Battery Charging Method for Electric Vehicles:From Wired to On-Road Wireless Charging

*

(Solace Power Inc., 1118 Topsail road Mount Pearl, Newfoundland and Labrador, A1N5E7, Canada)

Abstract: Recent fossil fuel shortages and global warming related problems have caused a substantial shift from internal combustion engine vehicles towards EVs. This paper explores the thorough review of battery charging infrastructure from wired connection to on-road wireless charging for an EV. The initial part of the paper deals with the wired charging and its power electronics infrastructure. The later portion deals with the wireless charging where both static and On-Road types are discussed. Furthermore, various aspects of wireless power transfer are also discussed. The Market scenario and future growth prospects are reviewed and presented in last section of the paper.

Keywords: Wired charging, static WPT, on-road WPT.

1 Introduction

The increase in price of oil and environmental issues has resulted in growing interest in clean vehicle technologies such as EV and Fuel cell EV[1]. As a result,electric vehicles(EV) are becoming a more attractive solution than conventional vehicles(CV). EVs are powered by electric batteries, which need to be recharged with electricity from the grid. It is clear that the EVs constitute a clear link between the electricity and the transport sectors. Moreover, the EVs can provide a good solution to reduce the environmental impacts of transportation and energy dependency because they have low energy consumption and zero emissions[2].

Generally, two types of battery chargers are used:off-board and on-board battery chargers with unidirectional and bi-directional power flow. Most of the battery chargers take a power from the utility grid, for this reason they often termed as unidirectional battery chargers(UBCs)[3]. Unidirectional charging reduces the interconnection issues and battery degradation. On the other hand, some battery chargers work in both directions and these are called bidirectional battery chargers(BBCs)[4]. These chargers support stabilization of power with proper power conversion. On-board chargers can be used to charge from the utility outlet at the workplace or household plug or shopping malls during the day time. Off-board charging is like a gas station used for conventional vehicles and thus its purpose is to charge fast. Compared to off-board charging, equipment is less for on-board charging.

Charging of an electric vehicle can be performed by either wired(conductive) charging or wireless(inductive)charging[5]. Wired charging uses metal contact between electric vehicle supply equipment(EVSE) and the charging inlet of the vehicle. Even though wired charging is popular, problems with messy wires and safety concerns in wet environment are major drawbacks of this system. These problems can be overcome by charging the battery of the vehicle without wires and this technology is termed as wireless power transfer(WPT).Wireless charging has been attracting more attention because of their advantages compared to the wired counterpart such as no exposed wires, ease of charging,and fearless transmission of power in adverse environmental conditions[6].

Depending on the charging time and power level of the battery, EV charging is classified into four types namely mode1, mode 2, mode 3 and mode 4 charging[7-8].Mode 1 charging is considered as slow charging and takes overnight. Mode 2 charging is typically described as semi fast or nominal charging. Both mode1 and mode 2 charging use single phase supply. Mode 1 charging is generally installed at home, but mode 2 charging is installed mostly at public places and shopping malls.Mode 3 and mode 4 are considered as fast charging which typically use the three-phase supply and can charge the battery in less than thirty minutes[9].Depending on various connections and plug type, they are classified as Case A, B, C and Type 1,2,3 respectively.

Now a days, the concept of vehicle-to-grid(V2G)has gained interest due to its ability of to supply stored energy to the grid[10]. It absorbs energy from the grid to charge the battery during peak electricity production and delivers to grid when there is a peak electrical demand.EVs with BBCs are able to implement V2G concept as bidirectional power flow capabilities of their battery chargers. So, BBCs can work in two operating modes,namely “recharge” mode when they absorb energy and“generation” mode when they deliver energy to grid.

In recent years, interest in wireless charging technology is growing for EV charging applications[11].It consists of two main stages, namely the transmitter and the receiver, each of them having a coil coupled to the other one with an air gap between them. By Faraday’s law of magnetic induction energy will transfer from the transmitter to receiver. Misalignment of coils,long charging times and degradation of the battery are major issues. The difficulties in static wireless charging can be overcome by on-road charging and charge the battery while in vehicle is moving which saves the charging time and degradation problems[12].

On-road EV charging is an emerging technology where one can charge their EV batteries while vehicle is on move[13-14]. Apart from their advantages such as less battery requirements, they suffer a problem of misalignment and further leads to synchronization failures[15]. Various loading conditions, frequency mismatch,misalignment and component tolerance are the main causes for the synchronization failure.

This paper is organized as follows: Section 2 considers the EV charging infrastructure and section 3 Power supply infrastructures. Section 4 considers and discusses wireless charging of EVs in static position and section 5 refers to On-Road wireless charging of and EVs. Section 6 discusses evaluation and the future scope and market scenario of battery chargers and section 7 concludes the paper.

2 EV charging infrastructures

2.1 Types of battery charger

Depending on the charging time available, chargers can be installed in houses, offices, shopping malls and public places to enable EV owners to charge their EV.Wired type EV battery chargers have direct connection to the supply using an extension power cord to plug from the wall outlet into the EV. It is popular, simple in design and highly efficient. The wireless battery charger uses coupling as the mode of energy transfer. Through inductive chargers, a charging station is used to transfer high voltage and current directly from the grid into an inductive paddle or pad with an electro-magnet that acts as half a transformer. The other half is situated inside the EV and once full contact is made between the two magnets, the current is allowed to flow across and into the battery, charging at a higher rate due to the charging stations direct power grid connection. The charging structure for the both chargers shown in Fig.1(a) and 1(b).

Fig.1 Wired and wireless charging[12]

2.2 Charging infrastructure-modes, cases and types

The success of EVs will be highly dependent on whether charging stations can be built for easy access.This is also critical for the potential grid supports that EVs can provide. The first place considered for charging stations should be homes and workplaces. Other potential locations with high populations include gas stations, shopping centers, restaurants, entertaining places,highway rest areas, municipal facilities, and schools.There have been various standards regarding the energy transfer, connection interface and communication for EV charging.

Mode 1 charging is the use of a standard AC 110 Volt (for US), 230V (for Europe and most of the world)and not exceeding 16A household outlet. Electric vehicles come with on-board charging electronics, as well as cords and equipment that allow the vehicle user to plug their car into an outlet in their garage. This is the cheapest and most convenient home-based charging method, but it is also the slowest. Charging times vary greatly from vehicle to vehicle, but generally take around 7~15 hours for a fully depleted battery to be at full capacity. For example, if the driver of a Nissan Leaf– which has about a 100-mile range – drives 30 miles daily, the battery will only be depleted 30% each day.Since Mode 1 charging will recover about 4.5 miles of range per hour, the Nissan Leaf will be back to full charge after 7 hours. It is generally installed in household garage. So, it doesn’t require special socket for the charging the battery in USA, this method of charging is prohibited as it requires earth connection.

Mode 2 chargers use a 230V or 440V AC mains not exceeding 32A. It can be charged through charging stations often located in public places, such as at the shopping malls, restaurants, city parks, or even workplaces.Mode 2 charging is generally referred to as “opportunity charging” because vehicle user usually uses this type of charging whenever they have the chance. Mode 2 charging takes around 3~8 hours for a full charge and nominal cost of installation of around $1000 to $2000.

Mode 3 charging is the fastest and most powerful type of charging available. It typically operates with three phase 440V supply and require off-board charger,as a result, it provides a vehicle with a full charge in minutes instead of hours. These charging stations are used for EVs as well as large vehicles like electric buses,and are found in public and commercial areas, airports,and transportation corridors.

The scenario for Mode 4 charging is a setup where the AC mains power is converted in the charging station into d.c. and the plug type ensures that only a matching EV can be connected. Using DC fast charging allows for considerable higher currents up to 400A. A Japanese protocol CHAdeMO is a d.c. fast charging standard designed for EVs that complies with Mode 4 charging. It charges in less than 30 minutes and up to 50kW with communication management protocol. Infrastructure cost of $30000 to $160000 has been reported[9].

Now, only Teslas can use the Tesla Supercharger network. Superchargers are installed widely across the US(and Europe) and can charge an electric car faster than any other chargers out there. Tesla is quickly growing the Supercharger network, and this creates one large competitive advantage for the popular EV company. At the moment, Tesla Superchargers have a max power output of 120kW.

