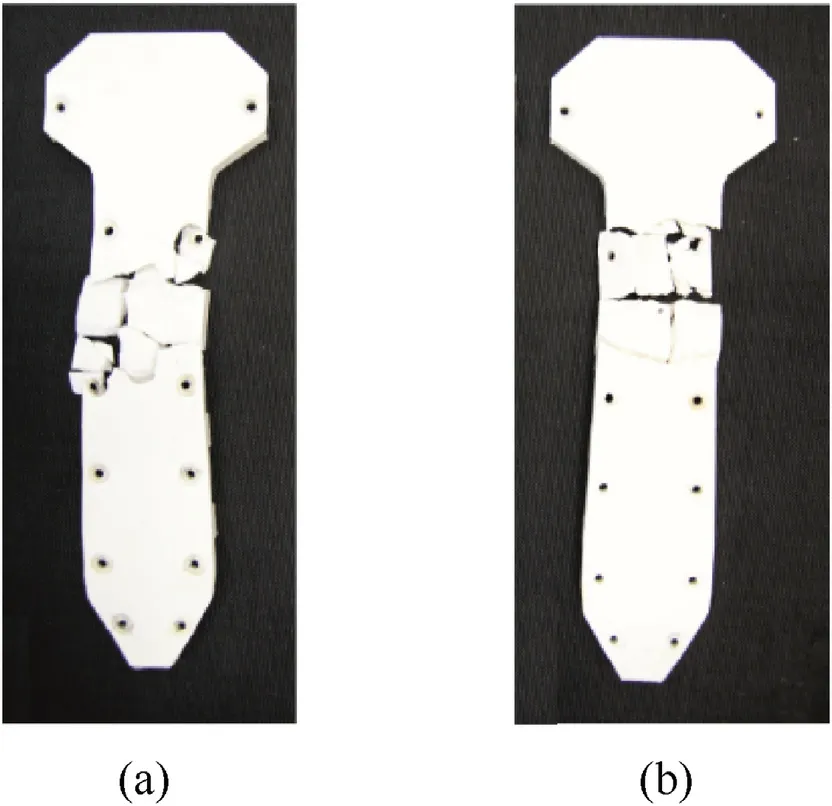

In the case of the bullet hitting the sternum in line with the heart position,fractures in the sternum model(Fig.16)were noted for both ballistic packages, made of biaxial and triaxial fabrics.

Fig.16. Damage to the sternum model after experimental research with the use of a packet made of fabrics: (a) Biaxial; (b) Triaxial.

During examination of the external injuries of the physical model of the human body, localised microdamage of the ballistic gel was observed.The sternum model suffered the greatest internal injuries, as it suffered numerous cracks in the ballistic packages made of biaxial and triaxial fabrics. It should be noted that the number of cracks and the area of damage were greater in the sternum model protected by packets made of biaxial fabrics. The medical analysis of the situation showed that the breakdown of the anatomical continuity of the sternum may damage the internal structure of the chest(e.g.lungs,heart)covered by the sternum.It should be noted that bone fractures may be multi-fragmentary and the damaged bone fragments may constitute the so-called 'secondary bullet', which can expand the area of damage.

