Strength properties of xanthan gum and guar gum treated kaolin at different water contents

Irem Bozyigit, Akr Jvdi, Selim Altun

a Department of Civil Engineering, Ege University, Bornova-Izmir, Turkey

b College of Engineering, Mathematics and Physical Sciences, University of Exeter, Exeter, UK

Keywords:Biopolymer Clay Unconfined compressive strength (UCS)Xanthan gum Guar gum Strength properties

ABSTRACT Nowadays, using biopolymer as a ground improvement method has become very popular. However,since biopolymers are organic and degradable,their long-term effect is not fully known.In this study,the effects of biopolymers on the mechanical behavior of kaolin clay were investigated through a comprehensive program of experiments.Two types of biopolymer,i.e.xanthan gum and guar gum were chosen to investigate the effect of biopolymer type. For this purpose, specimens were prepared using standard Proctor energy at four different water contents (25%, 30% 35% and 40%) with 0.5%, 1%, 1.5% and 2%biopolymer inclusions. The specimens were cured for 1 d, 7 d, 28 d and 90 d. Moreover, some of the specimens were kept in the curing room for 3 years to observe the long-term effect of the biopolymers.At the end of the curing periods, the specimens were subjected to unconfined compression test, and scanning electron microscopy (SEM) analysis was performed to observe the mechanism of strength improvement. The results revealed that the unconfined compressive strength (UCS) of the specimens treated with biopolymers increased in all biopolymer inclusion levels and water contents up to a 90-d curing period. For specimens containing xanthan gum, the maximum strength increase was observed at 25%water content and 2%xanthan gum with 90-d curing.The strength increased 5.23 times induced by xanthan gum addition when compared to the pure clay. Moreover, the increase in strength reached 8.53 times in specimens treated with guar gum. Besides, increasing water content caused more ductile behavior, thus increasing the axial deformation.

1. Introduction

Soil improvement methods are generally used to improve the engineering properties of weak soils and many chemicals are used for this purpose. However, many of these chemical substances are toxic and hazardous to the environment. As a consequence, application of environmentally friendly and economical ground improvement methods has become a necessity. Nowadays, the most common soil improvement method is cement stabilization.Many researchers have studied the mechanical and engineering properties of cement stabilized soils(Satoh et al.,2001;Chew et al.,2004; Horpibulsuk et al., 2004a,b; Lorenzo and Bergado, 2004;Sariosseiri and Muhunthan,2009;Kang et al.,2016).However,the environment is affected,directly or indirectly,by the use of cement and various chemicals.Five percent of global carbon dioxide(CO2)emissions are released by cement industries as 1 ton of cement produces 1 ton of CO2emission(Worrell et al.,2001).In general,in highly urbanized regions, the temperature is higher than that in rural areas. This phenomenon is called the heat island and was recognized by meteorologists a century ago(Miles and Esau,2017).The replacement of natural soil or natural materials by cementbased products and preventing vegetation causes these materials to store heat throughout the day, which is released to the atmosphere after sunset.Therefore,there is a temperature difference of about 6°C between the rural areas and the urban side.This causes the cooling systems to work more and to consume more electricity in the summer months (Santamouris and Asimakopoulos, 2001).Innovative soil improvement methods are being investigated which are not harmful to the environment in terms of both the production and application processes and throughout the service life. The use of natural and synthetic polymers for soil improvement has become a rising trend due to environmental concerns. While biopolymers are produced by living organisms,synthetic polymers are produced by the chemical industry. Most synthetic polymers used for soil stabilization provide similar advantages like carbon-based stabilizers such as cement. Synthetic polymers are durable, with high strength and thermal stability, and more environmentally friendly during the production phase compared to cement.A review of the literature indicates that synthetic polymers have an improving effect on many engineering properties such as tensile strength,flexural strength, compressive strength, toughness, and hydraulic conductivity, and have a promising future among ground improvement methods (Tingle and Stantoni, 2003; Al-Khanbashi and Abdalla, 2006; Orts et al., 2007; Tingle et al., 2007). Although the contribution of synthetic polymers to strength is similar to biobased polymers, most of the bio-based polymers are easily degradable by biological and natural processes, contrary to synthetic polymers (Ding et al., 2019). Due to the degradability of biopolymers, some undesired problems can occur such as instability, irreproducibility, and uncontrollable formulation characteristic. On the other hand, since biopolymers are produced from biological processes,they are more environmentally friendly,more economical and non-toxic (Bhatia, 2016).

Biopolymers are mostly used in medicine,food,agriculture,and cosmetics production. Historically, the biopolymer additives for civil engineering applications were first used in ancient China(Chang et al., 2016). Sticky rice mortar and lime were used to construct many important buildings such as tombs,water resource facilities, and even the Great Wall, due to the mixture’s great durability and strength. Moreover, some ancient buildings constructed with sticky rice mortar and lime were not damaged after the 7.5 magnitude earthquake that occurred in 1604 (Lin et al.,2005). Before the development of industry, every civilization used biopolymers such as flour, gum, oil, wax, resin, animal fat, egg white, blood and urine, depending on their traditions and geographical conditions(Eires et al.,2015).For example,cow dung and urine were used to improve the cohesion and plasticity of soils in India, and agave was used as a mortar (it was first boiled and then mixed with clay) in Mexico. These materials were used to increase strength or reduce permeability or water retention.

Nowadays,biopolymers can be used in the field for geotechnical applications for example as drilling muds and temporary excavation supports,and to prevent erosion.In this field,biopolymers are used to modify the permeability and mechanical properties of soils.In the initial applications, the main focus was put on reducing the permeability of soils but the effect on mechanical properties was not considered.Kalish et al.(1964)investigated the influence of the bacteria bloom on the permeability properties of sandstone and concluded that bacterial growth inside the soil reduced the permeability of sandstone. Barry et al. (1991) used three different types of natural polymers in soils that contained organic matter at varying ratios.They observed that the strength of soil was increased by natural polymers about 5 times when compared to untreated soil.Karimi(1998)carried out a comprehensive study on the effect of biopolymers on the mechanical properties of silty soils and concluded that the use of xanthan gum increased the strength of silty soils and reduced the permeability. The soil improvement methods using natural additives have gained significant popularity over the last decades.

