Thermal conductivity of PVDF/PANI-nanofiber composite membrane aligned in an electric field☆

Hong Guo ,Xin Li,Ziyi Wang ,Bao'an Li,*,Jixiao Wang ,Shichang Wang

1 Chemical Engineering Research Center,School of Chemical Engineering and Technology,Tianjin University,Tianjin 300072,China

2 State Key Laboratory of Chemical Engineering,Tianjin University,Tianjin 300072,China

3 Tianjin Key Laboratory of Membrane Science and Desalination Technology,Tianjin University,Tianjin 300072,China

4 Tianjin Collaborative Innovation Center for Chemistry&Chemical Engineering,Tianjin 300072,China

1.Introduction

Poly(vinylidene fluoride)(PVDF)is a semi-crystalline thermoplastic polymer which exhibits excellent thermal stability,electrochemical stability,nontoxicity[1],wide processing temperature and notable solubility in many organic solvents[2].PVDF has been widely used in the chemical industry,electronics,food processing and other fields in recent years[3-5].However,the poor thermal conductivity has limited its more extensive application in heat transfer area.

In order to improve its thermal conductivity, fillers with high thermal conductivity are blended or doped into PVDF matrix,such as metal,inorganic substance and conductive polymers[6-8].Three types of core-shell-structured aluminum particles were incorporated in PVDF by melt-mixing and hot-pressing processes.The results indicate that the particle size and shape of the filler affect the thermal conductivity of Al/PVDF[9].The addition of 1.0 wt%carbon nanotubes(CNTs)in the hybrid Al/CNTs particles obviously enhanced the thermal conductivity of the composites due to the heat conductive pathways formed in the matrix[10].In another study,SiC nanoparticles were selectively localized in the PVDF phase of the PS/PVDF blend polymer,which produced a slightly higher thermal conductivity than that of p-SiC in the PS phase[11].

Conductive polymer is a kind of potential material which has been widely involved in both direct application and hybrid modification[12-15].Polyaniline(PANI)is a particular conductive polymer which has attracted much attention for its particular electrical and optical properties,as well as thermal properties.The properties of PANI would be influenced by its preparation approaches,such as interfacial polymerization[13],soft template[14],and emulsion polymerization method[15].The PANI prepared by emulsion polymerization method has the same or even better conductivity,thermal stability,crystallizability and higher molecular weight than those prepared by the other methods[16].Various morphologies of PANI including spherical,hollow microspheres,nanotubes and nanofibers have been obtained[16,17].Among these nanostructures,the nanofibers of PANI are considered to be the most potential morphology which enjoy more superior heat conductive capacity.

A few studies have reported on the composite of PVDF and PANI[18-23].The advantages of PVDF/PANI composite material are listed as: firstly,its electrochemical performance of the hybrid material was improved;secondly,different morphologies of PANI could be blended with PVDF for exact control;thirdly,the mechanical properties of the polymer composites can be adjusted by aligning the fillers in the matrix with mechanical stretching[24],electric field[25,26],magnetic field[27,28]and so on.However,most studies focus on the first two advantages of PVDF/PANI composite material,especially on the electrical conductivity of PVDF/PANI composite material.For examples,Saidi[19]studied the effect of drying temperature on the structure,morphology and electrical conductivity of PANI:PVDF films;Martins[21]investigated the morphology,rheological behavior and electrical conductivity of poly(vinylidene fluoride)/polyaniline blends through TEM and combined electro-rheological measurements.So far,very few studies have been carried out on the thermal conductivity of PVDF/PANI composite material which is also an important parameter[29,30].In addition,we gave the third advantage to practice on the experimental method.The PVDF/PANI composite material was aligned by electric field in the course of the experiment which is also distinctive.The effect of electric field on the tensile strength and thermal conductivity of PVDF/PANI composite material was deeply investigated in our study.

In this paper,PANI nanofibers were synthesized by emulsion polymerization and blended with PVDF to form homogenous casting solution.The PVDF/PANI-nanofiber composite membranes were fabricated by the evaporation ofN-methyl-2-pyrrolidone(NMP)from the casting solution.On this basis,composite membranes were further aligned by the application of electric field.The thermal conductivity and mechanical properties of composite membranes with different ratios of PANI nanofibers(1 wt%,3 wt%,5 wt%,7 wt%,10 wt%,20 wt%,30 wt%,50 wt%and 60 wt%)were investigated.