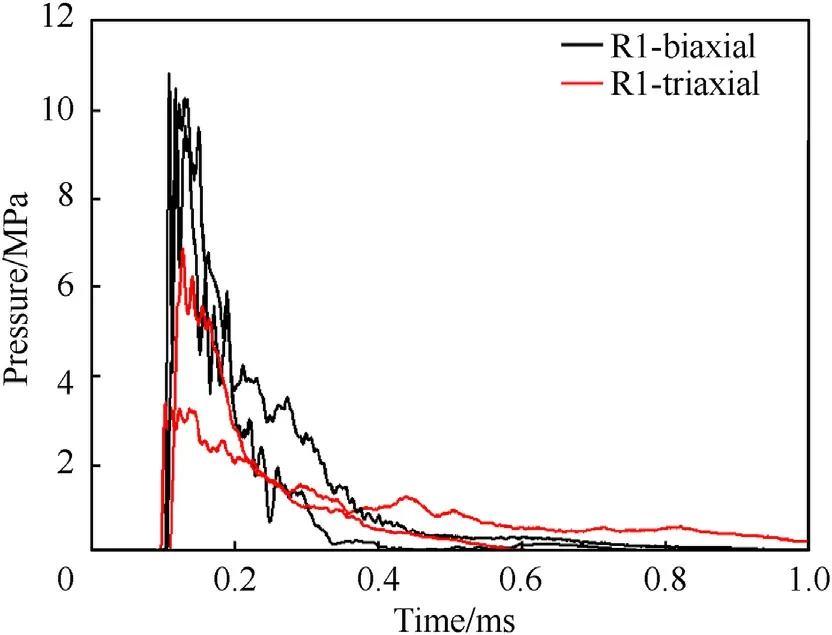

In the next stage, the results of the pressure values on the internal surface of the sternum, after the bullet hit the line of the heart position, were analysed (Fig.17). The tendency of the occurrence of higher pressure values in the sternum when protecting the human body model with ballistic packages made of biaxial fabrics,rather than triaxial fabrics, was noted. The maximum pressure for protection with a ballistic package made of biaxial fabrics was 12 MPa while,for protection with a package of triaxial fabrics,it was 7 MPa.It can be concluded that,as a result of the bullet hitting the packages made of biaxial fabrics,the pressure is more localised and covers a smaller body surface, which results in greater pressure at the point of impact.On the other hand,for the second variant,the acting pressure force of the packages made of triaxial fabric is distributed over a larger surface, resulting in a lower value of maximum pressure at the point of impact [29,32]. On the basis of the pressure course, it can be concluded that the characteristic decrease and then increase of the pressure value is a result of the rupture of the sternum model.Injury to the anterior chest wall from a non-penetrating impact can further injure internal organs. The recorded pressure values in the internal organs,in the case of body protection with packages made of both biaxial and triaxial fabrics,are shown in Fig.18.

Fig.17. The pressure course for the S1 sensor during the bullet impact on the centre line of the sternum, with body protection by ballistic packages made of biaxial and triaxial fabrics.

Fig.18. Pressure course for sensors H1,H2,Lu1,Lu2,R2,R3 and R4 during the bullet hitting the sternum with body protection with ballistic packages made of fabrics:(a)Biaxial;(b)Triaxial.

The protection pressure with packages made of biaxial fabrics reaches a higher value for the H1 and H2 sensors: 0.05 MPa and 0.7 MPa, respectively. While, for packages made of triaxial fabrics,the pressure values were lower,i.e. 0.04 MPa and 0.32 MPa.In the published studies,using the same type of bullet[32,33],the highest pressure value recorded on the heart’s surface was 0.85 MPa. On the basis of medical descriptions[27],pressure values in the range of 0.5 MPa-1.0 MPa in the heart muscle, cause injuries such as:haemorrhages of the anterior and posterior walls of the heart and,in extreme cases,rupture of the pericardial sac. The impact on the lower pressure amplitudes for the H1 and H2 sensors, when protected with packages made of triaxial fabrics, may result from the transmission of the stress wave through the three main thread systems in contact with the face of the bullet.When a bullet hits a package made of triaxial fabrics,the shock wave propagates radially along all the systems, causing the area of the fabric absorbing the kinetic energy of the bullet to be larger than for a package made of biaxial fabrics.The increase in the area covered by the deformation depends on the speed of propagation of the stress wave in the plane of the triaxial fabric.BABT injury in the human body during a firing on the sternum in line with the heart position,may lead to bruising of the integuments (abrasion of the epidermis, bruising and swelling), bruising of the subcutaneous tissue and muscles(ecchymosis and swelling) or haematomas within them (fluid reservoirs filled with blood). It should be noted that the fractures in the sternum are not dangerous in themselves but their complications,such as the possibility of pneumothorax or haematoma of the pleural cavity,are much more dangerous.In such cases,one would expect bruising of the lungs.It can also bruise the heart,which can result in heart rhythm disturbances and, possibly, fatal consequences.

The pressure values for Lu1 and Lu2 sensors were also lower when protected with packages made of triaxial fabric. The maximum pressure value of the Lu1 sensor was 0.06 MPa and, for the Lu2 sensor, it was 0.13 MPa, while for the packages made of biaxial fabrics it was 0.1 MPa and 0.18 MPa, respectively. The recorded pressure courses of the Lu1 and Lu2 sensors cover a similar time period. Higher pressure values for the Lu1 and Lu2 sensors,when protected with packages of biaxial fabrics,depend on the structure. Rapidly changing local displacement of the threads towards the bullet's flight path causes the formation of a stress wave, which propagates along the threads of the weft and warp,symmetrically in all four directions.Higher pressure values for the ballistic packets made of biaxial fabrics result from the nature of the local deformation of the shield and the impact of pressure on the human body model in a point-like manner.

The other three sensors (R1, R2 and R3) also registered lower pressure values while protecting the packages made of triaxial fabrics. The courses of the pressure curve for sensor R1, in both of the tested ballistic packages, shows significant increases and dynamic decreases in the pressure value.It is claimed that the impact of the bullet causes a dynamic deformation of the packet, which translates into the BABT strike, leading to the phenomenon of deflection and relaxation of the chest. As a result, the recorded pressure curves of sensor R1 record high, instantaneous pressure peaks and then a rapid drop.For the pressure curves of sensors R2 and R3,the amplitudes are smaller than for the pressure curves of sensor R1.This may be due to the location of these sensors,which were located below the line of fire and on the inside of the ribs.

