Ultraviolet 3D digital image correlation applied for deformation measurement in thermal testing with infrared quartz lamps

Yli DONG, Jiqing ZHAO, Bing PAN,*

a Institute of Solid Mechanics, Beihang University, Beijing 100083, China

b Institute of Nuclear and New Energy Technology, Tsinghua University, Beijing 100084, China

KEYWORDS Deformation;DIC;Front-surface;Quartz lamp heating;Ultraviolet 3D digital image correlation

Abstract In thermal-structural testing of hypersonic materials and structures, deformation measurement on the front surface of an object directly heated by quartz lamps is highly necessary and very challenging.This work describes a novel front-surface high-temperature deformation measurement technique,which adopts ultraviolet 3D digital image correlation(UV 3D-DIC)to observe and measure the high-temperature deformation fields on front surfaces directly heated by quartz lamps.Compared with existing blue light DIC techniques,the established UV 3D-DIC,which combines UV CCD camera, active UV illumination and bandpass filter imaging, can effectively suppress the strong disturbing light emitted by the quartz lamps and the heated sample itself during heating process. Two experiments were carried out to verify the robustness and accuracy of the developed technique:(1)direct observation of front surfaces of a hypersonic thermal structure sample heated from room temperature to 1050°C,and(2)front-surface thermal stain and coefficient of thermal expansion (CTE) measurement of an Inconel 718 sample up to 800°C. The well matched strain and CTE results with literature data show that UV 3D-DIC system is an effective technique for front-surface deformation measurement and has great potential in characterizing deformation response of hypersonic materials and structures subjected to transient aerodynamic heating.

1. Introduction

Aerodynamic heating is one of the main concerns for the design of hypersonic vehicles.1-5The heat caused by aerodynamic heating not only degrades the mechanical properties of the heat-resistant materials used in thermal protection system (TPS), but also can alter the original geometry of the aircraft components due to unavoidable thermal-mechanical deformation associated with the differential in expansion rates of dissimilar materials. To ensure the safety and reliability design of aircrafts, extensive thermo-mechanical and thermal-structural testing must be carried out to evaluate the effects of aerodynamic heating on hypersonic vehicle materials and structures in ground testing.

To reproduce the transient aerodynamic heating environments experienced by a hypersonic vehicle, quartz lamps are most popularly used. Compared with high-temperature wind tunnels, quartz lamps heating devices offer the following attractive merits:3(i) low thermal inertia and excellent electric control performance; (ii) high heating power and small size:quartz lamps can be assembled to different sizes and shapes,thus suitable for thermal-structural testing of both small and large objects with complex shapes; iii) cost-effective: the cost of infrared radiation heating using quartz lamps is much lower than that of a high-temperature wind tunnel.Further,it should be mentioned that, among all thermal-structural tests, loading conditions and thermo-mechanical responses(i.e.,temperature distributions,displacement and strain fields)of the test objects should be documented to quantify the effects of aerodynamic heating on the test articles.

To overcome the drawbacks of existing pointwise contacting methods for high-temperature displacement and strain measurements, a powerful contactless full-field optical technique, i.e., digital image correlation (DIC),6,7has been introduced for thermal-structural testing with infrared quartz heaters. Specifically, Pan et al.6-9first established a noncontact high-temperature deformation measurement system by combining a transient aerodynamic heating simulation device with 2D-DIC and 3D-DIC. In their first attempt, the sample was heated from one side (front surface) by an array of quartz lamps,a regular 2D-DIC system with white light illumination was used for image capture and subsequent deformation analysis of the back surface.Due to the intensified thermal radiation of the heated samples at higher temperatures,serious‘‘decorrelation effect” was observed above 600°C that restricted the deformation measurement only below 550°C.8To suppress strong thermal radiation caused by hot samples over 600°C, active imaging DIC systems that integrate monochromatic blue light illumination and narrow band-ass filter imaging, designated as blue light DIC systems hereafter,were proposed by Pan et al.9,10. By using the blue light DIC systems, full-field deformation responses on back surfaces of C/SiC composite panels11and superalloy honeycomb sandwich panels subjected to aerodynamic heating12were retrieved.

