Highly-efficient improvement of the mechanical strength of carbon nanotube fibers via UV-initiated click reaction

RAN Xuan, WANG Yimei, CHEN Shenghui, MIAO Menghe, ZHANG Daohong

(Key Laboratory of Catalysis and Energy Materials Chemistry of Ministry of Education & Hubei Key Laboratory of Catalysis and Materials Science & Hubei R&D Center of Hyperbranched Polymers Synthesis and Applications & College of Chemistry and Materials Science, South-Central University for Nationalities, Wuhan 430074, China)

Abstract To produce CNT fibers with stable mechanical performance, a highly-efficient and facile thiol-ene click reaction was used to functionalize the carbon nanotube(CNT)fibers.The effects of the functionality and content of mercaptans and other reaction conditions on the performance of the functionalized CNT fibers, and the enhancement mechanism were studied.The results showed that without damaging the structure of the CNTs, a crosslinked structure between individual carbon nanotubes was formed.Several mercaptans with different functionalities were used to functionalize the CNT fibers via the thiol-ene click reaction between the double bond of pristine CNT fibers(PCNTs)and the thiol groups.The tensile strength of the functionalized CNT fibers increased with the increase of thiol functionality, and continued twisting could further improve the tensile strength.The tensile strength of the functionalized and twisted CNT fiber was 191.7% higher than the PCNT.This facile method about improving the mechanical strength of CNTs fibers may be of great significance for their wide application.

Keywords carbon nanotube; fibers; thiol-ene click reaction; tensile strength

Carbon nanotubes(CNTs)have been extensively researched and used widely due to their excellent mechanical properties[1], high electricity[2]and thermal conductivities[3].In individual carbon nanotubes, the sp2hybridization proportion is higher than the sp3hybridization proportion, resulting in high modulus and high strength.However, single carbon nanotube is difficult to be applied on large scale because of large variation and unstability of property.Therefore, the single carbon nanotubes commonly is collected and aggregated into assemblies, including aerogel[4], films[5]and fibers[6].Among of them, fibers are considered as the more potential application due to the 1D characteristic of the individual nanotubes.But the simple approach to obtain high stably mechanical performance of CNT fibers is still a challenge.In order to improve the mechanical and multifunctional properties of CNT fibers, five main approaches were used to modify CNT fibers, including polymers or organic solvents infiltration[7], twisting[8], plasma treatment, cross-linking reaction and acidification[9].LIU et al[10]enhanced the mechanical properties of CNT fibers by ordinally pre-infiltrated, isothermal crystallized and hot-stretched processes.The result showed the tensile strength of the composite fibers was 212% higher than that of the pristine CNT fiber.The chemically cross-linked carbon nanotube fibers were investigated by a aryl cross-linking reaction method[11], and the tensile strength was increased significantly about 133% than before with the connection of aromatic linker augments into CNT bundles.And the acid treatment was also an efficient way to improve the electrochemical performance[9].As the polyaniline(PANI)was efficiently deposited around the fiber by acidization, the electrical conductivity and volumetric capacitance excitingly increased about 117% and 500%, respectively.However, the disadvantage of infiltration method is difficult to the uniformity and infiltration, which results in unstability of performance.Although mechanical properties of CNT fibers were improved distinctly by above methods, a highly-efficient and facile modification method of CNT fibers with stable performance is still the main target for the rapid development and commercial applications.

As a versatile and significant synthetic method of perfect networks in the polymer fields, thiol-ene click reaction has widely attracted increasing attention due to its high selectivity, mild reaction conditions, simple post-treatment, high yield and no by-products[12].This chemical modification method can gain uniform and stable performance of carbon nanotubes due to the integrity of CNT structure.ZHANG et al[13]demonstrated the radical mediated thiol-ene addition reaction was a convenient, efficient and robust reaction to covalently bond CNT with PE.The thiol-ene click reaction has shown a perspective in modifying CNTs and CNTs fibers.In this work, CNT fibers have been modified by using thiol-ene click reaction between thiol group of mercaptans with different functionality and double bond of pure CNT fibers(PCNTs).The effect of type and content of the mercaptans and reaction conditions on the performance of functional CNT fibers have been studied in detail, to obtain high and stable strength CNT fibers.