In general, biological soil improvement methods are divided into two groups: bio-clogging and bio-cementation. Either, the biopolymer is directly injected inside the soil or the biopolymer producing organisms produce particle-binding materials through microbial activity in situ.In the first case,various polymers secreted by microorganisms or extracted from plants or fungi such as xanthan gum,guar gum,carrageenan gum,starch,chitosan,and chitin are dissolved in water to prepare a solution and then mixed with soil.Bouazza et al.(2009)studied the treatment of silty sand using three different biopolymers: xanthan gum, guar gum, and sodium alginate, through a series of experiments. They concluded that these materials could be recommended as a temporary seepage barrier but a large amount of additional experimental and practical research is required to confirm this finding.Chang and Cho(2012)treated a Korean residual soil using liquid type β-1,3/1,6-glucan biopolymer derived from yeast, at different concentrations. The results indicated that β-1,3/1,6-glucan biopolymer is effective in improving the strength properties of soil as it is less harmful to the environment and more economical in comparison with cement.Chang et al. (2015a) used thermo-gelation biopolymers at various temperatures to improve the mechanical properties of clay and sand. They showed that gellan gum and agar gum (which are typical thermo-gelation biopolymers) have a strong potential as construction materials.The effectiveness of biopolymers also varies depending on the type of soil. Chang et al. (2015b) also used xanthan gum as an additive to investigate the performance of gum on the improvement of different types of soil.The results showed that the greatest strength improvement was obtained in well graded soils with fine particles at the maximum xanthan gum content.Cabalar et al. (2017) reviewed biopolymer applications in geotechnical engineering. They carried out hydraulic conductivity,odometer, unconfined compression, and triaxial shear tests on xanthan treated sandy soils and concluded that biopolymer treatment provides a promising technique to engineers. Soil improvement has been studied for many different soil types:clay,sand,red loess,peat, and collapsible soil. Ayeldeen et al. (2016) investigated the influence of two biopolymers(xanthan gum and guar gum)on the mechanical behaviors of collapsible soils.The results indicated that both xanthan gum and guar gum can be applied for improving the mechanical properties of collapsible soils successfully. Latifi et al. (2016) studied the ropical organic peat stabilized by using xanthan gum, and they stated that xanthan gum stabilization was effective for organic peat and an eco-friendly alternative method for soil stabilization. Latifi et al. (2017) extended their work by application of xanthan gum in swelling soils and reported a significant improvement in engineering properties of the soils after 28 d of curing. Cabalar and Demir (2020) investigated the undrained shear strength of various sands treated with xanthan gum by conducting a series of fall cone penetration tests. From experimental results, they indicated that xanthan gum has a great influence on undrained shear strength. Biju and Arnepalli (2020)investigated the effect of xanthan gum and guar gum on the permeability of sand-bentonite mixtures as a liner for construction of engineered landfills,and the regulatory requirement of the liner was met by xanthan gum treatment. Although gum types of biopolymers such as xanthan gum and guar gum are quite popular in biopolymer-soil improvement, there are many studies on the improvement of soil with different kinds of biopolymers. For example,protein-based biopolymers, casein and sodium caseinate obtained from milk were used by Fatehi et al. (2018) to stabilize dune sand. They studied the effects of curing time, biopolymer content, and curing temperature and concluded that the strength increased with increasing curing time and biopolymer content.They also indicated that the compressive strength increased with temperature values between 25°C and 60°C, while beyond this interval (80°C-120°C), biopolymers decomposed and the compressive strength decreased. More recently, sodium alginate was used on loess as a soil improvement technique by Zhao et al.(2020). They observed that the strength increment reached double of untreated specimens with the use of sodium alginate. Arab et al. (2019) proposed the use of sodium alginate for weak cohesive subgrades and pavement construction applications as well as the long-term durability for sodium alginate. Additionally,biopolymers can be used with other binders or waste materials.For instance,Soltani et al.(2021)examined the potential use of sodium alginate as a biopolymer additive with tire-derived ground rubber to improve the strength of high-plasticity clay. On the other hand,Soldo et al. (2020) investigated the effects of five different biopolymers(xanthan gum,β-1,3/1,6-glucan,guar gum,chitosan,and alginate) on the mechanical properties of soil, and after extensive laboratory experiments, they observed that the most effective biopolymers were xanthan gum,guar gum,and β-1,3/1,6-glucan.In the second case of the biological soil improvement, the most common method is mineral precipitation by biological organisms in soil pores (Mitchell and Santamarina,2005;DeJong et al.,2013;Montoya and DeJong, 2015; Terzis and Laloui, 2017). In this technique,bacteria are placed into the soil through two main methods:injection and premixing (Mujah et al., 2017). In the injection method, a bacteria solution is percolated into the soil, thereby bacteria are attached to soil grains. However, in the premixing method,bacteria are introduced into the soil by mechanical mixing.It should be noted that the most preferred method for microbial carbonate precipitation is the injection method. Kantzas et al.(1992) showed that the bacteria can precipitate calcium carbonate to transform unconsolidated sand into well cemented sand and the porosity and permeability are reduced in the areas where cementation occurs.Ferris et al.(1997)used bacteria to precipitate calcium carbonate as a cementing agent to control fluid flow in soils and the effectiveness of the method was confirmed through scanning electron microscopy (SEM) combined with energy-dispersive X-ray (EDX) (SEM/EDX), X-ray powder diffraction (XRD), and computed tomography(CT) scanning. To observe the performance of the microbial carbonate precipitation method under field applications, Whiffin et al. (2007) treated a 5-m sand column with bacteria. They controlled the injection and reaction parameters during the bacteria injection process to enable clogging of material.They also conducted mechanical tests to examine the improvement in soil strength and stiffness. In the bio-mediated calcite precipitation method, the most important factor is to obtain the bacteria culture which is suitable for the particular application.Cabalar et al.(2018a) used the microorganism Sporosarcina pasteurii for biocementation to study the behavior of bio-cemented sand at small strains and a similar response was observed at calcite and lime cemented specimens. The microbial-induced calcite precipitation method can be used for seepage control. Wu et al. (2019) studied the injection of bio-grout solution and the formation of precipitates along a circular one-dimensional(1D) flow channel,and proposed an equation to predict the distance that the bio-solution travels.Khaleghi and Rowshanzamir (2019) prepared a urease microorganism from single and mixed cultures to improve the mechanical properties of sand specimens. The mechanical and flow characteristics of the improved sand were examined using unconfined compression,direct shear, and falling head permeability tests. The results indicated that mixed culture could be recommended for soil improvement.

Previous studies have primarily focused on the short-term (up to 90 d) mechanical properties of biopolymer treated soils. However, as biopolymers are organic additives, their performance should also be examined many years after the treatment procedure.Existing literature focused on short-term performance of biopolymer treated soils. Moreover, long-term performances of biopolymers in soil improvement have not been studied yet.In this study, the long-term (3 years) strength behavior of biopolymer treated kaolin was investigated as well as the short-term behavior of kaolin clay treated with two different biopolymer types. Therefore, specimens were kept in a curing room for 3 years to observe the long-term behavior. Furthermore, the interaction between biopolymer and clay was examined using SEM images. The results showed that the strength of specimens containing xanthan gum significantly increases at 3 years of curing period, however, the strength of guar gum treated specimens reduces at lower guar gum content. It has been observed that the physical bonding of biopolymers is important in the strength increase mechanism according to SEM analysis.

2. Materials and methods

2.1. Materials

2.1.1. Kaolin

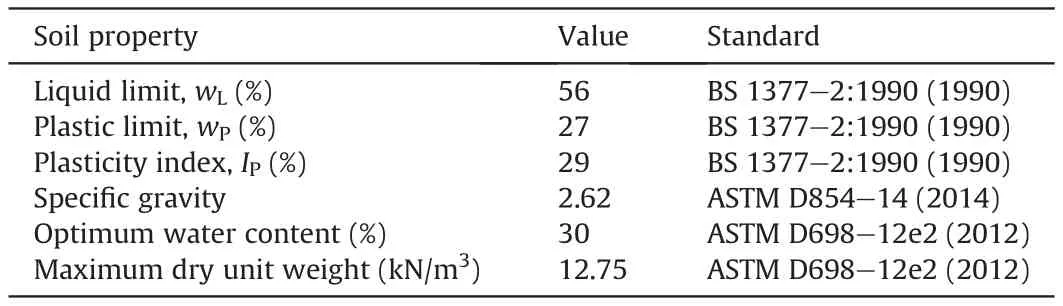

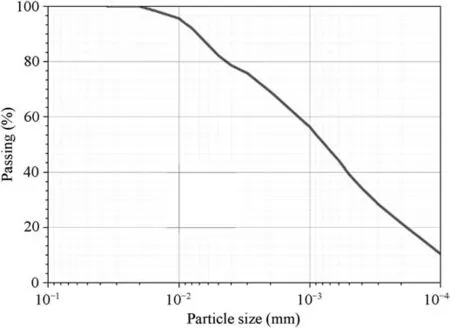

A kaolin clay was used to determine the effect of biopolymers on mechanical properties of fine grained soils. Atterberg limits,compaction characteristics and specific gravity of kaolin were determined in accordance with standards of BS 1377-2:1990(1990), ASTM D698-12e2 (2012), and ASTM D854-14 (2014),respectively. The physical properties and particle size distribution of the kaolin are presented in Table 1 and Fig.1, respectively. The kaolin is classified as clay with high plasticity(CH)according to the unified soil classification system(USCS).

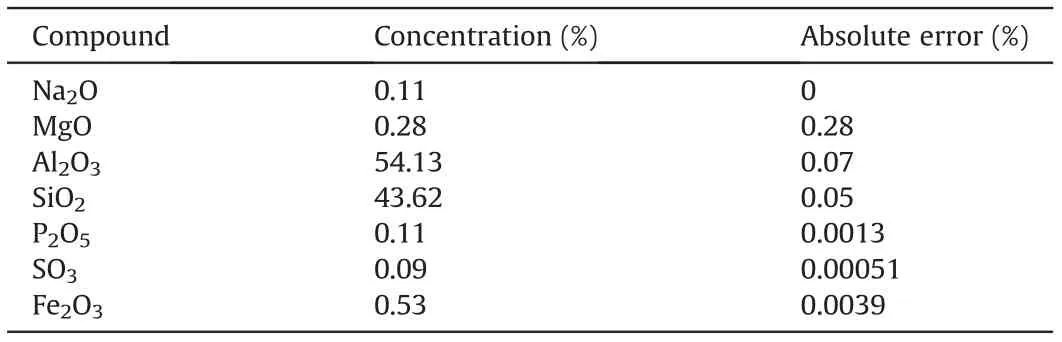

The chemical properties of kaolin were determined by using Xray fluorescence (XRF) method and are presented in Table 2.