2.Experiments

2.1.PANI nanofiber synthesis

PANI nanofibers were synthesized by emulsion polymerization method with surfactant of dodecylbenzene sulfonic acid(DBSA)[31].The aniline monomer was purified with vacuum distillation before application.0.08 mol of aniline monomer and 0.04 mol of DBSA were mixed in HCl solution(1 mol·L-1).The solution was ultra-sonicated for 20 min and put into ice bath subsequently.Then ammonium persulfate(APS)(aniline,DBSA and APS were purchased from Tianjin Jiangtian Chemical Technology Co.Ltd.,China)solution(0.27 mol·L-1,in deionized water)was gently added into the above mixture with vigorous stirring.After addition of APS,the mixture was allowed to react for 12 h.The precipitate was filtered and washed with acetone,ethanol and deionized water,respectively.The product was dried in a vacuum at 60°C for 24 h.

2.2.Preparation of PVDF/PANI-nanofiber composite membranes

The obtained PANI nanofibers were dispersed in NMP by bath sonication.PVDF was subsequently added to the above solution to prepare casting solutions.In a typical experiment,0.065 g of the above-synthesized PANI nanofibers was added into 43.5 g of NMP.The mixed solution was ultra-sonicated for 2 h.Then,6.5 g of PVDF was added to the above solution and mechanically stirred overnight to form a homogeneous casting solution.The prepared solution was casted on a smooth glass substrate and dried in an oven horizontally at 80°C for 6 h,making the solvent evaporated completely.PVDF/PANI composite membranes were finally obtained and peeled off from the substrate for subsequent characterization.The pure PVDF membrane was prepared with a similar method without the addition of PANI.

