Recent progress in developing ballistic and anti-impact materials:Nanotechnology and main approaches

Shuangyan Wu, Partha Sikdar, Gajanan S. Bhat

Department of Textiles, Merchandising and Interiors, University of Georgia, Athens, GA, 30602, USA

Keywords:Ballistic impact Body armor Nanotechnology Fabrication High-performance fiber

ABSTRACT With increasing international and civilian conflicts, developing advanced body armor has become an emerging field in academia and industry. Nanotechnology, by means of, incorporating nanomaterials, is considered a highly effective technique to achieve this goal. It has been widely studied in defense applications owing to high strength-to-weight ratios and excellent energy absorption capability of nanomaterials. Hence, this review encompasses the latest application of nanotechnology involving nanomaterials and nanocomposites in ballistic and anti-impact fields. Additionally, this paper outlines fiber materials utilized, and alternative approaches adopted to develop robust non-metal bullet-proof materials. These approaches include shear thickening fluids (STFs) incorporation, sandwich structures,polymer matrix composites (PMCs), and textile structure optimization. Meanwhile, ballistic-related performances of various materials developed using single or hybrid techniques are collected and compared.

1. Introduction

Starting with animal skin,wood,and stone,the development of protective equipment for human bodies against enemy attacks has a long history dating back to mankind[1].With the main functions of preventing penetration of sharp objects/projectiles and dissipating energy from high-velocity impact (HVI), body armors have been used for personal protection against severe and fatal injuries since the Roman era [2,3]. Nowadays, soft body armors with multilayered high-performance fabrics and hard body armors reinforced with stiff metal, ceramics, or polymer plates are widely used by soldiers, law enforcement officers, and other security personnel [4]. New and innovative materials are being developed for body armor systems.Due to the evolution and maturity of ultrahigh-molecular-weight polyethylene (UHMWPE) fibers, it is receiving rapidly increasing attention and acceptance in body armor market,which was dominated by aramid fiber-based products for the last three decades[5].In application,armor products protect users from various threats during international and civilian conflicts [6-8]. With increasing threats from enhanced firearms,more powerful ammunition, and a growing number of disputes,armor materials with improved performance are always in great demand for sufficient protection [9]. This, therefore, leads to extensive research on advanced lightweight ballistic materials for end-uses such as body armors,ballistic vests,helmets,and combat vehicles. The research goals include (1) improving ballistic materials,i.e.,higher impact resistance against low-velocity impact(LVI)and HVI,better energy absorption capability,higher flexibility,and lighter weight, and (2) developing novel bullet-proof materials.While LVI occurs in the velocity range of 1-10 m/s,HVI or ballistic impact occurs between 50 m/s and 1000 m/s [10]. LVI with a high impactor mass usually takes place during manufacturing,in-service time,and maintenance of ballistic and anti-impact materials[11].It may not cause puncturing for materials but possibly damage structural components largely reducing material stiffness and strength. To increase service life and improve impact strength of designed materials,the effect of LVI can be studied[12].In contrast,ballistic impact occurs with high-speed and high-energy projectiles, the projectile-material interaction time is much shorter(50-200 μs) [13]. Due to projectile penetration and afterperforation wreckage with kinetic energy, ballistic impact may cause fatal damage to the target. Thus, it is mainly concerned during the development of ballistic materials.

Nomenclature

B4C Boron Carbide

BFS Back Face Signature

CNTs Carbon Nano Tubes

DMTA Dynamic Mechanical Thermal Analysis

EDS Energy Dispersive X-ray Spectroscopy

FPNCs Fiber-based Polymer Nanocomposites

GNPs Graphene Nanoplatelets

GO Graphene Oxide

HDPE High-Density Polyethylene

HMPP High-Modulus Polypropylene

HVI High Velocity Impact

IF-WS2Inorganic Fullerene-Like Tungsten Disulfide

INT-WS2Inorganic Nanotubes of Tungsten Disulfide

LVI Low Velocity Impact

MWCNT Multi-Walled Carbon Nanotube

PE Polyethylene

PEG Polyethylene Glycol

PIPD Polyhydroquinone-Diimidazopyridine

PMCs Polymer Matrix Composites

PNCs Polymer Nanocomposites

POSS Polyhedral Oligomeric Silsesquioxane

PPTA Poly (p-phenylene terephthalamide)

PVB Polyvinyl Butyral

SEM Scanning Electron Microscopy

SP Silly Putty

STFs Shear Thickening Fluids

SWCNT Single-Walled Carbon Nanotube

UD Unidirectional

UHMWPE Ultra-High-Molecular-Weight Polyethylene

VARTM Vacuum Assisted Resin Transfer Molding

VHMAP Very High-Modulus Aromatic Polymer

XRD X-ray Diffraction

In academia and industries, various fiber products with high specific strength, modulus, and flexibility have been reported for developing ballistic and anti-impact materials.These materials can be used for protective garments, flexible bullet-resistant panels,fiber-reinforced ballistic composites, etc. Para-aramid and UHMWPE fibers are the two most commonly used fiber materials due to their outstanding mechanical properties,impact resistance,and chemical resistance[14-16].Other fibers such as glass,carbon,ceramic, high-modulus polypropylene (HMPP), and natural fibers have also been investigated for anti-ballistic applications [17,18].Hybrid systems with two or more types of fibers or fabrics are often applied to obtained combined properties[19-21].Nanotechnology is defined as the manipulation of materials in the nanoscale (at least one dimension <100 nm). Due to their high surface area-tovolume ratios and unique structures, various nanomaterials show extremely high strength & modulus and outstanding energy absorption capability. With these properties, nanomaterials have attracted considerable interest in developing robust anti-ballistic composites. Numerous researchers studied the effect of incorporating nanomaterials on the performance of polymer and fiberbased composites in ballistic applications and achieved promising results [22-25]. In the literature, nanotechnologies involving nanomaterials, nanofibers, and nanocomposites have been reported [26,27]. Varying fabrication methods (e.g. compression molding, impregnation, hand lay-up) can be adopted to make nanocomposites in different forms such as rigid polymer/nanofiller composites and flexible fabric/nanofiller/polymer composites[28-30]. Apart from the application of nanotechnology in ballistic materials,other approaches without nano-reinforcement have also been chosen by researchers to develop enhanced impact-resistant materials. These approached can be categorized into (1) incorporating shear thickening fluids,(2)sandwich structures,(3)polymer matrix composites, (4) textile structure optimization, and their combinations based on the material components and forms[31-35].

Over the past few decades, a great deal of research has been conducted to fabricate ballistic and anti-impact materials[36-42].These research mainly investigated materials’ impact resistance,energy absorption ability,and mechanical properties such as tensile strength,modulus,elongation,and toughness [43-54].Articles on different paradigms are found based on body armor application,modeling, and simulation [55-68]. However, critical reviews regarding various techniques adopted to develop advanced ballistic materials and the recent findings have yet to be amassed into a complete frame. To fill this critical void, this review article is devoted to addressing the techniques/approaches utilized by researchers to develop robust bullet-proof and impact-resistant materials, which include nanotechnology, shear thickening fluids(STFs) incorporation, sandwich structures, polymer matrix composites,and textile structure optimization.In addition,this review outlines mechanical properties of main fibrous products, nanocomposite fabrication methods, and performance of various ballistic materials developed for defense and anti-impact applications.

2. Fiber material

To provide protection against high-velocity impact and ensure sufficient comfortability and mobility, tough but lightweight materials are preferred for ballistic applications including body armors,structural components for helmets and military vehicles,etc.Polymeric fibers with a high specific toughness,high modulus,and low-density are extremely efficient for impact energy absorption and dissipation. Therefore, they are highly favored for lightweight anti-ballistic end-uses [69,70]. A brief review of main fiber materials studied in ballistic and impact resistant fields is presented.More detailed information can be found elsewhere[71].

2.1. Para-aramid fiber

Aramid fibers are high-performance fibers with aromatic rings and amide linkages in the backbones. They comprise highly oriented linear chains, hydrogen bonds in the molecular structures,and high crystallinity (76-95%). These characteristics lead to their tightly packed intermolecular structure and cohesive energy[72,73]. This unique structure confers their high heat resistance(decomposes ~400°C), specific strength, and modulus [74-76].Based on the chemical structures,aramids can be divided into paraaramid (Kevlar®, Twaron®), meta-aramid (Momex®), and copolymer aramid (Technora®). Among these, para-aramid fiber is mostly used for ballistic fabric panels and composites with its exceptional mechanical properties and impact resistance. Various research has been conducted to develop para-aramid fiber-based materials and composites.However,due to the high orientation of its molecular chains, aramid fiber has smooth and chemically inactive surface, which exhibits poor interfacial adhesion to polymer matrices.To improve its surface activity,wettability,and fiber/matrix adhesion, numerous attempts are made to modify aramid fiber surface including chemical and physical treatments, e.g.,chemical etching, surface grafting, chemical oxidation, polymerization, coupling agent, heat treatment, plasma treatment, ion sputtering, electronic beam, γ-rays, corona modification, and ultrasound [75-86]. Moreover, modifying resin matrices has also been reported to enhance matrix/fiber adhesion.

2.2. Ultra-high-molecular-weight polyethylene fiber

Ultra-high-molecular-weight polyethylene is one type of thermoplastic polyethylene with the chemical formula of-(C2H4)n-,the degree of polymerization (n) of UHMWPE can reach as many as 200,000 [87,88]. Its average molecular weight is up to 6 million g/mol with extremely long chains,high orientation(>95%),and high crystallinity (up to 85%).During impact,the long molecular chains transfer force efficiently to the molecular backbone through strong intermolecular interactions giving UHMWPE fiber excellent energy absorption and high impact strength capabilities. Besides,UHMWPE fiber (e.g. Spectra® and Dyneema®) possesses low density (0.97 g/cm3), extremely high specific strength, high modulus, and fairly high fracture strain (~3%) [89]. Compared to para-aramid fiber, UHMWPE fiber shows about 40% higher strength-to-weight ratio [1]. With its exceptional properties,UHMWPE fiber holds a great promise for lightweight anti-ballistic applications such as personal armors [90-94]. Countless researchers have studied UHMWPE fiber/fabric based bullet-resistant materials in fabric panels and textile-based composite forms[95-99]. However, when used in ballistic applications, UHMWPE fiber also has limitations such as low creep resistance,low melting temperature(144-152°C),and poor fiber adhesion to matrices due to its smooth surface and the lack of polar groups in its structure.

2.3. Glass fiber

Glass fibers are a versatile class of materials made with silica and minerals. They can be categorized into various types according to their compositions, performances and end-uses. For instance, Eglass fiber has low electrical conductivity, S-glass fiber has high strength,C-glass fiber has high chemical durability,and M-glass has high stiffness.Among all types,E-and S-glass fibers are researched for ballistic applications[100,101].E-glass fiber is extensively used for glass-reinforced ballistic composites while S-glass fiber,designed with high tensile strength has been applied for military ballistic impact applications since the 1970s. Its high tensile strength, elongation, thermal stability, and chemical stability lead to great energy absorption and protection functions against impacts, fire, toxic chemicals, and gases. Along with its low cost and lightweight,S-glass fiber becomes an alternative fiber candidate for bullet-proof applications. However, its limitations still exist including low Young’s modulus, poor fatigue resistance, and low compatibility with polymer matrices.

2.4. Carbon fiber

Carbon fiber is a strong and lightweight fiber material composed mostly of carbon atoms. The diameter of carbon fiber is about 5-10 μm.It possesses high strength and stiffness for weight,great chemical resistance, high thermal stability, and low thermal expansion. Being lighter than steel, carbon fiber is five times stronger and twice as stiff, making it an ideal reinforcing material for ballistic applications. Although carbon fiber is not ballistic resistant due to its brittle nature, one or more layers of carbon fabric can be applied in composites to obtain structural integrity and improve compression resistance in ballistic applications.Carbon fibers in the forms of tapes, fabrics,and heavier knits have been reported for fabricating bullet-proof laminates and composites [102-105].

2.5. Natural fiber

Most natural fibers, especially lignocellulosic fibers extracted from plants lack desired high-performance characteristics. However,due to their high cost efficiency,environmental sustainability,lower density, easy fabrication, and recyclable advantages, natural fibers have attracted an increasing attention in impact resistant applications [106]. In the literature, natural fibers such as jute,hemp, flax, sisal, ramie, kenaf, coir, curaua, bagasse, mallow,bamboo,and piassava fibers have been investigated for ballistic and anti-impact applications in composite forms [107-115]. For example, curaua fiber, which has lower density (0.96 g/cm3) than aramid and glass fibers (1.44 g/cm3and 2.58 g/cm3) and comparable specific tensile strength (~2.2 GPa cm3/g) to aramid fibers(~2.8 GPa cm3/g), showed promising ballistic properties when reinforced with epoxy and graphene oxide (GO) [108]. It can be further researched for multilayered armor use. Another natural fiber, basalt fiber, made from black volcanic magma, is non-toxic,eco-friendly, and easy to fabricate, therefore is considered as a green industrial material. Due to its great impact resistance and comprehensive performance, basalt fiber shows good potential in protective garments, fire blocking materials, and building insulation components.