2.1.2. Xanthan gum and guar gum

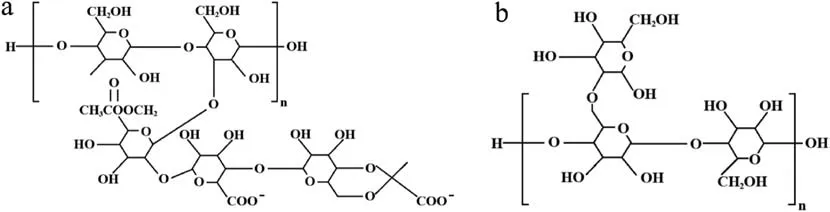

The first natural biopolymer produced for industry is xanthan gum; therefore, the safety of this biopolymer on human body has been investigated extensively (Freitas et al., 2014). Mostly, biopolymers are produced by microorganisms such as bacteria,fungus,and algae.Xanthan gum is secreted by the bacterium Xanthomonas campestris(Jeanes et al.,1961).A linear backbone of 1,4-linked β-Dglucose charged trisaccharide side chain is the main chain of xanthan gum molecule and the trisaccharides unit side-chain successively contains mannose, glucuronic acid and mannose (Jeanes et al.,1961).

Guar gum is a substance made from Cyamopsis tetragonolobus which belongs to the family of leguminosae(Thombare et al.,2016)and also classified as galactomannan. Guar gum consists of linear backbone chains of 1,4-linked β-D-mannopyrasnosyl units residues to 1,6-linked galactopyranosyl units (McCleary et al., 1985). The molecular chain of this gum causes viscosity increment of liquids(Thombare et al.,2016).

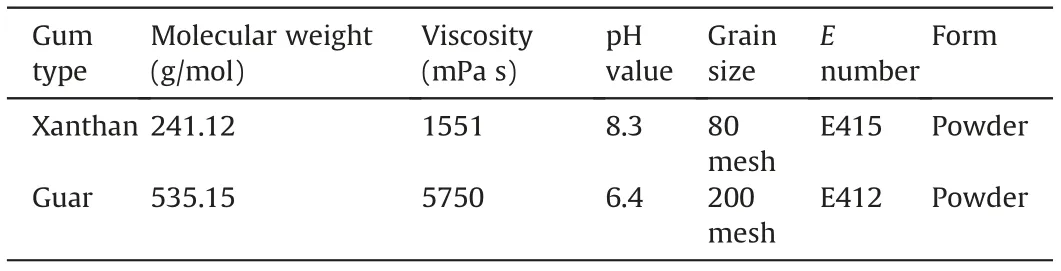

Chemical structures of xanthan gum and guar gum are shown in Fig.2.Also the chemical and physical properties of the biopolymers are tabulated in Table 3.

2.2. Specimen preparation and experiments

Two types of biopolymers (xanthan gum and guar gum) were selected for stabilization. The specimens were treated with the biopolymers at five polymer inclusion levels(0%,0.5%,1%,1.5%and 2%) by dry weight of kaolin. In order to prepare the specimens,firstly the biopolymer solution was prepared. The solution was prepared by mixing the biopolymer(0%,0.5%,1%,1.5%and 2%by dryweight of kaolin) in dry form with the required amount of water(25%, 30%, 35% and 40% by dry weight of kaolin) until the biopolymer was dissolved in water. Then, dry kaolin and the biopolymer solution were mixed until homogenous mixture was obtained. The mix designs of the specimens are presented in Table 4.After the mixing process,each specimen was compacted to standard Proctor energy by using a mini compaction apparatus.The mini compaction apparatus consisted of two parts: mold and hammer.The diameter of the mold was 50 mm and its height was 100 mm.The mass of hammer was chosen as 1.02 kg;therefore,the height of drop was designed as 15.4 cm to achieve the standard compaction energy. Water contents of the specimens ranged between 25%and 40%to obtain the behavior and strength properties of biopolymer treated kaolin at different consistencies. The specimens were wrapped with low-density polyethylene film (LLPDPE)to prevent desiccation and placed in a curing room(at temperature of 25°C and relative humidity of 97%) until testing date. The specimens are named depending on their biopolymer content and type,water content and curing time to distinguish specimens fromeach other. Here,GG and KX indicate guar gum and xanthan gum,respectively; and water content and curing time are identified by using letters W and D,respectively.As an example,GG2.0W35D28 label represents 28 d cured specimen with 35%water content and including 2% of guar gum.

Table 1 Index properties of kaolin.

Fig.1. Particle size distribution of kaolin.

Table 2 Chemical composition of kaolin.

Table 3 Physical and chemical properties of biopolymers.

The influence of biopolymers on Atterberg limits was investigated by using fall cone and rolling-thread plastic limit tests. The Atterberg limit tests were conducted in accordance with BS 1377-2:1990 (1990) procedures. Firstly, kaolin was thoroughly mixed with necessary amount of xanthan gum or guar gum to achieve maximum homogeneity. Then a predetermined amount of water was added and the mixing process was continued until a homogeneous mixture was obtained.At least four mixtures with varying water contents were prepared at each biopolymer inclusion level,and these mixtures were subjected to falling cone test to determine liquid limit. The addition of water to the mixture decreased the biopolymer concentration but still the kaolin-biopolymer ratio was constant during the experiment.

Unconfined compression tests were conducted according to ASTM D2166/D2166M - 16 (2016) to determine the strength properties. The unconfined compression test is usually used to measure undrained strength of cohesive soils. The maximum loading capacity of unconfined compression apparatus was 50 kN.For repeatability, at least three specimens were prepared and subjected to unconfined compression test for each case. The diameter and length of specimen were measured before test, and then the load was applied at a constant speed of 1.42 mm/min.The loading continued until 20% of strain was reached. It should be noted that the stress readings were automatically recorded at each 0.06 mm displacement value.

3. Results and discussion

3.1. Index properties of biopolymer treated kaolin

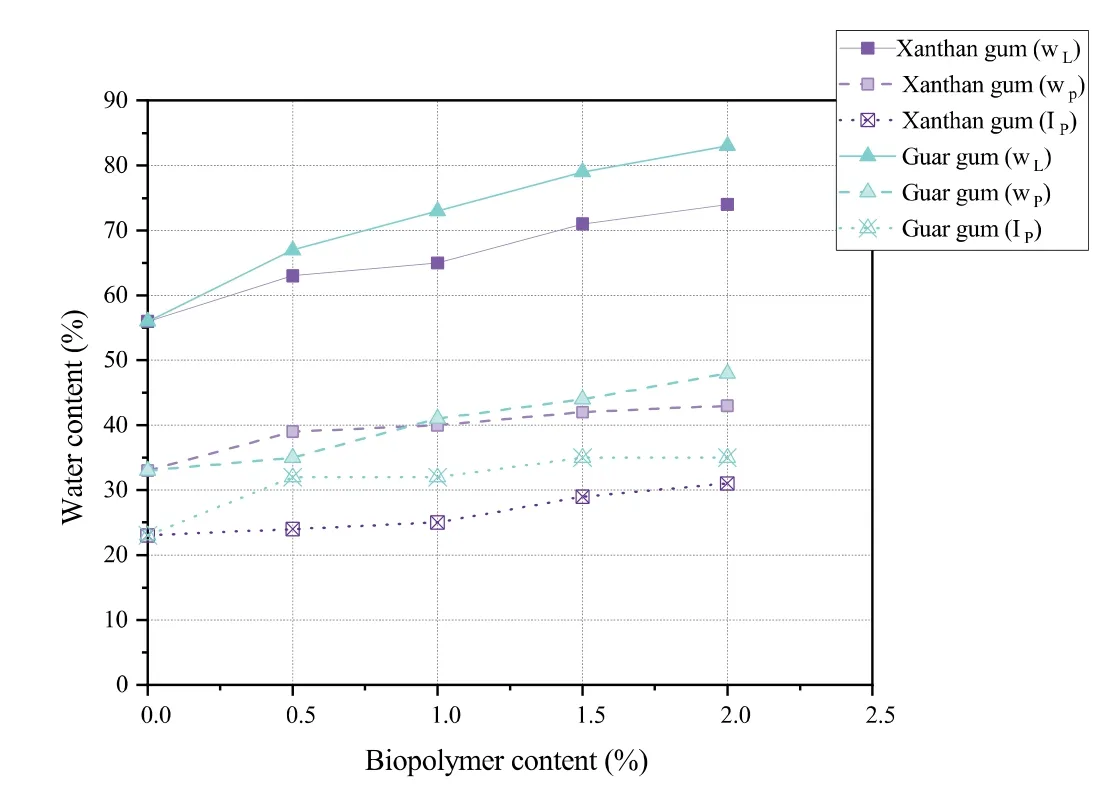

Liquid limit and plastic limit tests were conducted on biopolymer treated kaolin in order to determine the effect of biopolymer on consistency of kaolin.Liquid limit tests were carried out using the fall cone test device.The Atterberg limits of xanthan gum and guar gum treated soils are shown in Fig. 3.

Fig. 2. Chemical structures of (a) xanthan gum and (b) guar gum.