Depending on method of charging infrastructure and connection, cases are classified as three types namely Case A, B and C. “Case A”: connection of an EV to the a.c. mains utilizing a cable and a plug permanently attached to the EV. It is typically used with Modes 1 and 2 charging. “Case B”: connection of an EV to the AC mains utilizing a detachable cable assembly with a connector (to be inserted in the EV inlet) and a plug (to be inserted in the supply outlet). Case B1 corresponds to the connection to a wall-mounted socket-outlet. Case B2 corresponds to the connection to a charging station. Case B connection is typically used with Mode 3 charging.On the other hand, “Case C”: connection of an EV to the a.c. mains utilizing a cable terminated with a connector(to be inserted in the EV inlet) permanently attached to a charging station or a specific supply equipment. Only Case C is allowed for Mode 4 charging.

Type 1 connector introduced by Yazaki(SAE J1772)for charging the PEV battery from a single-phase supply.Type 2 connector introduced by Menneskes(IEC 62961)for charging the PEV battery from single-phase 230V and three-phase 400V supply with current up to 63A[9].Type 3 connector introduced by EV Plug Alliance:Scame/Schneider(IEC 62196) for charging from single and three-phase supply equipment. It has a maximum current of 32A and a safety shutter. There are two versions: Types 3A and 3C. Type 3A is for charging a light PEV battery(f.i. motorcycle) from a single-phase supply with 250V and 16A; Type 3C is for charging all-PEV battery from single and three-phase supply with up to 500V and 63A, all of them with control pilot."Type 4" – connector for fast d.c. charge(IEC 61851). It is termed CHAdeMO like Mode 4 charging.

An electric supply equipment(EVSE) consists of conductors, including the ungrounded, grounded, and equipment grounding conductors, the electric vehicle connectors, attachment plugs, and all other fittings,devices, power outlets, or apparatuses installed specifically for the purpose of delivering energy from the premises wiring to the electric vehicle.

Fig.2 Schematic of cable and wire types[16]

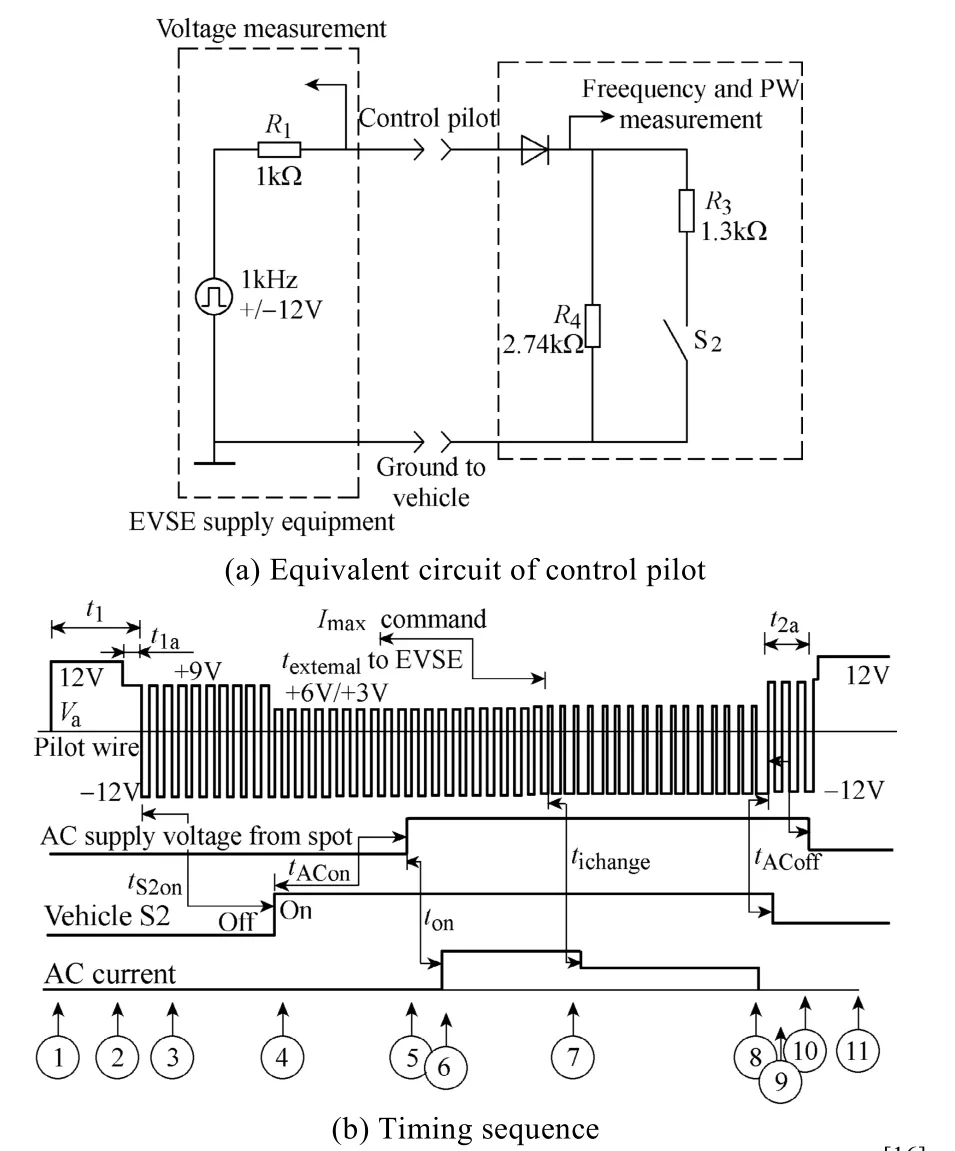

The control pilot sits in the charging cable assembly connecting the in-cable control box or the fixed part of the charging facilities and the EV earth through the control circuitry on the vehicle. Functions that shall be provided by the EVSE or the EVSE and vehicle system are. ① Verification that the vehicle is properly connected or not; ② Continuous checking of the continuity of the protective earth conductor;③ Energization and de-energization of the system.There are optional functions also provided by EVSE including selection of the charging rate, determination of ventilation requirements of the charging area, detection/adjustment of the real time available load current of the supply equipment, retaining/releasing of the coupling and control of bidirectional power flow to and from the vehicle. EV charging. Fig.3 shows the control function and how EVSE is operated at different conditions.

3 Power supply infrastructures

In order to charge a vehicle battery while considering the battery-charging characteristic and power factor from the grid is seen unity, there are two categories among many circuit topologies: unidirectional battery chargers(UBC) and bidirectional battery chargers(BBC).In the UBC, the set of converters arranged from grid to battery, all are not active/controlled converters(i.e. made of diode rectifier) and they are not able to support bidirectional power flow. Therefore, these kinds of chargers are less complex and can only fulfill the purpose of charging the battery. The other type is bidirectional chargers which have ability to charge the battery as well as transfer battery power to the grid in certain situations.The BBCs have active converters with bidirectional power flow, so these are more complex but also have more flexibility of power flow. Both UBC and BBC have circuit arrangement with and without electric isolation between load and supply side converters. The isolated battery chargers use a high frequency transformer that provide galvanic isolation as well voltage-matching(step up/down) between input and output side. The high frequency transformer has many other advantages like low volume, lightweight, low cost, less noise and reduced core saturation over a line frequency transformer.

Fig.3 Control function of EVSE at different conditions[16]

3.1 Unidirectional battery charger

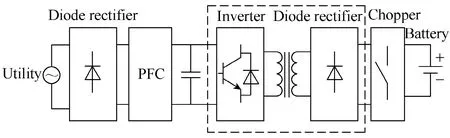

A typical battery charger performs rectifying and power-conditioning operations of the power extracted from grid. The input power of the charger is passed through a set of power converters, which include AC to DC(rectifier), DC to AC(inverter), or DC-to-DC converters (chopper) according to the requirement.Based on conversion stages, the chargers are again classified in single stage, two stage and so on. Since battery chargers for vehicle application work with high power and they have to follow fast charging strategy and grid power factor constraints as well, therefore not all this is possible in single stage. The multiple stages of a charger consist of rectification of ac power, power factor correction(PFC), DC to AC (high frequency) conversion,galvanic isolation, rectification and then DC-DC conversion to meet charging strategy. A typical schematic of this process is shown in Fig.4.

The diode rectifier takes AC current from the utility and provides DC current to the next stage. There is a capacitor before the second stage of power conversion;this keeps voltage of dc bus constant. Due to the constant dc bus voltage, the input ac current of the rectifier is not completely sinusoidal. The distortion in input ac current leads to poor power factor at utility. In order to improve PF at input side, a power factor correction(PFC) circuitry is introduced between dc bus and diode rectifier. The PFC is a dc-to-dc converter,which provides varying voltage conversion ratio to maintain the shape of input current sinusoidal.

