Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies

Ye XIE, Al SAVVARISAL, Antonios TSOURDOS, Dan ZHANG,Jason GU

a Intelligent Robot Research Centre, Zhejiang Lab, Hangzhou, 311100, China

b School of Aerospace, Transport and Manufacturing, Cranfield University, Bedford MK43 0AL, United Kingdom

c York University, North York, Toronto M3J 1P3, Canada

d Dalhousie University, Halifax, Nova Scotia B3H 4R2, Canada

KEYWORDS Aircraft;Convex optimization;Energy management;Fuzzy logic control;Hybrid electric propulsion system;Non-dominated sorting genetic algorithm;Sizing

Abstract The paper overviews the state-of-art of aircraft powered by hybrid electric propulsion systems. The research status of the design and energy management of hybrid aircraft and hybrid propulsion systems are further reviewed.The first contribution of the review is to demonstrate that,in the context of relatively underdeveloped electrical storage technologies, the study of mid-scale hybrid aircraft can contribute the most to both theoretical and practical knowledge. Meanwhile,the profits and potential drawbacks of applying hybrid propulsion to mid-scale hybrid airplanes have not been thoroughly illustrated. Secondly, as summed in the overview of design methodologies, the multi-objective optimization transcends the single-objective one. The potential of the hybrid propulsion system can be thoroughly evaluated in only one optimization run, if several objectives optimized simultaneously. Yet there are few researches covering the conceptual design of hybrid aircraft using multi-objective optimization. The review of the most popular energy management strategies discloses the third research gap—current methodologies favoured in hybrid ground vehicles do not consider the aircraft safety.Additionally,both non-causal and causal energy management are needed for performing a complicated flight mission with several sub-tasks.

1. Introduction

Over the last decades,the rapid growth in fossil fuel consumption has generated a need for energy sustainability. This is partly due to the widespread use of aircraft in both military and civilian applications.Additionally, the exhaust gas has a negative impact on the environment,for example,contributing to global warming.It is even worse if those emissions are from aircraft since the tail gas is directly discharged to the atmosphere. Concerning those adverse effects, NASA calls on the aeronautic industry to reduce aircraft fuel burn by 70% by 2025 in their N+3 concepts.

The aim to sustain natural resources and relieve environmental pollution are pushing the related research areas to develop less fuel consumption and environmental friendly aerospace propulsion technologies.The most prospective one is to shift towards electric propulsion systems,e.g. the Electric Motor (EM), replacing the conventional Internal Combustion Engine (ICE). Electric propulsion systems do not generate on-board emissions,so are more environmentally friendly.With reduced emissions,the electric aircraft has better stealth performance compared with the ICE-powered one.However, the energy density (specific energy) of electrical energy storage source, such as batteries, are much lower than that of fossil fuel.The truth is that at this point in time and for the foreseeable future,aerial vehicles using electric propulsion systems cannot achieve the same flight range/endurance as their conventional (i.e. combustion engine) powered counterparts.

An evolving propulsion technology—Hybrid Electric Propulsion System (HEPS) comes to the researchers’ mind and attracts much attention.HEPS integrates an electric powertrain with a conventional combustion engine to provide the propulsion. It can combine the clean power of an electric propulsion system with the extended range of an ICE. This results in decreased fuel burn and additional ‘stealth mode’(low emissions/noise mode) compared with ICE-powered aircraft, and increased flying range compared with electric aircraft. For these reasons, there is a significant interest in further research into this technology and applications for the aviation industry.However,those advantages come at the cost of increased complexity of the system design and hybrid energy management (hybrid control).

Most studies on the review of hybrid electric powered vehicles and its design and control methodologies mainly focus on one research area. Researchers with aeronautic background typically examined scholarly and business samples on hybrid electric powered aircraft (hybrid aircraft),rarely provided the comprehensive review of design and energy management methods. Brelje and Martinssurveyed design approaches of more-electric aircraft, but the paper did not concentrate on the hybrid electric ones. The authors did not find any fulllength-articles in the open literature providing the review of the state-of-the-art in the design methodology of hybrid aircraft and its HEPS, not mentioning the detailed comparative analysis and the study of research gaps.

On the other hand, energy management (supervisory control) strategies have been thorough overviewed by many researchers.Those reviews not only classified energy management strategies, but also put forward the most recent progress and advanced concepts. The pros and cons of each approach were addressed and compared. Lei et al.analysed the complexity and accuracy of different sorts of energy management strategies and evaluated their feasibility for real-time applications.However,most of the review studies and findings were in the context of hybrid ground vehicles(except Lei’s article). This paper would evaluate several the most popular energy management methods and select the appropriate ones for the aircraft applications.

This paper is structured as follows. Section 2 initially provides fundamental concepts of hybrid propulsion systems. In Section 3,an up-to-date review of the hybrid technology powered aircraft is addressed, extensively from small- to largerscale aircraft. Section 4 reviews the design methodologies for aircraft hybrid propulsion systems, classified into the optimization-based design and non-optimization-based one.In Section 5, the state-of-art of supervisory energy management strategies are investigated from two perspectives: noncausal control and causal control.Both Section 4 and Section 5 compare the strengths and weaknesses of various methods and propose the ones for our studies. Section 6 briefly introduces the proposed approaches with the case of retrofitting the prototype aircraft using the hybrid electric propulsion system.

2. Hybrid electric propulsion fundamental

2.1. Powertrain configuration

In a hybrid propulsion system, two or more power sources with different configurations are combined to improve the performance of the whole system. In this paper, only two energy storages are considered: fuel and battery. For the fuel/battery hybridization system, the most commonly used configurations are series, parallel and series-parallel architecture.

2.1.1. Series configuration

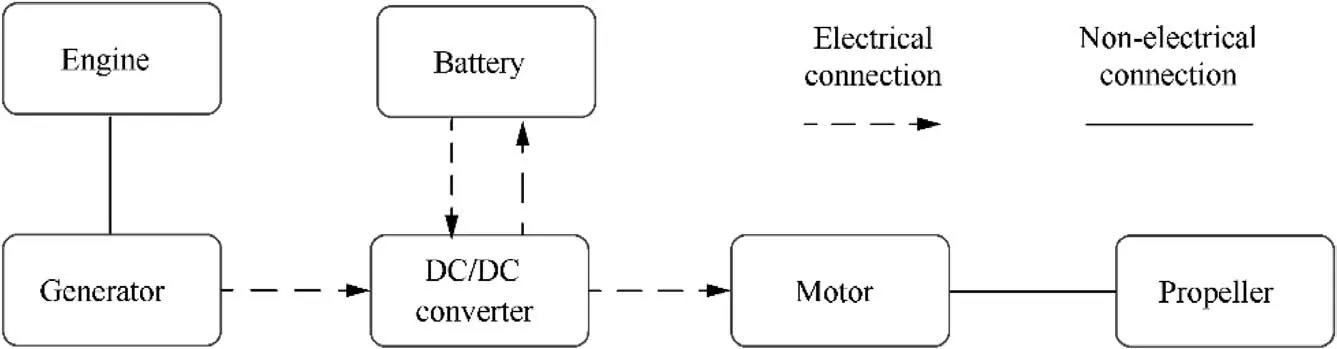

In a series hybrid configuration,the propeller is driven only by the electric motor (see Fig. 1).The engine power derived from combustion is converted into electrical power via a generator. The electrical power can be used to power the EM directly, or can be stored in the battery by a charging process.The series hybrid electric system is the one most easily extended to distributed electric powertrain. Therefore, it is widely accepted as the alternative propulsion system to hybridize the multi-rotor aircraft and large-scale airplanes.

The benefit of series hybrid configurations is that the engine is completely decoupled from the propeller and its output power is not related to the power demand of the powertrain.In other words, the engine can run at its optimal operating condition during the different working condition.The fuel efficiency of engine can remain high and its lifespan can be lengthened. Moreover, the series architecture has the definite advantage of flexibility for locating the ICE-generator set due to the mechanical decoupling.

However,the series configuration suffers from the poor system efficiency, since massive power losses exist in the combustion and electrical energy conversion.Another disadvantage is that it needs three propulsion devices: engine, generator and EM.All three propulsion devices need to be sized to cope with maximum power if the series HEPS is designed for sustained climbs. This makes series HEPS expensive and bulky.Last but not the least, series architecture cannot make use of the maximum combined power potential of the engine and motor,since the engine is not mechanically connected to the load.

Fig. 1 Series configuration.

2.1.2. Parallel configuration

In parallel configuration, the ICE and the EM are both connected mechanically to the propeller, so they can contribute to the propulsion energy either simultaneously or individually.In addition with the parallel configuration, the ICE can simultaneously drive the propeller and motor/generator,thereby charging the battery pack.Other advantage of the parallel over the series configuration is that it only needs two propulsion devices—engine and motor/generator. Also, a smaller engine and a smaller electric motor can be used to get the same performance.Even for long-climb trip operation,only the engine needs to be rated for the highest sustained power. The power losses are also reduced compared with the series configuration, with no need of mechanical-electrical energy conversion.

However,the rotational speed of propeller is not always the optimal speed of the engine, thus operating at the optimum region of engine cannot be guaranteed. In general, there are two approaches to deal with this issue. The first and more direct one is to implement a Continuously Variable Transmission(CVT),which permits the independence of the engine and propeller rotational speed. The second and more economical one is to develop an energy management strategy. The energy management strategy can optimize the power contribution of the engine and the motor,which enables the propulsion devices to operate at their optimum condition.