2.6. Other fibers

Apart from mentioned fiber materials, other fibers such as nylon, silk fiber, ceramic fibers, HMPP fiber, boron fiber, metallic fibers, aromatic polyester, and polyhydroquinonediimidazopyridine (PIPD) fiber have also be reported for body armor applications [116]. Different fiber materials are often hybrid with high-performance fibers to improve the strength and energy absorption of final ballistic materials with reduced cost.Table 1 lists physical and mechanical properties of fiber materials for ballistic applications.Such a comparison shows advantages of certain fibers and help select fibers for particular applications. As seen,commonly used para-aramid and UHMWPE fibers in armor materials show well-balanced properties of low density, high strength,high modulus, and high strain. Both fibers have comparable mechanical properties, however, UHMWPE fiber shows, in general,better specific tensile strength and modulus due to its lower density as shown in Fig.1. The figure presents a clear and direct comparison of the specific modulus and specific tensile strength of various fibers and steel for ballistic applications. A trend line(R2= 0.86) is plotted for the specific strength and modulus of ballistic fibers(UHMWPE,aramid,and glass)with the relationship shown in Eq. (1). To develop lightweight and robust fiber-based bullet-proof materials, fiber materials with high and balanced specific modulus and specific strength are preferred.This is due to their positive relationships to the velocity of longitudinal energy wave in fiber materials and the energy stored elastically in fibers under stress, which are shown in Eq. (2) and Eq. (3) [1,5]. It is expected future developed high-performance fibers would follow closely to this trend line in terms of their specific strength and modulus for ballistic end-uses [5].

Fig.1. Distribution of specific tensile and specific modulus of fiber materials for ballistic applications [5].

Table 1 Density and mechanical properties of fiber materials for anti-ballistic applications [1,17,107,108,117-121].

where STM is the specific tensile modulus and STS is the specific tensile strength.

where E is fiber Young’s modulus; ρ is fiber density; V is the longitudinal wave velocity; σ is fiber yield stress; ESis the work to rupture of the fiber; and ε is fiber strain at the yield point.

3. Nanotechnology

Nanotechnology(or“nanotech”)is the science,technology,and engineering conducted to manipulate matters on a nanoscale(1-100 nm for at least one dimension). It allows controlling and understanding matter at the most fundamental level involving individual atoms and molecules [122]. Nanotechnologies have been widely adopted in many areas such as defense, biomedical, agriculture, electronics, textile, and so on. In defense area, a previous review briefly introduced the application of nanofibers and nanoparticles in STFs, fiber-based composites, and/or polymer matrix composites (PMCs) for body protection. It also focused on the application of nanotechnology on smart functions such as sensor detecting,biological monitoring and self-medicating[22].Based on the literature, herein a thorough and systematic review of nanotechnology on anti-ballistic materials is presented.It is divided into nanomaterial, polymeric nanofiber, and nanocomposite according to their forms and components. Nanomaterials and nanofibers are rarely used solely to fabricate ballistic materials, they are often incorporated in composites forming nanocomposites, which are extensively studied for advanced bullet-resistant materials.Therefore, an important aspect of nanotechnology regarding nanocomposite fabrication in ballistic filed is also discussed in this section.

3.1. Nanomaterial

Nanomaterials are materials that have a unit size of 1-100 nm in at least one dimension. According to their overall geometries,nanomaterials can be divided into 0D (e.g. fullerenes), 1D (e.g.carbon nano tube(CNTs)),2D(e.g.graphene nanoplatelets(GNPs))and 3D (e.g. nano graphite) [123]. The structures of four carbonbased nanomaterials in these four geometries are shown in Fig. 2.With extremely high surface-area-to-volume ratios, excellent mechanical properties, and outstanding energy absorption ability,some nanomaterials, particularly CNTs, graphene, and their derivatives are investigated for developing lightweight ballistic and impact resistant materials. Meanwhile, the effects of other inorganic nanomaterials such as nanoclay, tungsten disulfide (WS2),and SiO2nanoparticles on ballistic performances of incorporated polymer matrix or fiber-based composites are also reported [13].

Fig. 2. Structure examples of 0D (fullerene),1D (carbon nanotube), 2D (graphene), and 3D (graphite) nanomaterials [124].

3.1.1. Carbon nanotube

Carbon nanotubes are hollow cylindrical tubes formed from rolling 2D graphene sheets. Their surfaces are made with pentagonal and hexagonal rings bonding with carbon atoms. They are considered 1D nanomaterials since the diameters of the tubes are in the nanoscale and their lengths can reach up to about 1 mm resulting in their high aspect ratios. CNTs have excellent mechanical strength and high thermal conductivity attributed to the carbon atom bonding in the rings and the heat conduction through carbon atom vibrations, respectively. As one of the strongest nanomaterials, CNTs have a calculated tensile strength of 200 GPa,modulus higher than 1 TPa,and relatively low density,making CNT a favorable material for developing high-performance nanocomposites.Based on the number of nanotube layers, CNTs can be grouped into single-walled carbon nanotubes (SWCNTs) or multiwalled carbon nanotubes (MWCNTs) [125]. While MWCNT has the highest tensile strength (about 63 GPa) among known materials, SWCNT shows a more uniform distribution of current in the structure and better electrical properties.

CNTs show great potential for ballistic, high strength, and high energy absorption materials due to their high aspect ratios, high tensile strength, extreme hardness, high stiffness, good ductility,and low density[126,127].CNTs reinforced PMCs can be extremely strong and effective ballistic materials when CNTs are properly incorporated. In recent years, a large amount of research has reported the application of CNTs in ballistic materials. For instance,the effects of different concentrations of MWCNTs on the ballistic resistance performance of Twaron/epoxy composites have been studied,the results showed incorporating 1.0 wt%of MWCNT could significantly increase the fracture toughness, energy absorption,and ballistic resistance of the final nine-layers composite panel[128]. Moreover, the influences of weight percentages, treatments(e.g., plasma functionalization), fabrication methods, and alignments of CNTs on the mechanical and ballistic properties of fiberbased composites were also studied [17,45,46,129-138]. Through these works, researchers adopted various methods to incorporate CNTs, which include forming STFs, crosslinking with epoxy,bonding directly to fabrics, transferring pre-grown CNT forests to prepreg,stacking pre-grown electron-spun CNT forests with fabric sheets, growing CNTs on target fabrics, flocculating on nanofiber films with vacuum assistant, press-drawing-winding, stretchdrawing-press-winding, and spray winding. To understand the effect of CNT alignment, they manipulated the length, waviness,entanglement, packing,realignment, twist, or compression of CNT and evaluated mechanical properties of corresponding composites.Textile substrates including Kevlar®fabric,Twaron®fabric,E-glass fabric, Kevlar® nanofibers, etc. were used. Different properties of the developed composites were analyzed, i.e., fiber-matrix interfacial adhesion, interlaminar shear stress, stiffness, specific strength, specific modulus, toughness, energy dissipation, and/or flexibility. Overall, the comprehensive results indicate that although the equivalent mechanical performance of CNTs may not be reached for their reinforced composites, CNTs can still significantly improve the mechanical and energy absorption properties for the target composites. Besides, their reinforcing effect may be affected by many factors such as nanotube amount, alignment,dispersion uniformity, modification, adhesion with matrix, the interaction between nanotubes, and load transfer efficiency.

For instance,in previous study,Izod impact test was conducted on Kevlar/epoxy/MWCNT composites with varying MWCNT amount (Fig. 3(a)). The impact strength and energy absorption of the specimens with 0.5% MWCNT were found to be 45% and 27%higher than the neat composite due to its extra energy dissipation mechanisms such as CNT fracture, pull-out, and CNT/matrix bridging/coupling [139]. Besides, both CNT amount and CNT modification by plasma treatment (100W) showed significant effects on the specific strength of CNT/epoxy composites in another work (Fig. 3(b)). Plasma treatment induced covalent bonds between CNT and epoxy matrix, enhanced the load transfer, and improved composite mechanical properties. The treated-CNT/epoxy exhibited clean and much sharper fracture than its counterpart indicating the improved CNT/matrix bonding [135]. Based on the literature, one of the highest mechanical properties of MWCNT composites was obtained from a MWCNT (46 vol%)/bismaleimide composite made through spray-stretch-winding approach. Of which, superior performance such as specific strength of 3.04 GPa/(g∙cm3) and specific modulus of 234.4 GPa/(g∙cm3) were achieved attributing to the CNTs’ high-volume percentage, long length, reduced waviness, and good alignment [17].

Fig. 3. (a) Izod impact strength and energy absorption of Kevlar/epoxy composites with varying MWCNT amount [139]; (b) Specific strength of pristine-CNT/epoxy and 100W plasma treated-CNT/epoxy composites with varying CNT content (a); Fractured ends of pristine CNT composite (I); and 100 W CNT composite (II) [135].

3.1.2. Graphene

Graphene, the first 2D nanomaterial discovered only over a decade ago,is a single layer of carbon atoms that are arranged in a hexagonal lattice[140,141].It has the thickness of one carbon atom(~0.335 nm). Due to its sp2 hybridized bonds, symmetrical plane structure, and strong covalent bonding, graphene possesses many unique properties including high ultimate strength(130 GPa),high elastic modulus (1 TPa), large specific surface area (2630 m2/g),exceptional electrical conductivity, good thermal conductivity(5000W/mK),high intrinsic mobility,etc[27].With these excellent properties, graphene and its derivatives, e.g., multilayer graphene,GNPs, and GO have been widely explored in nanocomposites for ballistic impact applications[142-149].And multilayer graphene is revealed to have specific penetration energy around 10 times as high as that of microscopic steel sheets [150].

Recently, nanoparticle-formed graphene laminates were inserted between Kevlar-29 fiber layers, and this new approach was found to significantly improve the ballistic performance of Kevlar-29 material. With 10 graphene laminates inserted, the total deformation of the vest material after ballistic test reduced and its stability increased [151]. Moreover, anti-ballistic performance of multilayer graphene/polyethylene (PE) composite was analyzed through molecular dynamic simulations, the results revealed that ballistic impact resistance of PE covered by one layer of graphene membrane increased by over 8 times, and multilayered graphene/PE nanocomposites could potentially provide protection against hypervelocity impacts [28]. While graphene shows poor surface adhesion with polymer matrices, its derivative, GO, has much better chemical reactivity with polymer fibers and easier handling properties. This is due to its amphiphilic structure with oxygencontaining groups such as carboxyl,hydroxyl,and epoxy [108].

The effects of GO coatings on different fibers (e.g. aramid and natural curaua fibers) using deposition-filtration or impregnation method have been reported[29,48,108].Fig.4 shows the(a)images of untreated and GO treated Twaron® fabric panels through filtration,(b)SEM images of treated fabrics after manipulation,and(c) specimens after the ballistic test. After manipulation, GO nanosheets were still retained on the fibers indicating good GO/fiber adhesion. Under the ballistic impact, the Twaron®/GO panel with twice filtrations absorbed 50% more impact energy than the plain fabric, and all three specimens showed cone-shape deformation, primary yarn pull-out, and primary yarn failure for energy absorption mechanisms, secondary yarns were less involved[29].Besides,grafting aramid fibers with GO was found to increase their interfacial shear strength by 210% [48], while GO/epoxy coated natural fibers could achieve comparable ballistic performance to Kevlar®fibers[108].Similarly,in some papers,the influence of GNPs on the mechanical properties of glass fiber/epoxy, PP, or epoxy was also studied. It was found that incorporating GNPs improved the tensile strength, Young’s modulus,fracture toughness, ductility and/or energy absorption capacity of the target materials to different extents [152,153].

3.1.3. Nanoclay

Nanoclay is formed with layers of mineral silicates that stack together by weak physical attractions such as Van Der Waals force.It has a sheet structure and high aspect ratio with the thickness about 1 nm. Based on its chemical composition and morphology,nanoclay can be categorized into different groups such as hectorite,bentonite,kaolinite,montmorillonite,and halloysite[60].Due to its anti-impact enhancement function and cost efficiency, nanoclay is often incorporated in fiber-based polymer composites as an alternative to organic nanofillers for mechanical and ballistic performance enhancement [154,155].

