周期式高梯度磁选机磁系磁场的分析与应用

陈志友,石 晴,冯其明

中南大学资源加工与生物工程学院,湖南 长沙 410083

周期式高梯度磁选机磁系磁场的分析与应用

陈志友,石 晴,冯其明*

中南大学资源加工与生物工程学院,湖南 长沙 410083

当励磁电流为200 A时,计算了周期式高梯度磁选机线圈轴线轴向和距轴线0.15 m处径向的磁感应强度,并运用ANSYS有限元分析软件分析了屏蔽铁铠和磁极对线圈磁场特性的影响,同时采用该设备进行了高岭土磁分离除铁实验.结果表明,距线圈中心0.1 m轴线轴向为0.326 T的均匀磁场,随着与中心距离的增加磁感应强度大幅下降;距轴线0.15 m径向的磁感应强度很小,在端面效应的作用下达到最大值0.064 T;安装屏蔽铁铠和磁极,线圈中心均匀磁场的磁感应强度提高至0.95 T.在矿浆流速为0.7 cm/s,背景磁感应强度为1.1 T下,一次磁选将高岭土的Fe2O3的质量分数由1.35%降至0.63%,白度由68%提高至89%.

磁选机;螺线管线圈;磁场特性;仿真;磁分离

为降低高岭土、钾钠长石等非金属矿中的铁含量,磁选[1]相对浮选[2]、还原酸浸[3-4]和氯化焙烧[5]等有无污染、成本低的特点.立环高梯度磁选机由于工作方式和磁介质等因素[6],对微细非金属矿的除铁效率较低,针对微细非金属矿除铁研制的周期式高梯度磁选机,多为除铁应用效果的报道[7-8],磁场特性的研究很少.磁系是磁选设备的核心[9],通过对磁系结构的磁场特性研究,完成设备磁场特性的研究.

采用ANSYS电磁仿真对磁系进行建模分析,清晰得到磁力线分布和磁场强度云图[10].卢东方等[11]仿真分析了履带式永磁磁选机磁系的磁场特征,比较了2种磁结构单元的仿真误差.张荣岭等[12]对条形永磁开路漏磁导磁场进行仿真计算.郑霞裕等[13]模拟了磁介质排列组合方式和充填率对磁场特性的影响.卢东方等[14]对旋流高梯度磁选机的磁力场进行仿真,计算了磁性和非磁颗粒的受力.目前,对周期式高梯度磁选机磁场的研究,为安装磁极铠装螺线管线圈磁场的仿真,但未研究铁铠和磁极对线圈磁场的影响.本文以周期式高梯度磁选机的磁系为研究对象,采用ANSYS软件对线圈及增加铁铠和磁极的磁场进行仿真,得到磁力线分布、磁场分布云图和磁感应强度值,理论计算螺线管线圈轴向和径向的磁场特性,清晰了解铁铠和磁极对线圈磁场的影响,并利用设备对微细高岭土进行除铁试验.

1 螺线管线圈磁场计算

1.1 螺线管磁场计算公式

多层密绕螺线管的内半径为R1,外半径为R2,线圈长2L,总匝数为N,导线中通过的电流为I,多层密匝螺线管磁场模型见图1.

图1 多层密匝螺线管磁场模型Fig.1 Magnetic field model of close layers solenoid

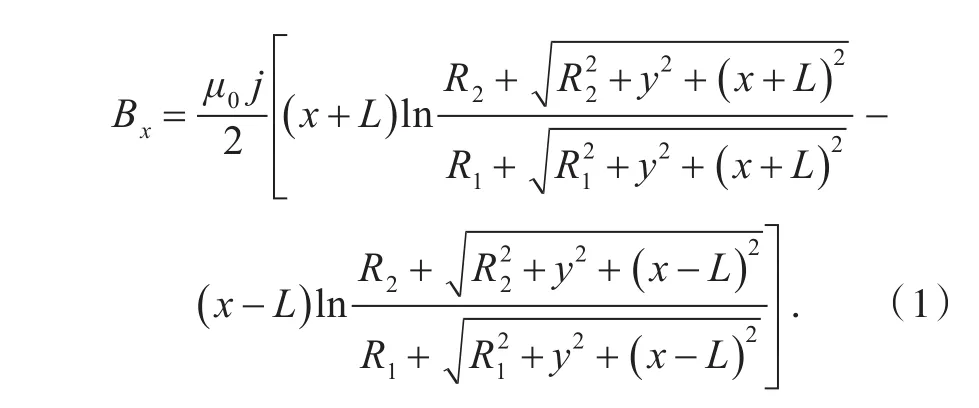

则多层密匝螺线管近轴沿中心轴线x轴轴向的磁感应强度[15]为:

