Semi-supervised gear fault diagnosis using raw vibration signal based on deep learning

Xueyi LI, Jilin LI, Yongzhi QU, Dvid HE,c,*

a School of Mechanical Engineering and Automation, Northeastern University, Shenyang 110819, China

b School of Mechanical and Electronic Engineering, Wuhan University of Technology, Wuhan 430070, China

c Department of Mechanical and Industrial Engineering, University of Illinois at Chicago, Chicago IL 60607, USA

KEYWORDS Deep learning;Gear pitting diagnosis;Gear teeth;Raw vibration signal;Semi-supervised learning;Sparse autoencoder

Abstract In aerospace industry, gears are the most common parts of a mechanical transmission system.Gear pitting faults could cause the transmission system to crash and give rise to safety disaster.It is always a challenging problem to diagnose the gear pitting condition directly through the raw signal of vibration. In this paper, a novel method named augmented deep sparse autoencoder(ADSAE)is proposed.The method can be used to diagnose the gear pitting fault with relatively few raw vibration signal data.This method is mainly based on the theory of pitting fault diagnosis and creatively combines with both data augmentation ideology and the deep sparse autoencoder algorithm for the fault diagnosis of gear wear.The effectiveness of the proposed method is validated by experiments of six types of gear pitting conditions. The results show that the ADSAE method can effectively increase the network generalization ability and robustness with very high accuracy.This method can effectively diagnose different gear pitting conditions and show the obvious trend according to the severity of gear wear faults.The results obtained by the ADSAE method proposed in this paper are compared with those obtained by other common deep learning methods. This paper provides an important insight into the field of gear fault diagnosis based on deep learning and has a potential practical application value.

1. Introduction

The aeronautic industry must rely on highly reliable components and systems.In the aeronautic industry,aeronautic gear pitting is one of the most common failures. Undetected aeronautic gear pitting failures can even lead to catastrophic failure of aeronautic machines. Therefore, rotating machinery represented by aeronautic gear has always attracted the attention of researchers.

The diagnostic methods for aeronautic gear pitting are mainly divided into model-based methods and data-based methods. The model-based approach is based on a dynamic model for diagnosis. Fan et al.1studied the influence of the crack of the planet carrier plate on the dynamic characteristics of the planetary gear train, and the dynamic model of the torsional vibration of the planetary gear train with cracked planet carrier was established. Thus an effective method for diagnosing crack failures was found.Endo and Randall2used the minimum entropy deconvolution(MED)technique to improve the ability to exist autoregressive (AR) filtering techniques to detect local gear failures.Wang and Wong3based on the signal averaging technique established an AR model of the vibration signal for the healthy state gear. The model is then used as a linear predictive error filter to process the future state signals of the same gear and to characterize the health of the gears by characterizing the error signals between the filtered and unfiltered signals.Shen et al.4proposed a fault diagnosis model based on empirical mode decomposition (EMD) and multisensor support vector machine (TSVM) and applied to the fault diagnosis of gear reducer. Due to lower adaptability of model-based methods, most of the data-based methods are used now.Hong et al.5summarized the wear mechanism(such as abrasive wear,fatigue wear and adhesive wear),debris characteristics (such as concentration, size, morphology, and composition), and analyzed the principle of the detection method.Pandian et al.6discussed alternative approaches to reliability design, including similarity analysis, testing, and data analysis for predictive and system health management.Li et al.7studied the use of deep random forest fusion (DRFF) technology to improve the performance of gearbox fault diagnosis by using acoustic emission sensors and accelerometers that simultaneously monitor gearbox conditions. Many studies have shown that the data-based approach performs well.

The gear vibration signal collected by the acceleration sensor is usually used as a detection signal for the gearbox failure,and generally can obtain satisfactory results. Cerrada et al.8studied a stable spur gear fault diagnosis system by selecting the optimal frequency and time-frequency domain data from the vibration signal. In the monitoring environment, genetic algorithms and random forest-based classifiers are used for fault diagnosis. Using the genetic algorithm, the classification accuracy of 97%or more was still achieved.Li et al.9reviewed research progress on decoupling diagnosis of hybrid faults in gear transmission systems using vibration sensor signals. In that paper, the hybrid gearbox fault decoupling technology was discussed.

In the era of the Internet of Things and Industry 4.0,monitoring data usually has the characteristics of large data volume, fast generation speed, and high sampling frequency.Classic intelligent fault diagnosis methods include data acquisition,feature extraction and selection,and fault identification of shallow architectures.Gan et al.10proposed a multi-domain manifold(MDM)method based on singular value decomposition (SVD) and manifold learning to diagnose the mechanical equipment fault. Maurya et al.11proposed a new discriminative feature extraction technique based on the fusion of lowlevel features or hand-crafted features and high-level features to detect each fault, as well as potential abnormal in the machine. Chen et al.12elaborated the application of wavelet transform based on an inner product in the fault diagnosis of rotating machinery. Sanchez et al.13extracted 20 features from each signal in the time domain, sort them by chi-square and input them into the K Nearest Neighbor(KNN)classifier,which allows for classification accuracy evaluation of each acquired signal and features analysis. Sanchez et al.14took advantage of ranking methods such as ReliefF, Chi-square,and Information Gain are used to selecting the feature with the largest amount of information, and then reduce the size of the feature vector.Sharma and Parey15summarized the survey research based on statistical indicators according to the method used. And the unique fault characteristics of fixed shaft gearboxes were identified and studied. These methods also face many challenges, such as feature extraction that requires expertise in machine models, diagnostics, signal processing techniques, and shallow structures.