In a recent work, polymer composite composed of 1.5 wt%nanoclay, E-glass woven roving, and polyester resin was proved to have significantly higher stiffness, strength, hardness, and energy absorption than the control without nanoclay under high-velocity impact tests [156]. Similarly, the effects of 1.5% and 3% of nanoclay on glass fiber/epoxy composites were compared.Adding 1.5 wt% nanoclay was found to be more efficient, which improved the peak load of the composite by 23%, enhanced its stiffness by 11%,and reduced its impact damage [157]. Moreover, the vacuumassisted molding method was used to fabricate ballistic composites with nanoclay. The test results suggested that the glass fiber/epoxy/nanoclay (5%) laminates could achieve 42% higher ballistic limit compared to the neat composite.The property enhancement was attributed to the nano-reinforcement, vibrational damping of material, and fracture improvement [158]. Besides, incorporating 5 wt% nanoclay in epoxy matrix was found to improve the maximum compressive strength and toughness of epoxy matrix(Fig.5(a))[159].And adding 5-10 wt%nanclay in epoxy/glass fiber composites reduced their average damaged area under ballistic impact with initial impact velocity of 134 m/s, since the dispersed nanoclay may change the fiber/matrix adhesion, mechanical performance, and wave propagation velocity, therefore affecting the perforation time, load area, and failure mode (Fig. 5(b)) [160].Similarly, the influences of nanoclay on anti-ballistic related properties of other fiber-based polymer composites (e.g. Kevlar®,glass, and carbon fiber) under impact tests have been reported[161-166].

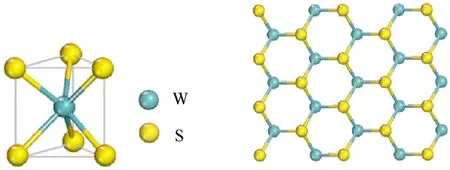

3.1.4. Tungsten disulfide

Tungsten disulfide is one of the inorganic layered nanomaterials similar to molybdenum disulfide, it comprises 2D stacked molecular sheets[167].Its one-layer chemical structure is shown in Fig.6.Analogous to the structures of fullerene and CNTs, WS2can be grouped into inorganic fullerene-like tungsten disulfide (IF-WS2)and inorganic nanotubes tungsten disulfide(INT-WS2)according to its formation. In particular, IF-WS2has a fullerene-like spherical and closed structure in nanoscale.Due to its inorganic components and closed spherical nanostructure, IF-WS2shows high chemical stability, ultra-low friction,good elasticity,high stiffness,excellent compression resistance, and outstanding shock absorbing ability(survive under pressure up to 25 GPa, temperature 1000°C)[168,169].These amazing properties and low cost make it a highly potential and practical material for ballistic impact applications.In recent years, IF-WS2and INT-WS2nanoparticles have been increasingly studied as reinforcing fillers in ballistic protective and energy absorption materials [170,171].

Fig. 4. (a) GO treated aramid fabric panels; (b) SEM of GO treated aramid after manual manipulation (1000 × and 3000 × ); and (c) the impacted areas after ballistic tests: a)untreated, b) GO treated (1 filtration), c) GO treated (2 filtrations) [29].

Fig. 5. (a) Compressive stress-strain behavior for nanoclay/epoxy specimens with varying nanoclay amount [159]; (b) damage area on glass fiber/epoxy/nanoclay composites after ballistic test with two initial velocities [160].

Fig. 6. Crystal structure of single-layer tungsten disulfide [172].

For example, the impact of IF-WS2on the mechanical and viscoelastic properties of aramid/phenolic/polyvinyl butyral (PVB)composites were reported previously. The results revealed that mixing 1 or 2 wt% of IF-WS2nanoparticles could improve mechanical properties, enhance impact resistance, and increase glass transition temperature of the composites [168]. Later on, applying INT-WS2was also found to enhance the impact resistance of the fabricated composite. Compared to the composite without nano reinforcement, the sample with 0.3 wt% INT-WS2showed 24.7%higher tensile strength, 64.1% higher toughness, 35.85% higher impact toughness, and 12% lower back-face deformation depth[170]. The scanning electron microscopy (SEM) images of IF-WS2,INT-WS2, their aramid/PVB composites, and the control composite are shown in Fig. 7. Also included are the energy dispersive X-ray spectroscopy(EDS)mapping images of IF-WS2and INT-WS2on the composites, as well as the stress-strain curves of the PVB and nanocomposite films. Uniform distribution of the nanoparticles is observed from EDS images, which plays a critical role in nanoparticle reinforcement. The addition of a small amount of either type of nanoparticles was found to significantly increase the mechanical properties(tensile strength,elongation,and toughness)of PVB films [170].

Fig.7. SEM images of(a)IF-WS2;(b)INT-WS2;(c)aramid/PVB/IF-WS2;(d)aramid/PVB/INT-WS2;and(e)aramid/PVB composite(center).EDS mapping of S and W elements on(f) aramid/PVB/IF-WS2 and (g) aramid/PVB/INT-WS2 composites; (h) Stress-strain curves for the PVB and composite films [170].

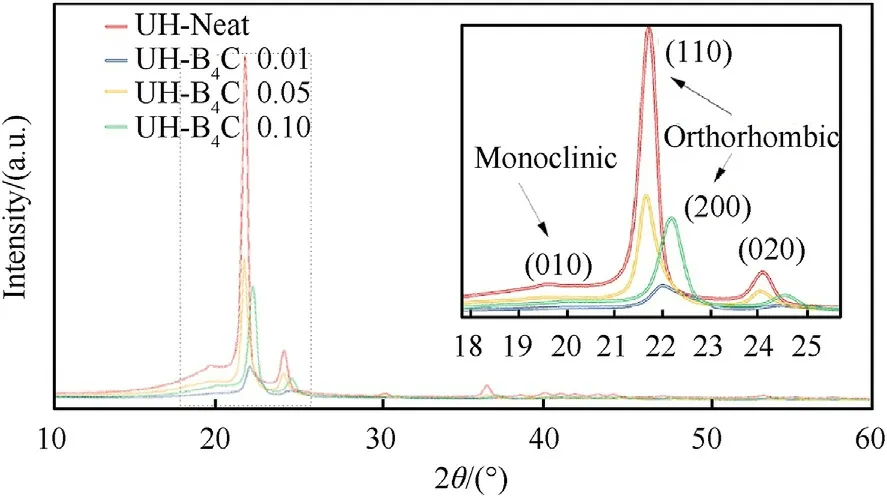

While nanomaterials such as CNTs,graphene,and nanoclay are extensively researched for high-performance ballistic impact materials, other nanomaterials including fullerene [173], polyhedral oligomeric silsesquioxane (POSS) [174], boron carbide (B4C) [175],core-shell rubber nanoparticles [133], SiO2nanoparticles [32,176],nano-Al2O3[25,177],nano-CaCO3[178],halloysite nanotubes[179],bucky paper [180], ZnO nanorods [181], etc. have also been incorporated into composites or STFs to improve their impact resistance, mechanical strength and/or energy absorption capability.For example,a recent study found the reinforcement of boron carbide (B4C) nanoparticles into UHMWPE provided enhanced storage modulus(89%)and ballistic performance and decreased its crystallinity (sample with only 0.05 wt% B4C showed the lowest bullet penetration depth-50% vs.neat-70%).

Fig.8 of X-ray diffraction(XRD)shows that the nanocomposites crystallinity index decreases compared to the neat UHMWPE,indicating that the B4C lowered the polymer macromolecular chains movements and hindering the matrix recrystallization[175].

Fig. 8. XRD patterns of neat UHMWPE and B4C/UHMWPE nanocomposites [175].

3.2. Nanofiber

Nanofibers are fiber materials synthesized in nanoscale of 100 nm or less for at least one dimension.However,industries often refer to “nanofibers” as fibers that have one or more dimensions less than 1 μm,and the sizes of nanofibers in most published papers are around 0.1-1 μm[182].Unlike nanomaterials,which are mostly made with small organic or inorganic molecules, polymeric nanofibers are composed of very large molecules. Compared to conventional fibers, nanofibers have smaller diameters, lighter weights, highly porous structures, and much larger surface-tovolume ratios, which make them ideal for various applications such as medical tissue engineering, filtration materials, protective clothes, functional materials, and so on [183]. In ballistic applications, nanofibers can be incorporated in composites. The potential and influence of adding nanofibers in ballistic composites have been investigated in several studies. For instance, one study showed that modifying E-Glass polyester composites with silane functionalized alumina nanofibers could increase the ballistic limit of the composite materials [184]. In another study, the poly(pphenylene terephthalamide) (PPTA) nanofibers were produced by immersion rotary jet-spinning. These nanofibers were proved to have 10-20 times larger surface-to-volume ratios and higher adhesion to composite matrices than commercial PPTA fibers.This improvement promotes their possible application in bullet-proof composites as the nano reinforcing components [185]. Moreover,carbon nanofibers also have been discussed as fiber strengthening materials in ballistic protection applications [62].

3.3. Nanocomposite

Composites are materials comprising at least two phases with different chemical and physical properties, and all phases are integrated to form a solid material with properties distinct from either component [186]. And nanocomposites are composites incorporated with nanofibers or nanomaterials [26]. With the structure different from a single component (e.g., fiber, polymer matrix, nanomaterial, and nanofiber), nanocomposites may show improved mechanical, thermal, and energy absorption properties.This is due to the property contribution from all components based on the rule of mixture [187]. Because of their versatile properties,nanocomposites are used in various applications including protective garments, biomaterials, coating materials, biomedical engineering, etc. In body armor field, a thorough review of nanomaterial-based polymer matrix composites was published in 2018.In which,the research findings for fabricated materials were mainly summarized based on the nanomaterial types (CNTs, Graphene, etc.), while another focus was natural fiber (e.g. curaua)reinforced PMCs,which showed promising performance even close to aramid fabrics [17]. However, an updated review that covers recent nanocomposite development, material components, and fabrication methods is urgently needed. In the ballistic area, fiberbased polymer nanocomposites (FPNCs) contributes to a large portion of developed materials due to their high strength-toweight ratios, enhanced energy absorption ability, and design flexibility [27]. These FPNCs comprise three main parts, which are(1)textile fibers in different forms,(2)nanofillers,and(3)polymer matrices.The selection of the components and fabrication method play an important role in the ballistic performance and structure of final nanocomposites.More details about these three parts and the fabrication methods for FPNCs will be explained later. Apart from FPNCs, there are also polymer nanocomposites (PNCs) developed for bullet-proof materials. They are usually made with polymer matrices and nanomaterials; no textile components are involved.The dispersing methods that will be reviewed for FPNCs can also be utilized to mix nanomaterials with polymer matrices forming PNCs for applications such as STFs and rigid ballistic materials.Common PNC materials used in ballistic and aerospace applications have been documented in another work[27].In which,their fabrication techniques, physical properties, mechanical properties, and the effect of preparation methods on performance were also summarized. In addition, fabric-based nanocomposites comprise fabric substrates and nanomaterials have also been reported in few papers. In their preparation processes, nanofiller/solvent dispersions were directly distributed on the fabrics through filtration or impregnation, the nanoparticles were mostly fixed on fabrics through newly formed chemical bonds or physical attraction after evaporating the solvents [29,48,108,188].

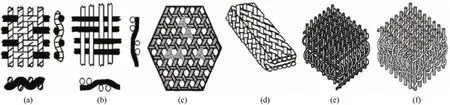

In this section, the review of FPNCs and their fabrication methods will be the main focus. As the first part of FPNCs, textile fibers can be incorporated as fiber reinforcing components or substrates in the forms of fibers,yarns,and fabrics.As mentioned in section 1, high-performance fibers (e.g., para-aramid, UHMWPE,glass fibers, and carbon fibers.) are commonly utilized or studied for lightweight body armors and textile-reinforced anti-impact composites due to their high specific strength, high flexibility,and relatively low cost. From the literature, textile fibers in varying structures and forms such as fibers,2D woven fabric(especially in plain weave, basket weave and triaxial weave), 2D nonwoven fabric,unidirectional laminates,cross-ply laminates,3D woven fabrics and knitted fabrics have been reported for fabricating either soft or hard materials for personal, vehicle, and equipment ballistic protections[36,189].The sketches of some 2D and 3D weave structure examples for fabrics are shown in Fig.9.When a fabric experiences a high-velocity impact, most of the kinetic energy from the projectile will be absorbed by the primary and secondary fibers through fiber strain and breakage. Various factors may affect the energy absorption capacity and ballistic resistance of the fabricated FPNCs including the fiber type, fiber weight percentage, fabric structure,and fabric thickness, etc. [13].

