Multi-faults diagnosis of rolling bearings via adaptive customization of flexible analytical wavelet bases

Chunlin ZHANG, Yuling LIU, Fngyi WAN,*, Binqing CHEN, Ji LIU,d,Binging HU

a School of Aeronautics, Northwestern Polytechnical University, Xi’an 710072, China

b School of Management, Northwestern Polytechnical University, Xi’an 710072, China

c School of Aerospace Engineering, Xiamen University, Xiamen 361005, China

d Department of Mechanical and Aerospace Engineering, Carleton University, Ottawa, ON K1S5B6, Canada

e Faculty of Printing, Packing and Digital Media Engineering, Xi’an University of Technology, Xi’an 710048, China

KEYWORDS Bearing defect identification;Fault diagnosis;Flexible analytical wavelet transform;Multiple faults;Spectral correlated kurtosis

Abstract Multi-faults detection is a challenge for rolling bearings due to the mode mixture and coupling of multiple fault features,as well as its easy burying in the complex,non-stationary structural vibrations and strong background noises. In this paper, a method based on the flexible analytical wavelet transform(FAWT)possessing fractional scaling and translation factors is proposed to identify multiple faults occurred in different components of rolling bearings.During the route of the proposed method, the proper FAWT bases are constructed via genetic optimization algorithm(GA) based on maximizing the spectral correlated kurtosis (SCK) which is firstly presented and proved to be efficient and effective in indicating interested fault mode. Via using the customized FAWT bases for each interested fault mode, the original vibration measurements are decomposed into fine frequency subbands, and the sensitive subband which enhances the signal-to-noise ratio(SNR) is selected to exhibit the fault signature on its envelope spectrum. The proposed method is tested via simulated signals, and applied to analyze the experimental vibration measurements from the running roller bearings subjected to outrace, inner-race and roller defects. The analysis results validate the effectiveness of the proposed method in identifying multi-faults occurred in different components of rolling bearings.

1. Introduction

The inter-shaft bearings are widely used, key components in supporting the twin spool rotor systems in modern aero engines. However, under fatigue loads and harsh working conditions, local defects like cracks may occur and propagate in the inter-shaft bearings, leading to potential operation failure and even catastrophic accidents.1-3Thus, condition monitoring and fault diagnosis of rolling bearings is of significance in preventing potential properties lost and providing sufficient maintenance time.4,5

Structurally, the inter-shaft bearings are usually ball or roller bearings locating between the high-speed and lowspeed rotors in aero engines. Due to the structural complexity and encapsulation, the feasible vibration measurement from the bearing house has motivated flourished research on vibration based fault diagnosis of the rolling bearings. To date,much efforts have been conducted on single fault detection and localization for rolling bearing.6,7From fault mechanism and dynamics, periodic impulses are introduced in the vibrations when the rotating components contact the local defect,8and different fault characteristic frequencies are predicted for defects locating in different bearing components. To extract the fault characteristic frequency, numerous vibration-based methods have been proposed and tested on experiment rigs and in situ engineering cases, including model-based method,9empirical mode decomposition (EMD),10,11ensemble empirical mode decomposition (EEMD),12,13wavelet package transform (WPT),14multiwavelet transform,15tunable Q-factor wavelet transform (TQWT),16,17wavelet and spectral kurtosis,18sparse decomposition,19and intelligent classification methods.20,21Most of these methods follow the procedures that decompose and reconstruct the vibration signals into different frequency subbands to enhance the signal-to-noise ratio of the fault induced impulses,22,23the fault characteristic frequency is further extracted when the sensitive subband is found followed by envelope spectrum analysis. Some of these methods are also found to be effectiveness in diagnosis the early-stage faults of rolling bearings.23,24These fruitful achievements of single fault diagnosis methods provide a solid and fundamental knowledge for multi-faults detection. Multiple faults commonly occur in rolling bearings under hashing operation conditions. When multiple faults occur simultaneously in the rolling bearings, such as cracks, peelings, and defacements. Rather than simple superposition of each fault feature, the multi-faults features become more complicated in vibration measurements:

(1) Coupled and co-existence in a narrow frequency range.Fault impulses are induced during the collision between the local defects and contacted bearing components,which are essentially similar to the process of impact modal test. Though the collision positions for multiple faults are different and always time-varying during the bearing rotation, the frequency responses of multi-fault impulses locate at or very close to the natural frequency of the bearing systems.