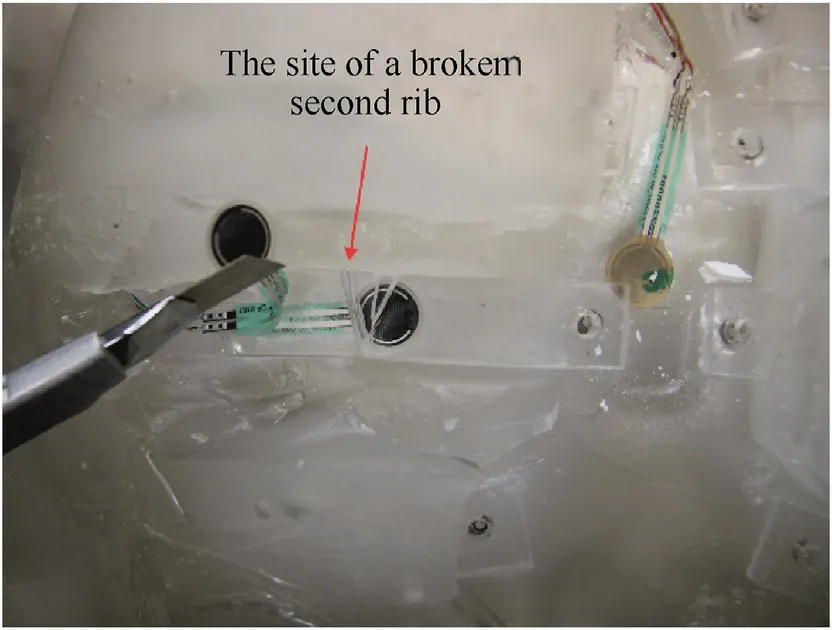

5.2. Bullet impact on rib II

In the next stage, the blunt BABT trauma was analysed in the human body model during a non-penetrating bullet impact in the line of the second rib on the left hand side.It should be noted that after the first shot at the sternum on the line of the heart position,both the sternum model and the S1 sensor were destroyed.Therefore, it can be assumed that reducing the stability of the connection of the rib models with the sternum model could increase the injuries in the area of the II rib and thus the obtained pressure values recorded by sensors located in the place of the bullet impact. In the first stage, the human body model was examined at the point of bullet impact. For the packages made of biaxial fabrics,it was found that the rib model cracked at the site of the bullet impact, which was not found after hitting the packages made of triaxial fabrics.Fig.19 shows a photograph of the location of the broken rib model.A fracture in the first three ribs can lead to a BABT injury and contribute to an injury to the respiratory tract.In contrast, fragments of a broken rib can stick into the structure of the lung parenchyma,leading to internal haemorrhaging.Research has shown that this type of injury can be reduced by using soft ballistic packages made of triaxial fabrics.

Fig. 19. The site of a broken second rib with the use of a ballistic package made of biaxial fabrics.

Fig. 20. Pressure course for the R1 sensor during the impact of a bullet against rib II while protecting the body with ballistic packages made of biaxial and triaxial fabrics.

