Artificial neural network techniques to predict the moisture ratio content during hot air drying and vacuum drying of Radix isatidis extract

You-Lu Li,Yao Liu,2,3,Jian Xu,2,3,Yong-Ping Zhang,2,3,Luo-Na Zhao,2,3,Yan-Yan Miao,2,3*

1School of Pharmacy, Guizhou University of Traditional Chinese Medicine, Guiyang 550025, China.2National Research Center of Miao Medicine Engineering Technology, Guiyang 550025, China.3Guizhou Research Center of Traditional Chinese Medicine Processing and Preparation Engineering Technology, Guiyang 550025,China.

Abstract Background: To predict the moisture ratio of Radix isatidis extract during drying. Methods:Artificial neural networks were designed using the MATLAB neural network toolbox to produce a moisture ratio prediction model of Radix isatidis extract during hot air drying and vacuum drying, where regression values and mean squared error were used as evaluation indexes to optimize the number of hidden layer nodes and determine the topological structure of artificial neural networks model.In addition, the drying curves for the different drying parameters were analyzed. Results: The optimal topological structure of the moisture ratio prediction model for hot air drying and vacuum drying of Radix isatidis extract were “4-9-1” and “5-9-1”respectively,and the regression values between the predicted value and the experimental value is close to 1.This indicates that it has a high prediction accuracy.The moisture ratio gradually decreases with an increase in the drying time, reducing the loading, initial moisture content, increasing the temperature, and pressure can shorten the drying time and improve the drying efficiency.Conclusion: Artificial neural networks technology has the advantages of rapid and accurate prediction, and can provide a theoretical basis and technical support for online prediction during the drying process of the extract.

Keywords: Radix isatidis extract; artificial neural networks; moisture ratio prediction; hot air drying;vacuum drying

Background

The drying of traditional Chinese herbs is an essential operation unit for the removal of the most moisture content [1].In China, the drying of traditional Chinese herbs has a long history, which had provided humans with valuable drying experience.Drying of traditional Chinese herbs was first recorded in the ancient book of Chinese medicine,HuangDi’s Canon of Internal Medicine(221 B.C.E.-220 C.E.),which only described exposure drying [2].Some processing monographs includePrescriptions for Fifty-two Diseases(475-221 B.C.E.)[3],Master Lei’s Discourse on Drug Processing(the Southern and Northern Dynasties, 420-589 C.E.) written by Lei Xiao [4], which summarized detailed drying methods, such as drying in the shade and drying in the air.With people putting forward higher requirements for product quality, modern drying technologies have been extensively used since the 1950s.These techniques include hot air drying (HD)and vacuum drying(VD).In recent years, control of the drying process has attracted the attention of researchers.

Since ancient times, traditional Chinese medicine (TCM) extract has been an important intermediate of solid preparations, and its drying process is based on the theoretical guidance of TCM [5].In the Eastern Jin Dynasty, theElbow Back Emergency Prescriptionwritten by Ge Hong(283-363 C.E.) first recorded the drying process of TCM extract [6];importantly, drying of the TCM extract not only retained the chemical ingredients obtained by boiling the herb, but also did not damage the specialty of TCM.Moreover, it retains effective ingredients to give full play to its special [7-9].TheRadix isatidis(Banlangen) extract is an intermediate of the Banlangen preparation on the market [10], which used in products, such as Banlangen granules, compound Banlangen granules, and Banlangen chewable.Radix isatidisextract was used as the model drug in this study for both its popularity and the fact that its drying control level remains to be improved.

Previous reports have identified that dynamic change in moisture content is a subject worthy of study to improve the quality of TCM extract.On the one hand,timely and accurate online monitoring of the moisture content of materials can effectively avoid excessive drying,to reduce the heating time of materials, save energy, better retain the effective components; and to avoid insufficient drying, which would prevent progression to the next stage of production.On the other hand,approaching the drying mechanism from a macroscopic view could facilitate process optimization, improved drying efficiency, and improved product quality.However, the moisture content is measured by an oven and a hygrometer, which is inconvenient for continuous production under good manufacturing practice requirements,especially in the vacuum state [11, 12].In addition, the test results of modern Chinese medicine pharmaceutical equipment are unstable and unreliable.Therefore, it is of great significance to establish a fast and reliable prediction model [13].However, the mean of the parameters contained in the thin-layer drying mathematical model is not clear,and the single fixed model is limited by its poor adaptability and low accuracy [14].

