Enhancing mechanical behavior of micaceous soil with jute fibers and lime additives

J. Zhang, A. Deng, M. Jaksa

School of Civil, Environmental and Mining Engineering, The University of Adelaide, Adelaide, SA, 5000, Australia

Keywords:Geosynthetics Jute fiber Unconfined compressive strength (UCS)Stiffness

ABSTRACT Micaceous soils are common in many tropical countries and regions, and in some locations with moderate climate. The soils are spongy and unstable when loaded and are not considered suitable as construction material in earth structures. To resolve the issue, this work examined performance of micaceous soil reinforced with a combination of jute fibers, hydrated lime or slag-lime. A total of 28 sample sets were prepared at various dosages. Unconfined compression tests were conducted on the samples cured for 7 d and 28 d,respectively.The test results suggested that the unconfined compressive strength(UCS)and material stiffness were increased with the inclusion of up to 1%fiber and decreased if additional fibers were used. The ductility was improved consistently with up to 1.5% fiber content. The inclusions of fibers combined with hydrated lime or slag-lime further enhanced strength and stiffness of micaceous soil, and the improvement depended on the dosages used. For the dosages examined, jute fibers outweighed lime and slag in gaining ductility,and the optimal fiber content was 1%where strength and ductility were considered.

1. Introduction

Micaceous soils outcrop widely in the world.Owing to the soft,spongy fabrics, micaceous soils may deform significantly under normal loads acted on soils, thereby affecting the ground compressibility (Harris et al.,1984). Given the platy, elastic nature of mica particles, the particles tend to rotate and orient, during compression or shearing,in a somewhat parallel fashion,resulting in low strength resistance(Zhang et al.,2019a).Low strength,high compressibility and poor compaction of micaceous soils cause significant issues in earth structures including road subgrades,building foundations, earth dams and embankments. To meet design requirements, stabilization of micaceous soil, aiming to improve strength and deformation characteristics of soils,has been explored.

Chemical stabilization is the point of departure. It involves incorporating a volume of cementitious additives in soils, generating mainly pozzolanic reaction or cement hydration to solidify soils. Additives such as cement, lime, fly ash, slag and polymeric matters have been used successfully for decades on expansive,collapsible or sedimentary soils (Al-Rawas, 2002; Sharma and Sivapullaiah, 2016; Ayeldeen et al., 2017; Soltani et al., 2019a;Baldovino et al.,2018,2019;Atahu et al.,2019;Zhang et al.,2019b;Zhao et al., 2019), as well as on micaceous soils (Frempong,1995;Zhang et al.,2019c).Although the material strength characteristics are improved, the stiffened micaceous soils become brittle as for other cemented soils (Basha et al., 2005) and are suboptimal in applications where greater tolerance to large-scale deformation(i.e. favorable ductility) is desired. Ductility can be obtained by incorporating in soils compressible or stretchable matters such as polyethylene pre-puffed beads (Liu et al., 2006) and rubber particles (Wang et al., 2018; Soltani et al., 2019b), and more widelyadopted geosynthetic materials, such as strips, grids, geocells and fibers (Ang and Loehr, 2003; Tang et al., 2007; Chen et al., 2015;Jamsawang et al., 2018; Mirzababaei et al., 2018; Abioghli and Hamidi, 2019; Liu et al., 2019). While many geosynthetics are applied in preferred orientations and in layers,fiber inclusions take the advantage of random, discrete distribution and reduce occurrence of potential weak planes that can possibly develop parallel to the oriented reinforcement (Xue et al., 2014; Yilmaz, 2015). In addition, incorporating fibers in soils reproduces the presence of plant roots which contribute to soil stability, and has become a verified solution of enhancing toughness, ductility and residual strength of soils(Tang et al., 2007; Wei et al., 2018).

This study seeks to enhance both strength and ductility of micaceous soil by reinforcing it with jute fibers, alone or with additives of hydrated lime(called lime thereafter)and slag-lime.Jute is a long,soft,shiny natural fiber extracted primarily from the stem and skin of the jute plant.Due to the vast supply sources,jute fiber is second only to cotton in the amount produced and variety of uses(mainly textiles). Jute fibers, or broadly natural or synthetic fibers,provide decent extensile strength and have been used, either discretely or as woven geotextiles, to reinforce soils (Danso et al.,2015; Wei et al., 2018; Yang et al., 2019). Lime additives have been widely used as an additive in roadways,railways,foundation layers and other infrastructures. The addition of lime to clay soils can facilitate cement hydration, resulting in the significant improvement of strength and stiffness(Bell,1996;Rajasekaran and Rao, 2000; Consoli et al., 2011; Baldovino et al., 2018, 2019).Introducing slag into the lime-clay hydration reaction can undoubtedly modify the original reaction process. The lime will provide the required alkaline environment for slag activation and hydration, forming crystalline cementitious products, which accelerate the bridging effect between the slag-lime and clay particles (James et al., 2008). Earlier studies (Wild et al.,1998; James et al., 2008; Manso et al., 2013; Kim et al., 2019) have confirmed the advantage of combining slag with lime, as opposed to using them individually. Moreover, utilizing the slag not only improves problematic soils in a cost-efficient and environmentally friendly manner, but also mitigates disposal burdens caused by the industrial waste materials.As no studies on the joint activation of fibers and cementitious additives as stabilizing agents for micaceous soils have been documented to date, this study is expected to lay the base in this area and can potentially achieve the optimal benefits for stabilizing problematic micaceous soils. This study aims to investigate the effectiveness of using the jute fibers,lime or slag-lime to reinforce micaceous soil and to develop the optimal dosage.Critical performance measurements including unconfined compressive strength (UCS), stiffness and ductility are examined, and some interesting relationships of factors influencing the soil performance are obtained.

