Experimental investigation on the effects of microwave irradiation on kimberlite and granite rocks

Samir M.Deyab, Hamed Rafezi, Ferri Hassani, Mehrdad Kermani, Agus P.Sasmito

Department of Mining and Materials Engineering, McGill University, Montreal, Canada

Keywords:Microwave irradiation Kimberlite Rock excavation Rock strength Abrasivity

ABSTRACT This study is a part of an overall research project on the effects of microwave(MW) irradiation on rocks for assisted rock breaking systems as well as mineral processing at McGill University.For the first time,this paper highlights a comprehensive investigation on the effects of microwave irradiation on Canadian kimberlites.Potential contribution to the continuous rock excavation and rock weakening effect prior to implementation of mechanical techniques was explored.Two different kimberlite rocks, i.e.volcaniclastic kimberlite (VK) and hypabyssal kimberlite (HK), and granite samples were studied.Some important physical properties of the rock samples were measured including rock quality designation(RQD), specific gravity, porosity, and specific heat capacity.Rock samples were treated for various exposure times using a multi-mode MW unit at different power levels ranging from 2 kW to 15 kW.The effect of MW irradiation on rock samples was investigated.The results indicate that the mechanical properties including unconfined compressive strength (UCS) and Brazilian tensile strength (BTS) were significantly dropped as a result of MW irradiation.Finally,the effect on rock abrasivity using the Cerchar abrasivity index (CAI) has also been discussed.

1.Introduction

One of the challenges in mining industry is finding the most expedient way to deal with hard rock breakage during the excavation as well as processing stages.Continuous mining or explosive-free rock breaking system is of great significance to the mining industry.A well-known method for breaking rocks is using mechanical excavation technologies, e.g.roadheaders, continuous miner, mobile miner, full-facer, oscillating disc cutter, and tunnel boring machines (TBMs).Over the years, some technologies have been discontinued by the manufacturers due to high cutting-tool wear and lower than expected production rates, e.g.mini fullfacer, disc boom miner, and mini mole.The remaining mechanical excavation technologies are also revealing that cutting-tool life is relatively short in hard rocks, the cost is high,and the penetration rate is relatively low.These drawbacks have become the primary limitations of mechanical excavators used thus far.Wear-resistant tools with increased levels of efficiency need to be developed and incorporated into mechanical excavation technologies in order not only to decrease related cost for bit replacements but also to boost rates of production(Wijk,1992;Hassani,2010;Hassani et al.,2016).

Recent studies are committed to explore the viability of hard rocks weakening before mechanical excavation.In this context,researchers are investigating the application of microwave (MW)irradiation to rocks prior to the use of mechanical rock-breaking techniques.MW heating applications were developed after the second world war (Osepchuk, 1984).Extensive works into highdefinition radars during the war led to the development of the frequencies of the MW from 0.5 GHz to 100 GHz (Meredith,1998)originally aimed for telecommunications (Gwarek and Celuch-Marcysiak, 2004).MW is considered as a form of electromagnetic(EM) waves with frequencies ranging from 300 MHz to 300 GHz and wavelengths from 1 m to 1 mm.The scientific and industrial sectors use different frequencies such as 915 MHz, 2450 MHz,22,125 MHz, and 5800 MHz (Meredith,1998).

