Investigations of entrainment characteristics and shear-layer vortices evolution in an axisymmetric rear variable area bypass injector

Guoping HUANG, Chao LI, Chen XIA, Qian LI

College of Energy and Power Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China

KEYWORDS Variable cycle engine;Rear variable area bypass injector;Bypass ratio adjustment;Mixed exhaust;Thermal mixing;Spanwise vortex

Abstract In this study, firstly, for the axisymmetric RVABI, the change-rule of adverse pressure gradient caused by radial velocity during the transition of internal flow mode in variable geometry is summarized, and a Bypass Ratio (BR) iterative algorithm based on the empirical correlation of non-equilibrium pressure is proposed. The algorithm can estimate the nonlinear relationship between area ratio and BR,with an error range falling below 6.5%.Then,we discuss the favorable effect of uniform mixing on the thrust augmentation of mixed exhaust under variable BR conditions. From this point of view, the characteristics of vortices evolution in different shear strength jets are compared,to clarify the effect of variable cycle parameters on jet mixing.As the results suggest,when Λ is as low as 0.22,the K-H disturbance is of high-frequency wavelet property,and it is difficult to induce large-scale spanwise vortices.The macro migrations of fluid elements in spanwise vortices and the diffusion effect caused by edge tearing is weak,which is not conducive to the energy exchange between the two streams. However, the low Λ jet will also correspondingly weaken the viscous dissipation effect of vortices. It is concluded that the dissipation level is proportional to the 2.31 power of the Λ.

1. Introduction

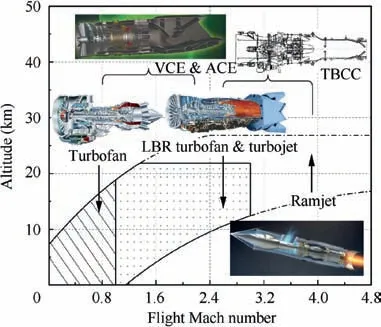

The desire to fly higher, faster and farther is the motive force for human beings to enter the era of jet. It promotes human beings from single spool turbojet to dual rotor turbofan and even high bypass ratio triple spool turbofan. Now it leads us to explore the most novel technology of Variable Cycle Engine(VCE). With the increasingly stringent requirements for aircraft multi-task adaptability, when the mission includes both supersonic and subsonic flight, or there are multiple design points, the traditional propulsion system with only one working mode is more and more difficult to meet the dual performance requirements of high specific thrustand low cruise fuel consumption.In this context, the variable cycle technology,which can adjust the air-flow and compression ratio of fan and core-engine through specific components,shows great potential (As shown in Fig. 1).

As the core component of internal flow mode transition,Rear Variable Area Bypass Injector (RVABI) is used in both variable cycle and combined cycle engine.By adjusting the area of the main duct and bypass, RVABI can cooperate with Mode Selector Valve (MSV), Front Variable Area Bypass Injector(FVABI),adjustable guide vane and other adjustable components to adjust the flow split between the fan and core streams. It also can equilibrate the static pressure between the outlet of fan and turbine within the wide working range of variable bypass ratio to achieve the best matching of each component.YJ101 is the first turbofan engine equipped with RVABI, which was tested in 1976. It has been proved that RVABI can control the speed of low-pressure rotor speed independently from the core engine to some extent.In the 1990s, the double bypass engine YF120, which was equipped with RVABI,FVABI and other adjustable components,made a successful test flight. Its demonstrator YF22 can cruise at supersonic speed without afterburner opening.The experiment further verified the feasibility of RVABI to regulate the internal flow mode.The above research results were used for reference by the near-space propulsion system project Revolutionary Turbine Accelerator (RTA) in the early 21st century. Based on YF120, the internal flow regulation performance of RVABI was developed to adapt to the mode transition of turbine/ramjet.Then, a technical verification engine RTA-1 which can meet the wide range operation of Mach number 0-4 was constructed.When the flight Mach number is above 3, afterburner combustion is gradually converted to ramjet combustion, and the turbine enters the idle state. The two-stage-to-orbit mission profile requires a 10x swing in bypass ratio.

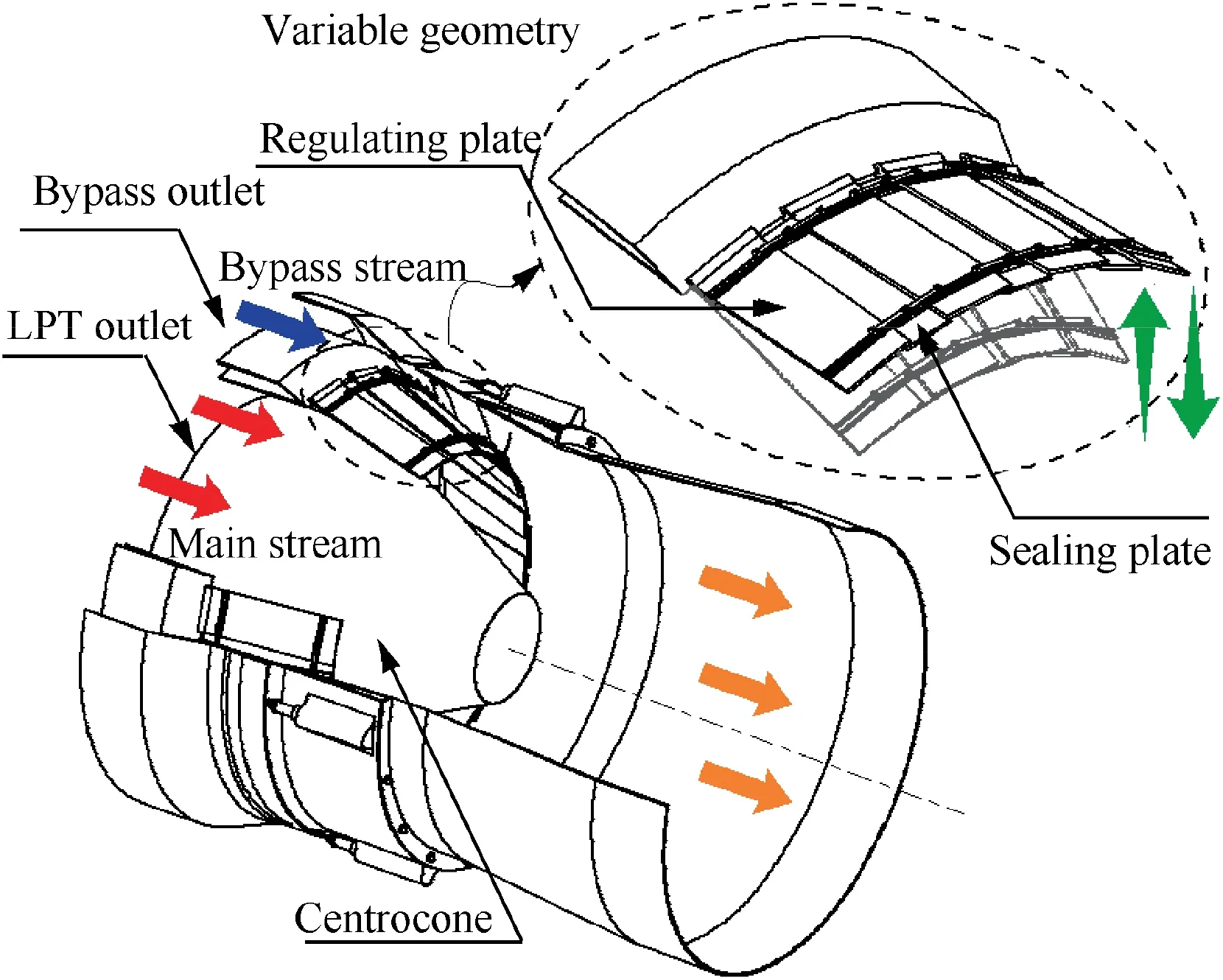

In this study, we focus on the role of RVABI in variable cycle, because it not only plays the function of internal flow regulation in turbine engine, but also is an exhaust mixer that can improves propulsive efficiency by reducing waste heat and residual kinetic energy loss.The performance of RVABI depends primarily on two factors.One is the regulation ability of bypass ratio,which can be regarded as the control ability to the fan working point and back pressure of turbine to a certain extent.The other factor is performance matching to the downstream afterburner and nozzle, that is, the flow quality at the outlet position, including the uniformity of momentum and scalar mixing,mechanical energy,etc.The object used in this research is an axisymmetric RVABI,which is composed of fish scale regulating plates and sealing plates overlapping each other,and changes the injector opening through the link mechanism to adjust the exit area of the main duct and bypass (As shown in Fig.2).It has the advantages of simple structure and less aerodynamic loss.The binary attribute of its flow is strong.

Fig. 1 Flight regimes of several types of engines.

In the past few decades, studies have widened the knowledge on jet flow mechanism. In their contribution, Rogers and Moserinvestigated the mixing layer development process under different initial disturbances by direct numerical simulation. The results show that the mixing layer will gradually enter the self-similar stage, after a period of time, in the case of no initial disturbance or weak disturbance, while the mixing layer will show quasi self-similar features with largescale vortex pairing when the disturbance is strong. Hernan and Jimenezon their part examined the evolution of largescale coherent vortex structure by analyzing the growth cycle of vortices and the entrainment of the surrounding fluid in the process of vortex pairing and merging. Result from their study pointed out that the vortex growth mainly depends on the entrainment of the surrounding fluid during the merging process. The vortex merging process was analyzed in detail by Overman and Zabusky,in which their findings showed that when two vortex structures with different local density merge, the low-density vortex structure will absorb the highdensity vortex, and the merging process tends to be stable.Pullin and Saffmanstudied the kinetic behavior of vortices in high Reynolds number turbulent flow, and considered that the essence of high-speed turbulent flow with wide energy spectrum characteristics is the interaction and energy cascade transport between different scale vortex structures. The problem of jet stability caused by velocity difference was first studied by Betchov and Szewczyk,and the results show that there is a correlation between the stability of mixing layer and the velocity ratio Λ = |u-u|/(u+u) (uand uare mainstream velocity and bypass velocity respectively).This stability theory has been confirmed in the experimental studies of Miksadand Hoet al.,with the experimental velocity ratio Λ of 0.68 and 0.31 respectively. Moreover, it is concluded that the spatial growth rate of disturbance is related to St, and the St corresponding to the fastest growing mode is 0.032.

Fig. 2 Concept of an axisymmetric RVABI.

Due to the adjustment of the variable geometry, jet flow conditions, such as Λ, BR (Bypass Ratio) and total temperature ratio θ are no longer fixed if the concept of a variable cycle is introduced into mixed exhaust propulsion system, thereby making the exploration of the mixed exhaust components’mixing and loss characteristics more complicated. To our knowledge, despite the mixing characteristics of conventional ejector mixers have been systematically and deeply studied,research on the mechanism of jet flow with variable geometry are quite limited, and few of them emphasis on the analysis of the entrainment effect on thrust augmentation from the aspects of mixing and variable bypass ratio. It is thus against this background that this part needs further study.

