Recent advances in application of moving bed bioreactors for wastewater treatment from recirculating aquaculture systems: A review

Abubkr Shitu , Gng Liu , Aliyu Idris Muhmmd , Ydong Zhng ,Mus Abubkr Tdd ,, Wnhe Qi , Dezho Liu , Zhngying Ye , Songming Zhu ,*

a Institute of Agricultural Bio-Environmental Engineering, College of Bio-systems Engineering and Food Science, Zhejiang University, Hangzhou, 310058, China

b Key Laboratory of Equipment and Informatization in Environment Controlled Agriculture, Ministry of Agriculture, Hangzhou, 310058, China

c Department of Agricultural and Environmental Engineering, Faculty of Engineering, Bayero University, Kano, 3011, Nigeria

Keywords:

Ammonia removal

Bio film carriers

Sustainability

Salinity

Nitrogenous compound

Accelerated start-up

A B S T R A C T

In recent years, government investments in implementing restrictive public policies on the treatment and discharge of ef fluents from the aquaculture industry have increased. Hence, efficient and cleaner methods for aquaculture production are needed. Recirculating aquaculture systems (RAS) offers water conservation by recycling the treated aquaculture water for reuse. RAS wastewater treatment using a moving bed bioreactors(MBBRs) process has been considered well suited for maintaining good water quality, thereby making fish farming more sustainable. Currently, improvements were achieved in tackling the influence of salinity, organic matter, disinfectant, and bioreactor start-up process on the MBBR performance efficiency. This review highlights an updated overview of recent development made using MBBR to treat the residual water from RAS. Precisely,nitrification and simultaneous nitrification-denitrification (SND), and other hybrid processes for nitrogen removal were elucidated. Finally, future challenges and prospects of MBBRs in RAS facilities that need to be considered were also proposed.

1.Introduction

Aquatic products have become an essential commodity in the global market. It has been estimated to approximately worth around US $ 250 billion (FAO, 2020). Because of economic benefits, a large number of research and development projects have been in progress. The increasing demand for food due to the fastest growing world human population and increasing higher living standards have necessitated the aquaculture industry to expand its production capacity to meet the market demand (Torno, Naas, Schroeder, & Schulz, 2018). The latest report released in March 2020 has indicated that world aquaculture production has recorded about 82.1 million tons in 2018 and is expected to reach 140 million tons in 2050 (FAO, 2020). However, conventional aquaculture production has been criticized for adverse environmental effects, greenhouse gas (GHG) emissions, water pollution and eutrophication, and destruction effects on mangrove forests (Ahmed &Turchini, 2021). Further, the increased environmental control, stringent standards regulations on wastewater discharge to water bodies, and water scarcity necessitated exploring best water management practices in aquaculture industries (Davidson, Good, Welsh, & Summerfelt, 2014;FAO, 2018). This is urgently required to minimize the environmental impact by reducing both water intake and ef fluent discharge to ensure optimal production (Ng, Ng, Mahmoudi, Ong, & Mohammad, 2018).Therefore, this made it possible for land-based recirculating aquaculture systems (RAS) to gain more attention globally (Chen et al., 2021; Ng et al., 2018). In RAS, water is continuously flowing in a closed circuit by pumps.

The indoor aquaculture production using RAS technology seems sustainable due to its environmental compatibility, in finitely expandable, producing higher yields by utilizing a small space and less vulnerability to disease (Boaventura, Miranda- filho, Or´e fice, Luz, & Luz,2018; Qi, Zhu, Shitu, Ye, & Liu, 2020). RAS allowed water conservation by recycling 90–99% of its water for reuse compared with conventional aquaculture systems, an essential aspect of water and energy-scarce areas (Gichana et al., 2018; Zhu et al., 2016). RAS has controllable cultural conditions over other aquaculture production systems, which is advantageous to the purging of fish for marketing (Azaria & van Rijn,2018). Moreover, it is one of the potential emerging technologies that have a less environmental impact (Yogev & Gross, 2019). Food and Agricultural Organization (FAO) of the United Nations (UN) has put forward more efforts in promoting sustainable aquaculture production,which is mainly represented by RASs (FAO, 2018). The most crucial water treatment in RAS is the oxidation of harmful nitrogenous waste compounds (Kinyage, Pedersen, & Pedersen, 2019). In this case, treatment of RAS wastewater using a biological treatment process has been considered a feasible method, mainly due to its economic advantage,efficiency, and environmentally friendly technique (Liu, Li et al., 2019;Rahimi, Modin, & Mijakovic, 2020; Waqas et al., 2020).

Among various types of biological treatment techniques, many studies have reported successful application of moving bed bio film reactors (MBBRs) for both small- and large-scale commercial fish farms(Gonzalez-Silva, Jonassen, Bakke, Østgaard, & Vadstein, 2016; Luo,Hou, Tian, & Tan, 2020; Pulkkinen, Kiuru, Aalto, Koskela, & Vielma,2018). MBBRs also called “bio film slurry reactors” combines the advantages of suspended and attached bio film growth processes onto freely mobile suspended carriers inside bioreactor (Narayanan & Narayan, 2019). Compared to conventional activated sludge (CAS) system,primary advantages associated with MBBR is its compactness, simple mode of operation, a lower hydraulic retention time, less space requirement, elimination of sludge recirculation, and can operate at a high loading rate (Kinyage et al., 2019; Zhang et al., 2016). MBBRs is a well-studied field, and numerous researches have been done extensively all over the globe. Additionally, numerous reviews have been published that discuss the MBBR application to treat different forms of wastewater.Leyva-Díaz, Monteoliva-garcía, Martín-pascual, Munio, and García--mesa (2020) performed a comprehensive review of several case studies of real wastewater treatment plants that use MBBRs. Their findings highlighted the potentials of MBBR to provide high-quality reclaimed wastewater and recovered waste pollutants for reuse in a circular economy model. Nur, Abu, Abu, and Wahab (2018) provided an insightful study of MBBRs application to treat palm oil mill wastewater.di Biasea, Kowalskia, Devlina, and Oleszkiewicz (2019) reviewed recent advancements of MBBRs applications for biological oxygen demand(BOD), chemical oxygen demand (COD), and nutrients removal from municipal wastewater. Leyva-Díaz, Martín-Pascual, and Poyatos (2017)conducted a review of various research work on novel biological processes using pure MBBR, hybrid MBBR with membrane bioreactors(MBR), or/and a settling tank for improved better performance of conventional ef fluent treatment processes. Both studies reported the application of MBBR for various forms of wastewater under different conditions but did not report on RAS wastewater treatment using MBBRs.

Indeed, recent findings pertinent to the MBBRs applications in treating both freshwater (FW) and seawater (SW) - RAS wastewater under various strategy has been documented. Besides, most of the published literature was fragmented and recorded in different locations.Thus, the need for a review and summary of recent progress made on the MBBRs application in RAS is inevitable. Hence, this review aims to provide an updated overview of advancements in applying MBBRs in treating residual water from RAS by conventional nitrification and the simultaneous nitrification-denitrification pathways. Finally, the challenges and prospects of MBBR technology in the RAS industry that require a greater focus were presented.

2.Characteristic of RAS wastewater

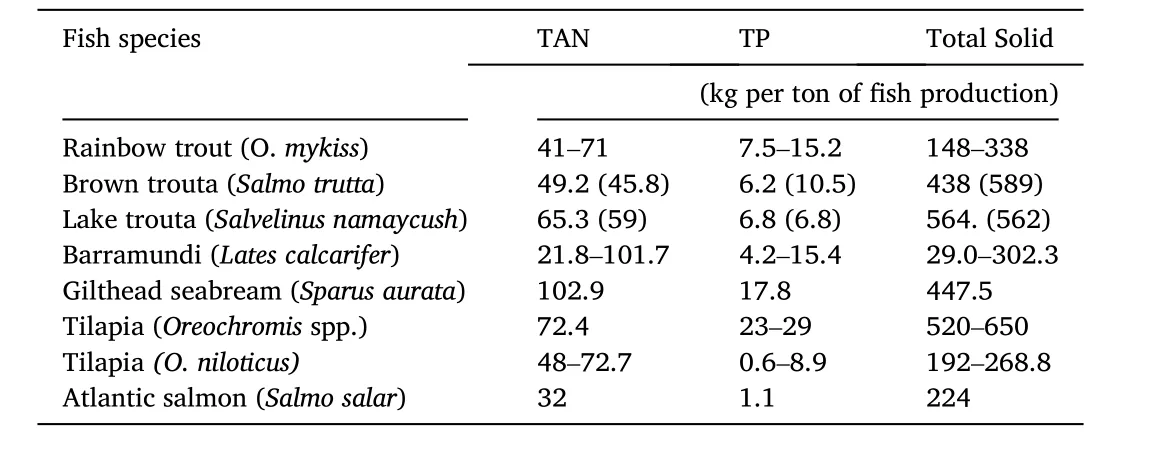

According to van Rijn (2013), RAS wastewater nutrients and solids composition reported in previous literature generated from different cultured species is presented in Table 1. For example, RAS wastewater from Rainbow trout (Oncorhynchus mykiss) contains total solids (TS) of 148–338, total phosphorous (TP) of 7.5–15.2, and total nitrogen (TN) of 41–71 kg per aquatic fish production, respectively. As can be observed,the highest and lowest TP generated were recorded by Tilapia (Oreochromisspp.) and Atlantic salmon(Salmo salar)with 1.1 and 23–29 kg per fish production, respectively (Table 1). Meanwhile, Gilthead seabream(Sparus aurata)and Atlantic salmon (Salmo salar) recorded the highest and lowest TN generation of 102.9 and 32 kg per fish production.

Table 1Waste production of different fish species determined by the nutritional approach. Reproduced with permission from van Rijn (2013) Copyright (2020)Elsevier.