同理可求出沿中心轴线向线圈y轴的径向磁感应强度:

1.2 计算结果

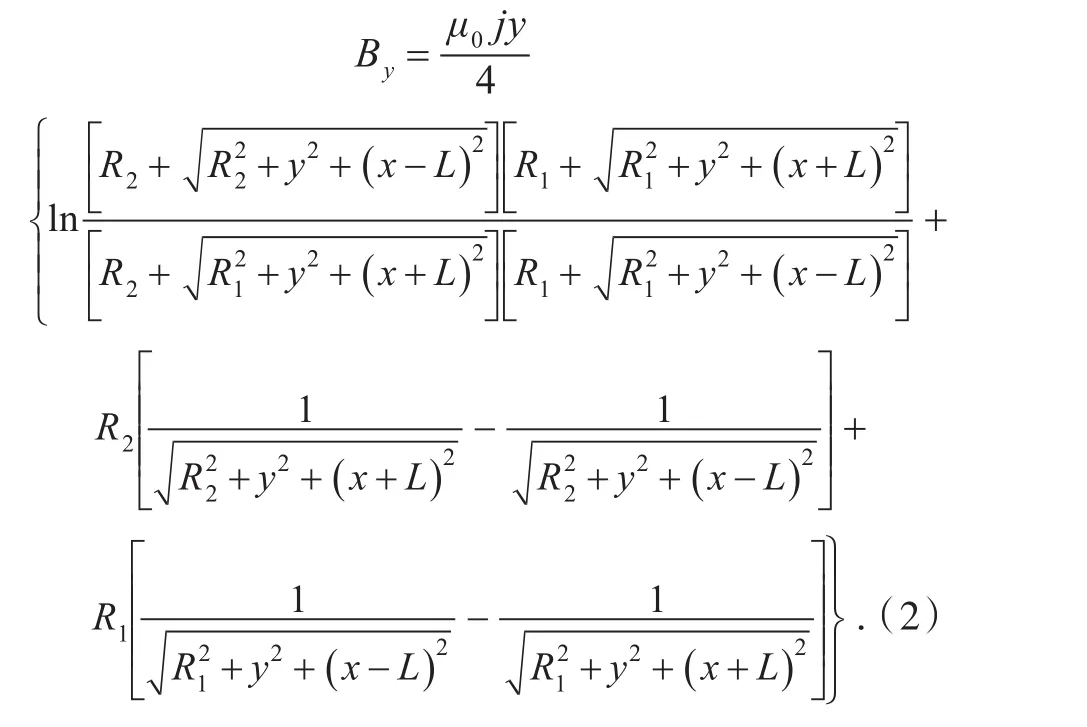

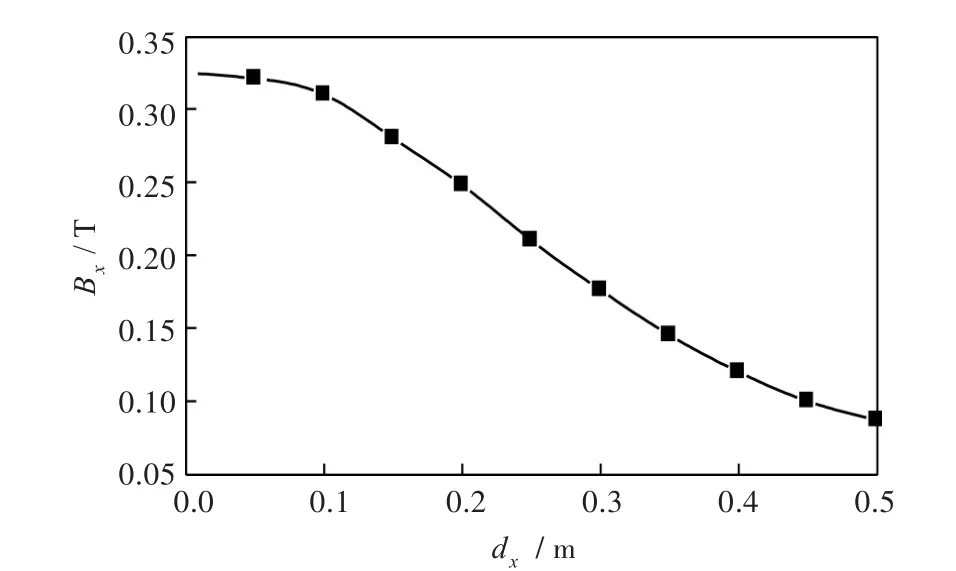

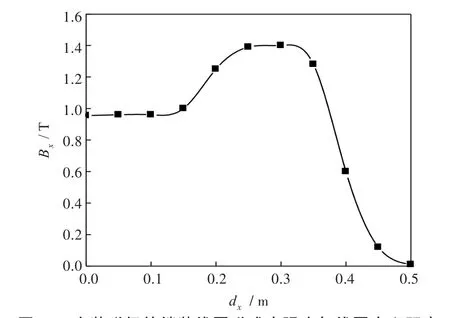

线圈参数:R1=0.22 m,R2=0.5 m,L=0.25 m,y=0.15m,N=2124匝,I=200A,μ0=4π×10-7N/A2,利用式(1)和式(2),计算线圈轴线轴向的磁感应强度Bx和距轴线0.15 m径向的磁感应强度By,结果见图2.

图2 磁感应强度与线圈中心距离的关系Fig.2 Relationship between magnetic induction intensity and center distance of coil

由图2可知,在线圈中心至0.1 m的区域内,轴线轴向磁感应强度变化很小,近似为均匀磁场;当与线圈中心的距离继续增加,磁感应强度大幅下降,当与线圈中心距离由0.1 