This paper which examined the high-temperature ratio shear flow in an axisymmetric injector with variable geometry consists of three sections.The first section summarizes the variation law of pressure ratio between the main duct and bypass under the influence of regulating plate deflection angle α.Based on this understanding, an iterative method for calculating the bypass ratio is proposed, which can quickly estimate the basic size of the injector and evaluate the regulation capacity of the BR. The second section analyzes the components of loss in thrust augmentation,which emphatically expounds that with the increase of BR, the mixing difficulty increases, and incomplete mixing will lead to a sharp decline in the energy utilization efficiency of core flow. For the third section in this paper, we extend the previous conclusions, and discuss the mixing capacity of jets with different Λ, and then analyzes the scale characteristics and coherent structure of spanwise vortex based on the high-fidelity numerical simulation.

2. Numerical method and validation

The reduction degree of viscous shearing effect and energy transport phenomenon between the primary and secondary flows in injector depends on the treatment and modeling capacity of the governing equation in turbulence model. The computation of all cases in this paper adopt the threedimensional LES turbulence model,which can accurately simulate the large-scale vortex structure,and solve the small-scale turbulence by establishing the Smagorinsky-Lilly subgrid model.A fixed time step is used to solve the unsteady process.The time step is 2 × 10s, and the Courant Friedrichs Lewy(CFL)Cr<2.0 is maintained in the whole domain.Moreover,the study employed the second-order implicit scheme for the transient equation as well as the second-order upwind scheme for pressure interpolation.

2.1. Grid and boundary conditions

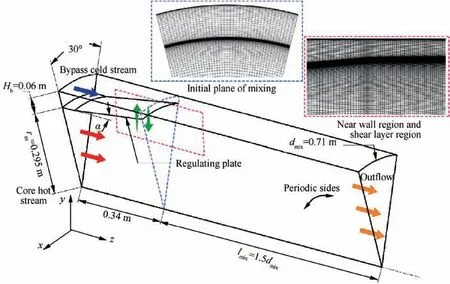

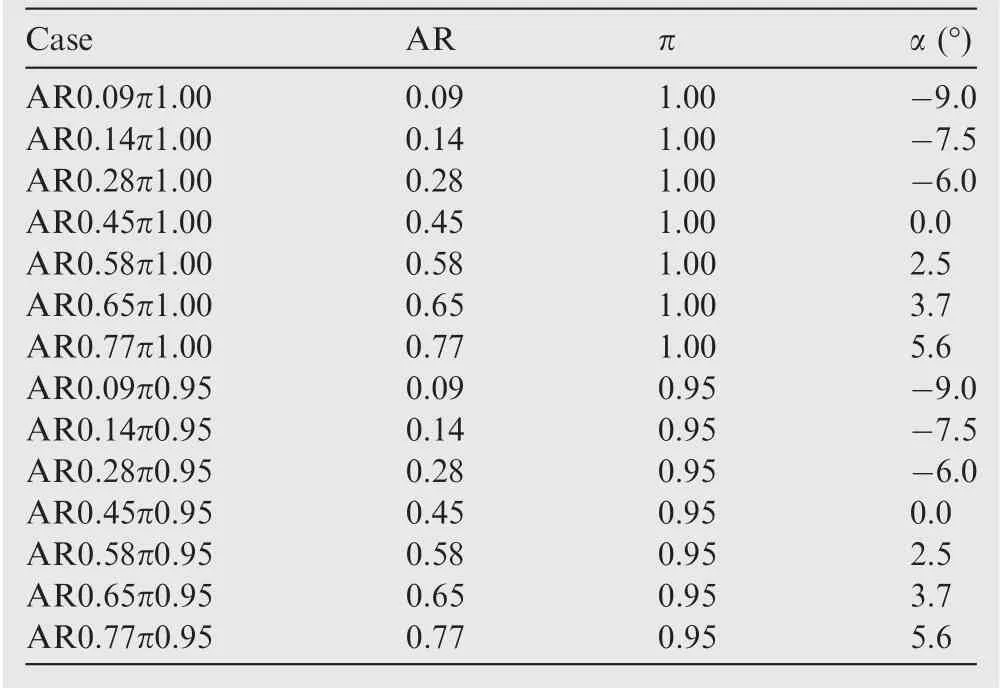

From the structural diagram and the sectional grid of the simplified injector model shown in Fig.3,it could be observed that the inlet radius of the main duct(r)and height of bypass(H)are 0.295 m and 0.06 m respectively, with the regulating plate having a length of 0.29 m.The diameter of mixing region(d)is 0.71 m and the length-to-diameter ratio (l/d) is 1.5.Furthermore,under the action of the regulating plate,the Area Ratio (AR = A/A, where Aand Arespectively represent the area of bypass and main duct at the initial position of mixing) varies from 0.09 to 0.77, and the jet angle α can be increased from -9° to 5.6°. It is considered that the mixing and entrainment characteristics of the injector mainly depend on the development of the shear layer at the junction of the two streams.However,the centrocone will form a vortex shedding wake at the center line, and this flow will not affect the development of the mixing layer or the key to the injector performance. Therefore, the structure is omitted in the simplified model,so as to study the development of shear layer more pertinently. A 30° region is intercepted as a period in the whole circular column since the change of flow parameters along the spanwise direction is weaker than that in other directions.Also,due to the large velocity gradient in the near-wall region and the mixing layer, the Y-grid block with 6.8 million elements is built in the calculation domain, and grid-encrypted is carried out for the above regions to satisfy LES requirement of y≈1 for the purpose of ensuring the turbulence details of shear flow can be captured in the simulation process.

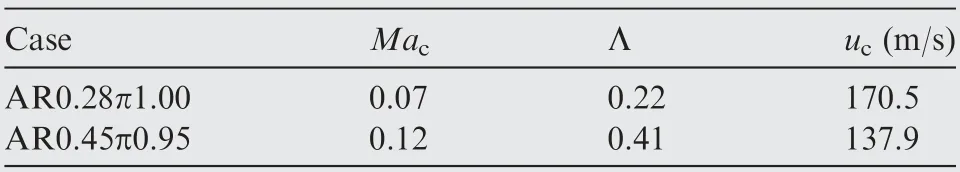

A nonslip adiabatic boundary condition is employed for all walls, the pressure outlet and inlet conditions are adopted for the outlet of mixing section and the inlet of main duct and bypass, both the inlet air flow along the z direction, and the rotating periodic boundary is set in the circumferential direction. The operating conditions of all cases in this paper are listed in Table 1. The total temperature ratio θ = T*/T*and pressure drop ratio (p/p*) are 0.46 and 0.92 respectively. Where T*and T*are the total temperatures of the mainstream and bypass respectively, pis outlet pressure and p*is total pressure at the mainstream inlet. For the sake of convenient discussion, the following cases will be named as AR and the bypass total pressure ratio π = p*/p*(p*is total pressure at bypass inlet).

2.2. Case verification of turbulence model

The LES method adopted in this paper is calibrated and verified, before the numerical simulation study. No matter for the Variable Cycle Engine (VCE) or the conventional turbofan engine,from the perspective of overall performance,the mixer is always designed and optimized to increase thrust augmentation as a special component of mixed exhaust system. Therefore, in order to reduce the energy loss of mixing, π is maintained around 1. Moreover, in order to meet the flame stability requirements of downstream afterburner, the main duct and bypass flow are subsonic.The Mach number difference between the two streams is not significant, under the constraint of similar static pressure. Especially in the case of π = 1, the Mach number is basically equal, and the velocity difference is mainly determined by the temperature ratio.Consequently,the level of compressibility and shear strength in the mixing layer is generally low,and the convective Mach number Mais introduced to characterize it.

where uand uare velocity of mainstream and bypass respectively, aand aare sound speed of mainstream and bypass respectively.

Fig. 3 Diagram of bypass injector and computational grid.

Table 1 Operating condition description.

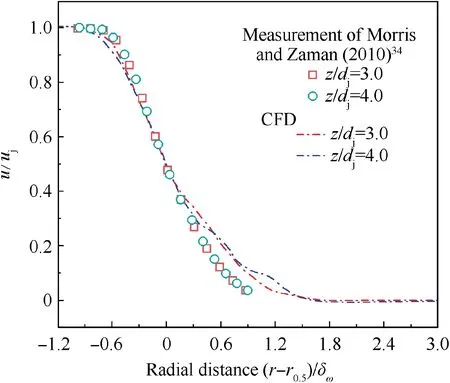

In this paper, the Marange is set between 0.07 and 0.13 according to the real operating condition of RVABI jet flow.Also, the verification data based on the same compressibility level of the mixing layer were obtained from the nozzle experiment conducted by Morris of Penn State University in 2010,with the Mavalue of 0.12. Fig. 4 shows the comparison diagram of axial velocity distribution at z/d= 3.0 and 4.0, the downstream positions normalized by nozzle diameter d.Additionally, for the dimensionless velocity profile (normalized by nozzle jet velocity u) the study adopted the radius of half velocity point(r)and local vorticity thickness,the definition of vorticity thickness δis expressed as Eq.(2).The parameter is related to the absolute maximum value of the gradient of the velocity profile(|∂u/∂y|).It can be seen that the jet velocity profile presents similar characteristics in those locations, and the numerical simulation is consistent with the experimental results.

Table 2 Convection conditions of jet shear layer.

Fig. 4 Radial distribution of u/uj at the downstream position.