In another study, wastewater discharges differ from one species to another and depend on the growth stages of that species attributed to the amount of feed, feedstock characteristics, biomass utilization, and stocking density (Tanveer, Moulick, & Mukherjee, 2020). Depending on the feed conversion ratio, Hu, Lee, Chandran, Kim, and Khanal (2012)estimated that approximately 0.75 kg for every 1 kg of input nitrogen in the fish feed is released into the water as a nitrogenous waste in the aquaculture system. Other studies reported that the concentrations of total ammonia nitrogen (TAN), phosphate (PO43−), and COD in aquaculture wastewater were typically in the ranges of 2.5–10, 1–18, and 30–150 mg/L, respectively (Daneshvar, Antikainen, Koutra, Kornaros, &Bhatnagar, 2018; Díaz, Ib´añez, G´omez, Urtiaga, & Ortiz, 2011).

3.Performance of MBBRs in RAS wastewater treatment

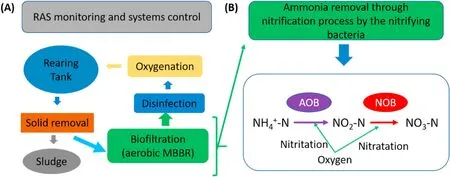

Among the RAS operating principle is the treatment of wastewater generated from the fish rearing tank for its reuse in the system. Pulkkinen et al. (2018) have indicated that in RAS, water quality management constituted a vital aspect of fish productions. RAS wastewater contains nitrogenous waste, suspended inorganic particles, and many bacterial flocs that originated from the leftover feed, fish feces, dead fishes, and bacteria, as demonstrated in Fig. 1A (Rojas-tirado, Pedersen,& Pedersen, 2017). These substances decreased water quality and can be toxic to aquatic life (Rojas-tirado, Bovbjerg, Vadstein, & Pedersen,2019). In this respect, to prevent and provide a suitable and sustainable living environment for marine life, efficient water treatment technologies are required to remove the substances above (Dauda, Ajadi,Tola-Fabunmi, & Akinwole, 2019). RAS wastewater treatment process accomplish in various stages (See Fig. 1A). Firstly, remove suspended and dissolved organic solids using sedimentation, settling chambers,screen filter, or foam fractionator devices. Secondly, nitrogenous compound removal by microbial treatment through the nitrification process.After that, water conditioning is performed, such as disinfection and oxygenation, and carbon dioxide (CO2) stripping processes (Boaventura et al., 2018; Li, Deng, et al., 2020; Liu, Li et al., 2019). Finally, the treated water is returned to fish tanks for reuse. However, some advanced RASs are equipped with additional denitrification units (van Rijn, 2013; Yogev, Barnes, Giladi, & Gross, 2020). The main reasons for introducing denitrification unit has been reported in section 3.3.

Fig. 1.(A) Simplified unit processes in RAS operation, and (B) the nitrification process; AOB: ammonium - oxidizing bacteria and NOB: nitrite-oxidizing bacteria.

Nitrification is the transformation of TAN to nitrate (NO3–N) in the presence of dissolved oxygen (DO). It is well documented that the conventional nitrification process consisted of two essential stages involving two groups of autotrophic nitrifying bacteria and is taking place in aerobic conditions, as demonstrated in Fig. 1B. The first stage is the TAN oxidation to nitrite (NO2-N) (nitritation), which is carried out by the ammonia-oxidizing bacteria (AOB). Then, the second stage is the immediate breakdown of NO2-N to NO3–N (Nitritation), performed by the nitrite-oxidizing bacteria (NOB) (Ebeling, Timmons, & Bisogni, 2006; Ge et al., 2015). These chemolithotroph nitrifying bacteria involved in the two-step nitrification process utilized nitrite ions and ammonia molecules as their sole sources of energy for metabolism and cellular growth(Stein & Klotz, 2016). Besides, nitrifying AOB and NOB are Gram-negative bacteria species. Previous studies have reported that AOB included the genusNitrosomonas,Nitrosospira, Nitrosococcus,Nitrosovibrio,andNitrosolobus(Ge et al., 2015; Li et al., 2021). At the same time, NOB was dominated by the genera ofNitrococcus, Nitrobacter,Nitrotoga arctica, Nitrolancea hollandica, Nitrospina, and Nitrospira moscoviensis(Ge et al., 2015; Li et al., 2021).

3.1.Ammonia nitrogen removal

In the past few decades, the rapid advancement of MBBR technology has improved the treatment of wastewater in RAS facilities, particularly the removal of TAN, NO2-N, and, as primary targets. In RAS, TAN is the most critical water quality parameter. Moreover, it is believed that MBBR is very suitable for slow-growing nitrifying bacteria, which are specifically for the nitrification process in removing TAN (Piculell et al.,2016; Young, Delatolla, Kennedy, La, & Stintzi, 2017). Indeed, nitri fication is necessary for RAS for water quality maintenance (Pedersen,Oosterveld, & Bovbjerg, 2015). For this reason, several researchers have evaluated the nitrification efficiency of MBBR in both freshwater and marine RAS facilities. Different water quality parameters influencing nitrification efficiency in MBBR operating in RAS were also investigated.

Research conducted by Fernandes, Pedersen, and Pedersen (2017)studied the impact of FBBR and MBBR on micro-particle dynamics in an 8.5 m3laboratory-scale RAS. During the whole test period of the study,TAN and NO2-N concentrations in the recirculating system were kept at very low and corresponded to 0.12 ± 0.02 and 0.26 ± 0.03 mg/L,respectively, by both bio filters studied. Also, the elevated nitrate reached average concentrations ranged from 40.8 to 44.3 mg/L at steady conditions. Another study by Pulkkinen et al. (2019) investigated the effect of different combinations of FBBR and MBBR on nitrification rate,water quality parameters, and rainbow trout (O. mykiss) growth and health in a laboratory-scale RAS. The researchers recorded the highest TAN removal rates by MBBR systems with a non-significant histopathological difference in the (O. mykiss) liver tissue, kidney, and heart among the RAS treatment groups. The bio filters tested by the above researchers proved to be effective, producing the recirculating water within the acceptable limits. It was suggested that the MBBR systems’performance was superior to other bio filters (Stavrakidis-Zachou, Ernst,Steinbach, Wagner, & Waller, 2019).

The determination of nitrification efficiency of MBBR has been related to biocarrier that provided a surface for adhesion of nitrifying bio film. The volumetric TAN removal rates (VTR) from marine RAS ef fluent using three different biocarriers packed in MBBRs were explored (Pfeiffer & Wills, 2011). The three biocarriers are MB3, AMB,and K1 Kaldnes. The RASs operated under the conditions of warm water culture, brackish water (11–12 g/L), and two different daily feeds loading rates (3.5 and 8.2 kg feed/m3biocarrier). The results showed that the three media’s highest VTR were 82.5 ± 25.9, 86.1 ± 27.5, and 92.2 ±26.3 (g TAN removed/m3biocarrier/day) for K1, AMB, and MB3,respectively, during a low feeding rate. Also, it was observed that the MB3 media obtained the highest TAN removal rates at both low and high feeding rates having an average of 12.30% and 14.40%, respectively.

In a similar study, Sikora, Nowosad, Biegaj, Kucharczyk, and Dębowski (2018) investigated the performance of an agglomerate elastomer (EPP) as MBBR carriers for treating wastewater from real RAS stocked with koi (Cyprinus carpio koi) and gold fish (Carassius auratus auratus). The influent ammonia concentration reached the highest concentration of 27.85 mg/L. The researchers reported that bio filter ef fluent was maintained at stable TAN and NO2-N levels lower than 1.0 mg/L, while NO3–N concentrations reached about 78.6 mg/L. It was concluded that the EPP proved to be cost effective and perform well as a carrier media in RAS moving bed bio filter. Owatari et al. (2018)investigated the feasibility of utilizing synthetic fibre as a bio filter carrier in an FW-RAS. The study initially used 120 Nile tilapia (Oreochromis niloticus) at an initial and final stocking density of 1.97 and 6.56 kg/m3,respectively, for 60 days and finally with 480 jundia´ (Rhamdia quelen) at an initial and final stocking density of 2.81 and 11.19 kg/m3, respectively, for another 60 days experimental period. The authors reported that both TAN and nitrite in the ef fluent were kept at a concentration less than 0.5 mg/L for the experiment’s duration, which confirmed an excellent nitrification process supported by synthetic fibres as bio film carriers. More recently, Shitu, Zhu, Qi, Abubakar, and Liu (2020) evaluated TAN removal from synthetic freshwater RAS wastewater using MBBR filled with novel sponge biocarriers operated at three different hydraulic retention times (HRTs) of 24, 12, and 6 h. Their experimental results indicated that at an optimal HRT of 6 h, the MBBR system could effectively remove TAN (>92%).

3.1.1.Effect of some factors on MBBR performance

Some factors that can impair the MBBR nitrification performance in treating RAS wastewater because of their impact on nitrifying bacteria include organic matter, alkalinity, salinity, antibiotics, reactor start-up,and disinfectant (Abakari, Luo, & Kombat, 2020; Kinyage et al., 2019; Li et al., 2019; Navada et al., 2019). To obtain the required MBBR performance, several researchers studied the impact of the factors mentioned above. Therefore, this section discusses how these parameters have affected MBBR performance and included their management strategies.

3.1.1.1.Organic matter, alkalinity, and other metabolic waste.The impact of organic carbon on nitrification performance was evaluated using three bio filter types (MBBR, fluidized sand, and floating bead bio filter) operated on a large-scale RAS. The RAS system was stocked with tilapia with average biomass of 6750 kg, and the concentration of organic carbon in the influent was elevated using sucrose. The researchers recorded a TAN removal rate of 267 g/m3/day and a moderate increase in dissolved oxygen (DO) as water exited the MBBR. The result indicated that the organic carbon reduced VTR by 50% for all the three bio filters tested (Guerdat, Losordo, Classen, Osborne, & Delong, 2011).Similarly, a decrease in TAN removal efficiency of about 40% has been recorded at a carbon-nitrogen ratio (C/N) of 4 for dissolved carbon in an MBBR treating RAS wastewater (Michaud et al., 2014). Navada, Knutsen, Bakke, and Vadstein (2020) reported a decrease in nitrification performances with an increase of the C/N from 0 to 3 in nitrifying MBBRs. They also noted a shift of microbial community structure attributed to the rise of organic carbon source supply.