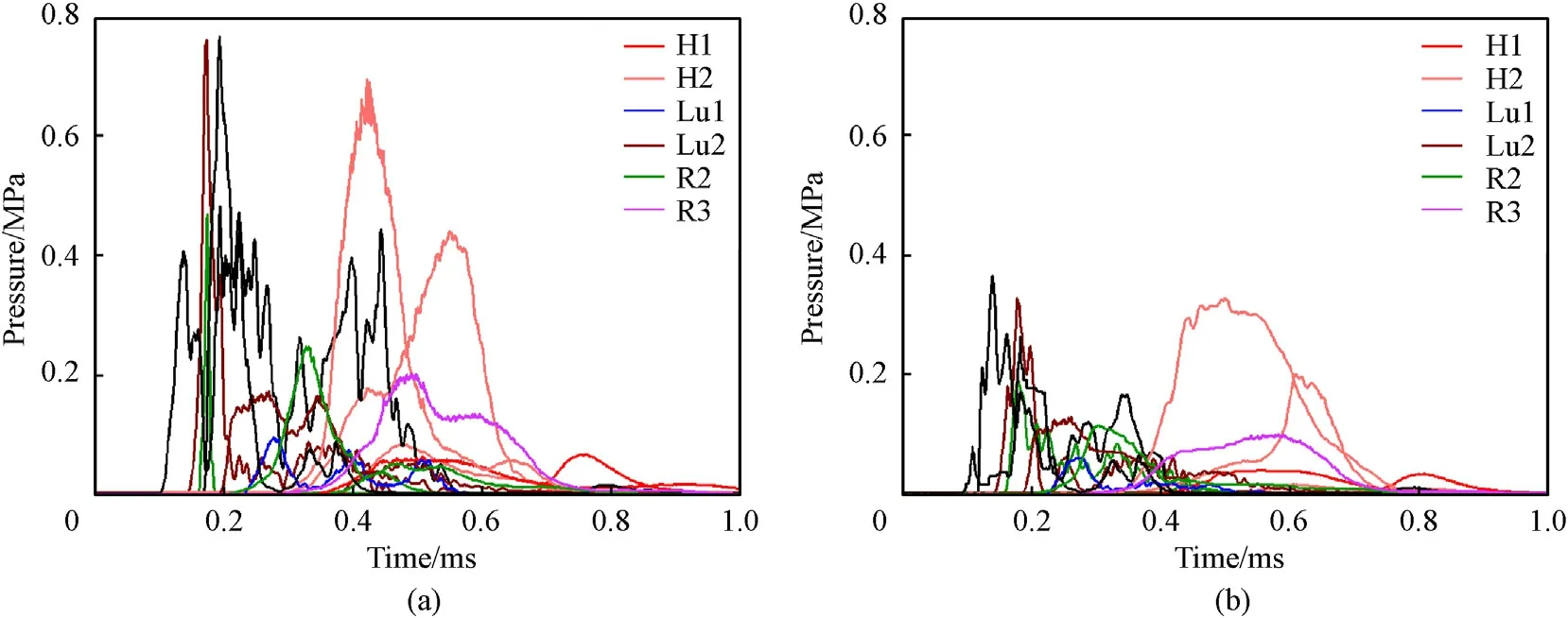

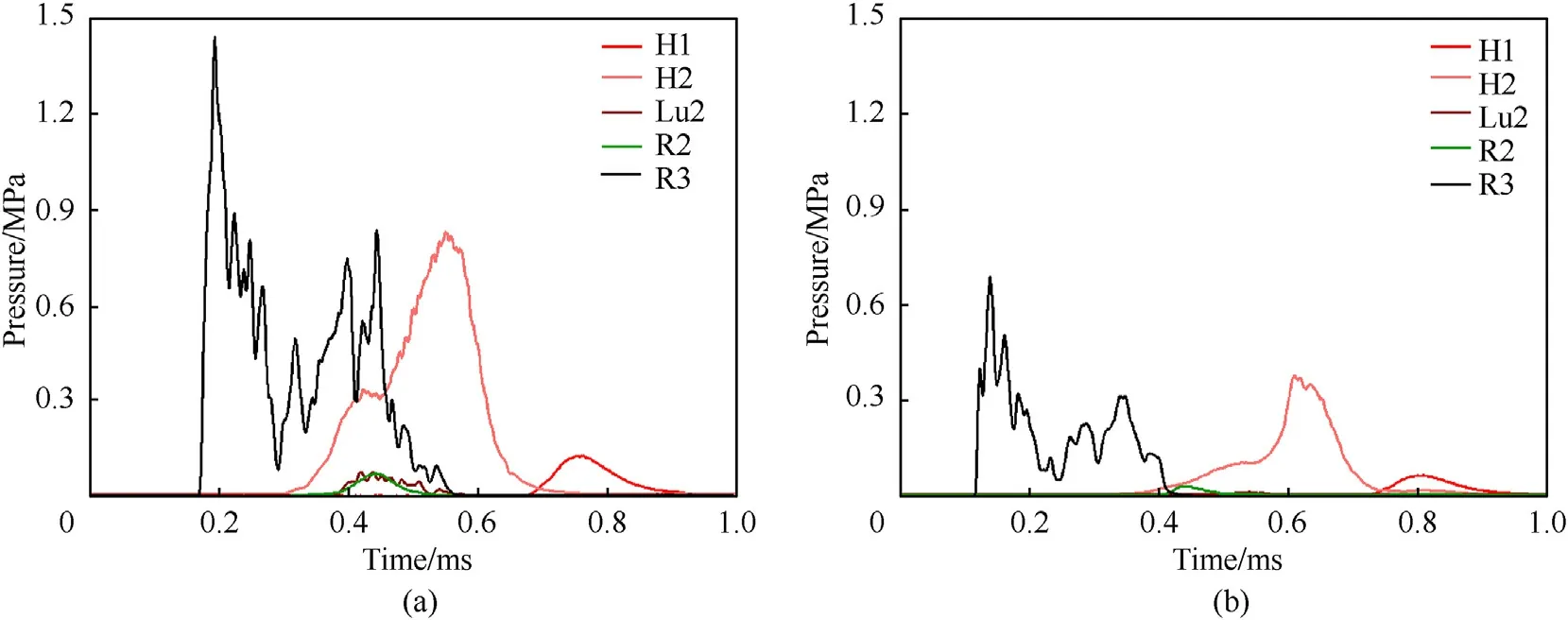

BABT injuries in bone are different from injuries in the areas of muscle tissue.This is mainly due to the greater stiffness and lower flexibility of the bones. The characteristics presented in Fig. 20 confirm that, when using the ballistic packet made of biaxial fabrics, the recorded pressure from the R1 sensor reaches higher values than for the packet made of triaxial fabrics. The maximum value of the sensor pressure R1 for packages made of biaxial fabric was 11 MPa while, for protection with packages made of triaxial fabric, it was equal to 3 MPa. It should be noted that the timing of the BABT impact by the registered pressure of the R1 sensor, was shorter for the packages made of biaxial fabrics and amounted to approximately 0.3 ms;for the packages made of triaxial fabrics,the pressure was gradually released in the time close to 1 ms. This tendency may depend on the geometric structure of the fabrics tested.During the impact of the bullet against the packages made of biaxial fabrics,the area of propagation of the stress wave is smaller,resulting from the two main systems of threads. The pressure depends on the surface and the force acting on it. In the case of packages made of triaxial fabrics,which have three main systems of threads in its structure,the surface of the propagating stress wave is increased and, consequently the decay time is extended.