Despite the blue light DIC techniques have been successfully adopted for many high-temperature applications,13-16it is not applicable for thermo-mechanical testing on the front surface of hypersonic vehicle materials and structures directly heated by quartz lamps. Recently, the authors constructed a front-surface high-temperature deformation measurement testing system, which combined a quartz lamp heating system equipped with an optical window with blue light 2D-DIC system.17However, it was found that the extremely intense light of the quartz lamps, which can be effectively obstructed by the adiabatic frame in back-surface high-temperature deformation measurement, can seriously degrade the quality of the recorded images.In fact,the light of the quartz lamps reflected from the test specimen surface is much more intense than the thermal radiation emitted by the heated object.17As a result,the brightness and contrast of front surface images captured by the blue light DIC system changed dramatically even at temperatures below 600°C.17Although design engineers are eager to know the displacement/strain responses on the front surface directly exposed to aerodynamic heating, existing blue light DIC systems are incompetent to fulfil this challenging task.

This work aims to address the challenging problem of front-surface high-temperature deformation measurement by using a novel ultraviolet 3D-DIC technique. Based on the combined use of active UV illumination, UV bandpass filter and UV cameras,18-20the strong thermal radiation encountered in quartz lamp heating tests can be effectively suppressed.Also,advanced quartz glass tubes with specific high reflectivity coating applied on half surfaces are used in the quartz lamp heating system, which help to mitigate the heat haze effect.For validation, direct observation of the front-surface of a hypersonic structure from room temperature up to 1050°C,and front-surface deformation measurement of Inconel 718 panels up to 800°C exposed to quartz lamps heating device were performed, confirming the efficacy and accuracy of the proposed technique.

2. Method

2.1. Experimental setup

Fig. 1 shows a schematic of the overall experimental setup designed for measuring deformation fields on the front surface of a test sample heated by quartz lamps. It consists of two main parts:a transient aerodynamic heating simulation device using quartz lamp heaters and a UV 3D-DIC system for hightemperature deformation measurement. The transient aerodynamic heating simulation device comprises one layer of arrayed 15 quartz lamps with each quartz lamp (10 mm in diameter and 480 mm in length) having a maximum rated power of 3.6 kW.It should be noted that,unlike the transparent quartz lamp tubes used in previous works, specially fabricated quartz lamps with a high reflective ceramic layer on the half internal surface of lamp tube, as shown in Fig. 1(a), were used for heating the test sample.21The half coated surface of quartz lamps was positioned facing the cameras of UV 3DDIC as shown in Fig.1(a)and(c).The high-temperature ceramic reflectance coating can reflect heat and light of the infrared radiation to the heated object,and offers three advantages:(1)improving heating efficiency of specimen;(2)reducing the light coming into the camera and(3)decreasing the air temperature between the specimen and the camera, thus lessening the heat haze effect. It is worth noting that, to allow the direction observation of the front surface of a test sample, one quartz lamp was removed.However,considering the fact that the size of one quartz lamp array is generally much larger than that of the test sample,the removal of the middle one quartz lamp had almost negligible effect on the temperature fields exerted on the sample surface.

Fig.1 Schematic illustration of front-surface deformation measurement by UV 3D-DIC system combining with reflector coated quartz lamp heating.

Fig. 1(a) shows the established UV 3D-DIC system, which consists of a tailor-made monochromatic UV light source,two optical bandpass filters attached just before the two fixed-focus lens and two UV CCD cameras(CM-140GE-UV,1392×1040 pixels sensor, 8-bit). Fig. 1(b) gives the quantum efficiency of the UV CCD camera and transmittance of the UV filter being used. The camera is sensitive to light ranging from 200 nm to 1000 nm, whereas the quantum efficiency of the CCD camera exceeds 50%for the light emitted in the range from 300 nm to 700 nm. The two optical bandpass filters, with a center wavelength of 325 nm±2 nm and a full-width at half maximum(FWHM) value of approximately 10 nm, have a maximum transmittance of 92% at 325 nm. During experiments, the UV lamp, emitting at 320-325 nm, is employed to illuminate the sample surface. Since only the actively illuminated UV light can pass through the bandpass filters to enter camera sensor, thermal radiation of the heated sample as well as the strong light emitted by quartz lamps can be effectively suppressed.