Secondly, nanofillers are often dispersed as the nanoreinforcements. Nanomaterials (e.g., CNT, graphene, nanoclay,WS2, and SiO2.) reviewed in subsection 3.1 can be introduced as reinforcing nanofillers for developing advanced ballistic nanocomposites.In the fabrication processes of FPNCs,these nanofillers are dispersed in polymeric matrices to form uniform mixtures.Compared with the composites without nanofillers, nanocomposites may achieve improved tensile strength, modulus,toughness,and energy absorption capacity with proper nanofillers and fabrication methods [190]. In detail, nanofiller factors such as filler type, shape, size, concentration, distribution uniformity, and orientation in polymer matrices can all influence the mechanical and ballistic performance of fabricated nanocomposites. Recent research shows that 3D networking arrangement leads to high aspect ratios of nanoparticles in polymer matrices contributing to excellent composite performance. Such arrangement can be achieved through several approaches such as intercalation, chemical vapor deposition, sol-gel process, chemical, freeze-drying, and direct mixing methods[13,27,191,192].

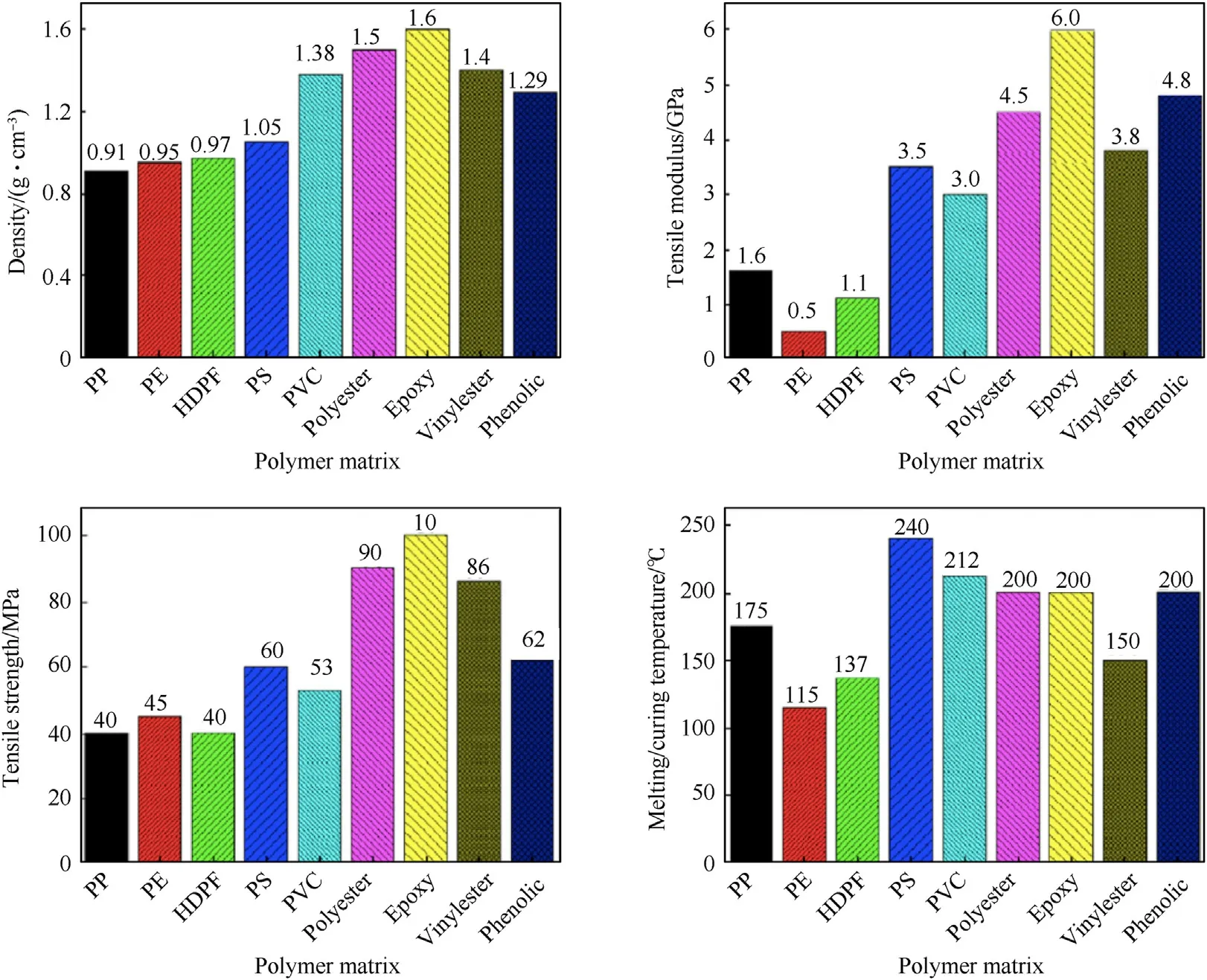

Thirdly, polymer matrices can be either thermoplastic or thermoset polymers. They function as binders and mediums to incorporate textile components with selected nanofillers and evenly distribute the nanoparticles. In detail, polymer matrices in FPNCs show three primary contributions,which are(1)improving ballistic performance of materials by adhering fibers together in position and dissipating projectile energy on more fibers/yarns during an impact event[193],(2)increasing total energy absorption capacity of composite laminates through matrix fracture, material delamination, and fiber/matrix debonding [194], and (3) protecting composites from environmental elements that may cause property damage such as ultra-violet light and high moisture [195,196].Based on their physical, mechanical, and thermal properties,different polymer matrix can be selected to meet the requirements of various protective composites.Fig.10 shows the density, tensile modulus, tensile strength, and melting temperature of common polymer matrices. With excellent mechanical strength, thermal stability, chemical resistance, and dimensional stability after curing,epoxy becomes one of the most popular thermoset matrices in high-performance composites [197]. Other thermoset polymers(e.g. polyester resin, phenolic resins, vinyl esters) and thermoplastic polymers with higher flexibility (e.g. polypropylene, polyethylene, polyurethane, polyamides) have also been applied as matrices in FPNCs with their unique properties [27]. While thermoset polymers are mostly chosen for developing stiff bullet-proof composites such as ballistic trauma plates and shields, thermoplastic matrices are preferred for fabricating flexible and lightweight ballistic materials such as soft body armors.Because of their weak adhesion with high-performance fibers, thermoplastic polymers allow the maximum deformation of fibers under impact and lead to higher energy absorption from impacting projectiles.

Fig. 9. Different 2D (a) Plain weave; (b) Basket weave; (c) Triaxial weave, and 3D fabric structures (d) 3D braid; (e) 3D orthogonal Weave; (f) 3D Triaxial Weave [1].

Fig.10. Physical, mechanical, and thermal properties of common polymer matrices [198].

For instance,in one work,phenolic resin and PVB were used as hybrid matrix for making aramid/IF-WS2nanocomposites, 1 wt%and 2 wt% of nanoparticles were used. The dynamic mechanical thermal analysis (DMTA) results indicated that incorporating IFWS2increased the glass transition temperature(Tg)of the aramid/phenolic resin/PVB composite, and the storage modulus of the sample with 2% IF-WS2increased at increasing frequency and decreasing temperature(Fig.11).The mechanical properties of the nanocomposites also increased owing to nanoparticle reinforcement according to nanoindentation tests [168]. Similarly, ballistic performance of other nanocomposites were investigated and reported in the literature, such as carbon/epoxy/nanoclay [199], Eglass/polyester/nanoclay [156,165], E-glass/epoxy/MWCNT[24,176], basalt/epoxy/GO, basalt/epoxy/zirconia [200], and glass/epoxy/nanosilica [201].

3.4. Nanocomposite fabrication

To obtain maximized performance of a nanocomposite, critical factors include not only the selection of its components but also the applied fabrication method, which involves nanotechnology with respect to nanocomposite fabrication. In the literature, various fabrication methods have been adopted to incorporate nanomaterials with fiber substrates. The fabrication processes for most FPNCs can be separated into two parts, (1) preparations of nanofiller-matrix dispersions/mixtures and (2) combining nanofiller mixtures with textile components.