2.3.Alignment of PVDF/PANI-nanofiber composite membranes

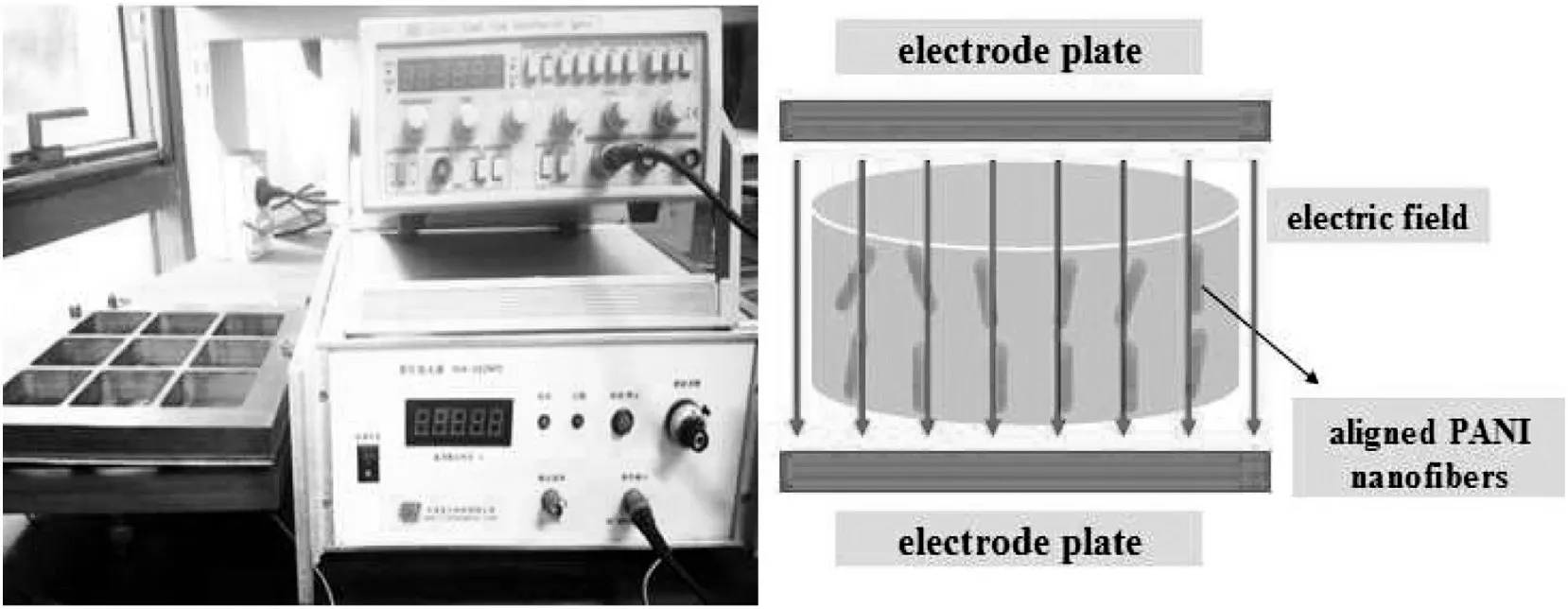

Electric field was added to the composite membranes for the alignment.After the casting solution was added on the glass substrate and placed in an oven,an electric field of 220 V was applied with a DC power supply(HVA-502NP5,Tianjing Shenghuo tech.Co.,Ltd.)perpendicular to the glass surface.It was worth noting that both the casting substrate and electrode plate of the electric field device were setup in the oven(Scheme 1).Then the glass substrate with casting solution was dried in the oven horizontally at 80°C for 6 h,making the solvent evaporated completely.During the evaporating process,the electric field was always present.Aligned PVDF/PANI composite membranes were obtained and then peeled off from the substrate for subsequent characterization.

2.4.Characterization of composite membranes

The morphologies of PANI nanofibers,PVDF membrane and PVDF/PANI-nanofiber composite membranes were characterized with scanning electron microscopy(SEM)(S-4800,Hitachi,Japan).The membranes were fixed on the conductive adhesive(NEM,Japan)and sputtered with a thin layer of gold before observing.The degree of crystallinity was determined with X-ray diffraction(XRD)with an X-ray diffractometer(D8-Focus,AXS Ltd.,Germany).

The thermal behaviors of the samples were recorded with a differential scanning calorimeter(DSC)(DSC1/500,Mettler-Toledo,Switzerland),with the heating rate of 10 °C·min-1and the scanning temperature range between 0 and 200°C.Tensile tests were performed in a small universal testing machine.The membrane samples were cut into strips with a width of 10 mm and the initial length between the two loading ends was 100 mm.The thickness variation of the membrane sample was less than 10%.The samples were slowly stretched with a constant speed of 10 mm·min-1until failure.Thermal conductivities of membranes were recorded with a thermal conductivity meter(TC 3000L,XIATECH,China).

3.Results and Discussion

3.1.Morphologies of PVDF/PANI-nanofiber membranes

Fig.1(a)and(b)indicates that the synthesized PANI nanofibers have the diameter of 150 nm and the length of 1 μm.The nanofibers are characterized with fibrous structure,coarse surface and disordered distribution.

The cross-section morphologies of pure PVDF and composite membranes before alignment are shown[Fig.1(c)-(g)].Compared to the pure PVDF membrane in Fig.1(c),the cross-section morphologies of composite membranes before alignment are coarser with disordered nanofiber distribution.It is also observed that PANI nanofibers are well dispersed in the PVDF matrix when the PANI content is below 50 wt%,which reveals a preferable compatibility between PVDF and PANI nanofibers[Fig.1(d)-(f)].When the concentration of PANI nanofibers is increased to 60 wt%[Fig.1(g)],a large amount of PANI nanofibers can be observed in the cross-section.The agglomeration phenomenon is aggravated and the uniformity and compatibility between PVDF and PANI nanofibers become poor.It makes adverse effects on the performance improvement of composites.

After alignment with electrical field,it can be seen from the crosssections that the arrangement of PANI nanofibers in the matrix is more orderly[Fig.1(h)and(i)].This phenomenon indicates that the structure of composite membranes can be significantly adjusted with the application of electric field.The obtained structure is more orderly with conductive PANI network,which is able to greatly increase the thermal conductivity of composite membranes.

Scheme 1.Experimental setup of electric field device and schematic of the application of electric field on PVDF/PANI-nanofiber membranes.The orientation of electric field was perpendicular to the surface of composite membranes.The aligned PANI nanofibers were embedded in the composite membranes.