m增加至0.25 m时,轴线轴向的磁感应强度由0.326 T下降至0.26 T;径向磁感应强度比轴向磁感应强度小得多,并在端面(x为0.25 m)附近出现最大值为0.064 T.

2 螺线管线圈磁场仿真研究

基于有限元软件ANSYS的磁场仿真,研究了屏蔽铁铠和磁极对螺线管线圈磁场的影响,线圈的仿真参数与计算参数相同,线圈中心轴线为y轴,径向为x轴.

2.1 螺线管线圈磁场分布特性

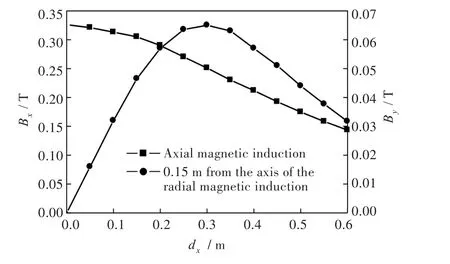

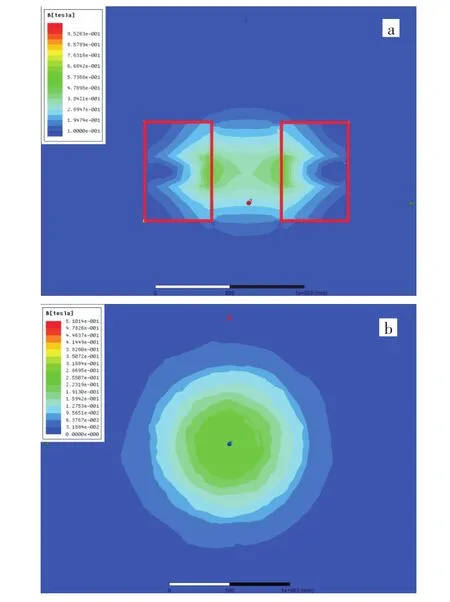

励磁电流为200 A时,螺线管线圈的磁力线分布见图3,磁感应强度分布云图见图4,轴线轴向的磁感应强度与距离的关系见图5.

由图3可知,线圈内部磁力线向下,外部向上,形成回路,在端面和周围漏磁严重;由图4和图5可知,线圈内部中心位置磁感应强度最高,沿四周下降;在线圈轴线中心一定距离内,为磁感应强度0.325 T的均匀磁场,与计算结果0.326 T基本一致,当与线圈中心距离增大,磁感应强度急剧下降.