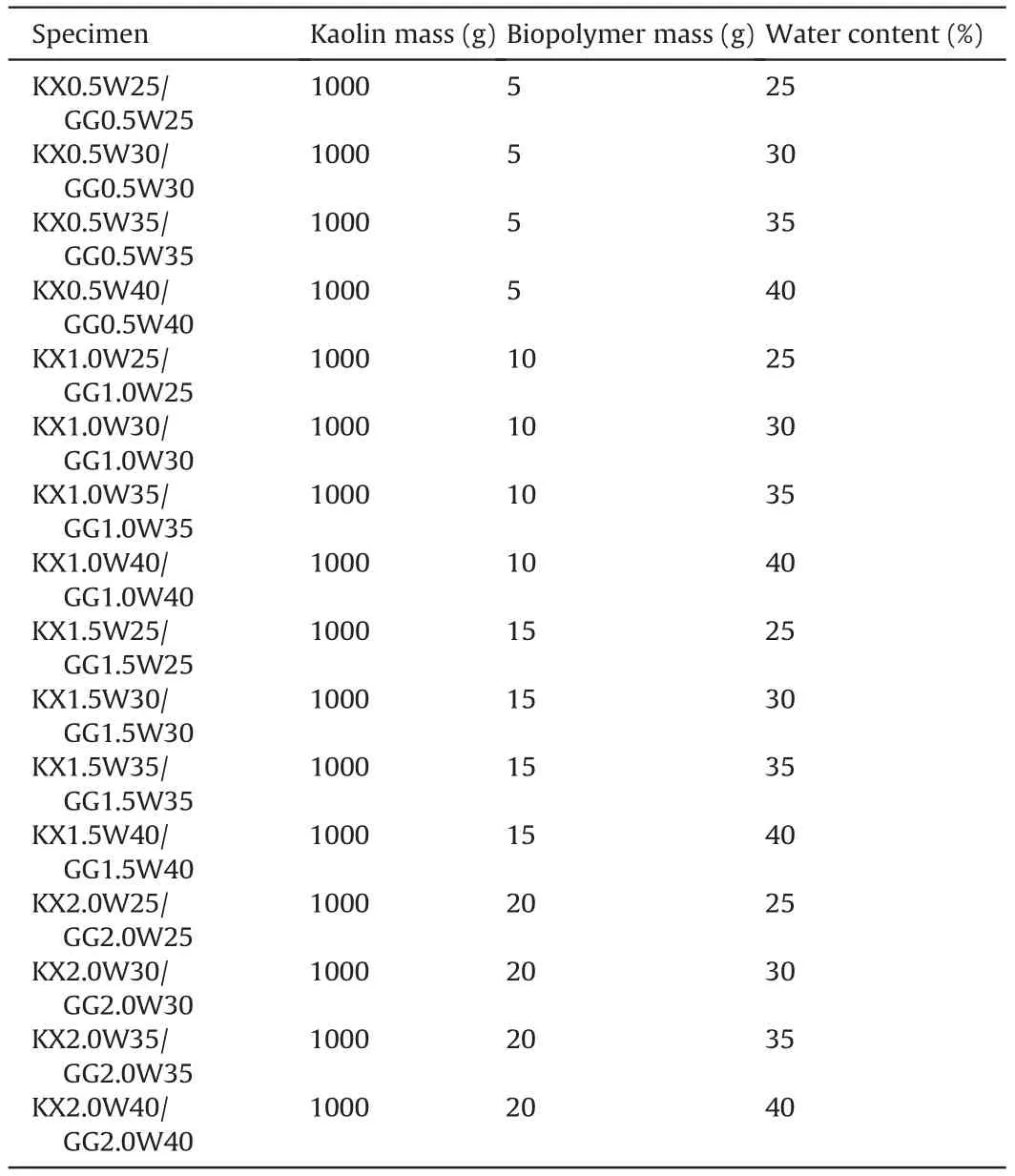

Table 4 Mix designs of the specimens.

Fig. 3. The effect of xanthan gum and guar gum on Atterberg limits.

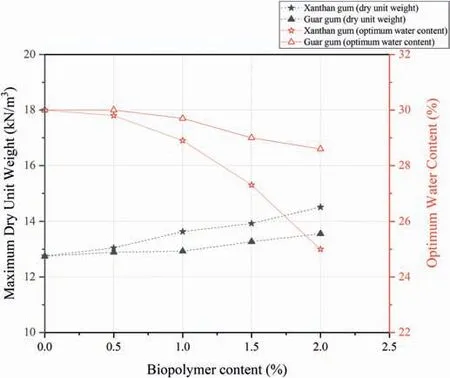

Fig. 4. Maximum dry unit weight and optimum water content of soil-biopolymer mixtures.

As can be seen in Fig.3,a significant increase in liquid limit value was observed by increasing the biopolymer content. The liquid limit of pure kaolin was 56% and it reached 74% and 83% at 2%xanthan gum and guar gum contents, respectively. Analysis of the mixtures containing the same inclusion level of the two biopolymers indicates that the liquid limit of the kaolin with guar gum was higher than that of the mixture containing xanthan gum. The most dominant mechanism for the increase in liquid limit by biopolymer addition is flocculation. As the biopolymer content increases, the tendency of the clay fabric to flocculation increases.In flocculated fabrics, water is trapped inside and between soil particles. Thus, soil fabric holds more water with increasing flocculation tendency and also flocculated fabric provides higher shear resistance which causes the increment of liquid limit value(Mitchell,1956;Kim and Palomino,2009).Besides,viscosity of pore fluid and polymer charge may also have some effects on the consistency. Garcıa-Ochoa et al. (2000) indicated that the viscosity of pore fluid is increased by addition of biopolymer. However, the viscosity also depends on the biopolymer type as well as the biopolymer content, dissolution and room temperature (Casas et al., 2000). It should be noted that viscosity of pore water is greater in specimens containing guar gum compared to those contain xanthan gum in that guar gum increases viscosity due to the chemical structure. Besides, different clay-biopolymer interactions based on the bonding type related to the polymer charge may induce a change of consistency. Since xanthan gum is an anionic additive, electrostatic attraction does not occur due to the negatively charged clay particles. Instead, a cationic bridge is formed between the clay and xanthan gum, caused by exchangeable cations in the interlayers. However, guar gum and kaolin particles are bound to each other by hydrogen bonds(Nugent et al.,2009). In summary, the liquid limit values vary depending on the viscosity of pore structure,bonding type and the most importantly flocculation. Considering these factors and the results of experiments, the guar gum treated kaolin has a higher liquid limit than xanthan gum treated kaolin.

3.2. Compaction properties of biopolymer treated kaolin

Optimum water content and maximum dry unit weight of biopolymer-tŕeated kaolin are important parameters for comparison and interpretation of the mechanical properties of the specimens. Unit weight of specimens would affect the mechanical properties such as strength, cohesion, permeability, and swelling.The optimum moisture content and maximum dry unit weight of the kaolin containing biopolymers at varying polymer inclusion levels were obtained. Compaction tests were performed using standard Proctor energy in accordance with ASTM D698-12e2(2012).

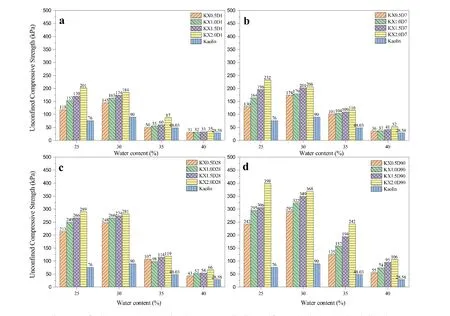

Fig. 5. Unconfined compressive strength of xanthan gum treated kaolin cured for (a) 1 d, (b) 7 d, (c) 28 d, and (d) 90 d.

The maximum dry unit weight and optimum water content of kaolin with different biopolymer contents for both xanthan gum and guar gum are shown in Fig. 4. The results show that the optimum moisture content decreased and the maximum dry unit weight increased due to the addition of both xanthan gum and guar gum.The dry unit weight of specimens incorporating xanthan gum increased from 12.75 kN/m3to 14.52 kN/m3by increasing the biopolymer content from 0% to 2%. Likewise, increasing the guar gum content caused an increase in the dry unit weight from 12.75 kN/m3to 13.56 kN/m3. Ayeldeen et al. (2016) indicated that the density of specimens containing xanthan gum increased with increasing xanthan gum content.This behavior can be attributed to the gum gels in the voids of the soil skeleton which cause the reduction of friction between the soil particles and induce contact lubrication in soil matrix during compaction. Therefore, the soil particles move with less effort and higher maximum dry densities are obtained (Meegoda et al.,1998; Park et al.,2006; Soltani et al.,2019).The optimum water content of the biopolymer treated kaolin was decreased as the percentage of additive increased. This could be due to the lubrication stage occurring earlier with less water content because of the presence of the biopolymer gels in the voids.Thus,the optimum water content decreased and the maximum dry weight of kaolin increased with biopolymer addition. Similar results were also obtained for guar gum by Sujatha and Saisree(2019)who reported that higher guar gum content induced lower optimum content and higher dry unit weight.On the contrary,Dehghan et al.(2019)stated that the addition of xanthan gum and guar gum caused an increase in optimum water content and a decrease in dry unit weight. Nevertheless, xanthan gum affected the compaction properties more than guar gum.