3.2.Crystallization and thermal property of PVDF/PANI-nanofiber membranes

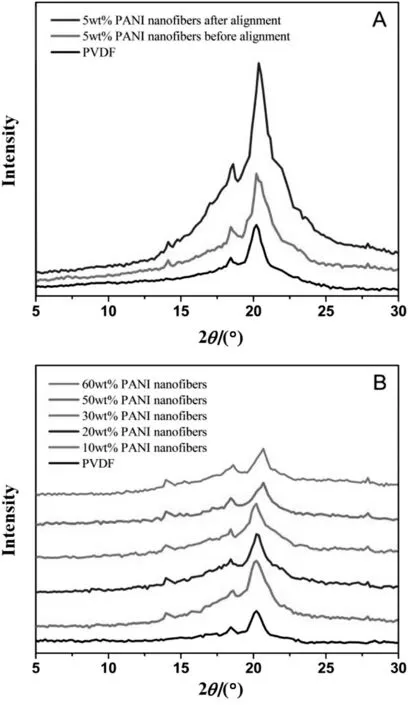

Pure PVDF crystallizes predominately in the α-phase with characteristic peaks at 18.5°and 20.1°as shown in Fig.2(A).The composite membrane with 5 wt%PANI nanofibers is determined here as a representative.In Fig.2(A),after the addition of PANI,the peak intensity of composite membrane is significantly higher than that of pure PVDF membrane.After alignment,the peak intensity of composite membrane is also significantly higher than that of the composite membrane before alignment.In addition,the shape of characteristic peak is sharp,which corresponds to the crystallization of PVDF in composite membrane[32,33].It shows that the crystallinity degree of PVDF in composite membrane can be increased by electric field orientation.

The XRD patterns of pure PVDF membrane and PVDF/PANI-nanofiber composite membranes with different PANI contents are provided.In Fig.2(B),a new reflection is observed at 2θ=20.7°with PANI contents of 50 wt%and 60 wt%.It is a characteristic β-phase.PVDF is mainly presented with α-phase when the content of PANI nanofibers is low.However,PVDF transforms from α-phase to β-phase when the content of PANI nanofibers is increased to 50 wt%.The reason may be that the increase of PANI nanofiber content results in the destruction of the structure of the metastable form(α-phase)and formation of the stable form(β-phase)through the rearrangement of PVDF molecule.The presence of the β-phase was further con firmed by DSC results(Fig.3).Moreover,the solid peak at 2θ=14.0°and the weak peak at 2θ=27.8°are representative of HCl-doped PANI nanofibers in composite membranes.The strong peak at 2θ=14.0°indicates high[Cl]/[N]ratio,which proves that the PANI nanofibers are highly doped with HCl in the composite membranes[34].

Fig.1.SEM images of PANI nanofibers,PVDF membrane and PVDF/PANI-nanofiber composite membranes before and after alignment:(a,b)PANI nanofibers;(c)the cross-section of pure PVDF membrane;(d-g)the cross-sections of composite membranes before alignment,corresponding to PANI contents of 1 wt%(d),10 wt%(e),50 wt%(f)and 60 wt%(g),respectively;(h,i)cross-sections of composite membranes after alignment,corresponding to PANI contents of 1 wt%(h)and 10 wt%(i).

Fig.2.XRD patterns of pure PVDF and PVDF/PANI-nanofiber composite membranes:(A)XRD patterns of pure PVDF membrane,composite membranes with 5 wt%PANI nanofibers before and after alignment.(B)XRD patterns of pure PVDF membrane,composite membranes with different PANI contents of 10 wt%,20 wt%,30 wt%,50 wt%and 60 wt%.

The endothermic peaks observed around 167°C correspond to the melting peak of PVDF[Fig.3(A)].The corresponding melting peaks for the composite membranes before alignment are also observed around 167°C in Fig.3(A).However,after alignment,the characteristic peaks of the composite membranes significantly move to a high temperature region.This result suggests that the thermal stability of polymeric composites can be improved by electric field orientation in the composite membranes.

Fig.3.DSC thermograms of pure PVDF and PVDF/PANI-nanofiber composite membranes:(A)DSC thermograms of pure PVDF membrane,composite membranes with 5 wt%and 10 wt%PANI nanofibers before and after alignment.(B)DSC thermograms of pure PVDF membrane,composite membranes with different PANI contents of 1 wt%,10 wt%,30 wt%,50 wt%and 60 wt%.

DSC curves are determined with pure PVDF and composite membranes having different PANI contents[Fig.3(B)].When the content of PANI nanofibers is lower than 50 wt%,the melting peaks for the composite membranes occur around 167 °C corresponding to the α-phase of PVDF in Fig.3(B).However,when the content of PANI nanofibers reaches 50 wt%in the composite membranes,the curves are transferred to two melting peaks,corresponding to both the α-phase and β-phase of PVDF.The result of DSC is consistent with the above results of XRD,PVDF also transforms from α-phase to β-phase when the content of PANI nanofibers is increased to 50 wt%.The second peak is at higher temperature(172°C).The intensity of the two peaks formed with 50 wt%PANI nanofiber content is almost similar,suggesting that PANI nanofibers facilitate the formation of the β-phase of PVDF.Comparing to the two peaks with 60 wt%PANI nanofibers,the intensity of characteristic peak for β-phase is further enhanced.