Currently, artificial neural networks (ANNs) have been widely applied [15-17] in the research of TCM to analyze the information of four diagnoses and to identify syndromes in TCM, as well as to predict prescription efficiency, optimize the process, and identify and control the quality of TCM [18, 19].However, there has been little research on the prediction and variation of moisture content during the TCM extract drying process [14].Therefore, based on the ANNs, we can predict its change to improve the level of process control.

In this study,Radix isatidisextract was used as a model drug to explore the applicability of ANNs using two common drying methods(HD and VD)to predict the moisture ratio (MR),and the drying curves under different drying conditions were established to provide the basis for the control and optimization of the drying process of the extract.

Materials and methods

Materials and instruments

Radix isatidisdecoction pieces (batch number: 202005) were purchased from the Guizhou Tongjitang Traditional Chinese Medicine Pieces Co., Ltd.(Hebei, China).A hot air dryer (101-3AB) was purchased from the Tianjin Taisite Instrument Co., Ltd.(Tianjin,China).A vacuum dryer (DZ-2BCIV) was purchased from the Tianjin Taisite Instrument Co., Ltd.(Tianjin, China).A closed two-piece decocting machine (YJ13/2B-G) was purchased from the Beijing Donghuayuan Medical Equipment Co., Ltd.(Beijing, China).An electronic balance (YHC) was purchased from the Ruian Yingheng Electric Appliance Co., Ltd.(Ruian, China).

Preparation of Radix isatidis extract for drying

Radix isatidisdecoction pieces were extracted by adding moisture at a ratio of 1:10 (w/v) for 2 h under atmospheric pressure, and filtered using filter paper.Then, the filter residue was extracted by adding moisture at a ratio of 1:8 (w/v) for 1 h, and the collected extract was filtered using filter paper.The filtrate was combined and concentrated to a thick liquid (37% wet basis(w.b.)).

Drying methods

In all the drying tests,Radix isatidisextract was loaded onto a ceramic plate with dimensions of 22 × 13 × 7 cm.In this study, a single factor test was carried out on two drying methods: HD and VD.The specific test parameters were shown in Table 1.

Table 1 Test design and arrangement of HD and VD

In the early stage of the drying process, the sample was quickly taken out and weighed every 30 minutes with the ceramic plate on the digital balance with 0.01 g accuracy.After drying for 12 h, it was weighed every 2 h.All drying experiments were stopped as the moisture content was about 10% w.b.

Calculation of drying data

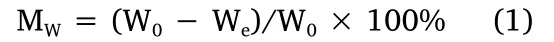

Initial moisture content (IMC) of Radix isatidis extract.Radix isatidisconcentrated solution(3-5g) was accurately weighed and tiled in a flat weighing bottle with constant weight, open the cap and dry it in an oven at 105 °C for 5 h.Then cover the cap and sample was quickly placed in a desiccator to cool for 30 min, followed by drying again at 105 °C for 1 h.Repeated this operation until the weight difference between the two samples weighed was not more than 5 mg.The IMC of the sample was calculated based on the weight loss,calculated according to equation (1):

where, Mwis the initial wet basis moisture content ratio of sample, %; W0is the total mass of sample before drying, g; Weis the total mass of sample after drying, g.

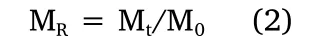

MR.During the experimental process, the MR of concentrate solution was calculated according to equation (2) [20]:

where, Mtis the dry basis moisture content at sampling point (g moisture/g dry solid);M0is the IMC (g moisture/g dry solid).

ANN model design

Structure of artificial neur alnetwork model.The basic structure includes an input layer, single or multiple hidden layers, and output layer.Commonly, a single hidden layer structure is used as shown in Supplementary Figure S1 [21].

