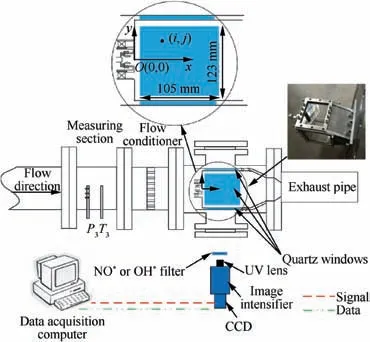

Experimental study on NOx emission correlation of fuel staged combustion in a LPP combustor at high pressure based on NO-chemiluminescence

Zhicho WANG, Yuzhen LIN, Jinchen WANG, Chi ZHANG,*,Zhijun PENG

a National Key Laboratory of Science and Technology on Aero-Engine Aero-thermodynamics, Collaborative Innovation Center for Advanced Aero-Engine, School of Energy and Power Engineering, Beihang University, Beijing 100083, China

b Creative Arts, Technologies and Science, University of Bedfordshire, Luton LU1 3JU, UK

KEYWORDS Combustors;Lean staged combustion;Low emissions;NOx correlation;Optical diagnosis

Abstract Experimental investigations on NOx emissions of a single-cup,Lean Premixed Prevaporized (LPP), module combustor were carried out at elevated inlet temperature and pressure up to 810 K and 2.0 MPa, close to the real operating conditions of aero-engine combustors. This LPP combustor adopts centrally staged fuel injections which could produce separated stratified swirling spray flame. In the NOx emissions measurements, the ranges of dome equivalence ratio and fuel stage ratio were from 0.55 to 0.58 and 8%to 24%,respectively.The optical diagnosis on separated stratified swirling spray flame were carried out with fuel stage ratio changing from 15% to 30%.Therefore, NO* and OH* chemiluminescence images were obtained. The results show that NOx emissions increase with the increase of the fuel stage ratio.And from the chemiluminescence images,the main flame and pilot flame are found weakly coupled.The pilot flame plays a significant role in NOx emission production because of its higher adiabatic flame temperature.Based on the results of chemiluminescence optical tests, a new NOx emission prediction model is proposed based on the Lefebvre’s single flame model. The estimate of local equivalence ratio of the pilot stage’s nonpremixed flame is modified considering the characteristics of spray combustion, and a ‘‘PLUS”emission prediction model suitable for separated stratified swirling spray flame is obtained. Compared to the experimental data, the ‘‘PLUS” model exhibits a good prediction in a range of±13% of deviation.

1. Introduction

The vigorous development of the aviation industry has brought environmental pollution problems.1,2The International Civil Aviation Organization (ICAO) has implemented increasingly stringent international standards on environmental emissions, putting forward higher requirements for the design of gas turbine combustor.Modern aviation gas turbine combustors have adopted different low emissions combustion technologies. Representative low emissions combustion technologies include Rich-burn/Quench/Lean-burn (RQL),3-5Lean Direct Injection (LDI)6,7and Lean Premixed Prevaporized (LPP).8-12

In order to achieve better combustion stability and lower emission performance, LPP combustor can adopt separated stratified swirling spray flame mode, such as Twin Annular Premixing Swirler (TAPS) of General Electric (GE),8Lean-Burn of Rolls-Royce(R-R),13Lean stage fuel injector of Japan Aerospace Exploration Agency(JAXA)14and the Technology of Low Emissions of Stirred Swirl (TeLESS) of Beihang University.15,16These low emissions combustors generally adopt a centrally staged structure which is comprised of the pilot and main stages. The pilot stage is located at the center of the combustor’s dome with non-premixed flame to guarantee the combustion efficiency and combustion stability under low power conditions such as idle and approach. The main stage is arranged in the out circle of the dome with a premixed flame mode to reduce NOxemission under high power conditions such as takeoff, climb and cruise. Many researchers had carried out detailed investigations on various properties of separated stratified swirling spray flame including flame structures,17-19flow field characteristics,20,21combustion instability,17,22-24NOxemissions25,26and so on.

For the NOxemission characteristics of separated stratified swirling spray flame, as the pilot stage flame adopts nonpremixed flame mode and the main stage flame adopts premixed flame mode,NOxemission characteristics of the double flame are complicated. Moreover, interactions of the two flames may have some impacts on the NOxemission, which will increase difficulty in investigating the NOxemission mechanisms in the centrally staged LPP combustor.

For the prediction of NOxemissions in combustors, the methods mainly include empirical formula,25,27,28reactor networks26and numerical simulation.29Compared to the reactor networks and numerical simulation methods, the empirical formula has advantages such as simplicity and simultaneously reasonable accuracy, which can provide guidance for the conceptual design of combustors and engines. The empirical formula for NOxemissions of diffusion flames in conventional combustors had been proposed by Refs.30-35,and the relationship between NOxemissions and combustor parameters, such as operating conditions, fuels and geometries, had been summarized. These empirical models were dedicated to provide good predictions of different conventional combustors’ emissions. However, for the separated stratified swirling spray flame in centrally staged LPP combustor, only few empirical NOxemission models were developed.25,28In order to make the NOxemission model of the separated stratified swirling spray flame in this paper achieve higher prediction accuracy,it is necessary to construct the emission model of separated stratified swirling spray flame based on the characteristics of NOxformation. Therefore, the emission model can achieve better accuracy of NOxemission prediction with sufficient consideration of physical process.