(2) Slight difference exists among different fault modes.The slight difference among multi-faults modes provides potential for isolating and identifying different bearing faults. From the fault mechanism of rolling bearings with the outrace mounted as the stator part, the outer race fault impulses are almost undiminished periodic impulses because the defect position and the transfer path from the defect to the measuring sensor are fixed;while for the inner race and roller elements, the fault impulses exhibit amplitude modulation phenomenon and become obvious when the defects pass through loading zone. Thus, different fault mode may become primary during different rotation intervals.

Due to the mode mixture and coupling of multiple faults,multiple faults are difficult to be isolated and identified via direct adoption of aforementioned methods, and only a few attempts have been conducted on detecting multiple faults of the rolling bearings.He adopted minimum entropy deconvolution method to identify the bearing fault combining with gear defect.23Wang et al combined blind source separation and EEMD for compound faults diagnosis of rolling bearings.25Jiang et al tried a method based on empirical wavelet transform and chaotic oscillator.26Some other methods are also proposed for compound faults detection of bearings including wavelet based approach,27,28sparse component analysis.29Overall, complicated post-treatment is required for the decoupled sub-signals in most of these publications to identify each fault mode.Compound faults identification of rolling bearings are still a challenge, and advanced signal processing technique is required for multiple faults identification.

In this paper, a novel technique is proposed based on the flexible analytical wavelet transform (FAWT) to identify multiple faults of rolling bearings.FAWT was originally proposed by Bayram,30and allows employing arbitrary sampling rates in both the lowpass and highpass channels, leading to a flexible TF partition manner. Moreover, FAWT possesses attractive properties such as shift-invariance, and oscillation-tunable wavelet bases, making it suitable for matching different oscillatory fault impulses.24,31In the route of the proposed method,the proper FAWT bases are constructed via genetic optimization algorithm (GA) based on maximizing the spectral correlated kurtosis (SCK) which is firstly presented and proved to be efficient and effective in indicating interested fault mode.Compared with traditional CK index, SCK is fabricated with half less data samples and without any parameters to be optimized such as shift parameter in CK.Via using the customized FAWT bases for each interested fault mode, the original vibration measurements are decomposed into fine frequency subbands, and the sensitive subband which enhances the signal-to-noise ratio (SNR) is selected to exhibit the fault signature on its envelope spectrum. The effectiveness of the proposed method is validated via simulation and experiment data.The results show that the proposed method exhibits good performance in detecting multiple fault signatures from even different defected bearings in the test rig. This performance of the proposed method provides promising potential in health monitoring of aircrafts where less sensors are always expected.

The rest of this paper is organized as follows.A brief introduction of the FAWT properties and detailed procedures of the proposed diagnosis method are given in Section 2.The performance and effectiveness of the proposed method are tested on simulated signals in Section 3,and on an engineering experiment in Section 4. Finally, the conclusions are drawn in Section 5.

2. Multi-faults diagnosis technique

During the route of the proposed multi-faults diagnosis technique,FAWT is a key procedure which decomposes the vibration signals into fine, arbitrarily divided frequency subbands.Thus, the effects of the sampling parameters in the FAWT on the frequency division manner is studied in the following subsection, and the proposed multi-faults detection route is then presented.

2.1.Effects of sampling parameters on FAWT frequency division manner

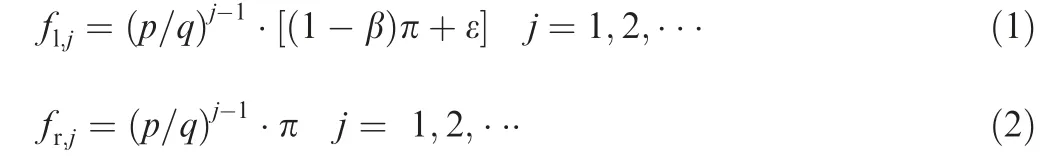

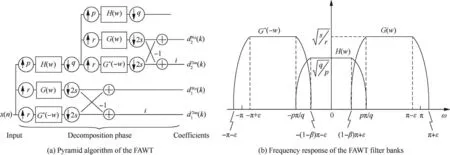

FAWT is implemented via pyramid algorithm with the iterated filter banks involving a lowpass and two highpass channels,30as illustrated in Fig.1.For input signal x(n ),is wavelet coefficient in the imaginary branch, whileis wavelet coefficients in the real branch where j is the decomposition layer. H(ω ), G( ω ), and G*(- ω) are the frequency responses of the iterated filter banks where ω denotes the frequency.G(ω ), and G*(- ω) separately allows the ‘positive frequencies’and ‘negative frequencies’, leading to the Hilbert transform pairs of the wavelet bases. β=0.8r/s and ε= (p -q+βq)π/[3 2(p +q)]affect the width of the transition band.p,q,r,and s are the sampling parameters of FAWT,and flexible time-frequency (TF) covering manner and oscillationtunable bases can be generated via varying these sampling parameters. Adopting these sampling parameters, the constructed FAWT basis is hereafter denoted as Bp,q,r,s.