3.3. Strength properties of biopolymer treated kaolin

In order to investigate the effects of biopolymer on the strength properties of kaolin,160 specimen sets(at least 3 specimens in each set) were prepared for unconfined compression tests, and the results were evaluated in terms of biopolymer content, biopolymer type, curing period and water content.

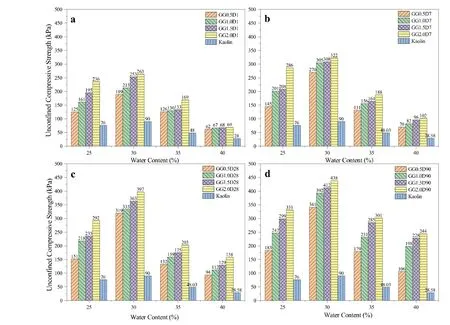

Fig. 6. Unconfined compressive strength of guar gum treated kaolin cured for (a) 1 d, (b) 7 d, (c) 28 d, and (d) 90 d.

Unconfined compressive strength(UCS)of pure kaolin was also determined at water contents of 25%-40%in order to compare the performance of the biopolymers. The results given in Fig. 5 show that the UCS of specimens treated with xanthan gum increased in all biopolymer inclusion levels and water contents.The interaction and strength gain mechanism between kaolin and xanthan gum can be understood better by considering the structure and chemical properties of kaolin and xanthan gum.Xanthan gum is a branched anionic heteropolysaccharide with high molecular weight(>106Da)(Rehm,2009).Kaolin consists of alternative layers of one tetrahedral sheet and one octahedral sheet, with the successive layers linked by van der Waals forces and hydrogen bonds that provide strong bonding (Mitchell and Soga, 2005). Due to the isomorphous substitution of clay,there are exchangeable cations in the interlayers of kaolin. After biopolymer treatment, these exchangeable cations and xanthan gum bond each other by cation bridging. Also, net-like formation which was a by-product of claybiopolymer attractions occurred. The net-like formation of xanthan gum wraps kaolin particles like a husk and this structure also bridges distant particles. As a result, the strength and cohesion of the soil increase by means of the composition of a stronger structure caused by the net-like formation of xanthan gum(Chang et al.,2015b). The interaction between the soil and the xanthan gum is influenced by several factors including water content, curing time and inclusion level of biopolymer. The UCS values were generally proportional to the inclusion level of biopolymer and the curing time. As expected, increasing the biopolymer inclusion level increased the strength gain;therefore,greater strength values were obtained for specimens containing 2% xanthan gum. Latifi et al.(2016) indicated that 2% xanthan gum was the optimum biopolymer content above which no significant effect on strength will be caused.If the effect of curing time is considered,the net-like formation or cementitious products which combine the soil particles and fill the pores would be grown by the passing of time(Latifi et al., 2016; Cabalar et al., 2018b). As the curing time increased, a remarkable increase in strength was observed (Fig. 5). Maximum strength values were obtained in specimens having 90-d curing period. After 90-d curing, the compressive strengths of the specimens containing 2%biopolymer reached 398 kPa,368 kPa,242 kPa and 106 kPa at 25%, 30%, 35% and 40% of water contents, respectively.In specimens with a curing time of 90 d,the lowest strength increase observed was about 1.92 times in the specimens with 40%water content,while the highest strength increase was observed as 5.24 times in specimens with 25% water content. Considering the biopolymer additive and water content, the maximum UCS was observed as 398 kPa in 90-d cured specimens. Also, there was a significant increase in strength in the 90-d cured specimens compared to the specimens with a 28-d curing time.However,in all curing times, except the specimens with 2% xanthan gum, the maximum strength was obtained in specimens prepared at 30%water content which is nearly the same as their optimum water content as can be seen in Fig.4.Beyond 1.5%xanthan gum content,the optimum water content decreased significantly.As a result,the maximum strength values were observed in specimen prepared at 25%water content.Hence,it can be concluded that dry unit weight has an important effect on strength parameters. The undrained shear strength values of the specimens prepared on the dry and wet sides of optimum water content were less than those prepared at the optimum water content. Comparing the dry and wet sides of optimum water content, the dry side of optimum water content shows greater strength values. However, the maximum strength was obtained at the optimum water content as the void ratio reached minimum value after the compaction. The UCS of pure kaolin specimens was obtained as 76 kPa,90 kPa,48 kPa and 29 kPa at 25%, 30%, 35% and 40% water contents, respectively. After biopolymer treatment, for each biopolymer inclusion level,maximum strength value was obtained at optimum water content,and specimens prepared at dry side of optimum water content showed greater strength than those prepared at wet side of optimum water content.On the other hand,the optimum water content decreased to 25% by addition of 2% biopolymer. Therefore, UCS of specimens containing 2% biopolymer decreased by increasing the water content. Greater strength values were obtained in the specimens prepared at 25%water content and 2%biopolymer inclusion level.

Fig. 6 shows the UCS values of guar gum treated specimens.Apart from some exceptions, generally the strength of guar gum treated specimens was greater than that of xanthan gum treated specimens.The difference between the chemical functional groups and structures of the biopolymers caused different soilbiopolymer matrices that led to strength gain. Similar to xanthan gum, guar gum is also a high molecular weight polysaccharide.However, unlike xanthan gum, guar gum does not contain any functional groups that induce any charges.Consequently,guar gum is a neutral polymer (Gambrell et al., 2010). The interaction between guar gum and kaolin is dominated only by hydrogen bonding while xanthan gum interacts with kaolin by cationic bridging and far less hydrogen bonding. Moreover, the guar gum shows higher viscosity in a water solution than xanthan gum,thus the guar gum treated specimens show greater strength gain(Ayeldeen et al., 2016). Meanwhile, increasing the curing period increased the growth of fiber-like cementitious/bonding materials between the soil particles.Maximum UCS values were observed at 90-d cured specimens with 2% biopolymer content. After 90 d of curing, the undrained strength of specimens containing 2%biopolymer was determined as 311 kPa, 438 kPa, 301 kPa and 244 kPa at 25%,30%,35%and 40%water contents,respectively.Also,the UCS of guar gum treated specimens increased by increasing the biopolymer content. The maximum strength was measured as 438 kPa for the specimen containing 2% biopolymer at 30% water content. In the specimens prepared at 30% water content, it was observed that the strength increased by 2.1-2.9 times in the 1-d cured specimens and by 3-3.5 times in the specimens cured for 7 d. The strength increment reached 4.4 and 4.8 times in the specimens with curing times of 28 d and 90 d,respectively.Unlike xanthan gum, guar gum had no significant effect on the optimum water content,as observed in Fig.4.For all guar gum contents,the optimum water content was 30% or close to this value, and the maximum strength values were also observed in specimens prepared at 30% water content. In this case, since the optimum water content is the same for all biopolymer contents, the specimens prepared on the dry side (25%)of optimum water content showed greater strength than those prepared on the wet side(over 30%)of optimum water content. Also, on the wet side of optimum water content,the strength decreased with increasing water content.The lowest strength values were observed in the specimens prepared at 40% water content. The strength of the specimens with a curing time of 1 d ranged between 62 kPa and 69 kPa. Moreover, UCS of 90-d cured specimens reached 244 kPa.

The results indicate that, overall, guar gum is more effective than xanthan gum in improving the strength of the soil and increasing the curing time or the biopolymer content increases the soil strength.

Besides the strength gain mechanisms that depend on biopolymer type, as explained above, the most important mechanism for strength,regardless of the biopolymer type,is flocculation.Guar gum is a neutral polymer,which generally causes edge-edge(EE) and edge-face (EF) inter-particle associations after the flocculation(Dwari and Mishra,2019).In addition,xanthan gum as an anionic polymer has EE associations as a result of interactions with kaolin (Kang et al., 2019). The aggregated and flocculated microstructure induced by polymers results in an interconnected soil structure with high resistance to external load which increases strength (Chang et al., 2015b). However, the flocculation mechanism is not entirely related to curing time, and the strength increases after a certain process such as 28-d or 90-d curing time,where a by-product of biopolymer and clay interactions are responsible for strength increment.