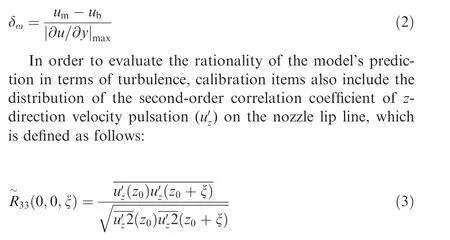

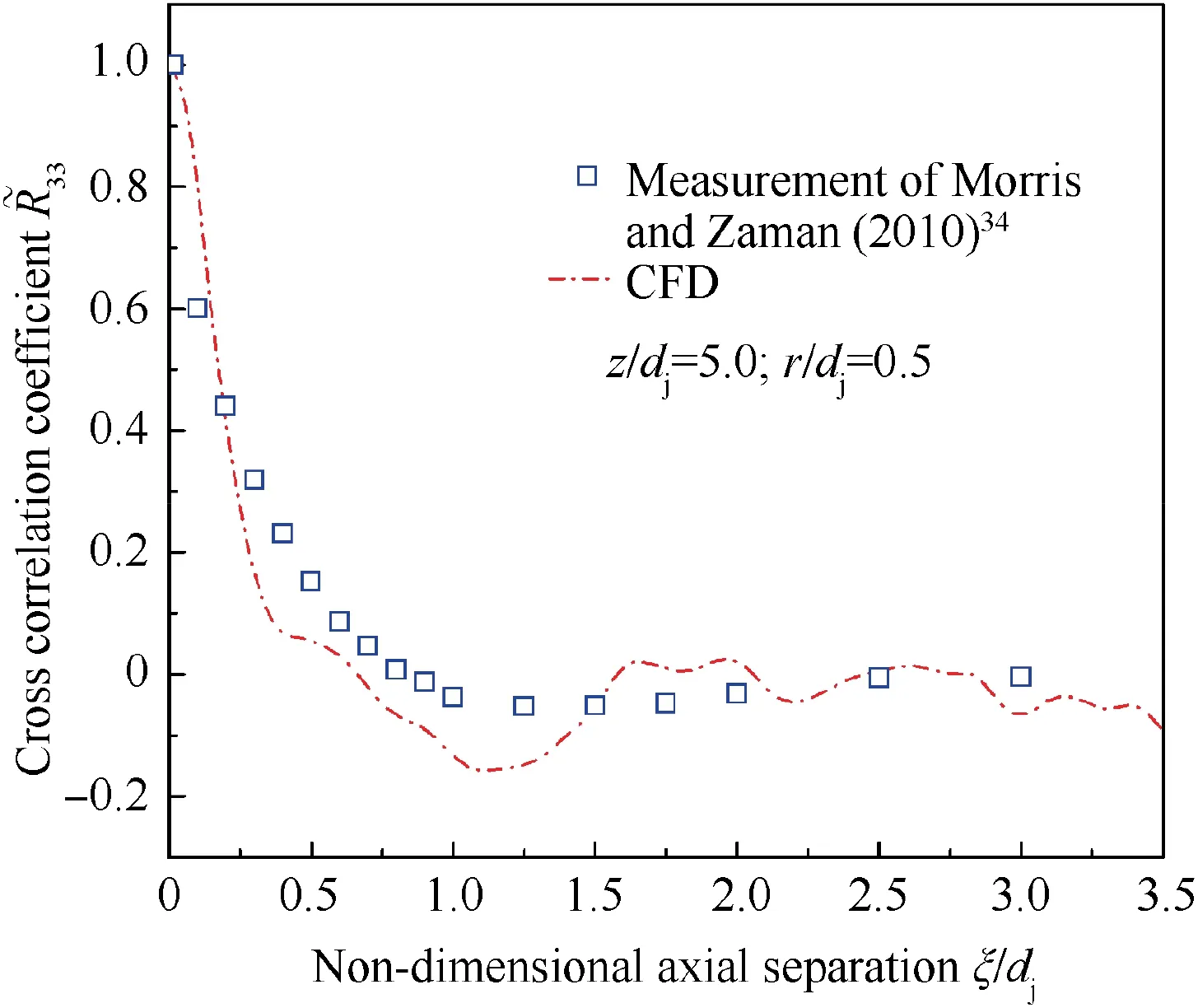

where ξ represents the spatial offset of two points in the zdirection. We regard the upulsation at z/d= 5.0, r/d= 0.5 as the reference, that is, the axial position of the reference point zis 5daway from the downstream of the nozzle.It can be seen from Fig. 5 that the correlation curve exceedingly coincides with the measured value, thus indicating that the numerical method adopted is reliable.

Fig. 5 Two-point spacial correlation coefficient R~33 at z/dj = 5.0, r/dj = 0.5.

3. Analysis of RVABI internal flow regulation characteristics

3.1.Analysis of entrainment characteristics in RVABI transition states

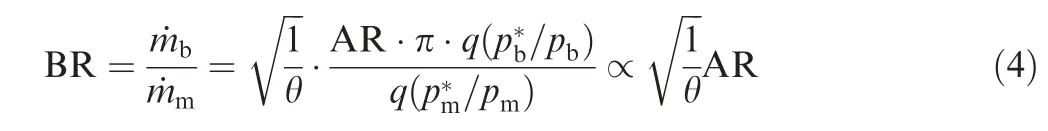

Different from the conventional ejector mixer,RVABI need to change the mixing AR through the action of the regulating plate, so as to realize the transition of the internal flow mode.Therefore,in order to understand the regulating effect of variable geometry on BR, we studied the regulating plate’s deflection angle α as a simple variable, where the relationship between AR and α is a single-valued mapping;and two control groups with π of 1.00 and 0.95 are set to better understand the flow regulatory mechanism of variable geometry. When the bypass pressure ratio π = 1.00, if the loss of the main duct and bypass is ignored, the aerodynamic function at the initial jet position has the following relationship, under the assumption of static pressure equilibrium, aerodynamic function q(p*/p) has an equation relationship q(p*/p) = q(p*/p),Then the BR can be expressed as:

where ˙mand ˙mare mass flow of mainstream and bypass respectively, p*/pand p*/pare the ratio of total pressure to static pressure of mainstream and bypass respectively.

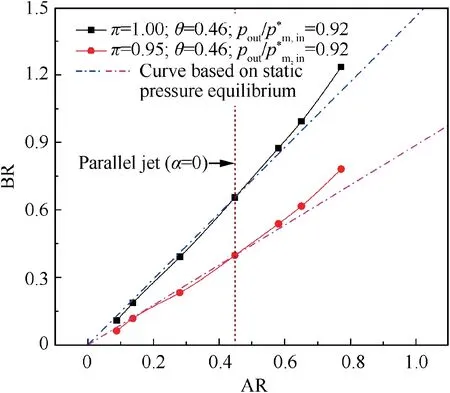

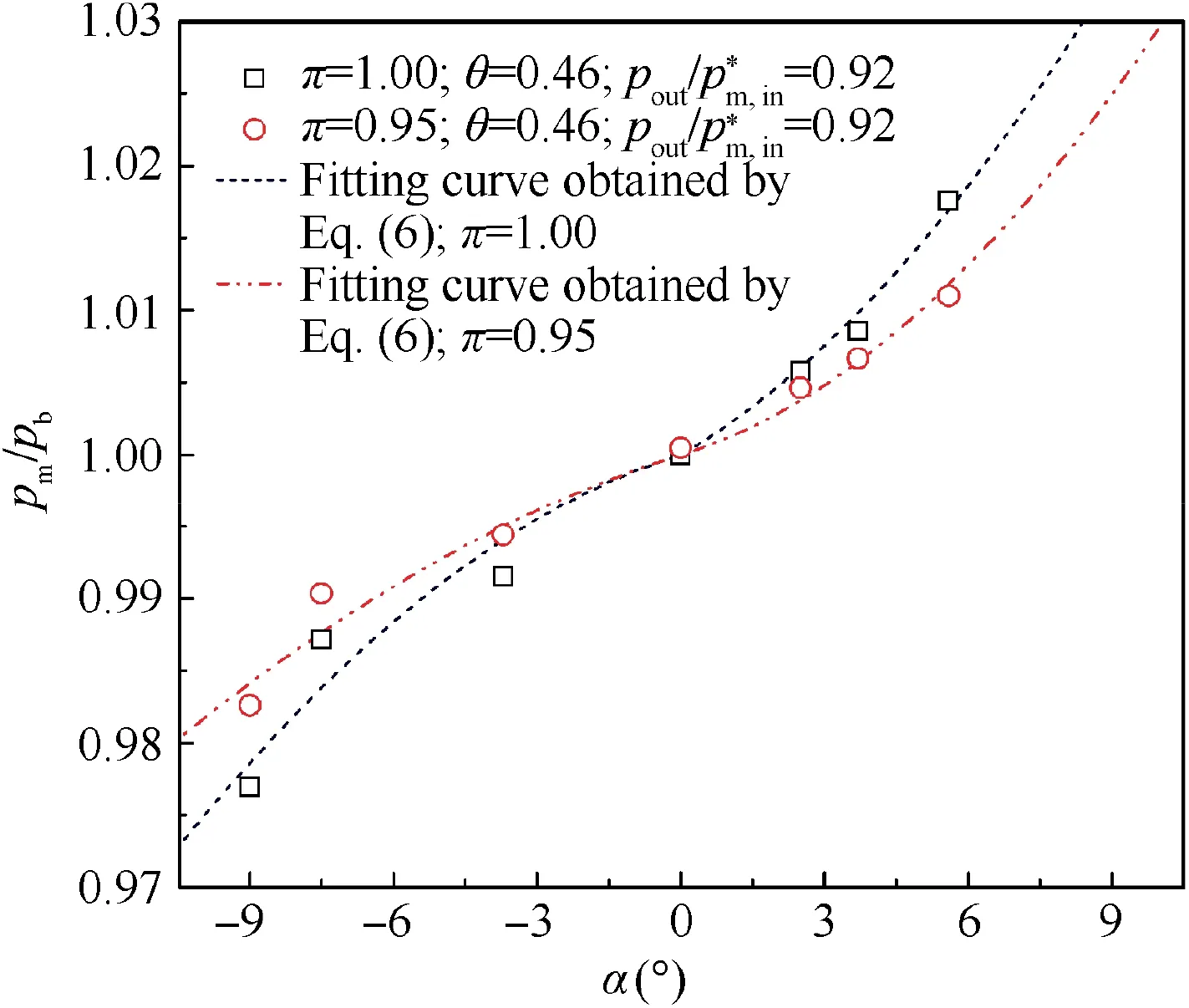

It can be seen from Eq.(4)that BR and AR are linearly and positively proportional when θ is fixed. According to the conditions in Table 1, in theory, BR should show the change rule of blue dotted line in Fig.6.Similarly,when π=0.95,if q(p*/p)/q(p*/p) is approximately considered to be a constant value, the corresponding AR and BR relationship lines can also be constructed, as shown by the pink dotted line in Fig. 6. However, compared with the numerical simulation results, the calculated value of Eq. (4), which are based on the static pressure equilibrium hypothesis, is only equal to the simulation result when AR = 0.45 (the corresponding α is 0, which is a parallel jet). When AR increases from 0.45 to 0.77, the deflection angle α increases from 0° to 5.6°, within which BR simulated values were always higher than those calculated by Eq. (4), and the deviation gradually increased. The maximum error is 9.4% (π = 1.00) and 14.4% (π = 0.95),respectively. But as AR decreases from 0.45, the difference between the two shows an opposite trend. On the general trend, the degree of deviation increases with the increase in the absolute value of α.From the above analysis,it can be concluded that for the injector with variable jet angle,the calculation equation of bypass BR, based on the static pressure equilibrium hypothesis, is no longer applicable in estimating its flow characteristics to a certain extent.

Fig. 6 Flow characteristics of RVABI under the action of regulating plate.

Fig.7 Radial distribution of static pressure at initial jet position.