1 Experimental

1.1 Materials

The pure CNT fibers(PCNTs)with a diameter of about 25 μm were supplied by Beijing Funat Innovation Technology Co., Ltd.The chemical structures of the used mercaptans(PMMP, TMMP and DEMP)are shown in Fig.1[14].2,2-Bimethoxy-2-phenylace tophenone(DMPA),ethanol and acetone were supplied by Sinopharm Chemical Reagent Co., Ltd., China.

Fig.1 Chemical structures of mercaptans

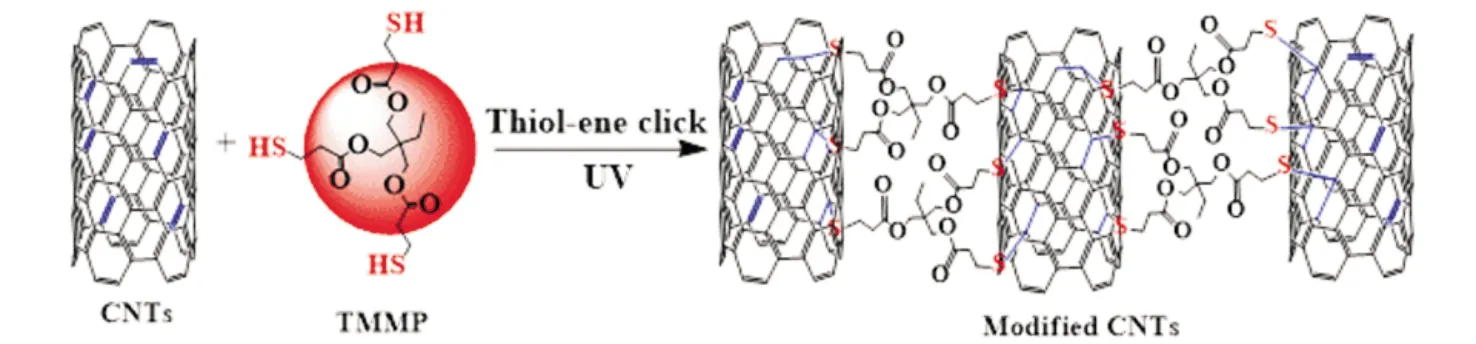

1.2 Preparation of functional CNT fibers by thiol-ene click reaction

In this process, the solution was obtained by mixing 2 g thiol, 2 g acetone and 0.02 g DMPA(photo-initiator).And then PCNTs with a length of 120 mm was impregnated completely in the above solution without light condition for 20 min.The infiltrated CNT fibers were put into a UV reactor to initiate thiol-ene click reaction about 30 min under 300 W.The resultant CNT fibers were washed by acetone for removing the unreacted thiol, and then dried at 60 ℃ for 1 h.Finally, the dried fibers were densified by a hand twisting clockwise instrument to obtain functional CNT fibers.The click reaction process is exhibited in Fig.2.The CNT fibers modified with PMMP, DEMP and TMMP are named as PMCNTs, DECNTs and TMCNTs, respectively.

Fig.2 Reaction process of CNT fibers by click reaction

1.3 Characterization

The chemical structure of the PMCNTs, DECNTs and TMCNTs fibers were characterized by Raman spectroscopy(Bruker).Scanning electron microscope(SEM)(Hitachi)with an accelerating voltage of 5 kV was used to observe the surface and fractured morphologies of the fibers.The thermal degradation behavior of CNTs fibers from 30 ℃ to 700 ℃ was analyzed by a thermogravimetric analyzer(NETZSCH)with a nitrogen flow of 20 mL/min and at a heating rate of 20 ℃/min.The functionalized fibers were twisted by a hand twister(Y321B).The diameter of the fibers was evaluated by Nikon Eclipse LV100N microscope.All kinds of fiber specimens were glued on to a hard paper frame with a 10 mm×10 mm square window and their tensile strength was tested on an Instron 5943 universal materials tester using a 10 N load cell and a loading rate of 1 mm/min.