Additional evidence provided by Li et al. (2019) reported a decrease in nitrifying bacteria abundance in the bio films after particulate organic matter (POM) addition in the MBBR influent wastewater. In higher C/N ratios, heterotrophic denitrifiers out-compete autotrophic nitrifiers for available oxygen, nutrients, and space in nitrifying bio filters, which eventually inhibit nitrification and increased denitrification (Navada,Vadstein, Spanu, Mikkelsen, & Kolarevic, 2020). It is reported that the C/N ratio to be attained relied on feed composition, strong aeration, fish feed digestibility, degradation of organic matter, and efficiency of solid waste removal units (Blancheton, Attramadal, Michaud, Roque, &Vadstein, 2013; Michaud et al., 2014; Rojas-tirado et al., 2019).Regarding the results mentioned above, for rapid and stable nitrification performance, RAS wastewater of low C/N ratios below three with suff i cient oxygen supply will provide a balance between heterotrophic and nitrifying bacteria in MBBRs (Rojas-tirado et al., 2019).

The nitrification process was influenced by alkalinity concentration,consumed during microbial metabolic activities (Davidson, Good,Welsh, & Summerfelt, 2011). Alkalinity is one of the influential parameters regarding the efficient operation of RAS bio filter (Godoy-Olmos, Martínez-Llorens, Tom´as-Vidal, & Jover-Cerd´a, 2016). A suf ficient supplement of alkalinity concentration must be maintained at least 40–80 mg/L (as CaCO3) for efficient wastewater treatment in RAS bio filter (Biesterfeld, Farmer, Russell, & Figueroa, 2003). The effect of alkalinity on nitrification, pH, and CO2stripping in a semi-commercial scale RAS coupled with MBBR, was studied by Summerfelt et al.(2015). In this research, RAS was stocked with Atlantic salmon smolt and recorded higher TAN removal efficiency with increased pH stability observed at 70 mg/L alkalinities. The study concluded that alkalinities concentrations of 10 and 200 mg/L led to significant accumulation of[H+] and high loss of inorganic carbon, respectively. These findings confirmed that optimum alkalinity is required for efficient nitrification,as Biesterfeld et al. (2003) reported.

Apart from ammonium and nitrite, urea content is also present in RAS wastewater due to its frequent application and excretion from aquatic animals. Ammonium molecules are produced when urea was hydrolyzed and dissolved in wastewater (Chen et al., 2019). The feasibility of using moving bed bio filter for TAN and urea-N treatment from FW-RAS rearing juvenile rainbow trout (O. mykiss) with different feeding levels was investigated (Dalsgaard, Larsen, & Pedersen, 2015).The results were promising, with about 0.208 g N/m2/day for TAN and 0.014 g N/m2/day for urea-N removals rates recorded in the ef fluent.MBBR evaluated for the degradation kinetics of ammonia, urea, and nitrite in freshwater flow-through RAS (von Ahnen, Pedersen, Pedersen,& Dalsgaard, 2015). The pilot-scale RAS was stocked with rainbow trout(O. mykiss) and fed with different feed loads. The results showed that removal of TAN and nitrite were described by zero-order kinetics, while urea biodegradation was described by first-order kinetics. The findings of these researchers demonstrated that MBBRs operating at both low temperature and loading rates could withstand the abrupt increments in influent ammonia concentrations. This was attributed to the bio filters designed with high removal rate capacity. The nitrification process in these bio filters is contributed by urea degradation and should be considered during the quantification of TAN loadings on bio filters(Dalsgaard et al., 2015; von Ahnen et al., 2015).

The application of MBBRs for organic matter removal is through the degradation of biomaterials and soluble organic matter. In a previous study, van Kessel et al. (2010) investigated the presence and activities of numerous functional groups of N-cycle bacteria in an MBBR for TAN removal from FW-RAS ef fluent. The researchers reported that nitrification using MBBR as a bio filter was advantageous and concluded that the aquaculture industry could benefit from relatively inexpensive anammox bacteria application via removal of ammonium, nitrite, and organic matter from RAS in a sustainable manner. A lab-scale experiment was conducted using synthetic marine RAS wastewater to evaluate three antibiotics’ removal and their influences on bio film formation (Li et al.,2017). The authors achieved removal efficiency of 32.9%, 28.4%, and 69.5% for rifampicin (RIF), nor floxacin (NOR), and oxytetracycline(OTC), respectively. The antibiotics elimination was attributed to biodegradation and adsorption of antibiotics by the bio films (Mailler,Gasperi, & Rocher, 2014; Matos, Pereira, Parpot, Brito, & Nogueira,2014). Similar results were observed by Shao, Hu, Cheng, and Chen(2019), who use a novel aerobic bacterium strain,Ochrobactrumsp.KSS10 in an MBBR for biodegradation of OTC from aquaculture wastewater. The MBBR demonstrated an average removal efficiency of 76.42% and 100% for OTC and TAN, respectively. However, the frequent use of antibiotics might have resulted in antibiotic resistance.Therefore, antibiotics drugs for disease control need to be minimized in RAS and move toward sustainable and efficient alternative approaches.The performance of a newly developed module for P removal from FW-RAS ef fluent that included an MBBR process was explored (Müller-belecke, von Plessen, Schmidt, Kühn, & Spranger, 2018). The experiment was conducted using a real ef fluent from a commercial scale FW-RAS stocked with pike perch (Sander lucioperca) species and recorded 95% of P removal efficiency.

Kamstra, Blom, and Terjesen (2017) investigated the mixing and scale effects on MBBR performance using a medium (200 L) and a small(0.8 L) scale set-up. The researchers observed a significant impact on TAN removal efficiency with better performance on a larger scale.Furthermore, the biocarriers filling rate and super ficial air velocity affected the mixing at the small-scale set-up. In both set-ups, TAN removal performances decreased when the external air velocity was below a threshold limit of 5 m/h. The author’s findings have opened the door for more studies on the TAN removal in MBBR at a particular scale to better design and dimension commercial-scale RAS. In another study,a performance comparison was conducted between the bio floc technology (BFT) and marine RAS coupled to MBBR for maintaining good water quality for shrimp production (Ray & Lotz, 2017). Concerning water quality and shrimp survival, the BFT resulted in the lowest shrimp survival (28%) than RAS attached to the moving bed bioreactor. The authors concluded that the lower survival rate obtained in BFT treatment was attributed to the system’s poor water quality.

Effective TAN removal using a moving bed reactor installed in a small-scale RAS was reported (Ramli, Giatsis, Yusoff, Verreth, & Verdegem, 2018). The experiment aimed to investigate the resistance and resilience of RAS on the pH stress with or without periphytic microalgae(Stigeoclonium nanum). The study comprised eight RAS, each stocked with 2200 g red Nile tilapia (O.niloticus). Four RAS were connected with a microalgae tank and the remaining without the microalgae tank. The authors achieved nearly 100% of TAN, and NO2–N removal efficiencies with both treatments studied. The same research group conducted another study using a microalgae couple with the MBBR process (Ramli,Yusoff, et al., 2018). The studies demonstrated no significant difference in TAN concentrations between the treatment with algae or without microalgae. Low levels of NO2–N, NO3–N, and P were observed in the RAS with microalgae than those without microalgae. 17β-estradiol (E2)is generated from aquatic excreta and the residue of antibiotics. Prolonged fish exposure to E2 has adverse effects on marine animals’reproductive systems (Li, Gu, Zhu, & Liu, 2020). E2 has been labeled an endocrine-disrupting chemical (EDC) that has adverse effects on endocrine function and can block endogenous hormones (Liu, Liu, et al.,2019). Devoting more efforts to improving the efficient removal of E2 from RAS wastewater is of great concern. Recently (Li, Lan, et al., 2020),conducted a 64 days study using lab-scale MBBR to find out the relationship between degradation of E2 and TAN removal in a synthetic RAS mariculture wastewater. The MBBR achieved 84.5–98.7% and 85.6–94.7% for E2 degradation and TAN removal. The batch experiment results using pureN. europaearevealed that E2 biodegradation is described by zero-order reaction kinetics. It also noted that a high concentration of E2 inhibited the nitrification process (the activity ofN.europaea) and affected the bacterial density during both batch and continuous MBBR operation. Nonetheless, E2 was significantly removed at the MBBR level as its inhibition is negligible, consistent with the previous observation (Li, Lan, et al., 2020).