High power chargers for EV batteries need isolation for safety reasons. The isolation is provided by a HF transformer, which works with some kHz frequency.As shown in Fig., the inverter converts DC bus voltage to high frequency ac supply to feed transformer input.Another main function of the transformer is to step-down voltage level, which is suitable for battery; this is not done by chopper, as it is less efficient. The secondary ac voltage of the transformer is rectified again with diode rectifier. In the next and final stage, the rectified dc voltage is fed to the battery and this is done by a DC chopper. At the beginning of the charge, the chopper operates in current control mode; when the battery voltage approaches its nominal value, the chopper enters into voltage control mode and completes the charging process.

3.2 Bidirectional battery charger

Fig.4 Schematic of a full functioned unidirectional battery charger[12]

The charger as discussed above and shown in Fig.4 cannot allow power flow in reverse direction, because of uncontrolled diode rectifiers. If converters in all stages are kept bidirectional converters i.e. full controlled converters, then the complete charger arrangement becomes bidirectional. In the first stage, instead of a diode rectifier, a fully controlled rectifier is then used as it can perform bidirectional flow as well as the function of power factor correction. In the same way in the secondary side of transformer if full controlled converter is utilized instead of the diode bridge, the dc chopper can be eliminated as shown in Fig.5.

The first bridge converter in the supply side has full flexibility to control DC bus voltage and power factor with desired direction of power flow. Other two bridge converters connected with a high frequency transformer performs the main function of this type of chargers. Both of these converters work with square wave pattern of voltage and frequency in kHz. There is an inductorLthat works as temporary energy storage and it support both converter to operate with soft switching. A good design of converters and their components can ensure much less switching losses and in this way, good efficiency is achieved. Because there are two controlled converters or active bridge across the HF transformer,this topology is called dual active bridge(DAB) battery charger.

The DAB technology was initially proposed in early 90’s when semiconductor devices were not well developed. Again, this is more popular today for on-board battery chargers for EVs but there are still some issues that are seeking more research interest.One of the problems with DAB is circulating current in the transformer. When the voltage amplitudes of primary and secondary do not match according to turn’s ratio,very small circulating current is flown, and this leads to more losses and heat in the transformer and converters.This problem can be fixed using an appropriate phase shift scheme in primary side or secondary side or both sides of the converters. Some examples of phase shift are single phase shift(SPS) where a certain phase shift is given between primary and secondary voltage, then extended phase shift(EPS) where one additional internal phase shift is given between 2 legs of one converter, one is dual phase shift(DPS) where an equal internal phase shift is given in both converters. There is a unified scheme of phase shift that is called triple phase shift(TPS) where both primary and secondary voltages have a phase shift with both converters have unequal internal phase shift.

Another big problem is range of soft switching of both converters with varying load condition. Actually,DAB has good efficiency at full load with a wide voltage conversion ratio, but the soft switching range decreases as load current decreases. Therefore, under light load condition, various resonant techniques are used as a solution to improve the range of soft switching.The DAB combination is designed using some additional passive components (inductor, capacitor) such that it has simple construction, lightweight, smooth, easy and robust control, wide soft switching range and less sensitivity with parameter variation.

Fig.5 Schematic of a bidirectional battery charger[12]

3.3 Integrated chargers

As charging and traction are not simultaneous in EVs, except during the regenerative braking, the so-called integrated chargers are also applicable. They use the electric drive system components also during charging. This leads to a significant reduction in volume,weight, and cost. This integration also allows galvanic isolation, but both the power electronics and the control circuit of the integrated charger have to take care of the reconfiguration of the electric drive systems. The aspects that need further research are charger isolation, charging voltage control, unwanted magneto motive force developed in the motor during charging, power factor operation, and harmonic content in the current from the grid, efficiency, and hardware/software complexity.

4 Static wireless power transfer

4.1 WPT: definition, structure and principle of operation

Wireless power transfer systems(WPTSs) are systems able to supply a load with the electric energy absorbed from the grid without requiring any wired connection between load and grid. Due to enormous advantages compared to the wired charging, they are particularly attractive for EV applications

The arrangement of a WPTS is sketched in Fig.6.Transmitter coil is buried in the road and the receiver coil is located on-board the EV. When the vehicle is properly parked over the transmitter coil, the two coils are coupled and energy can be transferred from the grid to the battery, which acts as the load of the system.By the Faradays law of magnetism, the emf will induce in the secondary coil, which further charges battery through power conditioning system. The elements in WPT system includes ① Utility grid with power conversion system; ② Magnetic coupling system in transmitter and receiver; ③ Power conditioning system to charge the battery[17].

Fig.6 Schematic of WPT system[17]

The technologies encompassed with the WPTS are electric[18], magnetic[19]and electromagnetic fields[20].These technologies broadly classified based on underlying mechanism, transmission range and power rating. Based on power transfer distance these are classified into near field and far field. Laser, Microwave and RF are considered as far-field methods. Inductive,capacitive technologies consider as a near field. Even though far field transfers large distances, they suffer from tradeoff between frequency and efficiency.Inductive technology, adopted in the so-called inductive or resonant coupling WPTSs, is most convenient for medium- and high-power equipment because it transfers a much higher energy per unit of volume than the electric-field technology, and does it with much higher efficiency than the electromagnetic-field technology.Simplified WPTS represents magnetic WPTS consist of inductive WPTS and resonant WPTS.

4.2 Aspects of WPT

Present day WPT system for an EV, mainly focus on the following aspects; ① Physics of WPT system;② Efficiency maximization techniques; ③ Coil coupling;④ Power supply requirement; ⑤ Safety and shielding issues; ⑥ Communication requirements. Therefore, this paper proceeds further with detailed explanation of each of the aspects. The detailed analysis is described as follows

4.2.1 Physics of WPT system

Critical issues of the WPT system lie in understanding of the physics, as it gives an overview of coupling system design which plays a crucial role in development of WPT system Different/various parameters.

(1) Inductive parameters.

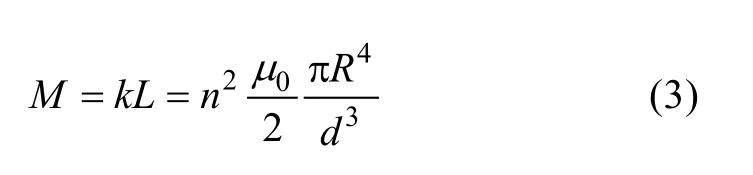

One of the key factors that define the performance of WPTS is the coupling coefficient of the coils. It depends on the size and the shape of the coils and on the distance between them. The magnetic flux density is calculated between the two coils with a distancez

WhereRis the radius of the coil and A is its crosssection. The last expression ofBin (1) holds when the distance from the coil is much longer than the coil radius.If the magnetic induction magnitude is assumed constant across the coil cross-section, the self-inductance of the coil is

wherenis no. of turns. The mutual inductance between two equal coils set coaxially at a distanced, much longer thanR, is

Figure of merit (FOM) is another important aspect in the wireless power transfer and [67] give the power loss in the WPT

Fig.7 The relationship between parameters of the WPT[67]

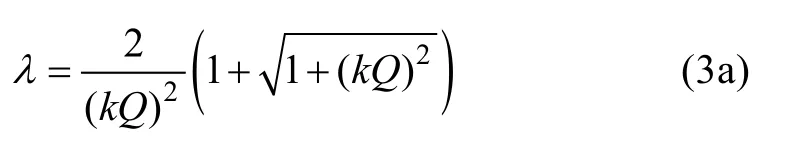

The graphical figure for the Eq.(3a) shown in Fig.7(b) which shows it is only dependent on the two basic parameters of the WPT: The coupling factork,between the receiver and transmitter coil and the system quality factorQ. Moreover, from the equation, it can say that the general FOM is product ofkandQ.

(2) Near field and far field.

Near fields[21-22]can be seen as the reactive field surrounding any electrically charged object. In the static case, these fields are simply the electro-static fields,while in the non-static case they form time varying electric and magnetic fields, which are out of phase close to the object (closer thanλ) and can be used to induce current in near-by objects. In contrast to the far-field waves, near-fields represent zero energy flow according to the Pointing vector due to the 90-degree phase difference between the electric and magnetic fields[23]. This gives nearfields an advantage in efficiency,as they do not radiate energy away from the source

(3) Loosely coupled and tightly coupled.