In recent years, deep learning, as a branch of machine learning,has become more and more important to researchers.Deep learning attempts to search the complexity and internal relevance of a data set.They are using multiple processing layers or complex structures to mine the hidden information in the data set for classification or other purposes.BP neural network was used to train the gears of four typical failure modes,and satisfactory results were obtained16.Jing et al.17proposed an adaptive multi-sensor data fusion diagnosis method based on deep convolutional neural network. The method is capable of learning features from raw data and adaptively optimizing combinations of different fusion levels to meet the requirements of any fault diagnosis task. Qu et al.18presented a method that integrates dictionary learning in sparse coding into an autoencoder(AE)network to perform gear pitting failure detection. That is the first time to apply unsupervised learning algorithm to pitting failure detection of gears. Wang et al.19proposed an intelligent diagnostic system based on batch normalization technology, which realized online monitoring and rapid fault diagnosis. In comparison with other existing methods, their method improved the training speed and diagnostic accuracy. Qu et al.20showed that a completely unsupervised method can potentially extract ‘‘trends” of machine health status and can be directly used for online anomaly detection or prediction. The experimental results show that the unsupervised deep sparse autoencoder (SAE)can separate the fault-related features from the uncorrelated noise.

The deep learning method, especially the unsupervised learning algorithm represented by the AE, has obvious differences from the traditional artificial neural network (ANN):deep learning can mine the hidden correlation among projects imported into the model,and unsupervised learning algorithm can extract the compression characteristics of input data without label intervention. There are certain advantages for introducing autoencoder into the field of aeronautic mechanical fault diagnosis.First,an autoencoder can learn in an unsupervised way. Therefore, when used for signal processing, it can extract features automatically and hence effectively reduces the needs for manual feature extraction that relies on human expertise in signal processing. Second, for big data training problems,autoencoder can avoid over-fitting effectively.Aeronautic machines usually have the ability to monitor data in large quantities and can use deep learning algorithms to extract features and find hidden information or correlation.A novel method presented in this paper, augmented deep sparse autoencoder (ADSAE), for diagnoses the pitting fault of the gear.

The remaining chapters of this paper are organized as follows:Section 2 elaborates on the ADSAE algorithm presented in this paper. Section 3 designed six experiments to verify the effectiveness of the ADSAE algorithm in the classification of gear pitting faults.Section 4 compares and discusses the experimental results and looks forward to future research directions.Section 5 summarizes the current research conclusions.

2. Methodology

The main idea of the ADSAE method is to make full use of the information extraction ability of SAE for high-dimensional signals, to extract the core information into lower dimension signals. And using restored high-dimensional information makes sure the SAE is efficient.The ADSAE is combined with the theory of autoencoder and data enhancement to diagnosis gear pitting faults.

2.1. Sparse autoencoder

The main methods of unsupervised learning include principal component analysis and AE. The AE is the mainstream unsupervised learning in deep learning. The autoencoder is mainly composed of input layer, hidden layer, and output layer. As shown in Fig.1,layer 1 is the input layer,from layer 2 to layer 4 are the hidden layer,and the layer 5 is the output layer.From layer 1 to layer 3 are the encoding part, and from layer 3 to layer 5 are the decoding part. In Fig. 1, there are five input units in the neural network and five corresponding output units.xirepresents the input of the neural network,and the circle labeled‘‘+1”is called the bias coefficient.The AE is a neural network model that can be used to extract features using unsupervised learning methods. The AE is reduced from the high-dimensional space to the low-dimensional space in the encoding process, and then the encoded low-dimensional feature vector is decompressed in the decoding process as shown in Fig. 1. The input data was reconstructed and mapped back to the high-dimensional space. It is suitable for target characterization, data compression, network pre-training and so on.The encoder maps high-dimensional data to low-dimensional data based on the correlation between the input data. The decoder decompresses the compressed data and uses the decoder to add data from the low-dimensional data back to the high-dimensional data during the decoding process.The encoder was used to get a valid representation.So after the training is over, the researcher generally removes the decoder and only retain the encoder. The output of the encoder can be used directly as an input to other machine learning models.