3.3.Tensile strength of PVDF/PANI-nanofiber membranes before and after alignment

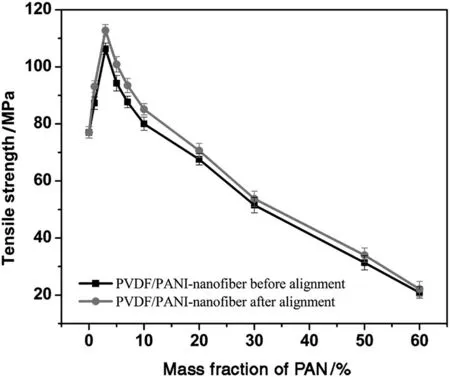

The tensile strength of the pure PVDF and composite membranes before and after alignment is provided in Fig.4.With the content of PANI nanofibers increasing to 3 wt%,the tensile strength is exponentially increased.This result can be attributed to the enhanced mechanical strength from well-dispersed PANI nanofibers in the PVDF matrix.The tensile strength is improved by connection and interaction between PANI nanofibers and PVDF matrix.However,when the concentration of PANI nanofibers is higher than 3 wt%,the tensile strength of composite membranes is dramatically decreased.When the content of PANI nanofibers is more than 10 wt%,the tensile strength of membrane is decreased to the level even weaker than that of pure PVDF membrane.

Fig.4.Tensile strength of pure PVDF and PVDF/PANI-nanofiber composite membranes with different PANI contents before and after alignment.

The potential reason is that intermolecular force between PVDF chains is weakened by too many PANI nanofibers added.Another reason is the aggregation and inhomogeneous distribution of the PANI nanofibers in the PVDF.The PANI nanofiber agglomerates would form steric hindrance,preventing polymer from immersing into the agglomerates.The gaps may be formed between PANI nanofibers and matrix,resulting in weak points.The low tensile strength of composite membranes with high nanofiber content may be caused by these reasons.

The tensile strength of composite membranes before and after alignment was explored.By comparing the two curves in Fig.4,it is found that the tensile strength of composite membranes is obviously enhanced after the alignment with electrical field.The maximum tensile strength of 112.814 MPa can be obtained when the content of PANI nanofibers is 3 wt%which is 46.44%higher than that of pure PVDF membrane.Meanwhile,before alignment,the tensile strength of composite membrane is increased by 38.03%.As previously discussed with XRD,the crystallinity of the composite membranes is improved by the application ofelectric field.Consequently,the tensile strength is enhanced by the increased crystallinity.However,when the content of PANI nanofibers is higher than 10 wt%,a lower improvement of tensile strength is observed in composite membranes after alignment.It may be attributed to the reduced effects of electric field orientation on composite membranes by PANI nanofiber agglomerates.

3.4.Thermal conductivity of PVDF/PANI-nanofiber membranes before and after alignment