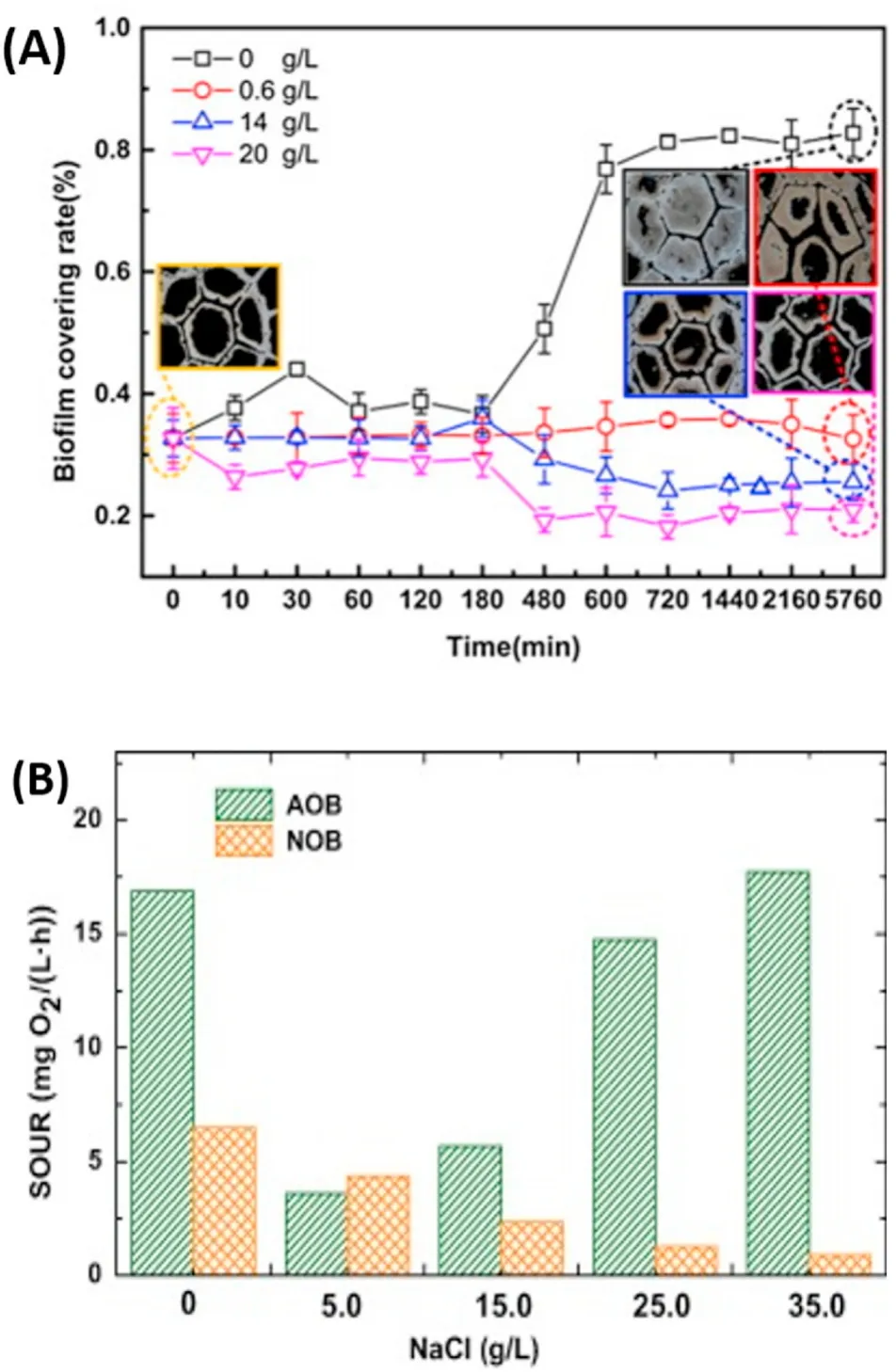

3.1.1.2.Salinity.Aquatic species can be adjusted physiologically to withstand the varying salinity changes in RAS rearing water (Navada et al., 2019). However, increased salt concentration has a substantial impact on bio filters’ efficiency, as it inhibits the activities of microbial communities (Jeong, Cho, Lee, Lee, & Bae, 2018). The effect of different salt concentrations on bio films attached to biocarriers is depicted in Fig. 2A. As can be observed, the increased salt concentration above 14 g/L caused a drastic decrease in bio film coverage attributed to the microorganism death (Wang et al., 2020). High salt concentration increased the cell osmotic pressure that caused cell plasmolysis, which subsequently reduced the nitrifying bacteria’s growth (Zhang, Wang,et al., 2020; Jeong et al., 2018), especially when microorganisms do not adapt to the saline environment (Gonzalez-Silva et al., 2016). Besides,incomplete nitrification leads to nitrite accumulation in RAS water due to salt’s detrimental effects on NOB. This compromised the cultured aquatic animal welfare and health. Also, it increased the time to remove TAN from RAS and operational cost, and the overall nitrogen removal rate.

Fig. 2.(A) Bio film morphologies images under different salt concentrations at 0 and 5760 min, reprinted with permission (Wang et al., 2020), and (B) the specific oxygen uptake rates (SOUR) of AOB and NOB, reprinted with permission of Elsevier (Gao et al., 2020).

In recent years, several strategies have been introduced to overcome the salinity inhibitory effect on nitrification and improve effective water treatment in RAS. Table 2 summarized some of the previous related studies of salinity effects on nitrification in MBBRs. For instance, Gonzalez-Silva et al. (2016) investigated the effects of salinity on nitrification in an MBBR treatment of RAS wastewater. The three reactors’average ammonium removal efficiency was more than 96% during the whole experimental period. In the freshwater MBBR, the highest nitrif i cation rate reaches 7.6 mg/L on day 57. It was observed that the nitrifying community structure was strongly affected by the salinity. These findings could help optimize the nitrification process in salty environments, as applicable in the treatment of marine RAS wastewater. Bakke et al. (2017) pointed out that, because of poor adaptation of high salt concentration beyond 22 g/L by nitrifying bacteria, a relatively low nitrification efficiency was observed when changing from FW to SW-RAS. The salinity influenced the microbial communities’ diversity.The bio film community pro files appeared to be steady among the three MBBR studied at different salinities (See Table 2) than those within the RAS water communities.

Table 2Summary of previous work on nitrification of SW-RAS in MBBRs.

Rud, Kolarevic, Buran, Berget, and Calabrese (2017) discovered that a change in salinity from 12 to 22 g/L in a commercial-scale RAS affected the nitrification efficiency of the MBBR bio filter. The highest TAN concentration in the ef fluent was observed with 22 g/L compared to 12 g/L salinity level. At the same time, it also affected the microbial community compositions as the most abundant NOB (Nitrospiraceae),which almost disappeared at 22 g/L. The AOB (Nitrosomonaceae) was more abundant in 12 g/L than 22 g/L. The researchers suggested a gradual increase of salinity in the RAS can reduce the impact on nitrifying species within the bio filter. In a recent effort, Kinyage et al. (2019)studied the effect of abrupt salinity on nitrification performance in six parallel MBBRs operating in a batch mode. Both active carriers and freshwater used were collected from RAS stocked with rainbow trout (O.mykiss), 20–25 kg/tank. The range of salinity levels tested in this experiment is listed in Table 2. The researchers conducted four sets of spiking tests at low (1 mg/L) and higher concentrations (5 mg/L) for the TAN and nitrite to evaluate their removal rates. They found the reduction of both TAN and nitrite removal rates of 25% and 93% at 10 g/L and 15 g/L salinity increase. The authors also observed that the sudden rise in the salinity concentrations in cultured species affected bacterial community compositions in the MBBR, causing nitrite accumulation.Overall, results suggested that ultimate care must always be taken when RAS salinities are abruptly increased to values of more than 10 g/L(Kinyage et al., 2019). Although the researchers had studied different salinity scenarios, the study’s limitations are that the experiments were conducted only in batch mode, and no microbial community structure changes were investigated.

The effects of salinity on MBBR were investigated by Navada et al.(2019) and found that the salinity increase rates affected the microbial community and the performance of MBBR during the treatment of FW-RAS. The salinity levels are listed in Table 2. The bioreactors exhibited excellent TAN removal efficiency when the rates of salinities were between 4 to 10 g/L. However, with salinities risen to the SW level (from 10 to 32 g/L), the nitrification performances recorded a sudden decrease of up to 90%. The researchers stated that the bacterial community dynamic was influenced by salinity rates, especially the NOB. It was reported thatCandidatus Nitrotogabacterial species were the only functional NOBs that tolerated the higher salinities of 32 g/L. TheCandidatus Nitrotogahas recently been reported as a predominant NOB in marine RAS bio films (Navada, Vadstein, et al., 2020). This showed that NOBs are more negatively sensitive to higher salt concentrations than AOB, as detected in other studies (Cort´es-lorenzo, Rodríguez-díaz,Sipkema, Ju´arez-jim´enez, & Rodelas, 2015; Gao et al., 2020; Navada,Vadstein, et al., 2020). At high salt concentrations, the autotrophic nitrite oxidation bacteria yield little energy, which might be inadequate to support their metabolic activities and favor thermodynamic osmoregulation (Oren, 2011). Feng, Luo, Yang, and Sun (2020) demonstrated that at high salinity 35.0 g/L NaCl, a decrease in the nitrification efficiency was observed, leading to high nitrite accumulation in the MBBRs during marine RAS wastewater treatment. It was also shown that for achieving more than 80% ammonia removal, 45 days of bio filter continued operation was required.

The studies mentioned above have intensively researched the impact of salinity on the performance of MBBR. Therefore, to reduce the effect of salinity on bioreactors’ performance, an efficient strategy is required to develop more robust RAS bioreactors (Navada, Sebastianpillai, et al.,2020). In light of this, previous studies developed novel immobilized carriers to mitigate the high salinity impact on functional microbes and improved reactor performances. Gao et al. (2020) study the effects of salinity on nitrification and active microbial community diversity in an MBBR treating SW-RAS wastewater. In the study, novel immobilized microbial granules (IMG) were used as bio film carriers. Also, daily ammonia concentration of 2.5 mg/L and salt levels (Table 2) were utilized. The researchers claimed IMG biocarriers achieved the highest ammonia oxidation of about 92% and 100% at high salinity and freshwater (near zero), respectively. The proposed IMG biocarrier demonstrated excellent resistance to high salinity effects on TAN oxidation.However, as shown in Fig. 2B, the metabolic activity based on specific oxygen uptake rates (SOUR) of NOB was decreased by 86.32% in the bioreactor at higher salinity (35.0 g/L NaCl). Meanwhile, the result indicated that the SOUR of AOB recorded 17.71 mg O2/(L.h), and ammonia oxidation was not affected even at the highest salinity level tested (Fig. 2B). On the other hand, it should be considered that the adaptation mechanisms and metabolic pathways of IMG carriers to high salinity conditions need further investigation. Notably, the study also showed that the microbial community structure in the IMG bio film changed significantly with increased aquaculture water salinity. In this case, it could be safe to treat mariculture wastewater at salinity levels lower than 25.0 g/L NaCl in an MBBR packed with IMG carriers. This is similar to the findings reported by Steinberg, Zimmermann, Meyer, and Schulz (2018). They recommended that low salinity levels should be employed for the appropriate reduction of nitrite toxicity to the cultured aquatic species in the RAS rearing tank. Similar studies have observed severe impacts of high salt concentration on AOB and NOB activities,and with an adaptation after the addition of more than 5 g/L of salt(NaCl), which usually prolong MBBR start-up time and subsequently lower the nutrients removal efficiency (Bassin et al., 2012).