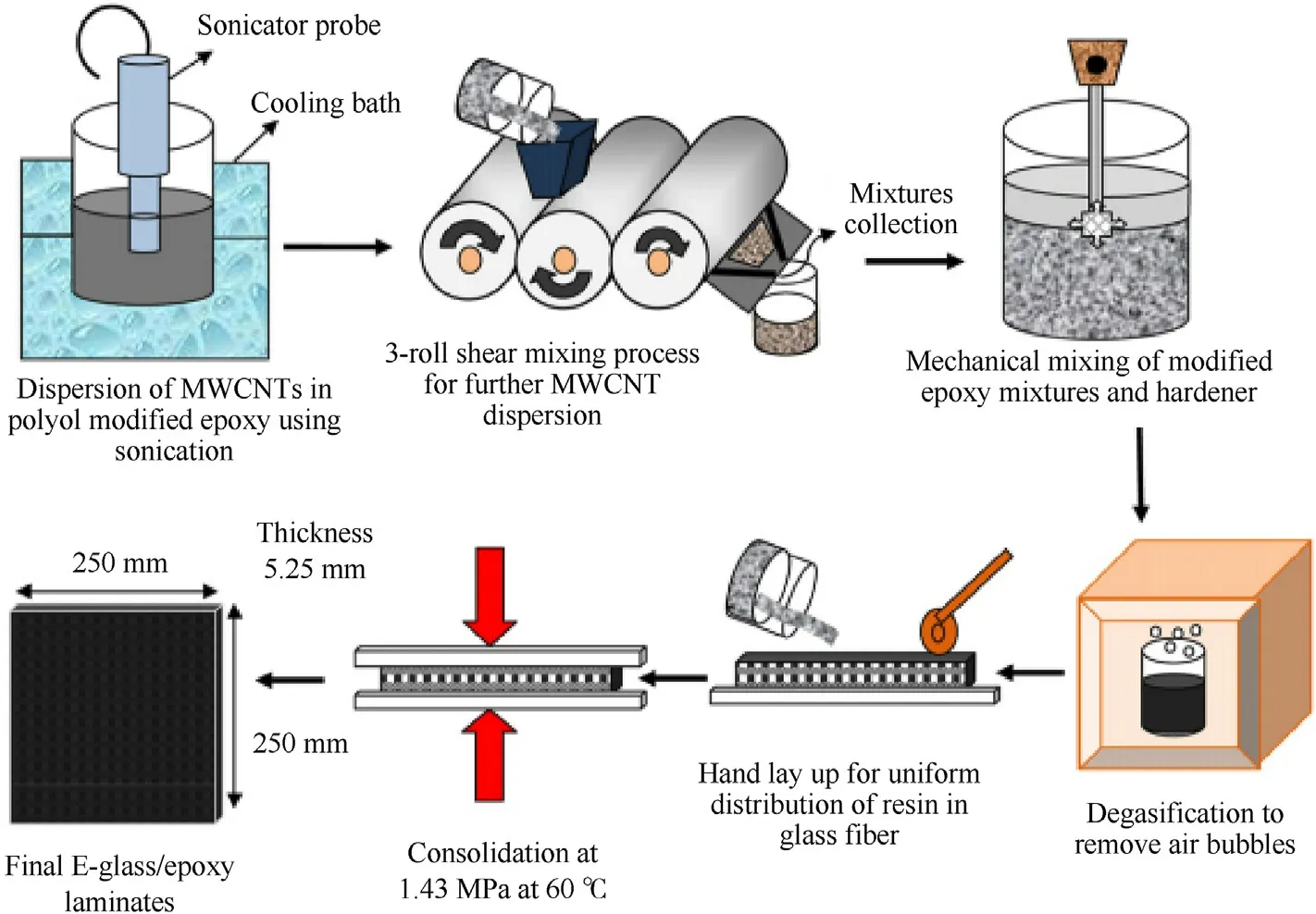

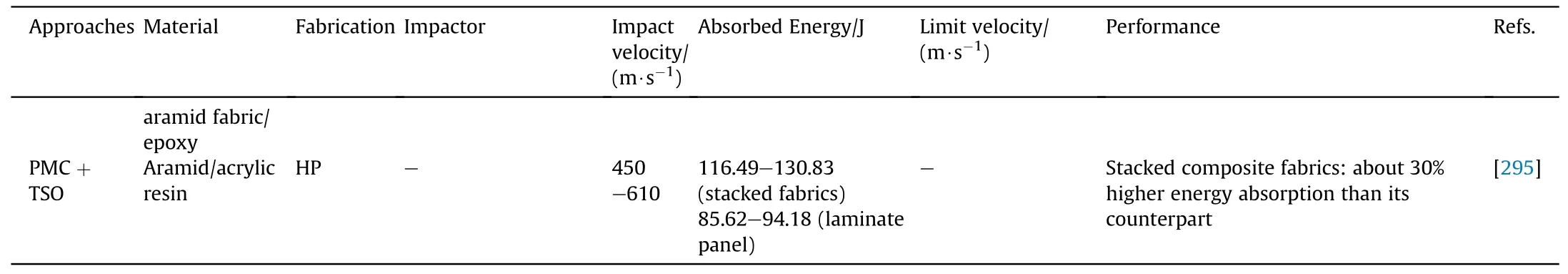

In many cases, the first step for fabricating FPNCs is to prepare nanomaterial/polymer mixtures. A major challenge in the preparation is to uniformly disperse nanofillers in selected polymer matrices.This is because most nanofillers(e.g.,CNTs and graphene)are hydrophobic and chemically inert with no oxygen containing active groups, which leads to their poor interfacial adhesion with polymer matrices and high-performance fibers. Many researchers have attempted to solve this nanofiller dispersing problem for fabricating ballistic FPNCs. The overall solutions can be grouped into two main directions: (1) functionalizing nanofillers and (2)optimizing mixing processes. As the first approach, nanofiller functionalization aims to improve nanofiller’s reactivity and surface affinity. Different treatments such as chemical reaction with agents and plasma surface modification can be applied on nanofillers [202,203]. After treatments, nanofillers can be grafted with functional groups (e.g. -COOH, -OH) that react and bond with polymer matrices and/or form defects on their surfaces. As the second approach, a proper mixing process may also be selected to prepare homogeneous nanofiller-matrix dispersions. Important mixing parameters include,but are not limited to the solvent type,viscosities of solvent and matrix,mixing method,and mixing time.For mixing methods, ultrasonication (using an ultrasonic bath or probe) has been utilized in most of the research due to its high mixing effectivity [50,204]. Other methods include mechanical mixing (using a stirrer blade), magnetic heat stirring (using a hot plate and stir bar), three roll shear mixing, etc. Different methods have been used individually or combinedly to achieve homogeneous distribution of nanofillers in matrices [205-208]. For example, in a previous work, a combined mixing procedure with ultrasonication,shear mixing,and mechanical stirring was applied to prepare MWCNT/polyol-modified-epoxy dispersions, the prepared dispersions were used to fabricate E-glass/epoxy/MWCNT nanocomposites.The processing schematic is shown in Fig.12.This hybrid method led to uniform distribution of MWCNT in the epoxy matrix and composites. Similarly, listed in Table 2 are other dispersing methods used for preparing nanofiller/matrix mixtures for ballistic material end-uses and their uniformity effects.

Fig.12. Schematic diagram of the fabrication process for E-glass/epoxy/MWCNT nanocomposites [24].

Fig.11. (a). DMTA results of the composites as a function of temperature: a) tan δ; b)loss modulus (G’’); c) storage modulus (G’); and as a function of temperature and frequency: (d) storage modulus (G’) of the aramid/phenolic resin/PVB/IF-WS2(2 wt%)[168].

After preparing the nano dispersions,FPNCs can be fabricated by combining nanofiller/polymer mixtures with textile substrates.Different methods such as impregnation coating [7,179], impregnation coating assisted with ultrasonication[188]and spray coating method[17,210]are found from the literature.After the fabrication step, a drying and/or curing process is often followed to remove water/solvents from the materials and/or form molecular chain crosslinks in polymer matrices. In comparison, impregnating fabrics in nano mixtures is one of the easiest and most common fabrication methods for preparing ballistic FPNCs, while spray coating may provide a more uniform distribution of nanomaterials on target fabrics. This is caused by two factors. During spray coating, the coating thickness and deposition of nanoparticles on the fabric surface can be precisely controlled, and the fast evaporation of some solvents can prevent nanoparticles reagglomeration [211]. Through these fabrication methods,nanomaterials are incorporated with selected materials (e.g. fiber or fabric)forming nanocomposites with enhanced properties such as better conductivity, higher strength, higher modulus, and improved shock absorption and energy dissipation abilities[212,213]. For instance, spray coating have been used to evenly distribute SWCNT/ethanol dispersion on UHMWPE fabrics for making nano-reinforced ballistic composites[210].Other methods such as direct application and vacuum infiltration of nanomaterials are also reported.In another work,IF-WS2/PVB solution have been directly applied on phenolic resin coated aramid fabrics using a spatula to manufacture aramid/IF-WS2/PVB/phenolic resin composites. Vacuum drying step was followed to solidify the PVB solution on coated fabrics, which formed a polymer film impregnating the fabric. Finally, a hydraulic press was applied to unite multiple layers of fabric and fabricate nanocomposite laminates [168]. Similarly, the vacuum filtration method has been adopted to deposit GO suspension on aramid fabrics followed by a vacuum drying process to make flexible ballistic nanocomposites[29].Furthermore,nanocomposite laminates may also be fabricated by applying polymer/nanofiller dispersions on individual fabrics and then forming laminates(rigid or flexible)or infusing arranged laminate structures with the dispersions (rigid). Different approaches may show significant influences on the mechanical properties, stiffness, and ballistic performance of final nanocomposites. In summary, the main factors shown in Fig.13 can all affect energy absorption capacity of fiber-reinforced polymer composites with fillers.

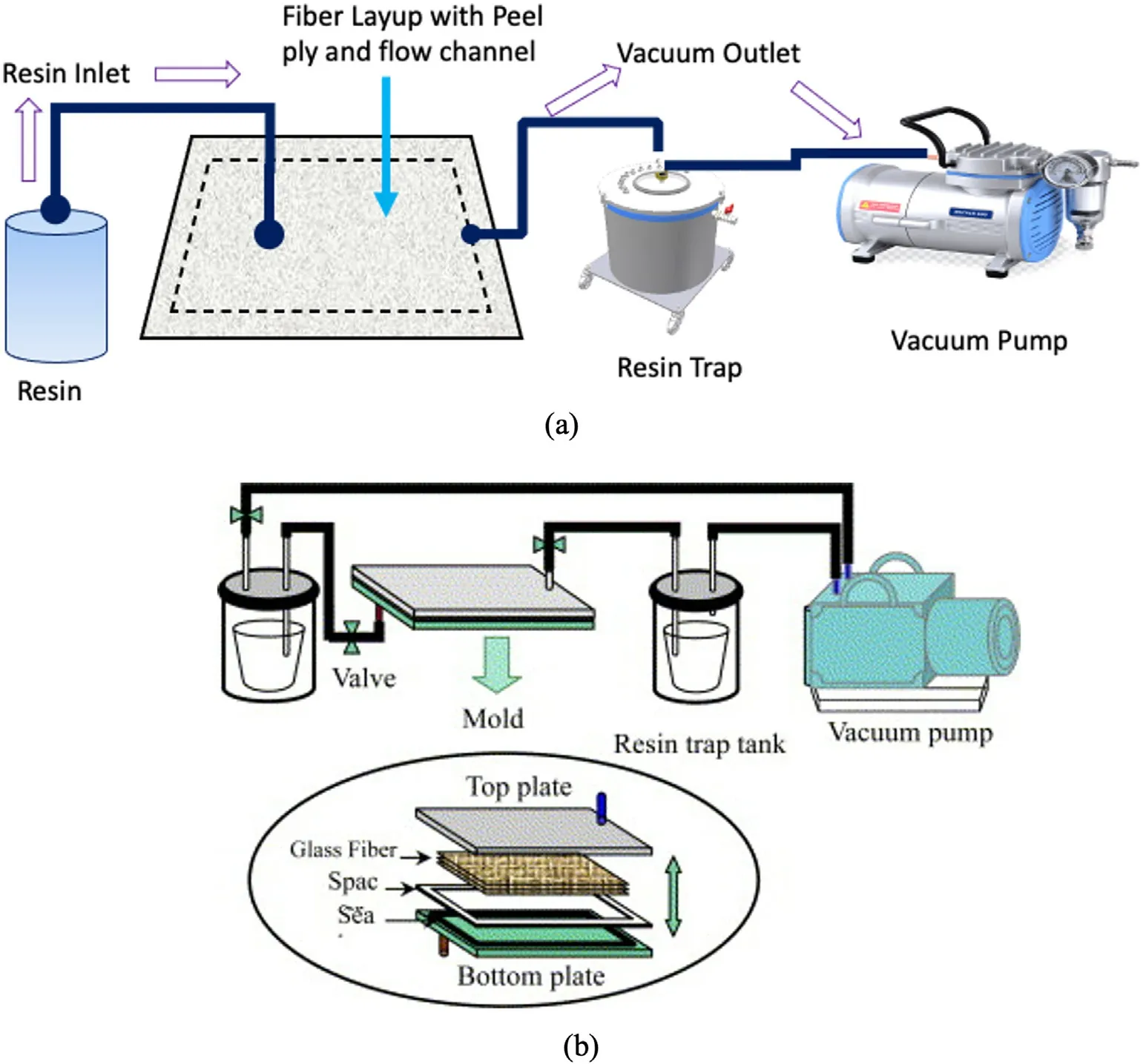

Other fabrication methods have also been used to fabricate nanocomposite laminates, polymer nanocomposites, and fiberreinforced polymer composites. Some of these methods include hand lay-up [214], pre-preg, compression molding [215], vacuumassisted resin transfer molding (VARTM) [216,217], prebuilding 3D nanofiller network[215,218],and 3D printing[219,220].Among these methods, compression molding can reduce defects and air bubbles of composite laminates, and it is cost-effective for massproduction. In VARTM process, matrices are infused into fabric reinforcing materials to form composites with vacuum support as shown in Fig.14.Prebuilding 3D network,as another novel method,was used in previous research to make polyamide nanocomposites,in which the closely packed pre-built 3D MWCNTs network functioned as a backbone for the polymer matrix assembly[218].Table 3 summarizes the fabrication methods and ballistic-related performances of various nanocomposites developed for body armor and ballistic applications that have been discussed here. The incorporation of nanotechnology/nanomaterials can be seen to enhance the composite mechanical, ballistic, or energy absorption performance in varying degrees.

Table 3 (continued)

Table 3 Summary of fabrication methods, impactor type, impact velocity,and ballistic-related performances for various nanocomposites.

Table 4 Fabrication methods, impactor type, impact velocity, and performances of various ballistic and anti-impact materials developed using alternative technique approaches.

Table 4 (continued)

Table 2 Preparation methods and uniformity of different nanomaterial/matrix dispersions in ballistic applications.

4. Other approaches

While nanotechnology is extensively studied in defense areas for flexible or rigid materials due to its application flexibility and contribution to enhanced mechanical & ballistic performance,other approaches without involving nano-scaled materials are also adopted by researchers to develop ballistic and anti-impact materials in various forms and with different levels of ballistic performance.According to the material components and structures,these approaches can be mainly categorized into four directions: (1)incorporating STFs with textile materials, (2) designing sandwich structures with skin and core materials, (3) fabricating PMCs with polymer matrices, fibers, and/or reinforcing fillers, and (4) optimizing textile structures. All four approaches are briefly reviewed for the benefit of future research and development of various

Fig.13. Factors affecting the performance of high-velocity impact resistant fiber-based polymer composites with fillers [13].

Fig.14. Vacuum-assisted resin transfer molding: (a) VARTM diagram; (b) Demonstration of preparing glass fiber/epoxy/nanoclay composites using VARTM [215,216].

