1MCDS-100A型铲筛式残膜回收机的设计与试验

游兆延,胡志超,吴惠昌,张亚萍,颜建春,严 伟,周新星

1MCDS-100A型铲筛式残膜回收机的设计与试验

游兆延,胡志超※,吴惠昌,张亚萍,颜建春,严 伟,周新星

(农业部南京农业机械化研究所,南京 210014)

为了减少铲筛式残膜回收机在工作中的振动,设计了双筛面呈上下平行排布的减振式自平衡残膜回收机,确定偏心轮旋转轴转速范围为260~330 r/min,采用DH5902动态测试系统对双筛面残膜回收机的振动参数进行了田间作业测试,试验结果表明振动频率在3~5.5 Hz变化时,机架左右方向振动测量值范围在4.2~5.4 m/s2,在设备可承受振动范围内,双筛面减振效果明显。通过单因素试验确定筛面形式为锯齿筛,另外,设计了电动推杆式自动卸膜装置,耗时4.1 s完成卸膜任务。选取机具前进速度、逐膜筛振动频率、逐膜筛振幅、锯齿间距作为试验因素,运用响应曲面法并在Matlab2013a软件中绘制四维切片图来分析各因素对残膜回收指标的影响效应,结果表明试验因素对残膜回收质量有较大影响,综合优化结果为机具前进速度0.73 m/s,逐膜筛振幅99 mm,逐膜筛振动频率为280 r/min,筛面锯齿间距12 mm,此时残膜回收率为91.26%,缠膜率为4.27 %,膜土比为2.16。该研究不仅为农机市场提供了一种实用机具,也为残膜回收机械创新研发和优化提升提供了理论依据和参考借鉴。

农业机械;设计;振动控制;双筛面;驱振装置;膜土分离;残膜回收机

0 引 言

沙土或沙壤土是中国主要土壤类型之一,主要分布在黄河故道沙土区、沿海平原沙土区等区域[1],各区因地制宜,为保温保墒[2],适宜于沙土的花生、棉花、马铃薯等作物常采用覆膜种植,收获后大量残膜污染农田造成严重的白色污染[3-6]。以华北地区为例,相比于玉米、蔬菜等其他土壤种植作物,花生和棉花的平均地膜残留强度最高,预计到2021年,花生地和棉田的地膜残留强度将分别达到69.1和70.4 kg/hm2,中国2010年制定了《农田地膜残留量限值及测定》标准,采用65 kg/hm2作为0~20 cm 土层的地膜残留量限值,如果不注重残膜回收工作,这些地区将成为残膜污染区域[7-8]。

由于沙土或沙壤土有较好的易碎性,在机械化回收农作物及残留地膜时,国内外多家单位对铲筛式挖掘收获机做了大量研究,意大利Checchi&Magli公司研制的SP100振动筛式马铃薯收获机,通过2个左右等水平排列的筛面在高频驱动下低幅抖动,物料在筛面上需改变运动方向,仅适合块状类作物的回收;南京农机化所和开封茂盛机械有限公司联合研制的4H-800型振动筛式花生收获机,该机采用单层筛床配振动偏心轮结构,偏心块的回转运动无法消除筛床的往复运动,机具作业过程中振动大,机手作业强度大[9-11];甘肃洮河拖拉机有限公司研制的4U-400型铲筛式马铃薯挖掘机,偏心轮推动主筛摆杆及副筛摆杆往复运动,带动挖掘铲,主、副筛栅条产生高频低幅往复运动,但主副筛栅条运动方向相同,作业过程中振动偏大,整机作业效率较低[12];山西长治永成三轮车厂生产的4S-80型马铃薯振动挖掘机,采用铲筛一体的振动结构,铲筛振动状态下可显著降低牵引阻力,但拖拉机也发生强烈振动,极易引发机具的损坏和驾驶员身体损伤[13];山东大学机械工程学院设计了摆动式挖掘收获机,将挖掘机构与筛选机构合二为一,并从纵向分为两部分,采用反平行四边形原理,使两部分等角度、反方向摆动,但整机功率较大,振动筛频率较慢。目前国内外鲜有铲筛式残膜回收机报道,究其原因是现有驱振方式大多无法很好解决振动平衡问题,另外筛面在筛分过程中无挡下滑设计,加上膜、土、杂等自身重力因素,造成土块堆积、筛孔堵塞,膜土分离效率低,残膜回收质量不高。

针对残膜回收机的作业特点,结合地膜回收农艺要求,本文设计了一种双筛体自平衡减振式残膜回收机,可一次性完成起膜、膜土分离、集膜、卸膜,作业可靠,具有良好的推广应用前景。

1 铲筛式残膜回收机总体结构及工作原理

1MCDS-100A型铲筛式残膜回收机结构图如图1所示,主要由以下几部分组成:机架、驱振装置、前筛、后筛、限深装置和集膜筐。

铲筛式残膜回收机收获时,挖掘铲组件挖掘膜土,膜土混合物落到前筛,在驱振装置作用下,前筛面在松破土的同时逐级将剩余的土和残膜继续往后筛输送,落到后筛的膜土混合物继续在后筛的筛程内完成膜土分离和输膜任务,最后将分离干净的残膜回收至集膜筐。