Several studies on the effect of MW irradiation on different types of rocks have been conducted during the last 20 years.In a study, various rocks (e.g.sandstone, granite, marble, limestone,magnesite, and granodiorite) underwent 5 min, 900 W of MW radiation exposure via a multi-mode cavity.In addition to a decreasein ultrasonic wave velocity,a high level of disintegration occurring in samples was found (Murová et al., 2000).In another study, researchers at the Moscow State University of Mining investigated how 600 W of MW radiation impacts rocks.The tests aimed to determine whether there was strength loss in the rocks postradiation.In their experiments, kimberlite was used due to its hard and abrasive properties and its connection to diamonds.The tests indicated that kimberlite can be broken or crushed quite easily under low-temperature conditions if the rock is first soaked in water for around 2 h prior to the MW irradiation (Didenko et al.,2005).Other researchers also used a multi-mode cavity for irradiation in various rock samples(granite,sandstone,and basalt).This study showed that granite’s mineral composition caused it to heat up notably slower than the other two rocks(due to the existence of the amount of quartz), but the granite was still damaged by the irradiation.In contrast, the basalt samples experienced significant damage within just 2 min under 3 kW of MW irradiation,whereas dry sandstone remained unaffected.However, when Peinsitt et al.(2010) repeated the experiments using water-saturated samples,they discovered different results.For example, wet sandstone experienced damage that was four times higher than the dry sample, and their granite samples heated up twice as fast.Meanwhile,the basalt samples remained unchanged.Zheng et al.(2017)studied the surface temperature distribution of gabbro rocks resulted from MW treatment.They employed a single-mode MW cavity,with exposure times between 30 s and 120 s and MW power between 0.5 kW and 2 kW.By applying a fluorescent resin technique,the researchers were able to examine the formed macro-and micro-cracks, after which they used ultrasonic transducers to assess the samples’ thermal-induced damage.Similar tests were conducted by Hassani et al.(2016) employing a multi-mode MW cavity.When investigating the strengths of basalt, norite, and granite samples subjected to various MW power levels and exposure times, they discovered that increasing the power level and exposure time led to reductions in both uniaxial compressive strength (UCS) and Brazilian tensile strength (BTS).Additionally,scanning electron microscopy(SEM)graphs revealed micro-cracks in the basalt slabs.In a more recent study, Lu et al.(2019) focused their investigations on how MW irradiation affects basalt,employing a multi-mode cavity for 60 s,180 s, and 300 s of exposure times.They found that after the treatment, the UCS, BTS, and point load strength all increased.Overall,Lu et al.(2019)found that longer irradiation sessions at higher power settings led to greater fragmentation of the basalt.Nekoovaght (2009) studied the effect of MW irradiation on Cerchar abrasivity index (CAI), BTS, and UCS using a multi-mode cavity.He subjected the rocks to 800 W,1250 W,and 3000 W of MW power at various exposure times.The rock samples experienced reductions in CAI and UCS values by around 30%.Lu et al.(2017)used a multimode MW at 2 kW power and tested 11 rock-forming minerals to investigate how the thermo-mechanical properties of the rocks get affected by the MW irradiation.They also used X-ray imaging to study the mineral composition and the elemental distribution of the rock samples.

It is crucial to note that there is a very limited amount of works reported on kimberlite rocks, which will be the main focus of this paper in addition to granite samples.Therefore, the paper is addressing the problem of rock breaking by exploring how hard rocks might first be weakened before they are excavated by mechanical techniques.The research involves investigating kimberlite rocks to determine how and what extent MW irradiation impacts their mechanical properties as well as their abrasivity.Furthermore, it is necessary to ensure the integrity of the enclosed diamonds during the process.

2.Dielectric properties affecting microwave absorption

Materials absorb the MW irradiation according to their dielectric and magnetic properties.Insulators or transparent materials such as glass transmit MW without heating.Conductors or opaque materials such as metals reflect MW and do not heat up.Dielectric materials such as rocks and minerals absorb MW and convert the absorbed energy into heat (Haque,1999).Dielectric and magnetic properties are represented by the complex permittivity (ε; a measure of the capacitance or ability to store energy) and complex magnetic permeability (μ).