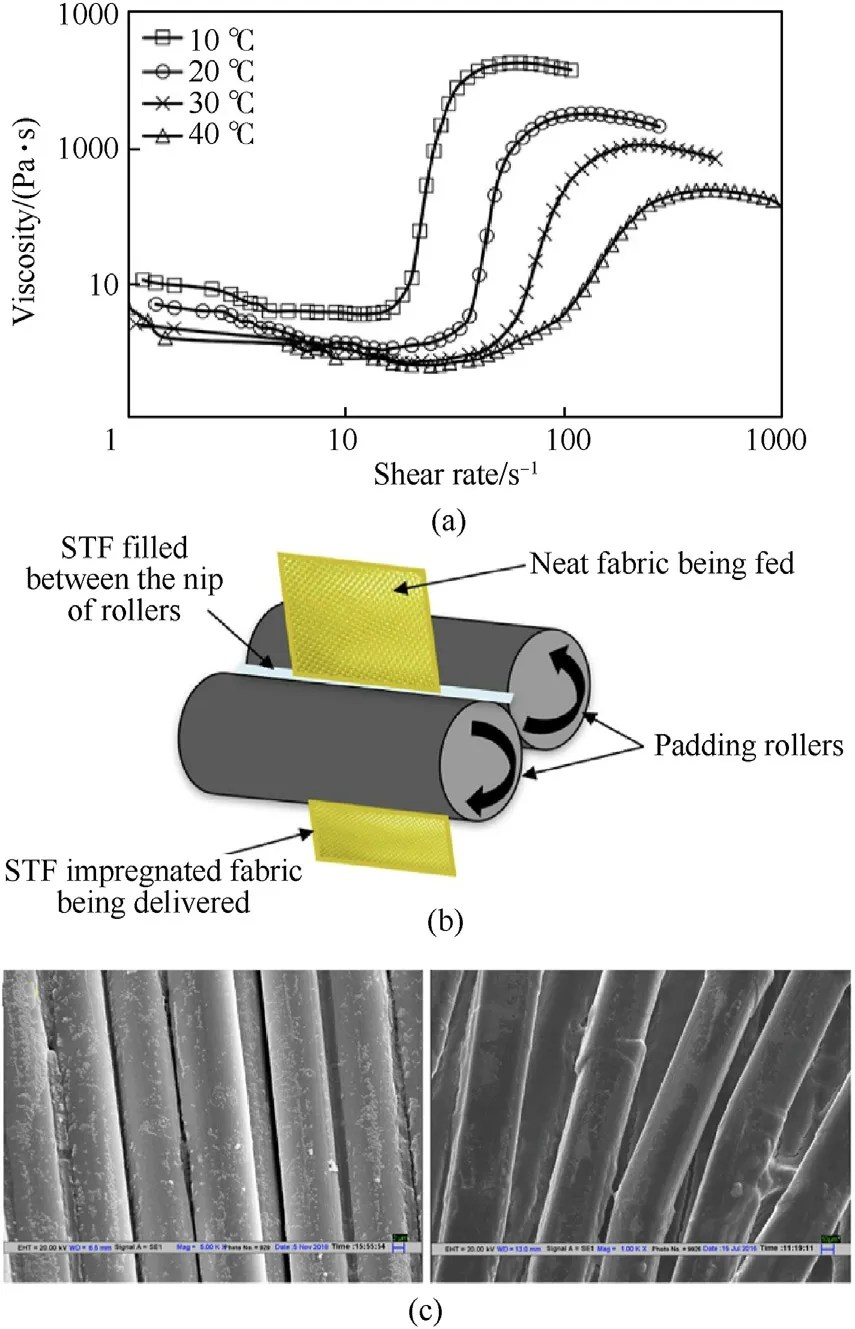

Fig.15. (a)Rheological behavior of the silica/PEG STF at varying temperatures (b) Diagram of fabric impregnation with STF; (c) SEM images of STF treated Kevlar® (left)and Spectra® (right) fabrics [229].

4.1. Shear thickening fluid incorporation

Shear thickening fluids are fluids or gels that are composed of highly concentrated small particles (e.g. silica, calcium carbonate)dispersed in hygroscopic liquid polymers (e.g. polyethylene glycol(PEG),ethanol)[225].As dense colloidal suspensions,STFs possess special shear rate vs viscosity characteristics. Their viscosities rise rapidly in response to high shear rate or shear stress. Therefore,under high-velocity impacts,STFs transmit from liquid mixtures to solid-like states [226]. Due to this special ability, STF are often incorporated into soft ballistic fabrics and damping devices. After being treated with STFs, fabric substrates may show improved energy absorption ability and impact resistance, especially under 200-300 m/s velocity impact[227].This is attributed to the friction increase between yarns and fibers, better load transfer on treated fabrics, and shear thickening behavior of STFs [227]. While the friction increment and shear thickening effects significantly affect the impact resistance of treated textiles under low-impact velocity.STF induced inter-yarn friction contributes to most of the impact resistance enhancement under high-velocity impact [63]. In the literature, STFs (e.g., silica/PEG) have been incorporated with different textiles to improve their impact resistance and ballistic performance. Some such textiles include Kevlar® fabrics, Heracron® fabrics, Kevlar® 3D-mats, multilayered HMPP fabrics,Spectra® fabrics, and Dyneema® yarns [227-231]. Different fabrication methods such as impregnation, spray coating, filling in cores of sandwich panels, fabric-STF composites were used. For example, silica/PEG STFs were incorporated with Kevlar® and Spectra® fabrics by impregnation to form soft armor materials.Increasing temperature was found to decrease the shear thickening property of the STF, and the impregnated filaments were partially covered by silica particles (Fig. 15). Both STF addition and panel stacking angle showed significantly effects on the impact energy absorption of fabricated materials,the impact energy absorption of STFs treated Spectra® and Kevlar® fabric panels (4 layers)increased up to 58% and 27%, respectively(Fig.16) [229].

Fig.16. Normalized impact energy absorption of neat and STF impregnated fabrics with different stacking angles: (a) Spectra®; (b) Kevlar® [229].

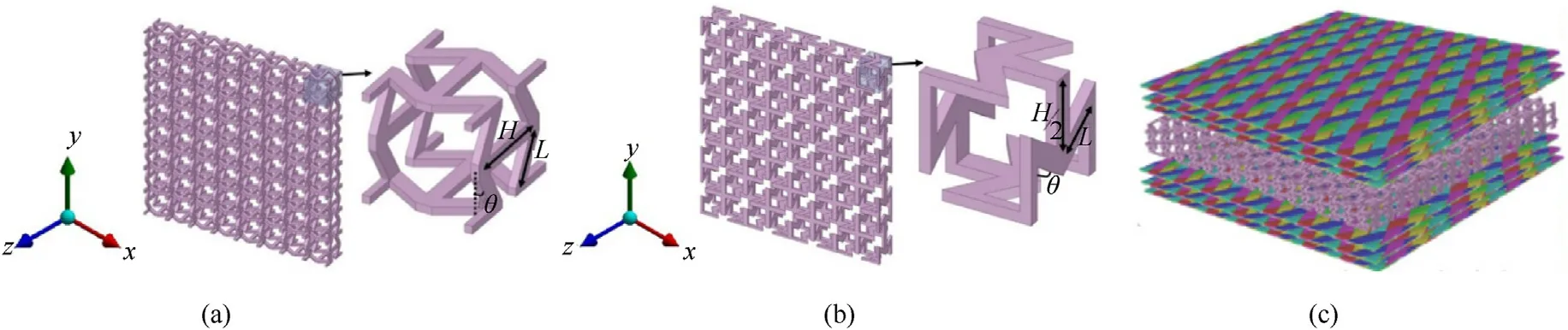

Fig. 17. Schematics of (a)-(b) the fabrication process for Kevlar/silly putty sandwich structure; its morphologies: (c) flat, (d) bent, (e) around the arm; shear-hardening behaviors of the SP/CaCO3 core: (f) soften by self-weight, (g) resist deformation under impact [236].

In fabric/STF systems, various factors were found to affect the impact resistance of materials for defense and protective applications including rheological properties of STFs, textile structure,impact location, etc [232-234]. The specific factors affecting rheological properties of STFs have been clearly discussed in a previously review, which include the particle factors (volume fraction, aspect ratio, size, size distribution, particle-particle interaction, hardness,roughness, and modification), additives, medium types,and temperature[63].Detailed shear thickening mechanism for STFs can also be found from the review. Thus, both aspects are not expanded here. Although the STF approach is widely reported in ballistic impact area,it has several shortcomings regarding STFs such as (1) its low environmental resistance (2) low-performance stability (e.g. peak viscosity and critical shear rate), due to temperature change, and (3) its significant effect on textile weight[235]. To summarize, STF approach is often used with STFs and high-performance fabrics to fabricate flexible ballistic materials for applications such as soft body armors.Improved energy absorption and impact resistance of STF coated fabrics can be achieved due to increased yarn and fiber friction, better stress transfer, and shear thickening behaviors of STFs. However, their sensitivity to environmental factors and temperature may lead to low performance stability of the final products in practical usage,therefore it needs to be considered during application. Besides, a high STF add-on may result in a large weight increase for final body armor products limiting the movability and reducing the comfort of users. Thus, a balance between weight increase and performance enhancement needs to be reached.

4.2. Sandwich structure

Unlike the STF approach focusing on the incorporation of STFs on fabrics,sandwich structure approach emphasizes the design and fabrication of sandwich composites comprising thin face skin materials and core materials with high thickness and low density.Core materials are sandwiched between face sheets.Thin materials such as aluminum alloys and fiber-reinforced polymers (e.g., glassepoxy, carbon-epoxy) are used for high-strength and stiff face skins, while low-density materials are used for core structures to enhance the strength and dissipate energy. The core materials can be in different forms such as honeycomb,corrugated,tubular,foam(with polymers, aluminum, etc.), and homogeneous monolithic(with balsa wood, etc.) [236]. For polymeric foam core materials,polymers such as polyvinyl chloride, polyethylene terephthalate,and polyurethane can be suitable[237].To bond the face sheets and foam cores, epoxy-based adhesives are often applied. With proper selections of the core material, skin material, and fabrication method, a sandwich material can achieve higher specific strength and stiffness than regular fiber-matrix composite laminates and metal materials. Sandwich structures are broadly studied for antiballistic impact and secondary aircraft materials due to their advantages of weight reduction, acoustic damping, thermal insulation,corrosion resistance,impact absorption,low cost,and easyto-process [238]. For their fabrications, it has been demonstrated that several factors regarding the skin and core materials may impact their mechanical properties, energy absorption, and damage resistance. These factors include(1)type,thickness,and layup of the skin material, and (2) type, density, thickness and crush properties (e.g. strength and stiffness) of the core material[239-241]. Higher core density may have a positive or negative effect on the material properties for different materials, while increasing the crush strength of core material can enhance impact resistance of the sandwich material.

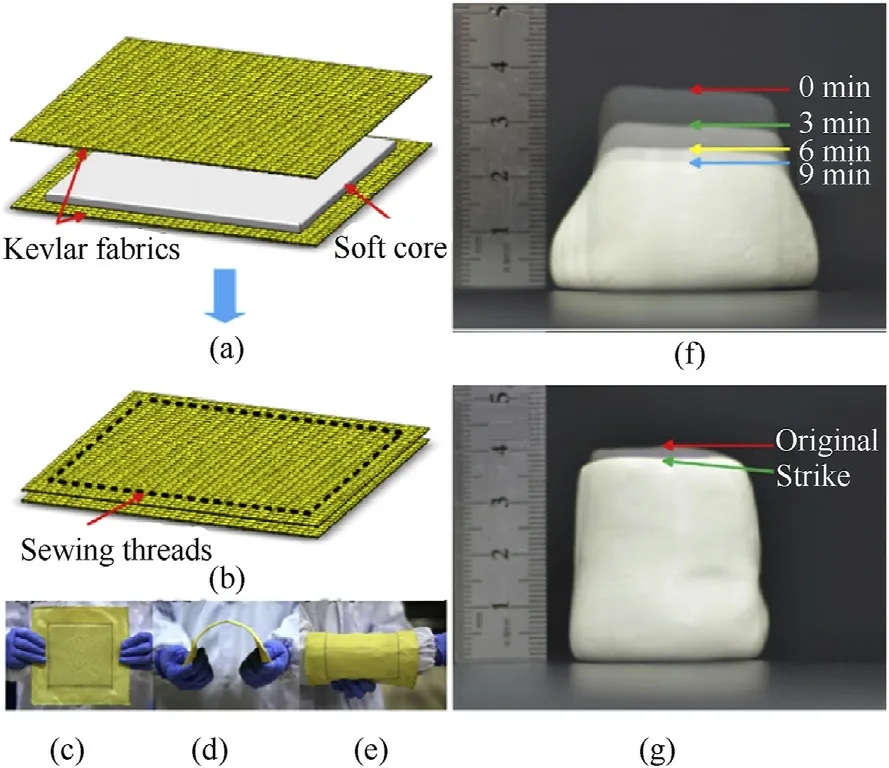

A soft sandwich structure was previously fabricated with two layers of Kevlar face sheets and a silly putty (SP) core. The SP core contains polyborodimethylsiloxane and different amounts of CaCO3particles [236]. Fig.17 shows the fabrication process and the soft sandwich material in different shapes. Also included in this figure are the deformation behaviors of the core material under normal and impact conditions. Due to the shear hardening benefit of the silly putty core, the developed Kevlar/SP-CaCO3-60%/Kevlar sandwich material could resist higher velocity ballistic impact and achieve 60%higher energy dissipation than the neat Kevlar/Kevlar material. And Kevlar/SP-CaCO3-50%/Kevlar showed 63% higher energy dissipation under ballistic impact than it under low-velocity impact based on the same impact energy[236].With the improved ballistic performance, this soft sandwich structure with SP core shows a great potential in ballistic protective materials, especially flexible personal body armors. In another research, a new auxetic sandwich structure composed of semi-auxetic braided face sheets and 3D re-entrant lattice A or B core was proposed for anti-impact purposes.Fig.18 presents the geometric description of the two 3D lattice cores and the schematic of the corresponding sandwich structure. Compared with the conventional non-auxetic sandwich material, the fabricated lightweight auxetic sandwich structures show higher energy absorption(37%higher with lattice-A core,49%higher with lattice-B core) and good stiffness under high-velocity impacts [242]. Similarly, other papers also studied the ballistic or anti-impact performance of sandwich structured materials with variable factors including skin materials, skin thickness, core materials, core density, core thickness, etc [243-247]. Overall, the sandwich structure approach is mostly used to develop strong and rigid impact-resistant materials for hard ballistic structures and aerospace applications. Since metal materials such as aluminum alloy sheets and stiff fiber-reinforced polymers are commonly used as face materials, and thick core material is sandwiched to absorb and dissipate energy.This sandwich combination not only reduces the chance of bullet penetration due to strong and stiff face materials but also largely increases the energy absorption and dissipation from impacting bullets due to low-density and highthickness core materials. Compared to STF method, sandwich structure method leads to stiffer materials with much higher antiimpact performance and protection levels.