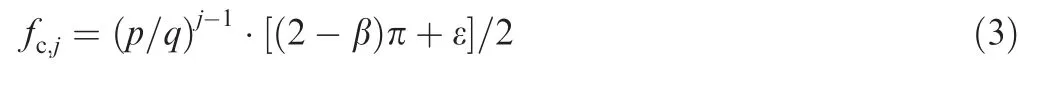

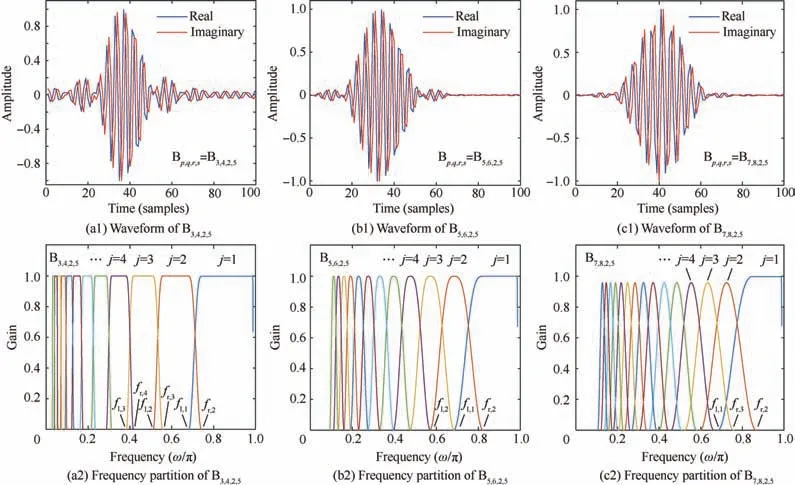

To explicitly illustrates the effects of the sampling parameters on the frequency division manner, Fig. 2 shows the waveforms and frequency responses of the FAWT bases with different sampling parameters. It reveals that different frequency division manners can be achieved via varying the sampling parameters ratio p/q. Based on the frequency responses of the filter banks and iterated algorithm in Fig. 1, the low and high boundaries of the limit supporting frequency band for j-stage FAWT wavelet basis, fl,jand fr,jin Fig. 2, are here derived to be

Thus,the center frequency fc,jand supporting band fband,jof the j-th stage FAWT filter are obtained and expressed as

Based on Fig. 2 and Eqs. (1)-(4), the center frequency and bandwidth of the FAWT filters are sensitively affected by the scaling factor p/q. By using the scaling factor p/q close to 1,FAWT is dilated gradually from scale to scale such that narrow frequency subbands with high frequency concentration are generated.It is also concluded that the sampling parameter s/r has significant influence on the shape of the transition band of the FAWT filters and the oscillation of the bases: a higher translation factor leads to higher oscillatory FAWT bases.24Considering the multi-faults features usually coexist in a narrow frequency range,32the proper frequency range can be obtained via optimizing the FAWT sampling parameters such that to persist and protrude the multi-faults information in the reconstructed subband signals.

2.2. Multiple faults detection method

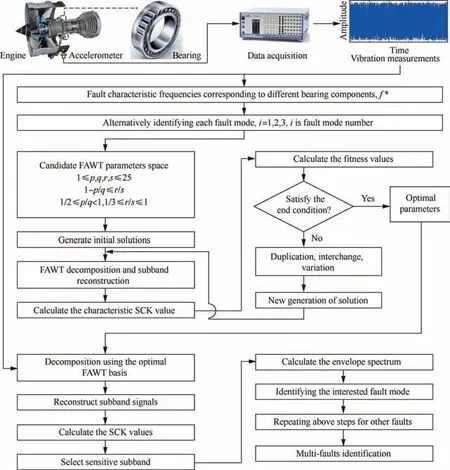

The proposed multi-faults detection method is a data driven approach with the procedures illustrated in Fig. 3. The main procedures of the proposed method can be summarized as the following steps:

(1) Vibration data acquisition. Considering the aircraft is structurally complex and the reachability to the bearing seat is limited, the accelerometer is usually mounted on the adjacent housing cage such that rich irrelevant vibrations from other machinery components and strong background noise are included in the acceleration measurements. Recalling the multi-fault impulses are mixed and different fault mode might become primary during different rotating intervals, it would be much helpful it sufficiently long-time vibrations are measured that allowing the bearing fault components to traverse all loading zones.