2 关键部件参数设计

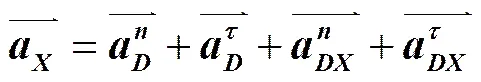

2.1 驱振系统平衡设计

驱振装置主要由变速箱、驱振轴、飞轮、偏心驱振臂组件、连杆组装等组成。振动平衡问题是本机的核心,驱振系统振动平衡设计如图2所示,包括两方面,一是回转运动振动平衡设计,通过飞轮的回转运动来抵消偏心驱振臂(图2a)的旋转,需配重轴承套、驱振臂板端盖、轴承、偏心套(按无中间通孔计质量)等合计总质量为2.67 kg,配重惯距为0.024 kg·m,设计的飞轮结构如下图2b,二是双筛面往复运动振动平衡,设计反配置等惯量自平衡双筛面(图2c),双筛面上下平行排布,且前筛床的后端和后筛床的前端上下重叠,前筛和后筛始终保持同时反向运动。

2.2 双筛面振动筛运动参数确定

双筛面振动筛机构运动简图如图3所示。偏心套圆心点绕驱振轴轴心点转动,从而带动连杆推动摇杆和,前筛面绕着铰接点2来回摆动,后筛面绕着铰接点4来回摆动,实现前后筛的同时反向往复振动,完成筛分任务。

1.变速箱组件 2.前筛框驱振臂组件 3.连杆组件 4.前筛 5.后筛框驱振臂组件 6.后筛 7.偏心驱振臂组件 8.张紧轮组件 9.支撑轮组件

1.Gearbox components 2.Drive arm components of forward screen frame 3.Connecting rod components 4.Front sieve 5.Drive arm components of back screen frame 6.Back sieve 7.Eccentric drive arm components 8.Tension pulley components 9.Supporting wheel components

c. 双筛面往复运动振动平衡设计

c. Vibration balance design for reciprocating motion of double-sieve

图2 驱振系统振动平衡设计

Fig.2 Vibration balance design of drive system

前期样机表明,偏心套偏心距=9~30 mm,=120~145 mm,=405 mm,=240 mm,=398 mm。为了膜土在筛面上完成一级或多级输送的同时,也能够松、破土,膜土分离效果好应满足如下条件[14-15]

前滑(1)

后滑(2)

抛离(3)

式中为筛轴角速度,rad/s;为摆动筛偏心套的旋转半径,mm;为膜土混合物与筛面的摩擦角,经试验测得摩擦角为20.75°;为质心加速度方向与轴所夹的锐角,43°;为筛面倾角,14°;为重力加速度,g/m2。

代入公式(1)、(2)和(3)得:双筛的质心加速度a范围为:5.3 m/s2<a<17.3m/s2。

通过矢量方程图解法对双筛面振动机构进行筛面质心加速度分析,进而求出曲柄转速的变化范围。

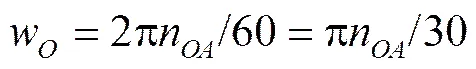

(5)

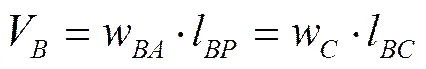

式中为绕点的角速度,rad/s;为杆的转速,r/min;w为杆的角速度,rad/s;l为杆的长度,m;l为点到和交点的长度,m。

式中为点线速度,m/s;为绕点的角速度,rad/s;l为点到和交点的距离,m;l为杆长度,m。

(7)

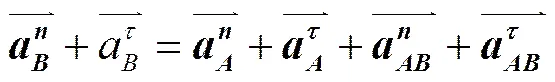

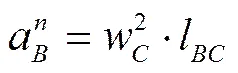

式中为点的线速度,m/s;为杆的角速度,rad/s;l为杆的长度,m;l为点到和交点的距离,m。根据同一构件上相对加速度原理,杆上相对加速度示意图如图4所示。

可知杆的矢量方程为

矢量方程(8)在杆上投影为

(9)

(11)

(12)

式中为与过点的垂线之间的夹角,(°);为和的夹角,(°);l为杆的长度,m。

同理可得杆的矢量方程为:

式(13)在轴投影:

(14)

联立式(4)-式(14)得:为满足膜土混合物实现有效分离与输送任务[16],偏心套转速范围:260 r/min <<330 r/min,变速箱输出轴与残膜回收机驱振轴的链传动比在1.21~1.53之间。

2.3 逐膜筛面设计

据前期样机研究,机具前进速度为黄海金马-254低速Ⅱ档[17],逐膜筛振动频率260 次/min,偏心套偏心距为9 mm,分别更换杆条筛、横杆筛、编织筛、圆孔筛、锯齿筛等5种不同结构筛面形式进行单因素试验[18],分析不同筛面对残膜回收质量的影响,经比较,锯齿筛的残膜回收效果最好。由于锯齿条具有单向输送性,且膜没有抛送速度,膜、土在筛面上的运动轨迹如图5所示,振动筛从图中位置1运动到2,试验过程中,刚开始土携带着膜一起运动,当驱振轴转速低于260 r/min时,会有堵住筛孔的现象,膜土分离不彻底,当高于260 r/min时,膜土运动到前筛尾部时,大部分土就已经分离出去了,膜土分离较彻底,没有堵住筛孔的现象,到了后面只有膜在筛面上运动。残膜在筛面上依靠振动筛振幅的水平分量x往后输送,为满足膜土分离与输送任务,每一个振幅周期内,振动筛振幅的水平分量A应大于一个锯齿的宽度,振动筛振幅的垂直分量A应大于一个锯齿的高度,本文中振动筛最小的振幅为62 mm,为保证了振动筛有效逐级输送残膜,设计锯齿条齿宽18 mm,齿高5 mm,锯齿条厚度1.5 mm,齿条长度为573 mm。