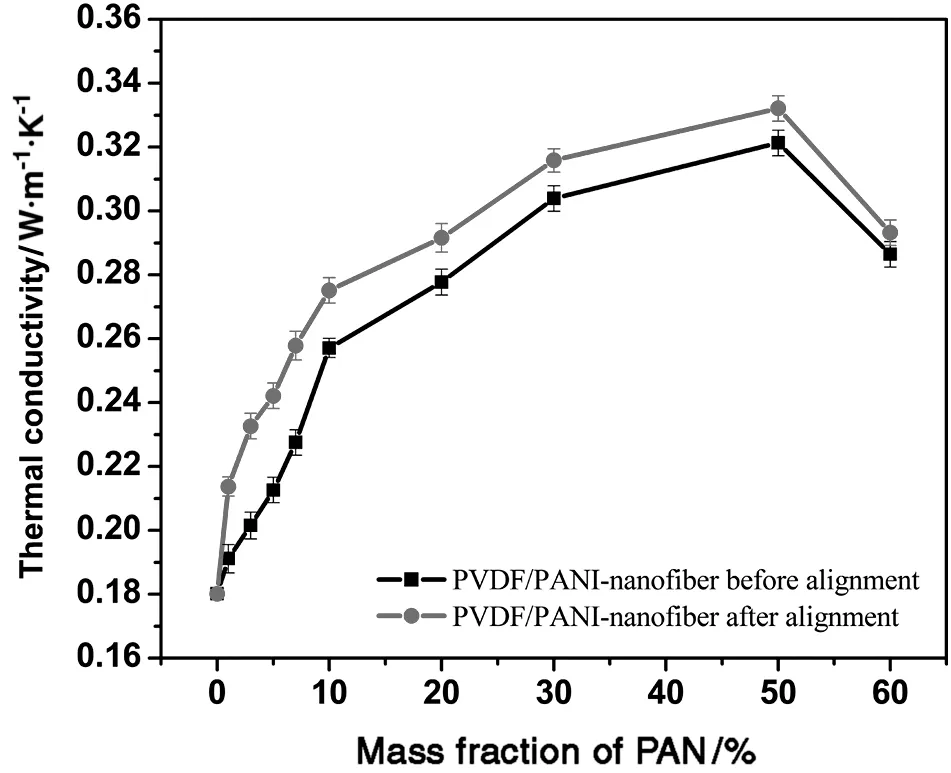

As shown in Fig.5,the concentration of PANI nanofibers plays a crucial role in the thermal conductivity of composite membranes.The thermal conductivity of composite membranes before and after alignment is continuously improved with increasing PANI nanofiber content before 50 wt%of the content.When the content of PANI nanofibers exceeds 50 wt%,the thermal conductivity of composite membrane starts to decrease.

As we know,PANI nanofibers have excellent thermal conductivity.The thermal conductivity of the composite membranes may increase with the increase of PANI nanofiber content.With the addition of PANI nanofibers,sufficient connections and interactions are formed between PVDF matrix and PANI nanofibers.Thus,the thermal conductivity of the composite membranes is enhanced.But when the content of PANI nanofibers is above 50 wt%,its thermal conductivity becomes decreased.The phenomenon may be induced by two factors.On the one hand,the agglomeration is aggravated in high content of PANI nanofibers,leading to severe scattering for phonon transport.On the other hand,the thermal conductivity may be even decreased by the interface thermal resistance between PVDF and aggregated PANI nanofibers.

Fig.5.Thermal conductivity of pure PVDF and PVDF/PANI-nanofiber composite membranes with different PANI contents before and after alignment.

Comparing the thermal conductivity of the composite membranes before and after alignment(Fig.5),the conclusion can be obtained that the thermal conductivity of composite membranes is significantly enhanced with the alignment.When the content of PANI nanofibers is lower than 10 wt%,the thermal conductivity of composite membranes is significantly increased after alignment with electric field.From the SEM images(Fig.1),it shows that the PANI nanofibers are arranged more orderly and the netlike morphology of PANI nanofibers is obviously formed in the composite membranes after alignment.Therefore,the thermal conductivity of composite membranes is increased significantly.When the PANI content is 3 wt%,the thermal conductivity is increased by 15.5%than that of before alignment,which is the most significant.Butthe increased trend of thermal conductivity after alignment is not kept when the content of PANI nanofibers is above 10 wt%,due to the PANI nanofiber agglomeration and the increased viscosity of the system that bring about the enhanced resistance for orientation.The maximum thermal conductivity after alignment is 84.5%greater than that of pure PVDF membrane when the content of PANI nanofibers is 50 wt%.However,before alignment,it is increased by 78.5%.

4.Conclusions

In this paper,PVDF/PANI-nanofiber composite membranes with various contents of PANI nanofibers were prepared and the electric field was further applied for the alignment of PANI-nanofiber in PVDF/PANI-nanofiber composite membranes.The results showed that:(1)The increased content of PANI nanofibers contributed to the transformation of PVDF from α-phase to β-phase.(2)Both the tensile strength and thermal conductivity of composite membranes were significant improved.This tendency was further enhanced by the application of electric field.The contents of PANI nanofibers were optimized for obtaining the maximum tensile strength and thermal conductivity.The blend and alignment of nanofillers in composite membrane would be promising approaches for improving material properties in heat transfer field and the mechanism explored in this study would be informative for further similar development of thermal conductive polymeric materials.

[1]J.H.Yu,P.K.Jiang,C.Wu,L.C.Wang,X.F.Wu,Graphene nanocomposites based on poly(vinylidene fluoride):Structure and properties,Polym.Compos.32(2011)1483-1491.

[2]Z.S.Wang,Z.L.Gu,S.Y.Feng,Y.Li,Application of vacuum membrane distillation to lithium bromide absorption refrigeration system,Int.J.Refrig.32(2009)1587-1596.