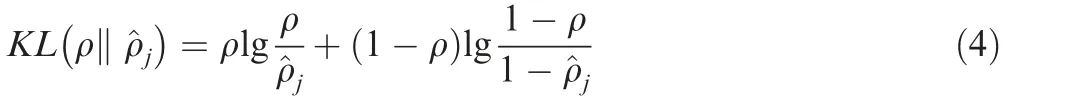

The number of artificial neurons in the hidden layer of the autoencoder may larger or smaller than the number of neurons in the input layer.If regularization constraints are added to the loss function of the artificial neural network, the autoencoder at this time can be regarded as an SAE21.In an SAE,the average value of the hidden layer neuron output should be as zero as possible, that is, most of the hidden layer neurons are inactive.Eq.(1)is the average activation^ρ of hidden layer neurons j:

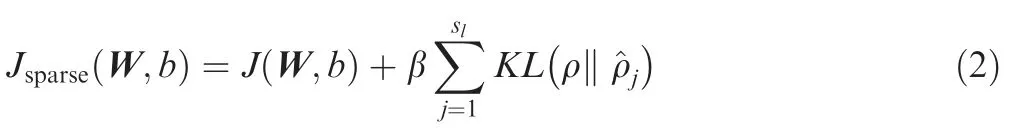

where ^ρjrepresents the average activation of the jth neuron,andmrepresents the total number of samples in the data set.indicates the degree of activation of the hidden layer neuron j given the input data is xi,and l indicates the lth layer of the neural network.The expression of the SAE loss function is:

where Jsparserepresents the loss function of SAE,W represents the weight matrix,b represents the bias term,KL represents the relative entropy (KL divergence), β is weight of the sparsity penalty term, ρ is the sparsity parameter, and slis the cells number of the lth layer.The first term in the Eq.(2)is the loss function of the AE without sparse constraints, including the mean squared term and the weighted decay term.The concrete expression of J ( W,b) is:

where λ is the weight attenuation coefficient, nl-1is network layer number, and slis the number of units in the corresponding layer.

The second term in the Eq. (2) is the sparse penalty term,and the KL distance expression is:

where the weighting coefficient for controlling the sparsity penalty term is β,and the sparsity parameter ρ is usually a smaller value close to zero.

Stacked autoencoder was proposed by Benjio et al.22Stacking autoencoder extracts the advanced features of input data layer by layer while reducing the dimension of the input data layer by layer.This process transforms a complex input data into a series of simple advanced features.Finally,the obtained advanced features are input into a classifier to classify the raw data.

2.2. The data augmentation algorithm

The data enhancement part of the proposed method mainly includes two parts. The first part is to use the stacked autoencoder,and the other part is to use the data shifting to enhance the SAE model.These two parts combine data enhancement of the raw vibration signal of the gear which was a relatively small amount of data. They can improve the detection ability of the SAE for the pitting corrosion fault of the gear effectively.

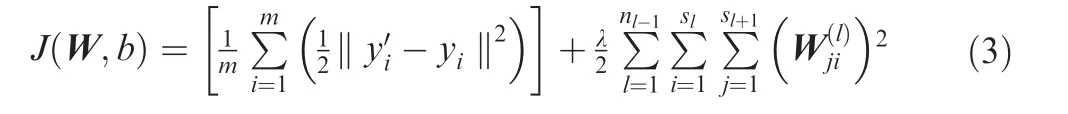

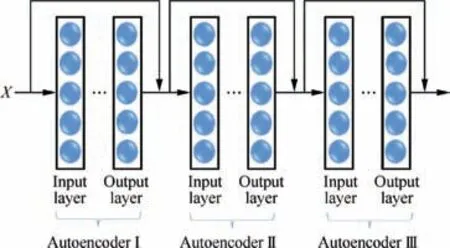

2.2.1. Augmentation of stacked autoencoders

The input characteristics of the SAE are compressed and reduced by the encoder to extract the most core information.After decoding, the data has the same dimensionality as the original data. The verified decoded data is very close to the original data,indicating that the SAE has the ability to expand the original data set while retaining the original features. As shown in Fig. 2, the original data enters the autoencoder I and is encoded and decoded to obtain decoded data of the same dimensional size as the original data set X. Then, the original data and the decoded data are input to the autoencoder II, and after encoding and decoding, we can obtain the data after decoding from the autoencoder II, and the output data is twice the size of the original input data X. The input data together with the output data from the autoencoder II as input data into the autoencoder III. After the encoding and decoding process of the autoencoder III,the encoded data of 4 times the original data is obtained from the autoencoder III. Therefore, the problem of insufficient data volume can be partially solved, and the deep learning algorithm is better for feature extraction.