2. Materials

2.1. Micaceous soil

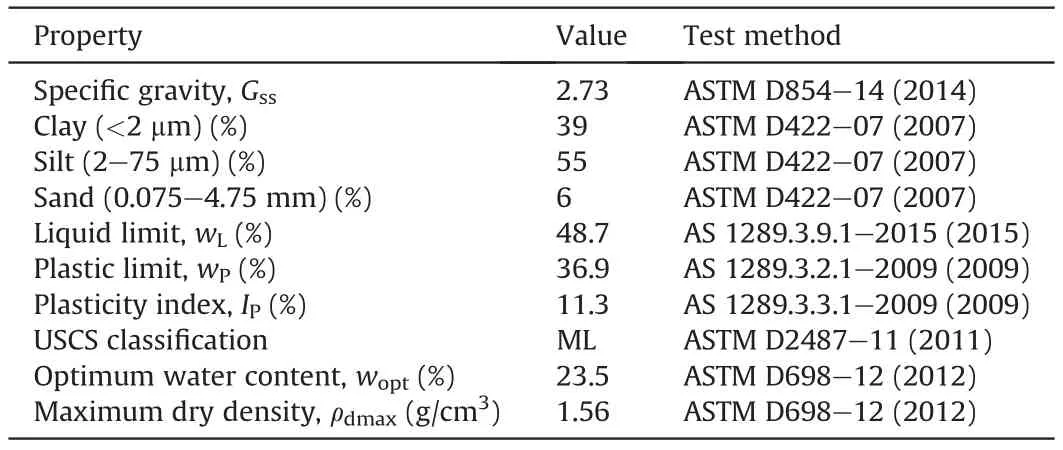

This study used an artificial micaceous soil comprising 80%kaolinite and 20% ground mica by weight. Both ingredients were sourced from the local suppliers. The base material, i.e. kaolinite,was relatively inert in activity and can avoid possible intervention to the process of stabilization. The choice of 20% of mica was selected to form the micaceous component, as it represents the upper boundary prerequisite to simulate the low strength and high compressibility exhibited by natural micaceous soils (Tubey,1961;McCarthy and Leonard, 1963). The blends manifested the same typical texture, sheen and friability properties as the natural micaceous soils commonly reported in the literature, and thus provided a basis for relevant comparison. The physico-mechanical properties of the prepared micaceous soil were determined as per relevant American Society for Testing and Materials (ASTM) or Australian standards, as summarized in Table 1. The liquid and plastic limits were measured as wL= 48.7% and wP= 36.9%,respectively. The index properties classify the soil as ML, a silt of low plasticity in accordance with the Unified Soil Classification System (USCS). Furthermore, the optimum water content and maximum dry density obtained from standard Proctor tests were wopt= 23.5% and ρdmax= 1.56 g/cm3, respectively. The test detailsand other geotechnical behavior of the micaceous soil were provided in Zhang et al. (2019a). It is worth comparing the obtained index properties with those of natural micaceous soils.In McCarthy and Leonard(1963),the natural micaceous silty sands of 30%mica content yielded specific gravity Gss= 2.76, maximum dry density ρdmax= 1.68 g/cm3, and compression index Cc= 0.78. In Tubey(1961), three natural micaceous sandy silts of 56%-68% mica were tested and gave results as: wL= 43%-65%, wP= 32%-44%,Gss= 2.65-2.8, optimum water content wopt= 12%-18%, and ρdmax= 1.57-1.72 g/cm3.

Table 1 Physical properties and compaction results of micaceous soil.

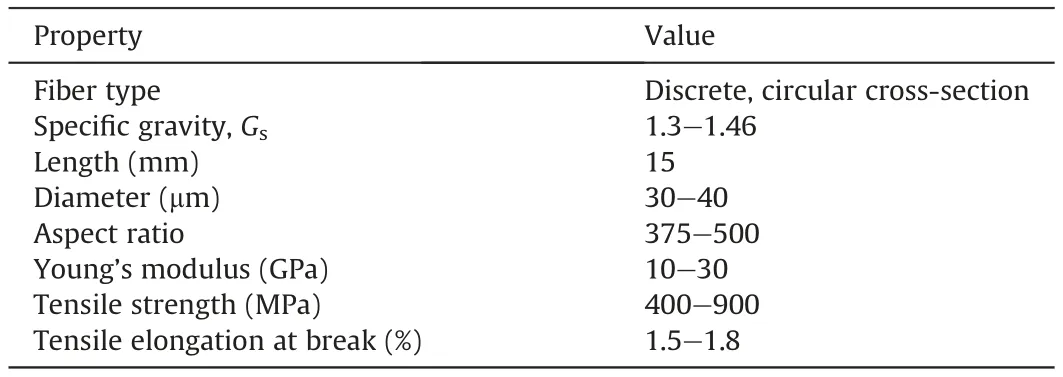

2.2. Jute fibers

Jute fibers were used to reinforce the micaceous soil.The fibers were manufactured from Corchorus capsularis (a shrub species in the Malvaceae family). This type of fiber consists of 56%-71% cellulose, 29%-35% hemicellulose and 11%-14% lignin, as commonly reported in the literature(Gowthaman et al.,2018).The jute fibers exhibit a highly rough surface texture, which likely promotes adhesion and induces frictional resistance between fibers and soils.The diameter of the fibers is typically 30-40 μm, and the length was cut into segments of approximately 15 mm. Representative physico-mechanical properties are summarized in Table 2. The fibers provide an excellent longitudinal tensile strength of at least 400 MPa and elongation rate of more than 1.5% at failure, which together provide an elastic modulus of more than 10 GPa. The strength characteristics are competent as compared to those of normal polyethylene fibers(Soltani et al.,2018),and are suitable as reinforcement for soils.