Fig.21 shows the pressure courses recorded by the other sensors(H1,H2,Lu1,Lu2,R2,and R3),which were located in the chest of the human body model. The graphs do not show the waveforms from the sensor located in the bridge (S1) because it was damaged during the first attempt, when the bullet hit the bridge. Additionally sensor Li1 and the sensorI1 did not register any values during this bullet shot.Therefore,it can be assumed that the human body model did not experience BABT injuries in the area of the intestine and liver.For the H1 and H2 sensors placed in the heart model,the pressure values are also lower when protected with ballistic packages made of triaxial fabrics. The pressure of the H1 sensor is close to zero and the pressure of the H2 sensor is less than 0.1 MPa.In the case of the ballistic packages made of biaxial fabrics, the pressure was about 0.1 MPa and 0.45 MPa,respectively.It should be noted that,despite the differences in the pressure values of the H1 and H2 sensors,the shape of the pressure curve is similar.It is also worth noting that,for the H2 sensor,when protected with packages made of triaxial fabrics, there is a pressure time delay of 0.1 ms,compared to packages made of biaxial fabrics.This is probably due to the geometric structure of the triaxial fabric, which provides a transmission delay and a reduction in the maximum pressure amplitude on the human body model.

The graphs in Fig.21 also show the pressure courses of the Lu1 and Lu2 sensors. In the case of the right lung (Lu1), the pressure value was close to zero for both tested soft ballistic packages.On the other hand,for Lu2,when protected with a bundle of biaxial fabrics,the pressure value was about 3.8 MPa and,when protected with a bundle of triaxial fabrics, it was 1.65 MPa. Again, this result confirms the advantage of triaxial fabrics over biaxial fabrics. The additional system of threads allows an increase in the speed of wave propagation, which should be as high as possible, from the point of view of the ballistic effectiveness of fabrics.

For the R3 sensor,the pressure value for both of the tested soft packets was close to zero. The pressure was registered by the R2 sensor located on the left hand side of the chest,in the area where the second shot was fired. The pressure value of the R2 sensor,when protected with packages made of biaxial fabrics, was about 2.3 MPa and, for packages made of triaxial fabrics, it was about 1 MPa. The tendency to achieve twice the pressure values when protected with packages made of biaxial fabrics, compared to packages made of triaxial fabrics, was confirmed once more. It should be noted that the time of action of the blunt BABT trauma exerted by the third left-hand rib(R2)is longer when protected by packages made of triaxial fabrics.On the other hand,with packages made of biaxial fabrics,the pressure in the R2 sensor is temporary but its amplitude is twice as high as that for packages made of triaxial fabrics. In both cases of protection with human body bundles,BABT can lead to banded effusions along the ribs and cause rib fractures but there are also potential complications, such as pneumothorax or pleural haematoma, as well as lung rupture.

Fig.21. The pressure course for sensors placed in the chest during the impact of the bullet against rib II while protecting the body with ballistic packages made of fabrics:(a)Biaxial;(b) Triaxial.