[3]G.Zeng,Z.Ye,Y.He,X.Yang,J.Ma,Application of dopamine-modified halloysite nanotubes/PVDF blend membranes for direct dyes removal from wastewater,Chem.Eng.J.323(2017)572-583.

[4]M.Choi,G.Murillo,S.Hwang,J.W.Kim,J.H.Jung,Mechanical and electrical characterization of PVDF-ZnO hybrid structure for application to nanogenerator,Nano Energy33(2017)462-468.

[5]S.Ayyaru,Y.H.Ahn,Application of sulfonic acid group functionalized graphene oxide to improve hydrophilicity,permeability,and antifouling of PVDF nanocomposite ultra filtration membranes,J.Membr.Sci.525(2017)210-219.

[6]J.Yuan,S.Yao,W.Li,A.Sylvestre,J.Bai,Anisotropic percolation of SiC-carbon nanotube hybrids:A new route towards thermally conductive high-k polymer composites,J.Phys.Chem.C121(2017)12063-12070.

[7]J.Che,K.Wu,Y.Lin,K.Wang,Q.Fu,Largely improved thermal conductivity of HDPE/expanded graphite/carbon nanotubes ternary composites via filler network-network synergy,Compos.A:Appl.Sci.99(2017)32-40.

[8]D.Yang,H.Xu,W.Yu,J.Wang,X.Gong,Dielectric properties and thermal conductivity of graphene nanoplatelet filled poly(vinylidene fluoride)(PVDF)/poly(methyl methacrylate)(PMMA)blend,J.Mater.Sci.Mater.Electron.28(2017)13006-13012.

[9]W.Zhou,J.Zuo,W.Ren,Thermal conductivity and dielectric properties of Al/PVDF composites,Compos.A43(2012)658-664.

[10]Z.Wang,W.Zhou,X.Sui,L.Dong,Enhanced dielectric properties and thermal conductivity of Al/CNTs/PVDF ternary composites,J.Reinf.Plast.Compos.34(2015)184-191.

[11]J.P.Cao,X.Zhao,J.Zhao,J.W.Zha,G.H.Hu,Z.M.Dang,Improved thermal conductivity and flame retardancy in polystyrene/poly(vinylidene fluoride)blends by controlling selective localization and surface modification of SiC nanoparticles,ACS Appl.Mater.Interfaces5(2013)6915-6924.

[12]Z.T.Li,L.Ma,W.L.Li,M.Y.Gan,W.Qiu,J.Yan,Characterization and anticorrosive properties of poly(2,3-dimethylaniline)/nano-Al2O3composite synthesized by emulsion polymerization,Polym.Adv.Technol.24(2013)847-852.

[13]E.Detsri,S.T.Dubas,Interfacial polymerization of polyaniline and its layer-by-layer assembly into polyelectrolytes multilayer thin- films,J.Appl.Polym.Sci.128(2012)558-565.

[14]S.Komathi,A.I.Gopalan,N.Muthuchamy,K.P.Lee,Polyaniline nanoflowers grafted onto nanodiamonds via a soft template-guided secondary nucleation process for high-performance glucose sensing,RSC Adv.7(25)(2017)15342-15351.

[15]W.J.Han,S.H.Piao,H.J.Choi,Synthesis and electrorheological characteristics of polyaniline@attapulgite nanoparticles via Pickering emulsion polymerization,Mater.Lett.204(2017)42-44.

[16]J.Stejskal,I.Sapurina,M.Trchová,Polyaniline nanostructures and the role of aniline oligomers in their formation,Prog.Polym.Sci.35(2010)1420-1481.

[17]J.W.Wang,C.Y.Chen,Y.M.Kuo,Chitosan-poly(acrylic acid)nanofiber networks prepared by the doping induction of succinic acid and its ammonia-response studies,Polym.Adv.Technol.19(2008)1343-1352.

[18]C.Merlini,A.Pegoretti,T.M.Araujo,S.D.A.S.Ramoa,W.H.Schreiner,G.M.D.Barra,Electrospinning of doped and undoped-polyaniline/poly(vinylidene fluoride)blends,Synth.Met.213(2016)34-41.

[19]S.Saidi,A.Mannai,H.Derouiche,A.B.Mohamed,Effect of drying temperature on structural and electrical properties of PANI:PVDF composite thin films and their application as buffer layer for organic solar cells,Mater.Sci.Semicond.Process.19(2014)130-135.