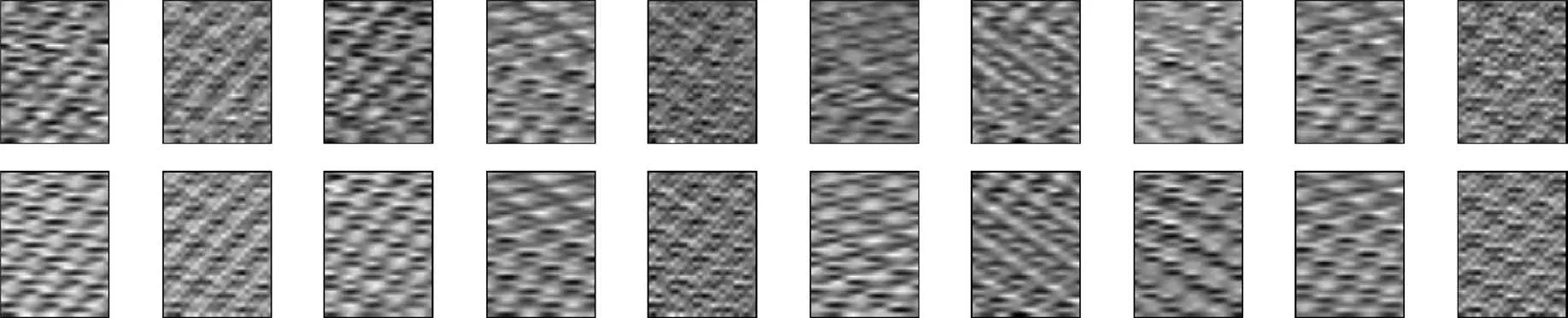

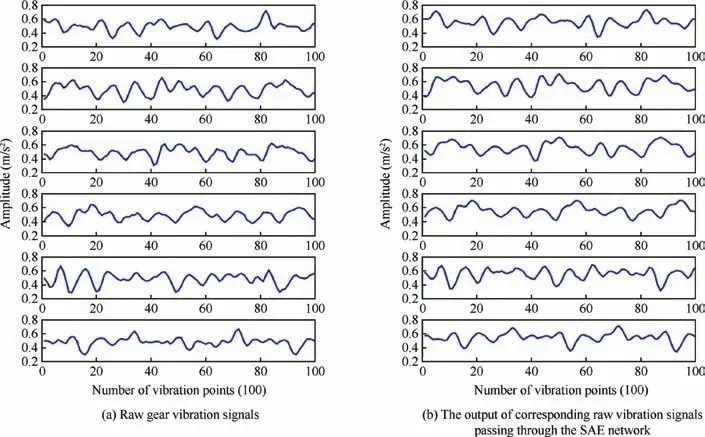

As can be seen from Fig.3,the image of the upper row is a visualized image formed by the raw vibration data of the gear before entering the encoder.It can be seen from the figure that there are some differences in different signal data. The lower row of images is an image formed by the SAE process. It can be seen from the figure that the gears of different states have very similar characteristics between before the SAE and after the SAE.These can be a good indication of the good performance of the SAE for the compression of the signature signal.

Fig. 2 Principle of using autoencoders to enhance data.

2.2.2. Augmentation of data shifting

Since deep learning is a fully connected network, each set of feature data enters the neural network for training in units of samples. And more group data can be obtained by shifting a specified length in the overall sample. In general, the more data that is trained in deep learning, the stronger the learning ability of the network for features and the better the learning effect. In the field of picture recognition,23this method has been used to improve the recognition ability of items in pictures and has achieved good results.

The total number of sample points for collecting data is N.The number of points that extract sample characteristics during a period of gear rotation is R. The starting position is ε,and k is a decimal between 0 and 1. So the initial position ε can be acquired by Eq.(5),where k is the coefficient.All points in this dataset Xican be expressed by Eq. (6).

2.3. The general procedure of the proposed method

In this paper, the augmented method of data smooth shifting extraction data is combined with the SAE method. On the one hand, the enhancement of data can be used to improve the learning ability of the network for gear pitting characteristics. On the other hand, SAE can be used again to compress and decompress the raw signal, extracting more efficient features from the input of the SAE to detect and classify the gear pitting failure.

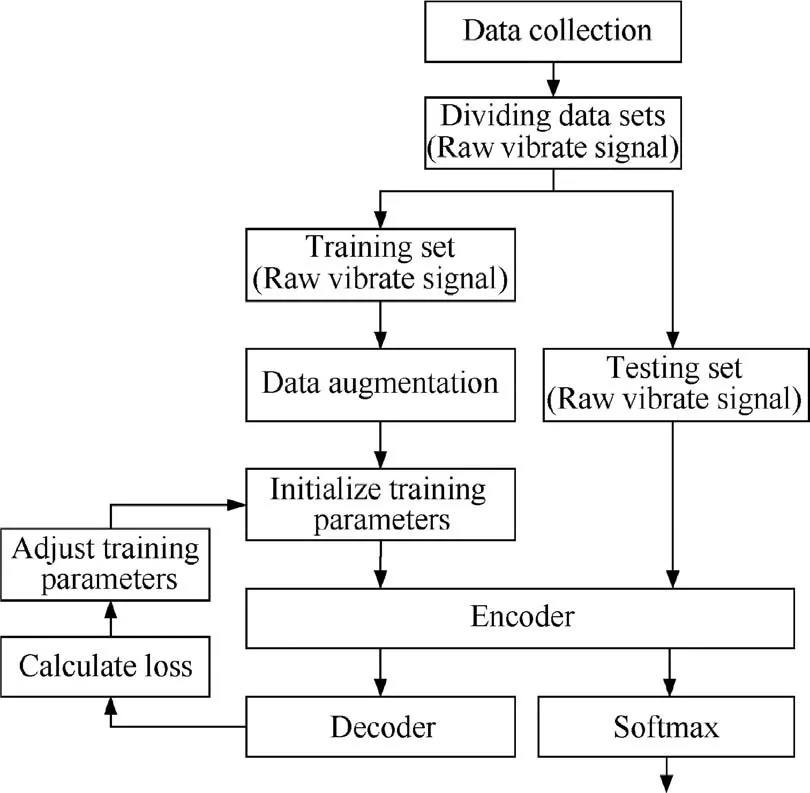

The method proposed in this paper is aimed at the diagnosis of gear pitting, which is mainly divided into three parts:data collection,network training,and gear pitting fault identification and classification. In the data collection part, the accelerometer sensor is mainly used to collect the raw vibration signals of the gear. In order to train in the deep learning network better, the collected data is normalized so that all the data have a uniform mean and variance.The network training part mainly uses the back-propagation algorithm to adjust the structure and hyperparameter of the network so that the ADSAE structure can effectively learn the core compressed information from the training data. In the fault identification and classification part,the softmax layer is used to classify the part of the encoder that was trained in the previous step. And the test set is used to verify the correct rate of the training result.