2.4 电动推杆式自动卸膜装置

实现自动卸膜是研制残膜回收机的关键[19-20],图6所示为设计的电动推杆式自动卸膜装置。集膜筐质量为16 kg,主体是一块1.5 mm厚的钢板经几道折弯加工,中间冲了很多20 mm的孔,质量轻且整体刚度够强。按照铺0.01 mm膜,幅宽1 m,聚乙烯地膜的密度在950 kg/m3左右,即使全部覆膜,每亩地铺膜质量大概为6.33 kg,因本机主要适收沙土或沙壤土作物,锯齿筛具有松破土和逐级输送功能,最后到集膜筐里都是相对干净的碎膜和长膜,膜装满集膜筐加起来不到10 kg。考虑到会有一些土块或石子无法被锯齿筛松破从而进入集膜筐,故设定最大回收质量为30 kg。

经计算,空载时,集膜筐旋转力臂192 mm,推杆拉力力臂57 mm,推杆启动拉力应不小于2 100 N,电动推杆选购北京中电宏立机电科技有限公司生产的型号:HLZ40-1-20-194-LT-IP65B,额定电压12 V,最大推力2 500 N,行程194 mm,满载速度47 mm/s,集膜筐在电动推杆活塞的作用下,绕着集膜筐回转套4.1 s内就能实现集膜筐的卸膜和归位,解决了卸膜环节人工费时费力、需停机卸膜等问题。

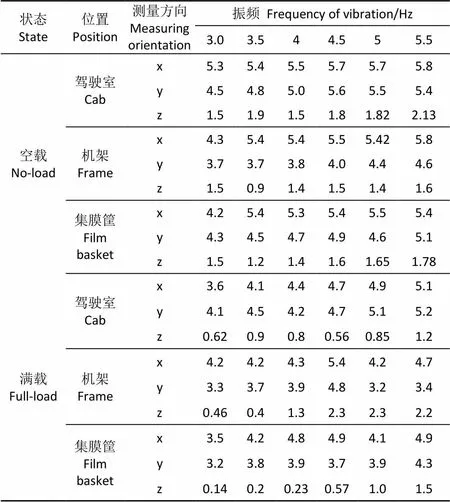

3 双筛面残膜回收机抗振特性测试

为验证振动平衡的设计,以江苏东华测试有限公司生产的DH5902动态测试分析系统和DHDAS分析软件为载体,DH5902测试系统有16个通道,最高采样速率256 kHz/通道;采用USB3.0与仪器通讯,实时传送采样数据;每通道独立的24bitA/D转换器。加速度传感器采用DH131E压电式加速度传感器(频率测量范围为1~10 kHz),灵敏度单位是0.1 (mV/pC),利用时域和频域信号分析方法,选取驱动轴转速由3 Hz增加到5.5 Hz(每次增加0.5 Hz),在1MCDS-100A铲筛式残膜回收机的3个测点位置驾驶室、机架和集膜筐处分别安装传感器,对各测点左右、前后、上下,3个方向的振动信号分别在空载和田间作业状态下进行测试[21-22],如图7所示。

经测量,前轮样机配置方式为单层筛床配有扇形偏心块,空载时机架、驾驶室、集膜筐处水平方向振动平均值超过16.4 m/s2。对残膜回收机进行测量,测量值如表1,测定结果表明,随着振动频率的增大,加速度总体呈增大趋势,对各测点位置加速度进行合成,满载作业相对于空载时,驾驶室振动强度总体降低了10%~23%,机架振动强度总体降低了8.7%~19.1%,集膜筐振动强度降低了12.4%~23.5%,各振动位置测量值均在机器可承受振动范围内,减振效果明显[23-24]。

a. 振动分析仪及处理软件a. Vibration analyzer and processorb. 机架测试方位坐标示意图b. Schematic diagram of test orientation for frame c. 田间振动测试c. Field vibration test

表1 各位置不同频率、不同作业状态下振动加速度测量

4 试验分析

试验地点选在山东胶州北王珠镇大赵家村。试验地为典型沙壤土土质,垄作马铃薯大垄双行种植模式,机具配套动力18~30 kW,挖掘深度设计为80~200 mm可调,作业幅宽1 m,生产效率为0.3~0.4 hm2/h,试验地长300 m,宽50 m,垄高11 cm,覆膜宽度为1 m,覆膜厚度为0.008 mm,土壤含水率为8.34%,地膜残留量为185 kg/hm2,残膜试样宽度为15 mm,试验速度为500 mm/min时,残膜受到的拉力峰值为1.2 N,拉伸强度为8 MPa(由深圳三思万能试验机测得,选用电动楔形拉伸夹具,型号为JXSA304B)。