2 Results and discussion

2.1 Characterization of functional CNT fibers

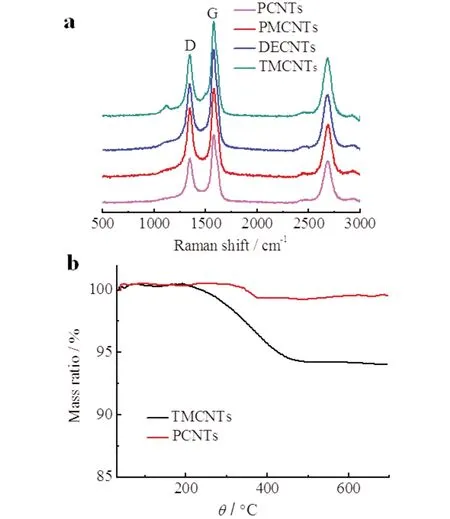

The Raman spectra of PCNTs, PMCNTs, DECNTs and TMCNTs are shown in Fig.3(a).The peaks at around 1575 cm-1and 1347 cm-1are attributed to the G-band and D-band of PCNTs, respectively.The D-band originates from elastic scattering caused by defects in the CNT framework(sp3-hybridized carbon).In this work, the thiol-ene click reaction broke the structure of the carbon nanotubes and created branches in the carbon nanotubes, resulting in an increase in disorder and in the Raman signal of D-band peak.The G-band is associated with the sp2-hybridized carbon[15].The reaction between double bonds and thiols transferred the sp2bonded carbon atoms into sp3bonded carbon atoms, and then decreased the Raman signal of G-band peak.The intensity ratio(IG/ID)of PCNTs, PMCNTs, DECNTs and TMCNTs are 1.538, 1.209, 1.207 and 1.200, respectively, indicating that with the increase of functionality of thiols, the more sp3-hybridized carbon are transformed by sp2-hybridized carbon.TGA curves of the PCNTs and TMCNTs are shown in Fig.3(b).Compared with the char yield(99.54%)of PCNTs, the residue of TMCNTs was 94.00%, indicating that the TMMP has been grafted successfully on carbon nanotubes fibers via thiol-ene click reaction.

Fig.3 Structural characterization of CNT fibers

The scanning electron micrographs(SEM)in Fig.4 compares the surface morphology of PCNTs and TMCNTs, and the difference is obvious between them.Fig.4(a)shows that there are lots of voids in the PCNTs, and the surface of individual carbon nanotubes is very smooth, and this phenomenon is clearly observed after magnification(Fig.4(b)).The Fig.4(c)shows the functionalized CNT fibers by the thiol-ene click reaction have been bonded together because of the cross-linking between the double bonds and thiols.This bonding increased the contact area between the CNT bundles.And the bundle size of functionalized CNT fibers is larger than the PCNTs because of several fibers tangled together as shown in Fig.4(d).

Regarding the stacking of CNT bundles in the CNT fibers, it is known that increasing the CNT bundle sizes and inter-CNT contacts results in an increase in their bearing load and improvement in mechanical properties[16].Comparing the SEM micrographs of Fig.4(a)with Fig.4(c), the CNT bundle voids decreased by the thiol-ene click reaction.Almost all the carbon nanotubes were bonded with TMMP and fewer pores were observed.TMMP connected the nanotubes with each other, increasing their bearing load and improving mechanical properties.The uniform bonding between TMMP and carbon nanotubes assists high impregnation efficiency and uniformity taking advantage of the high wettability of thiols in CNT fibers.

Fig.4 SEM micrographs

Fig.5 shows the fractured morphologies of PCNTs and TMCNTs after stretching.The fractured morphologies of PCNTs are relatively loose and smooth in Fig.5(a)and Fig.5(b), indicating the weak interaction between carbon nanotubes.The functionalized CNTs fibers in Fig.5(c)and Fig.5(d)show the functionalized carbon nanotubes becovery compact, suggesting strong interaction between CNTs due to the crosslinked TMMP chains among CNTs.And the phenomenon further demonstrated the chemical bonds between double bonds and thiols enhanced the interaction between carbon nanotubes, and formed a well-integrated polymeric network.The strong interaction between CNTs are substantiated by the fact that the regular fractured surface of functionalized carbon nanotubes in Fig.5(e).