Osmotic stress priming has been identified as another promising strategy for bioreactors stable operations under high salinity concentrations. Priming strategy involves the phenotypical modifications of microorganisms, which can be changed in gene expression or metabolism (Mitchell et al., 2009). The priming process prepared the microbial phenotype for an enhanced response to future salt stress resistance. The seawater priming as a strategy for salinity acclimatization enhancements in nitrifying MBBR treatment of marine RAS ef fluent was explored by Navada, Vadstein, Spanu, Mikkelsen, and Kolarevic(2020). The results indicated that prior exposure to SW (35 g/L) of FW-MBBRs bio film recorded about 90% nitrification efficiency, which was twice the ammonia removal efficiency achieved by the unprimed FW nitrifying bio film after transfer to SW. The excellent performance showed by the bio film reactor even at the SW level was attributed to an extracellular polymeric substance (EPS) strengthened and the physiological adaptation of the microorganisms via the seawater priming strategy. This made the bio film more resistant to future salinity increases. These authors recommend that the SW priming could be a promising method of salinity acclimation in nitrifying bio films for maintaining efficient nitrification in bioreactors treatment of mariculture wastewater, such as in RAS for Atlantic salmon and other saline ef fluents with highly salinity fluctuations. Nevertheless, the process for osmotic stress priming required a long-term acclimation period as such;the option might not be preferred all the time in treating high-salinity wastewater (Navada, Vadstein, et al., 2020; Zhu, Li, Wang, & Chen,2020). Therefore, the salinity levels and time of osmotic stress needed for priming strategy at different operating conditions required optimization in future research and the EPS quantification produced by the nitrifying bacteria.

Nevertheless, a more in-depth analysis of salinity effects on saline RAS wastewater’s nitrification with high water reuse is of considerable importance. Besides, nitrification might affect how salinity is changed either as a gradual increase (salinity acclimatization) or abrupt dose(Bassin et al., 2012; Shitu et al., 2021). On the other hand, it was proposed that rapid salinity increases of 14–15 g/L have little effect on bio film and ammonia removal (Ramaswami, Moin, Uddin, Behrendt, &Otterpohl, 2019). Overall, other researchers have reported that some microorganisms would adapt to the saline environment as the bio filter operation proceed because they will get used to the conditions and become dominant microorganisms. Besides, it was suggested that inoculation of the bio filters with microorganisms that possess the high salt-resistance ability or adding halophilic/halotolerant nitrifying bacteria groups may become the key to successful nitrification high-salt conditions (He et al., 2017). The addition of compatible solutes has also been considered an acceptable strategy for enabling the microbes to cope with osmotic stress at high salinity (Zhu et al., 2020). In both FW and SW-RAS bio films, the predominant AOB and NOB appear to be Nitrosomonas and Nitrospira, respectively, with few halotolerant exceptionsCandidatus Nitrotogaas the most dominant nitrite oxidizer(Table 2). As described above, with the rapid development of FW, BW,and SW-RAS, further research is recommended to better understand and optimize MBBRs operation at different salinities (Kinyage et al., 2019).Nevertheless, the complete degradation pathway, the interactions between microorganisms, and the salinity to varying concentrations by the MBBR are still quite limited. Therefore, the scope for further studies is quite bright in this aspect. Future studies should also focus on responses of different bacterial strains to the high salinity level in MBBR bio filters.

3.1.1.3.Acceleration of bio film formation strategies for MBBR rapid startup.It is well established that the bacterial community structure influenced the function and performance of the MBBR systems. Bio film is a polymeric slime matrix embedded with microbial communities, organic and inorganic materials attached to the carrier media surface. Bio films may consist of a single microorganism or multiple microbial species(Ruiz et al., 2019). Bio films are formed through the initial cell adhesion onto the biocarrier surfaces, leading to bacteria accumulation and EPS formation (Peng et al., 2019). Depending on the condition provided during the process, the acclimatization period needed for a stable biof i lm formation was reported to differ significantly, ranging from 7 to 42 days in FW bio filter (Bassin et al., 2016; Tang et al., 2016), whereas during natural colonization of nitrifying bio films, it can take several days (28–81 days) to develop in SW bio filter (Li et al., 2019). Bio film formation is a continuous process and influenced by other factors such as the nature of the substrates, oxygen availability, organic loading rate,operating conditions (temperature, salinity, and pH), characteristics of the media, and reactor hydrodynamics (Dias et al., 2018; Kinyage &Pedersen, 2016; Ruiz et al., 2019).

Previous literature has shown that rapid bio film acclimation is an essential factor influencing the quick start-up time and stable operation of MBBR systems (Mao et al., 2017; Zhang, Xie, Rong, & Liu, 2019). It is a crucial factor for the RAS wastewater treatment unit (Jiang et al.,2019). It was pointed out that bio filter start-up is essential for fish welfare, reduces the risk of fish diseases, and sustainable aquatic production from environmental and economic viewpoints (Roalkvam,Drønen, Dahle, & Inger, 2020). In this regard, there are more concerns for the more extended start-up periods of bioreactors. The acceleration of MBBR start-up strategies is summarized and depicted in Fig. 3. To overcome the challenges of a slow start-up process period of bio filters to treat mariculture RAS wastewater, many researchers have proposed different novel accelerated MBBRs start-up time strategies to reduce time consumption.

Fig. 3.Novel strategies for the rapid start-up of MBBRs.

Zhu et al. (2016) investigated the influence of varying seeding proportion on new bio film formation and nutrient removals in MBBR treatment of synthetic marine RAS wastewater. The study comprises five parallel reactors seeded with 0, 1, 5, 10, and 15% mature bio film carriers from a full-scale stable MBBR that operates for an Atlantic salmon RAS. The researchers noted that the reactors seeded with a high percentage of active bio film carriers achieved higher efficiencies in ammonia removal within the first 32 days. Later on, all the reactors,including the control reactor, gradually reached a uniform removal efficiency of about 95%. When the nitrite accumulation reached peaks between 40 and 80 days during the experiment, a rapid decline was observed in the removal and production of ammonia and nitrate,respectively (Zhu et al., 2016). Inoculation with mature seed bio film from existing bioreactors demonstrated the advantage of quick reactor start-up; however, the supply of nitrifying inocula might not always be available and sometimes require a relatively long period pretreatment before the seeding for removing the inhibitory substances (Peng et al.,2019). Also, procuring and transportation burdens of the inocula might be cost-intensive, which is not economically attractive.

On the other hand, a start-up without inoculum in brackish water appeared to be a new strategy to improve salinity adaptation and startup in bio films reactors recently (Navada, Vadstein, et al., 2020). This suggested that the reactor influent would function as a source of bacteria. These authors achieved complete nitrification within 60 days of continuous nitrifying MBBRs operation with intermediate salinity(brackish water 12 g/L) start-up strategy to treat RAS wastewater. They also report that a clean water start-up of bio filter eliminated the biosecurity risk in transferring the pathogenic microorganisms. In another approach, Pulkkinen et al. (2018) examined the feasibility of using three different chemical additions. It is aimed to accelerate the start-up of nitrification in an MBBR installed in a ten-unit individual RAS. Their study’s strategies comprised sodium nitrite, sugar cane, ammonium chloride, and start-up with fresh rainbow trout (O. mykiss) wastewater.The overall removal efficiency and rapid start-up of the nitrification one week ahead were achieved using 5 mg/L concentrations of combined ammonium chloride and sodium nitrite than other chemical mixtures. It indicated a faster bio filter startup could be provided by adding synthetic substrates (Pulkkinen et al., 2018). It is also interesting to note that both AOBs and NOBs are slow-growing organisms, and their metabolism is influenced by substrate availability. This indicated that ammonium and nitrite are required to support rapid bio film development for the bioreactor start-up due to the quick establishment of nitrifying bacteria,which could reduce ammonia and nitrite peaks in the system (Ferreira et al., 2020).

Liu and co-workers proposed the transfer of mature bio film carriers from trickling filter (TF) to the MBBR reactor for faster start-up of nitrification in simulated mariculture wastewater. Their study confirmed that the proposed strategy could accelerate the MBBR system nitrification via TF matured bio film biocarriers transfer (Liu, Li et al.,2019). Similarly, Li et al. (2019) evaluated the effectiveness of fast start-up strategies for efficient nitrification acceleration in saline RAS wastewater in a stepwise manner. A gradual increase of influent salinity was proposed (See Table 2). The augment in nitrifying bacteria populations indicated the mature, step-decreased influent ammonia concentration, inoculation with commercial nitrifying bacteria, and the addition of organic matter in laboratory-scale MBBRs, respectively. The authors use five parallel MBBRs. Reactors (R2 and R3) operational parameters were changed whenever the TAN, nitrite, and nitrate concentration remained stable. They reported that complete nitrification was attained after 63 days of R3 operation at maximum salinity (30 g/L)before the other reactors (16–18 days earlier). The influence of water exchange rates during start-up of 12 individual (334 L) small scale low saline RAS coupled to MBBR on the pikeperch (Sander lucioperca) and water quality parameters were explored (Steinberg et al., 2018). Nitrif i cation was achieved with TAN concentration not exceeding 0.6 mg/L and NO3–N concentrations in the range of 45.2–94.6 mg/L throughout the experimental period for the accumulating feed burden (AFB) levels.Moreover, they reported that for sustainable growth and survival of adult pikeperch (Sander lucioperca) in RAS, the threshold level of NO3–N should not exceed the range of 45.2–69.9 mg/L.

Most studies discussed above were focused on the performance and biofilm morphological changes during different operating conditions.However, Jiang et al. (2019) studied the bacterial community succession process during the start-up process of MBBRs in cold (17–18 ℃) freshwater RAS and the experiment lasted for 90 days. The system comprises 26 fish-rearing tanks, each coupled to a biofilter and stocked with a total of 35,000 steelhead trout (O. mykiss gairdneri). The MBBRs were filled with polyethylene carriers having a specific surface area of 360 m2/m.The results indicated that effluent ammonium and nitrite concentrations were effectively removed (100%) during the experimental period. The authors provide information concerning the designing and operation of RAS bio filters.