3.4. Long-term strength

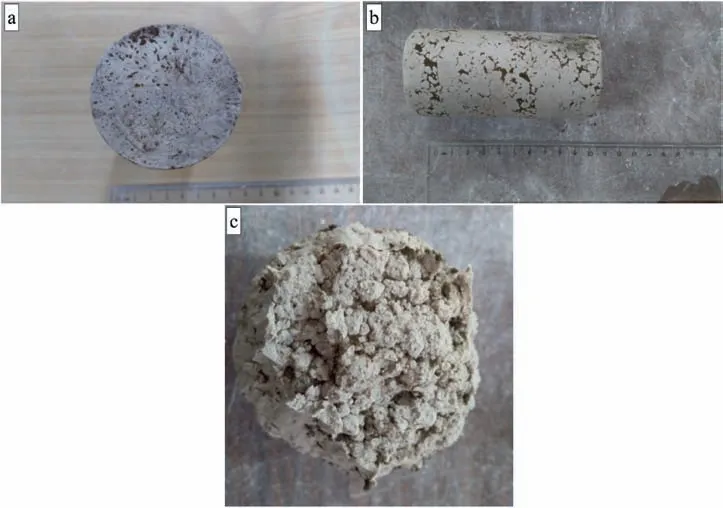

McArdle and Hamill(2011)indicated that xanthan gum viscosity had an excellent stability over a wide range of pH values and temperatures and it was also resistant to enzymatic degradation.Wüstenberg (2014) showed that the characteristics of xanthan solutions do not change over a wide range of pH values and it is more stable than other biopolymers. Wang et al. (2000) showed that guar gum is relatively stable under acidic conditions and its stability is reduced at higher temperatures and lower pH values.Although xanthan gum and guar gum are generally stable, it is important to understand the long-term mechanical properties of these organic biopolymers when they are used for soil stabilization.For this purpose, at least three specimens were prepared for each case and kept in a curing room for 3 years under controlled condition (97% relative humidity at 25°C). Although the specimens were wrapped with LLPDPE and kept in the curing room,moisture loss from specimens or change in water content was expected during 3 years. Therefore, after the specimens were subjected to unconfined compression test, their water content was obtained to determine the moisture loss in the curing room. After water content tests, it was understood that the water content of specimens decreased by approximately 5%.Therefore,the obtained results will be examined according to their water contents at the preparation stage and after curing.Besides the loss of water content,additional physical changes also occurred; as the biopolymers were organic,mold formation was observed both inside and outside the specimens, as shown in Fig. 7. Although it was initially considered that this would decrease the strength of the specimens, the results of the unconfined compression tests showed that the strength was increased after 3 years of curing.

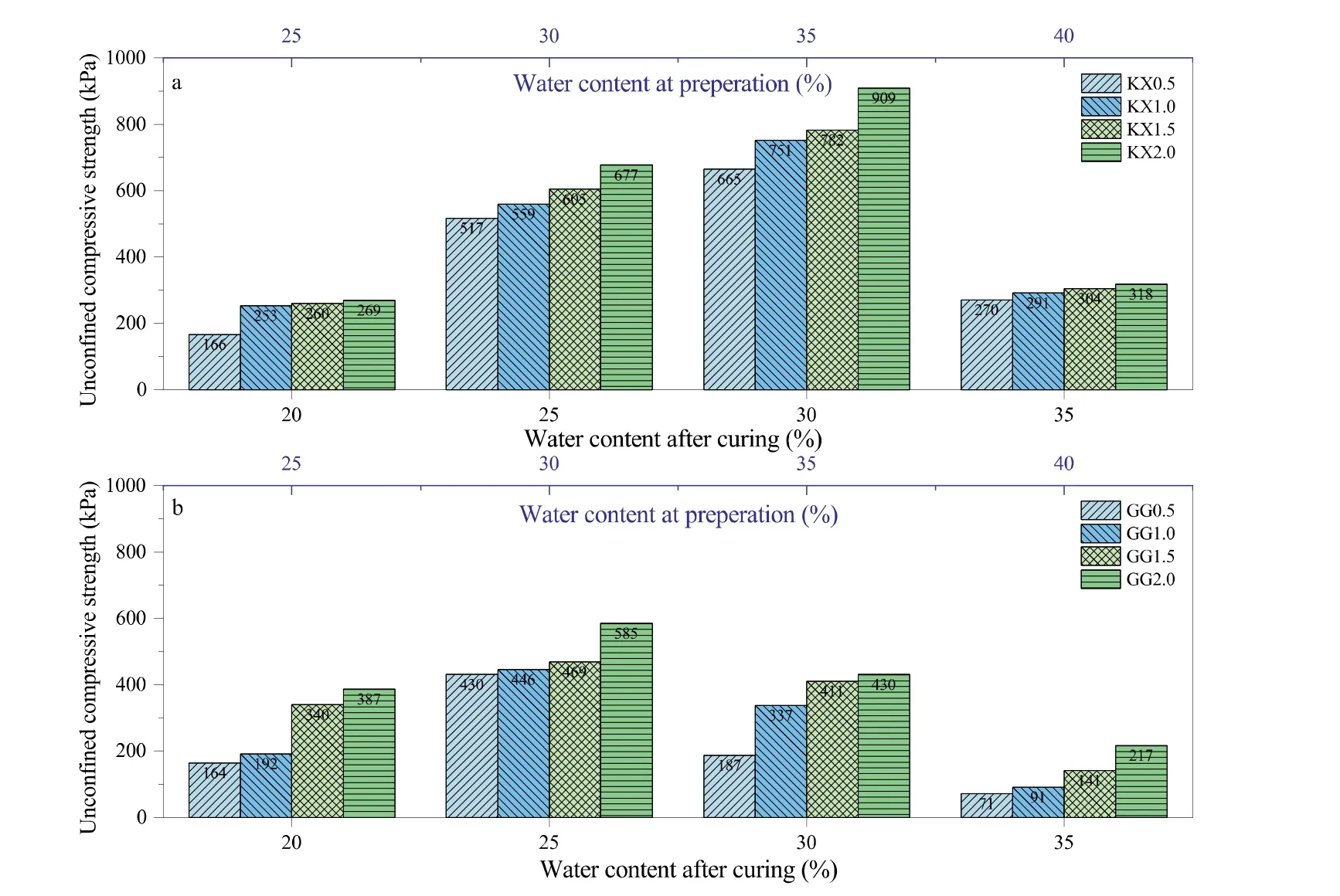

The results of UCS of the specimens cured for 3 years are presented in Fig. 8. Except the specimens containing xanthan gum with 25% (preparation) water content, the UCS was remarkably increased during 3 years of curing.The strength of the 3-year cured specimens was 2 or 3 times greater than that of 90-d cured specimens, however, the specimens prepared with 25% water content showed almost half of the strength of 90-d cured specimens. As mentioned above, the stability of xanthan gum is quite high, thus the increase in strength in long term was expected. Chang et al.(2015b) investigated the durability of clay specimens with 1%xanthan gum between 28 d and 750 d of curing and reported that compressive strength and elastic modulus increased slightly which can be attributed to possible long-term variations such as hardening or aging. Xanthan gum reacts with kaolin and also interacts with water in pores. At this stage, the amount of water loss from specimen during curing is very important. It should be noted that for the long-term tests,the maximum strength was observed in the specimens with 30%water content(prepared at 35%water content)(as was the case for 1-, 7-, 28- and 90-d cured specimens). During the unconfined compression tests,it was observed that specimens prepared at 25% water content tended to crumble due to drying.The decrease in strength could be caused by loss of binding properties of gelatinous structure due to drying during curing stage.The strength of the specimens prepared at 40% water content (and cured over 3 years) increased compared to 90-d cured specimens.However, lower strength values were obtained for the specimens with 30%water content(or 35%preparation).This can be explained by the fact that pure kaolin has less strength at this water content and the specimens show ductile behavior that was observed during shearing on the wet side of optimum water content.The maximum strength was observed at the specimens prepared at 35% water content.The strength increase in the long term can be attributed to(i) the loss of water at high water contents, and (ii) the reactions that produce binding materials between kaolin and xanthan gum.

Fig. 7. Mold formation: (a) Top side; (b) Side part; and (c) Inside of the specimens cured for 3 years.

Fig. 8. Unconfined compressive strength of (a) xanthan gum treated and (b) guar gum treated specimens cured for 3 years.