If all the flux links the secondary, thenkis 1 and if none of the flux links the secondarykis 0 i.e. 0≤k≤1.Based on the values ofkthe magnetically coupled system can be classified into two categories, namely tightly coupled systems and loosely coupled systems.In tightly coupled systems, such as transformer and induction motor, the primary is placed in proximity of secondary and flux is shaped by placing windings on the core of high magnetic permeability. Therefore, they have mutual inductance greater than the leakage inductance.Because of tight coupling,kusually lies between 95% to 98% for the transformer and approximately 92% for the induction motor[24].

In the case of using magnetically coupled system for powering EVs, a large air gap is required to allow for inconsistency in the road surface and better clearance between the road and vehicle. Because of this large air gap, the leakage flux is very high, and the coefficient of coupling is from 1% to 3% only. Such applications are classified under loosely coupled systems and poor coupling in loosely coupled systems leads to poor transfer of power. To improve coupling and compensate leakage inductance, capacitive compensation in primary and secondary windings is required.

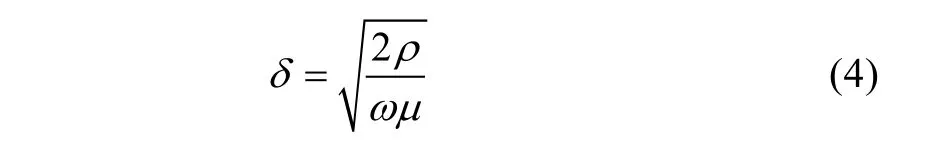

If the conductor is composed of one or more concentric circular elements, then the center portion of the conductor will be enveloped by a greater magnetic flux than those on the outside. Consequently, the self-induced back EMF will be greater towards the center of the conductor, thus causing the current density to be less at the center than at the conductor surface.This extra concentration at the surface is known as skin effect, and results in an increase in the effective resistance of the conductor. The skin depth,δ, is defined as the depth at which the current density falls to 1/e,(about 0.37), of the current density at the surface. This is given by

whereρis the resistivity of the material and is related to the conductivity as 1/σ,μis the permeability of the material andωis angular frequency of the electrical solicitation.

4.2.2 Efficiency maximization techniques

It can be observed that quality factor and coupling coefficient plays a major role in determine the efficiency of WPT system that maximizing efficiency techniques such as. ① Use of ferrite disks[25]; ② Compensation techniques by placing a capacitor[26-27]; ③ Power electronics control[28]. The detailed realization of above methods is explaining in following sections.

In an inductive WPT, without secondary resonant capacitors, the Power transfer to the load cannot be sufficient unless the input voltage is large. The reason is that the impedance of the receiver coil is quite large and therefore is responsible for a significant current drop in the load resistance. The best way is to increase the input voltage so that the power transferred to the load is sufficient, but this solution is not optimal because it requires higher current amplitudes in the primary coil,which in turn generates greater Joule losses. This may lead to dramatic results in terms of efficiency and Joule losses. Compensation topologies can be classified depending on reactive structures into single-resonant(SRT) and multi-resonant types(MRTs). The singleresonant structures shown in Fig.8(a) associate a capacitor to each coil whereas multi-resonant Fig.8(b),Fig.8(c) topologies employ multiple reactive components in the transmitter and/or the receiver side. The two compensation capacitancesCTandCRfor the main topologies give two degrees of freedom in the system. In addition to their simplicity, there exists a wider study on the single-resonant structures so that some design guidelines have already been identified in [29].

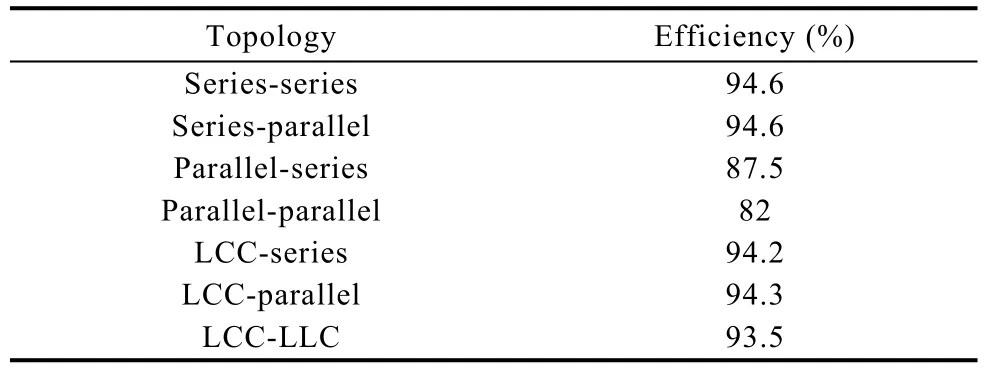

Among the three categories, TWERT is a promising topology because with SRT required reactive power compensation and complex methodologies with THERT.The efficiency is well explained in the Table 1, and the comparison of various parameters for the TERT is tabulated in Table 2.

4.2.3 Coil-coupling

(1) Sizing issues.

Coil coupling is heart of the WPT system design.Prior to design of the coupling system, one must have clear idea of the behavior of coil impact parameters such as coil design, core design, and coil alignment. The impact parameters are influenced by such as coil material, dimensions of the coil, core, and misalignment.Careful study of these parameters are useful for the best coupling system design.

Fig.8 Example of different types of resonant compensation topologies

Table 1 Efficiencies of different topologies[29]

Table 2 Comparison of topologies[26]

(2) Coil impact parameters.

Coil parameters such as geometry that includes diameter, no. of turns and coil material are important evaluating parameters of the design process. Coil geometry of WPT influenced by coil material and optimizing coil material can improve the system performance. Copper Litz wire is commonly used in most of the systems and multi-layer, multi-turn tubular coils have been adopted for improving the transmission efficiency, with a study of the skin effect.

The method of approach for coil design must constrained to following points:

●The inductance and power capability must meet the category requirements, including the working frequency and transferring power.

●The mechanical dimension must fit to the target application, including the coil area and thickness.

●The coil must provide the electromagnetic shielding for the associated electronic device, such as the mobile phone.

●Durable construction.

There is generally a trade-off between coil size,performance, and cost. Coil size and cost are inversely related smaller coils give a better performance, but at a higher cost. Coil structures can also influence the performance of the system. Spiral coil, flat coil, square coil, circular and DD coils have different performances according to the studies in [30].

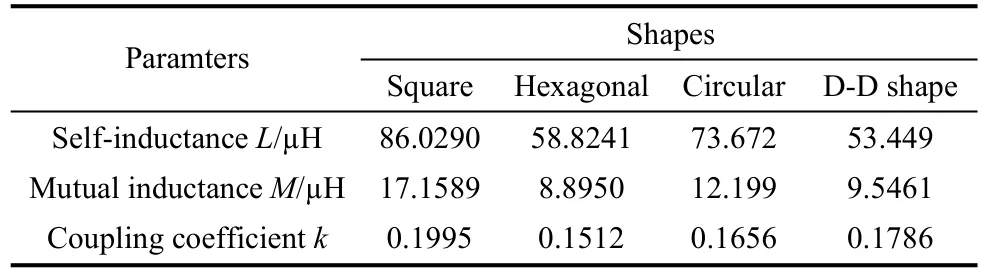

As an example, for the mentioned dimensions of 15 turns and with round wire cross section, inductive parameters of different shaped coils are built as shown in Fig.9. The turn distance in all the coils is kept 7mm(center to center). The values of inductive parameters simulated by COMSOL are mentioned in Table 3 for these spiral coils.

(3) Cored coupling.

To enable higher coupling coefficient and to direct the magnetic flux lines in proper direction, ferrite cores are used. Ferrite cores are utilized because of their properties of high magnetic permeability, useful in directing the flux, and low electrical conductivity that mitigates the magnetic losses under high-frequency flux cycles. Different ferrite core structures are illustrated in literature, for example, in [30], cores having the I, C and E sections shown in Fig.9, have been examined.

Table 3 Inductive parameters of different types of coils

Fig.9 Core structures(I, C and E)[30]

The difference between the coupling coefficient for coreless and cored coupling for the varying the no. of turns is examined. For the fixed distance of 0.15m, the coupling coefficient of cored coupling is 75% more than the coreless case[31].

(4) Coil misalignment.