Fig. 1 Implementation algorithm and filter frequency responses of FAWT.

Fig. 2 Waveforms and frequency partition manner of FAWT bases.

(2) Optimal FAWT basis construction. To fabricate the proper oscillatory FAWT bases with flexible TF covering manner for detecting different faults, the multiple sampling parameters need to be adaptively optimized based on the interested fault mode. The genetic algorithms (GAs) is a global optimization method and is adopted to adaptively construct proper FAWT basis via optimizing the sampling parameters p, q, r, and s.Considering the widely-used kurtosis is sensitive to fault impulses yet lacks the sensitivity indicating multi-faults with different fault characteristic frequencies, a novel index termed spectral correlated kurtosis (SCK) is proposed in this paper. For the repeated fault impulses induced from rotating bearings, the envelope spectrum exhibits primarily the fault characteristic frequency and its harmonic components. Inspired from the correlated kurtosis (CK),33the periodic fault characteristics can be evaluated from the envelope spectrum.

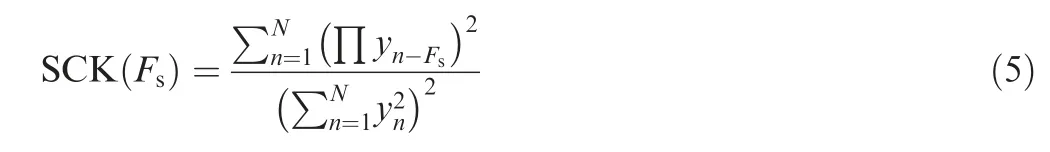

where SCK(Fs)is the spectral correlated kurtosis of the envelope spectrum ynwith N samples, Fsis the corresponding sampling points of the interested characteristic frequency and can be calculated via:

in which, len (x ) is the length of the vibration signal x whose envelope spectrum is denoted as y,fsis the sampling frequency and f*is the fault characteristic frequency. For periodic fault impulses,the Hilbert envelope spectrum is a sparse representation where the primary components are the fault characteristic frequency and its harmonic components. Thus, it is still periodic signature with the period equals the fault characteristic frequency. The definition in Eq. (5) essentially calculates the inner products of the envelope spectrum series ynand the delayed series yn-Fs,and outputs large when the periodic signature is primary in the envelope spectrum.Compared with CK,SCK is operated in the frequency domain with half less samples and without any parameters to be optimized such as shift parameter in CK,and thus SCK reduces the optimization procedures and computation cost.

To select proper sampling parameters of FAWT via GA,the objective function is set as maximizing the characteristic SCK which is determined as the maximal SCK from the subband signals divided by the FAWT. The main procedures include:

i. Fabricate the candidate FAWT bases space.Though the essential constraint 1-p/q ≤r/s allows countless valuation and combination of the sampling parameters. To obtain higher frequency resolution than dyadic WTs such as discrete wavelet transform (DWT) and dualtree complex wavelet transform (DTCWT) in which the scaling factor is constant as p/q=0.5, the scaling factor p/q of FAWT is further limited in the range 1/2 <p/q <1. Also, the existing research found that relatively high translation factor, ie., s/r ≥3, leads to ringing phenomenon on the constructed FAWT basis which may weaken its match performance to the fault impulses.24Thus, the translation factor is set in the range 1/3 ≤r/s <1. Moreover, to enhance the optimization efficiency, these integral parameters are constrained in the range 1 ≤p,q,r,s ≤25 in which the candidate scaling and translation factors densely cover the range[0.5,1]and[1/3,1],respectively.Thus,the candidate FAWT bases space is fabricated and expressed as

Fig. 3 Flow chart of the proposed multi-faults diagnosis method.