One of the main purposes of this paper is to investigate the NOxemission characteristics of separated stratified swirling spray flame in centrally staged LPP combustor, especially the effects of fuel stage ratio on NOxemission. The other purpose is to establish an empirical NOxemission model suitable for this kind of flame. In this paper, experimental investigation was conducted on the model combustor with the next generation of Technology of Low Emissions of Stirred Swirl (TeLESS-II)15,16developed by Beihang University which adopts separated stratified swirling spray flame. A single-cup module rectangular combustor was adopted to perform emission characteristic tests and optical diagnosis tests respectively under elevated temperature and pressure operating conditions. NOxemission data was obtained through emission characteristics tests at elevated inlet temperature and pressure, while NO* and OH* chemiluminescence images were obtained through optical diagnosis tests.The effect of fuel stage ratio on the NOxformation in the separated stratified swirling spray flame had been investigated from the relationship between emission data and chemiluminescence image. At last, a NOxemission prediction model of separated stratified swirling spray flame was built and validated.

2. Experimental setup

2.1. Module combustor configuration

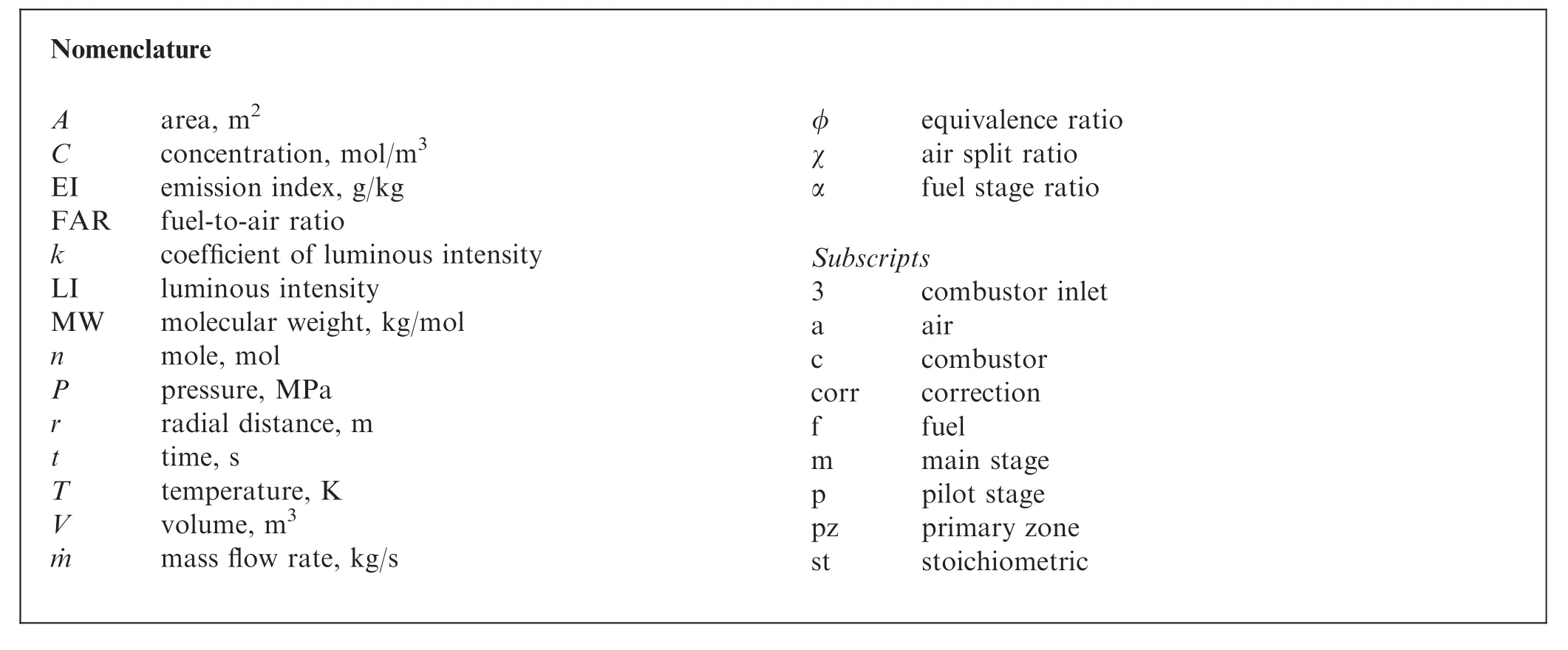

The TeLESS-II combustor tested in this paper is a single-cup module rectangular combustor.15,16The main structure of the module combustor and size of the swirler are presented in Fig. 1. In addition, the width of the module combustor is 110 mm. The combustor is comprised of two stages: the main stage and pilot stage.The pilot stage is comprised of a pressure swirl atomizer and a dual radial swirler,which can enhance the atomization of fuel and form a non-premixed flame to stabilize the flame under various operating conditions. The main stage includes an axial swirler and a fuel nozzle injecting fuel from multiple orifices which are uniformly distributed in the circumferential direction. The main stage fuel can mix with swirling air in the annulus passage,experiencing premixed and prevaporized process.The lean premixed flame of the main stage can reduce emissions under high power conditions by forming uniform fuel-air mixture and lowering the flame temperature. In Fig. 1, ˙ma,mand ˙ma,prepresent the air mass flow rate of main and pilot stage, respectively. ˙mf,mand ˙mf,pare the fuel mass flow rate of the main and pilot stage respectively.

2.2. Emission test rig

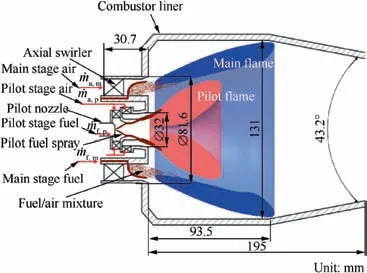

The experimental facilities for the emission characteristics test are shown in Fig.2.25The experimental system can provide the air with mass flow rate to 3.0 kg/s and pressure to 3.0 MPa,and the air can be heated by a heat exchanger up to a maximum temperature of 850 K. The mass flow rate of air is controlled by a flow control valve and measured by the orifice plate whose precision is ±0.5%. The air temperature is measured by a K-type thermocouple with the precision of ±1%.The mass flow rate of kerosene fuel is measured by fuel Coriolis mass flowmeter,and the measurement precision is±0.5%.