Clearly, coil orientation (alignment) is one of the major issues for EV charging application. Because of the tolerance in the vehicle-parking maneuver, the receiver coil may be not perfectly aligned with the transmitter coil during charging. This leads to a coupling coefficient lower than the nominal one with a consequent decrease of the efficiency in the power transfer. For EV charging applications, as with the tolerance in the vehicle-parking maneuver, the receiver coil may be not perfectly aligned with the transmitter coil during charging. This leads to a coupling coefficient lower than the nominal one with a consequent decrease of the efficiency in the power transfer

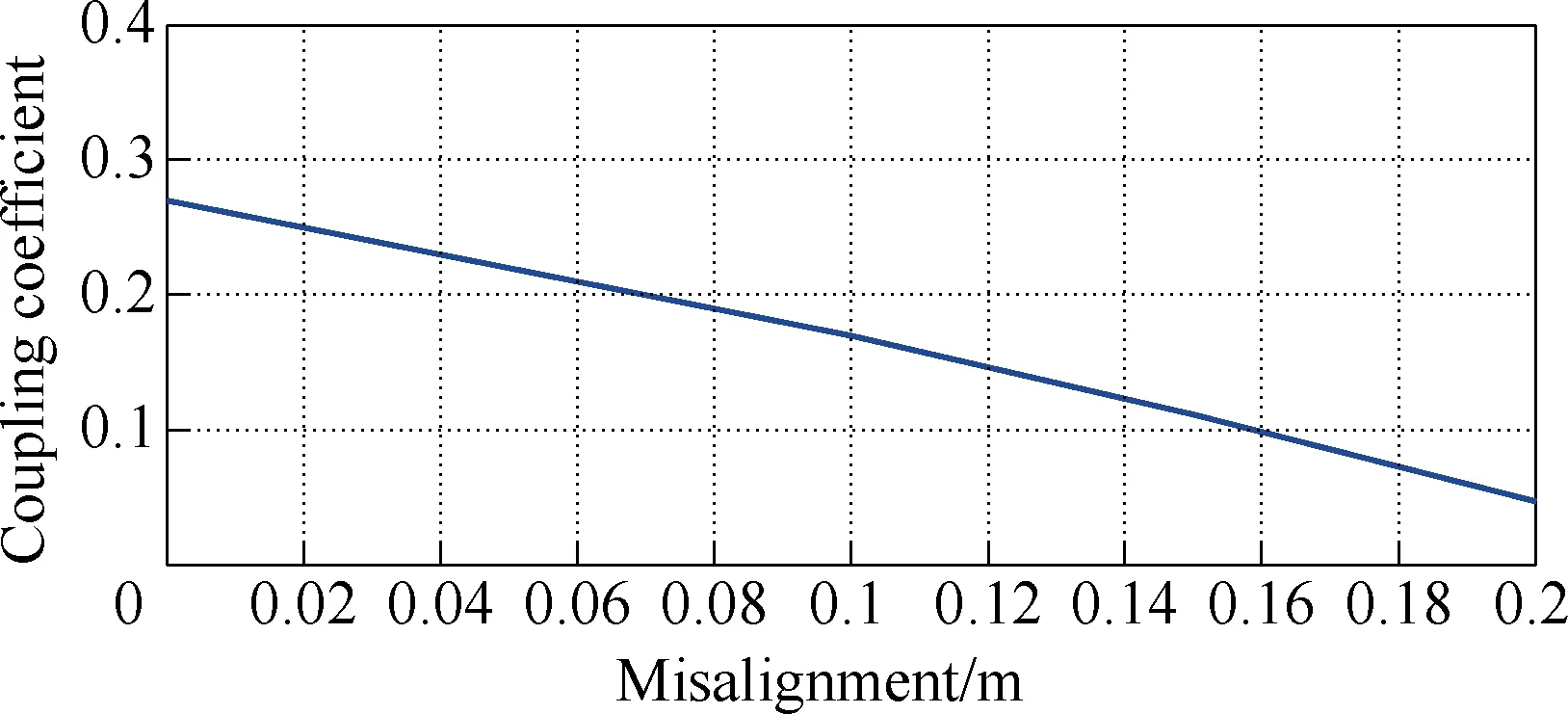

Fig.10(a), (b) and (c). Shows the coupling coefficient behavior of the 4-coil systems for coil distance, lateral misalignment and angular misalignment conditions.

Fig.10 Coupling coefficient for the

Fig.11 shows the behavior of coupling coefficient vs coupling coefficient. Which shows the coupling coefficient decreases with increase in misalignment scenario handled by the various researchers mainly by power electronics control circuitry and with compensation topologies Compensation circuits are placed in the primary and secondary side to improve power transfer,efficiency, voltage regulation, controllability etc[33].

4.2.4 Power supply requirements

(1) Frequency selection.

For effective wireless power transfer a high frequency alternating current is necessary. This frequency is in the order of 10kHz to 100kHz, which is much higher than the 50Hz of the electrical grid. The desired frequency is achieved by combining a rectifier with an inverter. In order to keep losses at a minimum soft switching was preferred (today WBG devices), where the transistors of the inverter only switches on or off when the current is zero. The specification on the operating frequency follows from the recent resolution of the SAE International J2954 Task Force for WPT that fixed at 85kHz the nominal frequency of operation of the WPT systems for light-duty plug-in vehicles[34].

(2) Power converter.

At first on the primary side, Power Electronic System (PES) converters having utility frequency i.e. 50 or 60Hz which is converted to high frequency AC(greater than 20kHz). Either a single stage or two stage can do this. In single stage, power conversion is done directly from low frequency AC to high frequency AC using AC-AC cycloconverters while, two stage can be done by initially converting AC to DC and then DC to AC conversion performed by high frequency inverter.

The DC-AC converters are commonly used to generate a high frequency current on the primary side of a WPT system. Practically, there are two approaches to achieve high frequency current generation: linear amplifiers or switch mode power converters. In the former case, the semiconductor devices are operated in a linear region. Even though the development of different classes of linear electronics amplifiers provides various improvements, the nature of high power loss in linear region limits a linear amplifier to low power applications, where power efficient is not so important.Comparing to linear amplifiers, switch mode power converters can achieve high efficiency by fully on/off control. Therefore, switch mode power converters are widely used to generate high frequency track currents for medium or large WPT applications, where the power efficiency is one of the major concerns.

Fig.11 Coupling coefficient vs misalignment[31]

Numerous switch mode power converters are currently being deployed to generate high frequency track currents for WPT systems. The input power source for a switch mode high frequency power converter can be either a DC or directly from AC mains. Thus, the switch mode power converter for a WPT system can be commonly classified further into two categories according to the type of their input sources. They are DC-AC inverters and direct AC-AC converters.Practically, because a direct DC source is not ubiquitous for accessing to generate high frequency currents, at present most of the power converters used for WPT systems are two stage AC-DC-AC converters. To obtain a constant DC power source, a front-end AC-DC rectifier is needed. In addition, energy storage elements are necessary to link the rectification circuits and the DC-AC inverter to buffer the difference between the instantaneous input and output power within a two-stage converter. In order to meet the requirements of international standards and improve efficiency, many methods are applied to the AC-DC conversion stage,such as synchronous rectifiers, filters, power factor correction circuits, etc. Once a stable DC power is obtained, a second stage DC-AC inverter is required for the high frequency track current generation.

A PWM hard switching technology is commonly used in the design of power converters. Using such a switching technique, the on and off transients of the switches may take place at non-zero voltage or current instants leading to a hard switching operation. In addition, during the on and off switching transients, the semiconductors have to withstand high voltage and current simultaneously resulting in high switching losses and stress. Passive inductive or capacitive components can be used as snubbers of semiconductor switches to reduce the switching dv/dtand di/dt. Any variation of the dead time caused by the switching control.