图3 线圈的磁力线分布Fig.3 Magnetic field distribution of solenoid coil

图4 线圈内部磁感应强度分布云图:(a)剖视图;(b)俯视图Fig.4 Distribution of magnetic strength of inside solenoid coil:(a)Sectional view;(b)Top view

图5 磁感应强度与线圈中心距离的关系Fig.5 Relationship between magnetic induction intensity and center distance of coil

2.2 铠装螺线管线圈磁场分布特性

螺线管线圈为开放磁场,为提高线圈内部的场强,一是增加线圈匝数或提高励磁电流,但材耗、能耗过高;或在线圈外部和两端安装屏蔽铁铠和磁极.铁铠和磁极被外磁场磁化,使得任意点的磁感应强度为传导电流和被磁化铁磁质分别作用时产生的磁场之和[16-17].

因此,考查螺线管线圈外部安装屏蔽铁铠对线圈磁场的影响.屏蔽铁铠厚度为20 mm,励磁电流为200 A,线圈磁力线分布见图6,磁感应强度分布云图见图7,轴线轴向磁感应强度与距离的关系见图8.

由图6可知,磁力线沿上端面向中心聚集,内部向下至下端面指向铁铠,沿铁铠向上形成回路,在屏蔽铁铠的作用下,线圈周围无磁力线分布,上下端面有漏磁.由图7和图8可知,在屏蔽铁铠的聚磁作用下,内部磁场得到提高,线圈中心的均匀磁场磁感应强度由0.326 T提高至0.37 T,当与线圈中心距离增大,磁感应强度急剧下降.

图6 铠装线圈的磁力线分布Fig.6 Magnetic field distribution of armored solenoid coil

图7 铠装线圈内部磁感应强度分布云图:(a)剖视图;(b)俯视图Fig.7 Distribution magnetic strength of inside armored solenoid coil:(a)Sectional view;(b)Top view

图8 铠装线圈磁感应强度与线圈中心距离的关系Fig.8 Relationship between magnetic induction strength and center distance of armored coil