where ε′is the real part of complex permittivity and represents the polarization of materials in an electric field to store the energy,ε′is the imaginary part of complex permittivity and represents the energy loss in materials through dissipative phenomena, μ′is the real part of complex permeability and represents a material’s reaction in a magnetic field,and μ′is the imaginary part of complex magnetic permeability and represents the energy loss from materials under the impact of a magnetic field.For non-magnetic materials, complex magnetic permeability is zero.The complex relative permittivity (εr) is obtained from the relation between ε and ε0in Eq.(3) stated in farads per meter (F/m) (Jones,1964):

where ε0is th e permittivity electric constant in a vacuum equal to 8.86 × 10-12F/m.The complex permittivity (ε) and loss tangent(tanδ)are the two important parameters to determine the ability of the material in absorbing the waves in Eq.(4).Loss tangent represents the energy lost from materials.The penetration depth of EM waves is inversely proportional to the wavelength and directly proportional to the frequency: as the wavelength decreases and frequency increases,the penetration depth decreases(Jones,1964).The penetration depth (z) is calculated by

where λ0is the wavelength in vacuum.

Moreover, the penetration depth directly depends on the dielectric properties of the material.For example,conductors such as metals have low complex permittivity and reflect EM waves.Therefore, the penetration depth is very low.Dielectric materials with high complex permittivity absorb EM waves and penetration depth is large(Chandrasekaran et al., 2012; Hassani et al., 2016).

3.Materials and methods

3.1.Materials and specimen preparation

Kimberlite rocks are igneous rocks which mostly occur as eroded volcanic pipes and dyke systems.Some kimberlite deposits host diamonds in economic quantities, which makes them of particular interest to the commercial mining industry.In general,olivine occurring in a groundmass of calcite, perovskite, apatite,spinel and other phases form the typical phenocrystic mineralogy of kimberlite.In addition,mantle-derived xenoliths and xenocrystssuch as garnet, olivine, and the aforementioned diamond (Sparks,2013) are found.Kimberlites may intrude as hypabyssal kimberlite (HK) in a dyke system or local fragment where they fill as volcaniclastic kimberlite (VK) that is often of carrot-shaped diatremes, which may reach a depth of over 2 km from the eruptive land surface.The crater on top of a diatreme may have a diameter of up to 1 km and is filled by primary pyroclastic deposits or resediment material from the tephraring surrounding the crater.In deeper levels of the diatreme, the volcaniclastic rocks may adopt specific textural and structural features which lead to the term“tuffisitic kimberlite”,although not all diatremes show this specific kind of infill (Hetman et al., 2004; Smith, 2008).

The present work investigates two types of kimberlite (VK and HK)as well as granite samples.The 2.5-inch(1 in =25.4 mm)core rock samples were obtained from Victor mine in northern Ontario and Gahcho Kue mine in the Northwest Territories of Canada.The core samples were cut into cylindrical and disk shapes according to the standards to be suitable for the MW treatment and the mechanical tests.For the disc-shaped specimens, the height (H) is equal to 0.5D (D is the diameter of rock sample), while the cylindrical-shaped specimens had a 2 to 1 height-to-diameter (H/D) ratio.The specimen ends needed to be completely flat to guarantee the even distribution of the applied load in the UCS test.Immediately following MW irradiation exposure,a thermal camera is used to assess the sample’s surface temperature.