4.1试验指标与因素

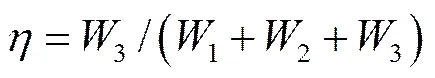

试验分别将残膜回收率、缠膜率[25]和膜土比[26]作为残膜回收机作业指标,试验指标计算方法如下:

1)残膜回收率

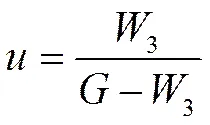

式中为残膜回收率,%;1为测区内漏在地里未回收膜的质量,g;2为测区内缠在筛面上膜的质量,g;3为测区内回收到集膜筐中膜的质量,g。

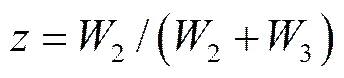

2)缠膜率

式中为缠膜率,%。

3)膜杂分离是残膜回收的难点,因为秸秆在土壤中会被分解,所以将秸秆当作土处理计算,在集膜筐下方放置一块大的彩条布,称下总质量,再将膜上的土尽可能抖干净,再称膜质量。

式中为膜土比;为集膜筐中膜土总质量,g。膜土比≥1时,收上的膜比较干净。通过对残膜回收机回收机理的分析,根据其结构特点,确定影响残膜回收率、缠膜率、膜土比的主要因素为:逐膜筛振幅,逐膜筛振动频率,锯齿间距和机具前进速度。

4.2 试验设计与方法

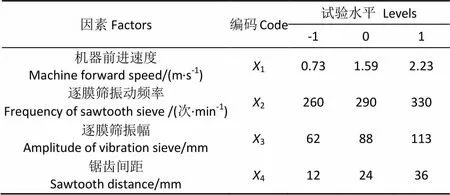

在膜土分离和输膜过程中,存在很多影响收膜率和膜土比的非线性因素,常需要选用二次或更高次的模型来逼近响应,模型可采用Box-Benhnken中心组合设计理论来建立[27]。以残膜回收率1、缠膜率2、膜土比3作为响应值,对逐膜筛振幅,逐膜筛振动频率,锯齿间距和机具前进速度等因素开展响应面试验研究。利用4因素2次回归试验设计方案,对影响残膜回收率、缠膜率、膜土比的4个主要参数组合完成优化。其中逐膜筛振幅指筛在振动过程中偏离初始位置的最大值,筛面振动频率指筛面在每分钟振动的次数,锯齿间距是指相邻2个锯齿条中心之间的距离。试验因素及水平设计见表2。

表2 响应面试验因素和水平

逐膜筛频率通过更换链轮来改变;更换不同偏心距的偏心套来改变逐膜筛的振幅[28];改变锯齿间距可通过更换可拆卸的焊有不同间距的筛面获取,拖拉机选用黄海金马-254,通过使用低速Ⅱ档、低速Ⅳ和高速Ⅰ档来改变机具前进速度。

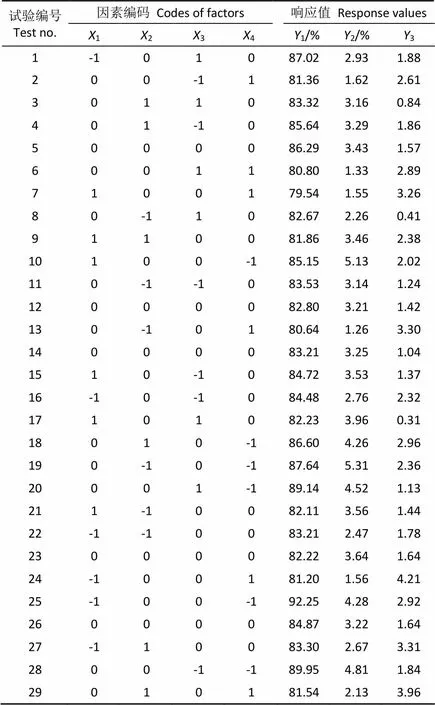

4.3 模型建立与显著性检验

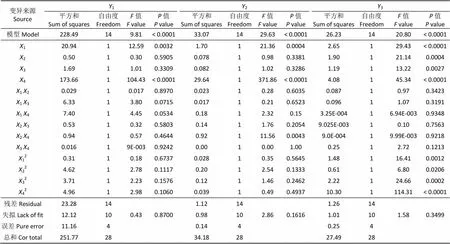

应用Design-Expert.V8.0.6.1软件进行试验设计、数据处理与统计分析,根据Box-Benhnken设计方法进行4因素3水平响应面试验,选择29个点,包括24个分析因子和5个零点估计误差,试验设计及响应结果如表3所示,并对试验结果进行方差分析(表3)。

表3 试验设计方案及响应值结果

注:1为残膜回收率;2为缠膜率;3为膜土比。

Note:1is the recovery rate of residual film, %;2is the rate of winded film, %;3is the film soil ratio.