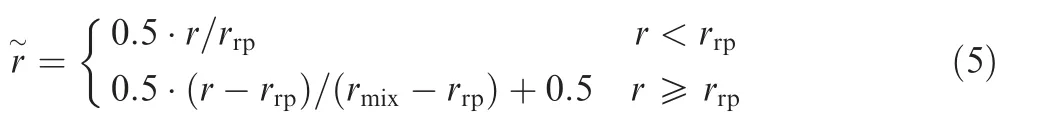

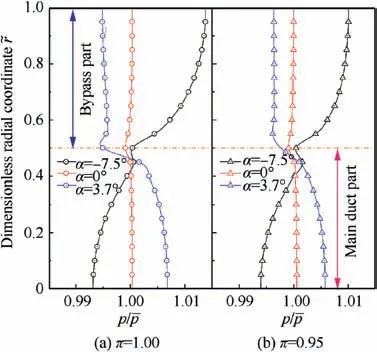

Fig. 7 shows the radial distribution of static pressure (p) at initial jet position,in which static pressure is normalized by the section average pressure(p).Combined with Fig.7 and Fig.8,it can be seen that the convergent-divergent degree of the passage is changed due to the action of the regulating plate; Both the main duct and bypass flow will generate radial velocity which toward the deflection side of the regulating plate. Until the mixing section,constrained by the duct wall,with the flow development, the final mainstream direction is bound to be parallel to the flow passage wall. In this case, the radial velocity deviating from the main flow will be weakened gradually.Therefore,start at the intersection of the two streams,in order to offset the flow deviation except from the mainstream direction, the flow will produce an adverse pressure gradient in the radial direction, which leads to the imbalance of static pressure. This is consistent with the previous conjecture. Besides,it can be seen from Fig. 7 that, as the flow guiding role produced by the regulating plate acts on both the two duct flow,with the decrease of π, the decrease in the proportion of the bypass stream weakens the effect of the incongruous flow.Therefore, the pressure distribution at the initial position of π 0.95 jet is relatively flat.

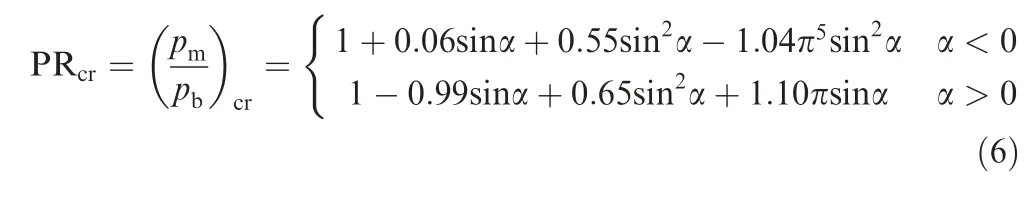

According to the previous analysis,the non-parallel jet will make the position of intersection get rid of the constraint of static pressure equilibrium. As can be seen from Fig. 9, the greater the absolute value of α, the more severe imbalance between the two streams static pressures will be,and the degree of it will be aggravated with the increase of BR. By fitting the transition state’s data, the disequilibrium relationship of pressure ratio (PR) between mainstream and bypass stream can be expressed by the piecewise Eq.(6),which takes into account two factors α and π, and can modify the BR calculation of axisymmetric ejector.

3.2. Calculation of injector BR based on non-equilibrium static pressure correction

Fig. 9 Variation curve of static pressure ratio at initial jet position.

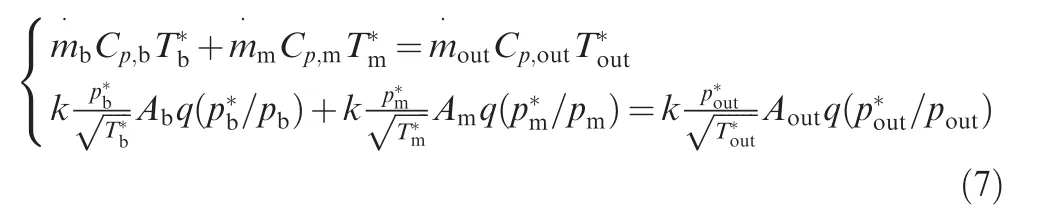

There are no energy-generating components in RVABI, and the flow from the inlet to outlet is subsonic. As such the working substance can be regarded as incompressible fluid.In order to obtain the ejecting characteristics of the component, we regard it as an adiabatic system. Hence, under this condition,the one-dimensional control volume method is used to analyze the system, and the following energy conservation equation can be listed:

where Cand k are specific heat capacity and flow coefficient respectively. Subscripts m, b, and out represent parameters at the main duct, bypass, and outlet respectively.

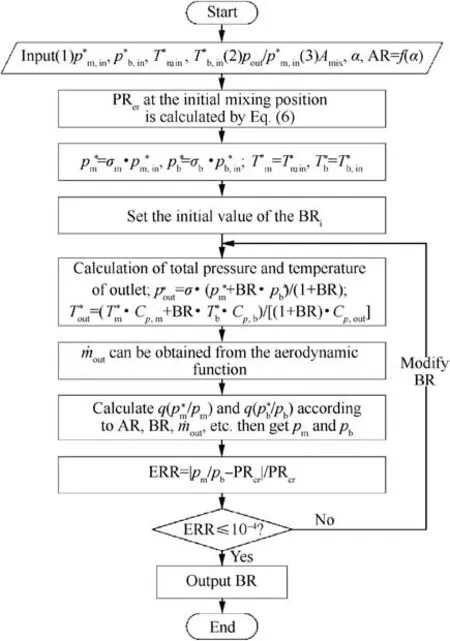

Moreover, the BR under different AR can be solved using an iterative method,if the total temperature,the total pressure of two streams and back pressure are known. This process of computation is shown in Fig.10.Because the simplified model is used in this study, the flow loss of both the main duct and bypass is very low. Compared with parameters such as π and p/p, the total pressure recovery coefficient (σ) of the two ducts is relatively small. Therefore, in this algorithm, they are simply treated as a fixed value of 0.995, then the iteration is started by setting the initial value of BR, and the iterative equations are closed with Eq. (6). The relative difference between the static pressure ratio PR and PRcalculated in each round is defined as the iteration residual ERR. It follows that the approximate solution satisfying the accuracy requirement can be obtained when the residual error is less than 10.

Fig. 8 Variation trend of uy distribution along flow direction (uy and umix are the y-direction velocity and the average velocity of the mixing section respectively).

Fig. 10 Iterative flowchart of RVABI BR.

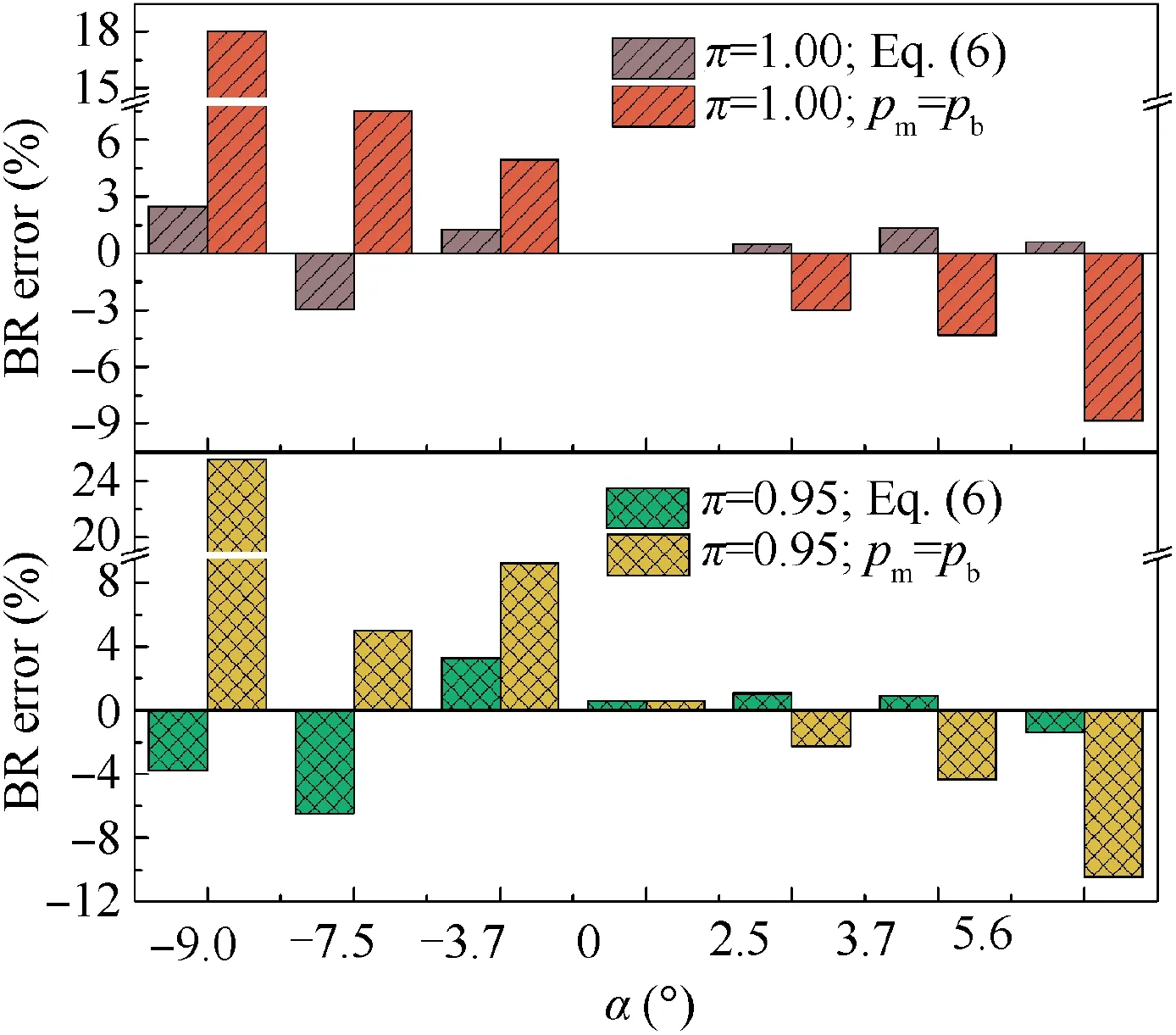

Fig. 11 shows the error between BR iterative calculation and CFD, where it could be seen that the absolute value of BR error calculated by the pressure equilibrium condition is positively correlated with |α|, thereby being is consistent with the analysis conclusion in Section 3.1. The correction effect from the regress mainstream will suppress the radial momentum, so an increase in |α| will exacerbate the radial pressure imbalance. After correcting by the static pressure nonequilibrium relation in Eq.(6),the maximum deviation degree of BR is reduced from 18.0% and 25.5% to 2.9% and 6.5%under the two π respectively. Except for the error peak at α = -7.5°, the overall error level is less than 3.8%. We attribute this situation to the deviation of the corresponding region in the fitting of Eq. (6). The above results indicate that the accuracy of the modified RVABI BR calculation method is acceptable.