3.2.XRD results

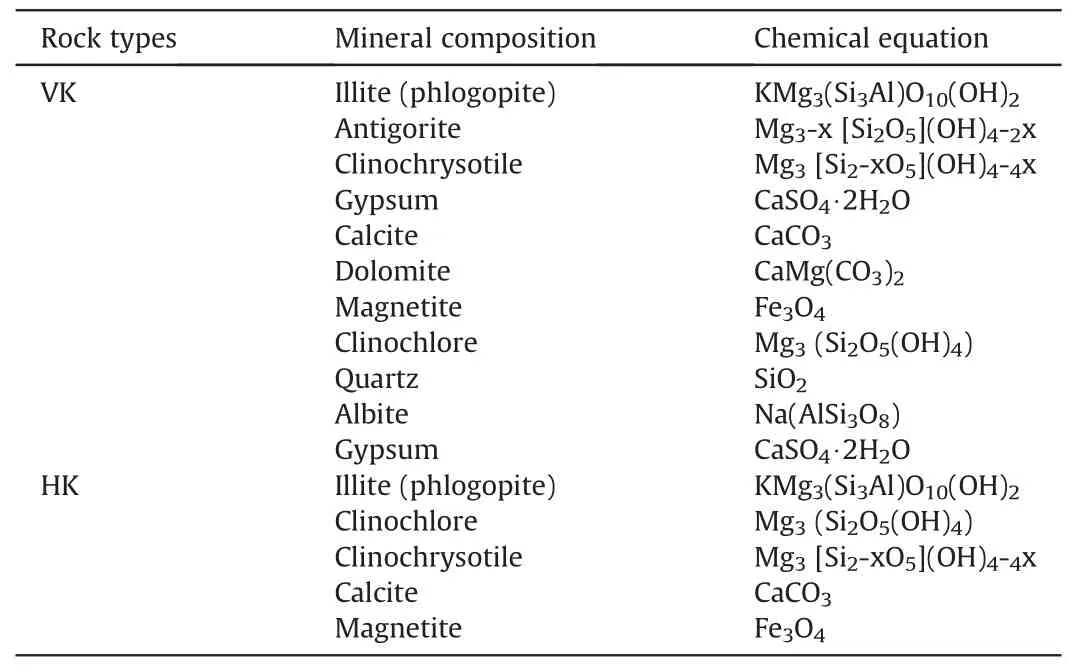

The main focus of this paper is on kimberlite rocks,therefore the mineral composition of VK and HK were analyzed and are presented in Table 1.

3.3.Physical properties of (VK, HK) and granite samples

The physical properties of core samples including rock quality designation (RQD), specific gravity, porosity, and specific heat capacity were measured.The RQD values of each core sample were determined according to ASTM D6032/D6032m-17 (2017).The specific gravity was measured according to ASTM D6473-15(2015).The porosity of the samples was measured according to ASTM C20-00(2015) (2015).The specific heat of the rock samples was measured according to ASTM D4611-16 (2016).Table 2 shows the physical properties of VK, HK, and granite samples.

Table 1XRD results of VK and HK specimens.

Table 2Physical properties of VK, HK, and granite samples.

3.4.Mechanical properties tests

The mechanical properties of the samples were investigated by conducting UCS and BTS tests.UCS test is a popular method to quantify the rock mechanical strength and it is an important predictor of TBM performance.The UCS test was conducted on treated and untreated rock samples according to ASTM D7012-04 (2004).The UCS test was carried out using “MTS 250 MN” compression machine equipped with a 250 MN load cell.Cylindrical rock specimens were subjected to 5 kW,10 kW,and 15 kW of MW power for up to 140 s,and then placed in a loading frame on a metallic plate on the UCS machine.

The BTS test is an indirect geotechnical laboratory test that is commonly used for indirect measurement of the tensile strength of rocks due to its simplicity and efficiency and it is also used to predict TBM performance.The tests were conducted on treated and untreated samples according to ASTM D3967-05 (2005) using a“Wykeham Farrance 100 kN” rig.Disc-shaped specimens were subjected to 3 kW of MW power for up to 180 s.Samples underwent the UCS and BTS testing and the average values of the results were recorded as the BTS and UCS values.