Fig. 3 Visual image of gear raw vibration signals before and after the SAE.

The general flow of the method proposed in this paper is shown in Fig. 4.

1. Collect the raw vibration signal of the gear, and divide the vibration signal data into a training set,verification set,and test set according to the ratio of 80%, 10%, and 10%.

2. Process the training set according to the two enhancement methods described above.

4. Using the back-propagation algorithm, the verification set data, and loss function to adjust the training parameters,optimize the network parameters and weights, and train the ADSAE network. Each ADSAE is independently trained before stacking to ensure that each ADSAE is converged.

Fig. 4 General procedure of the presented ADSAE method.

5. Input the test set to the encoder portion of the ADSAE and input the compressed feature from the encoder to the softmax classifier to classify the pitting of the gear.

3. Gear pitting diagnosis test setup

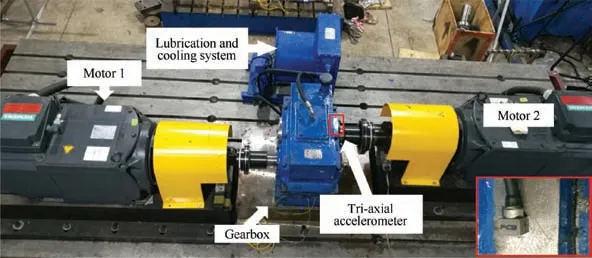

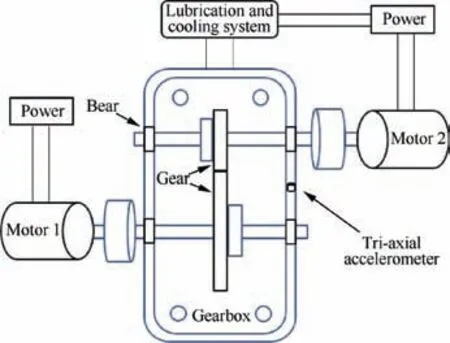

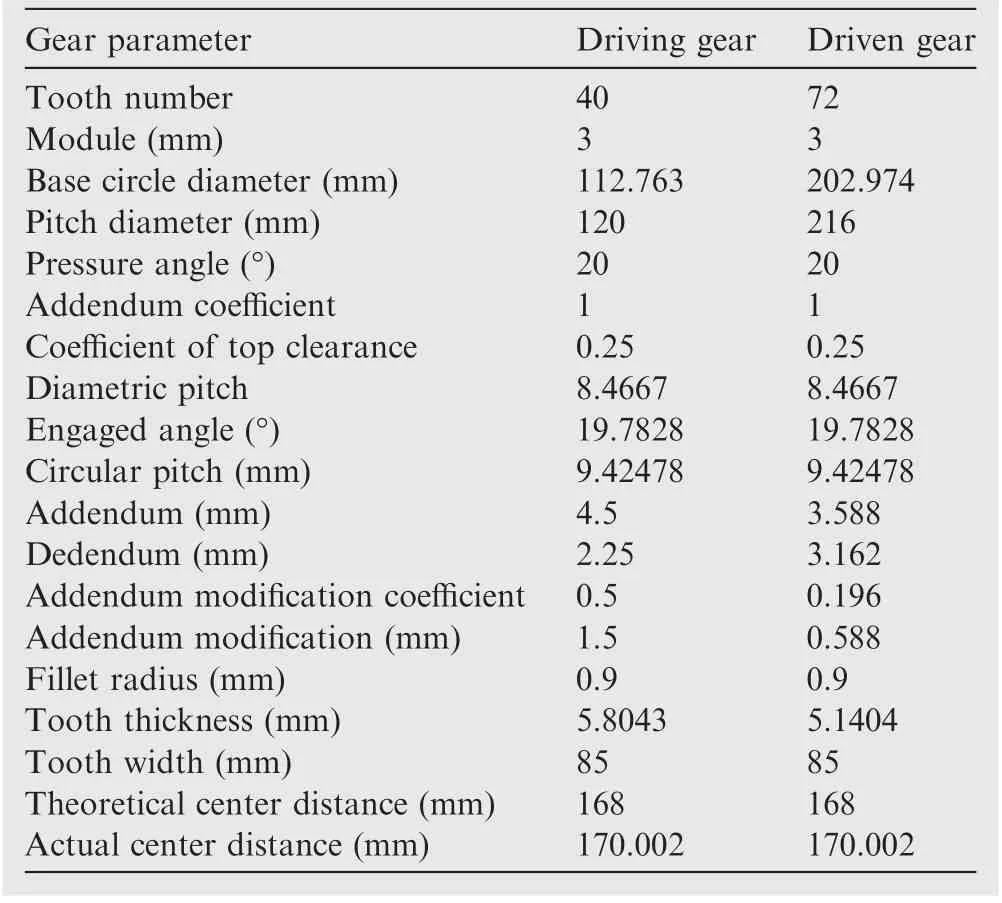

The test bench is shown in Fig.5,consisting mainly of lubrication and cooling system, tri-axial acceleration sensor, and two 45 kW Siemens servo motors.One of the motors act as a drive motor,and the other be configured as a load motor. The electrically enclosed test rig is more cost effective than a conventional open loop test rig. It can configure any load and speed specification within the rated power range. The experimental gearbox is supported by four sets of bearings and a pair of gears engage and rotate. The tri-axial acceleration sensors are mounted on the outside of the gearbox to collect vibration signals of the gearbox.All experiments were carried out under the same conditions to avoid the impact of changes in the external environment around the gearbox. In the experiment,the sampling rate was set as 20.48 kHz and the sampling time interval was 6 s. Five sets of sample data were collected for each condition and a total of 30 sets of independent sample data.During the experiment,vibrational signals in three directions were collected. In the data processing, only signals from the vertical direction were used. The principle of experimental verification device is shown in Fig. 6. Enough gears were purchased to ensure the smooth running of the experiment. The parameters of the experimental gear are shown in Table 1.