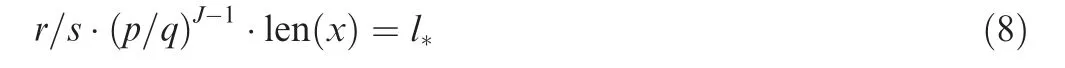

ii. After randomly generating the initial solution of the sampling parameters (p ,q,r,s), decomposing the vibration signals into subbands via the FAWT basis constructed by the generated sampling parameters. The decomposition layers J is usually manually determined and fixed in dyadic WTs,while fixed layer doesn’t satisfy FAWT with automatically running GA optimization:higher layer is needed for higher sampling ratio p/q which leads to narrow frequency bandwidth; on the other hand, higher decomposition layer may disaggregate FAWT if lower sampling ratio p/q is attempted in GA process. Thus, the decomposition layer is automatically selected based on sampling parameters, and its allowed maximal layer is estimated. Considering the vibration signals x with its length len (x ), and recalling the pyramid algorithm of FAWT shown in Fig. 1, the length of the J-th subband wavelet coefficients after FAWT decomposition can be calculated as:

where l*denotes the samples of the J-th subband wavelet coefficients and should be positive integer. To retain necessary length for analysis, here l*is chosen as l*≥5. Accordingly,the allowed maximal decomposition layer Jmaxand selected layer J for FAWT in this paper are determined as:

iii. The SCK(Fs)values of the interested fault mode are then calculated from each subband signals with Fsevaluated from Eq. (6), of which the maximum is regarded as the characteristic SCK(Fs) of the FAWT basis. The fitness of each initial solution is then evaluated from its characteristic SCK value, based on which the new generation of solutions can be obtained via duplication, interchange, and variation of the former generation. The optimal FAWT parameters leading to the maximal characteristic SCK(Fs)can thus be found via the iteration in GAs.

(3) Sensitive subband selection. Adopting the constructed FAWT basis, the vibration measurements are divided into subband signals.The subband signal corresponding to the characteristic SCK is chosen as the sensitive subband signal.Considering SCK is a sensitive indicator for the interested periodic fault impulses, the selected sensitive subband signal enhances the SNR of the fault information.

(4) Multi-faults identification. For the selected sensitive subband signal, the envelope spectrum is further calculated for identifying the interested fault mode. Thus,for defected rotating bearings with multiple faults, each fault mode can be identified via adaptively constructing its proper FAWT basis and selecting the sensitive subband to enhance the SNR of the fault information.

3. Simulation analysis

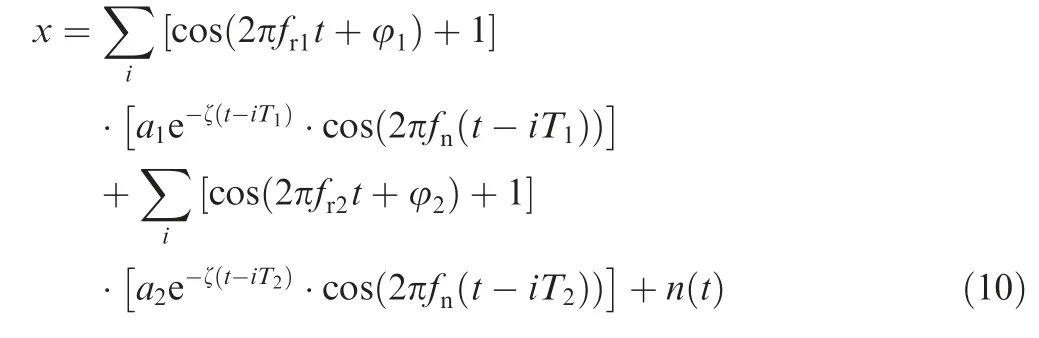

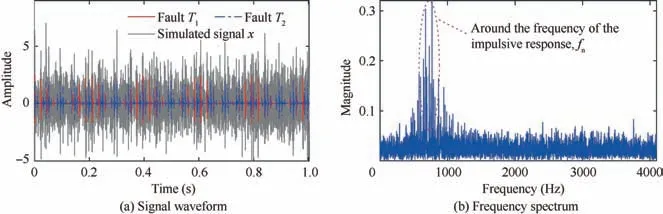

Based on the mathematical model of defected rolling bearings,23a simulated signal describing the vibration measurements induced by multiple faults is generated as:where T1and T2represent the periods of repeated fault impulses; fnis the response frequency of the fault impulses;aiand ζidenote the amplitude and decaying rate of the impulsive responses; friand φirepresent the convolution frequency and phase delay; and n(t ) is selected as the Gaussian white noise which represents the unrelated vibrations and background noise. The values of these parameters are listed in Table 1, and the Gaussian white noise n (t ) is added to the vibration signal with the SNR set as -10 dB. Under the sampling frequency of 8196 Hz, the simulated signal and its frequency spectrum are displayed in Fig. 4.