Fig. 1 Schematic diagram of separated stratified swirling spray flame in single module rectangular combustor.

The gaseous emission measurement system are configured in accordance with the test specifications in ICAO Annex 16 Environmental Protection Volume II for aviation engine emissions.36The measurement system is comprised of sampling probe, transfer pipe, gas analyzers, and smoke analyzers.The gas enters the transfer pipe after being collected by the probe with 10 sampling holes (diameter of 1.0 mm). The temperature of the transfer pipe is automatically controlled in the range of 165±5°C by electrical heating.Through the transfer pipe, the gas enters the gas analyzers. The gas analyzers are comprised of five parallel gas analyzers, including a CO analyzer, a CO2analyzer, an O2analyzer, an Unburned HydroCarbon (UHC) analyzer and a NOxanalyzer.25The measurement accuracy of NOxand UHC analyzer is ±1%while other analyzers’ accuracy is ±2%.

The emission data obtained from the gas analyzer are processed into the Emission Index (EI), which obeys the second part of the ICAO Annex 16 Volume II.36

2.3. Optical diagnosis

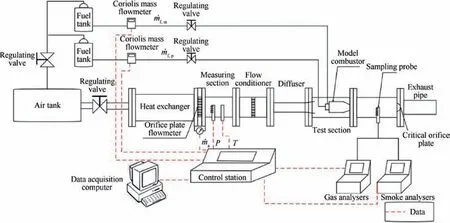

To investigate the mechanism of NOxformation in separated stratified swirling spray flame, optical diagnoses on NO* and OH*chemiluminescence were carried out at elevated temperature and pressure. The experimental facilities for optical diagnosis are shown in Fig.3.The system is mainly composed of an Intensified CCD (ICCD) camera, achromatic UV lens, filters and image acquisition computer.

The ICCD camera is composed of image intensifier and CCD camera (Imager ProPlus/ProX2M). The view field of ICCD camera is 40 mm×40 mm and the resolution is 1600 pixel×1200 pixel. Considering the chemiluminescence intensity of two different radicals, the gain of camera is set at 60 for OH* and 70 for NO*. The frequency of imaging is 30 Hz (exposure time 90 μs) and 100 snapshots of stabilized flame are taken for each operating condition. The UV lens(focal length f=105 mm, aperture f/4.5, filter range 290-1100 nm) is equipped on the ICCD. For the specific wavelength of the OH* and NO* chemiluminescence, the filters used in this paper are shown as follows:(A)OH*:center wavelength is 307 nm, bandwidth is 10 nm; (B) NO*: center wavelength is 240 nm, bandwidth is 10 nm.

A two-dimensional coordinate is marked in Fig. 3 for the propose of processing the flame image conveniently.The origin of coordinate is set at the center of the outlet of pilot stage.xaxis is defined as the flow direction and y-axis is defined as the radial direction.Therefore, each pixel on the flame picture are defined as a location (i, j). The view of optical glass windows starts at 9.5 mm downstream from the origin and the size of each quartz window is 105 mm×123 mm.

2.4. Test conditions

In order to investigate the NOxemission characteristics,a series of experimental parameters had been changed in this research including inlet temperature T3,inlet pressure P3,overall mass flow rate of air ˙ma,dome equivalence ratio φdome,and fuel stage ratio α.Since the fuel stage ratio α has great impacts on the properties of separated stratified swirling spray flame,it is chosen as the most important parameter and has been changed over a relatively large range.Fuel stage ratio α is defined as the ratio of fuel mass flow rate of pilot stage to total fuel mass flow rate, as shown in Eq. (1).

Fig. 2 Schematic diagram of experimental facilities for emission characteristics test.25

Fig. 3 Schematic diagram of experimental facilities for optical diagnosis tests.

Here, ˙mf,totalrepresents the total fuel mass flow rate.

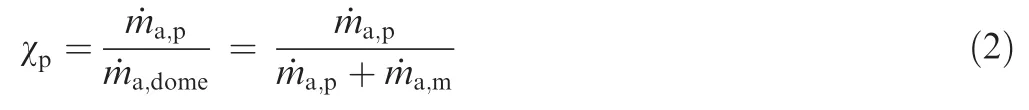

The air split ratio of the pilot stage χpis defined as the ratio of air mass flow rate of the pilot stage to air mass flow rate of the dome, as shown in Eq. (2).

where ˙ma,domerepresents the air mass flow rate of the dome.The air split ratio of the dome χdomeis defined as the ratio of air mass flow rate of the dome to air mass flow rate of the combustor, as shown in Eq. (3).

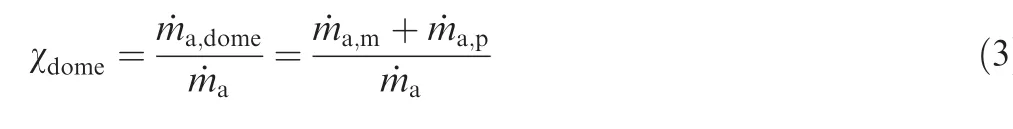

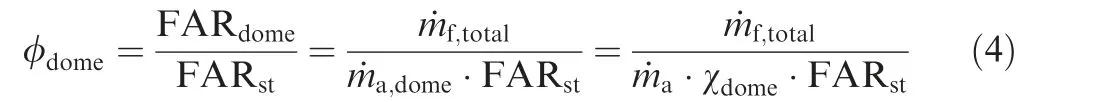

The dome equivalence ratio φdomeis defined as the ratio of dome fuel-to-air ratio to stoichiometric fuel-to-air ratio, as shown in Eq. (4).

Here,FARdomeand FARstrepresent the dome fuel-to-air ratio and stoichiometric fuel-to-air ratio, respectively. The FARstvalue of aviation kerosene is 0.068.