Determination of node number of input layer and output layer.Study on input and output nodes of ANN model development for HD and VD.Four independent variables, process parameters (L (loading),IMC, and T (temperature)), and drying time were considered as input layers for HD; likewise, five independent variables, process parameters (L, IMC, T, and P (pressure)), and drying time were considered as input layer for VD.MR was taken as the target variable and considered as the output layer.

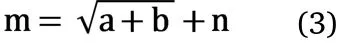

Determination of the number of hidden layer nodes.The key of neural network modeling is the selection of hidden layer nodes, which can be obtained by empirical formula (3) [22]:

where m is the number of hidden layer nodes; a is the number of input nodes; b is the number of output nodes; n is the adjustment constant between 1 and 10.In this study,a=4,b=1 in the model of HD,a=5,b=1 in in the model of VD.According to the formula(3),3 < m < 12 and 4 < m < 13 can be obtained respectively.The determination of hidden layer nodes usually depends on the mean squared error (MSE) and regression values (R) between the predicted value and the real value of the model [23].

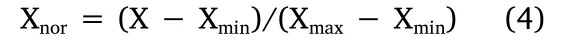

Training of network model.To improve the calculation efficiency and avoid over the fitting problem, the test data are normalized and transformed to [0, 1].The following equation (4) was used for normalization [24].

Before modeling, a total of 126 and 176 sets of input-output data were collected in the HD and VD process respectively.For this purpose,the MATLAB Neural Network Toolbox (MATLAB version 2020a) was used [25].The specific model parameters were shown in Table 2.

Table 2 ANN model parameters

Results

ANNs modeling

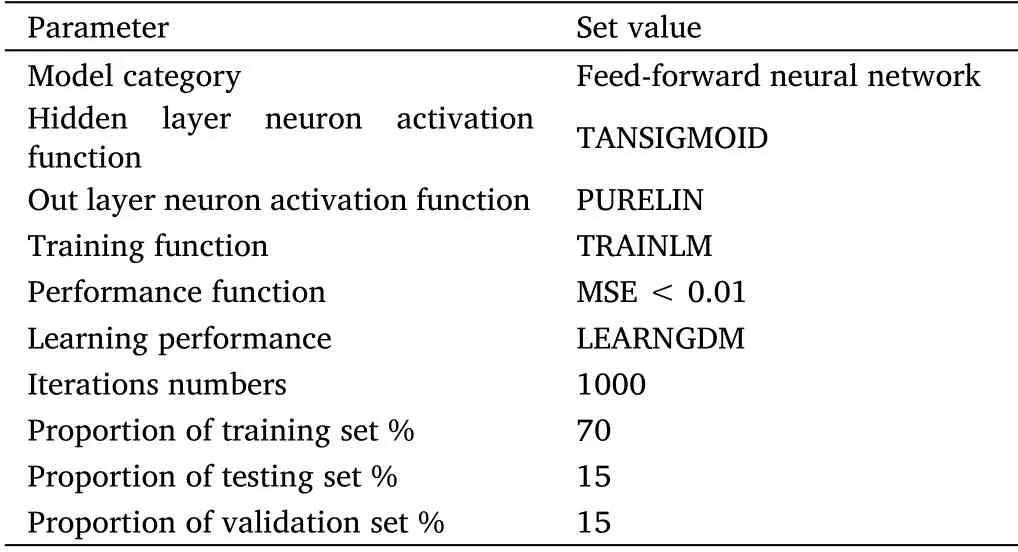

Under two drying methods to establish MR prediction model, training results with the different number of hidden layer nodes in terms ofRand MSE are shown in Figure 1.

Usually, higherRand lower MSE value of the model represent the better training performs to the optimal number of hidden neuron nodes [21], which can avoid unfitting or overfitting.It can be observed from Figure 1, when the same number of hidden neural nodes was 9 (intersection of the red dashed lines) for two drying methods, theRtraining(Rof the training set),Rvaluation(Rof the validation set),Rtest(Rof the test set), andRall(Rof all data sets) are the highest values, and the MSE value is the lowest.

Based on the experimental result above, the optimal topology structures of the ANNs model to predict MR were 4-9-1, 5-9-1 for HD and VD.