2.3 安装磁极的铠装螺线管线圈的磁场分布

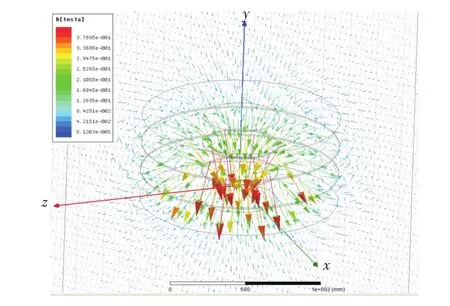

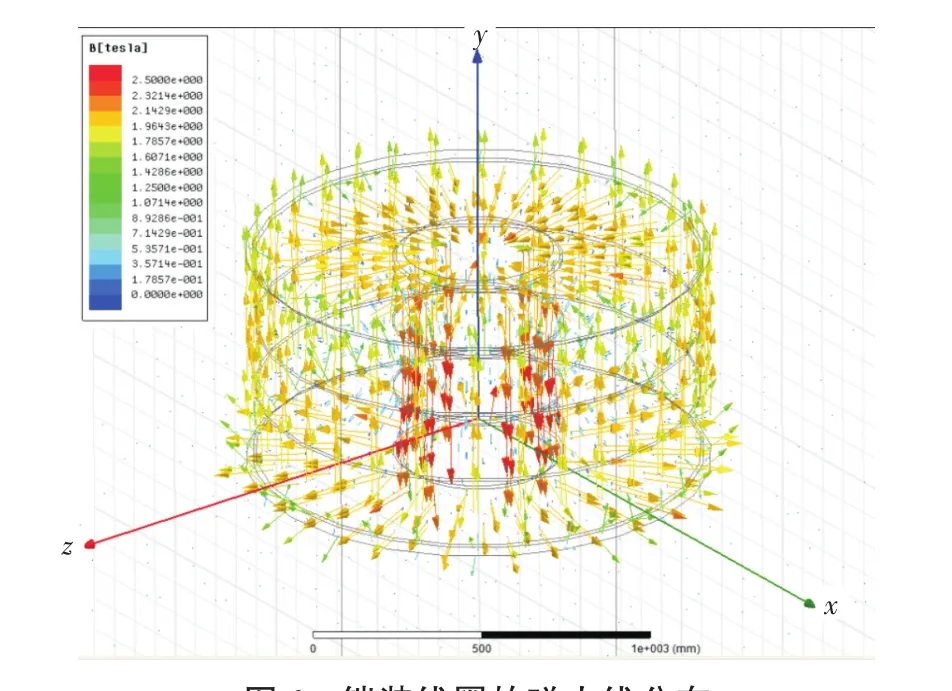

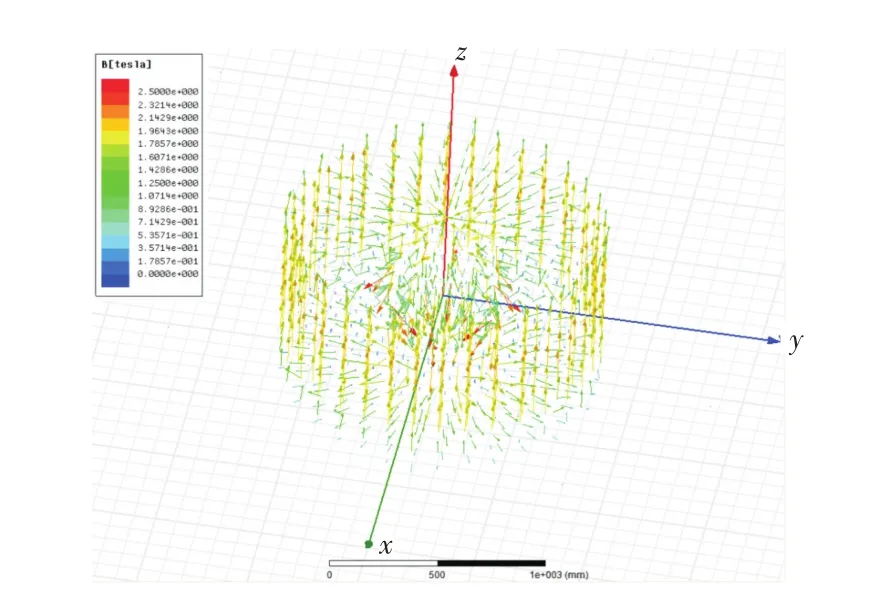

在铠装螺线管线圈端面安装磁极,进一步避免漏磁.磁极厚度为30 cm,孔隙率为25%,则磁力线分布见图9,磁感应强度分布云图见图10,中心轴线磁感应强度与距离见图11.

由图9可知,磁力线沿上磁极向中心聚集,内部向下至下磁极指向铁铠,沿铁铠向上,形成闭合回路,在屏蔽铁铠和磁极的聚磁作用下,线圈外部和端面无漏磁,由图10和图11可知,磁极被磁化,磁极的磁感应强度最高为1.39 T,同时线圈内部均匀磁场得到大幅提高,磁感应强度由0.38 T提高至0.96 T.

图9 安装磁极的铠装线圈磁力线分布Fig.9 Magnetic field distribution of armored solenoid coil with magnetic pole

图10 安装磁极的铠装线圈内部磁感应强度分布云图:(a)剖视图;(b)俯视图Fig.10 Distributions of magnetic strength of armored solenoid coil with magnetic pole:(a)Sectional view;(b)Top view

图11 安装磁极的铠装线圈磁感应强度与线圈中心距离的关系Fig.11 Relationship between magnetic induction and center distance of armored coil with magnetic pole

3 周期式高梯度磁选机的除铁效果

3.1 矿样性质

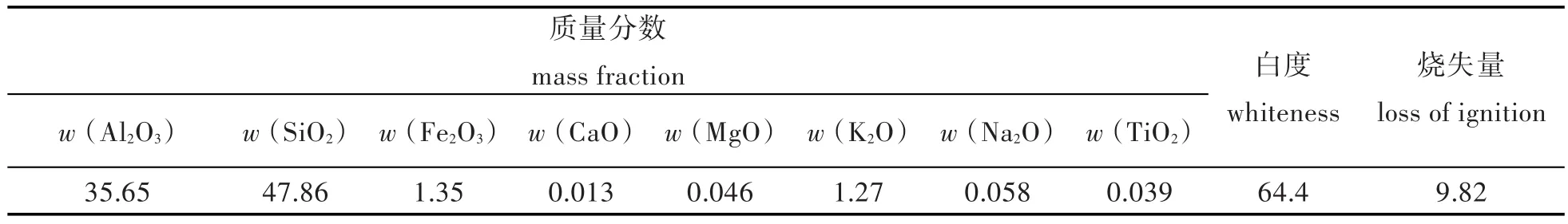

对某高岭土经制浆、分级,-43 μm粒级进行除铁实验.其主要杂质矿物为铁矿物、少量钛矿物,其中铁矿物主要为褐铁矿和少量磁铁矿.原料白度为64.4%,多元素分析见表1.