Fig.18. Geometric schematics of (a) 3D lattice-A; (b) 3D lattice-B; (c) The auxetic sandwich structure used [242].

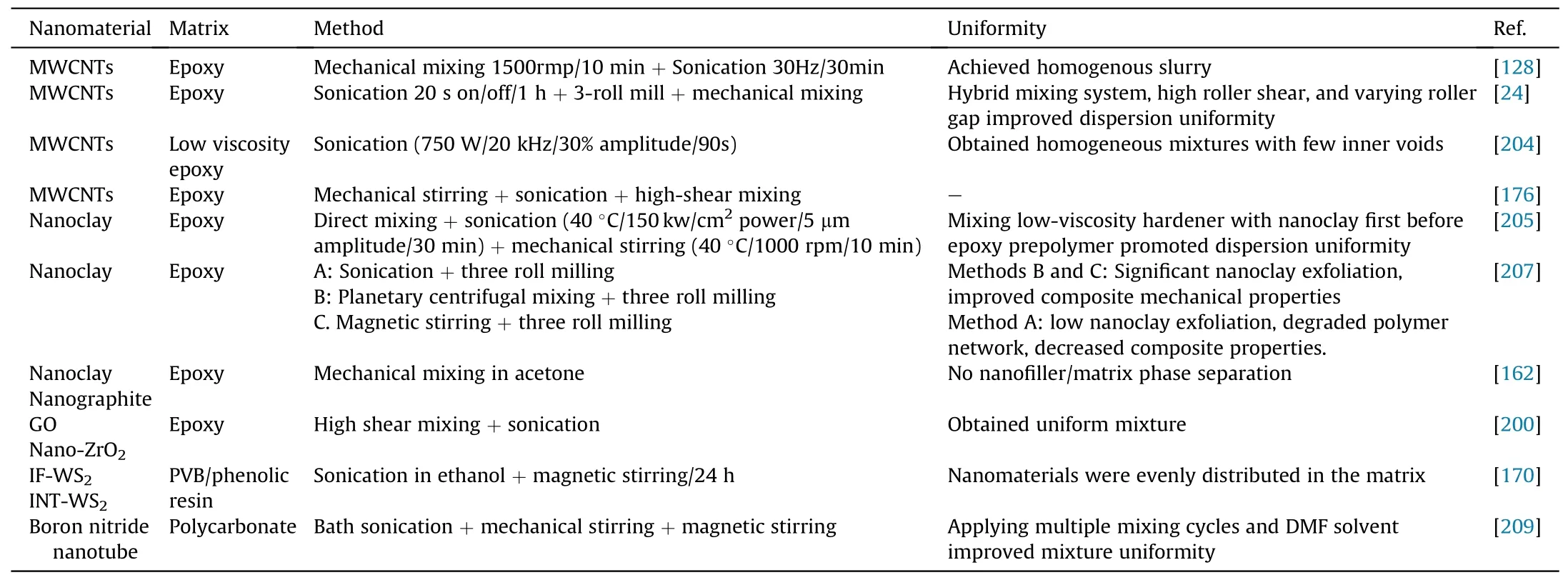

4.3. Polymer matrix composite

Unlike nanocomposites with reinforcing nanofillers, polymer matrix composites are made with thermoset or thermoplastic polymer matrices,textiles,and/or non-nano fillers[47].Depending on the reinforcing materials, they can be divided into PMCs enhanced with particles,short fibers,continuous fibers,and fabrics.PMCs are stronger than pure polymer materials and lighter than conventional metals. By controlling the components and fabrication methods, the properties and forms of PMCs can be manipulated to meet different demands for varying applications [248]. In ballistic protection and anti-impact areas, PMCs, especially fiber/fabric-reinforced PMCs have been studied for rigid (e.g., inserted polymer composite plates) or flexible forms (e.g., ballistic vests)bullet-proof applications. In their fabrication processes, highperformance fibers/fabrics such as aramid, UHMWPE, and glass fibers are included as reinforcing components while polymers such as epoxy, rubber, and polypropylene are used as matrices [198].Fabrication methods such as press molding, vacuum-assisted compression molding, VARTM, and hand layup can be applied.From the literature, researchers have investigated the impact behavior of textile reinforced PMCs with variables such as fabric type, fabric orientation, polymer type, and composite thickness[249-251].

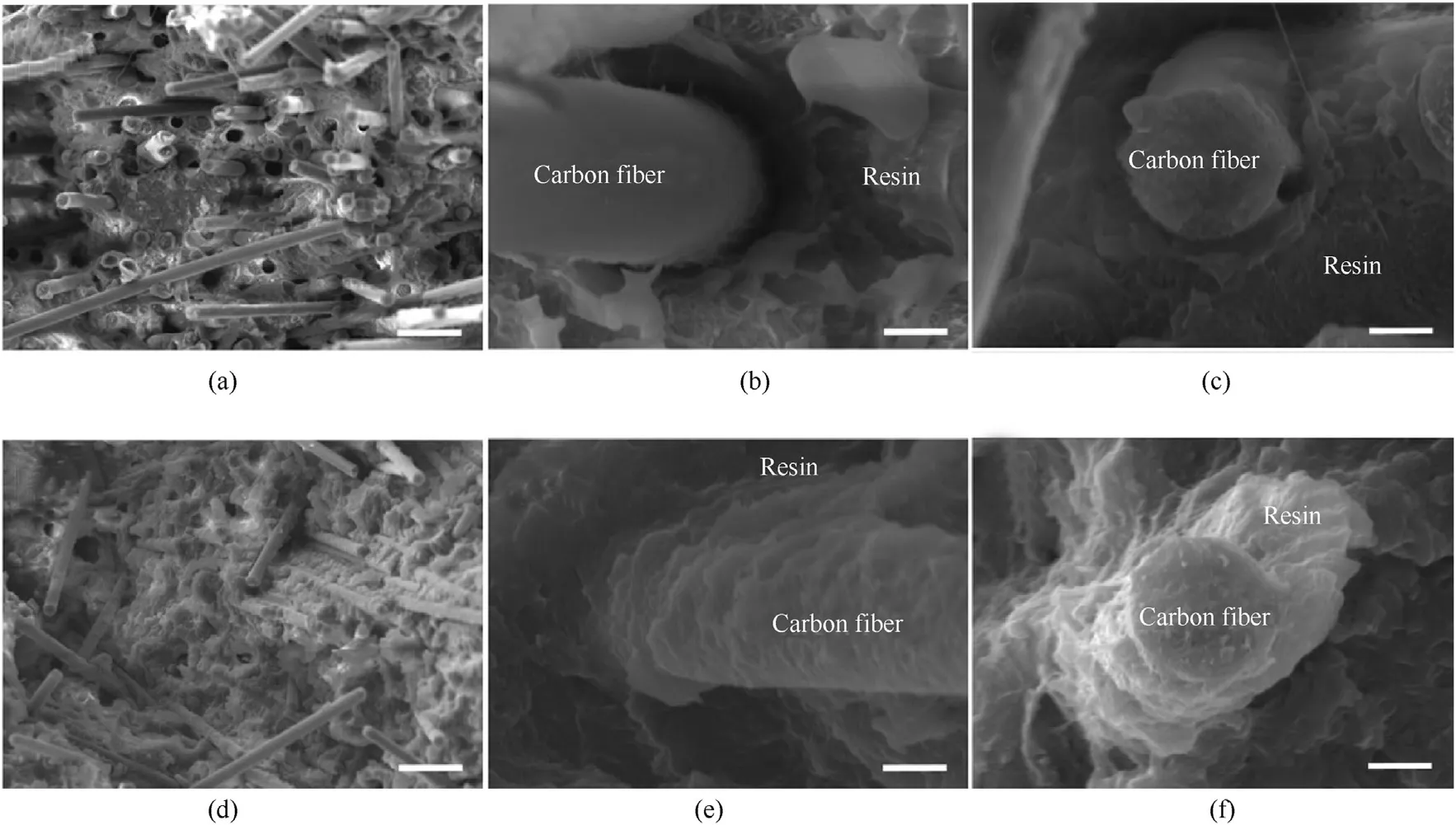

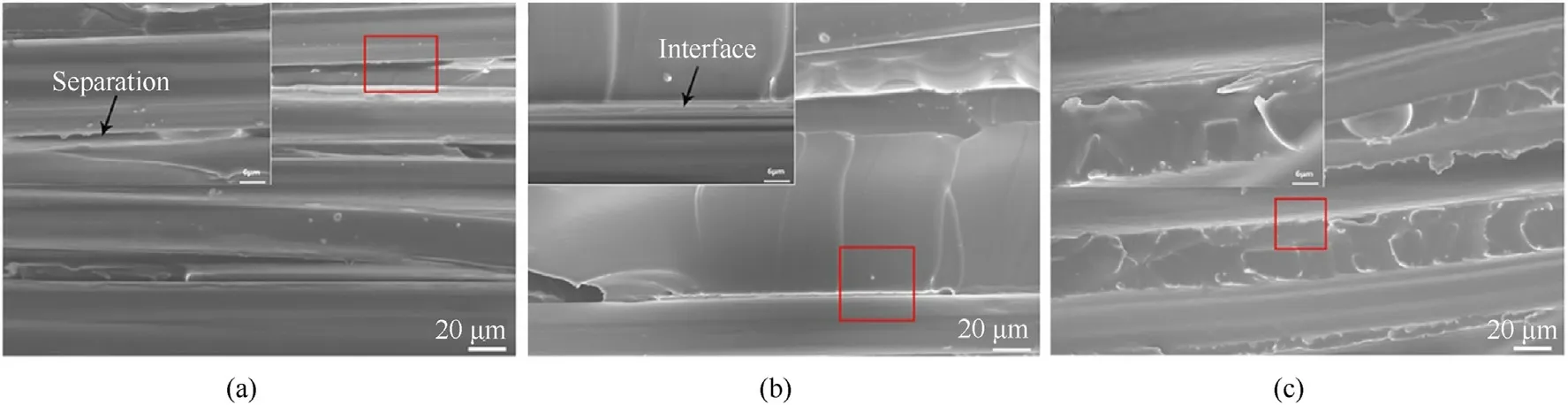

Fig.20. Fracture surface for carbon fiber/HDPE resin composites:(a)-(c)before irradiation and(d)-(f)after irradiation.The scale bar is 30 μm for(a)and(d),and 3 μm for(b),(c),(e),(f) [255].

Fig.21. Fracture surfaces of the UHMWPE/Epoxy composites prepared with neat or surface modified UHMWPE fibers:(a)neat(b)tannic acid-Na+coated-3 h;(c)coated-6 h[256].