Notwithstanding, other methods have been developed to shorten the start-up time of the MBBR systems. Bio filter inoculation using a consortium of microorganisms and multiplied EPS producing bacteria(bioaugmentation). For example, isolates ofMicrococcussp., Mycobacteriumsp., Bacillus amyloliquefaciens, Escherichia coli, Pseudomonas aeruginosa, Pseudomonas stutzeri strain XL-2,andBacillus cereusdemonstrated high capability in rapid EPS production, which eventually contributed to quick bio film formation for accelerated start-up (Ruiz et al., 2019; Zhang, Ding, Zhao, An, & Guo, 2020). Another bio filter activation strategy is by initially introducing the small density of the aquatic population in the newly establish RAS (Roalkvam et al., 2020).Still, operational parameters regulation such as substrate loading ratio,HRT, and novel process technology are among various strategies. Biof i lm carriers are usually modified to improve materials surface properties for better practical engineering applications. For instance, they decreased and increased hydrophobic, and hydrophilicity functional groups of biocarriers support materials. The main motives were to increase the substrate’s mass transfer, enhance the specific surface area,accelerate bio film formation, improve microbial adhesion, and decrease bio film detachment from biocarriers.

More information on the current state of the art and challenges on various commercial and laboratory scale modified MBBR biocarriers can be found in Zhao et al. (2019). Morgan-sagastume (2018) reviewed the development and modification of bio film carriers’ surface properties for practical application in MBBR to treat different wastewater forms.Future studies should explore the performance efficiency and feasibility of the new novel MBBR accelerated start-up approaches to treat actual pilot and full-scale commercial RAS, rather than only its evaluation at the laboratory level.

3.1.1.4.Disinfectants.A Chemical disinfection/sanitizer unit is commonly integrated into RAS with MBBR (Bio filters) units. It has been pointed out that proper disinfection of RAS facilities is of great concern for water quality improvements. It could also reduce the chances of aquatic species infections and diseases. However, the use of disinfectants in RAS caused a detrimental effect on TAN removal efficiency in the MBBR bioreactor. The potential challenge of using a disinfectant might be prolonged water retention times (Möller, Arvin, & Pedersen, 2010;Suurnäkki, Pulkkinen, Lindholm-lehto, Tiirola, & Aalto, 2020). The chemical disinfectants commonly utilized in RAS include hydrogen peroxide, ozone, water-born prophylactic, peracetic acid, formalin, and formaldehyde (Jia et al., 2019; Spiliotopoulou et al., 2018). To tackle this issue, Möller et al. (2010) investigated the degradation of hydrogen peroxide (HP) and its impacts on MBBRs nitrification performance in a small-scale freshwater RAS. The authors reported that the TAN removal rate was less affected by a single dose of HP. However, long-term HP exposure has a significant impact on the nitrification efficiency of the bio filters. It was also observed that the NOB inhibition occurred due to the prolonged HP exposure, which consequently caused a decrease in the nitrification rate that resulted in nitrite accumulation in the MBBR.The addition of HP should always be precise according to the required calculated amount because any excess could suppress the bio film developed on the biocarriers (Narayanan & Narayan, 2019).

Arvin and Pedersen (2015) developed a kinetic model to estimate HP decomposition in RAS ef fluent, and the model successfully performed well. The developed model is a valuable tool that can provide information for a safe application of HP, to meet the required disinfection demand in routine RAS operation with a lesser effect on nitrifying AOB and NOB in the moving bed bio filters. HP degraded exponentially in water following first-order decay (Pedersen, Rojas-Tirado, Arvin, &Pedersen, 2019). Regarding formaldehyde removal and its effect on nitrification in MBBR operating in RAS farm, one research conducted by Fredricks, Gaikowski, Cupp, Schleis, and Erickson (2018) setup 20 MBBRs packed with AnoxKaldnes™ K1 biocarriers and subjected them to different range of formaldehyde concentrations of 0, 9.25, 18.5, 37,and 55.5 mg/L. The results showed that single exposure ≥37 mg/L impaired the bio filters’ nitrification performance, although the bio filters recovered over time. When the bio filters were tested for four days of continuous exposure to 18.5 mg/L formaldehyde, it inhibited the AOB and NOB activities in the bio filters. The bio filters did not recover after 24 days of exposure trials. This study’s findings demonstrated the recommended formaldehyde concentrations subjected to bio filters without detrimental effects on the nitrification process.

The use of ozone in RAS facilities has raised more concern due to the ozone byproducts of ozone-produced oxidants (OPO) and bromate. The issues mentioned above are suspected of impacting nitrifying bio filters and potentially toxic effects on fish health (Ng et al., 2018; Schroeder,Klatt, Schlachter, Zablotski, & Keuter, 2015). For these reasons,Schroeder et al. (2015) conducted a study on the long-term effects of residual OPO and ozonation on the MBBR performances in RAS. They used 0, 0.05, 0.10, and 0.15 mg/L chlorine equivalent of OPO concentrations for an experimental duration of 21 days exposure. The RAS was stocked with tilapia (O. niloticus). The results showed no noticeable decrease in the bio filters performance, even at the maximum dosage of OPO concentrations. Compared to control (no ozonation), nitrifying activity was accelerated at all OPO concentrations. This suggested that nitrification could be enhanced at moderate ozonation. Ozonation units should be placed before MBBR to increase nitrification performance. For efficient nitrification and safe fish production, the OPO concentration should be within the limit of ≤0.05 mg/L (Schroeder et al., 2015). This is because high ozone concentrations are hazardous to bio film on bio filters and pose risks to fish, causing fish mortality and tissue damage (Gonçalves & Gagnon, 2011). Therefore, a moderated dosage could reduce the capital and operating costs of ozone application.

In RAS, water disinfection with ozone is quite complicated and relatively expensive (Gonçalves & Gagnon, 2011). Peracetic acid (PAA)was reported to possess properties similar to ozone, such as disinfectants and chemotherapeutants (Davidson, Summerfelt, Straus, Schrader, &Good, 2019). Besides, it has no known harmful byproducts, thus,considered as an alternative sanitizer to formaldehyde. When PAA was applied in RAS at absolute concentrations, it showed a more negligible effect on bio filters’ nitrification performance. The use of PAA in RAS stocked with fish has been approved in Europe. However, it was accepted as RAS equipment surface sanitizer only in the absence of fish stock in the United States by the U.S. Environmental Protection Agency(Davidson & Good, 2019). Davidson & Good (2019) pointed out that PAA may be accepted for water treatment use in aquaculture worldwide,pending further investigation and other regulatory approval. PAA-based products can be found in different combinations, such as acetic acid, and H2O2and with other various stabilizers (Lazado, Sveen, Soleng, Pedersen, & Timmerhaus, 2021). Overall, future studies should focus on determining the concentration of disinfectants and antibiotics that can effectively treat fish and are harmless to RAS nitrifying bio filters and microbial communities. The performance of MBBR depended on the activities and diversity of the microbial community. Generally, the MBBR systems are considered promising for nitrification in treating RAS wastewater because they allow, protect, and sustain a high density of nitrifying bacteria.

3.2.Nitrate nitrogen removal

Previous studies have shown that nitrate accumulation above 50 mgand its prolonged exposure in RAS could be harmful to the health and growth performance of cultured aquatic species with vulnerability varying among the marine species (Davidson, Good, Williams, & Summerfelt, 2017; Poulsen, Cedergreen, Hayes, & Hansen,2018; Torno, Einwächter, Schroeder, & Schulz, 2018). Xie, Zhang, Li,Chai, and Wang (2019) stated that more than 50 mg/L of nitrate exposure affected the metamorphosis ofBufo gargarizanstadpoles. It was also reported that prolonged exposure to accumulated nitrate caused aquatic deformities, affect osmoregulatory ability, and increased mortality rate(Steinberg et al., 2018). Wang, Chai, Zhao, Wu, and Wang (2015) noted that nitrate had disrupted both thyroid hormone and the thyroid gland function inBufo gargarizanslarvae. Yang, Song, Peng, Hallerman, and Huang (2019) examined the toxicity effect ofon the juveniles knifejaw (Oplegnathus punctatus)stocked in freshwater RAS. This study’s findings indicated that the optimal nitrate level for juvenileO. punctatusshould be below 165 mg/L. Meanwhile, it purported that post-smolt Atlantic salmon’s health and performance were not affected at NO3–N concentration ≤100 mg/L (Davidson et al., 2017). Both studies recommended the attachment of denitrification units in the RAS to reduce nitrate accumulation. It was projected that the incorporation of denitrifying reactors in RAS could reduce about 10% cost of investment and operation (Martins et al., 2010). Thus, controlling NO3–N from accumulating to harmful levels is vital in aquatic farms that use intensive RAS. In light of this, further investigation for the nitrate pathways and stress response mechanism on different marine cultured species is required.

Nitrate is the end product of the nitrification process in RAS biof i lters. The biological removal of nitrate from RAS wastewater is by converting it to nitrogen gas (N2), the safest form of nitrogen, and released it into the atmosphere (de Melo Filho, Owatari, Mouriño, Lapa,& Soares, 2020). The process is referred to as denitrification. Besides,excess NO3–N in RAS water can be also be controlled through daily water renewal. However, denitrification has been considered a feasible way to prevent nitrate accumulation compared to conventional water renewal, which consumes large amounts of new water around 11–59%(Díaz, Ib´añez, G´omez, Urtiaga, & Ortiz, 2012). Organic carbon sources and nitrate are used as electrons donor and electrons acceptor, respectively, under anoxic conditions.