Fig. 11 Error of BR iterative solution.

4. Loss components analysis of RVABI thrust augmentation

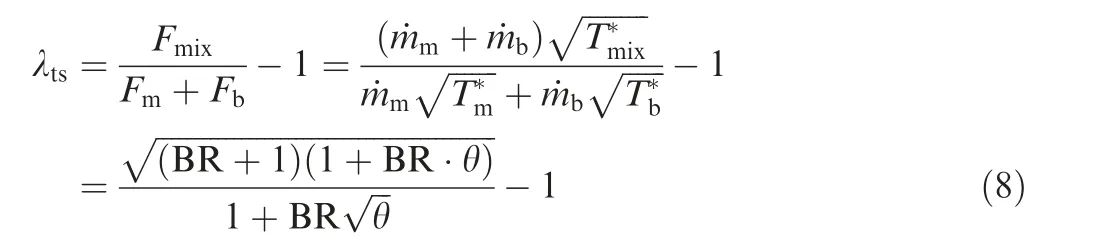

The RVABI, which integrates the functions of internal flow regulation and exhaust mixing, should give full play to the effect of mass addition and mixing exhaust to increase thrust,so as to highlight the advantages of high thermal efficiency of mixed exhaust turbofan mode. In terms of exhaust mixing for thrust augmentation, there are many parameters related to it,such as BR, θ, and nozzle drop ratio, etc. In a study, Frostpointed out that the calculation of thrust augmentation λ is complicated due to the different flight conditions and the corresponding nozzle pressure ratio. Therefore, in this study, the nozzle pressure ratio was made as a constant to assess the λ of RVABI. Under the assumption of C≈C≈C,the λ with complete mixing and no total pressure loss is approximately expressed as follows:

where F, Fand Frepresent the thrust generated by the main stream, bypass stream and the complete mixing of the two streams, respectively. T*is the complete mixing total temperature.

In the following,we will discuss the loss components of λ in an actual situation, which mainly including the three points:(A). incomplete mixing loss; (B). friction loss of two streams respectively and local total pressure loss caused by duct deformation; and (C). total pressure loss in jet shear layer. Among them, the loss caused by incomplete mixing can be measured by mixing function K, also known as the thermal mixing efficiency, defined as:

where Fand λare the thrust and thrust augmentation generated by incomplete mixing, respectively.

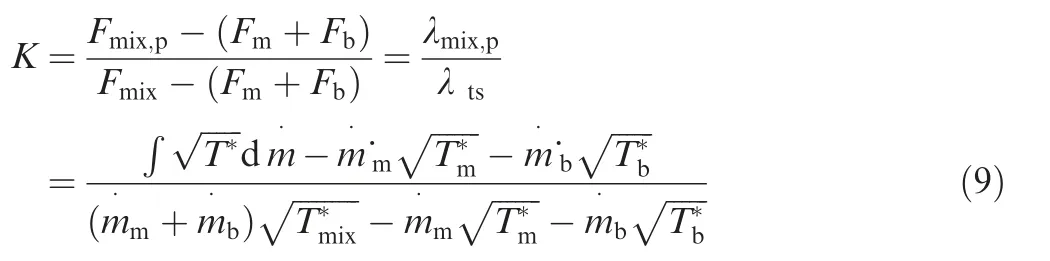

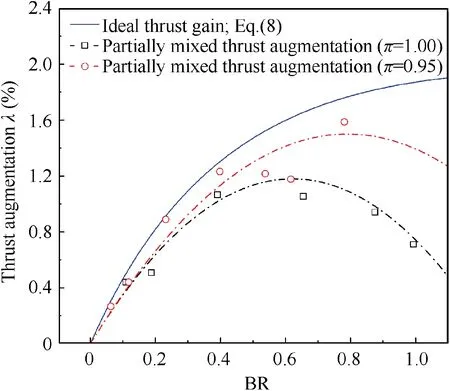

Result in Fig. 12 reveals that there is a corresponding increase in ideal thrust augmentation as BR increases. However, with the increase of the proportion of bypass stream,the characteristics of mixed flow are no longer controlled by the core heat stream alone, but affected by two streams with different properties.In this case,it will be increasingly difficult for the mixing flow to achieve internal homogeneity. Therefore, in the process of increasing BR, due to the aggravation of incomplete mixing degree, the thrust augmentation caused by mixed exhaust relative to the theoretical value with a slower growth trend, and the difference between their value will be larger and larger. Even in the later stage (π = 0.95 and π = 1.00 corresponding to the stage of BR greater than 0.79 and 0.64 respectively), λ shows different degrees of attenuation.As for the different mixing capacity of jet under different π, the detailed analysis is presented in the next chapter.

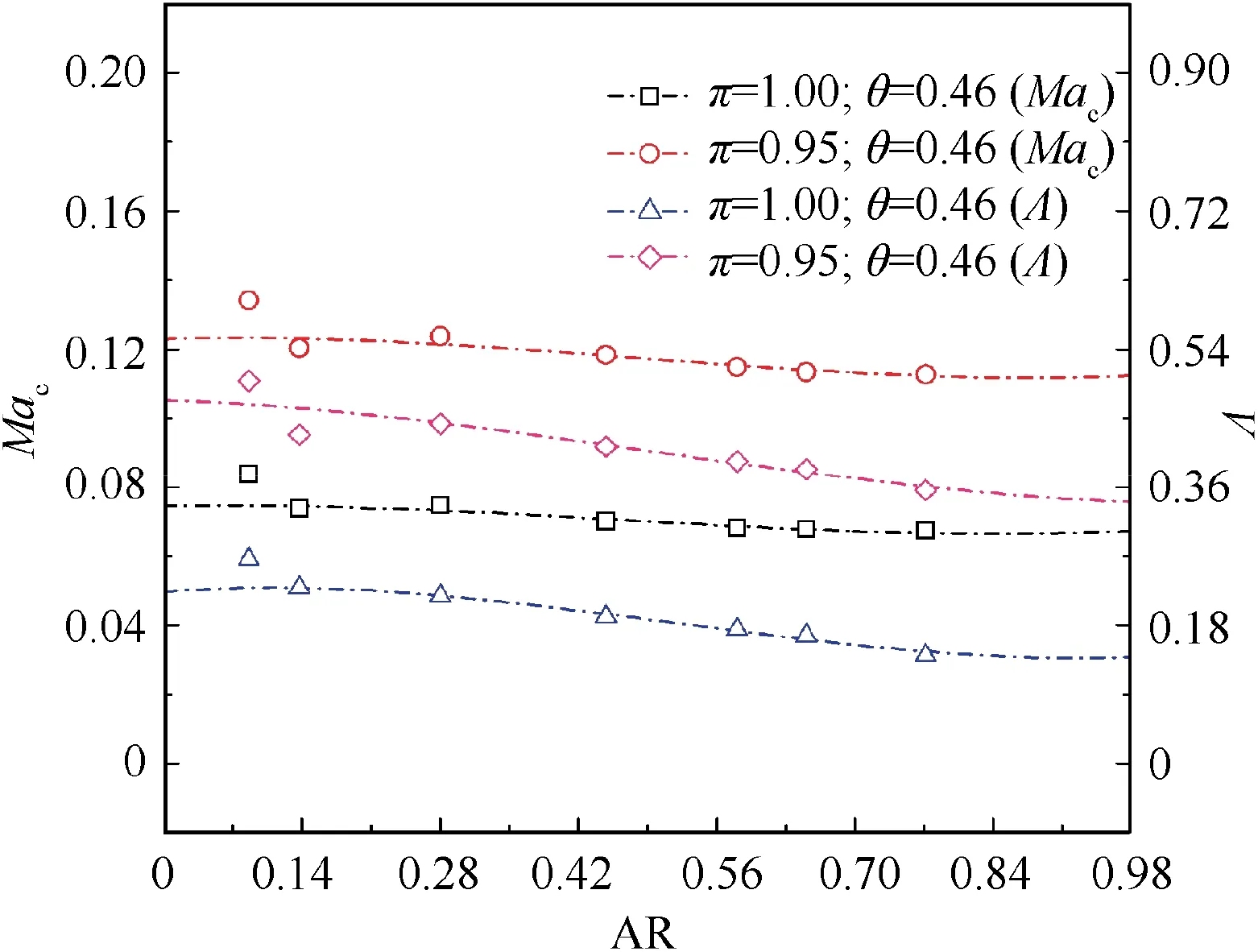

Fig. 12 Thrust characteristics of mixed exhaust incomplete mixing.

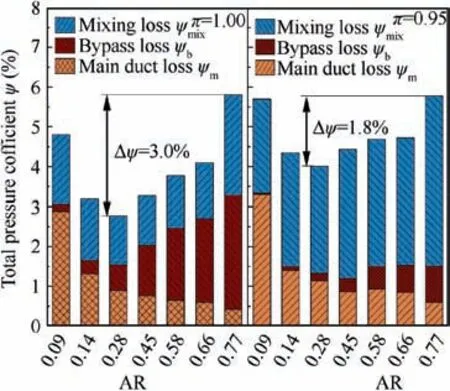

The influence of the other two types of losses on thrust augmentation cannot be directly presented in Eq. (8). Thus, these two losses and the variation law of their components with AR are shown in Fig.13.Under this,the mechanical energy loss is measured by the total pressure loss coefficient ψ = 2·Δp/ρu. In terms of the overall trend, due to the complex relationship between Mach number, BR and duct profile, the loss caused by wall friction and boundary layer instability in the expansion duct has become the main component of the total pressure loss under the support of the flow proportion. It should be noted that in the mixing region, no matter how the inflow Mach number and geometric configurations of two ducts changes, the ψdominated by jet shear force maintains the same level and accounts for more than 34.0% of the overall total pressure loss. It is analyzed in combination with Fig. 14, due to the similarity of static pressure between the main duct and bypass, when the θ is constant, π becomes an important factor to determine the interaction level between the two streams.Thus, the smaller the parameter,the stronger the shear force and compressibility of the mixing layer are. Under the circumstances, the transition states of different BR obtained only by AR regulation,their shear strength of the mixing layer and the resulting mixing loss are at the same level.In addition, as far as RVABI are concerned, the difference between the maximum value and the minimum value of ψ is 3.0% in the current AR research range, which indicates that the cost of variable geometry regulation of BR in terms of mechanical energy loss is acceptable and has a high gain-toinvestment ratio.

Fig. 13 Components of total pressure loss in transition state.

5. Mixing characteristics of spanwise vortex in injector shear layer

5.1. Correlation analysis between spanwise vortex and thermal mixing

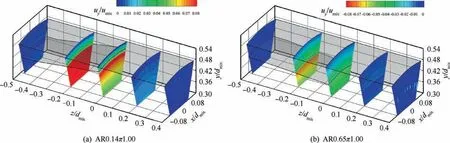

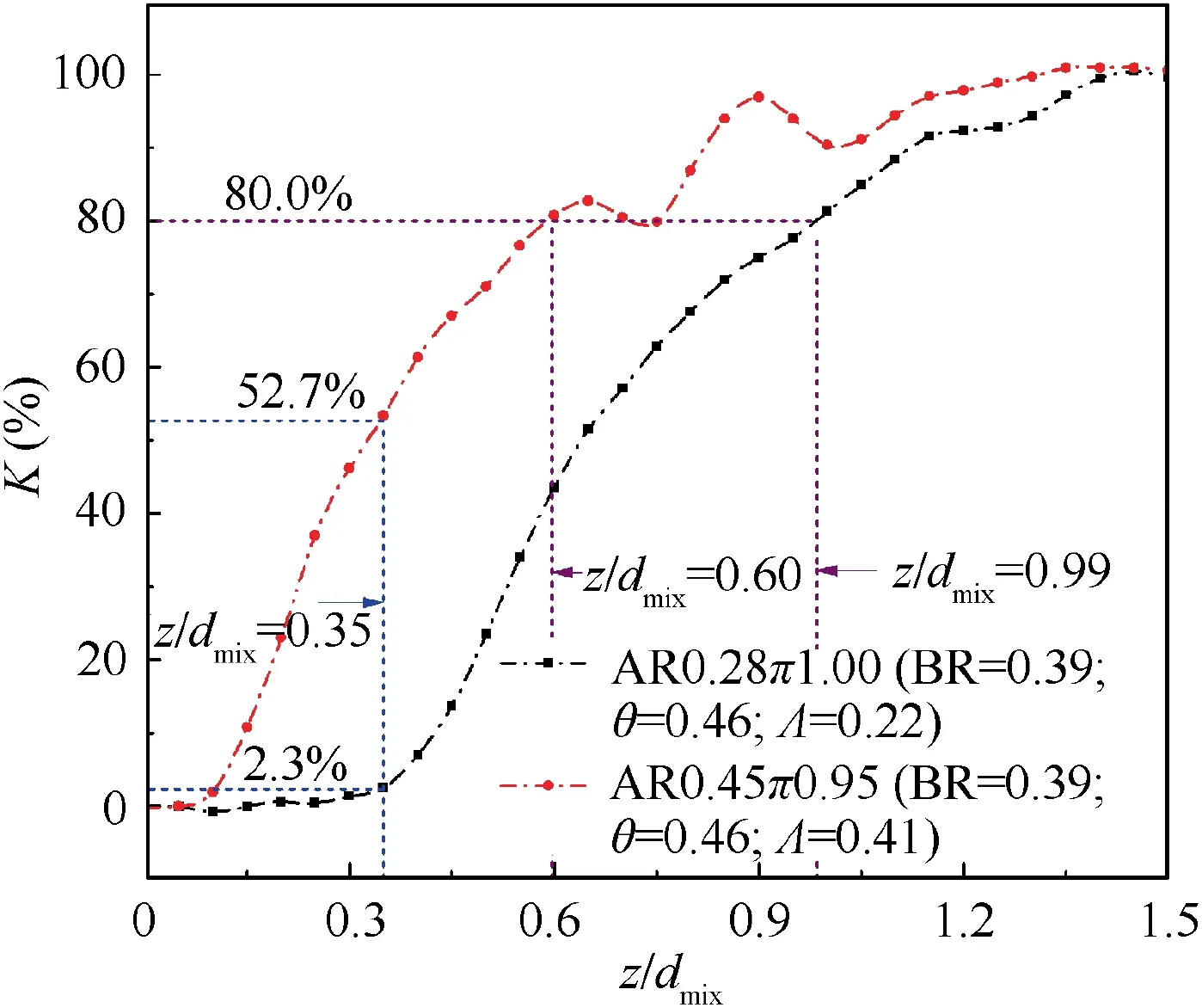

The analysis of the mixing capacity of spanwise vortex in the mixing layer is the focus of this paper. In order to study the scalar transport effect of spanwise vortex with different scales, two jets with different shear strength are selected to compare with each other and analyzed with emphasis. In accordance with the principle of making them more targeted and comparable, two cases of AR0.28π1.00 and AR0.45π0.95 with the same BR and θ are finally selected.The Λ parameters for characterizing the interaction strength of them are 0.22 and 0.41 respectively,which are used to identify the two types of jets for the convenience of discussion below.Fig.15 shows the variation trend of the thermal mixing efficiencies along the flow direction.It can be seen from the figure that the mixing development of Λ=0.22 jet has hysteresis.The temperature scalar of two streams does not appear obvious transport phenomenon within a long distance (z/d<0.35),and there seems to be a temperature discontinuity in the mixing layer. In contrast, the mixing capacity of Λ=0.41 jet is stimulated rapidly at the initial stage.The mixing length of Λ = 0.41 can be shortened by 39.4% compared with the other low Λ jet if the mixing level of both jets reaches 80%.This kind of phenomenon is reflected in Section 4,where there seems to be a correlation between the mixing capacity of the jet and the shear strength.

Fig.14 Variation of shear strength and compressibility inmixing layer under AR regulation.

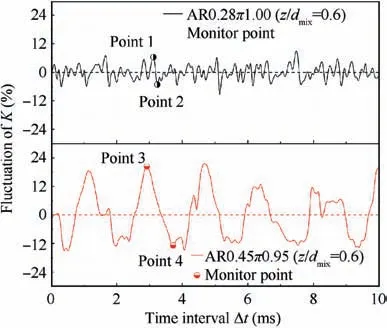

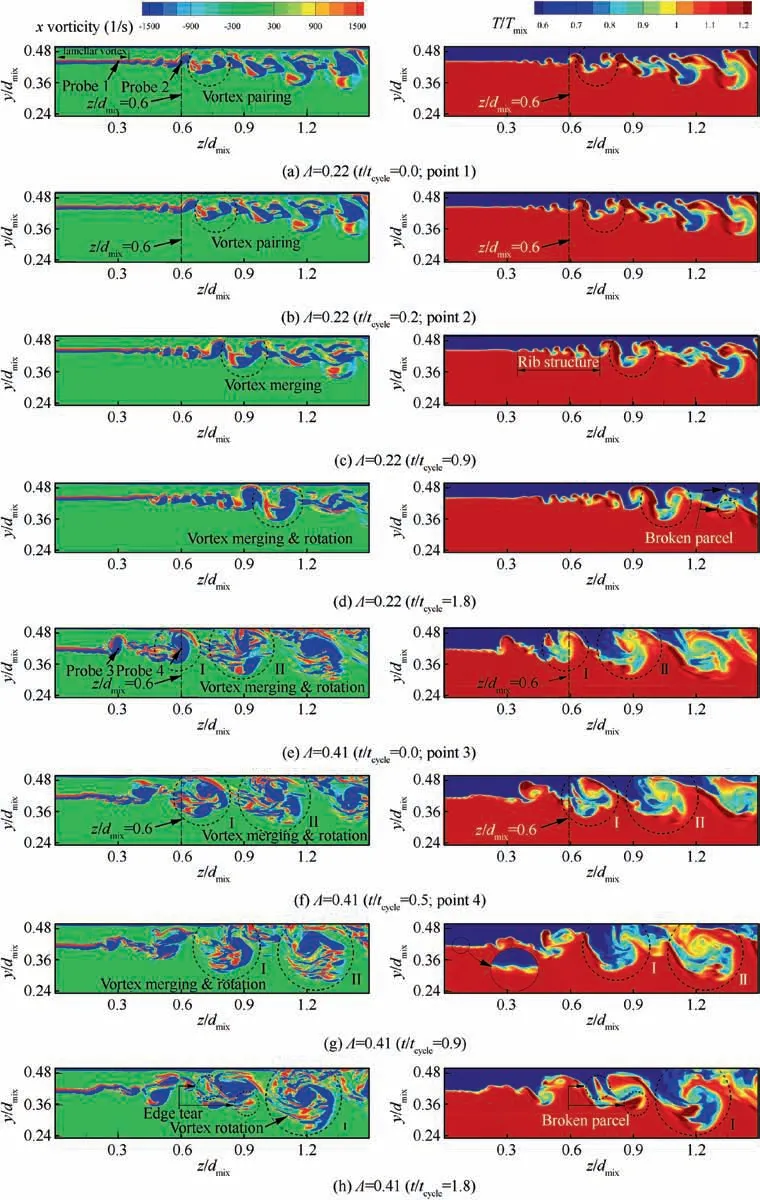

The dynamic history of the two jet motions is shown in Fig. 17, sampling snapshots were taken according to the proportion of the cycle duration (t) of jet flow. By comparing Fig.16,Fig.17(a),(b),(e)and(f),it can be found that there is a correlation between the fluctuation history of K and the rolling up process of the spanwise vortex.For low Λ jets,the vortex layer wrinkle under the action of K-H instability, causing local vorticity accumulation to generate potential energy for scalar transport. When the wave crest of rolled up structure passes through the z/d=0.6 monitoring surface,K reaches its peak(point 1);as the mixing layer develops downstream,K drops to the minimum value (point 2), when the backside of the rolled up structure after vorticity migration passes through the monitoring surface. For the jet with relatively high Λ, K also reaches the peak value of the sequence (point 3) when the core of larger vortex formed by pairing the upstream adjacent vortices pass through the monitoring surface; with the passage of the wake of the merging vortex cluster, the driving potential of scalar diffusion drops sharply, and K reaches the lowest level (point 4) in this period. The whole process alternately repeats and has periodicity. In addition, it can be seen that the coherent structures composed of parts with large temperature gradients has a synergistic distribution relationship with the spanwise vortex field.In conclusion,the mixing capacity of the jet mainly depends on the turbulent flow in the layer and its development; the viscosity effect plays an important role in energy and mass transfer between hot and cold streams.

5.2. Dynamic characteristics of high-velocity jet under different shear strengths

Fig. 15 Variation trend of K along the flow direction.

Fig. 16 K fluctuation histories at z/d mix = 0.6.

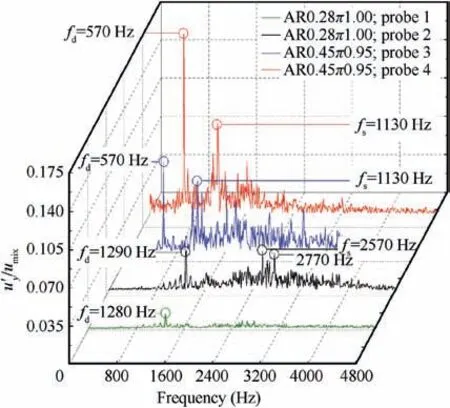

Fig. 18 shows the frequency spectrum distribution of the four probe positions in the mixing layer in Fig. 17(a) and (e). The frequencies of the maximum disturbance amplitude of probe 2 and probe 4 are 1290 Hz and 570 Hz respectively. It can be considered that these frequencies are the dominant frequencies of vortex layer’s roll-up or shedding, which are positively correlated with the convective velocity u= (a·u+ a·u)/(a+ a),see Table 2. Different fromΛ = 0.41 jet, the amplitude of second harmonic disturbance (corresponding frequency f) in Λ = 0.22 jet does not show a trend of attenuation,which indicates that the intensity of unstable subwave derived from K-H wave is equivalent to that of the original wave.Therefore,it can be inferred that the development of Λ= 0.22 mixing layer is not dominated by the growth of single vortex system structure. Besides the dominant frequency and its double frequency, there are still some high-frequency eigenmode which, to a large extent, influences the evolution of the mixing layer. The mixing layer features extreme complexity.

Driven by K-H instability, the shear layer flow is a cyclic process. The periodic time (t= 1/f) is defined based on the dominant frequencies fof the large-scale coherent structure in the shear layer so as to observe the details of the turbulence dynamic evolution over several periods. It can be seen from the frequency features of the disturbance wavelength(γ=u/f) present in Fig. 17(a)-(d) and Fig. 18 that the K-H instability of Λ = 0.22 jet at the initial stage is propagated in the form of high-frequency wavelet. The instability of this kind of disturbance is weak and easy to be damped by potential flow. Therefore, the mixing layer always maintains the basic morphology of stratified structure and temperature discontinuity in the z/d< 0.35 region. Different from the above phenomena, under the strong shear force, the vortex layer of Λ = 0.41 jet will lose its stability rapidly in the initial stage,and sways in the radial direction;in this process,a smallscale scalar transport phenomenon has occurred inside the vortex layer, as shown in the local picture of temperature field in Fig. 17(g).

Fig. 17 Dynamic evolution of spanwise vortex with different Λ.

When the instability increases to a certain extent, the end structure of the vortex layer is thrown out. The detached vortex entrains and rolls up with secondary instability, and gradually pairs with the downstream spanwise vortex to form a larger vortex. The merging process of vortex is accompanied by edge tear caused by viscous hysteresis of potential flow.Compared with the Λ = 0.41 jet, the unsteady roll-up and pairing of vortex layer in the Λ=0.22 jet occur later,and the tearing degree after the formation of large vortex is lower.It is worth noting that the roll-up frequency or shedding frequency of spanwise vortex is not equal to the rotation frequency of this structure, the two of which show a negative correlation; especially for the Λ = 0.22 jet flow, within the range of z/d m< 1.5, the rolled vortex cannot even complete a cycle of rotation.

Fig. 18 Disturbance spectrum distribution at probe position.

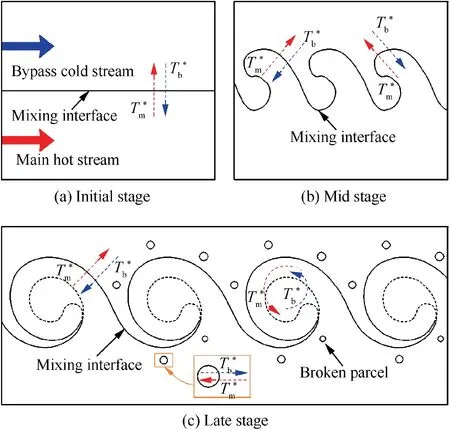

The dynamic evolution process of vortex structure in the mixing layer indicates that the temperature mixing mechanism of two shear strength jets is different. If the Λ = 0.22 jet with low shear strength is taken as an example, its mixing process can be classified into three stages as shown in Fig. 19. At the early mixing stage (z/d< 0.35), the discontinuous thermal interface is not affected by K-H wave,and the scalar transport is mainly completed by convection and diffusion. At the mid stage(z/dwithin the range of 0.35 to 0.90),the mixing interface is twisted and stretched to form a rib-like wrinkled structure. The temperature scalar is still transported by convection and diffusion. However, with the increase of the mixing interface,the convective transport effect of temperature is strengthened,which greatly improves the mixing efficiency.At the later stage (z/d>0.90), the entrainment and forced mixing of large-scale vortex become the dominant way of scalar transport, and the mixing interface has helical deformation and then gets involved in the vortex core and is no longer kept discontinuous. In this process, the micro broken parcels are continuously absorbed into the other side of the fluid, and then further deform and diffuse with the merging of the spanwise vortex. At this stage, the fluid elements with different properties are forced to collide together to exchange mass and energy,during which the thermal transport effect is the strongest.For the intensive shear jet of the Λ = 0.41, the development of mixing layer skips the first stage in Fig.19 and rapidly transits from the second stage to the third stage in the region of z/d<0.25.Moreover,most mixing regions are characterized by scalar transport with both strong entrainment and convection. Therefore, the mixing ability of this kind of jet is better than that of low shear strength jet, which also explains why the mixing efficiency in Fig.15 evolves based on different rules.

Fig. 19 Scalar transport mechanism in mixing layer.

5.3. Scale characteristics of statistic spanwise vortex

In the discussion of coherent structure of spanwise vortex,the scale problem plays an important role,but it is very difficult to discuss this problem in detail. From the perspective of research, since the motion at any point in the turbulent field may be affected by the propagation of pulsating pressure from other vortex blob, in order to quantify the development of spanwise vortices, the longitudinal integral scale of spanwise vortex is established by using the turbulence correlation function:

The average velocity thickness of the mixing layer is used to make it dimensionless. Its definition is as follows:

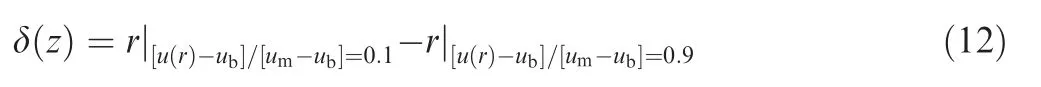

The statistic scale of vortex described by Euler method is the result of the interaction between vortex breaking and merging. It can be seen from Fig. 20 that before the mixing layer loses stability and rolls up, the vortex scale is almost the same as the thickness of the vortex layer,and the coherent structure is relatively simple. With the progress of jet flow, the vortex system in layer develops, and the related sub-vortexes are formed along with the main vortex structures. However, due to the limitation of characteristic length, the vortex scale in the mixing layer gradually becomes saturated. After|d[L/δ(z)]/d(z/d)|dropped below 0.5,the state was nearly stable,and the dimensionless scale will not change significantly even if it develops downstream.In addition,there is a correlation between the extreme vortex scale and the shear strength.For the convenience of quantization, we take absolute value of scale gradient lower than 0.5 as the judgment criterion for the mixing layer to enter the saturation state. Moreover, it can be seen that after full development, the overall level of Λ=0.41 jet’s dimensionless scale is higher,the statistical vortex scale of them accounts for about 0.43 and 0.34 of the local mixing layer thickness respectively.

Fig. 20 Development of statistic spanwise vortex scale.

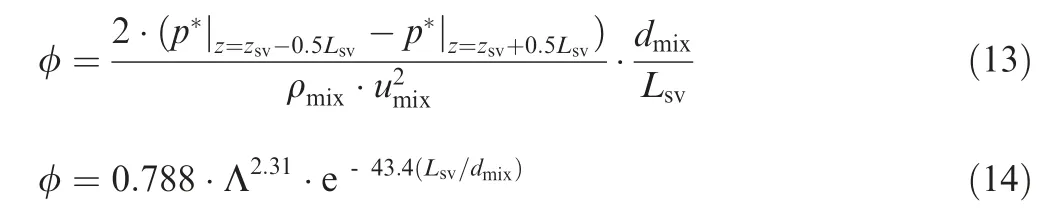

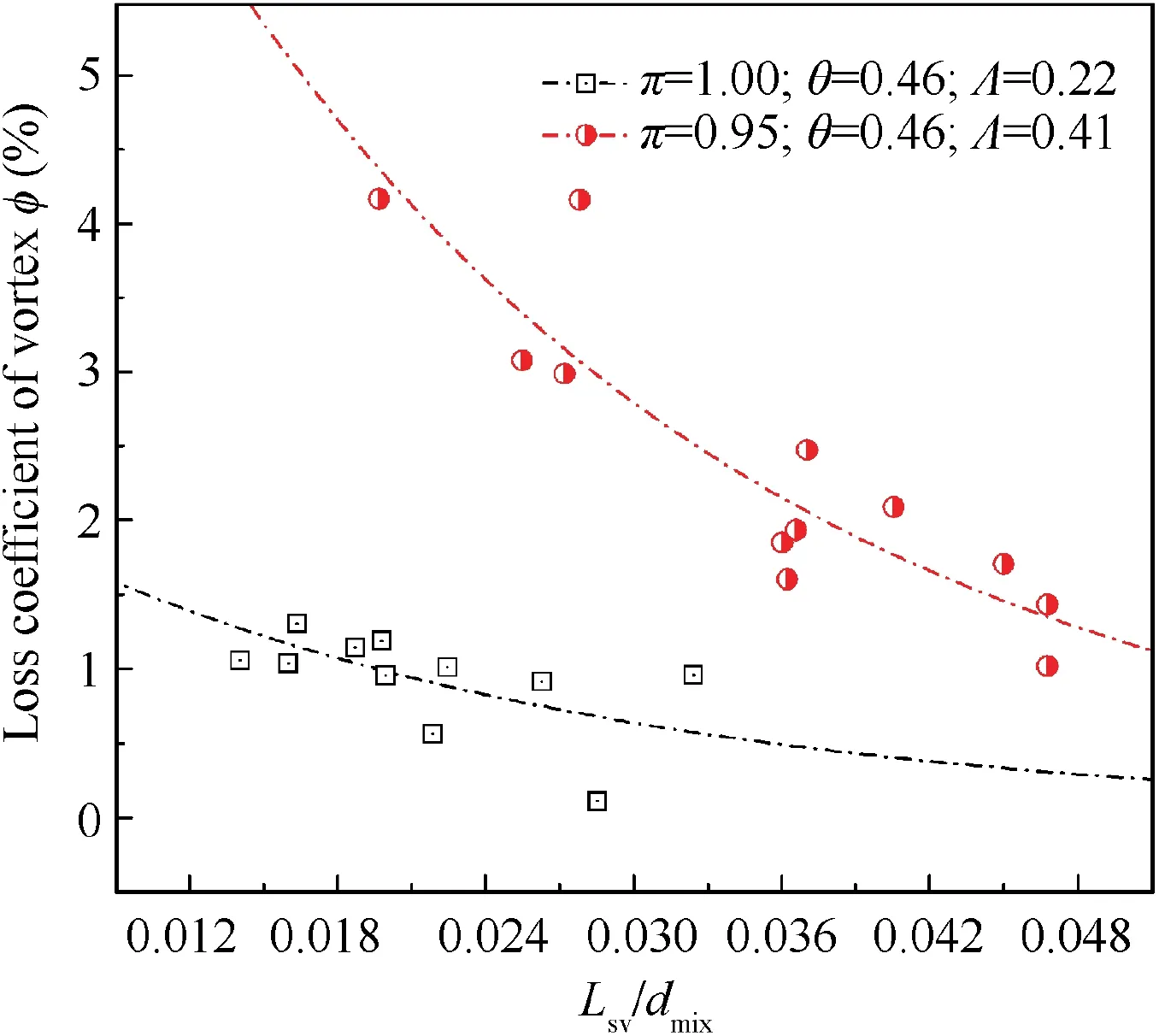

In order to analyze the loss characteristics of the spanwise vortex,the measuring point of the vortex is taken as the reference point to monitor the total pressure loss between two sections at the positions of 0.5Lbefore and after the vortex,and the vortex loss coefficient is defined as shown in Eq.(13).From the perspective of the variation trend of vortex loss coefficient in Fig. 21, the scale characteristics of statistic spanwise vortex are similar to those of large eddies and energy-containing eddies.With the increase of vortex scale,its energy dissipation level decreases.In addition,the energy dissipation capacity has a different sensitivity to vortex scale under different shear strength, and its variation trend is proportional to 2.31th power of Λ. On the macro level, the shear layer of the ejector mainly shows that the energy is captured from the potential flow,and then transfer it to the subordinate vortex;the energy dissipation characteristics of the vortex with extremely high wave number are not obvious.