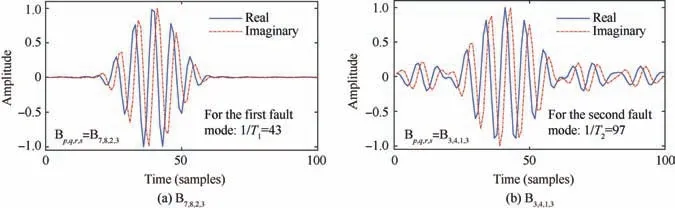

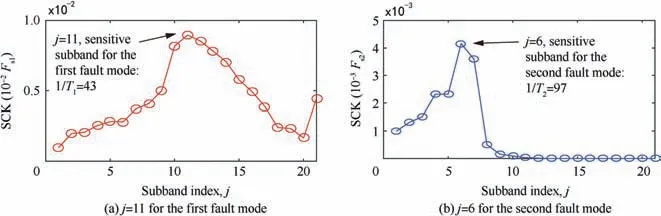

From Fig. 4, the periodic fault impulses with two different periods are all buried in the simulated vibration signals, and could not be directly observed from the time or frequency domain.Based on Eq.(6),the sampling points of the two fault characteristic frequencies are calculated to be Fs1=43 and Fs2=97,respectively.Adopting the GA optimization method,and based on the principle of maximizing the characteristic SCK value of the FAWT basis,the optimal sampling parameters (p, q, r, s) for identifying the two fault modes are separately obtained. For the first fault mode with Fs1=43, the optimized sampling parameters are (p ,q,r,s)= (7 ,8,2,3);and for the second fault mode with Fs2=97, the optimized sampling parameters are (p ,q,r,s)= (3 ,4,1,3).Based on these selected sampling parameters, the constructed proper FAWT bases for analyzing these two fault modes are shown in Fig. 5, respectively. Adopting the optimal FAWT bases for each interested fault mode,the original signals are divided into subband signals,with the SCK values of each subband are calculated and displayed in Fig. 6. Accordingly, Layer 11 of B7,8,2,3and Layer 6 of B3,4,1,3are selected as the sensitive subbands for identifying the two fault modes, respectively.

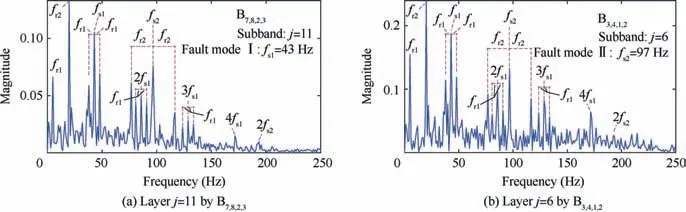

Furthermore, the envelope spectrum of the selected sensitive subband signals are calculated and shown in Fig. 7. In Fig. 7, the fault characteristic frequency fs1and its harmonic components are clearly observed, among which the side-band frequencies with interval fr1are existed, indicating the fault characteristic frequency fs1is amplitude-modulated by the frequency fr1. Also, the fault characteristic frequency fs2surrounded by the side-band frequencies with the interval fr2is clearly found in the envelope spectrum, indicating that the fault characteristic frequency fs2is amplitude-modulated by fr2.Moreover,due to the two impulsive faults possess common response frequency, the fault features are coexisted in narrow frequency range and are simultaneously exhibited in the sensitive subbands by the proposed method even though the FAWT basis is constructed based on one fault mode.

Fig. 4 Waveform and frequency spectrum of the simulated signal x.

Fig. 5 Constructed optimal FAWT bases for separately identifying the two fault modes.

Fig. 6 Selected sensitive subband after FAWT decomposition.

Fig. 7 Envelope spectrum of the sensitive subband signals.