表1 矿样多元素分析结果Tab.1 Chemical analysis results of composition of sample %

3.2 实验方法

将高岭土配制为质量分数为20%的矿浆,加入质量分数为0.2%的六偏磷酸钠,搅拌10 min,取10 L矿浆进行磁分离试验,磁介质不锈钢毛宽约0.1 mm,厚约0.07 mm,分析磁性和非磁性产品的Fe2O3的质量分数和非磁性产品的白度,研究矿浆流速和背景磁感应强度对高岭土除铁效果的影响.

3.3 矿浆流速对磁分离效果的影响

磁感应强度为1.0 T时,研究矿浆流速对高岭土除铁效果的影响,结果见表2.

表2 矿浆流速对除铁效果的影响Tab.2 Effect of pulp flow rate on iron removal

由表2可知,随着矿浆流速增大,非磁性产品产率随之增高,含铁量亦增高,而白度随之下降;流速超过0.7 cm·s-1,对非磁性产品的质量影响较大,矿浆流速应选择0.7 cm·s-1.

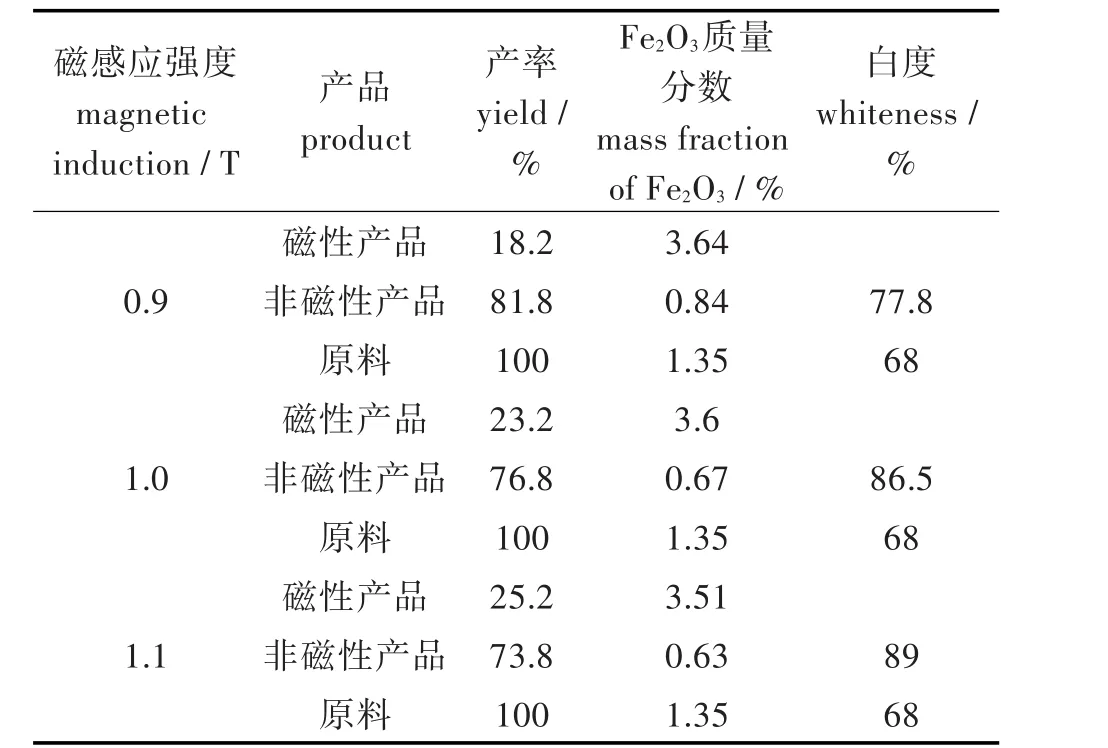

3.4 磁感应强度对磁分离效果的影响

矿浆流速为0.7 cm·s-1,背景磁感应强度对高岭土除铁效果的影响,结果见表3.

由表3可知,随着背景磁感应强度增大,非磁性产品产率随之增高,含铁量随之降低,白度随之提高,因此提高磁感应强度有利于提高非磁性产品的质量.

表3 磁感应强度对除铁效果的影响Tab.3 Effect of magnetic induction on iron removal

4 结 语

本文通过理论计算和ANSYS仿真,分析了屏蔽铁铠和磁极对周期式高梯度磁选机励磁线圈内部磁场特性的影响,并验证了设备对高岭土的除铁效果.