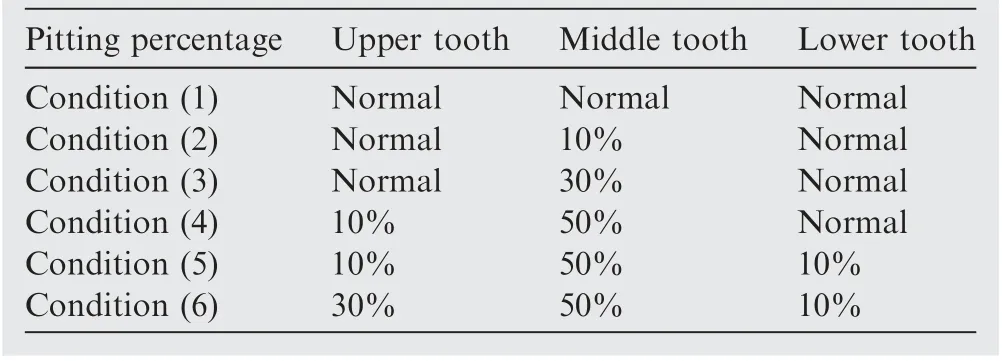

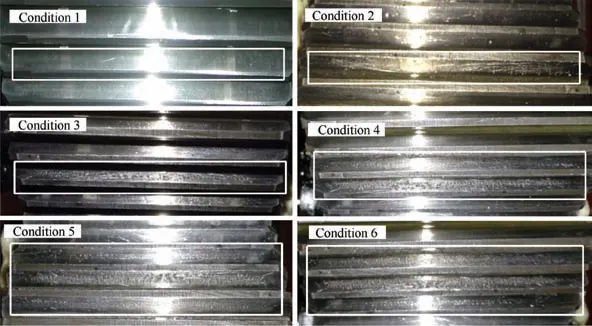

Pitting corrosion of six gears as shown in Table 2. The pitting percentage was quantified by identifying the pitting area using the Adobe Photoshop software. The percentage of pitting is the ratio of the area of the pitting of the tooth surface to the total area of the tooth surface. Pitting percentage is an approximation and is primarily used to distinguish the severity of gear pitting fault. Condition (1) is a healthy gear without pitting wear. The Condition (2) and the Condition (3) have only the middle teeth slightly pitting. The intermediate tooth pitting degree of Condition (2) and Condition (3) has about 20%and 30%,respectively.From Condition(4)to the Condition (6) in addition to the middle teeth have pitting, the adjacent tooth has different degrees of pitting corrosion. The intermediate tooth of the Condition (4) has 50% pitting,and the upper tooth adjacent to the intermediate teeth have 10% pitting. The intermediate tooth of the Condition (5) has about 50% pitting, and each of its adjacent upper and lower teeth has 10%pitting.The intermediate tooth of the Condition(6) has 50% pitting, about 30% of the pitting of the adjacent upper tooth,and about 10%of the wear of the adjacent lower tooth.

Fig. 5 Photo of experimental equipment.

Fig. 6 Experimental test device schematic.

Table 1 Main parameters of the gearbox.

Table 2 Percentage of pitting of gears in six states.

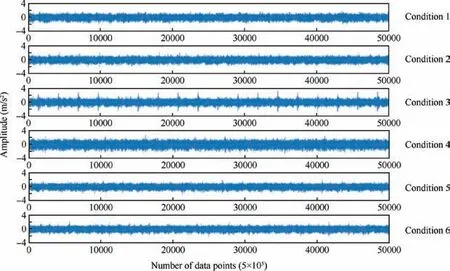

The picture of the specific degree of pitting is shown in Fig. 7. Different pitting degrees can be seen in the picture.Fig. 8 is a visualization of the raw vibration signal. The raw vibration signal data length for each pitting state is 50,000 points.It can be seen from the figure that there is no significant difference between the raw vibration signals of the gears of the six different pitting states. If look closely, one can see that the raw vibration signal of Condition (3) has a relatively obvious oscillation point. The raw vibration signal of Condition (4)has a slightly larger magnitude. In the remaining five conditions,the gears can hardly directly classified directly depending on the eyes. Under the premise of not transforming the raw vibration signal in the time domain, the raw vibration signal is processed by the ADSAE algorithm proposed in this paper.