4. Experimental validation

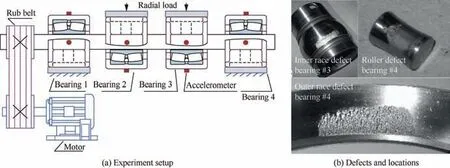

The effectiveness of the proposed multi-faults detection method is tested on the experimental run-to-failure data contributed by the Intelligent Maintenance System (IMS) in University of Cincinnati.31The bearing test rig contains four Rexnord double row bearings mounted on one shaft whose rotating speed remains constantly at 2000 r/min, as shown in Fig. 8. A radial load of 26648 N was applied on the shaft and bearings to lead to accelerated life test of the bearings,and eight accelerometers are installed on the bearing housings to measure the vertical and horizontal vibrations with the sampling frequency set as 20 kHz.The test lasted for 35 days,after which multiple local defects are found in the dismantling of the bearings: an inner race defect in bearing 3; a roller defect and an outer race defect in bearing 4.31Considering multi-faults detection using less sensors is significantly important for aircrafts, the acceleration signals measured from bearing 4 in the horizontal direction are thus attempted here to identify the multiple faults.

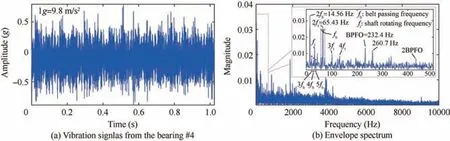

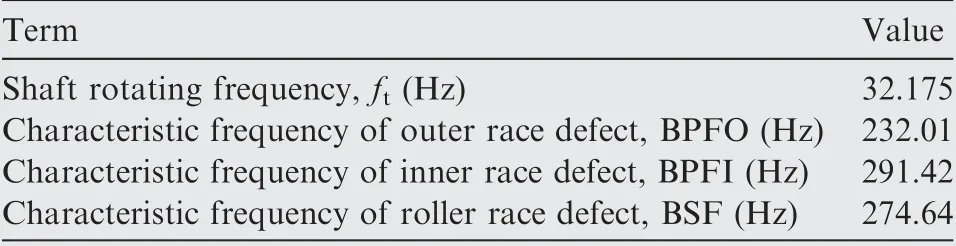

Fig. 9 shows the acceleration signals measured from bearing 4 and the envelope spectrum.It reveals that the fundamental and harmonic components of the belt passing frequency as well as those of the shaft rotating frequency are the primaries in the low range of the envelope spectrum. The side-band frequency with interval fblocated around 2ftindicate that the shaft rotations are amplitude-modulated by the belt passing frequency. Taking the measurement value 2ft=65.43 Hz for emendation of the shaft rotating frequency, and recalling the geometry dimensions of the tested bearings,34the fault characteristic frequencies of the bearing components in the test are then calculated and presented in Table 2.

Fig. 8 Experiment setup and defects found on the bearings after the run-to-failure test.34

Fig. 9 Vibration measurements and the envelope spectrum.

Table 2 Fault characteristic frequencies of the tested bearings.

From Fig. 9(b), the fault characteristic frequency of outer race defect BPFO=232.4 Hz and its harmonic component 2BPFO are clearly observed in the envelope spectrum of the raw vibration measurements, indicating severe damage occurred on the outer race of the tested bearings. However,the raw signal and envelope spectrum don’t exhibit any evidence of the inner race and roller defects. The proposed method is then applied to process the raw signals to identify these two fault modes.

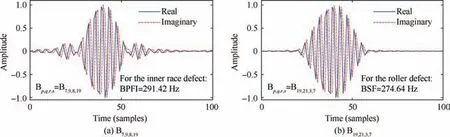

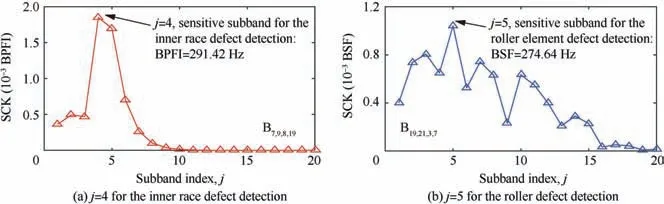

Adopting the GA optimization method with the objective functions separately set as maximizing the SCK values of inner race and roller fault frequencies, the optimized sampling parameters of FAWT for identifying the inner race and roller defects are (p ,q,r,s)= (7 ,9,8,19) and (p ,q,r,s)=(1 9,21,3,7), respectively. Based on the optimized sampling parameters, the corresponding FAWT bases are separately constructed and displayed in Fig. 10. The vibration measurements in Fig. 9(a) are then divided into subband signals via FAWT using the two adaptively constructed bases, respectively. The SCK values for each subbands are calculated and shown in Fig. 11. Based on the SCK maximization principle,Layer 4 of B7,9,8,19and Layer 5 of B19,21,3,7are selected as the sensitive subbands for further analysis.

Fig. 10 Constructed optimal FAWT bases.