ANNs performance

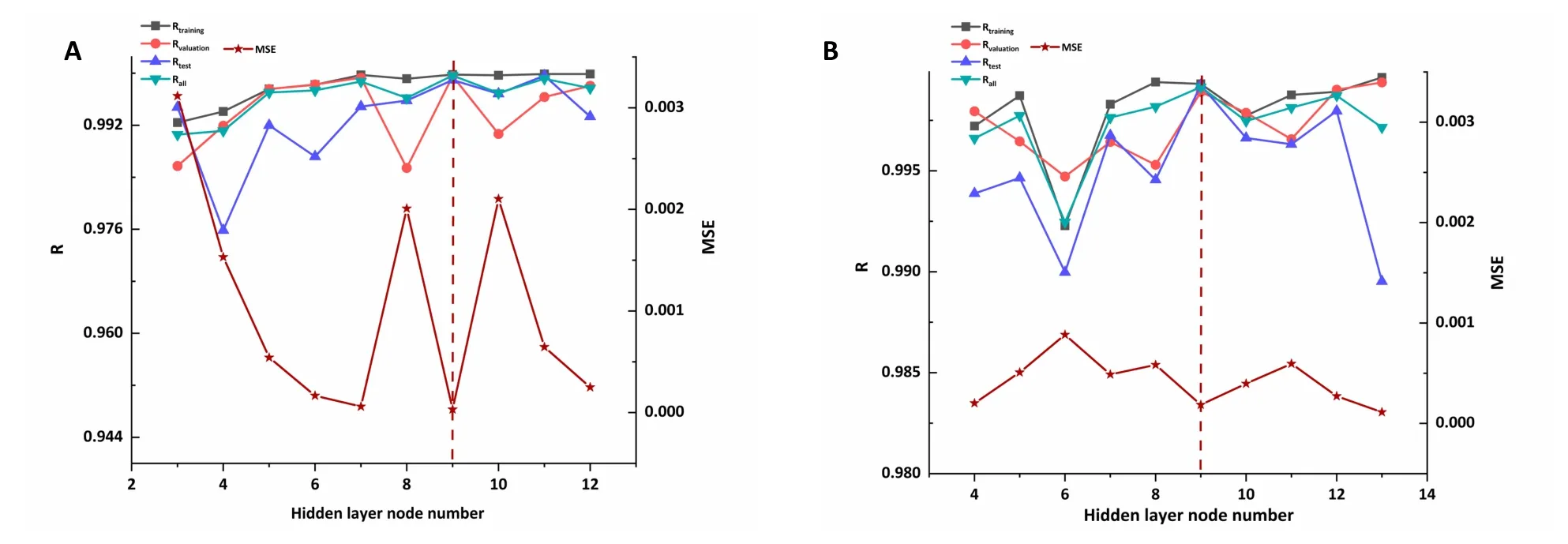

The convergence property and regression analysis of the prediction of MR are shown in Figure 2.

In Figure 2(A-B), the same iterative 55 times to reach convergence for two drying methods.In Figure 2(C-D),Rtraining,Rvaluation,Rtest,Rallare 0.99979 and 0.99931, 0.99957 and 0.99891, 0.99897 and 0.99925,0.99965 and 0.99915, which are very close to 1 and MSE were 3.0531× 10−5and 1.8552 × 10−4for two drying methods, respectively.In general, the currently designed ANNs model has high accuracy and high credibility, which can be used to estimate and predict MR ofRadix isatidisextract at HD and VD.

Weights and deviations of ANNs model calculations

In order to apply the abstract ANNs model to engineering practice, the network weight matrix of the neural network model is constructed, as shown in Supplementary Table S1.

In a previous study, common thin-layer drying models were used to fit the test data and did not achieve good results.It was found that the mathematical equations fitted were different owing to different drying conditions, even in the same drying mode.Moreover, the lower accuracy of the MR prediction limits its application [26].In contrast,the ANNs model designed here not only improves the prediction accuracy, but also has an improved versatility to predict the moisture loss behavior of the entire test range [27].It is worth noting that the model parameters defined in this study are expected to be extended to other drying methods or different varieties of extracts[28].