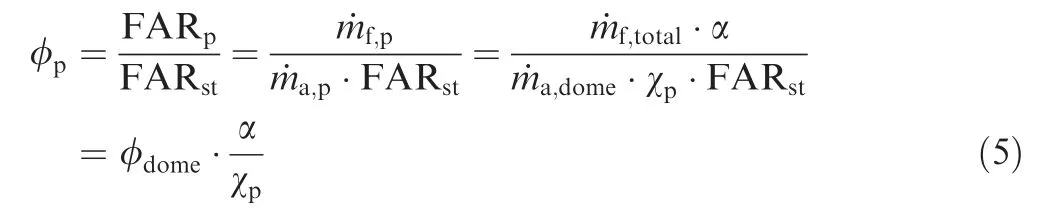

The pilot stage equivalence ratio φpis defined as the ratio of the pilot stage fuel-to-air ratio to stoichiometric fuel-to-air ratio, as shown in Eq. (5).

where FARprepresents the pilot stage fuel-to-air ratio.

The main stage equivalence ratio φmcan also be obtained,as shown in Eq. (6).

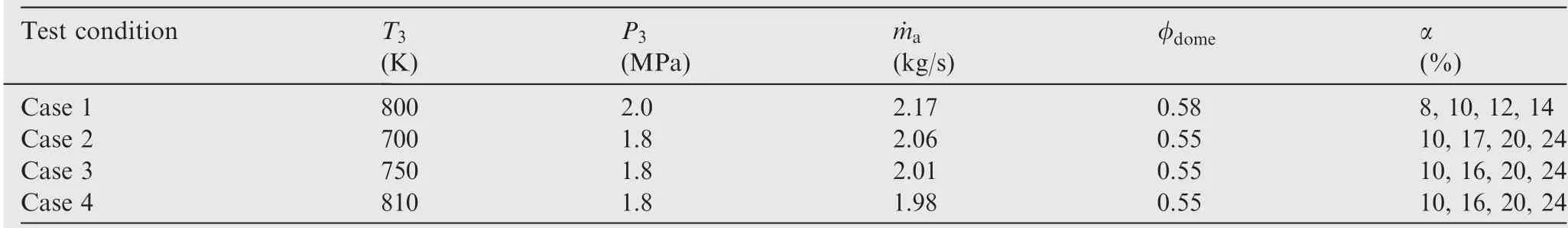

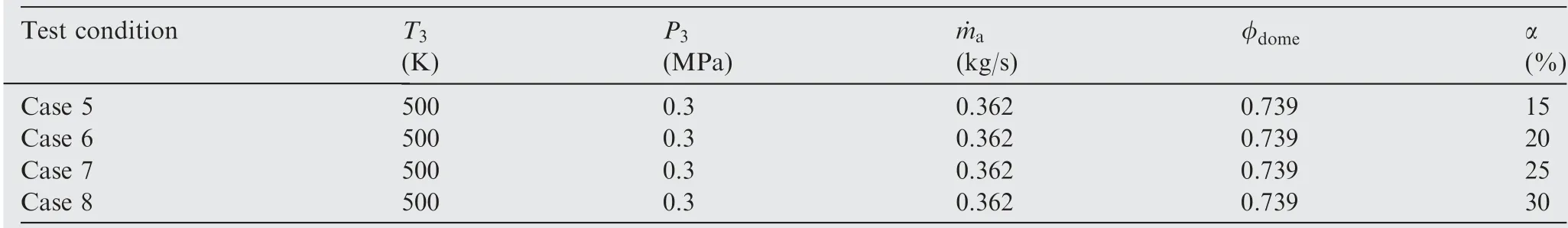

Operating conditions for NOxemission characteristics and optical diagnosis tests are shown in Tables 1 and 2,respectively.

3. Results and discussion

3.1. NOx emissions

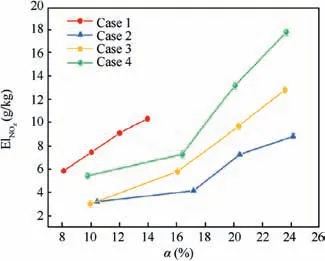

The NOxemission data of Cases 1-4 are shown in Fig. 4, and the uncertainty is ±1.86%. The uncertainty analysis methods for NOxemission index and accuracies of each gas analyzer proposed by Ref.25are adopted.

In Fig. 4, the horizontal ordinate represents the fuel stage ratio and the vertical coordinate represents the NOxemission index (EINOx, g/kg) which means the mass of formed NOx(g) by consuming one kilogram of fuel. For each curve, the NOxemission increases when α becomes larger.This is because the main flame works as the premixed flame mode,and its adiabatic flame temperature is lower than the pilot flame which works as the non-premixed flame mode. Therefore, with α increasing,the proportion of pilot flame becomes larger,causing the NOxemissions to increase.Moreover,Fig.4 shows that the NOxemission is sensitive to α. For example, while α increases from 9.77% to 23.67% for Case 4, the EINOxincreases from 5.45 g/kg to 17.87 g/kg. In addition, a comparison between Case 2 and Case 4 indicates that under specific P3and φdome, the NOxalso increases with T3increasing. This is because the increase of T3will make the adiabatic flame temperature of dual flame increase simultaneously, causing the NOxemission to increase.

Table 1 Test conditions for NOx emission characteristics.

Table 2 Test conditions for optical diagnosis.

Fig. 4 Effects of fuel stage ratio on NOx emission under different inlet temperature, pressure and dome equivalence ratio.