Fig. 11 Selected sensitive subbands.

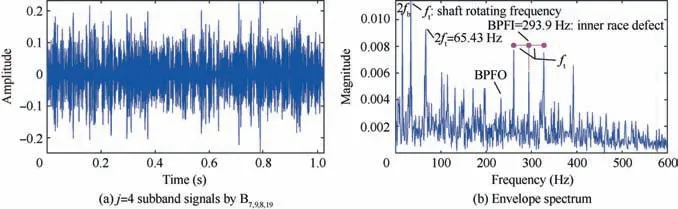

Fig. 12 Filtered signals and the envelope spectrum for identifying the inner race defect.

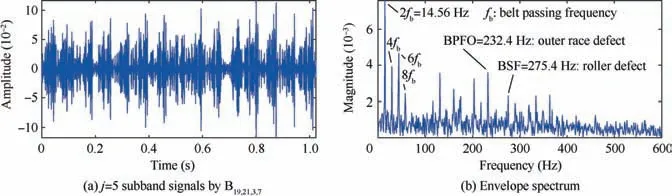

Fig. 13 Filtered signals and the envelope spectrum for identifying the roller defect.

Fig. 12 shows the filtered signal and envelope spectrum in j=4 subband decomposed by B7,9,8,19. In the envelope spectrum,besides the harmonic components of the belt passing frequency fband characteristic frequency of outer race defect BPFO, the characteristic frequency of inner race defect surrounded by side-band frequencies with the interval of the shaft rotating frequency ftis also clearly observed as BPFI=293.9 Hz,indicating the existence of inner race defect in the tested bearings.Fig.13 shows the sensitive subband signals in j=5 decomposed by B19,21,3,7and the envelope spectrum. The characteristic frequency of the roller defect BSF=275.4 Hz is revealed in the envelope spectrum, which exhibits the evidence of roller element defect in the tested bearings.The results of the experimental data analysis validate the effectiveness of the proposed method in identifying multiple faults of the roller bearings.Moreover,though multiple defects occurred in different bearings which reduces the SNR of the fault information of the defected bearing far away from the measurement point, it reveals that the proposed method is effective in enhancing the SNR of the fault information and identifying the fault mode via adaptive customization of proper FAWT basis and sensitive subband.

5. Conclusions

(1) A multi-faults detection method from the vibration measurements is developed in this manuscript for potential applications in health monitoring of the roller bearings that are widely used in aircraft. The effectiveness of the proposed method in identifying multi-faults is validated by simulated signals and experiment data analysis.

(2) During the route of the proposed method, the spectral correlated kurtosis (SCK) is fabricated in the frequency domain with the interested fault frequency considered,and has been proved to be a sensitive and effective index for indicating the interested periodic fault impulses.Compared with traditional CK index, SCK is operated in the frequency domain with half less samples and without any parameters to be optimized such as shift parameter in CK.

(3) FAWT possesses attractive flexible time-frequency division manner, yet many parameters to be determined than dyadic WTs. Adopting SCK maximization as the subject function, GA algorithm is used to obtain the optimized sampling parameters of FAWT, such that the customized FAWT basis is constructed for analyzing the vibration signals.

(4) The experimental results show that the proposed method exhibits good performance in detecting multiple fault signatures from even different defected bearings in the test rig. This performance of the proposed method provides promising potential in health monitoring of aircrafts where less sensors are always expected.

(5) The approach proposed in this paper is a universal method for compound faults identification of rolling bearings, and possesses potential application capability on fault diagnosis of the inter-shaft bearings during the aero engine operation.

Acknowledgement

Thanks are due to the editor and reviewers for the constructive comments and valuable suggestions. This study was co-supported by the Fundamental Research Funds for the Central Universities of China, China Postdoctoral Science Foundation (No. 2018M631196), and the National Natural Foundation of China (No. 51705420).

CHINESE JOURNAL OF AERONAUTICS2020年2期

CHINESE JOURNAL OF AERONAUTICS2020年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Delaying stall of morphing wing by periodic trailing-edge deflection

- Optimization and verification of free flight separation similarity law in high-speed wind tunnel

- Non-intrusive reduced-order model for predicting transonic flow with varying geometries

- Consideration on aircraft tire spray when running on wet runways

- Aeroelastic simulation of the first 1.5-stage aeroengine fan at rotating stall

- Experimental study on NOx emission correlation of fuel staged combustion in a LPP combustor at high pressure based on NO-chemiluminescence