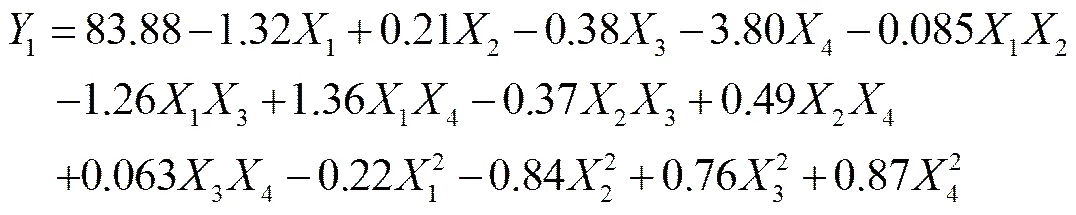

针对表3的样本数据,建立回归模型,如方程所示

由表4数据分析可知,残膜回收率1、缠膜率2、膜土比3的响应面模型的<0.0001,回归方程中各变量对指标影响的显著性由检验判定,概率值越小则相应变量的显著性越高[29]。从各因素值可以看出,锯齿间距、机具前进速度对残膜回收率有显著影响,各因素影响强弱次序为:锯齿间距>机具前进速度>逐膜筛振幅>逐膜筛振动频率。机具前进速度,锯齿间距对缠膜率有显著影响,且影响强弱次序为:锯齿间距>机具前进速度>逐膜筛振幅>逐膜筛振动频率。机具前进速度,逐膜筛振动频率,逐膜筛振幅,锯齿间距对膜土比有显著影响,且影响强弱次序为:锯齿间距>机具前进速度>逐膜筛振动频率>逐膜筛振幅。残膜回收率、缠膜率和膜土比各模型的决定系数分别为0.9575、0.9674和0.9541,说明该模型误差较小,可以用此模型对铲筛式残膜回收机的残膜回收率、缠膜率和膜土比进行分析和预测。

表4 回归模型方差分析

4.4 因素影响效应分析

依据建立的各指标的优化回归模型,按照因素重要性和显著性顺序,分别选取对各指标影响最为重要的3个因素,用Matlab2013a软件绘制四维切片图来直观描述各因素对残膜回收指标的影响效应[30-31]。

机具前进速度、逐膜筛振动频率、锯齿间距3个因素与残膜回收率影响效应如图8a所示,总体影响趋势为:机具前进速度越快、锯齿间距越大,残膜回收率越低。原因分析:当机具前进速度增加时,单位时间内的膜土喂入量增多,工作负荷加大,残膜回收率降低;当锯齿间距增加时,一些碎膜从锯齿间掉落到田块中,导致残膜回收率降低。

机具前进速度、逐膜筛振幅、锯齿间距3个因素与缠膜率影响效应如图8b所示,总体影响趋势为:机具前进速度越快、逐膜筛振幅越小、锯齿间距越小,则缠膜率越高,反之则缠膜率低。原因分析:机具前进速度越快,喂入量增加,筛床抖动膜土时,先进入筛面的膜土未完全分离又有新的膜土涌入筛床,造成输膜性能下降,缠膜率随机具前进速度的增加而升高,筛体间距减小时,单位面积的锯齿面积增加,缠膜的几率增加,缠膜率越高;另外,随着逐膜筛振幅的减小,残膜通过筛程内的时间增长,被筛面缠住的可能性也就越大,缠膜率也就越高。

锯齿间距、机具前进速度、逐膜筛振动频率3个因素与膜土比影响效应如图8c所示,总体影响趋势为:锯齿间距越小,机具前进速度越快,逐膜筛振动频率越低,则膜土比越低,反之膜土比越高。原因分析:锯齿间距较小时,大部分的土无法从锯齿间隙中落入地表,进入筛面的土量变多,筛分效率低,膜土比小;机具前进速度越快,喂入量增大,多余的膜土还来不及被筛面分离就被往后输送,导致膜土分离不彻底,膜土比低;逐膜筛振动频率越快,膜土混合物单位时间内在筛面上抖动的次数越多,膜土分散的越均匀,膜土分离效果越好,膜土比越高。

4.5 参数优化与验证

4.5.1 参数优化

本文按照残膜回收率最高、缠膜率最低、膜土比最大的残膜回收要求为优化目标,开展铲筛式残膜回收机各参数优化研究。运用Design-Expert 数据分析软件对建立的3 个指标的全因子二次回归模型最优化求解,约束条件为:1)目标函数:max1;min2;max3;2)变量区间:0.73≤1≤2.23,260≤2≤330,62≤3≤113,12≤4≤36。优化后得到的各因素最优参数为:机具前进速度为0.73 m/s,振动筛频率为280.63 r/min,逐膜筛振幅为99.63 mm,筛面锯齿间距12 mm。此时模型预测的残膜回收率为91.59%,缠膜率为4.15 %,膜土比为2.59。

4.5.2 试验验证

响应面试验中并未包括上述优化后的最优参数组合方案,为了验证响应面模型和优化结果的可靠性,采用上述最佳参数组合。考虑试验操作的可行性,在机构设计时将参数最佳条件修正为机具前进速度为0.73 m/s,振动筛频率为280 r/min,逐膜筛振幅为99 mm,筛面锯齿间距12 mm,在残膜回收机上进行 3 次重复验证试验,取平均值为试验验证值,试验结果分别为残膜回收率91.26%,缠膜率为4.27%,膜土比为2.16。对比分析可知,1、2、3 的理论优化值和试验值很接近,因此,上述预测模型是可靠的,得到的最优结构参数是符合要求的。