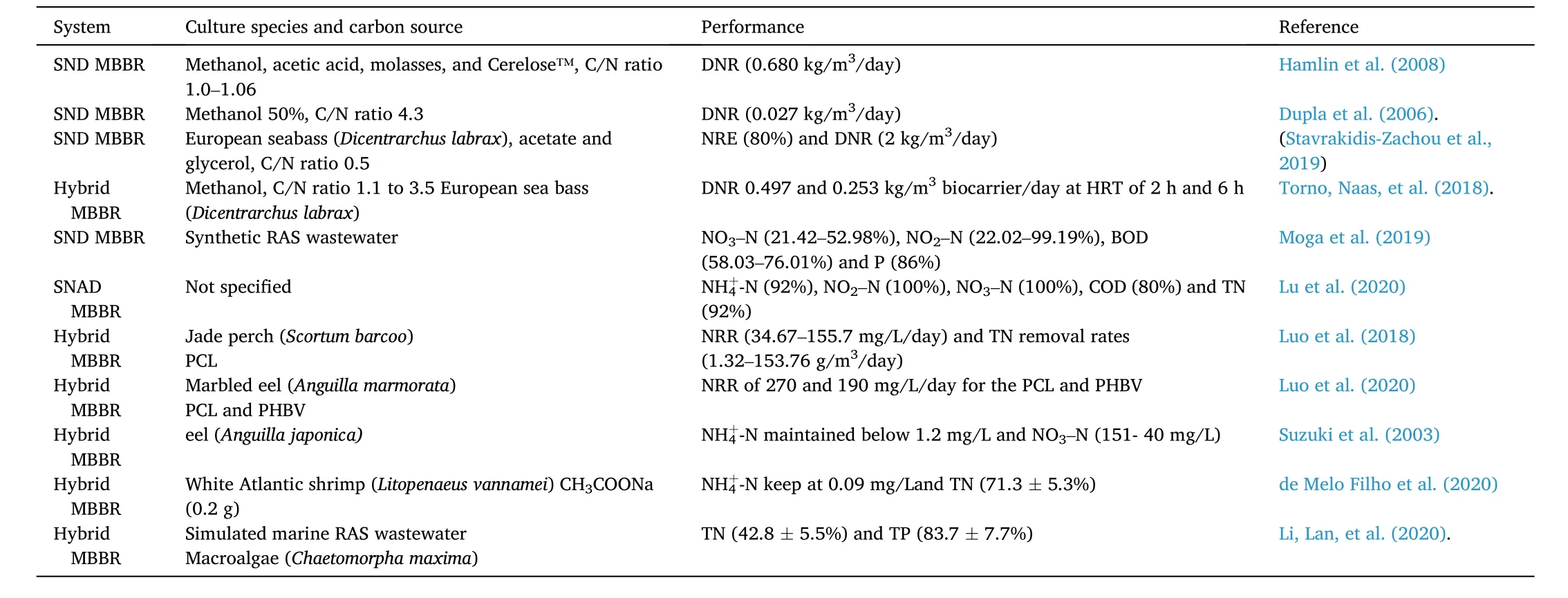

In this section, single MBBR reactors for short-cut SND pathways and hybrid MBBRs to treat RAS ef fluent are discussed. For easier reference,Table 3 showcased a summary of the performances of MBBR-based SND,SNAD, and hybrid processes for RAS wastewater treatment reported in the literature.

Table 3Summary of MBBR-based SND and hybrid process for RAS wastewater treatment reported in the literature.

3.2.1.Single stage SND-MBBR process

It has been widely reported that ammonium and nitrate removal processes are performed in two separate-stage bioreactors processes under aerobic and anoxic conditions. This was due to the opposite demands of dissolved oxygen and organic carbon by the various functional bacteria groups involved in the nitrification and denitrification processes. However, improvements were made in performing the two operations simultaneously in one integrated MBBR bioreactor process in recent years (Zinatizadeh & Ghaytooli, 2015). This has reduced the required equipment and space and smooth operation economically affordable with high-performance efficiency. Several researchers have evaluated the potential of denitrification for nitrate removal from RAS wastewater using various novel MBBRs configurations and processes.

Hamlin et al. (2008) applied stagnating MBBRs for the SND process in RAS for aquatic fish production. The authors achieved approximate daily denitrification rates (DNR) of 0.680 kg/m3media/day for all the four-carbon sources tested. The denitrification capacity of an MBBR system for treating SW-RAS was studied (Dupla, Comeau, Parent, Villemur, & Jolicoeur, 2006). During the denitrification experiment, the MBBR filled with Bio flow-9 carrier at a 30% filling rate. The authors obtained a satisfactory higher DNR of about 0.027 kg/m3/day. Stavrakidis-Zachou et al. (2019) studied the denitrification of wastewater from zero-exchange commercial SW-RAS. The research used three parallel identical SND MBBR (0.6 m3) loaded with K3 biocarriers connected to a fish tank (6.5 m3) rearing European seabass (Dicentrarchus labrax).During the experiment, acetate or glycerol were supplied to the anoxic MBBRs as organic carbon sources. The MBBR performance was evaluated for nitrate removal efficiency (NRE) and DNR. The first 19 days of RAS operation resulted in an unsteady NRE when glycerol was used in both reactors. However, from day 20–44, high and stable NRE (80%) was observed when glycerol was changed to acetate in all MBBRs. The highest DNR attained was about 2 kg/m3/day, and the overall average NRE reached 95% in both MBBRs from day 45 up to the final day (day 61). This was significantly lower than the findings by the Gutierrez-wing, Malone, and Rusch (2012), who achieved a DNR of 2.97 kg/m3/day using polyhydroxybutyrate as a carbon source in a SW- RAS bio filter.The authors concluded that glycerol is an attractive, cost-effective, and non-toxic carbon source that can be used in the RAS water treatment process.

In the treatment of marine RAS ef fluent using aerobic denitrification MBBR reactor, 98% of nitrogen and 99% of ammonia removal ef ficiencies were successfully achieved (Song, Yang, Hallerman, Jiang, &Huang, 2020). A new bio film carrier with hydrophilic properties developed and tested to obtain a larger specific surface area for better bio film formation and higher nitrate removal (Moga et al., 2019). These researchers investigated the performance of the developed biocarriers using laboratory-scale denitrifying MBBRs treating synthetic RAS wastewater. Results showed MBBRs could remove between 21.42 and 52.98% of NO3–N, 22.02–99.19% of NO2–N, 58.03–76.01% of BOD, and 86% of P. The study observed an inhibitory effect on the AOB population that attributing to the presence of organic compounds.

3.2.2.Hybrid process

MBBR bioreactor connected with other separate bioreactors for the total nitrogen removal in RAS facilities. This process was termed a hybrid MBBR process. In the current hybrid MBBR system configuration,two interdependent treatment processes were combined in series. For example, the efficiency of a polycaprolactone (PCL) fixed-bed denitrifying reactor connected with nitrifying MBBR for the treatment of real laboratory-scale RAS ef fluent was evaluated (Luo, Liu, & Gao, 2018).The PCL was used as bio film media and carbon source for denitrification.The aquaculture system was cultured with Jade perch (Scortum barcoo),having a stocking density of 28.39 ±1.25 kg/m3. The main ef fluent quality parameters from the MBBRs which served as the influent for the denitrifying bioreactors were reported as NO3–N: 89.3–101.68 mg/L,TAN: 0.08–9.74 mg/L, NO2–N: 0.15–3.349 mg/L, DO: 6.01–8.21 mg/L,pH: 7.25–8.01, and temperature: 23.4–25.9 ℃. This experiment achieved NO3–N and TN removal rates ranging between 34.67 and 155.7 mg/L/day and 1.32–153.76 g/m3/day, respectively, with 216.2 g/m3PCL consumption during the test. Also, the study reported that Bacteroidetes and Proteobacteria were the dominant species in the bacteria community of the bio film samples having relative proportions of 25.2% and 65%, respectively. PCL is a very low-cost and reliable carbon source used for RAS wastewater treatment than many other biodegradable polymers (Gichana et al., 2018).

The same research group compared denitrification performances using PCL and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)polymers as bio film carriers and carbon sources for treatment of RAS water for about 102 days (Luo et al., 2020). The RAS was stocked with marbled eel (Anguilla marmorata) with a stocking density of 45 ±1.25 kg/m3. The main ef fluent quality parameters from the MBBRs,which was the same as the influent for the six fixed-bed denitrifying bioreactors, were NO3–N: 81.1–132.65 mg/L, TAN: 0.05–1.71 mg/L,NO2–N: 0.02–1.73 mg/L, DO: 4.62–7.94 mg/L, pH: 6.49–8.10, and temperature: 21.6–27.4 ℃. In that research, the averageremoval rates of 270 and 190 mg/L/day for the PCL and PHBV were achieved,respectively. However, the PCL consumed was significantly higher than the PHBV during the period. Furthermore, the predominant genera for the PCL in the bacterial community wereAcidovoraxandDenitratisoma,with a relative abundance of 26.83 and 6.67%, respectively, whereas for the PHBVAcidovoraxandBdellovibriowere the most dominant genera with a relative abundance of 17.95 and 6.37%, respectively.

A hybrid MBBR system for water treatment from pacific white shrimp (Litopenaeus vannamei) culture recirculation system was proposed by de Melo Filho et al. (2020). The researchers used nitrifying and denitrifying MBBRs reactor units connected in series and were filled with 120 and 263 bioballs carriers, respectively. Sodium acetate was used as a carbon source in the denitrification reactor. After the wastewater is generated from the culture tank, the nitrification is carried out with nitrifying MBBR and subsequently followed by denitrifying MBBR.The system achieved significant TN removal (71.3 ±5.3%), and ammonia concentration was maintained at 0.09 mg/L. The shrimp had a 92.9% and 13.1 ±1.4 g survival rate and final weight, respectively, at the end of 36 days experiment. The authors reported that the process has the advantage of recovering some of the alkalinity consumed during nitrification in the subsequent denitrifying reactors. Finally, it was concluded that the proposed hybrid setup could be applied in marine shrimp farms. The feasibility of integrating the macroalgae with an MBBR treating marine wastewater for nutrient recovery and biomass production was demonstrated recently by Li, Lan, et al. (2020). This study found that macroalgae integration with MBBR enhanced TN removal efficiency from 3.9% up to 42.8%. Also, 83.7% of TP removal achieved with a specific growth rate of 3.86–10.35%/day for the macroalgae was recorded and attributed to the nutrient recovery. Another hybrid MBBR system was reported elsewhere (Suzuki, Maruyama, &Numata, 2003).