ANN, artificial neural network; MSE, mean squared error;TANSIGMOID, s-function; PURELIN, linear transfer function;TRAINLM, Levenberg-Marquardt backpropagation; LEARNGDM,gradient descent with momentum weight and bias learning function.

Figure 1 Experimental results used to determine the number of hidden layer neurons.A, the training result of hidden layer for HD; B, the training result of hidden layer for VD.The abscissa represents the node number of hidden layers tested, and the ordinate represents the R and MSE of the training set, validation set, test set and all sets during the test.HD, hot air drying; VD, vacuum drying; MSE, mean squared error; R,regression values.

Figure 2 Plot network performance and linear regression of ANNs model.A-B, the plotperform plots error vs.epoch for the training,validation, and test performances of the training record plotperform returned by the function train in HD and VD, respectively; C-D, the linear regression of targets relative to outputs in HD and VD, respectively.HD, hot air drying; VD, vacuum drying; MSE, mean squared error.

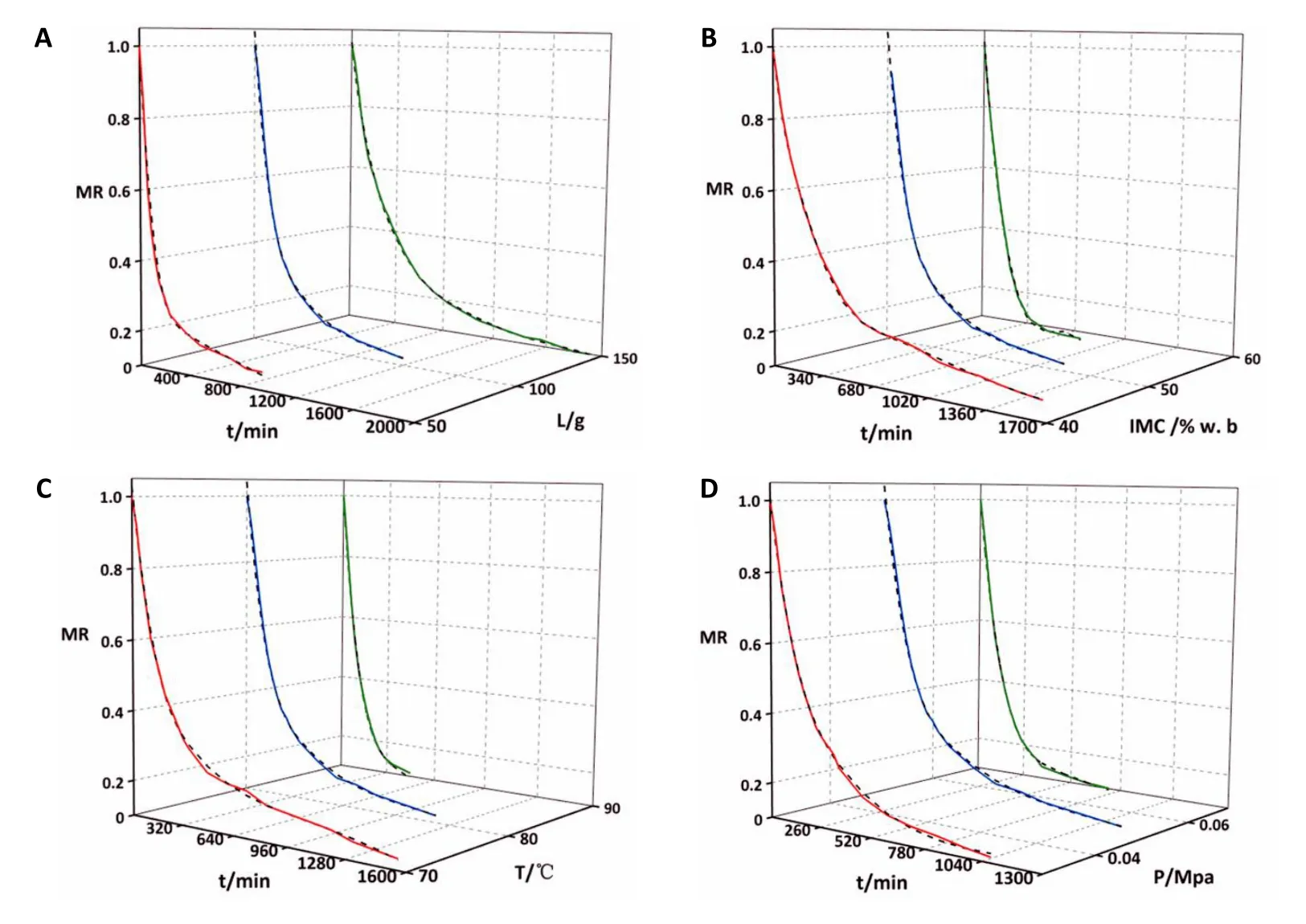

Drying characteristics

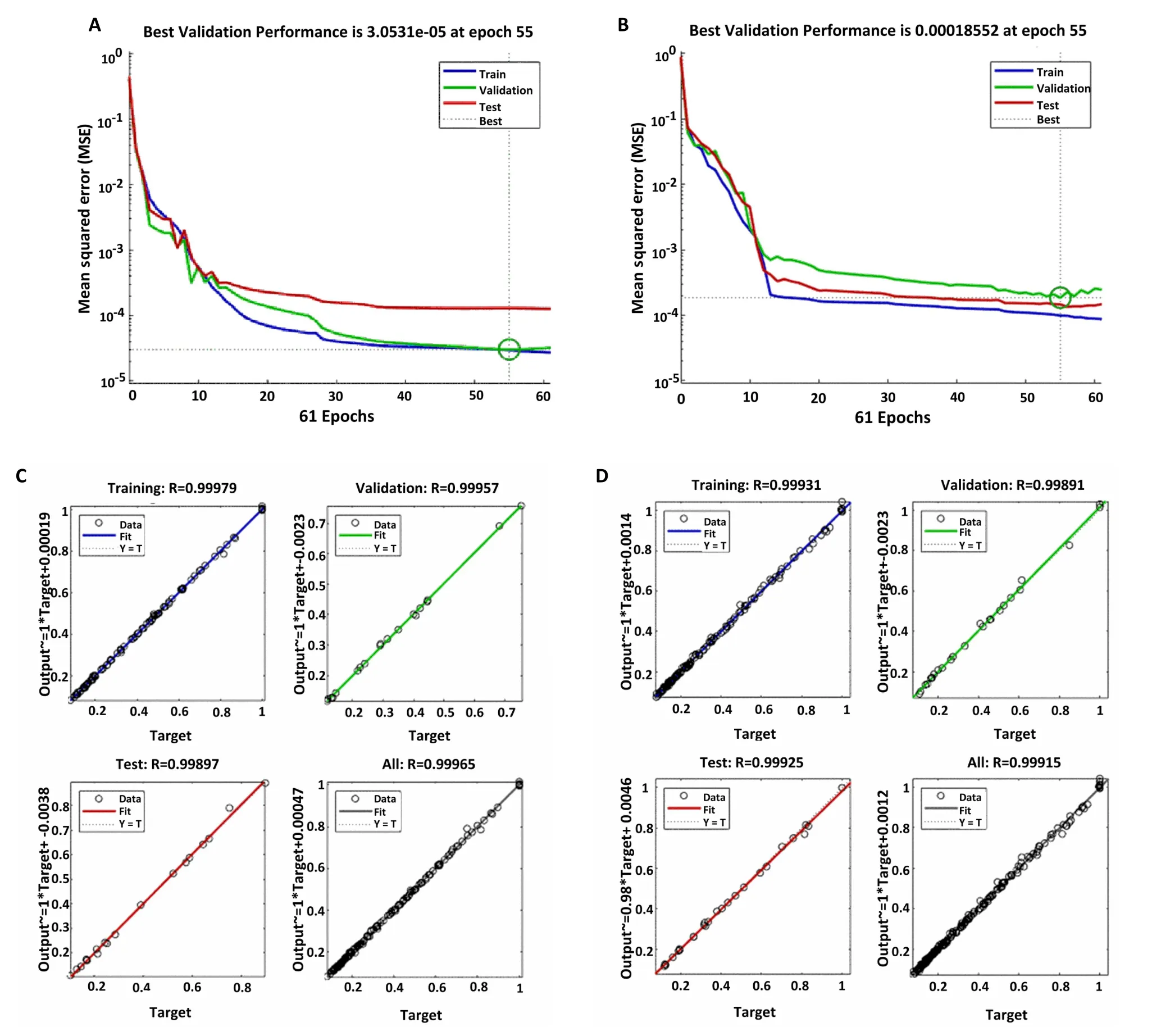

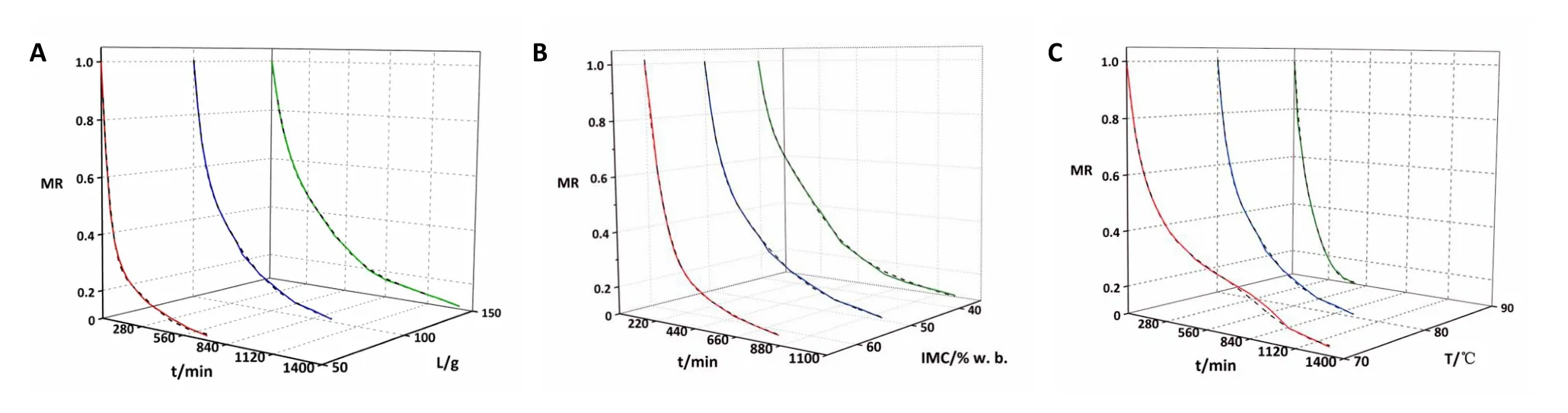

To directly reflect the law of moisture content change during the drying process of the extract, the curves of MR versus drying time under different drying conditions of HD and VD are shown in Figure 3 and Figure 4.The curves of the predicted value (dotted line) and measured value (solid line) almost overlap, which further illustrates the feasibility of the ANNs model.

As shown in Figure 3A and Figure 4A, the lower the loading, the steeper the MR decline curve, and the shorter the drying time.When the loading was set at 50, 100, and 150 g, the drying times required for HD and VD were 720 and 960 min, 960 and 1200 min, 1320 and 1920 min, respectively.Compared with the drying times of 50 g loading, the HD and VD drying times of 150 g increased by 45.45%and 45.98%, respectively.Because the material has the same surface area, the smaller the loading, the smaller the moisture migration distance and resistance, which enhances the power of the moisture and heat transfer, thereby accelerating the entire drying process as shown in Figure 3B and Figure 4B; the higher the IMC, the greater the change in MR, which is especially fast in the early staged.The samples with the different IMCs of drying time required for HD and VD were as follows: 40% w.b.1080 and 1680 min, 50% w.b.960 and 1200 min,60% w.b.720 and 720 min, respectively, which may be due to the higher IMC, the more heat is taken away in unit time; as shown in Figure 3C and Figure 4C, the temperature had a significant effect on the drying time, and the drying times of HD and VD were shortened by 63.63% and 69.23% less at 90 °C than at 70 °C, respectively.This indicates that the larger the temperature difference between the extract with the drying medium, the stronger the fluidity of moisture,the greater the power of heat and mass transfer, and the faster the drying rate.Therefore, increasing the temperature can shorten the drying time, but the effect of temperature on the quality of the extract should also be considered [29].