5 结 论

1)设计呈上下平行排布的双筛面减振式自平衡残膜回收机,确定了驱振系统振动平衡中的关键运动参数,利用DH5902动态测试分析系统和DHDAS分析软件,得到振动频率在3~5.5 Hz变化时,机架左右方向振动测量值范围在4.2~5.4 m/s2,验证了整机减振效果明显。

2)单因素试验确定筛面结构为锯齿筛,选取机具前进速度、逐膜筛振幅、逐膜筛振动频率和锯齿间距作为试验因素,运用Matlab软件分析试验数据,各因素影响残膜回收率的主次顺序为:锯齿间距>机具前进速度>逐膜筛振幅>逐膜筛振动频率;各因素影响缠膜率的强弱次序为:锯齿间距>机具前进速度>逐膜筛振幅>逐膜筛振动频率;各因素影响膜土比强弱次序为:锯齿间距>机具前进速度>逐膜筛振动频率>逐膜筛振幅。综合优化后的残膜回收机各参数为:机具前进速度0.73 m/s,逐膜筛振幅99 mm,逐膜筛振动频率280 次/min,锯齿间距12 mm,此时残膜回收率91.26%,缠膜率为4.27 %,膜土比为2.16。

1MCDS-100A铲筛式残膜回收机,可一次性完成起膜、膜土分离、集膜、自动卸膜等作业工序,对于种植花生、棉花、马铃薯等作物的沙土或沙壤土地中的残留地膜回收具有良好的推广应用前景。

[1] 邹碧莹,丁美,籍春蕾,等. 江苏省丘陵山区及平原沙土区水土流失综合治理及效益评估研究[J]. 水土保持通报,2012,32(1):156-160.

Zou Biying, Ding Mei, Ji Chunlei, et al. Assessment of comprehensive soil and water loss control and its benefits in hilly area and sandy plain area of Jiangsu Province[J]. Bulletin of Soil and Water Conservation, 2012, 32(1): 156-160. (in Chinese with English abstract)

[2] Braunack M V, Johnston D B, Price J, et al. Soil temperature and soil water potential under thin oxodegradable plastic film impact on cotton crop establishment and yield[J]. Field Crops Research, 2015, 184: 91-103.

[3] Wang Jun, Lü Shenghong, Zhang Manyun, et al. Effects of plastic film residues on occurrence of phthalates and microbial activity in soils[J]. Chemosphere, 2016, 151: 171-177.

[4] Zacharias S, Claudia W, Miriam S, et al. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation?[J]. Science of the Total Environment, 2016, 550: 690-705.

[5] 严昌荣,刘恩科,舒帆,等. 我国地膜覆盖和残留污染特点与防控技术[J]. 农业资源与环境学报,2014(2):95-102.

Yan Changrong, Liu Enke, Shu Fan, et al. Review of agricultural plastic mulching and its residual pollution and prevention measures in China[J]. Journal of Agricultural Resources and Environment, 2014(2): 95-102. (in Chinese with English abstract)

[6] 游兆延,顾峰玮,吴峰,等. 垄作花生残膜回收技术研究[J]. 农机化研究,2016(1):207-211.

You Zhaoyan, Gu Fengwei, Wu Feng, et al. Research on ridged peanut residue plastic film recycling technology[J]. Journal of Agriculture Mechanization Research, 2016(1): 207-211. (in Chinese with English abstract)

[7] 新疆维吾尔自治区农牧业机械试验鉴定站、新疆维吾尔自治区农业资源与环境保护站. 农田地膜残留量限值及测定:GB/T 25413-2010[S].

[8] 张丹,胡万里,刘宏斌,等. 华北地区地膜残留及典型覆膜作物残膜系数[J]. 农业工程学报,2016,32(3):1-5. Zhang Dan, Hu Wanli, Liu Hongbin, et al. Characteristics of residual mulching film and residual coefficient of typical crops in North China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 1-5. (in Chinese with English abstract)

[9] 胡志超,陈有庆,王海鸥,等. 振动筛式花生收获机的设计与试验[J]. 农业工程学报,2008,24(10):114-117.

Hu Zhichao, Chen Youqing, Wang Hai’ou, et al. Design and experimental research on vibrating type peanut harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(10): 114-117. (in Chinese with English abstract)

[10] 赵治永. 一种振动筛式花生收获机ZL200720044074.0[P]. 2009-02-25.

[11] 张子强,常焱. 振动偏心轮结构设计及其有限元分析[J].江南大学学报:自然科学版,2011,10(5):573-577.

Zhang Ziqiang, Chang Yan. Structure design of vibration eccentric and its finite element analysis[J]. Journal of Jiangnan University: Natural Science Edition, 2011, 10(5): 573-577. (in Chinese with English abstract)

[12] 刘晓丽. 马铃薯挖掘机的研制及应用[J]. 农业科技与信息,2014(23):44-45.

Liu Xiaoli. Development and application of potato digger [J]. Agricultural Science and Technology and Information, 2014(23): 44-45. (in Chinese with English abstract)

[13] 吴海平,侯建丽,郝琴,等. 4S-80马铃薯振动挖掘机牵引阻力的测试分析[J]. 山东农业大学学报:自然科学版,2009,29(4):351-354.