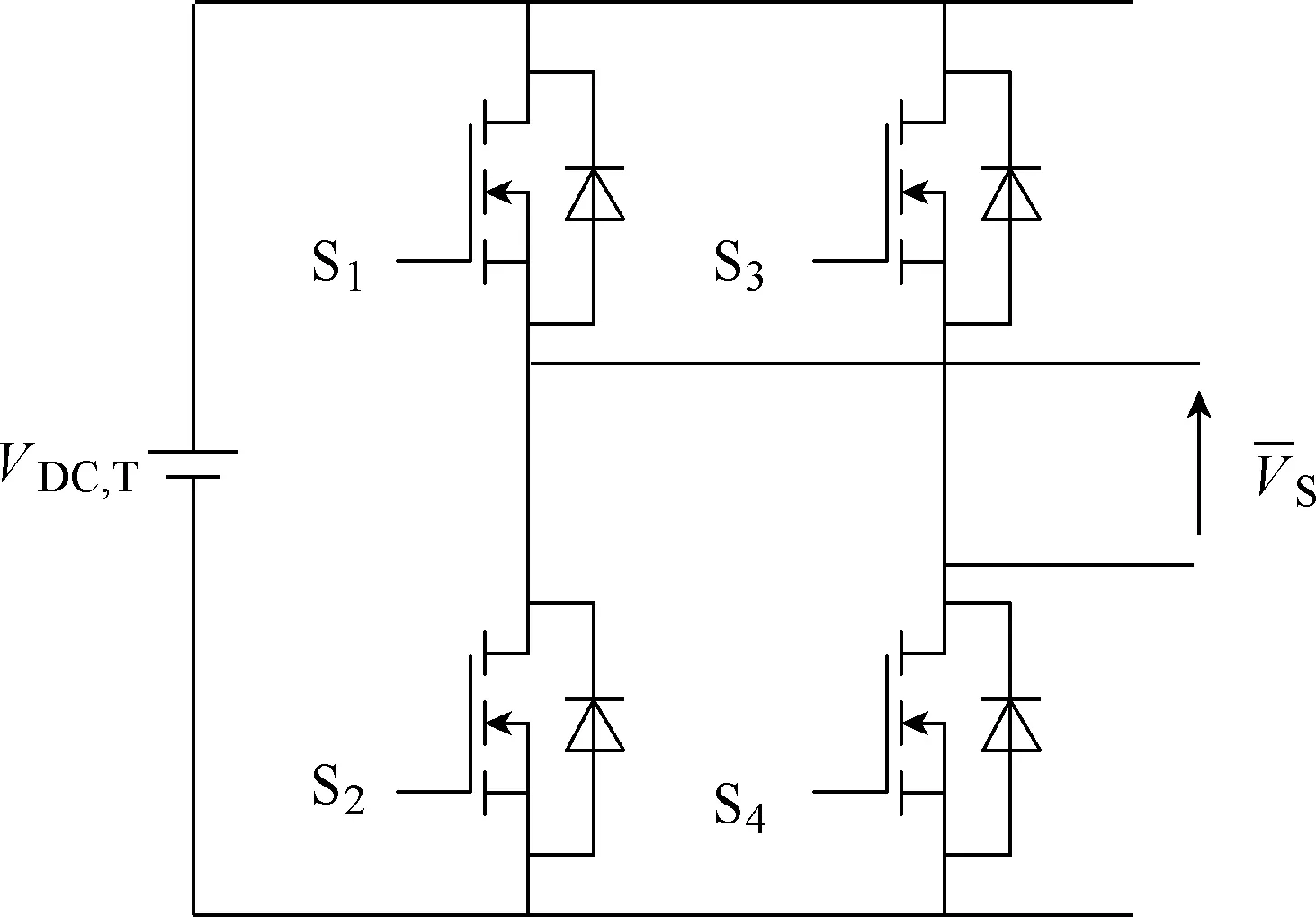

The inverter is a full bridge inverter shown in Fig.12, based on an existing Phase shift full bridge inverter, where the phase shift is driven to be as close to 100% as possible. This inverter is designed for a higher voltage and power level but approximately the same load current.

Fig.12 Full bridge inverter

The term phase shifted full bridge relates to a control scheme where both legs are separately driven to a duty ratio very close to 50% and then phase shifted against each other than the 180 degrees shift between the two legs’ waveforms there is also a delay between the turn off of one transistor and the turn on of the other one in the same leg. Primarily this ensures that the full bridge does not suffer from current shoot through, where it otherwise would have issues at time periods where both the upper and the lower transistor in the same leg are open, i.e. the supply is short circuited. The main point about phase-shifted control in comparison with using conventional pulse width modulation(PWM)waveforms is the possibility to not only control the duty cycle but also add some degree of control of the switching losses.

(3) Losses in converter.

Loss analysis is very important for any power electronics system. Due to the increasing use of power electronics in a wide range of applications, power loss measurement with high accuracy is of great importance in the design process to assess system performance and to optimize design characteristics. To measure the total loss of the system it is necessary to have the idea of losses of individual devices of the system.

Losses in the converter have two types, namely the conduction losses and switching losses. When switching the inverter at the resonance frequency, resonant switching takes place i.e., ZCS and ZVS can be accomplished thereby reducing the switching losses during the switching on and/or switching off. This also makes it possible to operate the converter at high switching frequencies when compared to hard switching PWM converters.

The other losses associated with the converter are the conduction losses that are dependent on the type of switches used. In case of SiC MOSFETs, the conduction losses are dependent on the current flowing through the switch and the on state drain to source resistance.Researchers have approached the system analysis aspect of WPT[35], studied the effect of multiple receivers on the transmitter and how the system can be better tuned by optimizing the load variations.

(4) Control techniques of converter.

There are various techniques used to control the output power and frequency of the system which includes fixed frequency and variable frequency.Different control methodologies such as voltage control,duty cycle control, frequency control and phase shift control. The advantages and disadvantages of different techniques are tabled in Table 4.

The main issues regarding type of converters are how they affect the various performance parameters.Various literature[36-37]deals with uncontrolled rectifier with power factor correction circuits[38-39]and the other hand uses the controlled rectifier. The previous one mostly used topology for its simplicity with less control mechanism rather than latter ones requiring the complex control mechanism[40-42].

Table 4 Comparison of different control schemes

In the receiver side, the transmitted power is converted to DC by using the AC-DC converter, which may be controlled, or uncontrolled[43]. DC-DC chopper can do the regulation of power level according to battery specification and the ripple content can be decreased by inserting a capacitor across the load[44-47].

The control mechanism and regulation of converters are important aspects in WIPTS. The control method of a wireless charging system is an important topic closely related to power electronics converters[48-49]. Many control methods have been developed in stationary charging systems as well as dynamic charging systems.In the stationary charging applications[50-51], the control methods are designed to achieve high system efficiency,desired outputs, and bidirectional power transfer between grid and battery packs[52-53]. On the other hand, for dynamic WIPTS applications, control and regulation have been developed to solve the synchronization and misalignment problems[54-55].

4.2.5 Safety and shielding issues

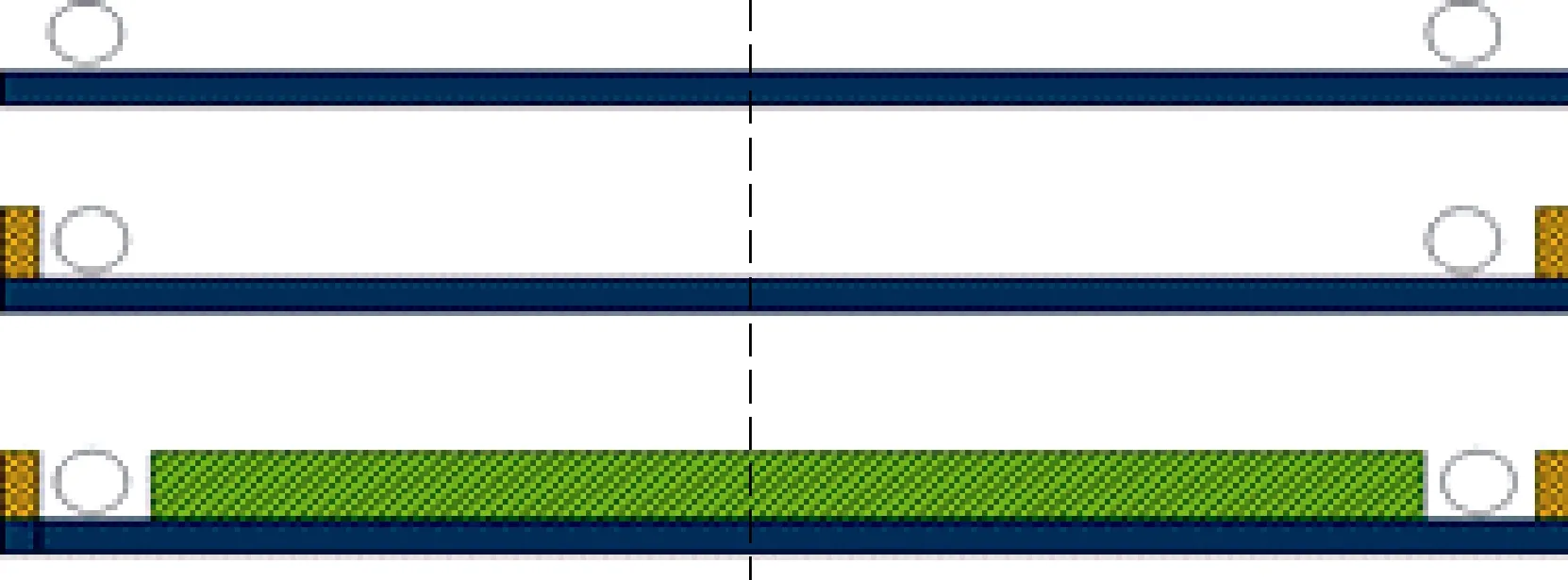

The design of the magnetic field distribution is also a significant factor in a WPT system, particularly in a high-power transfer system. As a magnetic flux of more than thousands of mill tesla from the current of thousands of amperes is generated between the transmitter and receiver coils, even 0.1% of leakage from the main flux can be hundreds of milli tesla, which is several times larger than the magnetic flux regulation suggested by the International Commission on Non-Ionizing Radiation Protection[55]. Therefore, it is essential to control the leakage magnetic flux for WPT applications the shielding will be mainly added under transmitter and above the receiver is important for the safe operation of WPT. Without shielding, following problems may occur:① The magnetic field may interfere with the device or other objects; ② May cause battery heating and ③ It may circulate current in metallic parts.