5.3. Bullet impact in the intercostal space on the lung position line

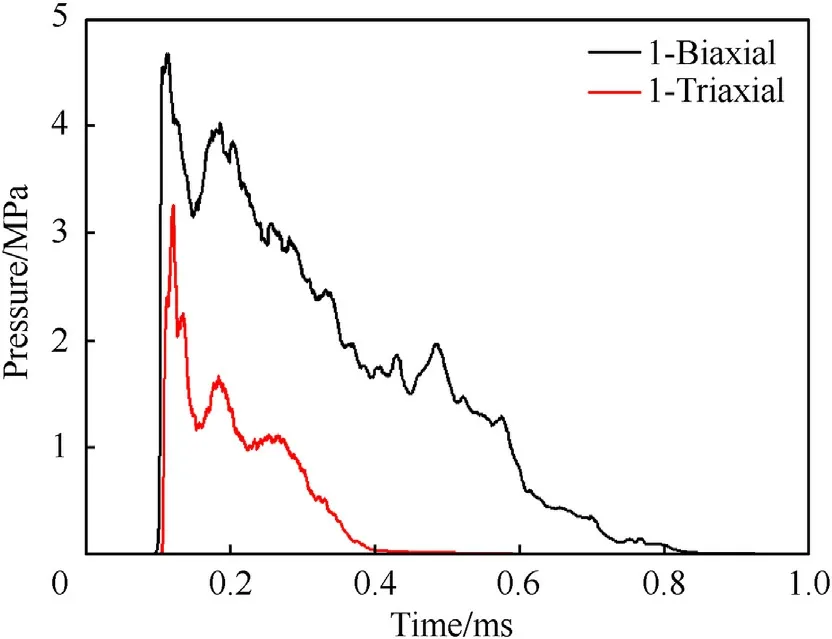

The main type of lung lesions resulting from a non-penetrating bullet impact and deformation of the ballistic shield are local parenchymal deformities that cause banded haemorrhages along the ribs.The mechanism for the formation of banded haemorrhages on the surface of the lungs and their potential injuries depends on the scale of the displacement of the skeletal system into the structure of the lung parenchyma [29]. The destruction of the sternum model and the sensor S1 during the first impact of the bullet could reduce the stability of the connection of the rib models with the sternum model.Therefore,it could increase the injuries in the intercostal area and thus obtain higher pressure values recorded by sensors located near the point of bullet impact.Fig.22 shows the pressure courses for the Lu1 sensor with protection from packages made of biaxial and triaxial fabrics.It should be noted that the influence of the tested ballistic structures on the maximum pressure amplitude was visible.For the right lung(Lu1),the sensor registered twice the pressure value when protected with packages made of biaxial fabrics (4 MPa) and for packages made of triaxial fabrics, it was 2.1 MPa. It is confirmed that the use of multi-axis fabrics for soft ballistic shields has the advantage of significantly reducing the maximum pressure amplitude at the point of bullet impact.By analysing the pressure curves of the Lu1 sensor,it can be concluded that the nature of the shape and time of the pressure curves is similar for both tested fabrics. In the final phase (from t = 0.3 ms to t = 0.4 ms) of the impact of the BABT injury, when protected with packages made of biaxial fabrics,a pressure increase close to 2 MPa was noted.The probable reason for this may be the stress and deformation waves of the soft ballistic packages, which are generated during the dynamic interaction with the bullet.

Fig. 23 shows the pressure courses recorded by the sensors H1,H2, Lu2, R2 and R3. The graphs do not show the waveforms from the sensor located in the bridge (S1) because it was damaged during the first attempt, when the bullet hit the bridge. Additionally sensor Li1 and the sensorI1 did not register any values during this bullet shot.Therefore,it can be assumed that the human body model did not experience BABT injuries in the area of the intestine and liver. Also, for the R1 sensor, no significant changes in the pressure course were recorded. The pressure value for the H1 sensor was 0.14 MPa and for H2 it was 0.8 MPa, when protected with packages made of biaxial fabrics.For the second tested fabric,the values were lower and amounted to 0.05 MPa and 0.38 MPa,respectively. The nature of the pressure curves for the H1 and H2 sensors for the tested ballistic fabrics,is similar.It should be noted that there is a slight delay in the timeline, when protected with packages made of triaxial fabrics. This is due to the geometric structure of the triaxial fabric, which allows the kinetic energy of the bullet to be distributed over a larger area than for a biaxial fabric. As a result, the shock wave action is delayed and the maximum pressure amplitude affecting the human body model is reduced.

Fig. 22. Pressure course for the Lu1 sensor during the impact of the bullet in the intercostal space while protecting the body with a ballistic package made of biaxial and triaxial fabrics.

It should be noted that there was little pressure in the left hand lobe of the lung (Lu2). A significantly low pressure value from the Lu2 sensor was recorded, when protected with packages made of triaxial fabrics while, during protection with packages made of biaxial fabrics, it was about 0.07 MPa. Also, the sensor located on the third rib on the left hand side (R2) registered small pressure amplitudes.In the case of protection with packages made of triaxial fabrics, the pressure value was only 0.02 MPa and, in the case of protection with packages made of biaxial fabrics,the pressure was about 0.07 MPa. It can be concluded that the stress waves and deformations during the firing in the intercostal space along the lung position is accumulated mainly on the right side of the chest,i.e.in accordance with the place where the bullet was fired.It is in this part of the chest that the greatest pressure amplitudes recorded by the R3 sensor appear. During protection with packages made of biaxial fabrics, the maximum pressure value of the R3 sensor was about 1.5 MPa.On the other hand,when protected with packages made of triaxial fabrics, the pressure value of the R3 sensor was twice as low and amounted to 0.7 MPa. This confirms the influence of the geometric structure of the multi-axial fabric over the biaxial fabric.A significant advantage of the triaxial fabric is having three systems of threads, which allow it to absorb a significant part of a bullet’s impact energy and spread it over the largest possible area, thus reducing the deflection of the ballistic packages. This, in turn, leads to lower pressure amplitude at the point of impact of the bullet and, possibly, less physiological complications in the body. Medically, a BABT injury can cause pneumothorax or haematoma, and bruise or rupture the lungs.