3.2. NO* and OH* chemiluminescence

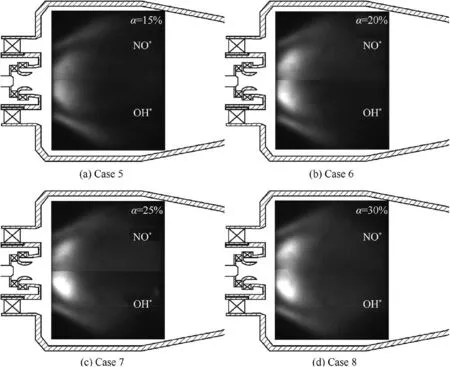

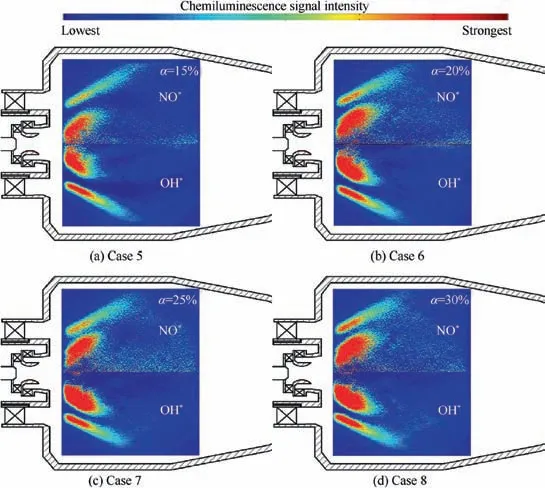

Fig. 5 shows the time-averaged images of line-of-sight NO*and OH* chemiluminescence of separated stratified swirling spray flame. For the convenience of comparison, the timeaveraged images of NO* and OH* chemiluminescence are stitched together.

In Fig.5 it is shown that the main flame and pilot flame are relatively independent, and the flame morphology does not change significantly with the increase of fuel stage ratio. Considering that the time-averaged flame in the combustor is approximately cylindrical symmetric, the images in Fig. 5 can be deconvoluted using Abel inversion transformation method, which can represent quasi-2D cuts through the flame.37Therefore,the distribution of NO*and OH*chemiluminescence in the central cross-section can be achieved. These images are then processed by pseudo color, with the red and blue regions indicating the strongest and lowest chemiluminescence signal intensity, respectively, as shown in Fig. 6.

According to Refs.38-40, the chemiluminescence signal intensity can represent the concentration of radicals, and the OH* concentration is positively correlated with temperature.In Fig. 6, the NO* radicals mainly distributed near the main flame and pilot flame while a little part exists in the center recirculation zone. From the deconvoluted images of OH*chemiluminescence, it is found that the separated stratified swirling spray flame of TeLESS-II is a kind of weakly coupled flame which means that the main flame and pilot flame are relatively independent. There is a clear demarcation between the main flame and pilot flame. However, Driscoll et al.17,23have different results compared with ours. Strongly coupled main flame and pilot flame without clear demarcation were found in their combustors.

As the distribution of NO* is consistent with that of OH*which is an indicator of temperature, the NO* formation is mainly caused by the local high temperature in the combustor.In other words, the thermal mechanism dominates the NO*formation and the flame temperature mainly affected NOxproduction.

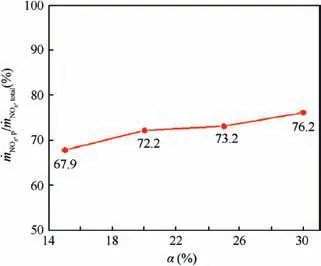

In order to clarify the effect of fuel stage ratio on NOxemissions, NO* chemiluminescence images are processed as follows. According to Ref.40, the spatial radiation is proportional to the molar concentration of the radical. The concentration of radical at each pixel (i, j) is approximately considered to be proportional to its Luminous Intensity (LI),as shown in Eq. (7).

Fig.5 Time-averaged images of NO*and OH*chemiluminescence (each image is averaged over 100 pictures with an exposure time of 90 μs each).

Fig. 6 Abel deconvoluted NO* and OH* chemiluminescence images.

where k is defined as a constant coefficient of luminous intensity.

The mole of NO* can be calculated by Eq. (8).

Here, Vijrepresents the circumferential volume which is achieved by rotating the pixel (i, j) around x-axis in actual space; rijrepresents the radial distance of pixel (i, j) from the x-axis in the actual space; Aijrepresents an area of the pixel(i, j) corresponding actual space.

The mass flow rate of NOx, ˙mNOxcan be calculated by Eq. (9).

where Δt is exposure time of each image;MWNO*is the molecular weight of NO*.

Therefore,the ratio of NOxemission formed by pilot flame and dual flame can be achieved, as shown in Eq. (10).

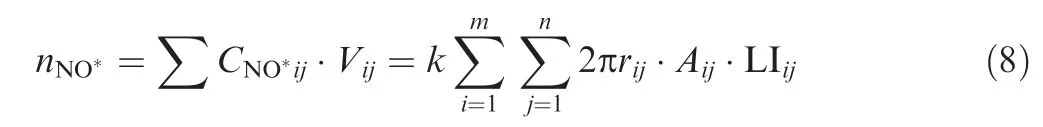

Using threshold method for the deconvoluted images of time-averaged NO*, a region of flame whose chemiluminescence intensity is greater than 20% of the maximum intensity is identified for clarifying the NOxformed by flame and flame boundary. Then the NOxemissions produced by pilot flame and dual flames can be calculated by Eq.(8),respectively.Proportion of NOxproduced by pilot flame can be achieved as shown in Fig. 7.

According to Fig. 7, the pilot flame contributes more to NOxemissions.Moreover,with the increase of fuel stage ratio from 15% to 30%, the corresponding pilot stage equivalence ratio increases from 0.88 to 1.76.The NOxproportion formed by pilot flame increases from 67.9% to 76.2%. Although the pilot stage changes from lean to rich (φpincreases by 100%),the proportion of NOxemissions produced by pilot stage only increases by 12.2%. Because of the special characteristics of pilot stage, its NOxemission should be paid more attention during the establishment of NOxemission model of dual flame in the following section.

3.3. NOx emission prediction model

Fig. 7 Proportion of NOx formed by pilot flame in optical diagnosis tests.