As shown in Fig. 9, the left part is the raw vibration signal of the gear,and the right part is the output of the corresponding raw vibration signal passing through the SAE network. It can be seen from the six sets of signals in the figure that the vibration characteristics after the SAE signal are very similar to the raw signal. Although the characteristic is compressed,almost all characteristic signals of the gear are retained in the process of the SAE. It is apparent from the image that the SAE can effectively retain the characteristics of the raw vibration of the gear and can generate a signal that is very close to the raw signal.

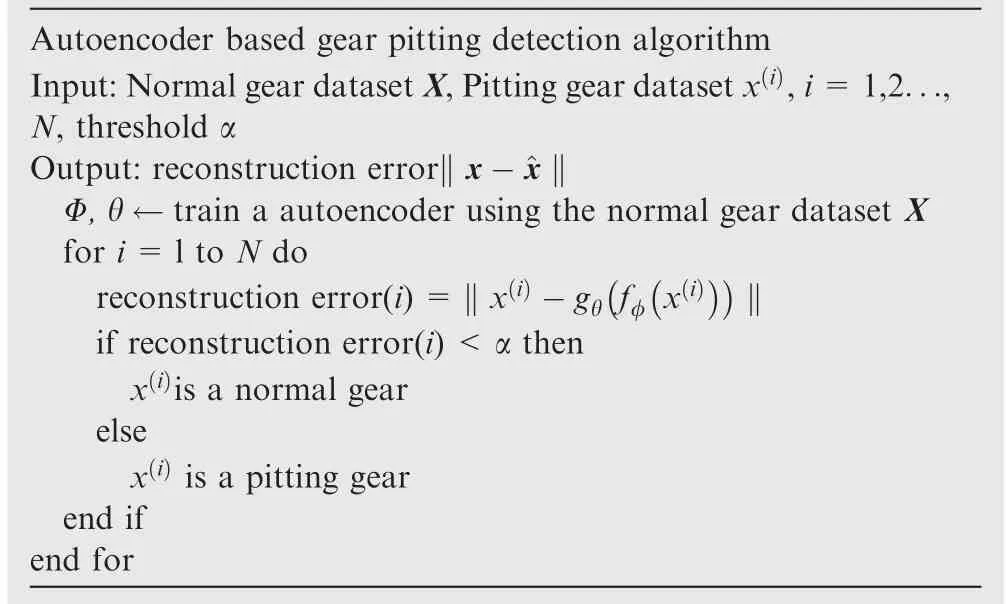

Judging whether the gear is normal or not according to the pseudo code of Table 3, the similarity of the pitting corrosion is also judged by a similar method. In this experiment, each sample includes 768 feature points,and the number of neurons in each layer of the neural network is 768-384-192-96-192-384-768, respectively. A total of 50 thousand augmented training set samples participated in the training of ADSAE networks.The optimizer uses the stochastic gradient descent(SGD)algorithm, and the loss uses the classification cross entropy. The initial learning rate was set to 0.01, the attenuation is 1×10-6,the momentum is 0.9,and the activation is relu.This training uses the Windows 7 operating system,with Intel Core i5-6500 processor, Nvidia GeForce GTX 1080 Ti graphics card, Kingston DDR4 16 GB memory. The software used in this experiment is mainly Python 3.6, CUDA 8.0, cudnn 9.2.

4. Results and discussions

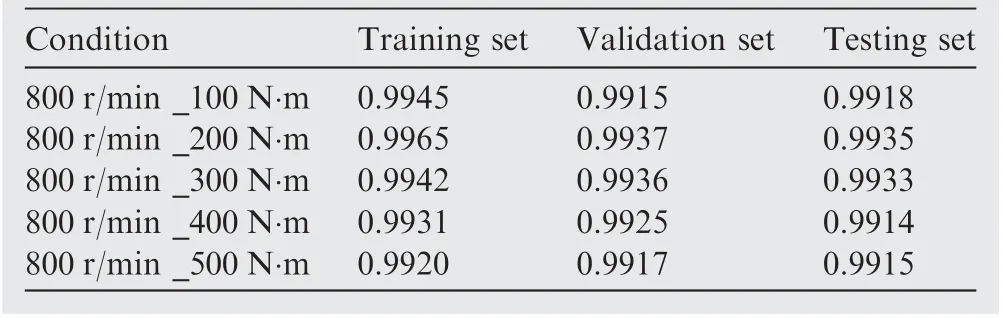

It can be seen from Table 4 that for the gear pitting faults of the same speed under different loads, the proposed ADSAE algorithms can effectively diagnose the different pitting faults of the gears, and the correct rate is over 99%. For different loads, the accuracy of the proposed method for the training set, the verification set, and the test set is similar, and there is no obvious over-fitting phenomenon. The results show that the proposed method is effective for gear pitting diagnosis.