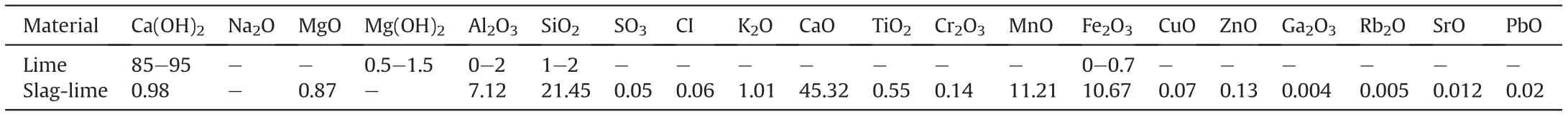

2.3. Cementitious additives

Two commercially available limes,i.e.lime and slag-lime,which were sourced from the local suppliers, were used as the cementitious additives in this study. The chemical compositions of two additives are provided in Table 3.It can be seen that both choices of lime contain appreciable amounts of ionized calcium(Ca2+),which facilitates time-dependent pozzolanic reactions(James et al.,2008)and builds to the long-term strength development.In addition,the slag-lime contains a significant amount of silica, which, at the presence of CaO and Fe2O3, contributes to the cement hydration.

Table 2 Physico-mechanical characteristics of jute fibers as provided by the supplier.

Table 3 Chemical composition (%) of lime and slag-lime as provided by the suppliers.

3. Experiment

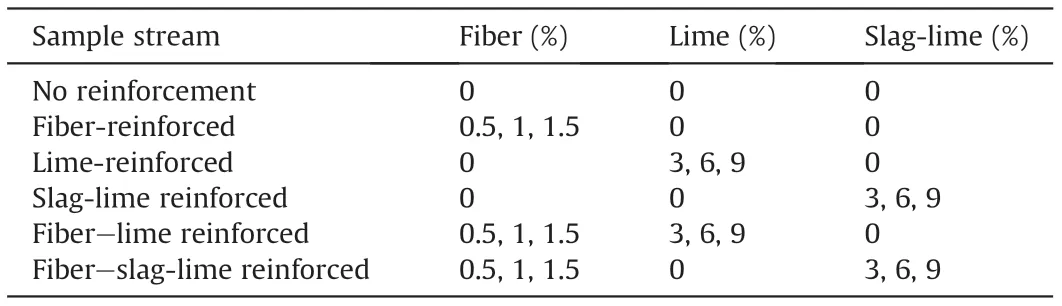

3.1. Sample streams

The sample streams are presented in Table 4. Six sample streams, i.e. one control (with no reinforcement) and five reinforced streams, were examined. The reinforced streams were categorized in terms of the reinforcement and/or additives used,i.e.jute fibers, lime and slag-lime. The three additives were incorporated, alone or in combination, into the prepared micaceous soils.The contents by weight were 0.5%,1%and 1.5%for fibers,and 3%,6%and 9%for lime or slag-lime.The test matrix produced a total of 28 sample sets.

The samples prepared for unconfined compression tests were compacted to the optimum water content and maximum dry density provided in Table 1. To achieve this, the static compaction technique as developed in Zhang et al. (2019c) was used. This technique determines dry mass of ingredients in terms of a desired dry density and sample size. The weighed materials are mixed for approximately 5 min to gain visible homogeneity of materials. A water volume that leads to the desired optimum water content is added to the mixture, followed by thorough mixing by hand for approximately 15 min. The fresh mixture is poured in five equal layers into a detachable mold of 50 mm in diameter and 100 mm in height. Each layer is statically compressed by a plunger at a constant rate of 1.5 mm/min until the target maximum dry density is attained.

In preparation for all samples, if fibers were solely used to reinforce the micaceous soils, the desired fiber content was added manually and incrementally to the dry soils, ensuring that all the fibers were evenly distributed to achieve uniform mixtures. The corresponding optimum water contents were subsequently added to the mixtures. If the lime or slag-lime was used alone, the required volume of water was added to the soil prior to the addition of additives,enabling effective hydration of these chemical matters.It is noteworthy that the additive contents were relative less and presumed less significant in affecting the compaction results.If the combination of fibers and a cementitious additive was used, the inclusions were added in the order of fibers,water,and the additive.Likewise,the order allowed fibers to spread evenly in dry soils and effective hydration of the additives in contact with water.Extensive care was undertaken to prepare homogenous mixtures at each stage to avoid the adverse effects of uneven samples on theexperiment. After compaction, the samples were wrapped with plastic film and then placed in a curing chamber for 7 d or 28 d until tested.

Table 4 Sample streams and additive contents used to reinforce micaceous soils.

3.2. Unconfined compresson tests

The unconfined compression tests were conducted in accordance with ASTM D2166/D2166M-16 (2016). The samples were axially compressed at a rate of 1 mm/min(i.e.a rate of 1%strain per minute), as commonly adopted by Ang and Loehr (2003). Axial strains and corresponding axial stresses were recorded at regular time intervals until at least the maximum axial stress required to fail samples was achieved. To ensure test accuracy, triplicate samples were tested for a sample set. In this regard, the coefficient of variation (CV) for the triplicate UCS values was found to be in the range of 4.15%-6.07%. These low values corroborate the repeatability of the adopted sample preparation technique,as well as the implemented unconfined compression testing procedure.

4. Results and discussion

4.1. Effects of fibers on strength

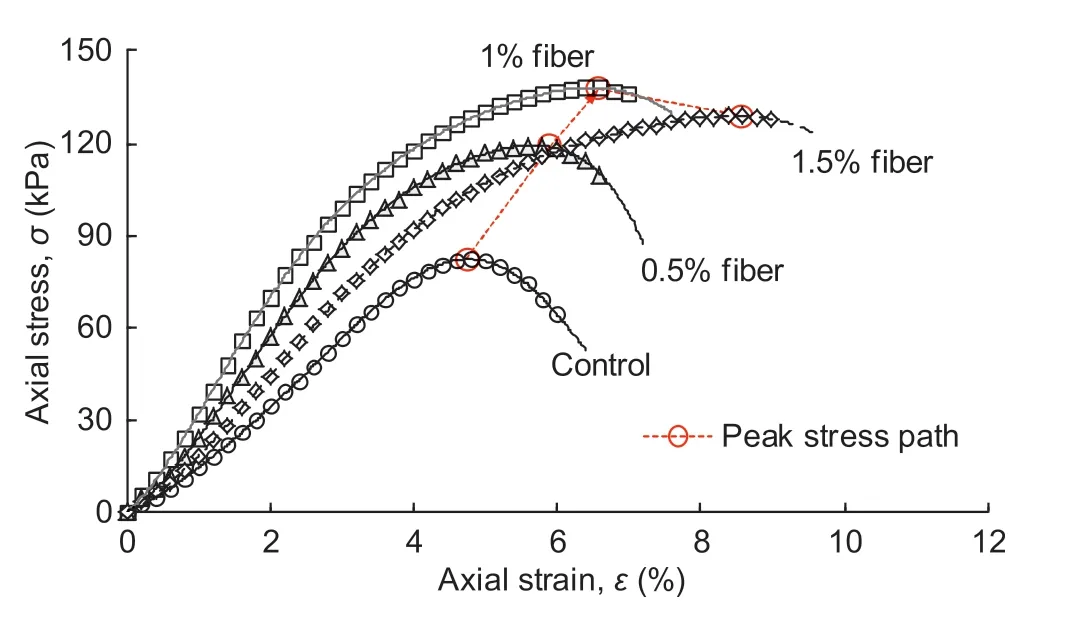

The effects of fibers on the strength of micaceous soils are presented in Fig. 1. This figure provides the stress-strain curves obtained from the unconfined compression tests conducted for the control and the three micaceous soil samples with 0.5%,1%and 1.5%fiber contents. For the control sample, the stress-strain locus exhibited a strain-softening behavior, and thus a more dramatic failure after reaching peak strength. The peak strength path suggests that the peak strength increased with the fiber content until it became 1%and slightly decreased if the inclusion increased to 1.5%.The peak strength values were qu=82.7 kPa for the control,118 kPa for the 0.5% fiber sample, 136 kPa for the 1% fiber sample and 127.4 kPa for the 1.5% fiber sample. Likewise, fiber inclusions increased the strain at peak strength, from 4.73% for the control sample to 8.55% for the 1.5% fiber sample, a nearly two-fold improvement. The increases in peak strength and strain suggest that fiber inclusions improved the strength and ductility of micaceous soils.

Fig. 1. The stress-strain curves of the control and fiber-reinforced micaceous soil samples in unconfined compression tests.

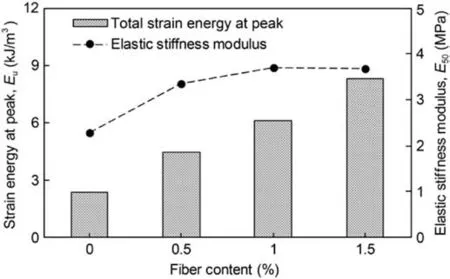

The area under a stress-strain curve up to the peak point measures the elastic strain energy at peak and the dissipation energy caused by plastic deformation.The area is defined as the total strain energy,Eu.It serves as a measure of the material’s toughness(Mirzababaei et al., 2013). The total strain energy can be approximated by slicing the area of interest and summarizing it.The results of Euobtained for the control and fiber-reinforced samples are presented in Fig.2.The values of Euincreased consistently with the fiber inclusion, from Eu= 2.36 kJ/m3for the control sample to 4.49 kJ/m3for the 0.5% fiber sample, 6.11 kJ/m3for the 1% fiber sample and 8.32 kJ/m3for the 1.5% fiber sample. The consistent increase is different from the convex relationship of peak strength vs.fiber content as discussed in Fig.1.The difference arises from the 1.5% fiber sample which provided a less peak strength but greater total strain energy at peak as opposed to the 1% fiber sample. The reason is that the total strain energy at peak measures both the axial failure strain and the peak UCS, which is crucial for deformation performance-based earth structures such as earth slopes.

Another important measure of material strength is elastic stiffness modulus, E50, which is defined as the secant modulus at 50%of the peak UCS(Iyengar et al.,2013).E50is superior to Young’s modulus in designing earth structures where a certain level of deformation is allowed.The values of E50are given in Fig. 2.It can be observed that E50= 2.27 MPa for the control sample, and 3.35 MPa, 3.7 MPa and 3.67 MPa for the 0.5%, 1% and 1.5% fiberstabilized samples, respectively. The convex relationship is similar in shape to that observed for the peak strength. In addition, all fiber-reinforced samples exhibit greater E50values compared to that of the control sample,indicating the improvement of material stiffness due to fiber inclusion.

4.2. Effects of fibers and lime on strength

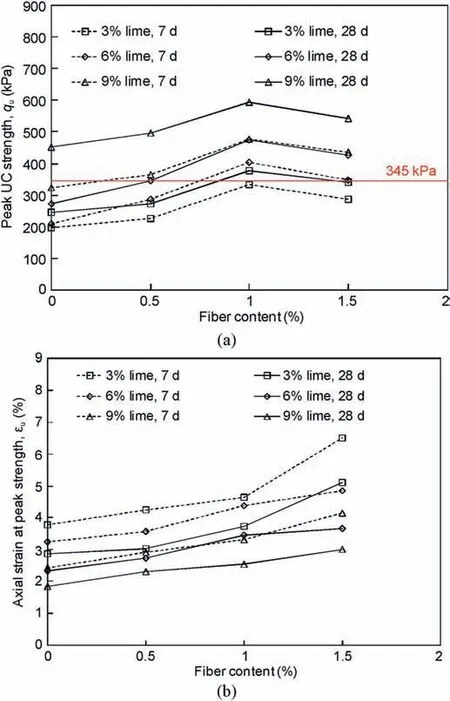

The effects of the fiber-lime combined inclusions on the strength of micaceous soils are provided in Fig. 3. Fig. 3a presents the peak UCS quobtained for micaceous soil samples that were reinforced by varying combinations of fiber and lime additives.The strength results were obtained at two curing periods:7 d and 28 d.Fig.3b shows corresponding results of axial strain at the peak UCS.As three factors including the fiber content,lime content and curing period were considered, multiple combinations of comparison were conducted as follows.

Fig.2. Total strain energy Eu and elastic stiffness modulus E50 of the control and fiberreinforced micaceous soil samples in unconfined compression tests.

Fig.3. The results of(a)7-d and 28-d peak UCSs and(b)axial strain at peak strength εu of micaceous soil samples reinforced with different fiber and lime contents.

In Fig. 3a, it is shown that the lime inclusion significantly improves the strength of micaceous soil,where the fiber content and the curing time remain the same. For example, the 3% lime inclusion alone yielded a peak strength qu= 196.6 kPa after 7-d curing and qu= 245.3 kPa after 28-d curing, as opposed to the control sample of qu= 82.7 kPa. The improvement rates are 138%and 197%, respectively. The curing time can also improve the material strength,where the additive contents remained the same.For example, when 1.5% fiber and 6% lime were added, the peak UCS increased from qu=348.7 kPa after 7-d curing to 426 kPa after 28 d curing. At any given curing time and fiber content, the greater the lime content, the higher the peak UCS. For example, for the 0.5%fiber samples of 7-d curing,the UCSs increased from qu=226.7 kPa for 3% lime inclusion to 286.7 kPa for 6% lime inclusion and 365.9 kPa for 9% lime inclusion. Similarly, for any given lime and fiber contents, the increase in curing time promoted a major increase in the UCS for the samples tested. Moreover, the UCS increased with fiber content of up to 1%and then decreased at 1.5%fibers.For example,the UCSs were 452.9 kPa for the control sample,496.3 kPa for 0.5% fiber sample,593.2 kPa for 1% fiber sample and 542.9 kPa for 1.5%fiber sample,where the 9%lime content and 28-d curing remained unchanged throughout. Therefore,1% fiber inclusion was the optimum from the perspective of strength gain.

The ASTM D4609-08(2008)standard suggests a UCS of 345 kPa as the threshold for an effective field strength (i.e. equivalent to a satisfactory site compaction). As presented in Fig. 3a, 28-d scenarios that satisfy the threshold strength are samples with 9%lime,0.5%fiber and 6%lime,1%fiber and 3%(or 6%)lime,and 1.5%fiber and 6%lime.As opposed to the sole fiber reinforced samples,the lime additive has added to the material strength and aided fibers to reinforce micaceous soil.

The material ductility can be assessed by examining the axial strain at peak strength, εu, as presented in Fig. 3b. The strain εudevelops in a means different from the peak UCS. Specifically, the greater the lime content or curing period is,the lower the material ductility will be. With the increasing fiber inclusions, εudid not fluctuate as noticeably as was observed with the UCS. Instead, εuincreased with the fiber content,indicating the capability of fibers building to the ductility. In consideration of the advantage of lime adding to the strength, the combination of fibers and lime outperforms its sole inclusion in improving the micaceous soils.

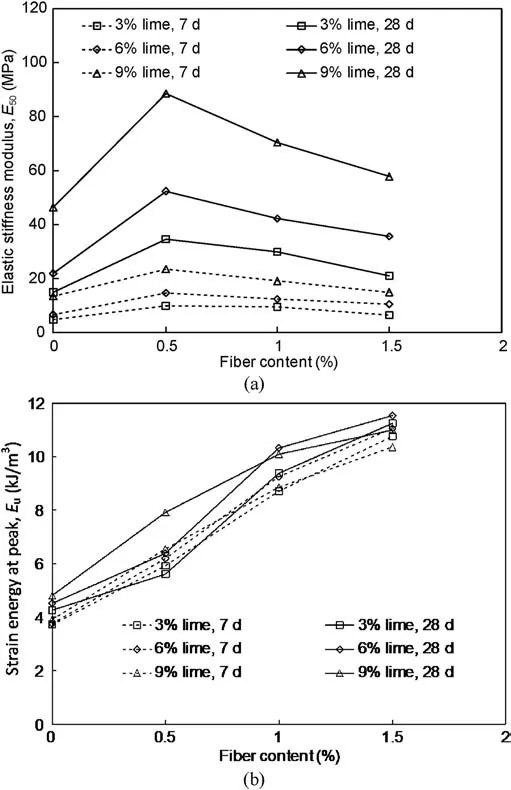

The elastic stiffness moduli, E50, of the samples tested were determined and the results are presented in Fig. 4a. E50increased with the lime content and curing period, where the fiber content remained the same.If the lime content and curing period remained unchanged,the stiffness increased with fiber content of up to 0.5%and then decreased. These trends suggest that E50is positively related to the lime content and curing period and approaches its optimum if fiber content is 0.5%or so.Meanwhile,the dependence of E50on the fiber content is less noticeable for samples after 7-d curing than that for samples after 28-d curing. The 9% lime samples improved material stiffness significantly, as compared to the 3%or 6%lime samples,if the fiber content remained the same.The scenario, which provides the greatest 28-d stiffness, is the sample with 0.5%fiber and 9%lime.This scenario is followed by the remaining samples of 1% fiber and 9%lime,1.5%fiber and 9% lime,0.5% fiber and 6% lime, and 0% fiber and 9% lime.

Fig.4. The results of(a)elastic stiffness modulus E50 and(b)total strain energy at peak Eu of micaceous soil samples reinforced with varying fiber and lime contents, which were obtained from 7-d and 28-d unconfined compression tests.

Fig. 4b presents the results of peak total strain energy, Eu,against fiber content for the control and reinforced samples that were tested after 7-d or 28-d curing period. For any given lime contents and curing periods, the greater the fiber content is, the higher the peak total strain energy will be.It should be noted that,at 0.5%fiber content for a given curing period,the peak total strain energy increased with the lime content, while at higher fiber contents (1% and 1.5%), 6% lime resulted in higher peak strain energies.

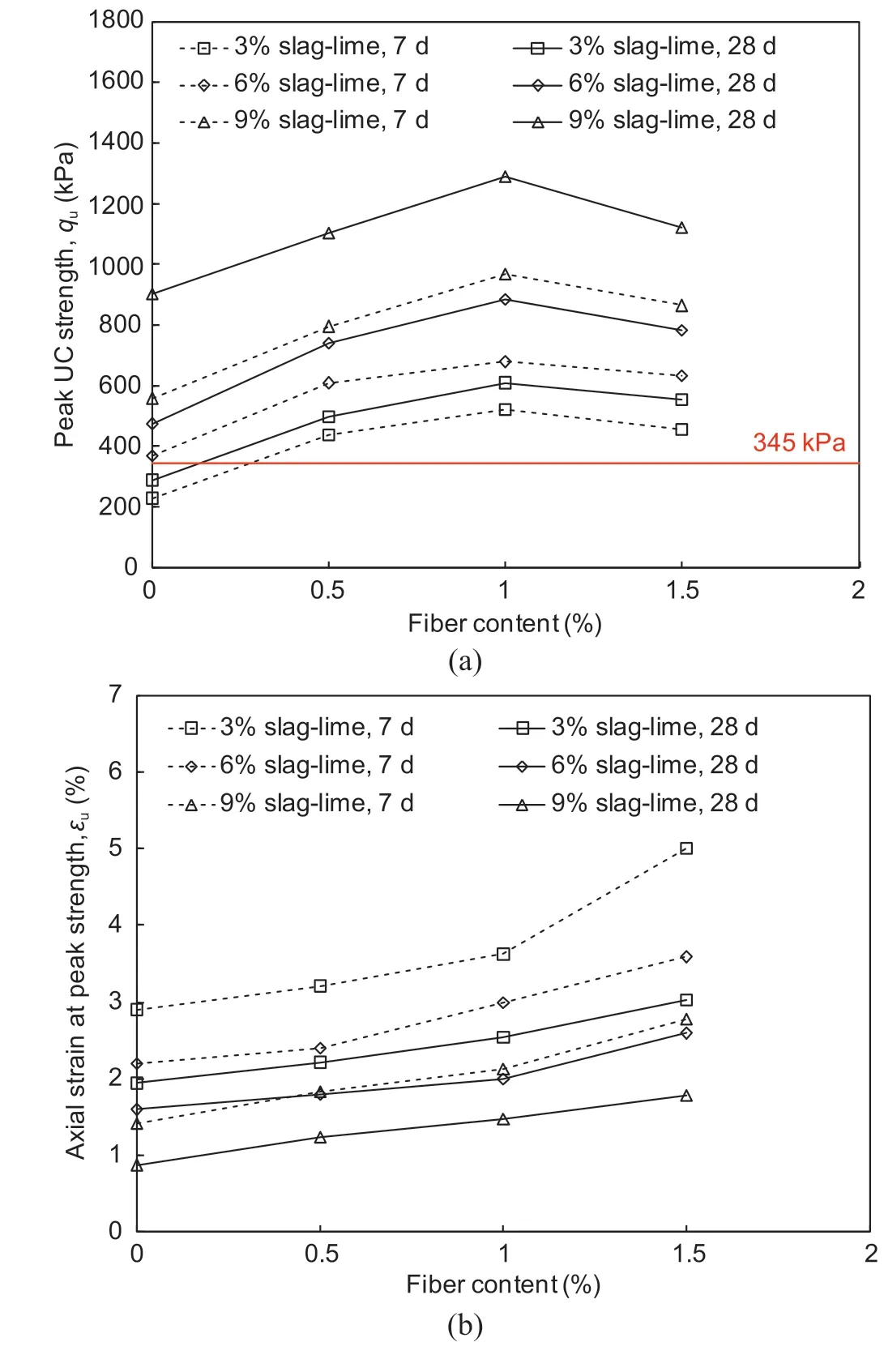

4.3. Effects of fibers and slag-lime on strength

The effects of fiber and slag-lime contents on strength characteristics of micaceous soils are presented in Fig. 5. Fig. 5a presents the relationship between 7-d and 28-d peak UCSs and slaglime and fiber contents of micaceous soil samples. At any given fiber contents, the strength increased with slag-lime content and curing time,at a significant rate.For example,the sample with 1%fiber and 9%slag-lime contents exhibited the greatest strength of qu=1287.3 kPa.This strength value is more than ten times that of the control sample.Similarly,the fiber inclusion added to strength development,if the content was not more than 1%;otherwise,the strength decreased slightly. Nonetheless, all 28-d samples except the 3% slag-lime sample meet with the 345 kPa strength requirement for field applications. As opposed to the fiber-lime based samples as presented in Fig. 3a, slag-lime outperformed lime in strength development, where the rest conditions including fiber content and curing period remained the same.The gained strength mainly arises from the significant calcium oxide(i.e.quicklime)in the slag-lime as provided in Table 3.The content was 45.32%, which is sufficient, and its chemical reactivity can neutralize the acidic oxides,i.e.SiO2,Al2O3,and Fe2O3,in the slaglime, thus producing the process of cementation hydration. By contrast, the hydrated lime comprises mainly calcium hydroxyl(i.e. slaked lime), which is relatively insoluble in water and a low strength base oxide.

The axial strains at peak strengths,εu, that are obtained for the fiber-slag-lime reinforced micaceous soil samples are provided in Fig. 5b. Similar trend was observed for the fiber-lime reinforced samples (Fig. 3b), i.e. the greater the slag-lime content and the longer the curing period,the lower the material ductility.The fiber inclusions, however, diminished material brittleness caused by slag-lime inclusion and prompted material ductility. The ductility increased with the fiber contents, where the slag-lime and curing time remained the same. It is plausible to suggest that the monotonically increasing relationship continues (i.e. better ductility) if the fiber content exceeds 1.5%. By contrast, the material UCS approached the peak if a fiber content of 1% was used, at least for the sample streams tested in this study.

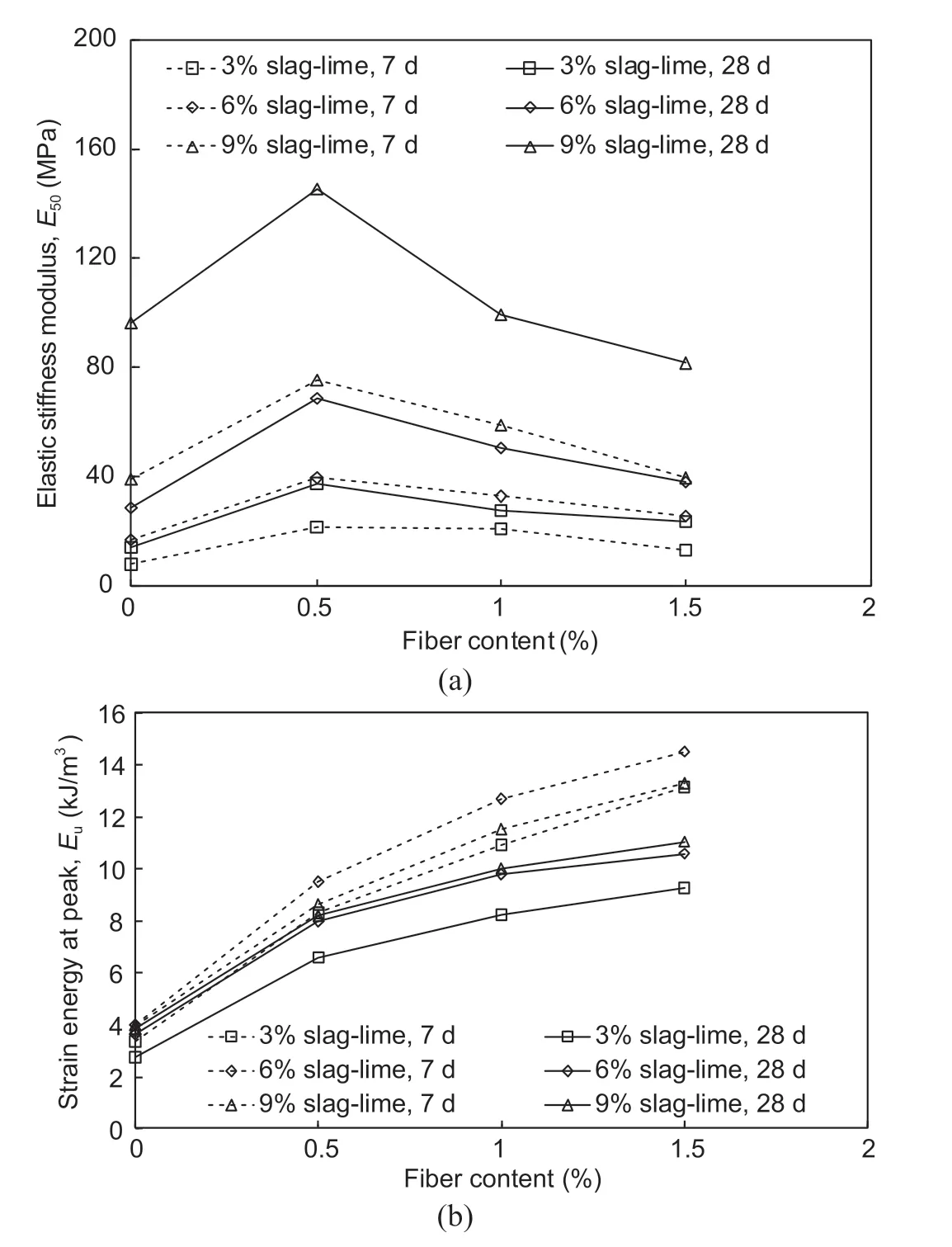

Fig. 6a presents the variation of elastic stiffness modulus, E50,against fiber content for the slag-lime treated soils tested after 7-d and 28-d curing, respectively. Likewise, the variations in E50follow a trend that was observed from fiber-lime treated soils,where the peak E50occurs at 0.5% fiber content. Fig. 6b shows the variation of peak total strain energy against fiber content for the slag-lime samples. The improvement in toughness with respect to an increase in binder content and/or curing time can be attributed value, the fibers are not evenly distributed and are present in clumps. As a result, the improvement in soil strength and toughness is modest or otherwise diminishes.

Fig.5. The results of(a)7-d and 28-d peak UCS qu and(b)axial strain at peak strength εu of micaceous soil samples reinforced with varying fiber and slag-lime contents.