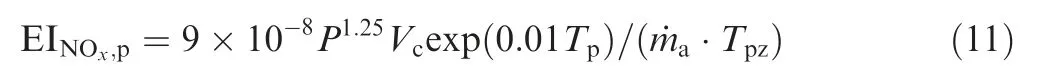

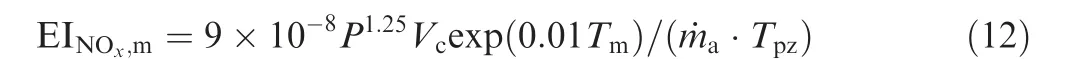

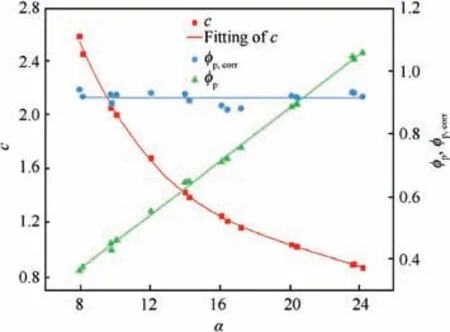

For the NOxemission model in conventional combustor,some important factors were proposed by Lefebvre,41including chemical reaction rate, mixing rate, and residence time. Based on those assumptions and fitting of experimental data, a NOxemission prediction model for the diffusion flame in conventional combustor was carried out, as shown by Eq. (11).41As the pilot flame in TeLESS-II combustor works like a non-premixed flame in conventional combustor, the stoichiometric flame temperature, Tst, in Ref.41is replaced by Tpwhich represents the stoichiometric flame temperature of pilot flame.

In Eq.(11),EINOx,pis NOxemission index of pilot stage,g/kg;P is inlet pressure,kPa;Vcis the volume of combustor,m3;Tpis stoichiometric flame temperature of pilot flame, K; ˙mais mass flow rate of combustor air,kg/s;and Tpzis primary zone temperature, K.

According to Ref.42, the flame combustion temperature(chemical reaction rate) is an important factor influencing the NOxemissions. According to Ref.29,residence time is also a key parameter affecting NOxformation for separated stratified swirling spray flame. In Ref.43, it is found that the fuelair unmixedness can lead to the increase of NOxemissions in lean premixed combustors. In summary, the factors affecting the NOxemissions of separated stratified swirling spray flame can be summarized as flame temperature, residence time and mixing degree.The three factors are the same as factors affecting the NOxformation proposed by Lefebvre for diffusion flame in conventional gas turbine combustor. Therefore,Lefebvre’s model is chosen as the basis for the establishment of separated stratified swirling spray flame emission prediction model.However,Eq.(11)is only suitable for diffusion flame in the conventional combustor. For separated stratified swirling spray flame, it is necessary to take local adiabatic flame temperatures of the main and pilot flames into consideration.

For the pilot flame of separated stratified swirling spray flame which behaves as non-premixed flame, the equivalence ratio at the flame front is close to 1,42making the local temperature the highest in the combustor. This is consistent with the OH*chemiluminescence distribution in Fig.6,and the highest local temperature of the pilot flame causes the NOxformed by pilot flame to be more than that of the main flame.Therefore,the prediction of pilot flame NOxemissions, in other words,the calculation of pilot flame temperature is critical to the accuracy of the separated stratified swirling spray flame emission model.

For the main flame, though the fuel mass flow rate of the main stage is higher than pilot stage, its temperature is lower by adopting LPP combustion mode, which makes the main flame contribute less NOx, as shown in Fig. 7. Because the attainable temperature of the main flame in LPP combustor is Tm, the NOxemission of the main stage can be attained through substituting Tminto Eq. (11).41

For the coupling region between the main and pilot flames,its flow characteristics were investigated using PIV by Han et al.28It was found that the turbulent intensity is maximal in the inner shear layer of flow,which indicates the happening of fast mixing of fuel, air and hot products, resulting in lower temperature in this region. Therefore, the concentration of NO* in the shear layer is low as shown in Fig. 6, and its NOxemissions will not be taken into account when establishing NOxemission model related to separated stratified swirling spray flame.

Due to the fact that the main flame and pilot flame are relatively independent in this paper,the NOxemissions produced by two flames can be analyzed separately while effects of the coupling zone between the two flames on NOxemission is ignored. The definition of NOxemission index of pilot stage EINOx,pis shown in Eq. (13).

The definition of NOxemission index of the main stage EINOx,mis shown in Eq. (14).

The total NOxemission index EINOxis defined as Eq. (15).

Combining definitions of EINOxwith EINOx,pand EINOx,m,EINOxcan be expressed as Eq. (16):

The total NOxemission index of separated stratified swirling spray flame can be achieved with taking the fuel stage ratio into consideration, as shown in Eq. (17).

Substituting Eqs.(11)and(12)into Eq.(17),the NOxemission model for dual flame can be expressed by Eq. (18):

In Eq. (18), Tp, Tmand Tpzrepresent adiabatic flame temperature of the pilot stage, main stage and primary zone,respectively. The adiabatic flame temperature of premixed the main flame, Tm, is calculated by using the main stage equivalence ratio φm.Tpzis calculated by using φdome.The pilot flame is regard as diffusion flame and Tpis calculated by setting φp=1.41Each adiabatic flame temperature is calculated by the standard NASA’s Chemical Equilibrium Analysis software NASA-CEA.44The fuel is set as Jet-A45,46and its initial temperature is set at 300 K.