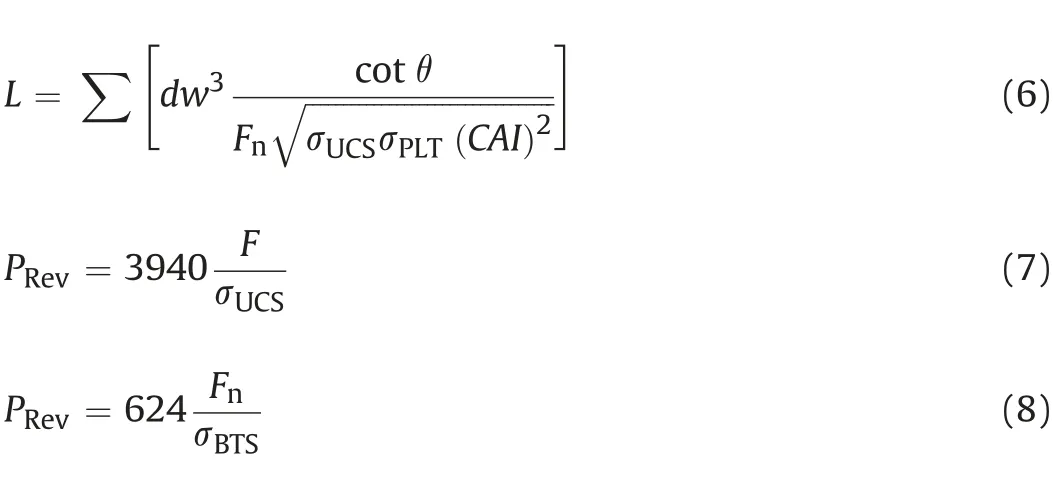

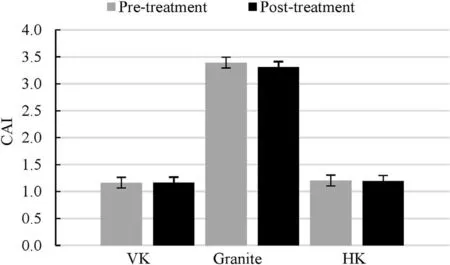

The CAI test was conducted according to the International Society for Rock Mechanics (ASTM D7625-10, 2010) on the saw-cut cylindrical sample surfaces prepared for the UCS tests (Fig.3),before and after 30 s exposure at 15 kW power.Each rock sample was firmly clamped in the rigid vice to prevent any lateral movement.A static load of 70 N was then placed on the top of the pin,which was carefully lowered onto the rock surface(Fig.2).The test was carried out by moving the pin across the rock surface for 10 mm at a constant speed(10 mm/s)to scratch the rock.After the test,the flat wear on the tip was measured under the microscope to calculate the CAI.The abrasivity is an essential parameter affecting the disk cutter lifetime in TBMs.The lifetime of a disc cutter of TBMsand its penetration per revolution (PRev) can be calculated according to the following equations (Wijk,1992; Hassani, 2010):

Fig.1.A disc cutter rolling on rock surface (Wijk,1992).

Fig.2.CAI apparatus.

where L is the distance that a disc cutter can roll on hard rock(m);d is the disc cutter diameter (m); w is the thickness of the disc cutter edge (m); θ is the angle of the disc cutter edge (°); Fnis the normal load applied to the disc cutter(N)(see Fig.1);and σUCS,σPLTand σBTSare the values of the rock UCS, point load strength, and BTS, respectively(MPa).

Fig.3.Rock cylindrical sample.

3.5.Microwave treatment

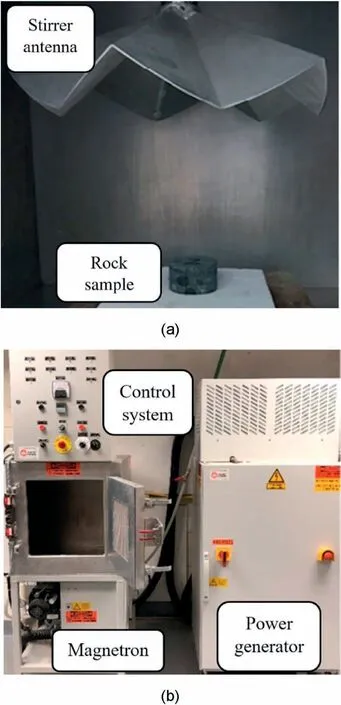

In the present work,all MW treatments were performed using a 2.45 GHz, 15 kW of MW system (Fig.4b).The MW system has a control unit to adjust the power from 1 kW to 15 kW.The MW experiments were performed with the air in the cavity.The cavity applicator is a metallic cube-shaped closed box with dimensions of 60 cm×60 cm×60 cm.To uniform the MW energy distribution,a stirrer was used, as shown in Fig.4a.