Some researchers have proposed another new advanced MBBR configuration recently. It combined simultaneous partial nitrification,anammox, and denitrification (SNAD) in a single-stage bioreactor (Ding,Bao, Wang, Zhang, & Peng, 2018; Guo, Niu, Sugano, & Li, 2020; Zheng et al., 2019). This SNAD process was introduced in 2011 (Guo et al.,2020). In this process, under the condition of limited DO, ammonia is converted to NO2–N by AOB; subsequently, anammox bacteria oxidized some residualand NO2–N to NO3–N, and the nitrate is reduced to N2gas via the denitrification process (Lu, Zhang, Wu, & Wang, 2020). In this regard, nitrifying, denitrifying, and anammox bacteria generally coexisted in the aerobic-anoxic-anaerobic conditions for the RAS water treatment (Ding et al., 2018). SNAD has several advantages, such as a 90% reduction in sludge production, eco-friendly, and economical approach. It has no demand for an external carbon source and has a 60%reduction in aeration energy consumption (Deng et al., 2020; Guo et al.,2020; Zheng et al., 2019). Also, it is highly effective in the treatment of COD and nitrogen-rich wastewater, with a low C/N ratio (Ding et al.,2018). The feasibility of using the SNAD process for the removal of NH4+-N and COD from actual RAS wastewater was investigated by Lu et al. (2020). The MBBR operated for about 180 days with 5 h of HRT.The researchers reported that the SNAD bioreactor demonstrated high performance for nitrogen and COD removal by achieving NH4+-N,NO2–N, NO3–N, COD, and TN removal efficiencies of 92, 100, 100, 80,and 92%, respectively. The SNAD bioreactor met the acceptable high-water quality needed for rearing and the fish’s health in RAS. Also,the treated water was within the permissible limit. The most dominant nitrogen functional bacteria genera detected in the bioreactor bio film samples wasPseudoxanthomonasand other typical nitrogen and COD beneficial bacteria for the SNAD process. The researchers concluded that RAS equipped with SNAD-MBBR could remove high nitrogenous compounds and low-concentration COD from recycling water efficiently with high DO concentration. However, the potential of using the SNAD process in the MBBR treatment of various types of RAS ef fluents for improving nitrogen removal efficiency and for a better understanding of the process mechanisms still requires further investigation.

Self-cleaning Inherent gas Denitrification bioreactor (SID - bioreactor) as an alternative denitrification unit for RAS facilities was reported (Müller-belecke, Zienert, Thürmer, Kaufhold, & Spranger, 2013).Recent research has suggested that for effective denitrification in SID-bioreactor, an accurate dosage of external carbon source, backf l ushing interval (BFI), and appropriate HRT need to be optimized(Torno, Naas, et al., 2018). The performance of the modified MBBR-SID-bioreactor on denitrification rate and water quality parameters in marine RAS was evaluated (Torno, Naas, et al., 2018). The study was conducted under different operating conditions of varying HRT (2,4, and 6 h), C/N (1.1–3.5), and BFI (10, 30, 60, and 90 min). They achieved a maximum DNR of 0.497 and 0.253 kg/m3/day biocarriers at HRT of 2 h and 6 h, respectively. In contrast, HRT of 6 h had nitrate removal efficiency of 81%, which is relatively higher than 64% denitrification efficiency obtained at HRT of 2 h. The authors reported that better results were collected after every 30 and 60-min intervals of BFI.Also, the optimum denitrification performance is deemed to be more appropriate at a C/N ratio of 2.3. Their findings proved that SID-bioreactor could efficiently and safely be employed for nitrate removal in RAS facilities. The SID-reactor eliminated bio film carriers from clogging that usually reduced denitrification MBBR performance in RAS (Torno, Naas, et al., 2018), previously ascribed to particulate organic matter and excessive microbial growth (Lepine, Christianson,Davidson, & Summerfelt, 2018).

From the above discussion, it is worth noting that SND processes in MBBR for treating RAS residual water are still minimal. A few recent studies have focused on applying SND in MBBR operating in RAS compared to nitrifying MBBRs. To some extent, SND in a single MBBR reactor has demonstrated its effectiveness for use in RAS (Feng et al.,2020). This could be a potential emergent area of research and development. TAN and nitrate removal via biological SND would reduce the need for numerous water renewal rates. Most RAS bio filter studies have focused more on nitrifying bacterial populations with a little on heterotrophic bacteria (Brailo et al., 2019; Ruiz et al., 2019; Rurangwa &Verdegem, 2015). Therefore, more studies in the future should focus on developing denitrifying MBBR in RAS, rearing different fish species in marine, brackish, and freshwater environments.

4.Challenges and prospects

RAS is considered a sustainable technology for the development of the aquaculture industry. It has been accepted as one of the most promising and efficient technology for fish production. Furthermore,RAS has flourished well in terms of protecting cultured species against disease outbreaks in aquaculture farms. The initial investment and operation costs have been reported to drop continuously, contributing to reduced operational expenses and improved farmers’ pro fit. The substantial advancement achieved by the MBBR as a bio filter in the aquaculture industry so far revealed its impressive performance in RAS wastewater treatment.

Notwithstanding, it was well understood that the microbial community structure is profoundly affected at different salinities, which consequently influenced the nitrification process performance of the MBBR in wastewater treatment. There is more concern for improving more efficient processes and materials in the future using innovative measures. Besides, some researchers are focusing on converting solid wastes into fish feed. Another major challenge is searching for alternatives and isolations of an inexpensive and suitable halophilic microorganism for nitrifying bioreactors in mariculture ef fluent treatment. This also has become the future research direction. Despite the rapid increase in the number of MBBR bio filters, the number of studies on removing nutrient and organic matter in MBBR is still scarce compared with the numerous studies carried out on activated sludge and other conventional reactors. For the MBBRs systems design, the bio film carrier is an essential part of MBBR, influencing the wastewater treatment performance. Thus, the development and application of more sustainable modified carriers that are environmentally friendly with enormous potential in wastewater treatment are required (Sonwani, Swain, Giri, &Singh, 2019; Zhang, Zhou, Xie, Rong, & Liu, 2019). The ongoing research on different bio filter rapid startup techniques for efficient nitrification in RAS wastewater seems promising. This will increase the sustainability of RAS in terms of water quality management and for good health and growth of fish.

It is noteworthy that the nutrient from RAS wastewater streams can also be recovered as struvite, which could be reused as fertilizer. Some studies have been reported in this aspect but are very limited and still require in-depth investigation (Huang et al., 2020; Rufí-Salís et al.,2020; Yogev et al., 2020). The MBBRs could also be integrated as an algae-based treatment system, which provides the opportunity to capture nutrients from RAS solids waste and the ef fluent. All these will support sustainable wastewater treatment, energy-saving, algae biomass production to supplant aquatic meals and promote the circular economy approaches (Villar-Navarro, Garrido-P´erez, & Perales, 2021). The SND and other nitrate removal processes from RAS wastewater reviewed in this context exhibited promising results in short operation time with less energy consumption and space requirement. However, understanding SND mechanisms and their optimization in freshwater and saline aquaculture water are crucial for its full utilization in MBBRs systems,which still requires further research. It is also desirable to develop more innovative strategies for the SND process for total nitrogen removal,which requires little or no additional external carbon sources, besides improving the overall economy that addresses the aquaculture industry needs. For instance, SID - bioreactor (Müller-belecke et al., 2013; Torno,Naas, et al., 2018), hybrid MBBR systems (de Melo Filho et al., 2020),and SNAD bioreactor (Ding et al., 2018; Guo et al., 2020; Lu et al., 2020;Zheng et al., 2019).

The present review findings indicated that organic matter and disinfectant accumulation in aquaculture wastewater need to be thoroughly investigated to influence water quality, fish welfare, and biof i lters efficiency. Therefore, good design and proper operation of solid waste removal units before biological treatment is a bright future research area. It is also suggested that the RAS managers should adopt innovative feeding techniques and feed compositions to reduce solid waste generation, as it was confirmed as the primary source of waste originated from the aquafeeds in the RAS (Gichana et al., 2018).

5.Conclusions

The recent progress of the MBBR application for the treatment of wastewater from RAS was reviewed. The MBBR that uses supporting suspended bio film carriers to grow the attached microbes demonstrated to be flexible, compact, simple to operate, environmentally benign, low operating costs, and an excellent tool for better water management in RAS. The application of MBBRs has eradicated the threat to the environment, reduced production cost, and made the farming activity a more sustainable venture. The various strategies for salinity adaptation in bio filters such as seawater priming, brackish water start-up, bioaugmentation with halotolerant bacterial strains, and the gradual increase of inlet salinity have proven to be feasible for effective saline RAS wastewaters treatment, suggesting more research is needed for a better understanding of phenomenon involved in those innovative approaches.

In this context, most of the reviewed studies reported that the water quality parameters were maintained at safer survival levels by the MBBRs for the reared aquatic species. Regardless of the achievement of MBBRs as RAS wastewater biological filters, more robust techniques for bio film carrier development and cost-effectiveness in terms of energy consumption and installation are still needed. Currently, the available literature is mainly focused on a lab-scale and very little on a pilot-scale evaluation. Therefore, more efforts are required in upscaling the technology for applications in intensive commercial-scale RAS facilities.

CRediT authorship contribution statement

Abubakar Shitu: Conceptualization, Methodology, Data curation,Validation, Formal analysis, Writing – original draft, Writing – review &editing. Gang Liu: Writing – review & editing. Aliyu Idris Muhammad:Conceptualization, Writing – review & editing. Yadong Zhang: Writing– review & editing. Musa Abubakar Tadda: Writing – review & editing.Wanhe Qi: Writing – review & editing. Dezhao Liu: Supervision,Writing – review & editing. Zhangying Ye: Supervision, Writing – review & editing. Songming Zhu: Conceptualization, Funding acquisition, Resources, Writing – original draft, Supervision, Project administration, Writing – review & editing, Gave final approval for submission of the article.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements