豆皮果胶类多糖的提取及其在大豆蛋白凝胶类食品的应用

沈晓梅,冉 根,陈家凤,侯俊杰,王金梅

豆皮果胶类多糖的提取及其在大豆蛋白凝胶类食品的应用

沈晓梅1,冉 根1,陈家凤2,侯俊杰3,王金梅1※

(1. 华南理工大学食品科学与工程学院,小麦和玉米国家工程研究中心,广州 510640;2. 广东科贸职业学院餐旅学院,广州 510430;3. 广西梧州冰泉实业股份有限公司,梧州 543000)

为提高大豆副产物利用率,拓展豆皮果胶类多糖(Soybean Hull Pectin Polysaccharide, SHPP)在凝胶类食品的应用,该研究采用盐辅助结合水热处理技术提取大豆豆皮中的豆皮果胶类多糖,并对其基本理化性质进行表征。通过以大豆蛋白为主要成分的凝胶类食品豆腐花为模型,探究不同添加量豆皮果胶类多糖(0~2.0%)与大豆蛋白的离散型相分离行为,分析其微相分离行为与宏观流变学性质、机械性能、持水性与感官评定的关联性,并与商品化柑橘果胶(Citrus Pectin, CP)作对比。结果表明,该提取法所得豆皮果胶类多糖提取率为17.95%±0.21%,其半乳糖醛酸含量为42.13%±2.05%,平均粒径为(210.3±2.9)nm,多分散性指数(Polydispersity Index, PDI)为0.466±0.037,豆皮果胶类多糖具有良好的亲水性和低黏度特性,易分散于水。添加0~0.5%豆皮果胶类多糖制备豆腐花,发现其微观上无相分离产生,具有良好的网络微结构;宏观上表现为外观白嫩,黏弹性、持水性与口感均良好。添加1.0%豆皮果胶类多糖的豆腐花宏观上出现明显析水,凝胶黏弹性和持水性均显著(<0.05)减少。继续增加豆皮果胶类多糖至1.5%添加量则会导致相分离产生,蛋白凝胶网络微结构变得无序,网状孔隙增大,凝胶强度进一步减弱,保水性极差(46.2%±3.2%)。由此确定,豆皮果胶类多糖适宜添加量为0.5%。与经优化的柑橘果胶添加量为0.1%的豆腐花作比较,发现添加0.5%豆皮果胶类多糖的豆腐花在质构特性以及色泽、组织状态、滋味气味、口感、可接受度各方面的感官评分上均优于含柑橘果胶的豆腐花。结果表明豆皮果胶类多糖更适用于蛋白凝胶类食品。研究结果为豆皮果胶类多糖的应用开发,大豆副产物的再利用以及全豆食品的发展提供一定推动作用。

凝胶;流变特性;大豆副产物;豆皮果胶类多糖;凝胶类食品;相分离;应用

0 引 言

由于人民生活水平的提高,食物趋向于精细化,由高碳水、高脂肪、高热量组成的“三高”饮食导致的肥胖、糖尿病、冠心病和高血脂患者日益增多[1-2]。随着对多糖特别是一些果胶类多糖的深入研究,发现它们具有抑制体重增长,控制脂肪消化,降低血糖和胆固醇,改善胃肠道功能等生理功效[3],受到各界人士广泛关注,已被用于药品和功能性食品中[4-5]。

大豆豆皮是豆制品加工过程中产生的主要副产物之一,含有相当丰富的豆皮果胶类多糖(Soybean Hull Pectin Polysaccharide, SHPP),它主要由同型聚半乳糖醛酸(Homogalacturonan, HGA)和鼠李糖半乳糖醛酸聚糖I(Type I Rhamnose Galacturonic Acid, RG-I)组成[6-7],在大豆豆皮中的含量高达30%[8]。尽管中国每年由豆制品产生的大豆豆皮副产物超过300万t[9],但由于豆皮口感粗糙,不宜直接食用,目前仍主要用作饲料或发酵成肥料,造成大量豆皮果胶类多糖资源浪费。若在豆制品生产过程中对豆皮副产物加以利用,提取出其中含量丰富的豆皮果胶类多糖,不仅能获取生理功效良好的功能性多糖资源,还能有效提高大豆副产物利用率,减少资源浪费,有利于全豆食品的发展。

另一方面,多糖的理化特性使其在食品中起到良好的稳定、乳化、增稠、起泡、凝胶等作用。其中,凝胶性是众多果胶类多糖具有的基本特性。其独特之处在于Ca2+、蔗糖或酸性环境下均可形成凝胶,故常用于凝胶类食品。然而,当果胶类多糖添加到含蛋白的凝胶类食品时,由于多糖和蛋白的热力学不兼容(Thermodynamic Incompatibility)往往会导致相分离现象(Phase Separation)[10]。再者,食品中常见的可食用蛋白其等电点(Isoelectric Point, pI)普遍小于食品体系pH值,而果胶类多糖均为阴离子型多糖(Anionic Polysaccharides),这就导致了该复合体系以离散型相分离(Segregative Phase Separation)为主[11-12]。该相分离的出现在某种程度上会对食品口感、质地、外观甚至风味等[13]产生不良影响,使产品品质变差。目前,关于蛋白/多糖复合体系相关的食品品质调控较多是从改变加工工艺条件(如pH值、盐离子浓度等)进行研究[14-15],但这直接改变了产品的基本配方。因此,开发一款价格低廉、来源广泛、与蛋白相分离程度更小、对产品品质影响较弱的果胶类多糖来制备相关蛋白凝胶类功能性食品具有重要意义。

目前,关于多糖的提取方法已有报道,其中盐辅助结合水热处理技术的提取方式更为绿色简单,提取率高,适合工业化大批量生产。因此,本研究拟采用盐辅助结合水热处理技术提取大豆豆皮副产物中的豆皮果胶类多糖,并对其基本理化性质进行表征,通过以大豆蛋白为主要成分的凝胶类食品豆腐花为模型,探究豆皮果胶类多糖与大豆蛋白的离散型相分离行为,分析其微相分离行为与宏观流变学性质、机械性能、持水性与感官评定的关联性,并与商品化柑橘果胶(Citrus Pectin, CP)作对比,研究豆皮果胶类多糖作为功能性多糖用于蛋白凝胶类食品的应用前景,并为全豆食品的开发提供可行性参考。

1 材料与方法

1.1 材料与试剂

大豆和大豆豆皮由广西梧州冰泉实业股份有限公司提供。六偏磷酸钠购于上海麦克林生化科技有限公司;D-(+)-半乳糖醛酸一水合物,咔唑购于上海阿拉丁生化科技股份有限公司;无水乙醇,柠檬酸,小苏打,硅化油(食品消泡剂),葡萄糖酸--内酯(Glucono--lactone,GDL),荧光素5-异硫氰酸酯(Fluorescein Isothiocyanate Isomer Ⅰ,FITC),罗丹明B异硫氰酸酯(Rhodamine B Isothiocyanate,RITC)购于美国Sigma-Aldrich公司。所用试剂均为分析纯或食品级。

1.2 仪器与设备

C40紫外可见光分光光度计(Implen公司,德国);Zetasizer Nano ZS纳米粒度电位仪(Malvern公司,英国);HAAKE MARS 600流变仪(Thermo公司,美国);Leica TCS SPE激光共聚焦显微镜(Leica公司,德国);Instron5943万能材料试验机(Instron公司,美国);冷冻干燥机(Christ公司,德国);CR22GII高速冷冻离心机(Hitachi公司,日本)。

1.3 方 法

1.3.1 豆皮果胶类多糖的提取

豆皮果胶类多糖的提取方法参考Liu等[16-17]并稍作修改。首先将大豆豆皮粉碎过50目筛(孔径0.35 mm),按料液比1∶30(g/g)将豆皮粉分散于1.5%六偏磷酸钠溶液,并用2 mol/L柠檬酸溶液调节pH值至4.0。持续搅拌30 min后进行水热处理(120 ℃,30 min),进而离心(5 000 r/min,20 min),所得豆皮果胶类多糖上清液经透析脱盐(72 h)和旋蒸浓缩(60 ℃)后,冻干备用。

1.3.2 半乳糖醛酸含量的测定

采用硫酸-咔唑比色法[18]测定豆皮果胶类多糖的半乳糖醛酸含量。标准曲线为=0.01+0.003 2,2=0.997。

1.3.3 酯化度的测定

采用国标方法GB 25533-2010[19]测定豆皮果胶类多糖的酯化度。

1.3.4 粒径、zeta-电位的测定

参考Zhang等[20]方法,用去离子水溶解并制备质量浓度为1 mg/mL豆皮果胶类多糖溶液,并用0.5 mol/L HCl/NaOH调节所需pH值。采用Zeta Nano ZS纳米粒度电位仪在25 ℃下测定粒径、多分散性指数(Polydispersity Index, PDI)和Zeta-电位。

1.3.5 豆腐花的制备

采用传统湿法磨浆方法[21-22]制备豆腐花。将大豆经清水浸泡(12 h)后,以豆/水比为1∶3(g/g)同时加入1.75%小苏打粉和0.1%食品消泡剂进行首次磨浆。取磨浆后豆渣并以1∶2(豆渣/水,g/g)进行二次磨浆,混合所得豆浆,过120目滤布,即为豆浆原液。根据Liu等[17]方法将豆皮果胶类多糖、柑橘果胶粉末分别溶于去离子水,水浴加热(60 ℃)并温和搅拌4 h使其充分水化,由此制备10%豆皮果胶类多糖溶液和5%柑橘果胶溶液。取80 g豆浆原液,用去离子水稀释使其蛋白质量分数为3%,记录去离子水添加量(),由此设定所需的豆腐花质量为(80+)g,并计算含豆皮果胶类多糖(0~2.0%)或柑橘果胶(0~0.5%)、白砂糖(7%)的豆腐花中各物质的添加量。

取80 g豆浆原液,添加相应计算量的豆皮果胶类多糖或柑橘果胶、白砂糖,并用去离子水补充至(80+)g。加热煮沸15 min后冷却至室温,称量并补回蒸发的水分,即为豆浆混合液。将GDL粉末溶于去离子水,制备40% GDL溶液。添加0.35% GDL于上述豆浆混合液,进行巴氏杀菌处理(88 ℃,30 min),室温放置4 h待豆腐花成型,最后置于4 ℃冰箱保存。

1.3.6 流变性质的表征

采用HAAKE MARS 60流变仪进行豆腐花流变学性质的测定,配件平板直径为35 mm,设定间隙高度为1 mm。首先,根据1.3.5方法在平板探头上进行原位制样,并于平板边缘覆盖液体石蜡薄层以防止水分蒸发。在线性黏弹区域内进行频率扫描(0.1~10 Hz),以及应变扫描(0.1~1 000%)。此外,对1%豆皮果胶类多糖和柑橘果胶溶液进行剪切黏度测定(剪切速率为0.01~100 s-1)。测试温度均设置为25 ℃。

1.3.7 持水性的表征

参考胡坦等[23]方法,采用离心法测量豆腐花的持水性,根据1.3.5方法,在15 mL离心管中制备豆腐花,离心处理(5 000 r/min,10 min)后去除上清液,测量相关参数并按式(1)计算豆腐花的持水性。

式中0为离心管质量,g;1为豆腐花和离心管原质量,g;2为离心去上清液后豆腐花和离心管质量,g。

1.3.8 质构性质的表征

参考Li和Singh等[24-25]方法,采用万能材料试验机对豆腐花样品进行压缩测试,将样品切成直径为14.46 mm,高为10 mm的圆柱体,选用直径25 mm探头,设定测试速度为0.5 mm/s,凝胶压缩程度为25%。

1.3.9 微观结构的表征

根据Chen等[26]方法,采用FITC共价标记豆浆中的大豆蛋白,RITC标记豆皮果胶类多糖和柑橘果胶。按照1.3.5方法使用经标记的材料于带凹槽的玻片上制备豆腐花,并密封处理防止水分蒸发。所制备的豆腐花使用CLSM观察其微观结构。采用氩灯在488 nm波长和氦-氖灯在532 nm波长同时激发,分别在495~525和560~600 nm处接收FITC和RITC荧光信号。

1.3.10 豆腐花的感官评定

参考任凯[27]的方法,选择色泽、组织状态、滋味气味、口感和可接受度作为感官评定指标。测试由8名接受过感官评定课程训练的人员组成进行评分,其中每项最高分为8,最低分为0。样本随机摆放。

1.4 数据处理

试验样品测定均独立进行3次及以上重复。通过SPSS26.0软件进行数据的方差分析(ANOVA),采用Duncan检验对多组样本间进行显著性分析(<0.05)。

2 结果与讨论

2.1 豆皮果胶类多糖的提取、理化性质表征

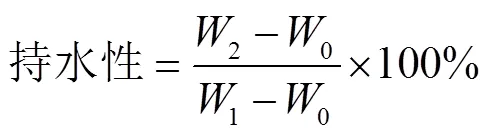

以大豆豆皮副产物为主要原材料,通过盐辅助结合水热处理技术提取豆皮果胶类多糖。经测定,该方法多糖提取率为17.95%±0.21%,所得豆皮果胶类多糖以果胶为主,半乳糖醛酸含量42.13%±2.05%,酯化度48.45%±0.98%。由图1可知,该豆皮果胶类多糖为阴离子多糖,pKa接近pH 2,具有良好的水溶性[28]。在水中经充分分散后测定平均粒径(D)为(210.3±2.9)nm,PDI为0.466±0.037。与1%柑橘果胶相比,所提取的豆皮果胶类多糖黏度更低,在100 s-1剪切速率下黏度为2.8 mPa·s,约为相同条件的柑橘果胶黏度1/3,说明其添加能更好地减弱对相关产品基本性质的影响。

图1 豆皮果胶类多糖的Zeta-电位、粒度分布和剪切黏度

2.2 添加豆皮果胶类多糖对豆腐花理化性质的影响

2.2.1 宏观形貌

上述试验结果表明,本研究提取的豆皮果胶类多糖具有良好的水溶性和低黏度特性。为进一步探究该豆皮果胶类多糖在蛋白凝胶类食品中的应用潜能,以典型蛋白冷致凝胶类食品豆腐花为模型。首先,参考豆腐花的工业化生产工艺流程[21-22],且经预试验确定GDL添加量为0.35%(pH终=5.80±0.05),并巴氏消毒(88 ℃,30 min),制备与市场销售的豆腐花商品相似的豆腐花模型。进而,通过添加不同浓度豆皮果胶类多糖,探究含该功能性果胶类多糖的豆腐花的较佳制备方法。

在此需明确的是,本研究拟制备的添加豆皮果胶类多糖的豆腐花实际上可看作是一种蛋白/多糖复合凝胶,且该pH值条件下豆浆主成分大豆蛋白和豆皮果胶类多糖可导致离散型相分离,可能对豆腐花的网络微结构及宏观性质产生影响。

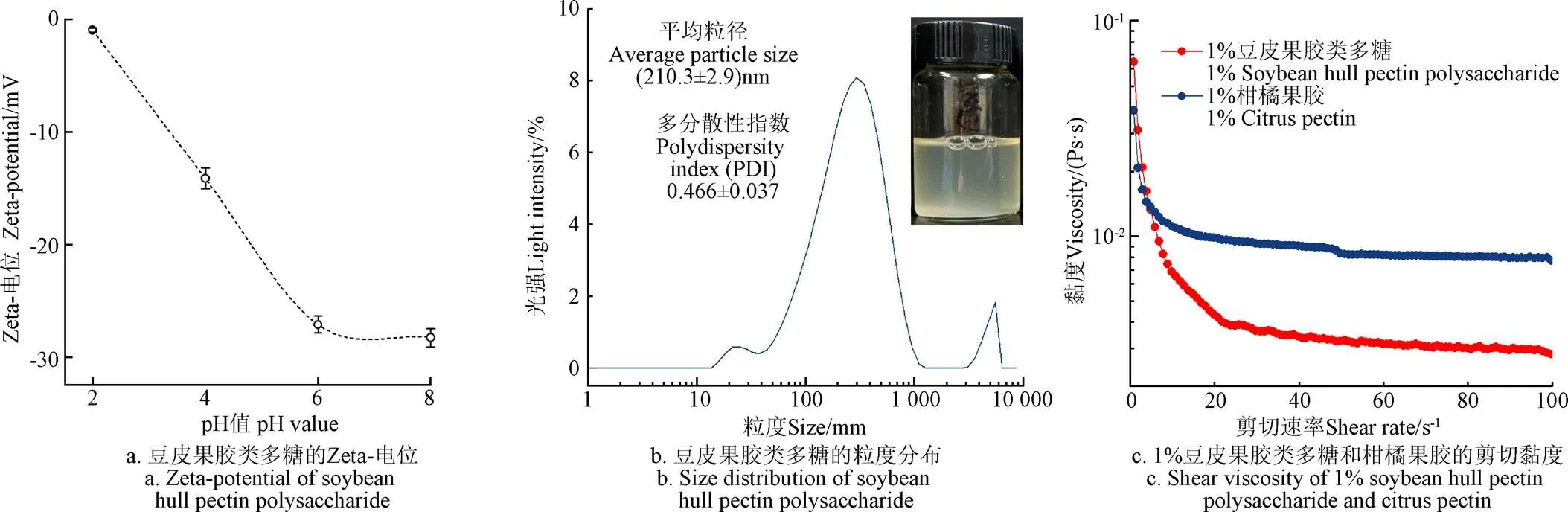

首先,对不同添加量豆皮果胶类多糖所制备的豆腐花的宏观形貌进行观察。如图2所示,添加0~0.5%豆皮果胶类多糖所得豆腐花均形成良好的可自我支撑的凝胶结构。增加豆皮果胶类多糖添加量(1.0%~1.5%),豆腐花虽已成型,但出现了明显的析水现象。继续提高豆皮果胶类多糖添加量至2.0%会导致凝胶网络崩溃,豆腐花无法成型,故后续不再进行该添加量样品的表征。

图2 不同豆皮果胶类多糖添加量(0~2.0%)的豆腐花的宏观形貌

2.2.2 流变特性和微观结构

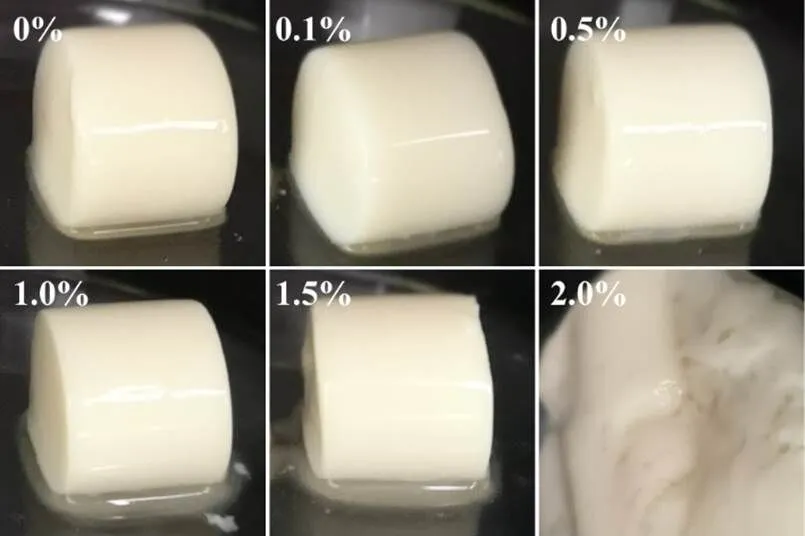

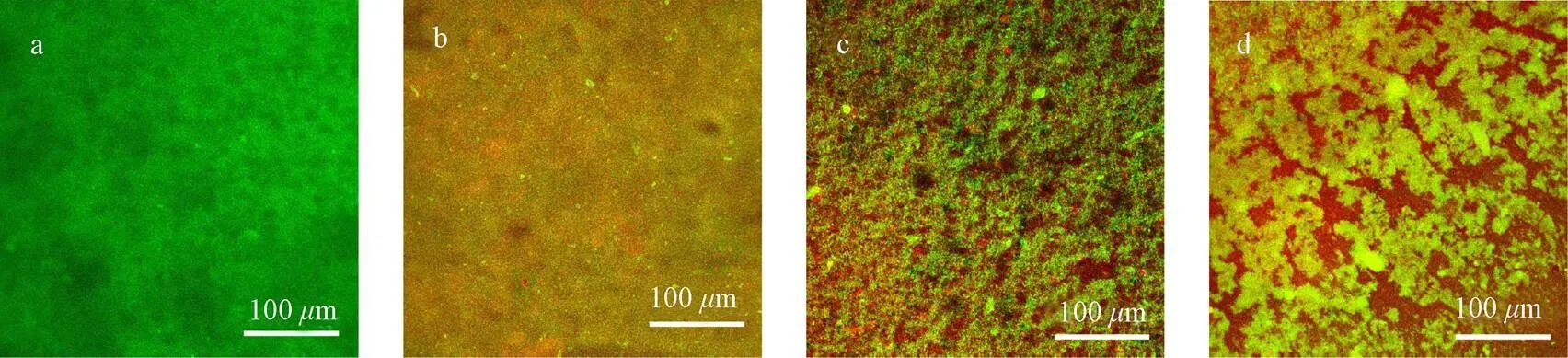

通过小振幅流变测试和激光共聚焦显微镜进一步探究豆腐花的网络微结构。豆腐花的频率扫描结果如图3a所示,整个扫描过程所有测试样品的弹性模量()均大于黏性模量(),且>10 Pa,表明凝胶网络结构形成[29-30]。而'和均随频率的升高呈微弱上升趋势,黏弹模量与频率呈线性相关,说明所形成的凝胶网络是一种较弱的三维空间结构[31]。当豆皮果胶类多糖添加量在0~0.5%范围时,和随多糖添加量的增加均呈微弱上升趋势。由CLSM结果(图4a, b)看到,添加0.5%豆皮果胶类多糖的豆腐花其网络微结构与空白样品相似,大豆蛋白和豆皮果胶类多糖均匀分布于视野内,未出现明显相分离现象。其和微弱上升是由于豆皮果胶类多糖在分子层面上起到空间占位效应,从而提高凝胶网络中的蛋白浓度,一定程度上增强了凝胶的黏弹性。但由于此时蛋白和多糖未能达到微相分离程度,因此对凝胶网络的影响实际上非常微弱[32-33]。进一步增加豆皮果胶类多糖添加量(1.0%~1.5%),和均呈下降趋势,说明过量添加豆皮果胶类多糖则会干扰凝胶网络的形成。当添加1.5%豆皮果胶类多糖时,和明显减弱。观察其微观结构(图4c),可以看到,此时豆皮果胶类多糖和大豆蛋白出现明显相分离,蛋白聚集粗化,网络结构变得紊乱无序。并且从豆皮果胶类多糖添加量2.0%时豆腐花无法成型的结果可以看出该条件下多糖已占据主导,发生相翻转。图3b是不同添加量豆皮果胶类多糖所制备的豆腐花的应变扫描结果。除添加1.5%豆皮果胶类多糖的样品其振荡屈服应变较小,其余样品均无明显差异。这也进一步说明了离散型相分离的发生对凝胶网络结构的影响。凝胶从单一相态转变成蛋白/多糖分相,致使网络微观结构不再均一,影响了凝胶网络强度。

注:实心圆点为G′,空心圆点为G″。

注:a~c依次代表豆皮果胶类多糖添加量为0%、0.5%、1.5%的豆腐花的微观结构;d代表柑橘果胶添加量0.5%的豆腐花的微观结构。FITC标记的大豆蛋白为绿色,RITC标记的豆皮果胶类多糖和柑橘果胶为红色。

2.2.3 持水性

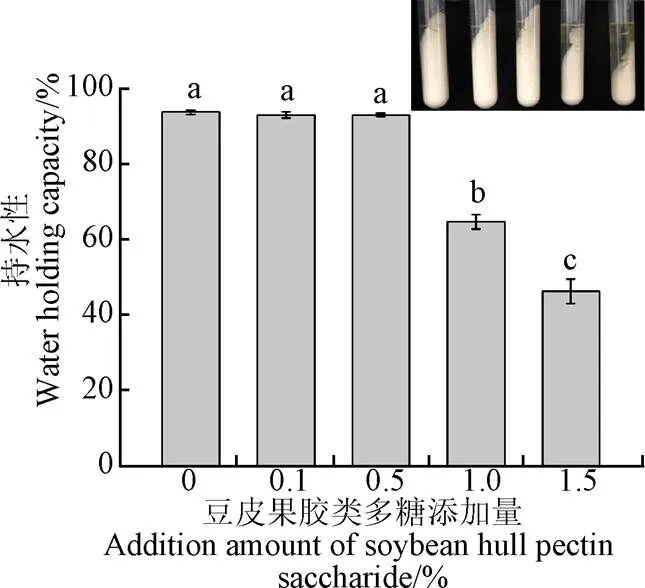

由于豆皮果胶类多糖的添加改变了凝胶的网络微结构,在宏观上可导致凝胶持水性的变化。如图5所示,添加0.1%~0.5%豆皮果胶类多糖所制备的豆腐花的持水性与空白样品(93.7%±0.6%)无显著性差异(>0.05),这是因为在此条件下豆腐花形成了相对有序的、强度较高的凝胶网络微结构,水分被束缚在凝胶致密的空间网络内部,不易流失,因而持水性较好[34]。当添加更多豆皮果胶类多糖(1.0%~1.5%)时,随着多糖含量增加,豆腐花持水性明显下降(<0.05),豆皮果胶类多糖添加量1.5%的豆腐花持水性下降至46.2%±3.2%。这是由于过量多糖的加入导致原本有序的凝胶网络结构被破坏,凝胶结构变得松散,孔隙增大,凝胶强度降低的同时截留水分子的能力也有所减弱[35-36]。

由上述分析可知,添加0~0.5%豆皮果胶类多糖时对豆腐花的凝胶网络微结构、流变学行为、宏观形貌及持水性均呈现协同增强或无显著影响,未出现不良效应;然而,当添加1.0%~1.5%豆皮果胶类多糖时由于破坏了凝胶网络的形成,导致其黏弹模量、宏观形貌及持水性均产生不良影响。在不影响豆腐花微观及宏观性质的基础上尽可能提高功能性果胶类多糖含量,故选择0.5%豆皮果胶类多糖添加量作为制备功能性豆腐花的较佳制备方案。

注:内插图是经离心(5 000 r·min-1, 10 min)的含0%、0.1%、0.5%、1.0%、1.5%(从左到右)豆皮果胶类多糖的豆腐花的析水情况。上标不同字母表示在0.05水平差异显著,下同。

2.3 豆皮果胶类多糖与柑橘果胶的比较分析

选取与豆皮果胶类多糖成分相近的商品化柑橘果胶作对比,分别添加两种多糖制备豆腐花,并以与实际应用更为密切相关的豆腐花理化性质(包括宏观及微观形貌、质构特性、持水性和感官评定)为主要表征内容,探究豆皮果胶类多糖替代柑橘果胶在凝胶类食品中的应用潜能。

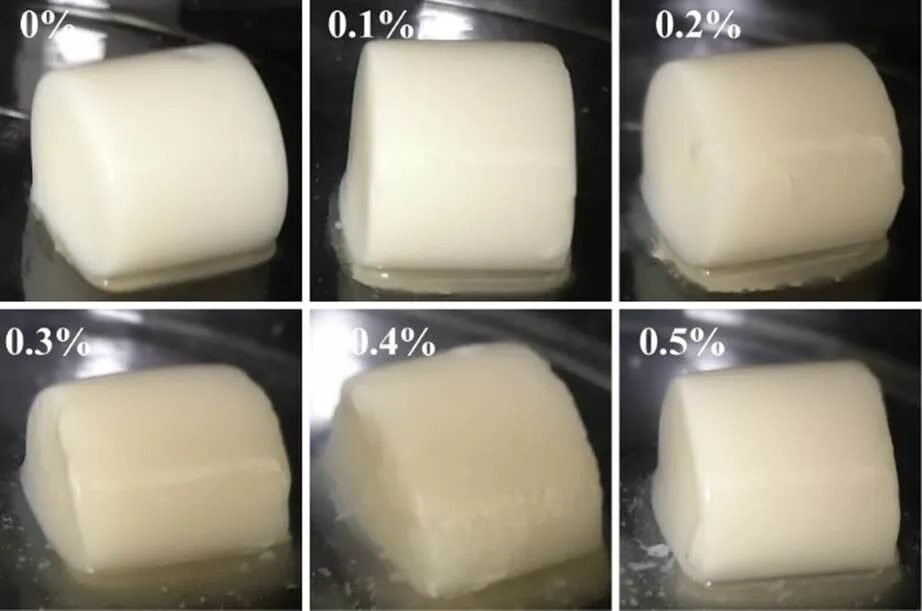

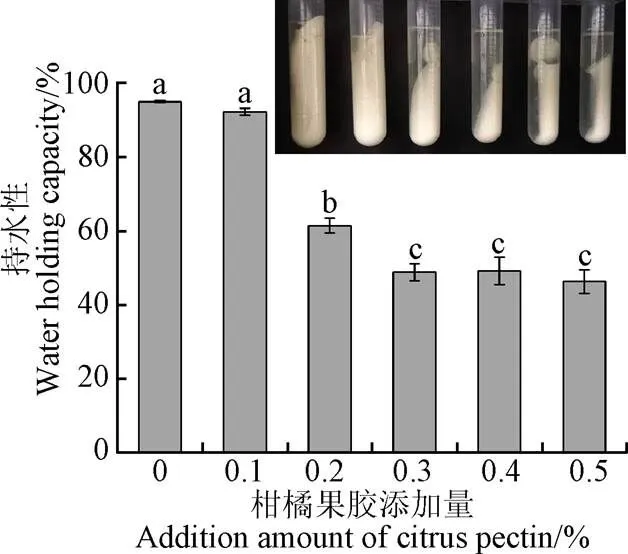

首先,对比不同添加量柑橘果胶的豆腐花的宏观形貌和持水性,以此得到柑橘果胶的较佳添加量。由图6和图7可知,添加0.1%柑橘果胶所制备的豆腐花外观与无多糖添加的空白样品相似,均表现为光滑白皙、成型性良好、底部析水较少。经5 000 r/min离心10 min,测得持水性为92.3%±0.9%,与空白样品无显著性差别(>0.05)。当柑橘果胶添加量为0.2%时,豆腐花底部有少量析水,持水性减弱(60.3%±0.3%)。进一步增加柑橘果胶添加量(0.3%~0.5%),所得豆腐花质地明显变软,容易坍塌,且底部析出较多汁液,持水性受到严重影响。豆腐花持水性减弱很大程度受到蛋白/多糖微相分离的作用,柑橘果胶从微米尺度上占据了蛋白凝胶的网络空间,干扰了凝胶的形成,使其网络结构变得无序(图4d)。

图6 不同柑橘果胶添加量(0~0.5%)的豆腐花的宏观形貌

注:内插图是经离心(5 000 r·min-1, 10 min)的含0%、0.1%、0.2%、0.3%、0.4%、0.5%(从左到右)柑橘果胶的豆腐花的析水情况。

由上述结果可知,豆腐花中柑橘果胶的较佳添加量为0.1%,所得豆腐花在外观和持水性上与无多糖添加的空白样品无显著性区别(>0.05)。为对比豆皮果胶类多糖与柑橘果胶对豆腐花的质构特性与感官体验上的影响差异,分别选取豆皮果胶类多糖(0.5%)和柑橘果胶(0.1%)较佳添加量条件下所制备的豆腐花作比较。

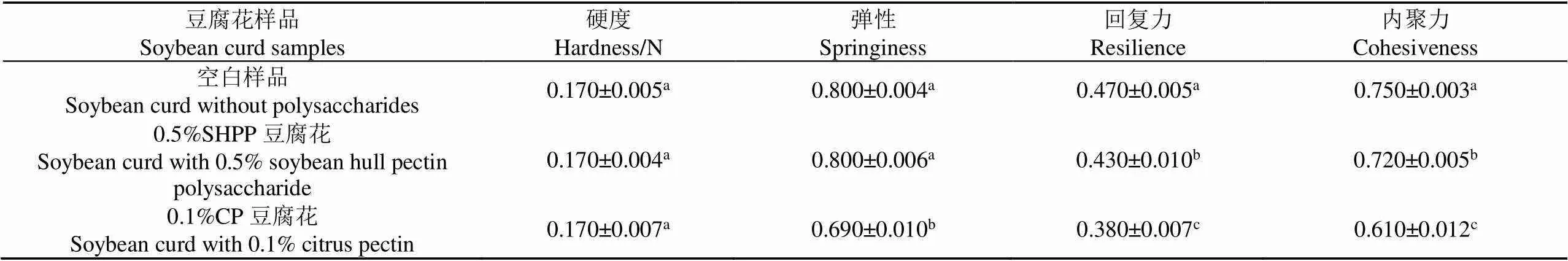

凝胶的质构特性可反映豆腐花在大变形条件下的力学特性,包括硬度、弹性、回复力和内聚力[37-38]。测定结果如表1所示,分别添加0.5%豆皮果胶类多糖和0.1%柑橘果胶的豆腐花的硬度与空白样品((0.170±0.005)N)无显著性差异(>0.05)。弹性方面,添加0.5%豆皮果胶类多糖的豆腐花仍与空白样品((0.800±0.004)N)无明显差别(>0.05)。对比之下,采用0.1%柑橘果胶制备的豆腐花的弹性明显减弱((0.690±0.010)N),说明该条件下柑橘果胶的加入一定程度上干扰了凝胶网络的形成。对于回复力和内聚力,0.5%豆皮果胶类多糖的添加对豆腐花回复力和内聚力的影响均较为微弱,而柑橘果胶则导致该两种性质参数明显下降。由此可知,相比于柑橘果胶,豆皮果胶类多糖对凝胶网络性质的影响较小,体现了豆皮果胶类多糖在蛋白凝胶类食品中应用的优势。

表1 添加0.5%豆皮果胶类多糖、0.1%柑橘果胶及未添加多糖的豆腐花的质构特性

注:在同类指标的比较中,不同字母代表数据间有显著性差异(<0.05),下同。

Note: In the comparison of the same type of index, data with different letters are significantly different (<0.05), the same below.

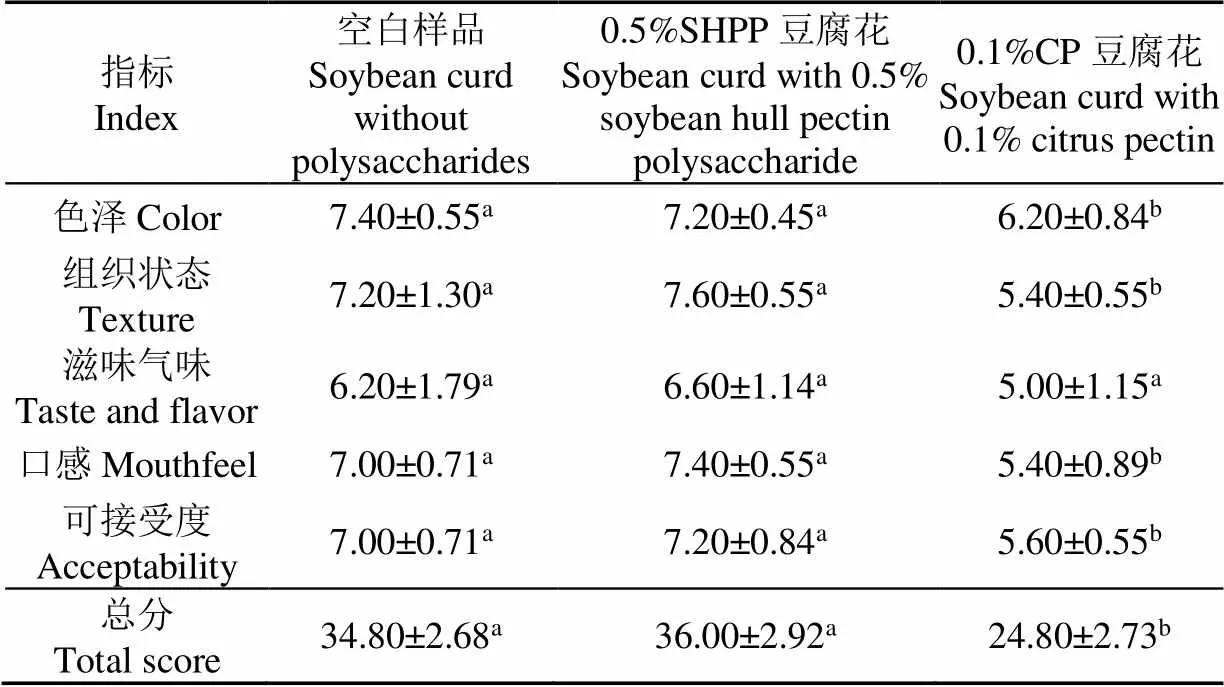

豆腐花宏观形貌、持水性和质构特性的差异必然会影响品尝时的感官体验。通过专业的感官评定测试能有效地反馈食品的感官综合信息,更真实地反映豆皮果胶类多糖在蛋白凝胶类食品中应用的可行性。测试结果如表2所示,添加了0.5%豆皮果胶类多糖的豆腐花在色泽、组织状态、滋味气味、口感和可接受度5个方面均与空白样品相近,无显著性差异,感官总分为36.0±2.92(满分为40),整体反馈良好。这说明豆腐花中添加豆皮果胶类多糖能在不影响豆腐花感官体验的前提下实现补充功能性多糖的目的,证明了豆皮果胶类多糖在蛋白凝胶类食品中的应用潜能。相较之下,0.1%柑橘果胶添加量的豆腐花的感官得分较低,除了在气味滋味上无显著性差异,其余各方面评分均明显低于空白样品和豆皮果胶类多糖豆腐花。这主要由于柑橘果胶影响了豆腐花凝胶网络结构的形成,进而导致其质构特性和持水性均呈现显著差异,最终使得感官评分结果较差,感官总分仅为24.8±2.73。

表2 添加0.5%豆皮果胶类多糖、0.1%柑橘果胶及未添加多糖的豆腐花的感官评定

3 结 论

1)本研究通过盐辅助结合水热处理技术,从大豆加工副产物大豆豆皮中提取豆皮果胶类多糖。经测定,该豆皮果胶类多糖以果胶为主,半乳糖醛酸含量为42.13%±2.05%,平均粒径为(210.3±2.9)nm,具有良好的水溶性和低黏度特性。1%豆皮果胶类多糖在100 s-1剪切速率下黏度为2.8 mPa·s,是相同条件的柑橘果胶黏度1/3。

2)以大豆蛋白凝胶类食品(豆腐花)为模型,探究豆皮果胶类多糖对豆腐花微观结构与宏观性质的影响。经研究发现,豆皮果胶类多糖添加量为0~0.5%时所得豆腐花具有良好的网络微结构、黏弹性、持水性与口感,而过多豆皮果胶类多糖添加(1.0%~2.0%)则导致不良影响,由此确定添加0.5%豆皮果胶类多糖为功能性豆腐花制备的较优浓度。

3)与柑橘果胶作对比,发现采用经优化添加浓度(0.1%)的柑橘果胶所制备的豆腐花在质构特性和感官评分低于含0.5%豆皮果胶类多糖的豆腐花。这说明了豆皮果胶类多糖更适用于蛋白凝胶类食品,可为其提供多种生理功效。

[1] Dicken, S J, Batterham, R L. The role of diet quality in mediating the association between ultra-processed food intake, obesity and health-related outcomes: A review of prospective cohort studies[J/OL]. Nutrients,2022, 14(1) : 23. https:// doi.org/10.3390/nu14010023

[2] 孙贺,于寒松,范宏亮,等.和′亚基缺失对大豆分离蛋白乳化特性的影响[J]. 农业工程学报,2020,36(10):261-268.

Sun He, Yu Hansong, Fan Hongliang, et al. Effects of the subunit-deficiency ofand′ on emulsifying properties of soy protein isolate[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(10): 261-268. (in Chinese with English abstract)

[3] Song Q, Wang Y, Huang L, et al. Review of the relationships among polysaccharides, gut microbiota, and human health[J]. Food Research International, 2021, 140: 109858.

[4] 韩晴,李军国,杨莹,等. 不同分子量大豆皮多糖的基本结构及功能性质研究[J]. 饲料工业,2019,40(17):35-41.

Han Qing, Li Junguo, Yang Ying, et al. Characterization of functional properties and basic structure of polysaccharides extracted from soybean hull[J]. Feed Industry, 2019, 40(17): 35-41. (in Chinese with English abstract)

[5] 任多多,江伟,孙印石,等. 果胶的分类、功能及其在食品工业中应用的研究进展[J]. 食品工业科技,2022,43(3):438-446.

Ren Duoduo, Jiang Wei, Sun Yinshi, et al. Research progress on the classification, function and application of pectin in food industry[J]. Science and Technology of Food Industry, 2022, 43(3): 438-446. (in Chinese with English abstract)

[6] Qu D, Wang S, Zhao H, et al. Structure and interfacial adsorption behavior of soy hull polysaccharide at the oil/water interface as influenced by pH[J]. Food Hydrocolloids, 2021, 116: 106638.

[7] Yang L, Zhang H, Zhao Y, et al. Chemical structure, chain conformation and rheological properties of pectic polysaccharides from soy hulls[J]. International Journal of Biological Macromolecules. 2020, 148: 41-48.

[8] Yang L, Zhang H, Zhao Y, et al. Chemical compositions and prebiotic activity of soy hull polysaccharides in vitro [J]. Food Science and Technology Research, 2019, 25(6): 843-851.

[9] Amaro Bittencourt G, Porto de Souza Vandenberghe L, Valladares-Diestra K, et al. Soybean hulls as carbohydrate feedstock for medium to high-value biomolecule production in biorefineries: A review [J]. Bioresource Technology, 2021, 339: 125594.

[10] Dickinson E. Particle-based stabilization of water-in-water emulsions containing mixed biopolymers[J]. Trends in Food Science & Technology, 2019, 83: 31-40.

[11] Singh P, Medronho B, Miguel M G. On the encapsulation and viability of probiotic bacteria in edible carboxymethyl cellulose-gelatin water-in-water emulsions[J]. Food Hydrocolloids, 2018, 75: 41-50.

[12] 陈家凤. 食品级水水乳液的形成及其功能性输送的研究[D]. 广州:华南理工大学,2020.

Chen Jiafeng. Fabrication and Functionality Delivery of Food Grade Water-in-Water () Emulsion[D]. Guangzhou: South China University of Technology, 2020. (in Chinese with English abstract)

[13] 侯俊杰. 大豆蛋白-甜菜果胶相互作用及其对食品微结构及感官性质影响的研究[D]. 广州:华南理工大学,2016.

Hou Junjie. Soy Protein and Sugar Beet Pectin Interaction and Its Appilication in Manipulating the Microstructure and Sensory Perception of Food[D]. Guangzhou: South China University of Technology, 2016. (in Chinese with English abstract)

[14] Zhang S, Hsieh F H, Vardhanabhuti B. Acid-induced gelation properties of heated whey protein–pectin soluble complex (Part I): Effect of initial pH[J]. Food Hydrocolloids, 2014, 36: 76-84.

[15] Zhang S, Vardhanabhuti B. Acid-induced gelation properties of heated whey protein− pectin soluble complex (Part II): Effect of charge density of pectin[J]. Food Hydrocolloids, 2014, 39: 95-103.

[16] Liu C, Cheng F F, Wang J M, et al. Preparation and characterisation of surface‐active pectin from soya hulls by phosphate‐assisted subcritical water combined with ultrasonic treatment[J]. International Journal of Food Science & Technology, 2016, 51(1): 61-68.

[17] Liu C, Lin X L, Wan Z, et al. The physicochemical properties, in vitro binding capacities and in vivo hypocholesterolemic activity of soluble dietary fiber extracted from soy hulls[J]. Food & Function, 2016, 7(12): 4830-4840.

[18] Taylor K A, Buchanan-Smith J G. A colorimetric method for the quantitation of uronic acids and a specific assay for galacturonic acid[J]. Analytical Biochemistry, 1992, 201(1): 190-196

[19] 中华人民共和国卫生部. 食品安全国家标准食品添加剂果胶:GB 25533-2010[S]. 北京:中国标准出版社,2010.

[20] Zhang D, Qi J R, Jiang W, et al. Extraction and characterisation of pectin polysaccharide from soybean dreg and its dispersion stability in acidified milk drink[J]. International Journal of Food Science & Technology, 2021, 56(10): 5230-5241.

[21] Murekatete Nicole. 酸诱导和盐诱导的软豆腐型大豆蛋白凝胶的凝胶性质、流变性能、微结构及感官特征[D]. 无锡:江南大学,2015.

Murekatete Nicole. Gelation Behaviour, Rheology, Microstructure and Sensory Characteristics of Acid and Salt-Induced Soy Proteins Soft-Tofu Type Gels[D]. Wuxi: Jiangnan University, 2015. (in Chinese with English abstract)

[22] 陶汝青,夏宁,滕建文,等. 大豆蛋白热变性程度对速溶豆腐花粉凝胶成型的影响[J]. 农业工程学报,2017,33(11):299-305.

Tao Ruqing, Xia Ning, Teng Jianwen, et al. Effects of heat denaturation degree of soybean protein on gel property of instant soybean curd[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 299-305. (in Chinese with English abstract)

[23] 胡坦,张珮珮,郑婷,等. 高场强超声-加热联用增强大豆分离蛋白冷凝胶凝胶特性[J]. 农业工程学报,2016,32(20):306-314.

Hu Tan, Zhang Peipei, Zheng Ting, et al. High intensity ultrasound-heat pretreatments improving gelation properties of cold-set soy protein isolate induced by glucono--lactone[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 306-314. (in Chinese with English abstract)

[24] Li Z, Zhang L, Mao C, et al. Preparation and characterization of konjac glucomannan and gum arabic composite gel[J]. International Journal of Biological Macromolecules, 2021, 183: 2121-2130.

[25] Singh Narayan K, Gaurkhede S, Sharma V, et al. Technological and functional assessment of riboflavin enriched probiotic soycurd[J]. Fermentation, 2021, 7(2): 47.

[26] Chen J F, Guo J, Liu S H, et al. Zein particle-stabilized water-in-water emulsion as a vehicle for hydrophilic bioactive compound loading of riboflavin[J]. Journal of Agricultural and Food Chemistry, 2019, 67: 9926-9933.

[27] 任凯. 豆腐的物性评价模型构建及感官品质优化研究[D]. 南昌:南昌大学,2019.

Ren Kai. Establishment of Tofu Physical Property Evaluation Model and Sensory Quality Optimization[D]. Nanchang: Nanchang University, 2019. (in Chinese with English abstract)

[28] 肖志刚,王依凡,王可心, 等. 高压均质-冷冻干燥技术制备大豆分离蛋白微粒及其功能特性[J]. 农业工程学报,2021,37(13):306-313.

Xiao Zhigang, Wang Yifan, Wang Kexin, et al. Preparation and functional properties of soy protein isolate particles by high pressure homogenization-freeze drying technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(13): 306-313. (in Chinese with English abstract)

[29] 金郁葱. 大豆蛋白凝胶结构和质构的控制研究[D]. 广州:华南理工大学,2013.

Jin Yucong. Control Study of Soy Protein Gel Texture and Structure[D]. Guangzhou: South China University of Technology, 2013. (in Chinese with English abstract)

[30] 江连洲,杨宗瑞,任双鹤,等. 空化射流对大豆分离蛋白结构及乳化特性的影响[J]. 农业工程学报,2021,37(3):302-311.

Jiang Lianzhou, Yang Zongrui, Ren Shuanghe, et al. Effects of cavitation jet on structure and emulsifying properties of soy protein isolate[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 302-311. (in Chinese with English abstract)

[31] 闵维,杨晓泉. 不同分子量葡聚糖对大豆分离蛋白冷致混合凝胶的流变性质和质构性质的影响[J]. 食品工业科技,2010,31(5):72-75.

Min Wei, Yang Xiaoquan. Effects of molecular weight of dextran on the rheological behavior and texture properties of soy protein isolate cold-set gels[J]. Science and Technology of Food Industry, 2010, 31(5): 72-75. (in Chinese with English abstract)

[32] Patole S, Cheng L, Yang Z. Impact of incorporations of various polysaccharides on rheological and microstructural characteristics of heat-induced quinoa protein isolate gels[J]. Food Biophysics, 2022, 17(3): 314-323.

[33] Yang X, Li A, Li D, et al. Applications of mixed polysaccharide-protein systems in fabricating multi-structures of binary food gels: A review[J]. Trends in Food Science & Technology, 2021, 109: 197-210.

[34] 陈振家,施小迪,杜昱蒙,等. 不同热处理大豆分离蛋白凝胶冻藏特性[J]. 农业工程学报,2016,32(11):283-289.

Chen Zhenjia, Shi Xiaodi, Du Yumeng, et al. Gel properties of soybean isolate protein with different heat treatments during frozen storage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(11): 283-289. (in Chinese with English abstract)

[35] Zhuang X, Wang L, Jiang X, et al. Insight into the mechanism of myofibrillar protein gel influenced by konjac glucomannan: Moisture stability and phase separation behavior[J]. Food Chemistry, 2021, 339: 127941.

[36] Cortez-Trejo M C, Gaytán-Martínez M, Reyes-Vega M L, et al. Protein-gum-based gels: Effect of gum addition on microstructure, rheological properties, and water retention capacity[J]. Trends in Food Science & Technology, 2021, 116: 303-317.

[37] Chen Y P, Chung H Y. Development of a lexicon for commercial plain sufu (fermented soybean curd)[J]. Journal of Sensory Studies, 2016, 31(1): 22-33.

[38] Jook H, Cavender G A. Investigation of tofu products coagulated with trimagnesium citrate as a novel alternative to nigari and gypsum: Comparison of physical properties and consumer preference[J]. LWT-Food Science and Technology, 2020, 118: 108819.

Extraction of soybean hull pectin polysaccharide (SHPP) and its applications in soy protein-based gel foods

Shen Xiaomei1, Ran Gen1, Chen Jiafeng2, Hou Junjie3, Wang Jinmei1※

(1.,&,,510640,; 2.,,510430,; 3..,,543000,)

Pectin polysaccharides can be closely related to various physiological functions, particularly for the resistance to obesity, diabetes, and cardiovascular diseases. Therefore, pectin polysaccharides can be often used in gel foods, due to their excellent gelation property, water solubility, and low viscosity. Among them, there is up to 30% of soybean hull pectin polysaccharide (SHPP) in the soybean hull byproducts, more than three million tons of which are produced every year in China. This study aims to improve the utilization efficiency of soybean byproducts for the better application of SHPP in gel foods. A salt-assisted hydrothermal method was also applied to extract the SHPP from soybean hulls. Physicochemical properties of SHPP were characterized, including the extraction yield, composition, size distribution, and viscosity. Then, the soybean curd (one of the soy protein-based gel foods) was applied as a case study. Segregative phase separation was investigated under various concentrations (0-2.0%) of SHPP in these mixed systems. A correlation analysis was implemented on the microphase behavior and the macro-properties (e.g., rheological behavior, mechanical properties, water holding capacity, and sensory evaluation). Besides, the commonly-used commercial citrus pectin (CP) was used as a control in foods. The results showed that the extraction yield of SHPP was up to 17.95% ± 0.21%. The obtained SHPP mainly consisted of pectin, with a galacturonic acid content of 42.13% ± 2.05%. The mean size of SHPP dispersion was determined as (210.3±2.9) nm and the polydispersity index (PDI) was 0.466 ± 0.037. The extracted SHPP was better dispersed in water, due to the hydrophilic property and low shear viscosity. There was no microphase separation, when the 0-0.5% SHPP was added to prepare the soybean curd. The obtained soybean curds were pretty white in a better appearance, particularly with the viscoelastic network and excellent water holding capacity. Furthermore, the leaking water was visible around the soybean curd, as the SHPP concentration increased up to 1.0%. A significant (<0.05) reduction was found in the viscoelasticity and water-holding capacity. The outstanding phase separation was observed when the addition of SHPP was up to 1.5%. There was a disordered microstructure with the enlarged pore of the network in the soybean curd, resulting in weak gel strength and low water holding capacity (46.2%±3.2%). Therefore, the optimal addition concentration of SHPP was 0.5% for the preparation of the soybean curd. A comparison was also made on the soybean curd that was prepared with the optimal CP concentration of 0.1%. The better texture properties and sensory scores were achieved in the color, texture, flavor, taste, and acceptability of the soybean curd prepared with 0.5% SHPP, compared with the 0.1% CP. Therefore, the SHPP can be expected to serve as a bioactive substance with various physiological functions in protein-based gel foods. The finding is conducive to the recycling of soybean byproducts in the whole bean food.

gels; rheological properties; soybean byproduct; soybean hull pectin polysaccharide; gel food; phase separation; application

10.11975/j.issn.1002-6819.2022.19.032

TS214.2

A

1002-6819(2022)-19-0295-08

沈晓梅,冉根,陈家凤,等. 豆皮果胶类多糖的提取及其在大豆蛋白凝胶类食品的应用[J]. 农业工程学报,2022,38(19):295-302.doi:10.11975/j.issn.1002-6819.2022.19.032 http://www.tcsae.org

Shen Xiaomei, Ran Gen, Chen Jiafeng, et al. Extraction of soybean hull pectin polysaccharide (SHPP) and its applications in soy protein-based gel foods[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(19): 295-302. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2022.19.032 http://www.tcsae.org

2022-09-15

2022-09-30

河南工业大学小麦和玉米深加工国家工程研究中心开放课题(NL2021001)

沈晓梅,研究方向蛋白质加工与利用。Email:xiaomeishen@foxmail.com

王金梅,博士,副教授,研究方向蛋白质加工与利用。Email:fejmwang@scut.edu.cn