5.4. POD analysis of the coherent structure of shear layer

In the theory of fractal dimensions,the turbulent field is superimposed by different levels of coherent structures. The flow of each layer is regular.We use the Proper Orthogonal Decomposition (POD) method to decouple the space-time structure of the pulsating field into modes with different amplitudes according to the energy hierarchy. The superposition form of its finite items is:

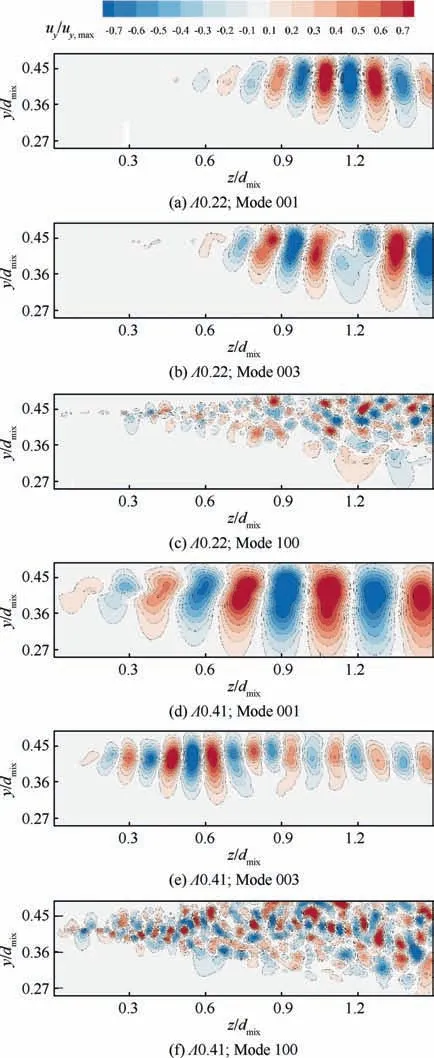

Here Θ(y,z)is the k-th order modal eigenvector,the eigenvector contains the spatial characteristics of the turbulent field structure in the mode, and the temporal characteristics of modes are reflected by the time coefficient ε(t). In view of the direct correlation between the vortex rolling up and the radial velocity pulsation in shear layer, in order to show the structural characteristics of the spanwise vortex in a targeted manner, we only perform POD decomposition on the upulsating field in a part of the shear layer.The snapshot interval is approximately 0.025t, and it contains about 25 rolling-up cycles in the time domain.

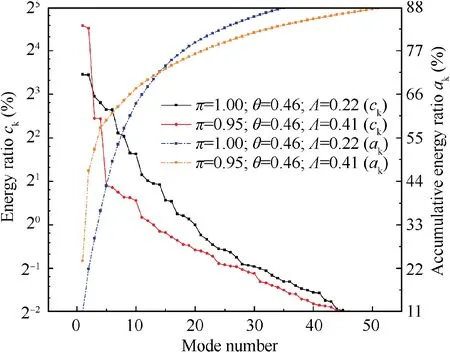

Fig.22 shows the energy distribution of each mode.We can see from the figure that the energy decay of mode is very rapid.The first 10 modes contain a large part of the energy in the pulsating field, and the odd-even modes present a similar energy level pairing. In addition, the energy proportion of the first paired modes in Λ = 0.41 jet reaches 46.5%, presenting a strong dominance. This shows that the conjugated modes can better represent the coherent structural characteristics of shear layer; after the 14th mode, the remaining 28.6% energy of the jet pulsation field becomes more dispersed. It is speculated that this phenomenon is due to the action of strong shear,which makes the tearing effect at the edges of large spanwise vortex clusters become more severe, resulting in the turbulent kinetic energy to be correspondingly transferred to the vortex structure formed by breaking. In contrast, low shear strength jets seem to be difficult to find modes that represent the coherent structure of the mixing layer. The energy ratio of the first paired modes in this state is only 21.8%. The energy distribution is relatively scattered overall.

Fig. 22 Energy ratio of POD eigenvalues for uy.

Fig. 21 Variation of vortex loss coefficient under different Λ.

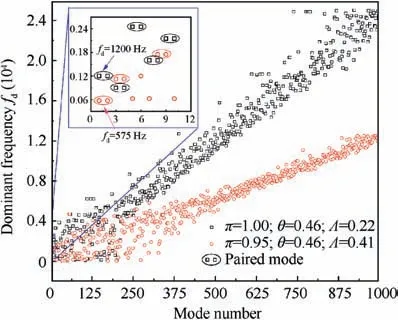

Fig. 23 Dominant frequency of POD mode.

Fig. 24 Spatial structure of POD with different Λ.

It can be seen from Fig.23 that the dominant frequency of POD mode presents an overall trend of approximately linear growth.The dominant frequencies of mode 1 and mode 2 with the largest energy proportion are basically the same as those of the shear layer, and appear in the form of pairing. The modal differentiation is mainly affected by the vortex breaking process, and most of the other modes can be regarded as submodes derived from the mode 1 and mode 2,and the edge tearing of the vortex clusters will cause the motions of related small vortex to grow in the form of harmonics. Combined the spatial characteristics of different jets in Fig. 24, It can be found that the array of large vortex in Λ=0.22 shear layer does not appear until the mid and late stages of the jet,and the vortex core region is significantly smaller than the Λ = 0.41 jet. This once again confirms the conclusion obtained from the previous analysis in Section 5.2:Λ determines the strength of K-H instability, which affects the transition position of the vortex layer. In addition, it can be seen from (c) and (f) of Fig.24 that the high-order modes of the jet all present a disordered chaotic state., which represent the high-frequency background eddy in the turbulent field, and is a manifestation of the random breaking of large structures caused by viscosity.It is also obtained from the analysis in Section 5.2 that these small-scale turbulent structures can carry the micro parcel into the fluid environments with different properties.Although they make less contribution to the flow,they play an important role in scalar transport.

6. Conclusions

This paper takes the large temperature difference ejecting flow in RVABI as the research object,an iterative method of BR for axisymmetric adjustable injector is proposed in the conceptual design stage. That is used to quickly determine the reference size and evaluate the regulating ability of BR. Then we used high-fidelity numerical simulation methods to analyze the thrust augmentation characteristics of the jet with variable BR, and the turbulent structure feature of the mixing layer and the thermal transport mechanism of the spanwise vortex under different shear strengths are studied.Finally,the following conclusions based on the findings are drawn:

(1) For axisymmetric bypass injector,under the influence of the regulating plate deflection,the flow in the main duct and bypass will have radial component. This deviation from the main flow will produce an adverse pressure gradient in the corresponding direction,resulting in the static pressure equilibrium relationship at the initial stage of mixing is no longer tenable. As a result, the AR and BR, which are subjected to variable geometry, present a non-linear relationship.

(2) When the BR increases,the thrust loss caused by incomplete mixing also increases and the thrust augmentation no longer shows a monotonically increasing relation with BR. Under the two conditions with π of 0.95 and 1.00, the reach the maximum at BR of 0.79 and 0.64,respectively, and then present a decay trend. In terms of mechanical energy loss, a large proportion (34.0%-73.8%of the totality)of them come from the mixing loss dominated by π and ; during the whole process of state transition, the did not change prominently, and the difference between its peak and valley value was controlled within 3.0%. From this point of view, there is a higher gain-to-investment ratio and engineering application value of this RVABI.

(3) In addition, there are three main characteristics of 0.22 low shear strength jet. Firstly, the wavelength of initial K-H instability is small, so the mixing layer is not easy to lose stability and always maintains a layered structure in the early stage. Secondly, the rotation frequency of spanwise vortex is lower in the middle and late stages,and thermal mixing relies mainly on the ribbed structure rolled by mixing layer to enhance the convection transport effect. Thirdly, under the combined action of high-frequency disturbance and low shear strength, the turbulence in mixing layer has extreme randomness,and it presents multi-modes characteristics with similar structure, and the energy is fairly dispersed.

(4) For 0.41 jet with strong shear effect, its primary modes gather a large proportion of kinetic energy, which make the characteristic structure of its turbulence is fairly evident. Under the action of strong shear force,the mixing layer becomes unstable earlier and enters into the saturation state of vortex scale. Moreover,the energy dissipation capacity of vortex in layer is at a relatively high level, and thermal mixing is mainly carried out in the form of vortex rotation, vortex breaking and eddy diffusion with strong entrainment and convection effects.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

s

This work was supported by National Major Science and Technology Projects of China (J2019-II-0007-0027), Fundamental Research Funds for the Central Universities, China(3082018NP2018102), National Natural Science Foundation of China (12002162) and Jiangsu Province Natural Science Foundation, China (BK20200449).

Chinese Journal of Aeronautics2022年4期

Chinese Journal of Aeronautics2022年4期

- Chinese Journal of Aeronautics的其它文章

- Reduced-dimensional MPC controller for direct thrust control

- A multiscale transform denoising method of the bionic polarized light compass for improving the unmanned aerial vehicle navigation accuracy

- Periodic acoustic source tracking using propagation delayed measurements

- Optimal predictive sliding-mode guidance law for intercepting near-space hypersonic maneuvering target

- Sea fog detection based on unsupervised domain adaptation

- Unsteady characteristic research on aerodynamic interaction of slotted wingtip in flapping kinematics