5.4. Bullet impact along the line of the liver

The abdominal wall is made of skin, subcutaneous tissue and muscles that easily transfer energy and deformation to the internal organs. The literature shows that the liver is an organ which is susceptible to injuries,mainly due to its size and its location in the abdominal cavity,as well as its structure(parenchymal organ).The human body model did not have a liver model but in ballistic research,the pressure on liver surface was measured by the sensor Li1 located inside of gel in place where there is centre point on liver surface. The pressure courses resulting from the impact of the bullet in line with the liver position, depending on the tested ballistic fabric, are presented in Fig. 24.

Fig.24. Pressure course for the Li1 sensor during the impact of the bullet on the line of the liver with body protection from ballistic packages made of biaxial and triaxial fabrics.

According to Fig. 24, the pressure value for the Li1 sensor is,again,lower when protected with packages made of triaxial fabrics and amounts to approximately 0.7 MPa. However, for the second tested fabric, the value is equal to 1 MPa. The dynamics of the pressure increase of the Li1 sensor is similar for both of the tested ballistic fabrics. After reaching the maximum values, the curves gently descend. The structure of the biaxial fabric, which leads to propagation of the shock wave in only two directions,may have an influence on the maximum amplitude and the momentary pressure increases and drops.As a result,the area covered by deformation is smaller and the accumulated energy of the deformation and destruction of the textile barrier may cause the packages to undulate, leading to momentary pressure increases and drops in the Li1 sensor curve.

Fig.23. Pressure course for sensors placed in the chest during the impact of the bullet in the intercostal space on the line of the right lung while protecting the body with a ballistic package made of fabrics: (a) Biaxial; (b) Triaxial.

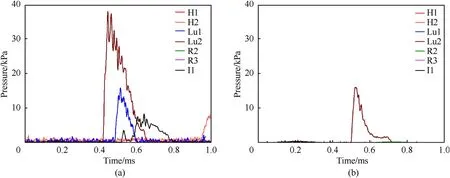

The graphs in Fig. 25 do not show the waveforms from the sensor located in the bridge (S1) because it was damaged during the first attempt, when the bullet hit the sternum. Also, for the sensors H1, R1, R2 and R3, no significant changes in the course of the pressure were recorded.In the case of protection with ballistic packages made of biaxial fabric, after 0.9 ms the pressure was recorded for the H2 sensor,which was about 10 kPa.The apparent time delay may indicate blunt BABT trauma in the area of the heart surface, caused by the shockwave following a non-penetrating bullet impact. It should be noted that no significant changes were recorded in the pressure course of the H2 sensor, when protected with packages made of triaxial fabrics.It is,therefore,assumed that the geometric structure of the triaxial fabric led to minimisation of the BABT trauma to the heart surface.

Fig. 25. Pressure course for sensors located in the chest and abdominal cavity during the impact of the bullet on the liver line while protecting the body with ballistic packages made of fabrics: (a) Biaxial; (b) Triaxial.

The pressure curves for the Lu1 and Lu2 sensors were also recorded while protected with packages made of biaxial fabrics,and these were 15 kPa and 47 kPa, respectively. For the second tested ballistic fabric,no significant changes were recorded for the Lu1 sensor,while the pressure value was 16 kPa for the Lu2 sensor.The tendency towards higher pressure values for the ballistic packages made of biaxial fabrics was again visible, which may result from the nature of the local deformation of the cover and the impact on the body in a point-like manner. On the other hand, for the structure of the ballistic packages made of triaxial fabrics, the pressure force of the shield covers a larger area of the human body model,which translates into a lower pressure value at the point of impact. It should also be noted that, during a hepatic impact, the shock wave is transmitted to the thoracic human body model.The structure of the multi-axis fabric better absorbs the shock waves,which leads to a reduction in the pressure value for the Lu2 sensor and minimisation to values close to zero, for the Lu1 sensor.

It should also be noted that the sensor I1 only recorded a value of about 8 kPa when protected with packages made of biaxial fabrics. This confirms the belief that the biaxial structure leads to easier transfer of the stress wave in the area of the small and large intestine, due to the weave geometries during the impact of the bullet; this was not observed in the case of the packages made of triaxial fabric. It should be stated that, in the model of the human body there was no model of the small and large intestine, and the recorded pressure values represented the responses of the ballistic gel. The sequence of the BABT trauma during the impact of the bullet along the line of the liver position may lead to breaking the coatings(abrasion of the epidermis,bruising,swelling),bruising of the subcutaneous tissue and muscles (ecchymosis, swelling) and haematomas within them (fluid reservoirs filled with blood), to rupture the liver with complications, i.e. bleeding into the abdominal cavity.

5.5. Bullet impact in line with the location of the small and large intestines

One of the types of abdominal damage that occurs when a nonpenetrating bullet hits the ballistic shield is the rupture of organs containing gases or digestive contents. Fig. 26 shows the pressure increase as a result of the impact,as a function of time,depending on the given textile structure.During the impact of the bullet along the line of the location of the small and large intestines, no significant changes in the course of the pressure were recorded for the sensors H1,H2,Lu1,Lu2,R1,R2,R3 and Li1.The waveforms from the sensor located in the sternum (S1) were also not given, because it was damaged during the first attempt when the bullet hit the sternum.