Fig.5 SEM micrographs of fractured surface

2.2 Effect of reaction conditions on performance of CNT fibers

The effects of thiols type on the tensile strength of the functionalized carbon nanotube fibers are shown in Fig.6.At least 30 specimens were tested for each type of functionalized fibers.Every specimen tested with the tensile strength of PCNTs, PMCNTs, DECNTs and TMCNTs are shown in Fig.6(a).With the increase of functionality of thiols, the tensile strength of functional CNT fibers increased.The strength improvement of the functionalized CNT fibers may be attributed to the molecular chains of thiols between CNTs that provides short sliding distances and high ability to load transfer[17].Furthermore, the strong interaction between CNTs minimizes intertube slippage and then substantially improves stress transfer under loading[15].TMCNTs with three functional degrees has the highest tensile strength among the three functionalized fibers.With the increase of the proportion of thiol groups, the thiols increase the crosslinking density of network structure and further improve tensile strength.Therefore, under the same reaction conditions, the enhancement function of tri-mercaptan is the strongest.The stress-strain curves of the PCNTs, PMCNTs, DECNTs and TMCNTs are shown in Fig.6(b).The elongation of functionalized CNT fibers is less than PCNTs, and especially TMCNTs has the lowest elongation.The high crosslink structure limited the slippage and movement after thiol functionalized CNTs, leading to an increase in the tensile strength of TMCNTs, which corresponded with the SEM image of Fig.5(e).

Fig.6 Tensile properties of functionalized CNTs fibers with various thiols

The influence by tuning thiols content and click reaction time on tensile strength of CNT fibers are explored by using TMCNTs as an typical example, because TMCNTs shows the highest tensile strength.Fig.7(a)shows the TGA curves of TMCNTs fibers functionalized by different TMMP content, and their residues were 97.59%, 94.00% and 90.49%, respectively.Compared with the residues of PCNTs(99.54%), the content(mass ratio)of TMMP were 1.95%,5.54% and 9.05%, respectively.With the increase of the content of TMMP, the tensile strength of TMCNTs fibers increases first and then decreases as shown in Fig.7(b).The formation of chemical bonds between CNT layers enhances the tensile strength of CNT fibers, and excess thiols cannot crosslink with CNTs fiber and form pendulous chain and finally reduce the tensile strength.Therefore, the functionalized fibers with the content of TMMP about 5.54% have the best tensile strength of about 1034.2 MPa.Under the same content of TMMP, with the increase of reaction time, the tensile strength of the functionalized CNT fibers increases first and then decreases in Fig.7(c), displaying a maximum value at about 30 minutes of UV time.And the main reason is that enough reaction time assists the complete thiol-ene reaction between double bond in CNT and thiols groups, and excess UV time may result in degradation of organic chain because of the high energy of UV.

It is expected that the twisting of CNT fibers has a positive effect on tensile strength for torque-stabilized CNT fibers[8].Fig.7(d)contrasts the tensile strength of PCNTs, TMCNTs and twisting PCNTs and TMCNTs(named PCNTs-T and TMCNTs-T, respectively).The tensile strength of the untwisted fibers is lower than that of the twisted fibers, indicating that the twisted fibers are much more compact and not easy to slip between the tubes.The higher tensile strength of TMCNTs-T(1270.8 MPa)than PCNTs-T(1034.2 MPa)demonstrated the cross linking by thiol to increase the contact area between the CNT bundles is effective.Especially, the strength of TMCNTs-T with 5.54% TMMP is higher than that of the PCNTs by 191.7%.

Fig.7 Mechanical properties of functionalized CNTs fibers under different conditions

3 Conclusion

Thiol-ene click reaction was used to functionalized CNTs and improved the mechanical properties of CNTs fibers.The structure of functionalized CNT fibers was characterized by Raman spectra, TGA and SEM techniques.The effects of type and content of thiol, reaction time and post-treatment twisting of CNTs fibers on the mechanical properties have been investigated.The tensile strength of the functionalized CNTs fibers increased with the increase of the functionality of thiols, and their tensile performance increased first and decreased then with the increase of content of mercaptan and reaction time.The tensile strength of functionalized and twisted CNTs is about 1270.8 MPa, being higher about 191.7%, compared with that(435.7 MPa)of the pure CNTs fibers.The fractured micrographs of CNTs fibers were analyzed in detail and substantiated the improving mechanism of mechanical strength.This simple method about improving mechanical strength of CNTs fibers will assist the wide application of CNTs fibers.