Calcium-based chemical binders, such as lime, initiates a chemical reaction, which is commonly referred to as pozzolanic reaction in the soil-water medium, which improves the strength and toughness of micaceous clays. During pozzolanic reactions,ionized calcium (Ca2+) and hydroxide (OH-) units are released from the water-binder complex. These ions gradually react with the silicate (SiO2) and aluminate (Al2O3) units in the soils,thereby forming a strong cementation gel of calcium-aluminatesilicate-hydrates (CASH), and in some cases calcium-silicatehydrates (CSH) and calcium-aluminate-hydrates (CAH). These products promote further solidification and flocculation of the particles, which accommodate the development of a dense,uniform matrix with strong performance (Sharma and Sivapullaiah, 2016; Firoozi et al., 2017). Owing to the timedependent nature of pozzolanic reactions, the stabilization by lime is a long-term process, indicating that the longer the curing time, the greater the improvement of the UCS of soils. In addition,the formation of cementitious compounds in the soil matrix leads to an increase in the bonding and interlocking forces between the soil particles, due to the rough surface and high rigidity of the cementitious compounds, which further improves the strength and roughness of soils. Introducing slag into the clay-lime hydration reaction undoubtedly results in a noticeable to an increase in the peak UCS and/or the axial strain at failure.The rise in peak total strain energy as given in Fig.4b was due to greater fiber and slag-lime contents and/or a shorter curing time. At 28 d,the peak strain energies were Eu=6.6 kJ/m3for the sample of 0.5%fiber and 3%slag-lime and 8.2 kJ/m3for the sample of 0.5%fiber and 9% slag-lime. The strain energy values increased to 9.3 kJ/m3and 11 kJ/m3, respectively, if the fiber content increased to 1.5%.

Fig.6. The results of(a)elastic stiffness modulus E50 and(b)total strain energy at peak Eu of micaceous soil samples reinforced with varying fiber and slag-lime contents,which were obtained from 7-d and 28-d unconfined compression tests.

4.4. Discussion

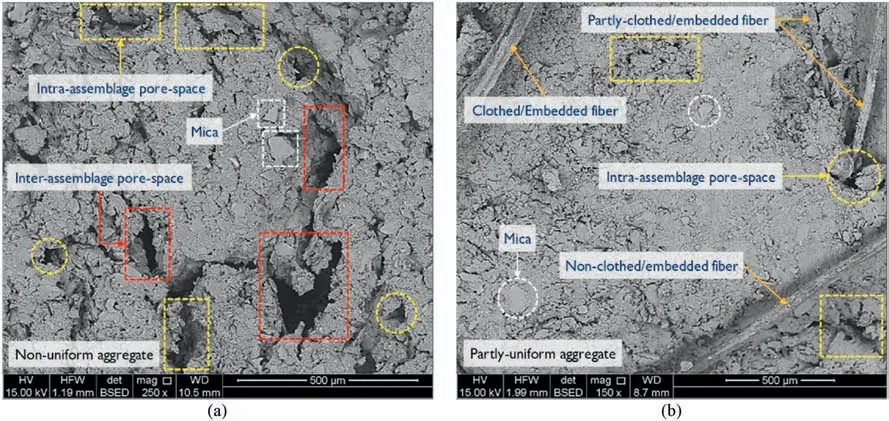

Fig. 7. Microscale views obtained by scanning electron microscope for micaceous soils: (a) Control and (b) stabilized samples (Zhang et al., 2019c).

It is observed that the presence of fibers promotes the UCS of micaceous soils. This gained strength is influenced by the internal frictional resistance between the soil particles and the fibers,which in turn is a function of the soil-fiber contact area. Therefore, a greater number of fibers within the soil will lead to larger frictional resistance between the soil particles and the fibers,which results in increased UCS. Moreover, as demonstrated in Fig. 7 which shows microscale view of stabilized micaceous soils,the presence of fibers can bridge across voids and cracks associated with micaceous soils.As per Mirzababaei et al.(2018),this weave reinforcement leads to enhanced shear strength and toughness of materials. However,when the proportion of fibers within the soil exceeds a suitable increase in strength when compared with lime-treated soils.This is indicated by the slag hydration, which is activated by the lime.Particularly, this is a more rapid reaction than the traditional lime-clay reactions discussed above. Moreover, lime will also provide the required alkaline environment for slag activation and hydration, forming crystalline cementitious products, which accelerate the bridging effect between slag-lime and clay particles (James et al., 2008). The inclusion of fibers further enhances the UCS of cementitious additive-treated soils. This is because the effective contact areas of fibers and lime- or slag-limetreated soils are quite large due to the smaller pores in the cementitious binder-treated soils. Thus, the total effective friction between soils and fibers in the cementitious binder-treated soil is greater, resulting in the larger UCS and stronger performance (Cai et al., 2006).

5. Conclusions

The effects of jute fiber,lime,and slag-lime additives on the UCS of micaceous clays were studied.The test results suggested that the addition solely of fibers,or mixtures of fibers with lime or slag-lime,increased the UCS and stiffness of micaceous soils.

The inclusion of fibers can increase the UCS of micaceous soils,and the greater the fiber proportion is, the higher the measured strength and stiffness are. However, the largest peak strength was obtained at a fiber content of 1%.At any given fiber proportion,the UCS of the reinforced soil increased with the addition of lime or slag-lime, with slag-lime providing more favorable strength. The greater the cementitious additives and/or the longer the curing time are, the higher the developed strength, stiffness, and toughness will be.However, the ductility of the samples decreased with the cementitious additives and/or the longer curing period and increased with fiber contents.

Stabilization by the combination of fibers and slag-lime shows greater efficacy in reinforcing the micaceous soils.This stabilization scheme is relatively more effective to satisfy the ASTM strength requirements. In fact, the majority of mix designs that were examined in this study meet the strength standard, and therefore are recognized as suitable dosages. The optimal, cost-effective dosage for the micaceous soil was determined as 1% fiber and 3%slag-lime.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This study has been supported by the Australian Government Research Training Program Scholarship and University of Adelaide Scholarship.

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Surface characteristics analysis of fractures induced by supercritical CO2 and water through three-dimensional scanning and scanning electron micrography

- Prediction of fracture and dilatancy in granite using acoustic emission signal cloud

- Hysteresis in the ultrasonic parameters of saturated sandstone during freezing and thawing and correlations with unfrozen water content

- Coupled Eulerian-Lagrangian simulation of a modified direct shear apparatus for the measurement of residual shear strengths

- A novel true triaxial test system for microwave-induced fracturing of hard rocks

- Hydromechanical behavior of unsaturated expansive clay under repetitive loading