Wu Haiping, Hou Jianli, Hao Qin, et al. Experimental study on traction resistance for 4S-80 potato shaking digger[J]. Journal of Shanxi Agricultural University: Natural Science Edition, 2009, 29(4): 351-354. (in Chinese with English abstract)

[14] 贾晶霞,张东兴. 马铃薯收获机摆动筛与块茎运动仿真分析[J]. 中国农业大学学报,2006,11(3):79-82.

Jia Jingxia, Zhang Dongxing. Moving simulation analysis on swing sieve of potato harvester[J]. Journal of China Agricultural University, 2006, 11(3): 79-82. (in Chinese with English abstract)

[15] 张学军,吴成武,马少辉,等. 残膜分离筛机构的运动仿真与分析[J]. 农业工程学报,2007,23(7):113-116.

Zhang Xuejun, Wu Chengwu, Ma Shaohui, et al. Motion simulation and analysis of separating sieve mechanism for scrap plastic film[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(7): 113-116. (in Chinese with English abstract)

[16] 宋江,邱胜蓝,王新忠. 4B-1200型平贝母药材收获机的设计与试验[J]. 农业工程学报,2015,31(8):34-41.

Song Jiang, Qiu Shenglan, Wang Xinzhong. Design and test on 4B-1200 type bulbusmedicinal material harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(8): 34-41. (in Chinese with English abstract)

[17] 中国农业机械化科学研究院. 农业机械设计手册(上)[M]. 北京:中国农业科学技术出版社,2007.

[18] 孙小丽,坎杂,李景彬,等. 5XS系列脱绒棉种色选机参数优化试验[J]. 农业工程学报,2010,26(增刊1):42-45.

Sun Xiaoli, Kan Za, Li Jingbin, et al. 5XS series color sorting cottonseeds parameter optimization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(Supp.1): 42-45. (in Chinese with English abstract)

[19] 靳伟,张学军,张朝书,等. 自动卸膜式残膜回收机捡拾齿和滚筒的优化[J]. 中国农业科技导报,2016,18(3):96-103.

Jin Wei, Zhang Xuejun, Zhang Chaoshu, et al. Optimization of pick-up teeth and roller for automatic unloading film recycling machine[J]. Journal of Agricultural Science and Technology, 2016, 18(3): 96-103. (in Chinese with English abstract)

[20] 李斌,王吉奎,胡凯,等. 残膜回收机顺向脱膜机理分析与试验[J]. 农业工程学报,2012,28(21):23-28.

Li Bin, Wang Jikui, Hu Kai, et al. Analysis and test of forward film removing mechanism for polythene film collector[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 23-28. (in Chinese with English abstract)

[21] 鹿芳媛,马旭,齐龙,等. 基于离散元法的杂交稻振动匀种装置参数优化与试验[J]. 农业工程学报,2016,32(10):17-25.

Lu Fangyuan, Ma Xu, Qi Long, et al. Parameter optimization and experiment of vibration seed-uniforming device for hybrid rice based on discrete element method [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(10): 17-25. (in Chinese with English abstract)

[22] 农业轮式拖拉机和田间作业机械驾驶员全身振动的测量: GB/T 10910-2004 [S].

[23] 吴国瑞,李耀明,邱白晶,等. 水稻播种机振动试验研究[J]. 江苏理工大学学报,1997,18(6):12-17.

Wu Guorui, Li Yaoming, Qiu Baijing, et al. Studies on vibration test of the rice seedling machine[J]. Journal of Jiangsu University of Science and Technology, 1997, 18(6): 12-17. (in Chinese with English abstract)

[24] 往复式机器振动分类和指导值: ISO 10816-6:1995 [S].

[25] 程兴田,赵建托,潘卫云,等. 两级升运链卷轴式残膜捡拾机的设计与试验[J]. 中国农机化学报,2016,37(4):31-34.

Cheng Xingtian, Zhao Jiantuo, Pan Weiyun, et al. Design and experiments of two elevator chain reel plastic film collector[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(4): 31-34. (in Chinese with English abstract)

[26] 张文群,金维续,孙昭荣,等. 降解膜残片与土壤耕层水分运动[J]. 中国土壤与肥料,1994(3):12-15.

Zhang Wenqun, Jin Weixu, Sun Zhaorong, et al. Motion of degradable film fragments and soil water in the tilled layer [J]. Soil and Fertilizer in China, 1994(3): 12-15. (in Chinese with English abstract)

[27] 于昭洋,胡志超,王海鸥,等. 大蒜果秧分离机构参数优化及试验[J]. 农业工程学报,2015,31(1):40-46.

Yu Zhaoyang, Hu Zhichao, Wang Haiou, et al. Parameters optimization and experiment of garlic picking mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 40-46. (in Chinese with English abstract)

[28] 尚书旗,刘曙光,梁洁,等. 摆动式花生收获机整体载荷的试验与分析[J]. 农机化研究,2007(11):173-176.