For instance,mixing natural piassava fibers and epoxy matrix to fabricate fiber-reinforced PMCs through press molding was reported in a previous work. The ballistic behaviors of the materials were investigated with varying amounts of piassava fibers(10 vol%,20 vol%, 30 vol%, 40 vol%, 50 vol%) against high impact energy ammunition.The results indicated that the composite with 50 vol%piassava fibers achieved the highest energy absorption among all specimens and it showed comparable results to that of Kevlar fabrics[115].In general,fiber reinforcement is mostly used for rigid PMCs, in which fibers are uniformly distributed in matrices.Whereas high-performance textile fabrics, along with proper polymer type/amount and fabrication method,can be used to make either stiff or flexible PMCs for different end-uses such as body armors, helmets, and vehicles. One previous work compared the impact resistance and energy absorption of Kevlar®/rubber and Kevlar®/epoxy composites with their pure polymer counterparts under high-velocity impacts. The results suggested the flexible Kevlar/rubber composite obtained higher energy absorption than that of the control. Whereas incorporating thermoset epoxy negatively affected the ballistic performance of the material by restricting its deformation under impact [47]. Additionally, mechanical properties and ballistic performance of PMCs can be enhanced by improving the textile/polymer matrix interface adhesion [252]. For instance, as shown in Fig. 19, the pineapple leaves (PALF) have a naturally rough surface morphology, which allows for efficient penetration and anchoring of the epoxy matrix,resulting in good interface adhesion. Because of the strong adhesion,the load was transferred more efficiently from the PALF to the composite matrix, resulting in PALF composites with a higher Young's modulus (301%) and tensile strength (251%) than those of the coir composites [253,254]. Similarly, Fig. 20 and Fig. 21 investigate the fiber matrix interaction in carbon fiber/HDPE and UHMWPE/Epoxy composites respectively [255,256]. It was found surface modification by composite irradiation or fiber surface coating with tannic acid-Na + could enhance the fiber/matrix bonding leading to improved mechanical properties for the PMCs.

To sum up,PMCs can be used for soft or rigid ballistic and antiimpact materials based on the material components and fabrication methods. With the presence of textile and/or filler materials,PMCs can obtain enhanced impact resistance and energy absorption ability than pure polymer materials. While fiber-reinforced and filler-reinforced PMCs are often used for rigid protective materials, fabric-reinforced PMCs are investigated for soft armor materials when a low amount of polymer matrix with high flexibility is applied or rigid armor materials otherwise.PMCs are mostly stable to different environmental factors due to the high stability of matrices after drying or curing. However, mechanical and energy absorption performance of PMCs largely relies on the distribution uniformity of the components and fiber/matrix or filler/matrix interfacial adhesion. In preparation, surface modification may be conducted for hydrophobic textiles and/or chemically inert fillers to improve the component distribution uniformity, bonding adhesions, and therefore, PMC properties.

4.4. Textile structure optimization

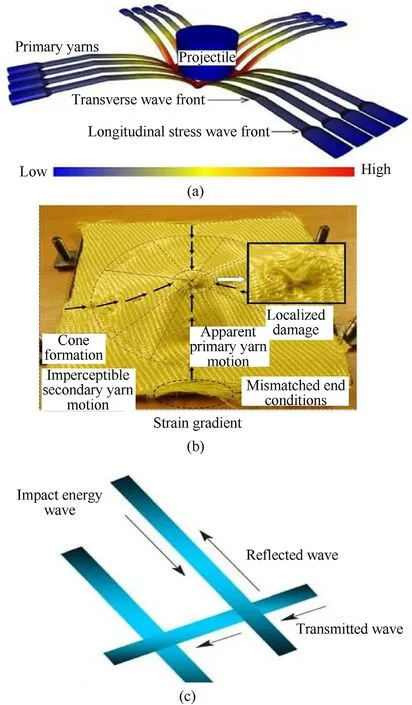

Textile structure optimization can be achieved by manipulating the fiber, yarn, fabric, and laminate structures to improve the ballistic performances for textile materials. In contract to all other methods mentioned, textile structure approach involves only textile materials and no polymer matrices or filler materials.Before outlining the factors affecting the ballistic performance of textiles,the ballistic impact mechanism on fabrics needs to be quickly reviewed. When a bullet impacts with a single layer of fabric, it creates both transverse waves(out of fabric plane)and longitudinal waves(in the fabric plane),the longitudinal waves propagate away with time along the axes of primary yarns from the impact center.Meanwhile, the fabric undergoes transverse conical-shaped deflection and longitudinal strain deformation in primary yarns towards the impacted area (Fig. 22(a) and Fig. 22(b)). At the beginning of the impact, only a small amount of strain occurs around the impact area,with increasing time and strain caused by stress,the transverse wave quickly moves along the yarn axes and transmits to yarn adjacent points and neighboring yarns for energy absorption and dissipation(Fig.22(c)).And in the transverse wave direction, fabric material often floods in the opposite direction of the impact, towards the thicker area of the fabric [1,257]. The propagation speed of a transverse wave on a fabric largely depends on factors such as the fiber contents,fabric structures,and Young’s modulus of the fabric, yarn volume density, and fabric density. In neat ballistic fabrics, most of the projectile energy stress is distributed on primary yarns [258]. The stress wave propagates along the primary yarns and dissipates in the forms of yarn kinetic energy,strain energy,yarn failure,and frictional sliding energy[1].Secondary yarns are not fully stretched due to the weave structures.Therefore, to improve the energy absorption capacity of textile materials, various factors can be investigated or optimized including fiber type and parameters, fabric structure (e.g. woven/nonwoven, weave type, 2D/3D), fabric ply number, laminate stacking order, stacking angles, etc [259-262].

Fig. 22. Ballistic impact mechanism and result: (a) impact response schematic of the primary yarns from a layer of armor fabric, (b) Kevlar panel after ballistic test, and (c)wave propagation and transmission among yarns [1,263-265].

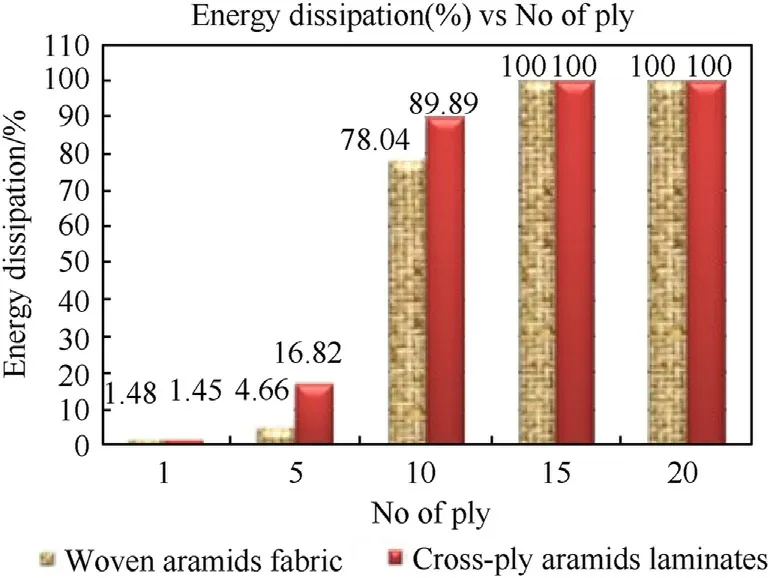

Fig. 23. Energy dissipation of woven and cross-ply aramid materials based on the number of fabric layers [260].

Various research has been conducted to understand the influence of textile structures (e.g. fabric types, yarn density, yarn stitching, weave types, fabric thickness, fabric crimp, and fabric architecture)on the ballistic performance and energy absorption of textiles, in the forms of yarn, fabric or fabric laminate [266-271].For example, one paper investigated the effects of fabric structure(woven or 0/90 cross-ply)and number of layers(1,5,10,15,20)on the ballistic performance of aramid fabric panels under projectile impact (390 m/s). It was suggested the cross-ply aramid laminate had higher energy dissipation than the woven fabric laminate with 5 and 10 layers(Fig.23).And a minimum 1 and 6 layers of cross-ply and woven aramid fabrics are required to stop the projectile,respectively [260]. For woven fabrics, it is difficult to maintain the equal position for warp and filling directions for certain layers.And the material performance is negatively affected by the uneven status of stacked fabrics.Similarly,another publication showed that the unidirectional Kevlar® fabric panels absorbed 12.5%-16.5%more energy than the woven Twaron® fabric panels based on the same areal density indicating the energy absorption ability of textile materials is strongly depended on their structures [272].Additionally, the effects of weaving structures (plain, basket, twill,and satin weaves) of Twaron® fabrics on their ballistic impact resistance were investigated. One-layer fabric model with each weave type was subject to the projectile ballistic impact(velocity of 84 m/s). The projectile showed different velocity history and specific energy loss representing fabric energy absorption with varying woven structures (Fig. 24). The highest energy absorption was obtained from the plain weave fabric due to its better stress concentration at the impact center [269]. Overall, the textile structure optimization approach is only depended on the architectures of textiles in various forms to enhance material ballistic performance.No additional components (e.g., polymer and small particles) are required.Therefore,no additional non-textile weight is added,and the comfort and flexibility of ballistic textiles can be largely maintained. However, due to the limitation of textile materials, the ballistic performance of optimized materials is still much lower compared to most materials developed using other approaches such as sandwich structure and PMC.The potential applications of optimized textile materials are soft body armors and other flexible protective products.

Fig. 24. (a) Velocity history of the projectile and (b) its specific energy loss (fabric energy absorption) during the impact event [269].

Fig. 25. Peak force and total energy absorption of single-layer UHMWPE (PE), very high-modulus aromatic (A), and their STFs treated counterparts (PE*, A*) during the dynamic impact tests [279].

Fig.26. (a)Back face signature of the 10 fabric panels comprising unidirectional UHMWPE fabric(U),very high-modulus aromatic fabric(A),woven UHMWPE fabric(PE),and their STF treated counterparts (*); (b) pictures of the bullet deformation after ballistic tests on the fabric panels [279].

All main techniques and approaches mentioned in sections 3 and 4 are categorized based on the incorporation or manipulation of nanomaterial, STF, sandwich structure, PMC, and textile architecture. In research, hybrid methods are often adopted to further enhance the ballistic and impact resistance of different materials.In the literature, various method combinations have been reported such as PMC/textile architecture [273-275], PMC/sandwich structure [244,276], nanomaterials/STF [277,278], textile architecture/STFs [279], PMC/nanomaterials/STF [280], sandwich structure/nanomaterials/STFs[32].For instance,in a published paper,ten soft body armor panels were fabricated. Different components including UHMWPE woven fabrics (PE), very high-modulus aromatic polymer (VHMAP) fabrics (A), UD UHMWPE (U) fabrics, and STFs(*)were used.The effects of STF incorporation,fabric type,and fabric stacking sequence on the ballistic performance were investigated. The results indicated that incorporating STFs significantly enhanced the peak force and total energy absorption of single-layer UHMWPE (~19% and ~90%) and VHMAP woven fabrics (~52% and~133%) during dynamic impact tests (Fig. 25). All specimens with UD fabrics at the striking face had lower BFS than 33 mm,while the A/PE*/U panel yielded a large BFS of 39.6 mm (27.5% higher than the least one from U/PE/A*)(Fig.26(a)).This result was confirmed by the bullet deformation degree after ballistic tests(Fig.26(b)),all bullets tested on specimens with UD fabrics at the striking face showed more severe deformation than the rest after the first shot.Based on the results,this paper proposed a promising textile panel structure for higher ballistic performance, which comprises a striking face with high modulus UD fabrics,and a rear side with STF incorporated very high modulus woven fabrics [279]. To compare different alternative approaches, Table 4 presents the fabrication methods,impact test,and performances of ballistic and anti-impact materials developed using alternative techniques mentioned in this section.

Among reviewed approaches, the STFs and textile structure optimization methods are often adopted to make flexible ballistic materials with enhanced impact-resistance. The fabricated materials can provide protection against handguns up to level IIIA.However, low performance stability of STFs with varying temperatures and other environmental factors may limit the application of STFs in armor materials.Also,the STF amount on fabrics needs to be strictly controlled for lightweight purpose. In contrast, the textile structure method requires no additional materials other than highperformance textiles. It is much easier to process and less costly.But the property enhancement due to textile structure optimization is limited by the nature of textiles. When PMC or nanotechnology approach is selected,both stiff and flexible ballistic and anti-impact materials can be fabricated depending on the fabrication conditions. In PMCs, polymer matrices with textiles and/or non-nano filler particles are used, while in nanocomposites, nanofiller with textiles and/or polymer matrices are incorporated. The fabricated materials in different forms provide a broad range of ballistic protection from level IIA to III against handguns and rifles. And incorporating nanomaterials with large surface area-to-volume ratios may lead to dramatically increased impact resistance and energy absorption capacity of the matrices and/or textiles. However, possible nanomaterial-related issues such as difficulty for dispersing nanomaterials and poor nanofiller/fiber adhesion need to be solved.At last,materials developed with sandwich structures are mostly stiff with rigid skin materials, however more flexible sandwich composites are being developed for ballistic uses in recent years.With metal or rigid composite materials used as skin components and materials with high energy absorption ability used as core materials,sandwich composites can achieve extremely high ballistic protection up to level III(against riffle).However,due to the high thickness of core materials and rigid skin materials,most sandwich composites are bulky and stiff. Therefore, they are more suitable for military armored vehicles and anti-impact aircrafts than for body armors.

5. Conclusions and prospects