The influence of VD pressure on the change in MR is shown in Figure 4D.Compared with 0.03 MPa and 0.05 MPa, the drying time was significantly shortened at 0.07 MPa.In practice, it was observed that the surface of the extract was brittle and its thickness increased.The steam pressure of the internal moisture of the extract increased when the pressure increased, forming to a porous structure,which was more conducive to the moisture migration to the surface[14].

Figure 3 Drying curves of Radix isatidis extract under three different drying methods of HD.A, drying curve at 50, 100 and 150g of loading;B, drying curve at 40, 50, and 60% w.b.of IMC; C, drying curve at 70, 80 and 90 °C of temperature.The Denal line denotes the ANNs predictive value, the solid line denotes to experimental value.HD, hot air drying; ANNs, artificial neural networks; MR, moisture ratio; IMC, initial moisture content; L, loading; T, temperature.

Figure 4 Drying curves of Radix isatidis extract under four different drying methods of VD.A,drying curve at 50,100 and 150 g of loading;B,drying curve at 40, 50, and 60% w.b.of IMC; C, drying curve at 70, 80 and 90 °C of temperature; D, drying curve at 0.03, 0.05 and 0.07 Mpa of pressure.The Denal line denotes the ANNs predictive value, the solid line denotes to experimental value.VD, vacuum drying; MR, moisture ratio;IMC, initial moisture content; P, pressure; T, temperature.

Discussion

The dried products of most TCM extracts have a high viscosity, high sugar content, and poor air permeability, makingRadix isatidisa typical drug [30].Radix isatidisextract was selected as the model drug and research object, as it shows all these common characteristics, and an ANNs model was established to simulate the change more accurately in the water ratio during the drying process.The results show that the best topologies are 4-9-1 and 5-9-1.As shown in Figure 4,theRbetween the predicted value and the measured value is close to 1, and the MSE is less than 10%.We can see that ANNs can accurately predict the change in MR during the drying process of the extract.The ANNs model suitable for this study was selected not only because of its accuracy, but also because of its universality.All factors in the drying process were included in one model to predict the water loss behavior over the entire test range.However, the ANNs technology also has its own shortcomings.Because it is a “black box”model, its internal structure is hidden, the model parameters cannot be explained, and there is no in-depth understanding of the relative importance of various input variables, resulting in an imperfect interpretation model [31].

The change in MR during the drying process of the extract directly depends on the drying time and parameters.The ANNs parameters defined in this study are useful for the prediction of the MR of other extracts.At the same time, the MR also changed with different drying parameters.The drying parameters are controlled by changing the MR to avoid adverse results, such as excessive drying, insufficient drying,and high temperature.This is conducive to improving the existing drying equipment, improving the applicability between the equipment and TCM, ensuring the quality of the extract, and reducing the energy consumption and production cost [32-33].Unfortunately, the ANNs model in this study only predicted the change in MR during the drying process.In the future, a multi-input and multi-output simulation model can be established to design more indicators, such as quality,temperature, and system energy consumption.The model was retrained to cover a wider range of process variables.

Conclusion

The ANNs model can provide a new, useful modeling method for the hot air and VD process ofRadix isatidisextract.The application of this method could better guide industrial production.

Traditional Medicine Research2022年1期

Traditional Medicine Research2022年1期

- Traditional Medicine Research的其它文章

- The artificial intelligence watcher predicts cancer risk by facial features

- Evaluation of bioactive flavonoids in Citri Reticulatae Pericarpium from different regions and its association with antioxidant and α-glucosidase inhibitory activities

- Exploring the anti-diabetic effects and the underlying mechanisms of ethyl acetate extract from Sophora flavescens by integrating network pharmacology and pharmacological evaluation

- Effects of Shenling Baizhu powder on endoplasmic reticulum stress related signaling pathway in liver tissues of nonalcoholic fatty liver disease rats

- Safety of Lycium barbarum L.:more information needed

- Mechanisms and status of research on the protective effects of traditional Chinese medicine against ischemic brain injury