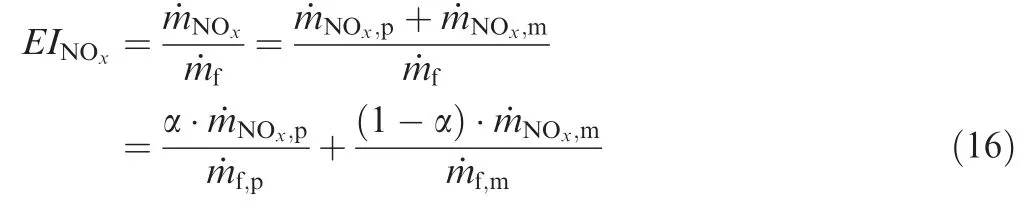

The results of NOxcorrelation for emission characteristics tests are shown in Fig. 8, in which EINOxcalculated by Eq.(18) is compared with experimental EINOxvalues. In Fig. 8,the empirical NOxmodel as shown by Eq. (18) cannot give a good prediction for NOxemission and the deviation between calculated and measured EINOxis from +55% to +250%.The R2(coefficient of determination) of nonlinear fitting by correlation shown in Eq. (18) is 0.6933.

Fig. 8 Calculated EINOx by Eq. (18) vs measured EINOx(P3=1.8-2.0 MPa, T3=700-810 K).

The flow characteristics of separated stratified swirling spray flame have been investigated in Refs.22,29through experiment and calculation. It is found that recirculation zone created by swirling flow allows hot products to be mixed with the fresh reactants in upstream and increases the evaporation rate, causing a more homogeneous fuel-air-mixture. The pilot stage adopts a typical swirler structure consisting of a pressure swirl atomizer with a dual radial swirler which can also enhance the mixing of fuel and air efficiently. Therefore, the pilot flame does not exhibit a complete diffusion flame mode,resulting in the actual adiabatic flame temperature of pilot flame lower than diffusion flame whose equivalence ratio at the flame front equals to 1. In other words, Tpshould not be calculated by stoichiometric equivalence ratio and a corrected equivalence ratio of pilot stage, φp,corr, should be used when establishing emission model.

φp,corris defined as follows:

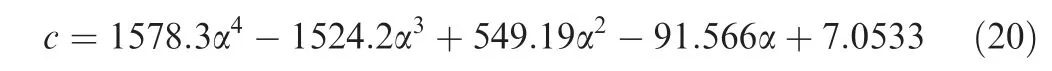

where c is the correction coefficient of pilot stage equivalence ratio.

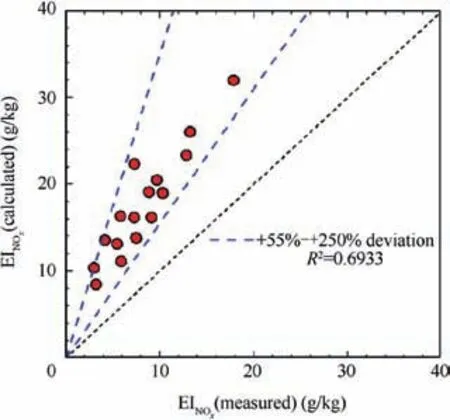

Combining EINOx,mcalculated by Eq. (12) and EINOxobtained from experiment, EINOx,pcan be calculated by Eq.(17). Then Tpcan be obtained from Eq. (11). It is noteworthy that solving Tp= f(φp,corr)will obtain two different φp,corrvalues(one is lean and the other is rich).According to conditions for emission characteristics tests in this paper, the local equivalence ratio of the pilot is between 0.363 and 1.057, most of which are in lean range. Combining the influence of the pilot stage fuel diluted by recirculated hot mixture, the lean φp,corrvalues are selected. Fig. 9 shows the fitting results of relationship between c and α.

In Fig. 9, the horizontal coordinate axis represents α. The left longitudinal coordinate axis represents the correction coefficient of pilot stage equivalence ratio c.The right longitudinal coordinate axis represents the pilot and corrected pilot equivalence ratio. The ranges of φpand c are 0.363-1.057 and 0.868-2.590, respectively. The range of φp,corris 0.917-0.939,which is lower than the equivalence ratio 1 of the diffusion flame.It indicates that though φphas a large increase,the pilot flame performs as an approximate diffusion flame, in other words, partially premixed flame, causing φp,corrto remain in a relatively narrow range (increases by 8.85%), which makes Tpremain in a narrow range. Therefore, the violent increase of α will not cause Tpto increase by a great margin, causing EINOx,pto increase by a finite margin, which is consistent with the results proposed by Fig.7.The polynomial fitting results of c and α is shown in Eq. (20), and R2of nonlinear fitting is 0.9991.

Fig. 9 Relationship between correction coefficient of pilot stage equivalence ratio and fuel stage ratio.

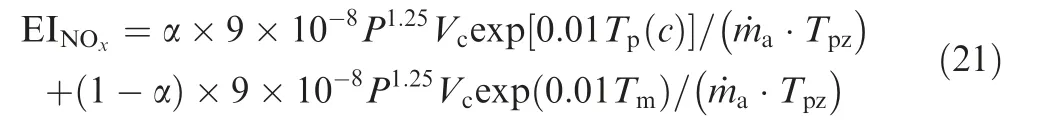

The ‘‘PLUS” (Premixed Lean Ultraclean Stratified) emission prediction model can be expressed by Eq. (21) by substituting the Eqs. (19) and (20) into Eq. (18).

Here, Tp(c) is the adiabatic flame temperature of pilot flame after its equivalence ratio corrected by Eqs. (19) and (20).

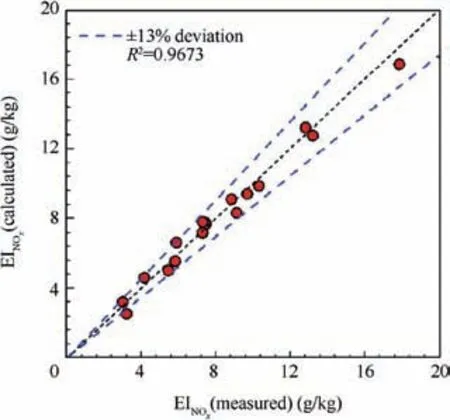

Fig. 10 shows the correlation results by the ‘‘PLUS” emission prediction model for NOxemission data. The deviations between measured and calculated EINOxare within ±13%for all data while R2of nonlinear fitting is 0.9673.The‘‘PLUS”emission prediction model exhibits a better prediction for the NOxemission of separated stratified swirling spray flame compared with the Eq. (18).