1)由理论计算和仿真结果可知,距螺线管线圈中心100 mm区域内约为0.326 T的均匀磁场,当距离继续增加,磁感应强度大幅下降.

2)由ANSYS仿真结果可知,屏蔽铁铠和磁极避免了螺线管线圈的漏磁,大幅提高了线圈内部均匀磁场的磁感应强度.当励磁电流为200 A时,螺线管线圈中心均匀磁场的磁感应强度为0.325 T,安装屏蔽铁铠后提高至0.38 T,安装屏蔽铁铠和磁极后提高至0.95 T.

3)在背景磁感应强度1.1 T,矿浆流速0.7 cm·s-1时,对Fe2O3质量分数为1.35%、白度为68%的高岭土进行磁分离除铁实验,可将Fe2O3质量分数降至0.63%,白度提高至89%.说明周期式高梯度磁选机对微细粒高岭土除铁有一定的效果,能适应微细粒非金属矿的除铁要求.

[1] 陈丽昆,李亦然,王军,等.超导磁分离工艺替代化学漂白用于高岭土除杂增白的可行性研究[J].非金属矿,2014,37(3):57-59.CHEN L K,LI Y R,WANG J,et al.Research on using superconducting magnetic separation as a substitute for chemical bleaching in kaolin treatment [J].Non-Metallic Mines,2014,37(3):57-59.

[2] 夏光华,李晓鸣,苏小丽.混合捕收剂去除高岭土中含铁矿物试验研究[J].地质找矿论丛,2012,27(1):121-124.XIA G H,LI X M,SU X L.The experiment research on iron removal from kaolin by using mixed collecting agent[J].Contributions to Geology and Mineral Resources Research,2012,27(1):121-124.

[3] TUNCUK A, CIFTLIK S, AKCIL A.Factorial experiments for iron removal from kaolin by using single and two-step leaching with sulfuric acid [J].Hydrometallurgy,2013,134/135(3):80-86.

[4] CAO W,XIA G H,LU M,et al.Iron removal from kaolin using binuclear rare earth complex activated thiourea dioxide[J].Applied Clay Science,2016,126:63-67

[5] 郑水林,杜玉成,毛钜凡,等.煤系高岭土氯化焙烧除铁增白工艺及机理研究[J].矿冶,1997,6(3):66-69.ZHENG S L,DU Y C,MAO J F,et al.Study on chloridizing roasting process and mechanism of kaolin containing coal[J].Mining and Metallurgy,1997,6(3):66-69.

[6] 陈俊明,钟森林,谢宝华,等.ZQS周期式高梯度磁选机的研制和应用[J].现代矿业,2016(7):235-236.CHEN J M,ZHONG S L,XIE B H,et al.Development and application of ZQS periodic high gradient magnetic separator[J].Modern Mining,2016(7):235-236.

[7] 王龙.电磁浆料高梯度磁选机的优化改进及在非金属矿磁选中的应用[J].陶瓷,2016(1):31-34.WANG L.Optimizationandimprovementofhigh gradient magnetic separator for electromagnetic slurry and its application in non-metallic magnetic separation[J].Ceramics,2016(1):31-34.

[8] 李小静,徐星佩,周岳远,等.CRIMM型高梯度磁选机在高岭土精制中的应用[J].矿产保护与利用,2005(6):25-27.LI X J,XU X P,ZHOU Y Y,et al.Application of the CRIMM cyclic high gradientmagnetic separators(HGMS) to kaolin cleaning[J].Conservation and Utilization of Mineral Resources,2005(6):25-27.

[9] 袁致涛,高太,郭小飞,等.永磁强磁预选设备的研制与应用[J].东北大学学报(自然科学版),2010,31(8):1188-1191.YUAN Z T,GAO T,GUO X F,et al.Development and application of high-intensity permanent magnetic separator for pre-concentration[J].Journal of Northeastern University(Natural Science),2010,31(8):1188-1191.

[10] TAKAYAMA T, KAMITANIA, TANAKA A.Numerical simulation of permanent magnet method:influence of experimental conditions on accuracy of jC-distribution[J].Physic C:Superconductivity and its Applications,2010,470(20):1354-1357.