The pressure value for the I1 sensor shown in Fig. 26 is lower when using packages made of triaxial fabrics and amounts to 3.3 MPa.For packages made of biaxial fabrics,the pressure value for the I1 sensor is 5.7 MPa. The tendency towards higher pressure values for the ballistic packages made of biaxial fabrics was again visible, which may result from the nature of the local deformation of the cover and the impact on the body in a point-like manner. It should also be noted that the duration of the potential BABT injuries is longer and that the pressure amplitudes over this period are greater in the case of packages made of biaxial fabrics. There was no model of the small and large intestines in the human body model and so the recorded pressure values are the response of the ballistic gel. The results of the ballistic tests showed that higher pressure values, when protecting the body with a ballistic packet made of biaxial fabrics, may lead to integuments of subcutaneous tissue and muscles, mesenteric tearing or even intestinal rupture.The mesentery is a thin membrane composed of two adjacent peritoneal plaques, acting as a ligament for the internal organs of the abdominal cavity,mainly the small intestine.A complication of mesenteric rupturing may be life-threatening bleeding into the peritoneal cavity and intestinal rupture may cause peritonitis.Both of these conditions can be directly or indirectly fatal.

Fig.26. Pressure course for the I1 sensor during the impact of a bullet along the line of the navel with the protection of the body by ballistic packages made of biaxial and triaxial fabrics.

6. Conclusions

This article focuses on experimental research into the injuries on the human body during the non-penetrating impact of a Parabellum 9 mm × 19 mm FMJ bullet at a speed of 406 ± 5 m/s, protected by ballistic packets made of biaxial and triaxial fabrics. In experimental research,the fabrics had a comparable surface weight and were made of the same Kevlar®29 yarn.The ballistic packages were made of 30 layers.As part of this study,a physical model of the human body was developed.The human body model consisted of a model of the heart, lungs, and skeletal and muscular systems.During bullet impact, the pressure forces were recorded using sensors located at selected points of the human body. During the firing, the bullet hit five selected places on the body that were considered critical from the point of view of maintaining vital functions. It was found that, during firing, pressure increases both at the site of impact and in the internal organs, which can lead to multiple organ damage. The experimental analysis shows that the pressures exerted on specific organs are always lower in the case of body protection with a ballistic packet made of triaxial fabrics compared to a packet made of biaxial fabrics.

Experimental research has shown that,for the ballistic packages made of triaxial fabrics,the pressure values were usually more than half that for the ballistic packages made of biaxial fabrics. Additionally it was noted that for these packages, the number of shot through layers was 12 for triaxial and 10 for biaxial type of construction in each points of bullet impact.The larger number of shot through layers in the ballistic package made of triaxial fabrics is influenced by the hexagonal openings in the structure of the fabric,as opposed to the biaxial fabric, which is completely enclosed.

It is assumed that the geometric structure of the fabric has a significant influence on the maximum pressure amplitude. When the bullet hit packages made of biaxial fabrics, the pressure was more localised and covered a smaller area of the human body model, which resulted in greater pressure at the point of impact.However, for the second variant, the acting pressure force of the packages made of triaxial fabrics was distributed over a larger area,resulting in a lower value of maximum pressure at the point of impact of the bullet. It should also be noted that the blunt BABT trauma caused by hitting the sternum along the line of the heart showed sternum fractures using both the packages made of biaxial and triaxial fabric.The number of cracks and the area of damage to the sternum were smaller when using the ballistic packages made of triaxial fabrics.As a result of breaking the anatomical continuity of the sternum,the internal structure of the chest(e.g.lungs,heart),covered by the sternum,may be damaged.It should be added that bone fractures may be multi-fragmentary and the damaged bone fragments may constitute a so-called ‘secondary bullet’,which can extend the area of damage.When the bullet was shot into the II rib,while protecting the human body model with ballistic packages made of biaxial fabrics,a rib fracture was found.This type of injury was not found when examining a human body model protected by packages made of triaxial fabrics.

Blunt BABT trauma can lead to a wide variety of injuries,ranging from minor, non-life threatening injuries (with no significant consequences for those affected) to significant, potentially fatal,injuries.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- Defence Technology的其它文章

- Trans-scale study on the thermal response and initiation of ternary fluoropolymer-matrix reactive materials under shock loading

- An improved SLAM based on RK-VIF: Vision and inertial information fusion via Runge-Kutta method

- Shock response of cyclotetramethylene tetranitramine (HMX) single crystal at elevated temperatures

- A super resolution target separation and reconstruction approach for single channel sar against deceptive jamming

- Camouflaged people detection based on a semi-supervised search identification network

- Angular disturbance prediction for countermeasure launcher in active protection system of moving armored vehicle based on an ensemble learning method