2.2. UV imaging concept

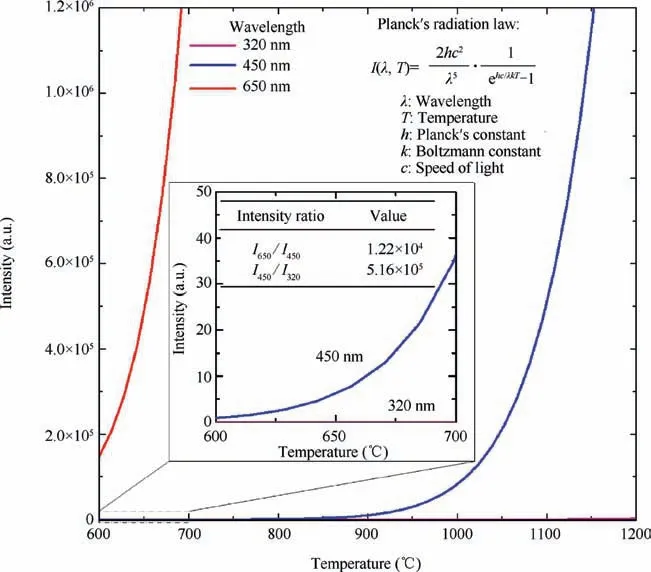

Thermal radiation from a heated object can significantly increase the brightness and decrease contrast of the images captured by an ordinary imaging system with white illumination.8The radiation energy is itself a function of temperature and wavelength, and can be mathematically described by the Planck’s radiation law.22Fig. 2 compares the thermal radiation intensity of typical wavelengths of 650 nm, 450 nm and 320 nm at different temperatures according to Planck’s radiation law.It can be seen that at 600°C,the thermal radiation of light with wavelength of 650 nm already occurs. By comparison, the thermal radiation at 450 nm is weak as the ratio of thermal radiation intensity of 650 nm (I650) to 450 nm (I450)is 1.22×104. Consequently, the combined use of filters and blue illumination for acquiring images at elevated temperatures can be an effective solution as advocated in Ref. [9]and widely adopted by others.13-15

However, at higher temperatures, thermal radiation at 450 nm is not absolutely zero,there are still some thermal radiation as shown in the detailed temperature-intensity curve marked by the square dotted line in Fig. 2. More seriously,the light emitted by the quartz lamps contains much energy at the wavelength of 450 nm, which can dramatically intensify the light entering the camera sensor.Due to these reasons,serious decorrelation effect was observed during the observation of the front surface of samples heated by quartz lamps using a blue light DIC system.15However, both thermal radiation and the light emitted by quartz lamps was negligible at 320 nm. As a result, the UV spectral region is used for the observation in the proposed imaging system. Specifically, to eliminate the adverse effect of thermal radiation and strong light disturbance,the visible and infrared radiation is removed by a UV filter,while a UV illumination is employed as the light source. By using the specially-designed UV imaging system,surface images of the objects directly heated by quartz lamps can be captured and the full-field deformation measurement on front surface become feasible.

To indicate the advantages of the proposed UV imaging system in suppressing the thermal radiation and ambient light disturbance, an experiment for direct observation of heated sample was carried out.We examined the influence of dramatic changes in thermal radiation light induced by quartz lamp heating on the images recorded both by the blue light 3DDIC system15and the proposed UV 3D-DIC system. The experiments were performed on a real hypersonic structure made of C/C composites. Before the experiment, stochastic speckle patterns were decorated on the sample surface by spraying white heat-resisting paint,which can sustain a highest temperature over 1500°C.23,24Fig.3 shows the typical images recorded by left cameras of the two systems at different temperatures. It is observed that the images obtained using existing blue light 3D-DIC system started to be saturated above 600°C, well matching the result reported in Ref. [17].However, the images captured by the UV imaging system maintains almost unchanged during the whole heating process,implying that the intensified thermal radiation of quartz lamps has no evident adverse effect on the images recorded by the UV 3D-DIC system. Consequently, the reliable and accurate deformation information can be readily obtained using the regular 3D-DIC algorithm.

Fig. 2 Thermal radiation intensity at 650 nm, 450 nm and 320 nm at different temperatures according to Planck’s radiation law.

Fig.3 Recorded front surface images of a specimen heated by quartz lamps captured by blue light 3D-DIC system and the proposed UV 3D-DIC system at different temperatures.

3. Experiments

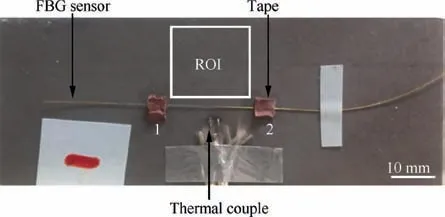

To verify the accuracy of the proposed technique for frontsurface deformation measurement, a nickel-base superalloy Inconel 718 panel, with the dimensions of 100 mm×40 mm×2 mm, was employed as the reference sample because it had the well-characterized coefficient of thermal expansion (CTE). To ensure quality DIC measurements, the same commercial white paints were decorated on the sample surface to generate random speckle patterns. A K-type thermocouple was welded onto the heating surface for recording temperature data of the sample surface. For comparison, a fiber bragg grating (FBG) sensor with 0.3 mm optical fiber diameter (GS-YB-G-I, Jisheng Technology Co.,Ltd., Beijing) was glued onto the sample surface using hightemperature adhesive tape at the positions of 1 and 2 to determine the average strains between these two points. The gauge length of FBG measurements well matches the region of interest (ROI) area measured via UV 3D-DIC, as shown in Fig. 4.