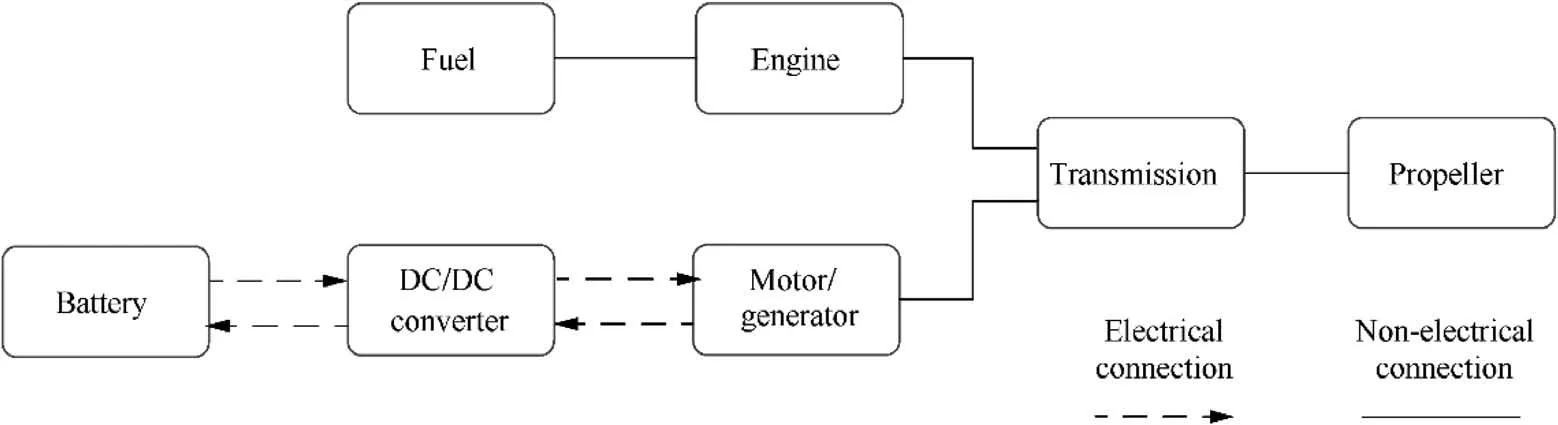

Parallel hybrids are further classified according to the position of the motor/generator in the drivetrain.For aircraft application, the double-shaft and single-shaft architecture are the two most popular ones.Parallel hybrids are further classified according to the position of the motor/generator in the drivetrain.If the engine and the motor/generator are mounted on two separate drive shafts, as shown in Fig. 2,the speed of the engine and motor/generator can be different from the propeller and each other. This architecture is called as double-shaft parallel configuration. Similarly, if a CVT is applied in this architecture, the speed of two propulsion devices can be decoupled from the speed of the propeller.

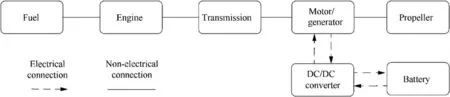

If the engine is connected to the motor/generator but not directly linked to the propeller, the architecture is called single-shaft since the transmission has only one input shaft(see Fig. 3). Generally, the electric machine is directly linked to the propeller, while the engine is connected to the electric machine via decoupling devices and gears.In this architecture,the speed of motor/generators is always rigidly linked to that of the propeller. The mid-scale hybrid airplane particularly favours this architecture due to its lower mechanical complexity,which is significant to save system weight and improve system safety.

2.1.3. Series-parallel configuration

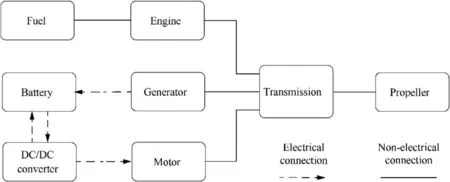

The series-parallel configuration, also recognized as powersplit configuration,is a mixture of the two architectures shown above.Here, the propeller, engine, motor and generator are connected to a planetary gear, provided by Fig. 4. This structure not only makes power distribution more flexible,but also allows the engine and motor to operate in its most efficient region. The series-parallel configuration is the most advanced configuration of the hybrid propulsion system, but it also requires the most complicated clutch/gearing mechanism and energy management.

Overall, the most commonly used configurations are illustrated above. Among them, the series configuration enables the engine to operate at its ideal operating condition.However,its system efficiency is relatively low since large power losses exist in the energy conversion. The series-parallel is the most functional, but complicated configuration out of the three architectures. It is the least popular configuration concerning aircraft application due to high complexity.

Fig. 2 Double-shaft parallel configuration.

Fig. 3 Single-shaft parallel configuration.

Fig. 4 Series-parallel configuration.

2.2. Charge strategy

In addition to the powertrain configurations, hybrid propulsion systems also differ in the battery operating strategy, having two classifications: charge-sustaining and charge-depleting strategy.

The charge-sustaining strategy aims at maintaining the State-of-Charge (SoC) of the battery at a certain level with on-board recharging.This ensures the battery will always have an adequate reserve SoC in the case of an emergency, but the electricity cannot be made the biggest use of. The chargedepleting strategy differs in that the battery charge does not take place. The battery SoC is allowed to decrease continuously until its minimum value is reached. A consequence of not charging the battery in a charge-depletion system is that the battery needs to have enough capacity to provide enough power during the specified run time. Therefore, the chargedepleting strategy tends to lead to a large battery.

3. Hybrid electric powered aircraft

The widespread researches and advances in hybrid electric propulsion systems in automobiles are transferrable to the aircraft industry. The automotive hybrid systems bring the benefit of increased endurance time as compared to electricpowered cars, with additional benefits of reduced noise, emissions and fuel consumption which are not attainable using gasoline-power. After acknowledging of those profits, aeronautic academia and industry begin to introduce the HEPS to power the aircraft. There is a significant interest in further research into this technology and its application to from small to large-scale aircraft.

3.1. Small-scale hybrid aircraft

Initially, academics focused on the small-scale sector—Unmanned Aerial Vehicle(UAV),to validate and demonstrate the feasibility of the hybrid electric technology.In 2005,Harmon et al. from the University of California-Davis, began the investigations of the small hybrid unmanned aircraft for the Intelligence, Surveillance, and Reconnaissance (ISR) mission.Harmon et al. proposed a conceptual design method to simultaneously size the aircraft wing and the hybrid propulsion system components. The sizing process yielded a 13.6 kg hybrid UAV with 4.65 m wingspan and 220 Wh battery.A neural network control was applied to optimize the energy distribution of the hybrid UAV and propulsion system.Simulations demonstrated that the designed hybrid electric UAV could consume less 54% energy than the gasoline-powered UAV for the three-hour ISR mission.

Harmon continued his research at the Air Force Institute of Technology(AFIT).A comparison between various configurations and battery-discharging profiles was conducted by him and Hiserote.It was concluded that, for the small unmanned airplane,the clutch-start parallel configuration with the battery charge-sustaining strategy was the best design and achieved the lowest empty weight. Continuing this design, the hybrid electric system was built and integrated to the remotelypiloted UAV, by Aussererand Molesworth.The Honda GX35 engine (969 W) and Fuji motor (1.2 kW) were selected based on the optimal sizing by Hiserote. Ground integration partly validated the previous conceptual design, but the flight test had not been completed.

The research team from the Queensland University of Technology (QUT) developed a test rig for the parallel HEPS that combined a 10 cc combustion engine and a 600 W brushless motor.An Ideal Operating Line (IOL) control strategy was applied to minimize the fuel consumption by Hung and GonzalezNumerical simulations demonstrated that the aircraft performance could be improved by a large marginand fuel usage could be decreased by 6%,with only a 5%weight penalty compared to the non-hybrid system.

Scho¨mann,from the Technical University of Munich,studied generic models of the components for the small-scale aircraft HEPS.A scaling method was applied to model the ICE,since it is difficult to develop an accurate model for small engines.Following this work,a preliminary design method was developed to size hybrid propulsion systems for UAVs.The method had three advantages: high accuracy, generality and low computational time consumption.A series of optimization designs were yielded from a range of payload requirements(from 10 kg to 70 kg).One exemplary result was a 35 kg hybrid airplane capable of taking 16 kg payload.

Friedrich and Robertsonsized a 20 kg UAV using the hybrid design of a manned airplane. The benchmark hybrid airplane had plus 200 kg Maximum Take-Off Weight(MTOW). Several engine sizes were compared and one of 900 W was determined as the best selection for the UAV.The selected small engine was parallel-connected with a 400 W motor. This configuration had up to 47% fuel saving in comparison to the original ICE-powered scenario.

The multi-rotor UAV has been considered as the gamechanger for the agricultural and industrial operator once coming to the market. However, its widespread applications had been retracted due to its relatively short endurance. Until 2017, Quaternium launched its first hybrid fuel-electric quadrotor drone, HYBRiX.20, capable of flying over 4 h.Its series-hybrid technology solved the substantial restriction of the application of multi-copters to the medium-long missions. Equipped with a two-stroke petrol engine, HYBRiX.20 can achieve over 2 h of flight time when carrying around 6 kg maximum payload.Another two series-hybrid multi-copters,Perimeter 8and GAIA 160acquire similar MTOW and payload capability, but have a certain decrease of flight duration.Perimeter 8 is the product by Skyfront providing security and surveillance solutions, while GAIA 160 was developed by Foxtech with rain-proof capability.

Harris Aerial is expected to release its newest hybrid quadrotor, Carrier H4 Hybrid HL,which can carry up to 18 kg payload in 40 kg MTOW. Carrier H4 Hybrid HL will be powered by its own developed H5000 generator that can continuously output 4.3 kW power. If 15 L gasoline is packed on-board, 3-h flight (with 15 m/s flight speed) could be reached. Top Flight Tech launched a quad-arm 8-rotor UAV platform, Airborg,with similar MTOW as Carrier H4 Hybrid HL. Airborg, the multi-function industrial drone, has an estimated flight time of over 1 hour with 10 kg maxpayload.

Yeair! creatively applied the parallel hybrid configuration to the multi-copter.Each rotor of four rotors is powered by a 600 W electric motor and 1 kW two-stroke combustion engine. Since the parallel architecture allows the combination of the EM and ICE power,the available power of the quadrotor can be summed to 6.4 kW. This total combined power enables it around 1-h flight carrying 5 kg payload.

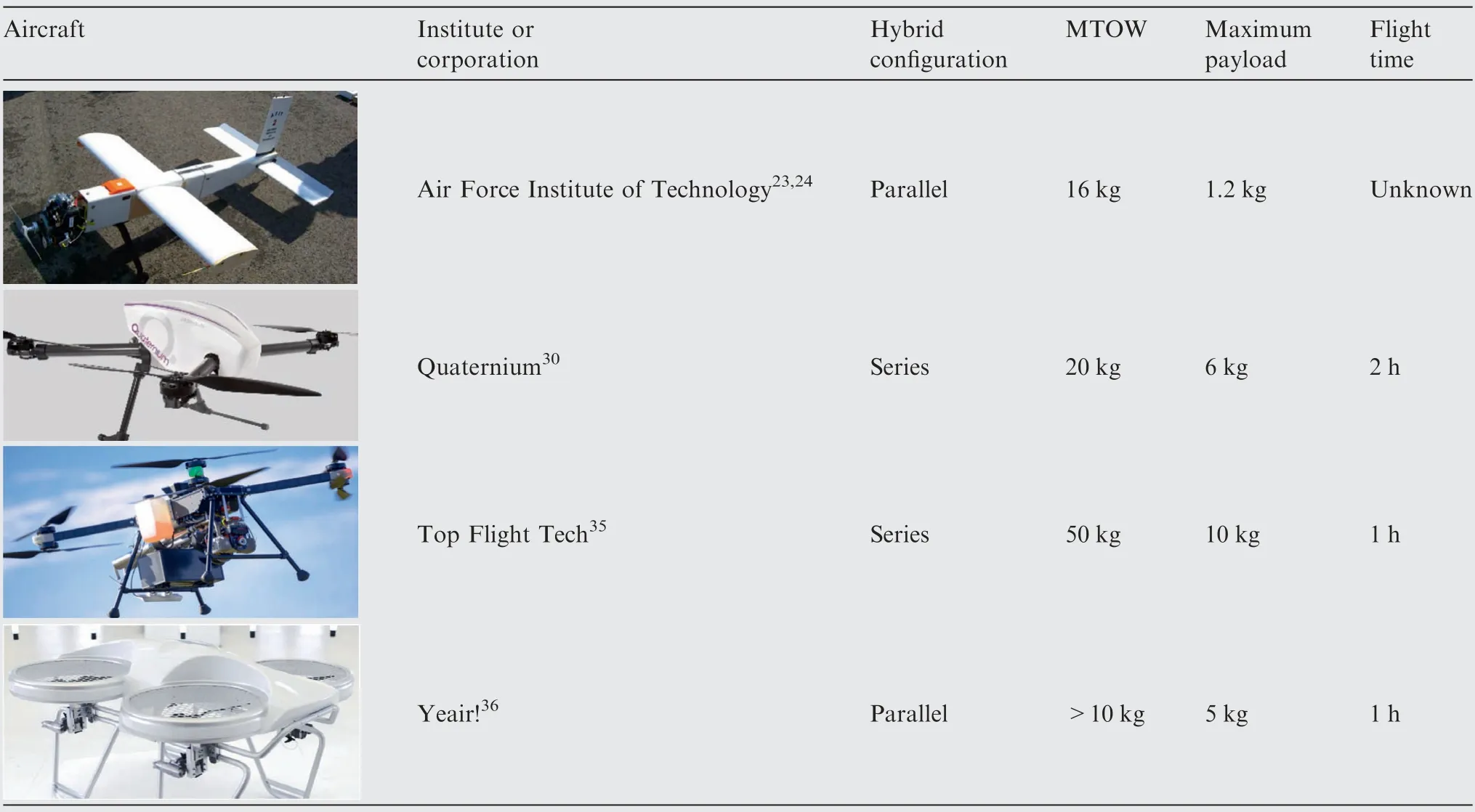

Some typical examples of aforementioned unmanned hybrid aircraft are listed in Table 1, with information of the hybrid configuration, global weight, and flight time under the maximum payload.

3.2. Mid-scale hybrid aircraft

The study of the HEPS technology for mid-scale aircraft(general aviation aircraft or other light aircraft) also has drawn much attention. As mentioned above, researchers from AFIT investigated the potential application of HEPS to the unmanned aircraft.The studies suggested that HEPS technology represents a viable trade-off solution for smallscale aircraft, promoting the mitigation of emissions and fuel consumptions while providing adequate range and endurance performance. However, Hiserote questioned the adaptability of hybrid propulsion technologies to larger aircraft.Another graduate student from AFIT, Ripple, examined the feasibility of HEPS for mid-scale aircraft,by retrofitting the General Aviation (GA) and remotely-piloted platforms—DA 20, Cessna 172 Skyhawk and Predator.Taking Cessna 172 as the example, the MTOW of retrofitted hybrid aircraft was basically equal to the original Cessna one. The potential fuel savings of the designed mild HEPS could be up to 54 kg but 27 kg payload was sacrificed.

Glassock et al.designed a parallel hybrid propulsion system for an 8-passenger skydiving airplane.The performances of fuel usage and climb rate were explored under different hybridization ratios. A constant hybridization ratio of 0.67 was finally selected, resulting in one 224 kW turbine engine and two 224 kW electric motors. Results demonstrated that the effective flight duration was severely limited at this ratio.Therefore,the short-duration high-power mission,such as skydiving,could benefit more from the hybrid propulsion technology in comparison with the conventional long-duration mission.

Boggero et al.retrofitted the Piper PA-38 Tomahawk using a 22.6 kW EM and a 54.5 kW ICE.If the hybridization of HEPS was set as 30%, the empty mass of the reference Piper airplane was reduced from 512 kg to 466 kg. The fuel mass could be reduced by around 10 kg, since the sized smaller ICE could operate in a higher efficiency working area.

Finger et al.compared the series configuration and parallel configuration of HEPS for general light aircraft.The paper claimed that the parallel hybrid architecture is superior to the series one in terms of decreasing the global weight and on-board fuel weight. The engine failure emergency was considered in a later study by Finger et al.Authors found out that the original optimal design was not available due to additional engine failure constraints. Furthermore, the MTOW of the sized hybrid aircraft would increase dramatically (50%) if 100 km diversion was requested after the engine failure.

In 2009,German aircraft builder Flight Design presented a hybrid electric system where a 40-hp (30 kW)EM can provide approximately 5 min of additional power to a 115-hp(86 kW)ICE.Based on this hybrid system, a light airplane—EcoEagle was developed by Embry-Riddle Eagle Flight Research Center to compete in the NASA’s Green Flight Challenge 2011.On the other hand, the University of Cambridge in association with Flylight Airsports Ltd retrofitted a glider Alatus by replacing the original two-stroke ICE with an HEPS.The hybrid propulsion systems consisted of 11.2 kW EM and 76 cc ICE. However, though using a parallel configuration,both EcoEagle and Hybrid Alatus have no capability to recharge the battery during flight.Following a new project—SOUL, in 2014, the University of Cambridge completed on-board regeneration by adopting the rule-based charging strategy. The SOUL was believed the first parallel-hybrid manned airplane with fully hybrid functions.

Table 1 Summary of small-scale hybrid aircraft.

The first series-configured hybrid-electric manned airplane,named DA36 E-Star, was demonstrated by EADS (Airbus),Diamond Aircraft and Siemens.The two-seat light aircraft launched its debut flight on June 2011,featured a 70 kW motor made by Siemens and 30 kW rotary engine made by Austro Engine. A more advanced version, DA36 E-Star 2, benefited from the revised electric powertrain and was approximately 100 kg lighter than its predecessor.Also, an increase in range/duration was expected. Three industrial giant claimed that the developed series HEPS was the future for commercial air transport and scalable for larger aircraft up to 100 passengers.

The University of Maribor and Slovenian aircraft manufacturer (Pipistrel) led the European project HYPSTAIR,aiming to develop and validate hybrid drive systems for light aircraft, from the year of 2013.After a four-year study,the HYPSTAIR project, unveiled the prototype of the world’s most powerful series hybrid powertrain (200 kW)for the general aviation. Pipistrel then planned to adopt the series HEPS to its gasoline-powered four-seat Panthera and the flight tests was expected to be conducted in 2020.Similar to the HEPS of DA36 E-Star, though the HEPS of HYPSTAIR was developed for the light aircraft,it was capable of being scaled up to power the 70-seat regional airliner.

On June 2019, Ampaire flied a hybrid powered airplane Ampaire EEL(337).Ampaire EEL was based on the Cessna 337,replacing the original rear piston engine(Continental IO-360) with a 180 kW electric motor. The two propulsors could power the aircraft in concert by driving two independent propellers.Ampaire refers to this combination of powerplants as a‘‘parallel hybrid architecture”. Yet the output shafts of ICE and EM were totally decoupled, so the ICE could not charge the battery in flight.

Many aeronautical and automotive magnets (Bell, Honeywell and Uber etc.)believe that the urban and inter-city air travel will be a crucial part in the future of transportation since it provides the fast, efficient and congestion-free travel. The city airborne travel especially favours Vertical Takeoff and Landing (VTOL) than conventional takeoff and landing, due to the complex and compact urban environment.The world’s first flied hybrid VTOL aircraft, Surefly, was unveiled by the Workhorse Group. Its first untethered hover took place on April, 2018 and lasted around 10 s.Surefly was driven by eight motors, every two of which were mounted on each of four arms.The eight motors were powered by a 150 kW piston engine and dual generators.The 150 kW ICE will eventually be replaced by a 223 kW turbine-powered ICE, thus the MTOW increases from 680 kg to 1 ton.

However, the rotor-powered aircraft has its own inherent shortcoming—lower propulsion efficiency and lower cruising speed.Therefore, the tilt-rotor/wing aircraft gains enhanced popularity and interest since combining the profits of VTOL aircraft and conventional airplane. Honeywell Aerospace believes that the age of Urban Air Mobility(UAM) is upon us and VTOL propulsion with both vertical and horizontal thrust has the bright future.They are developing a hybridelectric turbo-generator, combining the HTS900 turbine engine with two 200 kW generators, to drive tilting electric motors.At 2019 Consumer Electronics Show (CES), Bell revealed its conceptual air-taxi, Nexus, a hybrid electric-VTOL (eVTOL) aircraft utilizing six tilting ducted fans and a turbine generator.One year before Nexus’s appearing,Rolls-Royce unveiled its own EVTOL concept at the Farnborough Airshow.The concept described the tilting wing and M250 engine based hybrid propulsion system. Next year,Rolls-Royce completed the ground test of the HEPS that innovatively allows both series and parallel configuration using the gas turbine engine.

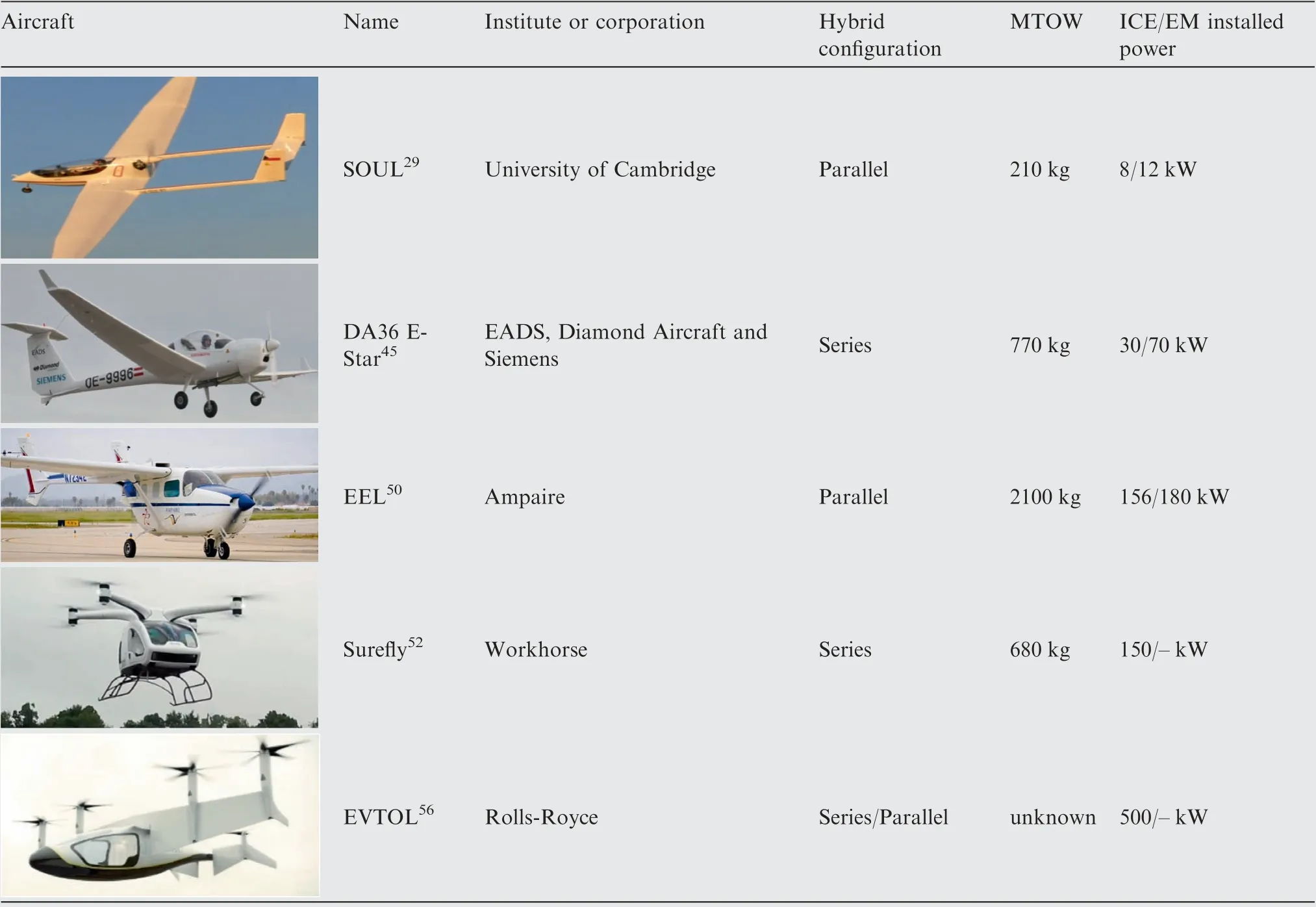

Table 2 presents several airplanes and eVTOL air vehicles that are equipped with hybrid electric powertrains.The hybrid architecture and installed ICE/EM maximum power of hybrid electric powertrains are given, in addition to the MTOW of aircraft.

3.3. Large-scale hybrid aircraft

Delft University of Technology have conducted a series of studies on the application of HEPS to the regional airliners.Bogaert assessed the potential fuel reduction and emission mitigation of hybrid electric regional aircraft.The hybrid regional aircraft was designed based on the ATR 72-600 capable of carrying 68 passengers. The largest airframe difference between the reference aircraft and hybrid aircraft was in the wing area with a difference of 18%. The fuel consumption of hybrid aircraft was then investigated and proved to highly depend on the flight range. Thus, Voskuijl and Bogaert et al.derived a new analytical range equation to estimate the ranges of hybrid airliners.Results demonstrated that the parallel hybrid-electric design could reach a 28%decrease in fuel mass at the cost of a 14%increase in MTOW.Note the conclusions were yielded under the progress of various electric and aerospace technologies. Zamboni et al. compared the fuel saving performance of three hybrid configurations, under different assumptions of technology levels.Results illustrated that the parallel architecture is a conservative option considering today’s state of the art technology, while the series one can benefit the most from the technology improvement. Vries and Hoogreef et al.discussed the aero-propulsive profits of the hybrid electric system, for example the leading edge and boundary layer ingestion.It was concluded that these revenues are easily negated by the increased masses, unless the improved technology could significantly decrease the powertrain mass.

Pornet et al.(from Bauhaus Luftfahrt)completed the sizing and assessment of the parallel hybrid electric system that com-prised motors mounted on the output shafts of conventional gas-turbines, for a 180 PAX reference airliner.A variable called cost specific air range was introduced by authors since the primary need of airliners is to minimize the operating economics.Then, results were presented and demonstrated that the advantages of HEPS would be degraded by the significant increased weight of the electrical system.Similarly, Another one of their studies claimed that the utilization of hybrid electric systems is practical only for short-medium range mission,even using the 1.5 kW/kg battery.For instance, the retrofitted hybrid airliner achieved 16% fuel reduction for a 900 n mile off-design mission, but failed to reach the original long range (3300 n mile) unless being sized with larger wing area.

Table 2 Summary of mid-scale hybrid aircraft.

The world’s largest aerospace magnates have been exploring the potential of hybrid-electric technology on large-scale transport aircraft, i.e. regional or even intercontinental airlines. Airbus invited Rolls-Royce and Siemens as the third partners to support the E-Fan X program in 2017, as a first step in the long-term goal of developing a hybrid-electric regional airliner.E-Fan X is anticipated to embark on its first flight in 2021 by employing BAe 146 as its testbed. BAe 146 will have one of its four turbofans replaced by a Siemens 2 MW EM, while the 2 MW EM will be powered by both a 2.5 MW generator and 2-ton battery.Boeing, paving the way for all-electric regional aviation, had funded the startup Zunum to develop the hybrid electric commercial airplane.Zunum is expected to have its first hybrid-electric aircraft(ZA10) delivered in 2022.

The Georgia Institute of Technology won the 2012-2013 Federal Aviation Administration (FAA) Design Competition in electric/hybrid-electric aircraft technology category.The developed technology suite was implemented on the NXG-50 hybrid aircraft to provide a future regional jet with expected reductions of 15% for life-cycle energy consumption.

The distributed propulsions for large-commercial-transport airplanes are highly rewarded in recent years.NASA leads the concept of Turboelectric Distributed Propulsion (TeDP)that hybridizes turboshaft engine and distributed electric powertrain in a series architecture.Note that in our article,the turboelectric architecture is classified as a special type of the series configuration, instead of an independent category.Since 2010s, NASA has been supporting the Empirical Systems Aerospace (ESAero), Inc. to lay the ground for the electricdistributed airplane,X-57 ‘‘Maxwell”.ESAero developed an 18-motor propelled wing as the ground testbed of the hybrid electric propulsion for X-57. Another example of TeDP by ESAero was ECO-150 concept that drove EMs using turbofan generators and distributed these small EMs along the wing.

NASA also funded Boeing SUGAR team to boost the promotion of subsonic air transport using hybrid electric concept design.The SUGAR Freeze was an early-phase example of the partially turboelectric architecture.It utilized liquefied natural gas instead of jet fuel,and generated electricity in flight to power advanced cryogenically-cooled motors.NASA then demonstrated its own fully-turboelectric concept, N3-X. N3-X was a TeDP-propelled blended-wing-body airplane equipped with a number of boundary-layer ingesting fans.The STARC-ABL concept germinated in NASA after researching SUGAR Freeze and N3-X.STARC-ABL carried the boundary-layer propulsion analogous to N3-X, while it had the similar airframe outline as SUGAR Freeze.

Following the success of mid-scale hybrid aircraft—hybrid DA36 E-Star,Airbus started a joint project DEAP with Rolls-Royce and Cranfield University.The proposed E-Thrust concept could also be described as a TeDP method using superconducting motors. Closing the DEAP project, Airbus participated in another programme EcoPulse, to developed a TeDP aircraft demonstrator, and announced his collaboration with Daher and Safran at 2019 Paris Air Show.

United Technologies formed a special group in 2019 to following the most promising technologies. Recently, this group started its first product demonstrator—a hybrid-electric Xplane under the Project 804.The X-plane will be powered by a 2-MW-class motor and a geared turbofan providing 107 kN thrust.

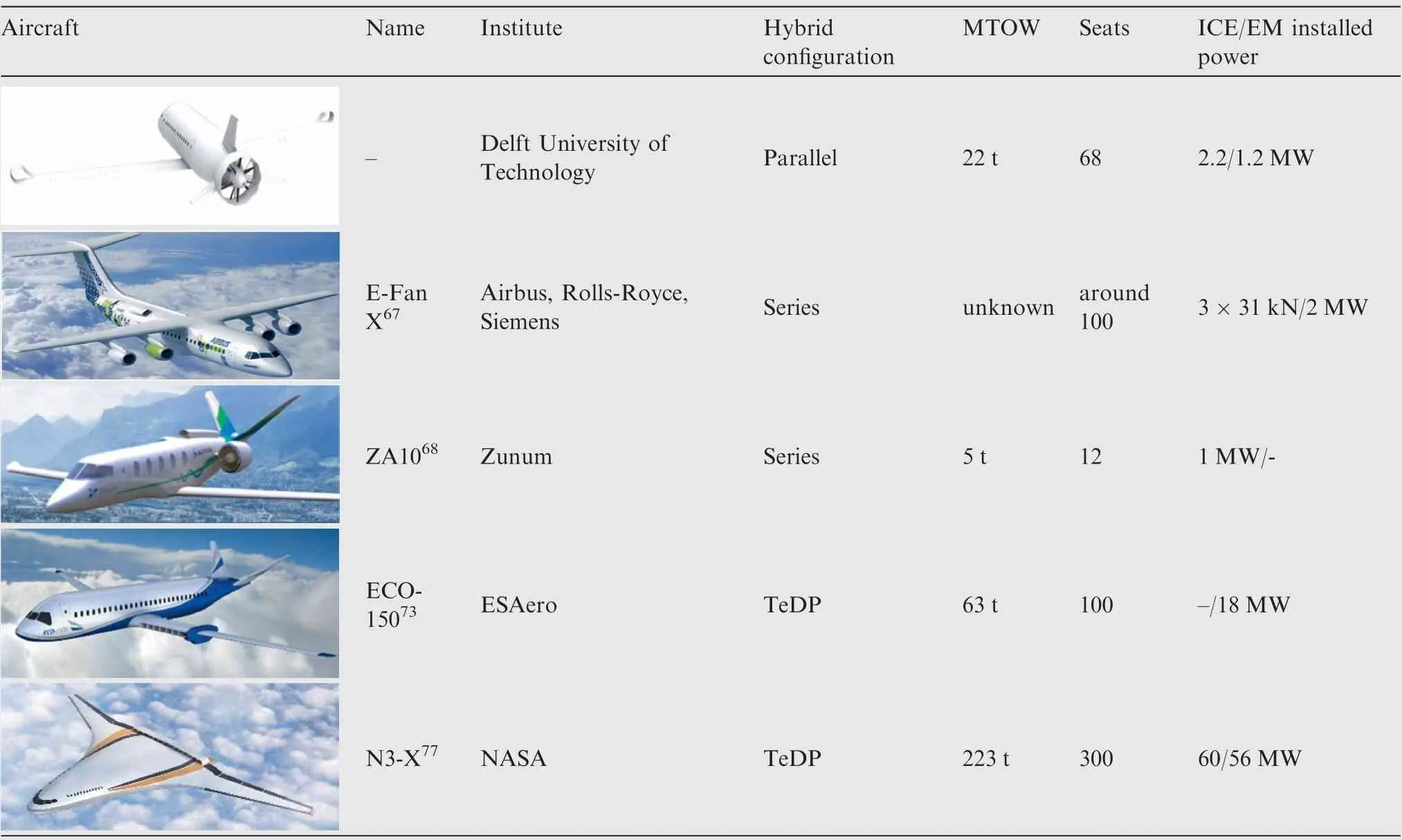

Table 3 displays design blueprints of several large commercial airplanes mentioned-above.The information of the powerclass of turbine engines and motors are collected but some details are not available for ZA10 and ECO-150. The passenger load capacity is shown using the number of the seat.Table 3 also provides the summary of the hybrid architecture for each hybrid airliner concept.

3.4. Summary

In general, the main target of studies on hybrid airplanes at small-scale level is to assess the feasibility and exam the potential of HEPS.The research group from AFIT has concluded that the hybrid propulsion technology can reduce the fuel usage and exhaust with satisfying endurance performance.The multi-rotor drones also benefit a lot from HEPS with increased payload and mission duration.The game-change technology remarkably affects the industry-drone market,since the hybrid propulsion technology can enhance the UAVs’capabilities for the agricultural/industrial spraying, inspection and surveillance,among other applications.Several drone manufacturers,providing industrial UAV solutions,started to produce hybrid powered multi-copters.Similar to small multicopters,the eVTOL‘‘air-taxi”suffers the short flight duration though the tilt-propelling is integrated. The hybrid combustion-electric propulsion can significantly lengthen the air-travel time per unit of on-board energy,thereby facilitating the process of UAM.

However, as referred to the light fixed-wing aircraft, the pros and cons are not clear since many researchers saw the compromise of performance if the airplane was retrofitted or designed using the hybrid electric powertrain.

For the small- and mid-scale sector, both academic and industrial institutes presented the flied or flyable demo. Furthermore, the drone companies already launched a series of off-the-shelf products. Yet the studies of large hybrid aircraft have been staying at the stage of concept design and analysis due to the limitation of electrical and other technologies. The project SELECT demonstrated that the NASA N+3 goals could not be met with evolutionary improvements of conventional technologies for large air-transport vehicles.

The objective (reference aircraft) of our study is the light airplane,since the profits and potential drawbacks of applying HEPS to this type of aircraft have not been thoroughly illustrated. Meanwhile, for our study, the used electrical technologies(like battery energy density and motor power density etc.)are normally at current level.In short, the study of theapplication to mid-scale airplane has not only theoretical significance, but also practical significance.

Table 3 Summary of large-scale hybrid aircraft.

4. Design of hybrid electric powered aircraft

The first technological problem to be resolved when introducing hybrid electric technology,is the synergetic design and sizing of the propulsive system at aircraft level. This problem generally can be solved using the optimization-based approaches or other trial-and-error methods.

4.1. Optimization-based design

In early 2000s, Nam et al. classified all propulsion systems that consume unconventional energy as one category. This category included (hybrid) electric propulsion systems. Nam et al. formulated a generalized design method for sizing the aircraft equipped with those unconventional propulsion systems.Though this generalized method was not specifically developed for the hybrid-combustion propulsion system, its power-flow based modelling method keeps inspiring the following studies.

The pioneer of hybrid technology—AFIT firstly applied the conventional aircraft design method to size the aircraft wing and HEPS components for the UAV.The sizing problem was formulated as a constrained optimization problem, in which UAV performance requirements were represented by the constraints. Though the resulted payload capacity cannot meet the original performance requirement, the hybrid UAV saved approximately 40% fuel consumption over a similarly sized ICE-powered UAV.Ripple, from AFIT, applied the same optimization routine to study the retrofit of several mid-scale Remotely-Piloted Aircraft (RPA).The difference is that the wing spans of the retrofitted RPA were fixed as the same as the original gasoline-powered RPA (the reference aircraft).Case studies demonstrated that the retrofit of the reference airframes can be achieved with small margin of sacrifice of payloads(about 18%).The fuel savings of hybrid RPA were from 20%to 40%,compared to their corresponding reference RPA.

Generally, it is difficult to detach the design of hybrid propulsion system from the aircraft design process, since the power sizing of HEPS is coupled with the estimation of aircraft power requirements. Scho¨mann, in 2014, innovatively introduced the aircraft scaling approach and successfully decoupled the HEPS sizing and the aircraft design.The computation burden was reduced by removing aircraft design variables.Scho¨mann studied models of all components of the hybrid propulsion system.Computational efficiency was further improved by fitting the mathematical surrogate models,instead of using the original discrete data. Scho¨mann applied the proposed optimization procedures to retrofit the reference small UAV and the resulted hybrid powered aircraft could reach 5% fuel mass reduction.

Pornet et al. firstly introduced the concept of supplied power, which represents the used engine/motor power for a given time step.They achieved to simultaneously size the hybrid propulsion system and optimize the flight profile, by defining the energy specific air range as the objective. In 2015, Pornet et al. extended the concept of supplied power and defined a new optimal variable-the power setting, which is the power distribution factor between the engine and motor.The power allocation was, therefore, well considered in the retrofit of a 180-PAX commercial transport aircraft.Another overall sizing of HEPS and aircraft was carried out by Pornet et al.The research illustrated the relative changes in optimal block fuel versus different battery energy density.For example,results demonstrated that up to 20% fuel reduction could be reached if 1.5 kWh/kg battery was available.

Delft University of Technology has been working on the conceptual design and assessment of the application of hybrid propulsion systems on regional transport aircraft.Bogaert concluded that a hybrid powered regional airliner(68-PAX)could save 30%fuel mass if the battery technique could be promoted to 1 kWh/kg.In this initial sizing study, Bogaert integrated weight estimation of energy sources to the optimization iteration,but did not consider the weight changes of energy sources over the time.What’s more,the average split,instead of the one per unit time,was employed to calculate the power use of energy sources. Based on Bogaert’s design framework, Voskuijl et al.introduced the supplied power split that varied throughout the flight mission.The study claimed that the traditional Breguet range equation is inapplicable to the hybrid aircraft,since more than one energy sources are used.Voskuijl et al.developed a new range equation for hybrid aircraft cruise flight.Up to 28%emission reduction was yielded with 1 kWh/kg battery.Note that the power distribution is assumed to be constant throughout the cruise flight in Voskuijl’s study. As opposed to the constant power distribution, Zamboni et al. introduced power control parameters that was supplied by segment specific control laws.The mass models of hybrid propulsion components had relatively low fidelity,while the performance characteristics of these devices were approximated with high-fidelity models.The paper claimed that this approach not only enabled a quick design in vastly diverse hybrid architectures, but also retained the most significant features. The final fuel saving varied from 20% to 40%, depending on different assumptions of the technology maturity levels.

Finger et al. proposed an initial sizing methodology for hybrid electric GA aircraft.At the beginning,the matching diagram was employed to create an available design space,using the power-to-weight ratio and wing-loading parameter.The design space was then searched to optimize the configuration of the hybrid aircraft and its propulsion system. The impact of engine failure constraint on the design of hybrid GA aircraft was investigated in a later study of Finger et al.The failure constraint, call as One Engine Inoperative constraint, was integrated to the previous proposed sizing procedures. The available design space was re-produced and found out to be shrunk with additional engine failure constraint.Results showed that up to 50% of take-off weight increased if 100 km distance was sized to engine-failed hybrid aircraft.

Bryson et al.creatively applied the multi-objective optimization to design a quiet small hybrid UAV.The vehicle noise and aircraft range were defined as two contradictory objectives.The acoustics models were developed,mainly including the wing and propulsion-noise sources. Authors found out that advanced hybrid propulsion technology could mitigate the propulsion noise,thereby the wing aeroacoustic noise becoming the critical adverse factor when increasing the aircraft range.

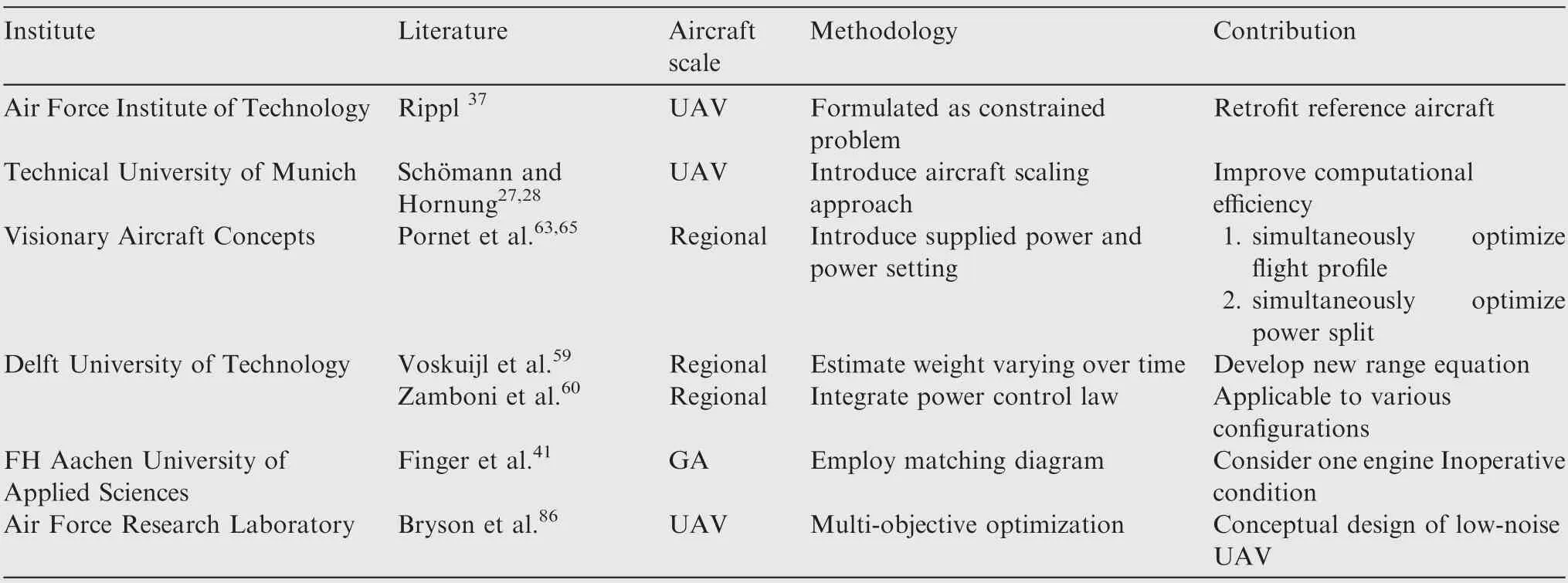

Within above-mentioned researches, some are worthy of particular attention, as listed in Table 4. Table 4 summarizes the methodologies they performed and the contributions they made, in addition to some general information (like institutes,references and applications).

4.2. Non-optimization-based design

Isikveren et al.proposed an engineering trade methodology to size the aircraft with dual-energy propulsion system.The algebraic expressions of fractional change in lift-to-drag ratio were first established. Parameters called partial synthetic densities were then introduced to estimate the fractional changes in take-off weight. A verification specific to hybrid-electric powered aircraft suggested that the objective of minimizing block fuel should be constrained by the requirement of energy specific air range (nm/kWh). The multi-objective formulation,featuring the block fuel and operating economics, was highly recommended for the future study.In 2018,Isikveren polished his previous study and proposed a new graphical-based approach.This universal quadrant-based algorithmic nomo-graph method, with its analytical nature, allowed the possible maximum transparency for the designer.

Table 4 Summary of optimization-based hybrid aircraft design.

Friedrich and Robertson proposed a methodology that employed the optimal design of HEPS for mid-scale aircraft to analyse the feasibility of HEPS for UAVs and transport airliners.Based on the sizing results of HEPS for microlight aircraft and the scaling approach, the potential of fuel reduction of a 20 kg and 50 tonne hybrid aircraft was evaluated to be 47% and 10%, respectively. The method could be generalized to design hybrid propulsion systems for a wide range of aircraft, with no need of optimization.

Sliwinski et al. were also interested in retrofitting methodologies with potential scale-up to different categories of aircraft.The paper initially investigated the integration of hybrid propulsion technology in a small RPA, using a socalled hybridization method. This hybridization way was applied to size the hybrid propulsion system of the small UAV, considering different ranges and endurance requirements.Yet Sliwinski et al.did not verify the method in medium or large aircraft. Glassock et al. introduced the hybridization approach to examine the potential of HEPS for the skydiver lift mission aircraft.A wide range of possible fuel burn and battery weight were explored by covering the full spectrum of hybridization ratio. Lastly, a constant value (0.67) of hybridization ratio was selected since all concerned performance were improved under this condition.

A new preliminary sizing method was introduced by Hoogreef et al. to size a 150-PAX hybrid electric aircraft.As opposed to the traditional sizing method, constraints were not exposed and no explicit design variables existed for the new method. In other words, this method implemented the‘‘feasilization”process,rather than the optimization approach to get a converged aircraft design. The new method was validated to be within 5%agreement,in comparison with the traditional sizing method, for the reference aircraft.

4.3. Summary and discussion

As mentioned in the previous section, many studies of hybrid propulsion systems for aircraft look at the opportunities when battery storage technologies or other electrical systems have significant advancement, as referred to the articles.Especially, in the context of large-scale transport aircraft, all benefits of hybrid propulsion would be negated by the increased masses of HEPS if state-of-art battery technology was applied.Therefore, the values from 1 kWh/kg to 2 kWh/kg of battery energy density were assumed in those studies.Our study would like to assess the feasibility of HEPS with current levels of technology and exemplify the fact that hybrid propulsion technology can have utility in aviation today. Thus, the battery energy density of 180 Wh/kg will be nominated in this study.

Many studies on the design and sizing of hybrid propulsion powered aircraft employed optimization-based methods. The optimal parameters and configurations of the hybrid propulsion system could be achieved both with or without the resizing of the aircraft. On the other hand, several researches applied engineering try-and-test methodologies, without need of optimization, to start the preliminary sizing of hybrid powered aircraft or scale the existing hybrid aircraft to the different sizes. Actually, in 2014, Perullo and Mavris claimed that an overall design of the aircraft hybrid propulsion system should be considered as a constrained optimization problem, not just a root-finding exercise.

Another worth-mentioning factor is that most optimization-based studies employed the single-objective method to reach the optimal sizing and design.2However, the single objective (such as fuel minimization) can only give one optimal sizing at one specific performance request (like range), in one optimization run.Therefore, several optimization runs have to be carried out to examine the different performance demands.The flight range or endurance is one of the most concerned performance for studies on the design or retrofit of hybrid powered aircraft. These studies evaluated variations in different optimal variables (fuel/battery mass, payload, take-off weight and electric-only time)under multiple range/endurance demands.Typically, several optimization runs with an increase in range were performed to investigate the feasibility and benefit of hybrid propulsion system.Sliwinski et al. demonstrated the range and endurance of hybrid powered aircraft were lengthened by the increase of fuel mass,i.e. the decrease of fuel economy.

The multi-objective optimization can simultaneously optimize several costs,like fuel burn,take-off weight,vehicle noise and range. If the performance needs (such as range) are included in the cost function, the potential of the hybrid propulsion system can be thoroughly evaluated in one optimization run, by using multi-objective optimization.Bryson et al. assessed the acoustic performance of hybrid UAV along various mission range requirements. The decrease of the aircraft noise was well-balanced by the increase of flight distance.The findings were published in an engineering note in a concise manner.As yet there is no open full-length-articles covering the detailed analysis of hybrid propulsion system sizing using multi-objective optimization. In our study, the multiple objectives are considered: the fuel consumption is minimized and the flight range (or duration) is maximized.

The study of multi-objective genetic algorithm is as early as the 1980s.Schaffer and Grefenstette applied genetic algorithm to multi-objective learning, but their algorithm suffered from biasness towards some Pareto-optimal solutions.To eliminate the bias, Srinivas and Deb proposed the famous Nondominated Sorting Genetic Algorithm (NSGA) in 1994and its second version NSGA-II in 2002.Compared with itself reduced bias and better spread of solutions,the computational complexity of NSGA-II is still relatively high,unless the computation of non-dominated sorting can be reduced considerably.Efficient Non-dominated Sort (ENS), proposed by Zhang et al. in 2015,is one of the most promising non-dominated sorting approach. Both theoretical analysis and empirical results show that the ENS is computationally more efficient than all previous non-dominated sorting methods. Our study proposed a new Benchmark based Non-Dominated Sort(BNDS) algorithm, based on the ENS algorithm, to further reduce the computational complexity of NSGA.

5. Energy management of hybrid electric propulsion system

Different from the one in a conventional non-hybrid vehicle,the controller in an HEPS is generally recognized as two levels:supervisory control and component control.The supervisory controller functions at the energy management level,splitting power or torque request between the combustion and electric powertrain. The lower level component controller, which receives commands from the supervisory controller, aims to regulate the performance of each subsystem (component).With the demand for the energy management,supervisory control strategies attract more attention and have been widely studied. Broadly, the energy management strategies of hybrid propulsion system can be classified into non-causal and causal ones.

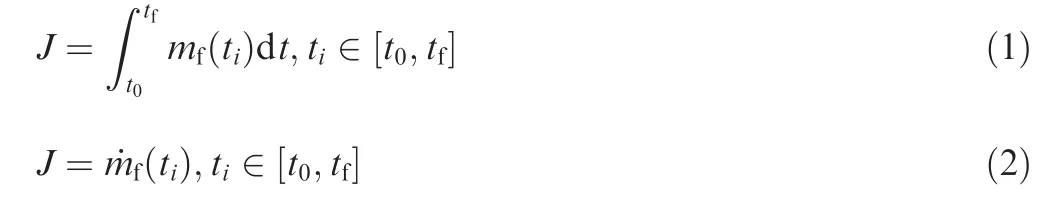

The main difference between non-causal and causal energy optimization is the objective.The non-causal one aims to optimize the performance along the complete mission profile,while the causal approach concerns on the optimization at one time node.If the objective of the energy optimization is to minimize the fuel consumption of the engine, the cost functions of noncausal and causal methods can be addressed by Eqs. (1) and(2), respectively:

where J stands for objective function;mand ˙mrepresent fuel and fuel rate,respectively;t denotes time,of which tand tare initial and final time.

Though the objective is diverse, the powertrain models are the same.The HEPS combines the energy from the fuel and electric storage to power the vehicle, regardless of the hybrid powertrain configuration. Considering the instantaneous power flow in the powertrain,the power output of combustion engine, P, and electrical energy source, P, always equals to the sum of system power requirement, P, and power loss P. The state variable (x) of the hybrid propulsion system is the battery’s SoC, while battery power depends on its output current (I) and voltage (V). The battery voltage is governed by battery’s SoC and current.In addition,physical limitations of each component are considered and expressed by the bounds of variables. Powertrain models as briefly provided by Eqs. (3)-(6):

where ˙x gives the differential of state variable x, while x,x, Iand Idefine the minimum and maximum value of state variable and battery current.

5.1. Non-causal control

Normally, the non-causal control cannot be implemented on the practical application unless future mission information is priori-known.Despite this,the non-causal optimization is still the most studied energy management strategy for the hybrid propulsion system.

In general, there are two approaches handling the energy management non-causal problem: the one is to solve the original nonlinear problem directly; another one is to simplify the original problem with approximation techniques. The Dynamic Programming (DP) is the dominant one for solving the complicated original nonlinear system, thereby being one of the most popular non-causal controls for (fuel-cell) hybrid aircraft applications.Compared with the causal energy management, DP achieved improved hydrogen fuel consumption and operational cost.

The downside of DP is the large computational cost due to the nonconvex characteristics of the energy management problem. On the other hand, several approximation approaches have been implemented to simplify the original problem,including (mixed integer) linear programming,quadratic programming,and convex programming problem.The convex programming is worth further studying and more attention,since it can avoid over-simplification compared with the linear programming and quadratic programming.However, almost all of researches on the convexification of the hybrid energy management problem concerns on hybrid ground vehicles.

Convex Optimization: The convex optimization was firstly proposed by Murgovski et al.to solve the component sizing and energy management of a plug-in hybrid city bus. The convex programming simultaneously optimized the battery size and energy distribution, on the condition that the city bus was driven along a perfectly known bus line.

The original non-convex, mixed integer problem was converted to a new problem by two main steps. The first one was the convexification process. The battery pack energy was first introduced as the state variable. The state transition equality became convex but not affine,by replacing the battery SoC with battery pack energy. Then, the non-affine equality constraint was relaxed to a convex inequality constraint.Finally, the battery constraints were converted to a convex form. The second step was to relax the mixed integer convex problem into conventional convex programming. Two integer control variables—gear ratio and engine on/off were tuned outside the optimization loop with the heuristic decisions.The heuristic approach removed the need for solving a mixed integer problem, thereby reducing the complexity of the problem. Results indicated that both the convexification process and heuristic approach have a small influence on the optimal solution.The convex optimization pointed toward similar battery size to one of the DP.

As opposed to the previous study, Elbert et al. calculated the optimal engine on/off command using Pontryagin’s maximum principle.The engine is switched on if and only if the requested power exceeds a certain threshold, which is dependent on the co-state and electrical buffer energy. The study also gave the necessary condition for a globally optimal solution of the convexified problem. It was shown to deliver optimal results in less time than DP even in the presence of active state constraints.

The convex programming has been proved to be an efficient optimization to solve the component sizing and energy management problem.However, the approximation and relaxation methods used in the convexification process, may lead to the errors between the original problem and the convexified problem. Murgovski et al. illustrated that the relaxation of state transition equality does not bring any errors between the original and the convexified model.On the other hand,the error of approximation has not been discussed in the paper.

5.2. Causal control

Though the simplification can reduce the complexity of the original problem, the application of non-causal energy management still cannot be implemented in the real-time application, if the complete mission profile is not priori-known.Therefore the causal control is introduced to the energy management of hybrid propulsion system. In addition to the optimization algorithm, the causal energy management can also refer to the rule-based control.The rule-based energy management and optimization-based causal one are illustrated in the following text.

5.2.1. Rule-based one

The rule-based control is comprised of a series of logic statements, which can determine the modes of operation only dependent on past and current system states. Therefore it is easily implemented as the real-time supervisory control. The rule-based control can be further subcategorized into deterministic rule-based and fuzzy rule-based one.

The deterministic rule-based control employs the classic set theory and elements to define different modes of operation.The transitions between those modes are determined by the logic rules.The rules are normally designed based on the operation states of the engine, such as the most efficient point,engine optimal operation lineand engine peak efficiency region.Hung and Gonzalez firstly introduced the concept of Ideal Operating Line (IOL) to the rule-based control of hybrid electric UAVs.If the IOL consists of low fuel consumption points, the UAV should be able to achieve reduced fuel usage but without guarantee of the optimality. Normally,the deterministic rules-based strategy is simple and easy to apply in hybrid aerial vehicles, but not robust to the model uncertainties and measurement disturbances.

Fuzzy Logic Control: Unlike the classical rule-based control, the Fuzzy Logic Control (FLC) deals with reasoning using an approximate way rather than the precise way. As a result,the FLC is tolerant to imprecise measurements and variations, thereby being robust against system uncertainties.As early as the 1990s, Lee and Sulapplied the fuzzy logic decision-making to generate motor torque command of the hybrid powertrain of a city bus. With regards to hybrid aircraft, the fuzzy based energy management is also preferred to the deterministic rule-based one due to its robustness. A fuzzy control was designed to hybridize the power of fuel cell and battery for a UAV.By practicing it to several testbench based experiments, the fuzzy strategy was validated to be superior to another two online strategies and consumed the least amount of hydrogen fuel.Though the fuzzy logic based methods were applied and proved to be insensitive to model uncertainties and measurement noises, it still cannot give any necessary or sufficient conditions for the control to be optimal. For a fuel cell/battery hybrid aerial vehicle,Karunarathne et al. proposed to combine the neuro network inference and fuzzy control to improve the adaptivity of power management.

5.2.2. Optimization-based one

The optimization-based strategy becomes more and more attracting, as its optimality can be, to some extent, supported by the theoretical basis.The difference between the non-causal and causal optimization is that the latter one does not need the future information. Many studies have found that the noncasual optimization problem can be converted to a causal optimization problem based on optimal control theories.

Pontryagin’s Maximum Principle: The Pontryagin’s Maximum Principle (PMP) can find the best possible control for the original non-causal problem, by solving several causal functions. The primary benefit of PMP is that it can provide the necessary condition for the solution to be the optimal control of the original non-causal problem.Another advantage of PMP is that it can give the analytical solution of energy optimization problems.Basically,the PMP can be taken as an approach of converting a non-causal optimization to the corresponding Hamiltonian function minimization.

Equivalent Consumption Minimization Strategy:The Equivalent Consumption Minimization Strategy (ECMS) is one of the most promising causal optimizations since proposed by Paganelli.It can be considered as the extension of PMP by replacing the co-state variable with the so-called equivalence factor.Then the Hamiltonian function is converted to a new objective—the equivalent consumption. This new objective has a real physical meaning as the sum of actual fuel consumption from ICE and equivalent electric energy consumption from the battery. Yet, only a few studies considered to apply the ECMS to optimize the hybrid propulsion system of aerial vehicles.Motapon et al.compared several commonly used energy management strategies and tested on a 14 kW fuel-cell hybrid aircraft.Experiments demonstrated that ECMS would be favoured if the objective of optimization was to minimize the fuel consumption. When managing the energy of a Wankel-engine-powered hybrid UAV, ECMS was verified to transcend genetic algorithm in terms of less computational burden.

The key issue with the ECMS,when applied in real-time,is that it cannot sustain the battery SoC due to the equivalence factor being evaluated off-line.As a consequence, the Adaptive-ECMS (A-ECMS) have been addressed to regulate the equivalence factor on-line. Generally, A-ECMS can be classified into two kinds.The first one is to update the original equivalence factor with a correction term regarding the SoC value. In the early study, the penalty function was already applied to regulate the SoC behaviour.The control variable was corrected by the penalty function if the SoC deviates from its desired value. Currently, the commonest way to adaptively update the equivalence factor was to adopt the P or PI controller.The input of the controller was the error between the current SoC and desired SoC. The second category of AECMS, sometimes, is also called as predictive ECMS, since it needs to predict the future information on-line.A neural network based velocity predictor was constructed to forecast the short-term future driving behaviours by learning the data stored in 3-D maps.Instead of keeping updating the optimal equivalent factor, a new study demonstrated an approach to estimate the upper and lower bounds of the optimal equivalent factor, which were independent of drive cycles.

5.3. Summary and discussion

The brief review of non-causal and causal energy management strategy for HEPS is presented above. Basically, the noncausal and causal energy management are preferred under different circumstances. If the flight mission varies depending on the flight environment, the causal control needs to be adopted to update control variables on-line. If a specific sub-task is demanded for the part of the future flight,the non-causal control is preferred to achieve the optimal results, since all information about this sub-task is previously known. Therefore,both the non-causal and causal control are required to complete a complicated mission.

For the non-causal control, the convex programming will be studied, where a new convexification approach is needed to simplify the original non-causal problem. Currently, there still no research is conducted to apply the convex programming to the HEPS of aircraft, except that our study proposed a new convexification method. It can not only retain the feature of lossless relaxation from previous studies, but also lead to a more straightforward and explicit form of convexified problem.

The aforementioned causal control aims to realize the charge-sustaining strategy,which is typical of hybrid ground vehicles.However,the charge-sustaining strategy is not ideal for aerial vehicle applications.If the SoC is sustained at a very low level,the residual battery capacity cannot guarantee a safe landing when there is a failure of the engine;on the other hand,maintaining a high-level SoC,means full use cannot be made of the electrical energy in the battery.Therefore,for aircraft,it is better that the SoC is held within a range instead of at a specific value. The most intuitive way is to combine the ECMS with a rule-based control,since the desired SoC requirement can be achieved using logic rules.This means,the control performance will not be heavily dependent on the selection of equivalence factor.Our study proposed to integrate the fuzzy control into the conventional ECMS. The authors did not find in the open literature articles applying fuzzy based ECMS specifically to the aircraft HEPS.

6. Hybrid electric propulsion system for reference mid-scale aircraft

The research aim of our study is to retrofit a light-sport prototype aircraft with the hybrid electric propulsion system.Improved fuel economy must be achieved by the optimization design(system sizing)and optimization control(system energy management).

6.1. Reference aircraft

The prototype aircraft was developed based on Ercoupe, first manufactured by the Engineering and Research COrporation(ERCO).Ercoupe is a low-wing monoplane aircraft and usually equipped with a Continental combustion engine of 48 kW to 67 kW(64-hp to 89-hp).For this study,a Continental C-75-12 powered model was selected as the template of a prototype aircraft. The original range and endurance of the prototype were approximately 500 km and 5 h, respectively.More properties of the prototype and its performance are given in our article.

6.2. Hybrid aircraft design

The system design generally started by first covering the analysis of the prototype aircraft. The performance requirements were evaluated on the basis of the aerodynamics of prototype airframe. The power-weight models of different sorts of engines and motors were also established and compared.Then, the hybrid aircraft design was formulated as a multiobjective optimization problem. Fuel consumption and flight range/duration were considered as contradictory objectives.The multi-objective optimization (NSGA) could simultaneously minimize fuel consumption and maximize flight range,but leads to low computational efficiency. A new nondominated sort algorithm—BNDS was proposed and proved to improves the computation burden and lots of unnecessary comparisons.

If the range and endurance of the hybrid were not sacrificed with respect to the prototype, the maximum increase in fuel economy was 17.6%. This point of the multi-objective Pareto front was set as the preferred solution,which achieved the minimum fuel consumption without compromise of endurance and range. The details of these work have been published in our article.

6.3. Hybrid energy management

The primary energy management problem was first formulated in the convex optimization. The simplified model of powertrain was developed using first principle and experimental data. The experimental data were analysed and approximated to clarify the convexity of the original problem. The main novelty of this part of work is the proposal of a new lossless convexification. By comparing with DP,the convex optimization performed minimal optimal cost results, with much lower optimization time. The most significant advantage is that the convexification reduces the optimization computation to a level compatible with the practical application.

The conventional ECMS was established by introducing the Hamiltonian function. It can convert the original noncausal fuel minimization problem to an equivalent causal one, but cannot sustain the battery SoC. The main contribution of this part of work is to extend the original ECMS by a fuzzy control. It was illustrated that the fuzzy based ECMS is more suitable for hybrid propulsion of aerial vehicles, compared with other ECMS based optimizations. Those ECMS based optimizations were designed for ground vehicles, with no consideration of vehicle safety if the engine fails.The fuzzy based ECMS can sustain the battery SoC among a range to guarantee the aircraft landing using the remaining electrical energy. The fuzzy based ECMS also allows the SoC to drop to the lower level if the flight mission requests high power for a short duration. In other words, the fuzzy based ECMS can not only sustain the SoC in a range around the desirable value, but also take advantage of the electrical energy source to power the aircraft.

The convex optimization and fuzzy based optimization were combined to complete a complicated flight mission with several sub-tasks. If the profile of sub-task is not accessible before the flight, the fuzzy based ECMS needs to be adopted to update control variables on-line. If a specific sub-task is demanded for the part of the future flight, the convex optimization is preferred to achieve the optimal results, since all information about this sub-task is previously known. When compared with a weight-adjusted prototype aircraft, the fuel saving further increased to 18.7%. The designed hybrid aircraft with optimal power distributions also had better 12.5%energy economy. More details of the two studies could be found in our articles.

7. Conclusions

This paper reviewed the current research state of the design and energy supervisory for hybrid electric propulsion systems, in addition to different scales of hybrid electric powered aircraft. The paper demonstrated that the study of mid-scale hybrid airplanes can contribute the most to both researches and practices. The small-scale hybrid aircraft have been widely studied and put into practice, while large hybrid aircraft will be staying at the stage of concept analysis unless electrical storage technologies experience evolutionary improvements. As summed in the overview of design methodologies, the multi-objective optimization has several advantages over the single-objective optimization and nonoptimization-based methods. Both non-causal and causal control are worth studying to manage the energy distribution with concentrating on SoC regulating methods that guarantee aircraft safety. All in all, there are few researches covering the conceptual design and energy management of hybrid aircraft using multi-objective optimization, convex programming and fuzzy based ECMS.

The conclusions of the literature review guided our original research work, briefly introduced by the paper. Regarding the conceptual design,the multi-objective optimization is the best,but suffers from high computational complexity. The new BNDS algorithm was proposed to reduce the computation burden of the multi-objective optimization. A convexification method was newly proposed in the study of non-causal energy management. A fuzzy optimization was integrated to ECMS,in order to fill the research gap that currently most of energy management did not consider the vehicle safety if the engine fails.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

sThis work was supported by the InnovateUK (No. 102361).AIRSTART is a £3.2 million collaborative Research and Development project developing key technologies to support general aviation, which includes the development of advanced propulsion systems.

This work was partly supported by the Zhejiang Lab’s project ‘‘From Hybrid eVTOL Air Vehicle to Urban Air Mobility” (No. 2018DF0ZX01), which aims to build the autonomous manned hybrid eVTOL aircraft for the future urban air transport.This work was partly sponsored by Leading Innovation and Entrepreneurship Team of Zhejiang Province of China (No. 2018R01006).

The authors would like to thank the China Scholarship Council(CSC)for funding Ye Xie(No.201506830053)to pursue her Ph.D. degree at Cranfield University.

CHINESE JOURNAL OF AERONAUTICS2021年4期

CHINESE JOURNAL OF AERONAUTICS2021年4期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Time delay compensation in lateral-directional flight control systems at high angles of attack

- Dual stability enhancement mechanisms of axial-slot casing treatment in a high-speed mixed-flow compressor with various tip clearances

- Development cost prediction of general aviation aircraft using combined estimation technique

- Improvement on shaped-hole film cooling effectiveness by integrating upstream sand-dune-shaped ramps

- Modeling and parameter identification of linear time-varying systems based on adaptive chirplet transform under random excitation

- An experimental method to obtain the hard alpha anomaly distribution for titanium alloy aeroengine disks