[20]B.Hudaib,V.Gomes,J.Shi,C.Zhou,Z.Liu,Poly(vinylidene fluoride)/polyaniline/MWCNT nanocomposite ultra filtration membrane for natural organic matter removal,Sep.Sci.Technol.190(2018)143-155.

[21]J.N.Martins,M.Kersch,V.Altstadt,R.V.B.Oliveira,Electrical conductivity of poly(vinylidene fluoride)/polyaniline blends under oscillatory and steady shear conditions,Polym.Test.32(2013)862-869.

[22]G.Liu,T.Yan,Y.Wu,X.Yi,B.Chen,R.W.Li,Polyaniline-poly(vinylidene fluoride)blend micro filtration membrane and its spontaneous gold recovery application,Sci.China Chem.(2017)1-9.

[23]F.Xie,C.Kou,Y.Yuan,W.Zhu,J.Zhu,High-performance supercapacitor based on polyaniline/poly(vinylidene fluoride)composite with KOH,Energy Technol.5(4)(2017)588-598.

[24]G.F.Yu,J.T.Li,W.Pan,X.X.He,Y.J.Zhang,Electromagnetic functionalized ultra fine polymer/γ-Fe2O3fibers prepared by magnetic-mechanical spinning and their application as strain sensors with ultrahigh stretchability,Compos.Sci.Technol.139(2017)1-7.

[25]P.C.Ma,W.Zhang,Y.Zhu,L.Ji,R.Zhang,N.Koratkar,Alignment and dispersion of functionalized carbon nanotubes in polymer composites induced by an electric field,Carbon46(2008)706-710.

[26]M.Abbasipour,R.Khajavi,A.A.Yousefi,M.E.Yazdanshenas,F.Razaghian,The piezoelectric response of electrospun PVDF nanofibers with graphene oxide,graphene,and halloysite nanofillers:A comparative study,J.Mater.Sci.Mater.Electron.28(21)(2017)15942-15952.

[27]E.Camponeschi,R.Vance,M.Al-Haik,H.Garmestani,R.Tannenbaum,Properties of carbon nanotube-polymer composites aligned in a magnetic field,Carbon45(2007)2037-2046.

[28]T.Kimura,H.Ago,M.Tobita,S.Ohshima,M.Kyotani,M.Yumura,Polymer composites of carbon nanotubes aligned by a magnetic field,Adv.Mater.14(2002)1380-1383.

[29]J.Zhao,Z.Wang,J.X.Wang,S.C.Wang,High-performance membranes comprising polyaniline nanoparticles incorporated into polyvinylamine matrix for CO2/N2separation,J.Membr.Sci.403(2012)203-215.

[30]H.Derouiche,A.B.Mohamed,Structural and microwave dielectric properties of ferroelectric poly(vinylidene di fluoride)-polyaniline composite thin films,Thin Solid Films526(2012)274-277.

[31]Y.Chen,J.Xiong,H.Chang,Effect of adding PANI-DBSA in dope on diameter of electrospun PAN nanofibers,J.Textile Res.31(2010)16-20.

[32]H.Guo,X.Li,B.A.Li,J.X.Wang,S.C.Wang,Thermal conductivity of graphene/poly(vinylidene fluoride)nanocomposite membrane,Mater.Design114(2017)355-363.

[33]M.P.Silva,V.Sencadas,G.Botelho,A.V.Machado,A.R.Rolo,α-and γ-PVDF:Crystallization kinetics,microstructural variations and thermal behaviour,Mater.Chem.Phys.122(1)(2010)87-92.

[34]A.Subramania,S.L.Devi,Polyaniline nanofibers by surfactant-assisted dilute polymerization for supercapacitor applications,Polym.Adv.Technol.19(2008)725-727.

Chinese Journal of Chemical Engineering2018年5期

Chinese Journal of Chemical Engineering2018年5期

- Chinese Journal of Chemical Engineering的其它文章

- Controlling dispersion and morphology of MoS2 nanospheres by hydrothermal method using SiO2 as template☆

- Morphological,mechanical and thermal properties of cyanate ester/benzoxazine resin composites reinforced by silane treated natural hemp fibers☆

- A simple strategy to synthesize and characterization of zirconium modified PCs/γ-Al2O3☆

- Antioxidant activity of phytosynthesized biomatrix-loaded noble metallic nanoparticles

- Cr(III)removal from simulated solution using hydrous magnesium oxide coated fly ash:Optimization by response surface methodology(RSM)☆

- An innovative trigeneration system using biogas as renewable energy