The strength gain mechanism for guar gum treated specimens is more complicated than that for specimens with xanthan gum since guar gum is relatively stable. At 30% and 35% preparation water content levels, the long-term UCS of specimens was much greater than that of 90-d cured specimens. The maximum strength was obtained at 30%preparation water content.Besides,at both dry and wet sides of optimum water content, lower strength values were attained. Likewise, the maximum strength was observed in specimens at optimum water content in early period. Due to its lower stability,guar gum could be affected by mold formation in voids.In the classification system, molds belong to the Kingdom Fungi that can be harmful and cause inherent weakness for guar gum.Usually molds grow in aqueous environments with high humidity. Therefore,mold formation was higher at high water content,resulting in further degradation in guar gum.In the specimens containing 25%water,strength loss was observed at lower gum contents(0.5%and 1%) and strength increase was determined at higher guar gum inclusion levels. Two different mechanisms affect the behavior of gaur gum treated soils: the first one is the mechanism of strength gain owing to guar gum, and the second one is the mechanism of guar gum degradation due to mold formation. At lower guar gum contents,degradation due to mold is dominant while strength gain mechanism is more effective at higher guar gum contents.

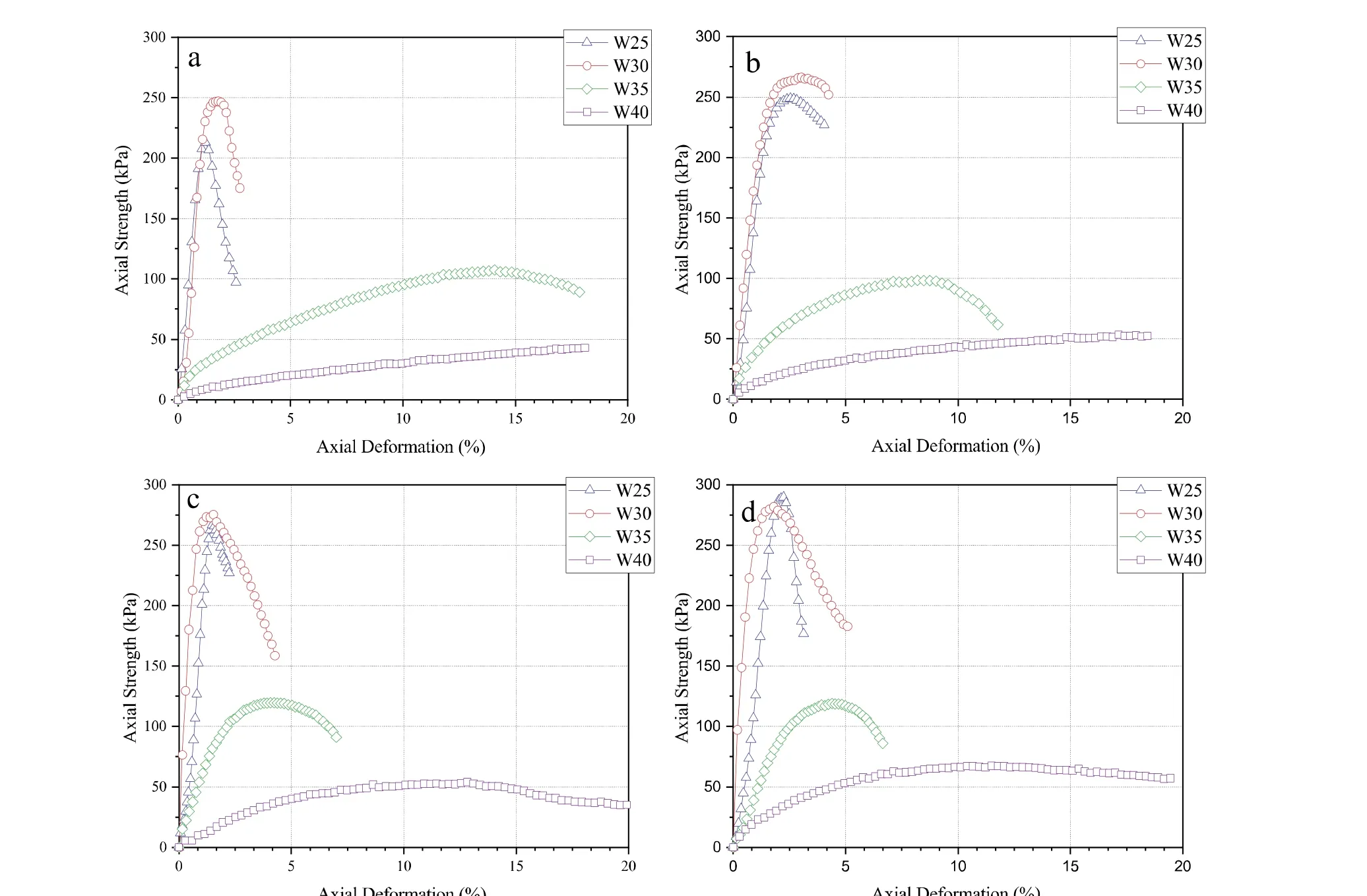

3.5. Deformation characteristics of biopolymer treated kaolin

The stress-strain relationship of biopolymer treated clay was also investigated in terms of biopolymer type,biopolymer inclusion level,curing period and water content.The stress-strain curves of specimens prepared at various xanthan gum inclusion levels are shown in Fig. 9. The results show that the biopolymer inclusion level and water content have strong effects on the stress-strain behavior of specimens as well as elastic modulus. As expected,increasing the water content caused more ductile behavior, therefore, axial deformation corresponding to the maximum UCS increased at water contents of 35%and 40%.On the other hand,the biopolymer inclusion level had no significant effect on the stressstrain behavior of kaolin. Therefore, it can be said that the water content has more effect on the deformation behavior of biopolymer treated clay than biopolymer content. Pakbaz and Alipour (2012)investigated the influence of addition of cement on mechanical properties of clayey soils. They stated that in all cement contents,with the increase of water content, the specimens showed much more ductile behavior. However, they emphasized that brittle behavior was observed only at lower water contents. Karakan(2018) reported that in geotextile reinforced soils, axial deformations increase with increasing water content, that is, reinforced soils exhibit a more ductile behavior. Therefore, in biopolymer-, cement- and fiber-reinforced soils, the stress-strain behavior is predominantly affected by water content rather than by the additives.

Fig. 9. The stress-strain curves of specimens prepared at (a) 0.5%, (b) 1%, (c) 1.5%, and (d) 2% xanthan gum inclusion levels.