3.6.Thermal analysis

Cylindrical rock specimens were treated at MW powers of 2 kW, 4 kW, 6 kW, 10 kW, and 14 kW to evaluate the thermal profile and the time required for a sample to reach a maximum temperature of not more than 500°C (to avoid potential damage to the diamond crystal embedded in the rock).At time intervals,the surface temperature of the samples was measured using a thermal camera.

Fig.4.Multi-mode MW cavity (a), and MW system components (b).

4.Results and discussion

4.1.Dielectric properties of VK, HK, and granite samples

The dielectric properties give an insight into the ability of material in absorbing MW irradiation.Using the coaxial probe technique, the dielectric properties of samples at different frequencies were measured.The samples of VK,HK,and granite were analyzed in a range of frequencies (2-12 GHz).At this frequency range, the complex permittivity was the highest for HK, followed by VK and lowest for granite.Thus, HK and VK appear to have a relatively higher ability to store EM energy as heat,whereas the granite has a lower capacity.The loss tangent was relatively higher for VK and lower for HK and granite at 2 GHz and 12 GHz.The granite’s loss tangent-a measure of dissipation of EM energy-was also lower.The values of real complex permittivity and loss tangent for VK are in agreement with the results reported by Prokopenko et al.(2011).

Due to the different mineral compositions of the rock samples,the real part of the complex permittivity showed a declining trend in the frequency range of 2-12 GHz for VK,HK and granite samples(see Fig.5), which became less sensitive to changes at higher frequencies (>8 GHz).Across all frequencies, HK had a relatively higher real complex permittivity, whereas granite and VK had relatively low real complex permittivity.Thus, HK is expected to heat up more as a result of MW irradiation.For VK,HK,and granite samples, the imaginary part of complex permittivity (Fig.6) and loss tangent(Fig.7)showed an incremental trend at frequencies of 2-7 GHz; however, at frequencies above 7 GHz, the loss tangent trend became decremental.The VK and HK had higher values for both variables than granite across all frequencies, indicating that they should have a stronger capability to dissipate MW energy.

4.2.Thermal analysis of VK, HK, and granite samples

Figs.8-10 show the mean surface temperature variation at the five power levels across all rock types.At a given power level, the surface temperature of the samples increased linearly with exposure time.As the power level increased,the rate of this temperature increase became steeper.Thus, a shorter exposure time was required to reach a given temperature at higher power levels.It can be observed that the results of the thermal analysis are in agreement with the dielectric properties results.HK followed by VK absorbs the MW irradiation more than the granite samples.For example, at 14 kW power for 50 s of exposure time, the average surface temperature was recorded equal to 310°C and 386°C for VK and HK, respectively.

Fig.5.Real part of complex permittivity for VK, HK, and granite samples.

Fig.6.Imaginary part of complex permittivity for VK, HK, and granite samples.

Fig.7.Loss tangent for VK, HK, and granite samples.