There are two basic methods for shielding against low to medium frequency magnetic sources, which includes diversion of the magnetic flux with highpermeability materials[56]and the generation of opposing flux via Faraday’s law. Assuming the external medium is free space withμ=μ0and the shield is constructed of a ferromagnetic material havingμr>>1, the magnetic field will tend to concentrate in the low-reluctance ferromagnetic path, and as such will be diverted from affecting the free space region. To achieve this effect,the ferrite plate has to be thick enough; otherwise, the leakage flux into free space is considerable. An alternative to the mentioned above is the field distribution when an aluminum sheet is attached to the ferrite plate. According to Faraday’s law, a current circulates in the aluminum sheet and associated magnetic flux is generated.

The induced magnetic flux is of a polarity or direction as to counteract the original incident magnetic field, and so the net magnetic field in the vicinity of the loop is reduced. Fig.13 shows the behavior of magnetic flux density for three cases i.e. without shield, with ferrite shield and with both ferrite and aluminum shielding.

4.2.6 Communication and standards

In terms of communications and standards for wireless power transfer, relev ant work in development includes IEC 61980-2 SAE[57]between Plug-in Electric Vehicles and the Utility Grid. Communications for wireless charging will use DSRC(Dedicated Short Range Communications). This is a coordinated effort between US DOT, SAE DSRC Committee as well as the SAE Communications Committee, and will open up numerous opportunities for electric vehicles. The firms working in different part of world and their technological relevance is summarized in Table 6.

5 On-road WPT (ORWPT)

Fig.13 Magnetic field distribution

From the vehicle viewpoint, ORWPT enables infrastructure where EVs can be charged continuously while in motion, However, employment of such system is reliant on the infrastructure development, which in turn is limited by its cost. The schematic diagram of ORWPT is shown in Fig.14. In addition, the amount of energy gained through WPT depends on the power level of the system[58-60], vehicle speed and duration that vehicle travel. In general, ORWPT track can be categorized into two types; elongated track and segmented track[61]. The first type consists of a substantially long transmitter track connected to a power source. Segmented track has multiple coils connected to high frequency power sources as shown in Fig.15. The single transmitter track can be few meters to several tens of meters long.However, this type of design suffers from several drawbacks. Firstly, the electromagnetic field emitted within the uncoupled region has to be suppressed to eliminate harmful exposure. Secondly, the compensation capacitor has to be distributed along the track to compensate large inductance. This brings additional constraints in construction. Thirdly, coupling coefficient is low because of the smaller transmitter region covered by the receiver resulting lower efficiency. On the other hand, segmented track eliminates issues raised by single transmitter track such as field exposure and requirement for distributed compensation while lowering coupling issues. However, it introduces the design challenges such as synchronization between track and pickup. In addition, separation between transmitter coils needs to be carefully optimized by placement of the segmented coils on track. However, coils cannot be kept too close to each other due to two reasons. Firstly, negative mutual inductance between adjacent transmitter coils is significant generating negative current stress. Secondly,design cost will be increased with many transmitters in a given length of the track. On the other hand, designing the Power supply such as HFI for each segmented track is not a feasible solution. In addition, integrating the control of overall mechanism with synchronization poses major design challenges.

It is necessary to track the receiver position and switch the appropriate power source as the load moves along the array. In addition, separation between transmitter coils needs to be carefully optimized. When coils are placed too apart, efficiency reduces steeply and when the receiver moves away from the transmitter and power transfer will not be continuous. However, coils cannot be kept too close to each other due to two reasons.Firstly, negative mutual inductance to all between adjacent transmitter coils are significant generating negative[62].

Apart from charging issues, the ORWPT requires controlling and design of driving cycles of the vehicle,charging lane length and its performance over a range of the driving cycles. In [63], researchers are considered three driving cycles (UDDS, HWFET and VAIL2NREL)and the three type of vehicles (compact car, large car and SUV). Several power levels for the charging station were tested (up to 60 kWh); the results are the optimal length of the charging lanes, location in the drive cycle and battery size. It was concluded that when minimum track length is the only optimization criterion the track length becomes very short. Therefore, it is beneficial to size the batteries to easily meet the peak power requirements.

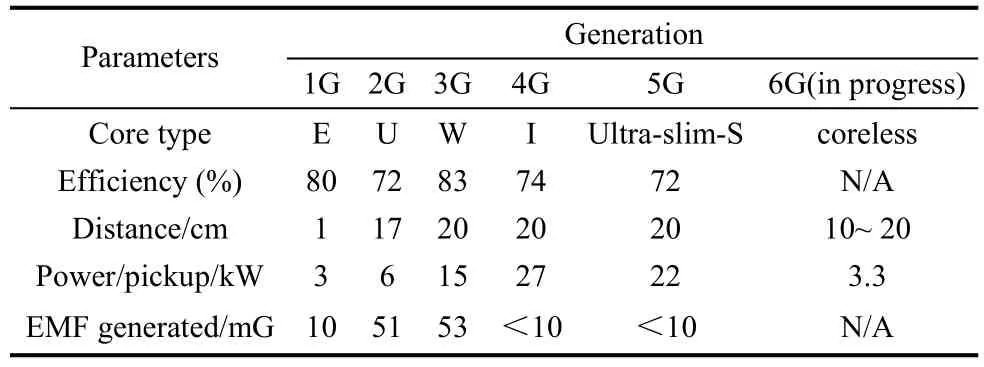

Korea Advanced Institute of Science and Technology(KAIST) proposed online electric vehicle(OLEV) which passed through many generations and they used various types of ferrite cores like U-type, E-type and I-type and coreless. Present generation uses coreless for transmitter and receiver. Supply lines are twisted to each other and creates alternating poles in the track. This phenomenon reduces leakage inductance and unwanted EMF. In the pick side, there is a couple of coils which covers consecutive poles to make the magnetic path complete.The main point of this arrangement is narrow width transmitting track and wide pickup[64-65]. The transmitting poles produce magnetic field which is spread in a wide area towards the pickup. The deployment is shown in the Table 5.

Another solution for OR WPT found in research is based on field containment by source-receiver interaction.There are many coils are distributed along the road and supplied by a single inverter. These coils have high self-inductance and the supply frequency is high, so only a small amount of current flows in these coils in normal conditions due to high uncompensated reactance.Another situation when a pickup coil appears in vicinity of a transmitting coil, the reactance of secondary coil is reflected into primary side. This reflected reactance can be adjusted by compensation of secondary circuit and this also can compensate primary side reactance.When a pickup coil is coupled with a primary coil and compensates its reactance, current in the primary coil increases. The increased current in coupled coils creates a strong magnetic field and power transfer happens.

Table 5 Various generations of OLEV[62]

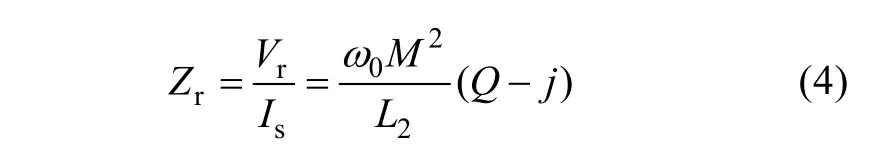

Compensation using the reactance of other coil is an attractive solution to eliminate switching and sensing arrangement when vehicle passes through a particular part of the track. In other words, it doesn’t require receiver position tracking system. Moreover, since the magnetic field generated by a primary coil is much less when no pickup is coupled, unwanted EMF remains inherently under control. The receiver coil circuit is designed such a way that transmitting coil reactance can be compensated completely. The receiver is tuned based on the operating frequency of primary supply and it reflects resistive and reactive impedances back to the primary. Only resistive component is reflected when its series compensation, and in parallel compensation case the reflected impedance is

Nevertheless, the reflected reactance results in higher power supply VA rating, and therefore, increased inverter current, without contributing the real power to the load. This is considered as the disadvantage of the parallel-compensated receiver. Therefore, some different series-parallel combinations are preferred to achieve more power transfer and better efficiency.