Fig. 4 Tested Inconel 718 sample.

The test sample was vertically placed with its bottom end fixed in front of the quartz lamps heating device as shown in Fig.5(a).To allow direct imaging of the front surface with premade speckle patterns (surrounded by a dotted-line rectangle)by the UV imaging system, one quartz lamp located in the middle of the quartz lamp array was removed. The UV 3DDIC system was placed in front of the sample. Note that to protect the safety of the imaging system,a wool insulating felt with a central 109 mm×187 mm square hole was placed between the quartz lamps array and UV 3D-DIC system to prevent the light of quartz lamps from entering the digital cameras as shown in Fig. 5(a). A region of interest (ROI) of 320×290 pixels (corresponds to 20.3 mm×18.4 mm as shown in Fig. 5(b)) on the sample surface was imaged and recorded, and the corresponding magnification factor is approximately 15.7 μm/pixel. The test specimen was heated from room temperature of 20°C to 800°C with a rate of 1°C/s, once reaching each temperature of 100°C, 200°C,300°C, etc., 1 min dwell time was used to stabilize the heated specimen as shown in Fig.5(c).During the whole heating process, in-situ images were captured at a frame rate of 5 fps.

3.1. Noise floor of the established UV 3D-DIC

To quantify the performance of the established UV 3D-DIC system, a sequence of 160 pairs of static images of the rectangular Inconel 718 panel at temperatures of 20°C, 400°C and 800°C, respectively, was recorded by the UV cameras at the same framing rate.These image series were processed to calculate the displacement distributions using the same calculation parameters.Since no external load was applied to the test sample, the applied in-plane and out-of-plane displacements should be zero and the measured displacements thus can be attributed to the measuring errors.Fig.6(a)-(f)show the mean values of u, v, w displacements and standard deviation (SD)errors of the measured u, v, w displacements extracted from the 160 continuously recorded static images.

Fig. 5 On-site image of front-surface deformation measurement of Inconel 718 by UV 3D-DIC under quartz lamp heating.

Fig. 6 Mean values of u, v, w displacement and standard deviation of u, v, w displacements for the continuously recorded 160 static images of the Inconel 718 panel at 20°C, 400°C and 800°C.

It is observed that the mean values of the three displacement components all fluctuate around zero while the variations in W displacements are much larger than those of u and v displacements, which is independent of temperature of the test sample. The mean values of w displacements increase tremendously at 400 and 600°C compared with at 20°C, with the maximum mean value approaching 0.04 mm.The SD errors of w displacements are approximately 10 times larger than those of u and v displacements independently of temperatures as shown in Fig. 6(d)-(f). The SD errors of w displacements also increase significantly at 400°C and 800°C compared with at 20°C. The large differences in mean values and SD errors between u, v displacements and w displacements at each temperature are related with structural parameters of the 3D-DIC system, such as the pan angle, baseline distance and effective focus lengths of the two cameras.25Furthermore,the mean values and SD errors of w displacements fluctuate more seriously at elevated temperatures, which indicates the fact that heat haze is the most detrimental error source in front-surface strain measurement under quartz lamp heating.

3.2. Determinations of displacement field and coefficient of thermal expansion (CTE)

Fig.7(a)-(c)show the typical front surface images captured at different temperatures by the left camera of the UV 3D-DIC system. The almost unchanged brightness and image contrast proved the extraordinary performance of the proposed UV 3D-DIC technique in suppressing light disturbance caused by quartz lamps and thermal radiation. The corresponding displacement fields of Inconel 718 can be calculated via regular 3D-DIC algorithm with the image captured at 20°C as the reference images. In DIC calculation, the subset size used was defined as 29 pixels×29 pixels and the grid step was chosen to be 5 pixels. Fig. 7(d)-(i) show the displacement fields after eliminating the in-plane rigid-body motion at 400°C and 800°C, respectively. The evenly spaced contour lines in Fig.7(d),(e),(g)and(h)indicate homogeneous thermal expansion. Also, from the W field displacements shown in Fig. 7(c)and (i), we can see that the W displacements are almost zero.