The ADSAE proposed in this paper is compared with other deep learning methods.The experimental conditions are under 800 r/min and 400 N·m torque. It can be seen from the results in Table 5 that the proposed method not only has high classification accuracy for gear pitting but also can effectively avoid over-fitting. Other deep learning methods have more or less over-fitting, and the accuracy is not particularly desirable.

Fig. 7 Pictures of pitting wear of six gears.

Fig. 8 Raw gear vibration signal under different pitting failure condition.

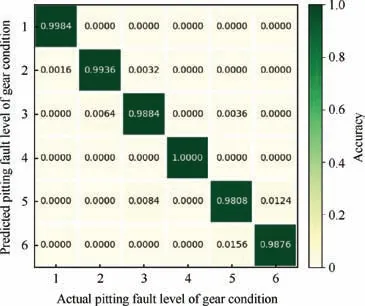

As can be seen from Fig.10,the identification rate of Condition (4) is 100%. The recognition rate of the other gear pitting is also above 98%.Looking at the confusion matrix,it can be seen that for gears with only intermediate tooth pitting,0.16% of Condition (1) (normal gears) are misjudged as Condition(2)(gears with 10%pitting).0.64%of gear in Condition(2) was mistaken for Condition (3) (gear with 30% pitting).Similarly, Condition (3) is 0.32% misjudged as the gear of the Condition (2). For Condition (5) and Condition (6), gears with intermediate tooth 50% pitting and the adjacent upper and lower teeth also with pitting failure,the probability of misjudging each other are 1.56% and 1.24% respectively. In general,the misjudged gears are mainly concentrated on the gears that are close to their pitting characteristics. This may be because the gear pitting is relatively close, resulting in similar original vibration signals.

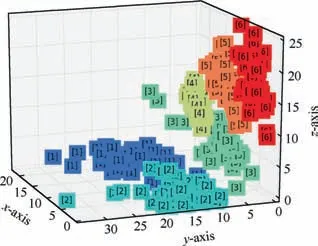

Fig. 11 shows the clusters of the features in a threedimensional space. The numerical values are the outputs obtained by using the ADSAE method proposed in this paper to pass the test to the trained encoder. According to Section 3 of this paper,the number of neurons in the middle layer of the trained autoencoder was 96. In order to be able to display the features in the three-dimensional plane,the number of neurons in the middle of the autoencoder hidden layer was gradually reduced to 3 to carry out dimensionality reduction. The number of neurons in each layer of the ADSAE network was 96-48-24-12-6-3-6-12-24-48-96. The positions of the gears with different pitting degrees are different in the three-dimensional visualization. It is showing a certain change trend with the change of the degree of pitting of the gears. The numbers on each color in the figure are the digital status labels for the different gears in Table 2. It can be seen from Table 2 that the greater the number, the more serious degree of gear pitting fault.As can be seen from Fig.11,the normal gear of the condition (1) has a large value in the x-axis direction, the data coordinate in the y-axis direction is relatively large, and the coordinate value in the z-axis direction is small. As the degree of pitting corrosion increases, the coordinate value in the xaxis direction gradually decreases, and the coordinate value in the y-axis direction also gradually decreases.The coordinate value increases continuously with the increase of the degree of gear pitting failure in the z-axis direction.The contrast in the zaxis direction is most pronounced. Gear pitting with larger zaxis values must be more severe than gear pitting wear with smaller z-axis values. Gear pitting faults for the condition (6)generally have smaller x and y-axis coordinate values and have larger z-axis coordinate value. The gear pitting fault in the middle is also consistent with the overall trend.

Fig. 9 Gear vibration signals.

Table 3 Pseudo code for gear pitting fault detection based on sparse autoencoder.

Table 4 Accuracy comparison between 800 r/min under different loads.

Fig. 10 Confusion matrix by the presented algorithm for the testing set.

Fig. 11 Visualization of three-dimensional features of gear pitting conditions.

The future research will include extending the developed ADSAE algorithm to diagnosis of other types of mechanical component faults, for example, bearing and engine faults.

5. Conclusions

In this paper,an ADSAE algorithm for gear pitting fault diagnosis was presented. This algorithm uses SAE and data shifting methods to enhance the semi-unsupervised learning.Therefore, the gear pitting fault can be effectively detected.The method presented in this paper can effectively expand small training samples, and use the raw vibration signals and semi-supervised learning method to detect the pitting faults of the gear. The effectiveness of the proposed method was tested by experiments. The results of the gear pitting fault detection rate exceeded 99%.By comparing it with other deep learning methods, the accuracy of the ADSAE method is the highest, which can meet the classification and detection requirements for gears with different pitting conditions.

Acknowledgements

This study was supported by the Natural Science Foundation of China (No. 51675089).

CHINESE JOURNAL OF AERONAUTICS2020年2期

CHINESE JOURNAL OF AERONAUTICS2020年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Delaying stall of morphing wing by periodic trailing-edge deflection

- Optimization and verification of free flight separation similarity law in high-speed wind tunnel

- Non-intrusive reduced-order model for predicting transonic flow with varying geometries

- Consideration on aircraft tire spray when running on wet runways

- Aeroelastic simulation of the first 1.5-stage aeroengine fan at rotating stall

- Experimental study on NOx emission correlation of fuel staged combustion in a LPP combustor at high pressure based on NO-chemiluminescence