Fig. 10 Calculated EINOx by ‘‘PLUS” emission model vs measured EINOx (P3=1.8-2.0 MPa, T3=700-810 K).

Currently,Han28and Li25et al.focus on the NOxemissions prediction models of separated stratified swirling spray flame based on the model proposed by Tsalavoutas et al.,47who thought inlet pressure, adiabatic flame temperature and residence time are the key parameters affecting the NOxemission in conventional combustors. Han et al.28took the effects of fuel stage ratio into consideration and proposed a new NOxemission prediction model. Li et al.25considered not only the effects of fuel stage ratio but also the interaction between pilot and main flames. The final NOxemission prediction models proposed by Han28and Li25et al.can give a good prediction for the NOxemissions of specific flames in those studies.However, owing to the lack of detail flame structures and distribution of emission and temperature data, these researchers only adopt macroscopic hypothesis methods for the establishment of emission model which may be different from the actual physical process in the combustor.

The NOxemission prediction model for separated stratified swirling spray flame in this paper is based on the flame’s NOxformation characteristics. Guided by the results of optical diagnosis tests and characteristics of pilot flame,the NOxemission model proposed by Lefebvre is modified, including the processing of the coupled dual flames, the correction of pilot stage temperature, resulting in a good ability in predicting NOxemissions. Moreover, the ‘‘PLUS” emission model can also provide guidance for the construction of separated stratified swirling spray flame emission models with similar features.

3.4. Discussion on prediction model

The ‘‘PLUS” NOxemission prediction model in this paper is applicable for separated stratified swirling spray flame in centrally staged LPP low emission combustor.However,there are some deficiencies existing in the present work.Firstly,based on the experimental results of optical diagnosis, the developed‘‘PLUS”emission prediction model is suitable for weakly coupled dual flames. The pilot flame and main flame are weakly coupled,which allows to ignore the NOxproduced in the interaction region and sum the NOxemission of the pilot and main flame according to fuel stage ratio. Therefore, the ‘‘PLUS”NOxemission prediction model may be only applicable to those weakly coupled flames like the flame structure in TeLESS II combustor but not suitable for the strong coupled flames mentioned in Refs.8,17,23,25. Secondly, the ‘‘PLUS”NOxemission prediction model is mainly based on the Lefebvre’s model,and the pressure index is 0.5 for the chemical reaction rate. Since the fuel stage ratio is an important parameter that affects the emissions of dual flames, the test conditions were mainly designed to change the fuel stage ratio instead of inlet pressure, causing the pressure to maintain in a relatively narrow range. Therefore, whether the pressure index for the dual flames equals to 0.5 or not needs to be verified.Thirdly, the pilot stage adiabatic flame temperature is corrected by the concept of pilot equivalence ratio correction coefficient. The relationship between corrected pilot equivalence ratio and fuel stage ratio was mainly obtained by nonlinear fitting and requires further validation whether the relationship is consistent with the actual physical process.

Taking the deficiencies mentioned above into consideration,the following research would be carried out in the future.In order to verify the prediction ability of ‘‘PLUS” emission model, more experiments under a wider range of pressure will be carried out. Other separated stratified swirling spray flame with similar or distinct thermodynamic features should also be proposed to explore the applicability of this model.At last,more optical diagnosis tests would be carried out to measure the local equivalence ratio of pilot stage to verify its relation with the fuel stage ratio as proposed in this paper.

4. Conclusions

For the purpose of investigating the NOxformation mechanisms of separated stratified swirling spray flame, experiments of emission characteristics and optical diagnosis and correlation of NOxemission have been carried out in a single-cup module rectangular combustor. The conclusions are as follows.

(1) From the emission characteristics results tested at elevated temperature and pressure,NOxemission increases with the increase of the fuel stage ratio at a given inlet temperature, pressure and dome equivalence ratio.

(2) Based on NO*and OH*chemiluminescence images,the NOxmechanism in separated stratified swirling spray flame is mainly dominated by thermal NOxmechanism.According to the OH* chemiluminescence image, the local temperature of the pilot stage is higher. Through processing NO* chemiluminescence images, most of the NOxexists in the pilot stage region. The pilot flame contributes mostly to the NOxproduction.

(3) The separated stratified swirling spray flame is a kind of weakly coupled flame.The NOxformed by the main and pilot stages are relatively independent. Moreover, there is little NOxproduced in the interaction region.

(4) Based on the NO* chemiluminescence data and NOxemission model proposed by Lefebvre, ‘‘PLUS” NOxemission prediction model is proposed. The pilot stage ratio correction coefficient decreases with the increase of the fuel stage ratio in this model.The corrected equivalence ratio of the pilot flame is always kept in a narrow range less than 1,and the adiabatic flame temperature of pilot stage in the emission model was corrected by those equivalence ratios. The accuracy of NOxemission prediction model is within±13%,giving a good prediction for the NOxemission data.

Acknowledgement

This work was supported by the National Natural Science Foundation of China (No. 91641109).

CHINESE JOURNAL OF AERONAUTICS2020年2期

CHINESE JOURNAL OF AERONAUTICS2020年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Delaying stall of morphing wing by periodic trailing-edge deflection

- Optimization and verification of free flight separation similarity law in high-speed wind tunnel

- Non-intrusive reduced-order model for predicting transonic flow with varying geometries

- Consideration on aircraft tire spray when running on wet runways

- Aeroelastic simulation of the first 1.5-stage aeroengine fan at rotating stall

- Research on nonlinear model predictive control for turboshaft engines based on double engines torques matching