4.3.Mechanical properties analysis

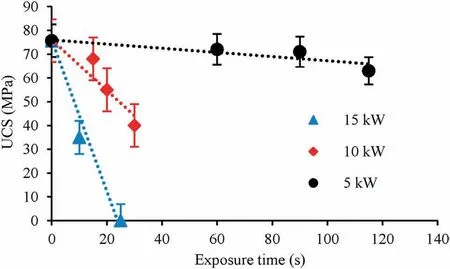

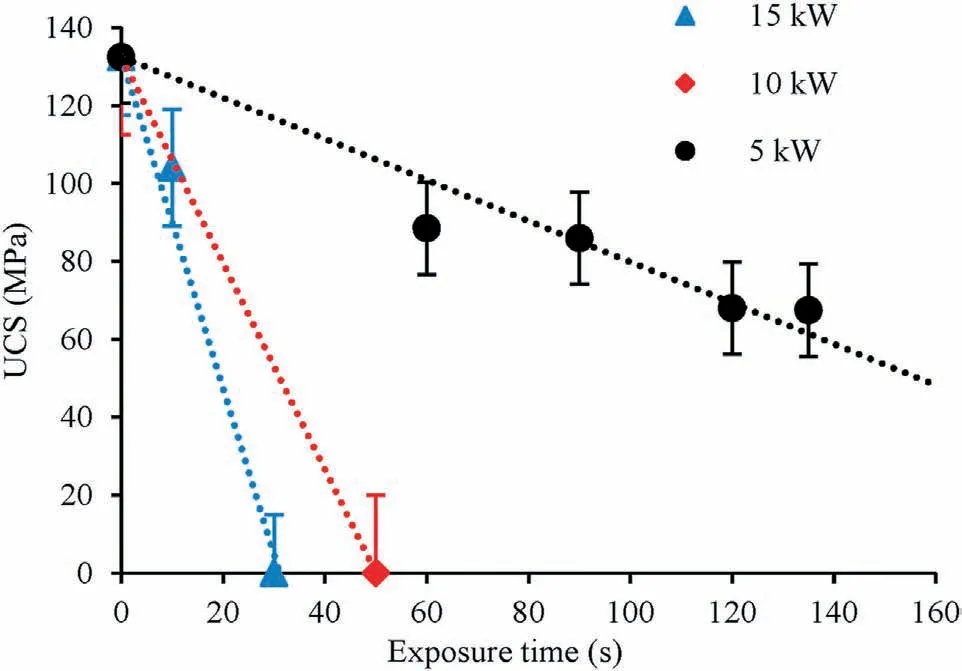

The mean UCS values for untreated VK, granite, and HK were measured equal to 76 MPa,136 MPa,and 114 MPa,respectively.The UCS of all rock samples decreased with MW exposure time at rates that increased with power level.For example, the UCS of VK decreased by 0.09 MPa/s, 1.06 MPa/s, and 3.19 MPa/s after treatments at 5 kW, 10 kW, and 15 kW of MW power, respectively(Fig.11).Lower power had a minor effect on UCS(i.e.17%reduction at 5 kW and 115 s);while at 10 kW and 30 s,the UCS reduction was 47%for VK,and at 15 kW,the samples completely fragmented after 25 s of exposure.A similar pattern was observed for granite samples(Fig.12).HK lost strength more rapidly at the highest power level and specimens disintegrated and extensively cracked after 40 s when they were treated with 15 kW power, therefore the UCS values were considered equal to zero.For 20 s of exposure time at 10 kW,the UCS reduction was recorded as 32%for granite samples(Fig.13).

Fig.8.Mean surface temperature change vs.MW exposure time at five power levels for VK samples.

Fig.9.Mean surface temperature change vs.MW exposure time at five power levels for HK samples.

Fig.10.Mean surface temperature change vs.MW exposure time at five power levels for granite samples.

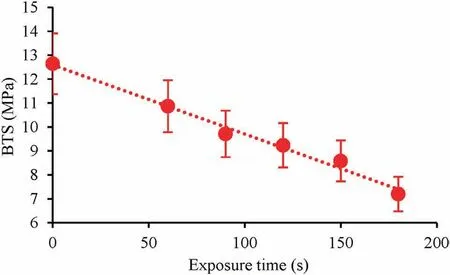

The mean BTS values of untreated VK, granite, and HK were measured equal to 8.75 MPa,12.64 MPa,and 8.54 MPa,respectively,and decreased with exposure time (Figs.14-16).The BTS of VK decreased by 59%after 60 s of exposure.In comparison to VK, BTS reduction at 60 s for HK and granite samples was recorded as 34%and 14%, respectively.The BTS reduction rates for VK, granite, and HK were measured as 0.09 MPa/s, 0.03 MPa/s, and 0.03 MPa/s,respectively.

Fig.11.Unconfined compressive strength(UCS)vs.exposure time to three MW power levels for VK.

Kimberlite and granite samples were treated using 15 kW of MW power for 30 s.The CAI test results demonstrated that MW treatment did not affect rock abrasivity.In other words,the CAI was not changed after MW treatment(see Fig.17).The specimens could not be treated in MW at 15 kW of power for more than 30 s due to disintegration and melting in some cases.

5.Conclusions

This study was aimed to investigate the applicability of MW treatment for rock preconditioning in the mechanical excavation of kimberlite and associated granite under the multi-mode irradiation.For the first time,a comprehensive set of data is achieved for the physico-mechanical properties of kimberlite.Comparison of pre- and post-microwave treatment results of the rock samples is promising.For a given rock type, the longer the samples exposed,the higher the MW power,and the higher the reductions of the BTS and UCS.For instance, a 47% reduction in UCS was observed after 30 s of exposure at 10 kW for VK samples,while the reduction was recorded equal to 17%at 5 kW power and 115 s of exposure time.At 15 kW power, the sample broke after 25 s of exposure.Regarding the granite,the samples broke after 30 s and 50 s of exposure when they were treated at 15 kW and 10 kW power, respectively;whereas the reduction of UCS was 35%at 5 kW and 60 s.For HK,the samples disintegrated at 15 kW and 40 s of exposure time.BTS also showed a decremental trend as a result of MW treatment.In HK,approximately 60%reduction after 150 s of treatment and VK about 59%reduction after 60 s of exposure at 3 kW power were measured.Additionally, it was found that MW irradiation had no evident effect on the abrasivity of the samples and CAI in the given test conditions.Dielectric properties showed that HK has more ability to absorb MW energy,followed by VK and granite.Thermal analysis results showed a good agreement with the dielectric properties.The results indicated that MW treatment can effectively reduce the strength of the rocks; therefore, the mechanical excavation machines can be equipped with MW antennas to improve the rate of penetration and further work is being conducted in our research team to optimize the microwave treatment process.

Fig.12.Unconfined compressive strength(UCS)vs.exposure time to three MW power levels for granite.

Fig.13.Unconfined compressive strength(UCS)vs.exposure time to three MW power levels for HK.

Fig.14.Brazilian tensile strength(BTS)vs.exposure time to 3 kW of MW power for VK.

Fig.15.Brazilian tensile strength(BTS)vs.exposure time to 3 kW of MW power for HK.

Fig.16.Brazilian tensile strength (BTS) vs.exposure time to 3 kW of MW power for granite samples.

Fig.17.CAI for three rock types before and after 30 s exposure to 15 kW of MW power.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) and our industrial partners,DeBeers,Metso,and Argex companies as well as PhD scholarship to Mr.Samir Deyab from the department of mining engineering,Tripoli University are gratefully acknowledged.The authors would like to thank Brain Rauch,Stephan Kurszlaukis,and Peter Sergeant for their contributions and comments.

Journal of Rock Mechanics and Geotechnical Engineering2021年2期

Journal of Rock Mechanics and Geotechnical Engineering2021年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Case study of a driven pile foundation in diatomaceous soil.I: Site characterization and engineering properties

- Particle breakage of sand subjected to friction and collision in drum tests

- Permeability and setting time of bio-mediated soil under various medium concentrations

- Novel experimental techniques to assess the time-dependent deformations of geosynthetics under soil confinement

- Physics-informed deep learning for one-dimensional consolidation

- Numerical modeling for rockbursts: A state-of-the-art review