6 Evaluation, future prospective of wireless charging

Recent reviews of WPT technologies and their transportation applications are optimistic about their prospects for deployment and growth. A promising strategy for competing WPT technology providers is to enter into partnerships with bus or LRV manufacturers in order to demonstrate in service operations, their commercial reliability, cost-effectiveness, and market niche viability. From this WPT review of emerging and existing transit applications in the U.S. and worldwide,it is evident that there are multiple candidate WPT technologies for transit applications in various stages of technology maturity: from development to prototype test/evaluation, to some in-service deployment.

Progress in WPT products standardization and the harmonization of international WPT standards will broaden market access to competing EVSE and on-board products for electric light duty and heavy-duty vehicle applications, including public bus and rail transit as a market niche. WPT developers and technology providers claim multiple core benefits for EV owners and electric transit operators and users that are yet to be proven in an operational environment, including convenient choice of fast (On-Road) or slow (in station or depot), battery recharging with one infrastructure system; automatic trigger of charging high power transfer potentially in all weather, without corrosion or exposed terminals; no loose cords or potential for electrocution or tripping; no adverse human safety or health impacts (as long as emissions of and exposures to magnetic and electric fields and radiation comply with applicable guidelines,standards and regulations).

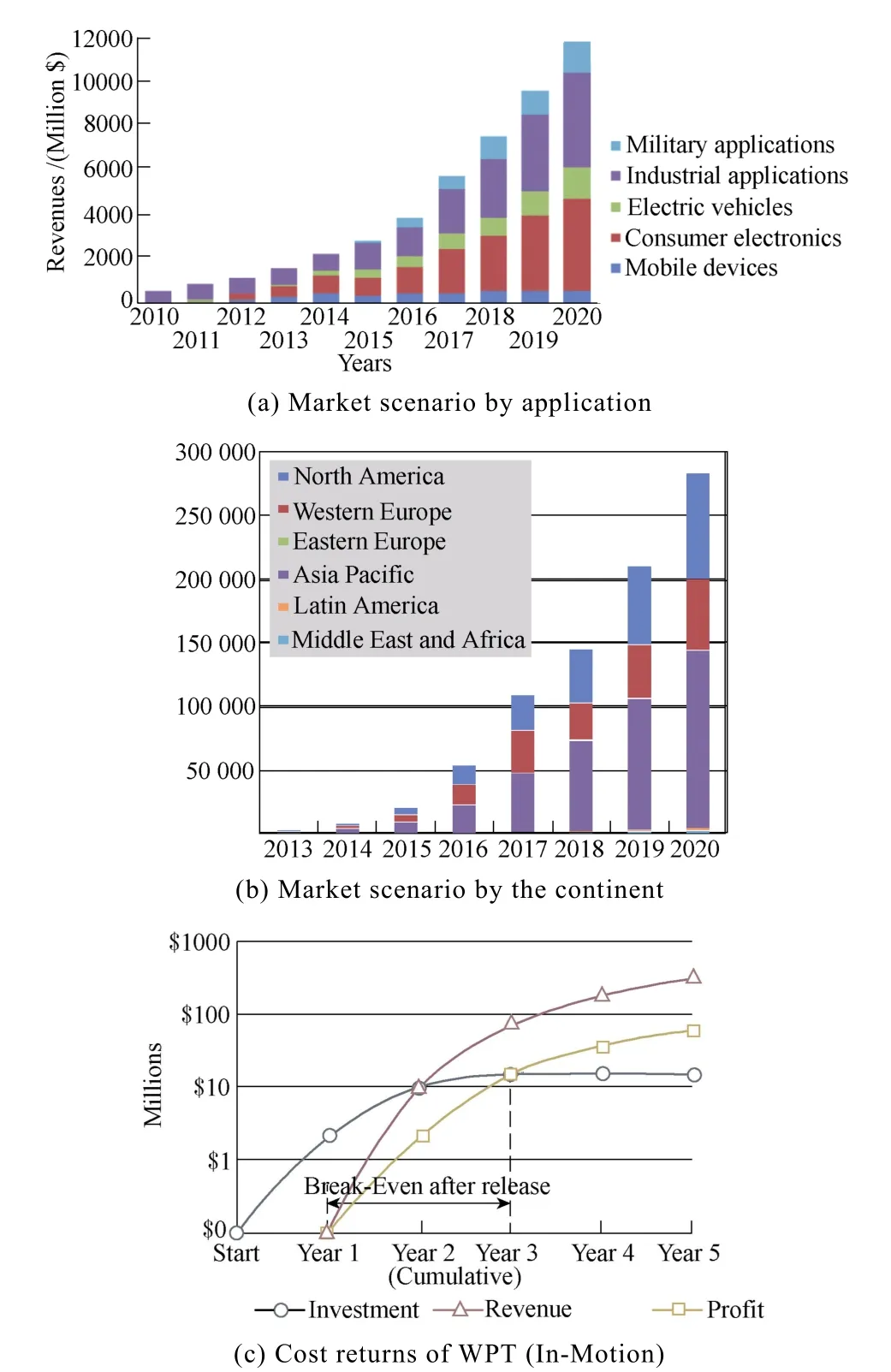

Fig.16 shows the Market scenario of the Wireless Power Transfer industry. The graph reveals that, by end of 2020, the market will increase enormously and for the applications of the electric vehicle, the growing rate is increasing about 6%~10% every year. In 2017,Mercedes-Benz(Germany) is expected to launch the luxurious hybrid-powered sedan car(probably from S-Class series) that is enabled with the wireless charging technology. BMW AG(Germany) is also on the list of future wireless charging car manufacturers. Toshiba Corporation also had a trail run for 45-seaters electric bus for wireless charging. The contactless charger based on the magnetic resonance technology is designed in association with the Waseda University.

Europe, being one of the early adopters of this technology, is expected to grow at a high rate. Europe is the automotive hub, and the developments in the European market, especially in electric vehicles and wearable electronics, are expected to boost the growth of the wireless power transmission market in this region.The European Green Vehicles Initiative Association(EGVI), a Europe-based company, has undertaken UNPLUGGED and FABRIC projects on wireless charging of electric vehicles. The major players involved in the wireless power transmission market include Samsung Electronics Co., Ltd. (South Korea), Qualcomm Inc.(U.S.), Texas Instruments Inc. (U.S.), TDK Corp.(Japan), Witricity Corp.(U.S.), and Integrated Device Corp.(U.S.), momentum dynamics (U.S)[66].

Fig.16 Market scenario of the WPT industry[66]

Table 6 Various products and their relevance

Various start-ups in the wireless power transmission market include Ossia, Inc. (U.S.), Wi-Charge Ltd.(Israel), Energous Corporation(U.S.), Humavox Ltd.(Israel), and Fulton Innovation LLC(U.S.)

7 Conclusion

This paper reviewed the battery-charging infrastructure for the Electric Vehicle and the charging and power infrastructure for the wired charging. The different aspects such as coil coupling and Power electronics infrastructure of Static and ORWPT charging were discussed. Finally, Market scenario and future prospective growth opportunities were detailed.

Chinese Journal of Electrical Engineering2018年4期

Chinese Journal of Electrical Engineering2018年4期

- Chinese Journal of Electrical Engineering的其它文章

- Using Inverter-Based Renewable Generators to Improve the Grid Power Quality—A Review

- Review of Power Decoupling Methods for Micro-Inverters Used in PV Systems

- Resonance Active Damping and PCC Voltage Quality Improvement of DFIG System Connected to Parallel Compensated Grid

- The Characteristics Analysis and Cogging Torque Optimization of a Surface-Interior Permanent Magnet Synchronous Motor

- Field-Oriented Control and Direct Torque Control for a Five-Phase Fault-Tolerant Flux-Switching Permanent-Magnet Motor

- Study of Pressure Balance for Press-Pack IGBTs and Its Influence on Temperature Distribution