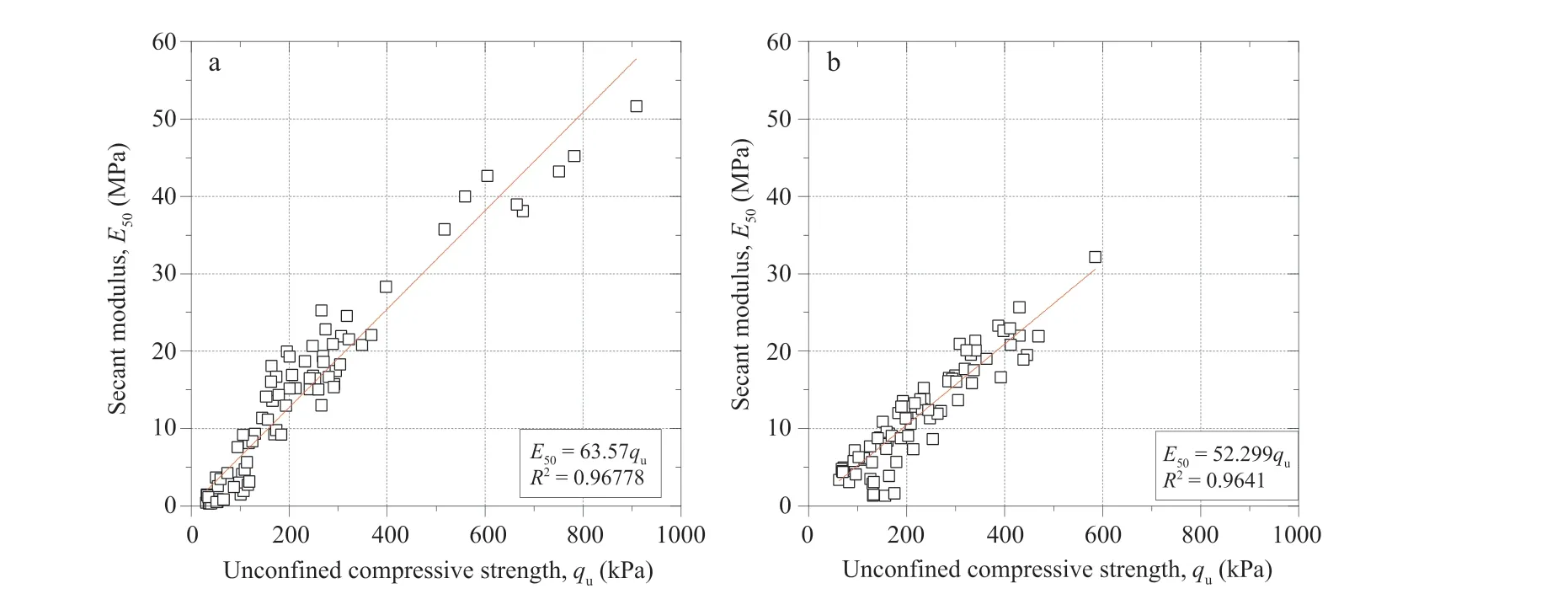

Secant modulus (E50) is defined as the resistance capacity to elastic and plastic deformations and is an important parameter that gives valuable information about deformation characteristics of soils, which is also used for estimating elastic settlements that occur in soils (Wang et al., 2013). The secant modulus was calculated from the stress-strain relationship obtained from unconfined compression test, simply formulated as the ratio of the stress to strain at 50% of the UCS (Lorenzo and Bergado, 2004; Zhang et al.,2014).Considering the UCS and secant modulus of all specimens,a distinct linear relationship was observed between these two parameters. In the literature, quantitative correlations have been obtained for several soil improvement techniques, especially cement stabilization (Kukko, 2000; Tang et al., 2000; Qiao et al.,2007; Wei et al., 2011; Wang et al., 2013). For biopolymer treated soils,correlations between the UCS quand E50are shown in Fig.10.The linear function is expressed as E50= 63.57quhaving a coefficient of determination (R2) value of 0.96778 for xanthan gum and E50= 52.299quwith a R2value of 0.9641 for guar gum. These relationships would be useful for indicating the relationship between E50and quof biopolymer treated clays. Previous studies generally focused on calcium hydroxide-based additives such as lime and cement. However, in the literature, there is no known expression derived for biopolymer treated soils.

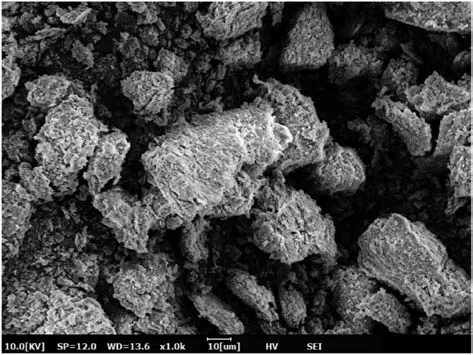

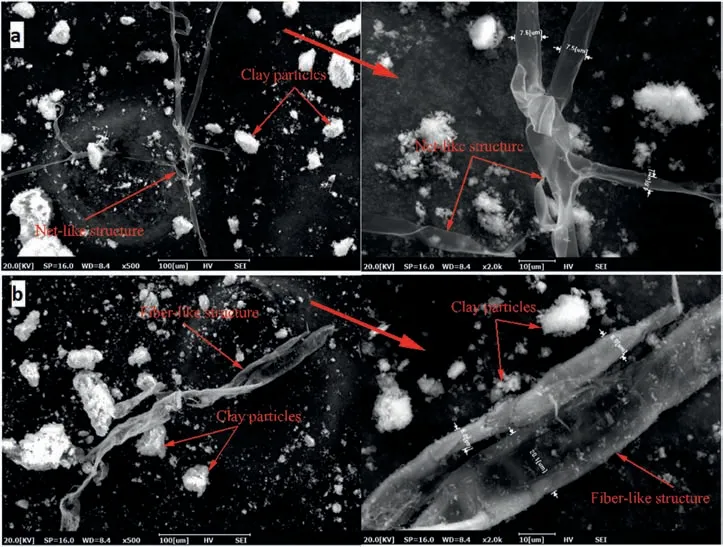

3.6. Scanning electron microscopy analysis

After 3 years of curing,the specimens were subjected to UCS and SEM analysis to better understand the strength increase mechanism. The SEM image of the naturally flocculated kaolin clay is shown in Fig.11.As is known,kaolin particles consist of alternative layers or stacks of one silica sheet and one alumina/gibbsite sheet(Holtz and Kovacs, 2010). However, after biopolymer treatment, a different clay-biopolymer matrix was formed depending on the biopolymer type.The SEM images of 2%xanthan gum and guar gum treated clays are shown in Fig.12. While filamentous and net-like structures were formed between the clay and xanthan gum,thicker binding/cementitious fiber-like products developed after treatment with guar gum.Although the thread-like structures were multi-sleeve and long,their overall radius varied between 4 μm and 8 μm. Moreover, for guar gum treated soils, the radius of binding material approximately reached 20 μm.These differences between binding materials were caused by variation of molecule structure,electrical charge and molecular weight of the gum.Guar gum has a shorter molecular structure than xanthan gum, and hydration interactions with fine soil particles occur due to hydrogen bonding.On the other hand, xanthan gum has a longer and extended structure that causes the formation of a structure that wraps the fine soil particles.

Fig.10. Relationships between unconfined compressive strength and secant modulus for: (a) Xanthan gum treated and (b) Guar gum treated specimens.

Fig.11. SEM investigations on kaolin clay.

For SEM analysis, specimens cured for 3 years were selected to observe the maximum amount of by-products. When the biopolymer and clayey soil are mixed, flocculation, which is the most important factor of the strength increase,is completed within a certain period of time. After that, the by-products and their bonding are responsible for strength increase. As seen in the SEM analysis in Fig.12,by-products eventually fill the gaps and cause an increase in strength.

They wandered forth11 to seek another country, but nowhere did they find a shelter, or a human being to give them a mouthful of bread, and their need was so great that they were forced to appease12 their hunger with nettles13

Fig.12. SEM investigations on kaolin clays of (a) 2% xanthan gum and (b) 2% guar gum contents.

4. Conclusions

In this experimental study, the effects of two different biopolymers on strength and deformation characteristics of a biopolymer treated kaolin clay was investigated. The results were evaluated in terms of biopolymer content, water content,biopolymer type and curing time.The following conclusions can be drawn from the results obtained in this study:

(1) The maximum dry unit weight increased and the optimum moisture content decreased by increasing both xanthan gum and guar gum inclusion levels. The dry unit weight of xanthan gum treated kaolin increased from 12.75 kN/m3to 14.52 kN/m3by increasing the biopolymer content. Moreover,increasing the guar gum content caused an increase in the dry unit weight from 12.75 kN/m3to 13.56 kN/m3.

(2) A significant increase was observed in both liquid limit and plastic limit values by increasing the biopolymer content.The guar gum treated kaolin had a higher liquid limit than kaolin treated with xanthan gum. The liquid limit value of kaolin clay reached 1.32 times with xanthan gum addition and 1.48 times with guar gum treatment.

(3) UCS of specimens treated with biopolymers increased at all biopolymer inclusion levels and water contents. The maximum strength values were observed in the specimens prepared at their optimum moisture content.Moreover,guar gum showed higher viscosity and stronger bonding than xanthan gum, thus guar gum treated specimens showed greater strength.The maximum UCS was obtained as 398 kPa in xanthan gum treated specimens and 438 kPa in the specimens treated with guar gum.

(4) Except the specimens containing xanthan gum with 25%preparation water content, the UCS remarkably increased at 3-year curing period. On the contrary, in the specimens prepared at 25% water content at lower gum contents (0.5%and 1%),the strength decreased due to the lower stability of guar gum that could be affected by mold formation in voids.Strength loss was observed in the specimens prepared at 40%water content, for all biopolymer contents.

(5) Increasing water content caused more ductile behavior,thus the axial deformation corresponding to the maximum UCS increased. However, the biopolymer inclusion level had no significant effect on the stress-strain behavior of kaolin. A linear function is obtained as E50= 63.57quhaving a R2of 0.96778 for xanthan gum and E50=52.299quwith a R2value of 0.9641 for guar gum.

Declaration of competing interest

Acknowledgments

The authors would like to thank Emre Buzkan and Ilteris Memduh Kiyak for their support on laboratory experiments. Results presented in the paper have been generated in the context of the research project “Investigation of strength properties of xanthan treated kaolin clay” (Grant No. 16MUH013) funded within Research Projects program of Ege University, Turkey.

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Surface characteristics analysis of fractures induced by supercritical CO2 and water through three-dimensional scanning and scanning electron micrography

- Prediction of fracture and dilatancy in granite using acoustic emission signal cloud

- Hysteresis in the ultrasonic parameters of saturated sandstone during freezing and thawing and correlations with unfrozen water content

- Coupled Eulerian-Lagrangian simulation of a modified direct shear apparatus for the measurement of residual shear strengths

- A novel true triaxial test system for microwave-induced fracturing of hard rocks

- Hydromechanical behavior of unsaturated expansive clay under repetitive loading