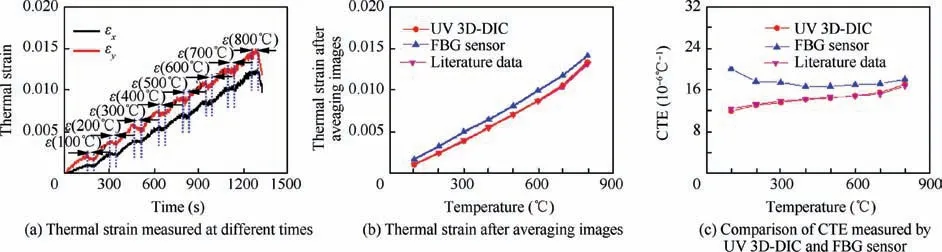

Based on the in-plane displacement fields shown in Fig. 7,thermal strains in the x and y direction can be computed using linear plane fitting. Fig. 8(a) shows the front surface thermal strain of Inconel 718 from 100°C to 800°C with different image numbers.It is clear that the thermal expansion increases as the temperature increases. In addition, it can be seen that the thermal strain of εxand εycompletely match the step heating progress(as shown in Fig.5(c)).The differences between as well as the little jagged noise in the measured εxand εyvalues indicating the adverse influence of heat haze, namely the unavoidable variation of the refractive index of the air caused by temperature gradients between the heated sample and the camera lens.

A two-step average method was used to obtain more accurate strain results. First three hundreds images captured at each constant temperature (as shown in Fig. 8(a)) were averaged before 3D-DIC analysis. Also, the obtained strain in x and y directions was further averaged at each temperature to get the final thermal strains from 100°C to 800°C. Fig. 8(b)shows the comparison of averaged thermal strain measured by UV 3D-DIC and FBG sensor.As the coefficients of thermal expansion of the same material at a temperature range of 100°C to 800°C can be found in Ref. [26], from which the thermal strains can be calculated. The well matched result of UV 3D-DIC and literate data is shown in Fig.8(b),confirming the accuracy of the proposed UV 3D-DIC for front-surface high temperature deformation measurements. However, the strain measured by the FBG was deviating from literature data and results of UV 3D-DIC. The maximum relative error was about 17% which is mainly due to the bonding characteristics of optics fiber and sample.27

Fig.7 Front surface images captured by the left camera of the UV 3D-DIC system and u,v,w displacement fields measured at 400°C and at 800°C.

Fig. 8 Thermal stain and CTE measured by UV 3D-DIC system.

Further, based on the measured strain shown in Fig. 8(b),the CTE can be determined by the following equation:

where α is the average CTE of the Inconel 718,ε is the average strains measured at elevated temperatures as shown in Fig. 8(b), t-t0is the change of temperature with t0=20°C. The measured α agrees well with the result of the CTE as shown in Fig. 8(c) having the maximum relative error less than 0.045%.It is important to note that although the highest temperature measured is up to 800°C in the preliminary frontsurface deformation measurement, the proposed front surface measurement technique has a great potential for higher temperature applications.

4. Conclusions

UV 3D-DIC is proposed for non-contact full-field measurement of front-surface deformation of hypersonic materials and structures subjected to aerodynamic heating. Compared with the widely used blue light 3D-DIC technique, UV 3DDIC offers extraordinary performance in eliminating the strong light disturbances caused by quartz lamps heating.Real-world experiments showed that high-fidelity images with almost constant brightness and contrast can be recorded by the UV imaging system, and these images can subsequently be processed with regular 3D-DIC method to extract full-field surface 3D deformation.The UV 3D-DIC provides a practical and effective solution for visualizing and characterizing deformation response of hypersonic materials and structures subjected to transient aerodynamic heating.

Acknowledgements

This work is supported by the National Natural Science Foundation of China(Nos.11602011,11872009,and 11632010),the National S & T Major Project of China (No. ZX069), the Aeronautical Science Foundation of China (No.2016ZD51034) and the Postdoctoral Science Foundation of China (No. 2017M610029).

CHINESE JOURNAL OF AERONAUTICS2020年3期

CHINESE JOURNAL OF AERONAUTICS2020年3期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Experimental investigation on operating behaviors of loop heat pipe with thermoelectric cooler under acceleration conditions

- Investigation of hot jet on active control of oblique detonation waves

- Experimental study of rotor blades vibration and noise in multistage high pressure compressor and their relevance

- Unsteady wakes-secondary flow interactions in a high-lift low-pressure turbine cascade

- Effect of protrusion amount on gas ingestion of radial rim seal

- Optimization design of chiral hexagonal honeycombs with prescribed elastic properties under large deformation