[11] 卢东方,王毓华,何平波,等.基于ANSYS的履带式永磁磁选机磁场模拟[J].中国有色金属学报,2014,24(8):2188-2195.LU D F,WANG Y H,HE P B,et al.Simulation of magnetic field on tracked permanent magnetic separator based on ANSYS[J].The Chinese Journal of Nonferrous Metals,2014,24(8):2188-2195.

[12] 张荣岭,郑艳明,崔浩,等.条形永磁开路漏磁导磁场仿真计算方法[J].机电元件,2008,28(4):24-27.ZHANG R L,ZHENG Y M,CUI H,et al.Magnetic field simulation method for calculating leakage permeance of bar permanent magnet in open magnetic circuit[J].Electromechanical Components,2008,28(4):24-27.

[13] 郑霞裕,李茂林,崔瑞,等.基于ANSYS的高梯度磁选机磁场特性影响因素分析[J].金属矿山,2013,42(7):139-143.ZHENG X Y,LI M L,CUI R,et al.Analysis of factors influencing magnetic field's characteristics in HGMS based on ANSYS[J].Metal Mine,2013,42(7):139-143.

[14] 卢东方,王毓华,何平波,等.旋流高梯度磁选机的原理及分选性能预测[J].中南大学学报(自然科学版),2014,45(1):1-8.LU D F,WANG Y H,H P B,et al.High-gradient magnetic separatorwith rotationalflow field and predictions of its separation performance[J].Journal of Central South University(Science and Technology),2014,45(1):1-8.

[15] 魏群.螺线管磁场分布特征[J].长春工业大学学报,2003,24(3):68-70.WEI Q.A study on the magnetic field distribution characteristics of coils[J].Journal of Changchun University of Technology,2003,24(3):68-70.

[16] 何桂春,黄开国,何平波.高梯度磁选机铠装圆柱形螺线管磁系磁场分布的间接边界单元法(IBEM)研究[J].有色矿冶,2002,18(1):16-19.HE G C,HUANG K G,HE P B.Study on the distribution of the magnetic flux density of magnetic system of HGMS by indirect BEM[J].Non-Ferrous Mining and Metallurgy,2002,18(1):16-19.

[17] 何健全,许丽敏.高梯度磁选机磁系结构设计校核及优化[J].机电工程技术,2009,38(11):72-73.HE J Q,XU L M.Magnet system design,checking and optimizing of high gradient magnetic separator[J].Mechanical and Electrical Engineering Technology,2009,38(11):72-73.

Research and Application of Magnetic Field for Periodic High Gradient Magnetic Separator

CHEN Zhiyou,SHI Qing,FENG Qiming*

School of Resources Processing and Bioengineering,Central South University,Changsha 410083,China

Magnetic induction intensity of the radial axis and 0.15 m from the axis of the coil in periodic high gradient magnetic separator were calculated at an excitation current of 200 A.The influences of shielded iron armor on magnetic field characteristics of the coil were analyzed by ANSYS finite element analysis software as well.Simultaneously,kaolin magnetic separation and iron removal experiment were carried out.The results showed that axial magnetic induction intensity around 0.1 m of the coil center was in a uniform magnetic field of 0.326 T,and the magnetic induction decreased significantly with the distance from center increasing.The magnetic induction of the site of 0.15 m around the axis was very small in the radial direction,and the maximum value of that was 0.064 T by the end effect.The magnetic induction of the uniform magnetic field in the coil center might increase to 0.95 T after an armored iron and a magnetic pole in the solenoid coil were installed.When the background magnetic induction intensity was 1.1 T at pulp flow rate of 0.7 cm/s,the mass fraction of Fe2O3in kaolin reduced from 1.35%to 0.63%,and the whiteness of it increased from 68%to 89%by one magnetic separation only.

magnetic separator;solenoid coil;magnetic field characteristic;simulation;magnetic separation

2017-05-26

国家重点基础研究发展计划“973”项目(2014cb643400)

陈志友,博士研究生.E-mail:496916449@qq.com

*通讯作者:冯其明,博士,教授.E-mail:qmfeng@126.com

陈志友,石睛,冯其明.周期式高梯度磁选机磁系磁场的分析与应用[J].武汉工程大学学报,2017,39(5):482-487.

CHEN Z Y,SHI Q,FENG Q M.Research and application of magnetic field for periodic high gradient magnetic separator[J].Journal of Wuhan Institute of Technology,2017,39(5):482-487.

TD97

A

10.3969/j.issn.1674-2869.2017.05.014

1674-2869(2017)05-0482-06

苗 变