Shang Shuqi, Liu Shuguang, Liang Jie, et al. Study on the load of the swing type peanut harvester[J]. Journal of Agricultural Mechanization Research, 2007(11): 173-176 (in Chinese with English abstract)

[29] 郑晓伟,沈建,蔡淑君,等. 南极磷虾等径滚轴挤压剥壳工艺优化[J]. 农业工程学报,2013,29(增刊1):286-293.

Zheng Xiaowei, Shen Jian, Cai Shujun, et al. Process optimization of roller extruder with equal diameter of Antarctic krill[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(Supp.1): 286-293. (in Chinese with English abstract)

[30] 陈杰. MATLAB宝典[M]. 北京:电子工业出版社,2011.

[31] 王东伟,尚书旗,韩坤,等. 4HJL-2型花生联合收获机摘果机构的设计与试验[J]. 农业工程学报,2013,29(14):15-25. Wang Dongwei, Shang Shuqi, Han Kun, et al. Design and test of picking mechanism in 4HJL-2 peanut combines[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(14): 15-25. (in Chinese with English abstract)

Design and experiment of 1MCDS-100A typed shovel-sieve residual film recovery machine

You Zhaoyan, Hu Zhichao※, Wu Huichang, Zhang Yaping, Yan Jianchun, Yan Wei, Zhou Xinxing

(210014)

Plastic mulching planting pattern is usually adopted when planting peanut, cotton and other crops in modern agriculture, and the planting soil type is mostly in sandy soil or sandy loam with good fragility. As more and more residual membrane left in the field surface, accumulation of the residual film which is not clearly picked up all the year round, causing serious “white pollution”. Taking typical croplands in North China for example, it is estimated that, the quantity of residual film in peanut and cotton fields would reach up to 69.1 and 70.4 kg/hm2by 2021, If we do not pay attention to the recovery of residual film, these areas would become the pollution area contaminated by residual plastic membrane. In order to solve serious pollution of residual plastic film left in the field after harvest, several residual film recovery machines are commonly used, such as tooth type (spike tooth, elastic claw, telescopic tooth, etc.), curl-up film roller type, shovel-chain type, and multi-function duplex machinery, but both domestic and international shovel-sieve type residual film recovery machines which adapt to sandy soil have been rarely reported. First, the current sieving surface had no structural design of blocking glide in the process of screening, while film, soil and impurity substance could easily cause soil accumulation because of its own gravity, leading to the clogging of sieve holes with low membrane separation efficiency. Second, the step by step transmission ability of vibration sieve was poor, causing residual film winding, membrane leakage, reversing and other issues. In addition, most of the existing shovel-screen type residual film recycling machines had only one single sieve. As such cleanliness of recycled residual film needs to be improved. At the same time, in order to reduce vibration, the existing eccentric drive arm equipment was often equipped with rotary parts when screening, such as the eccentric block, flywheel or other parts, but rotary motion of chosen rotary parts could not eliminate the reciprocating movement of sieve, causing large vibration in the process of machine operation, high labor intensity of drivers and poor stability of machinery. In order to reduce vibration in the operation of shovel-sieve type residual film recycling machine, in this study, a up and down parallel arranged double-sieve type self-balancing residual film recycling machine was designed, rotation speed of drive shaft was determined, ranging from 260 to 330 r/min, a DH5902 dynamic testing system was used. A field experiment was carried out to test the vibration parameters of the double-sieve residual film recycling machine and the experimental results showed that vibration frequency from 3 to 5.5 Hz, horizon vibration measurement value of the frame was 4.2-5.4 m/s2, among which the equipment could withstand, the damping effect of double-sieve residual film recycling machine was obvious, five sieves with different sieve surface structures including the bar sieve, cross bar sieve, wire gauze sieve, round hole sieve and saw-tooth sieve were tested by single factor experiment. Finally, saw-tooth sieve was determined as the optimal sieve form. Moreover, an electric pushing rod typed automatic film uploading device was designed, film collecting basket completed the unloading task in 4.1 s, solving longtime labor issues currently exist in uploading link. Machine forward speed, vibration frequency of saw-tooth sieve, amplitude of saw-tooth sieve and saw-tooth distance were selected as experiment factors. The response surface method was used, and the effect of each factor influenced on the targets of the residual film recycling was analyzed by drawing four-dimensional chip figure on Matlab2013a software. The experimental results showed that the test factors had a great influence on residual film recovery quality. The optimal parameter combination was obtained: machine forward speed was 0.73 m/s, amplitude of saw-tooth sieve was 99 mm, vibration frequency of saw-tooth sieve was 280 r/min, saw-tooth distance was 12 mm, when the recovery rate of residual film was 91.26%, rate of winded film was 4.27% and film soil ratio was 2.16. It met the requirements of the residual film recycling quality. This study not only supplies the residual film recycling market with a both urgent and practical tool, but also provides theoretical basis and reference for the innovation development and optimization of plastic film recovery machinery.

agricultural machinery; design; vibration control; double sieve; drive mechanism; membrane-soil separation;residual film recycling machine

10.11975/j.issn.1002-6819.2017.09.002

S223.5

A

1002-6819(2017)-09-0010-09

2016-09-02

2017-04-11

公益性行业(农业)科技“残膜污染农田综合治理技术方案”(201503105);中国农科院创新工程—土下果实收获机械

游兆延,男,江苏泰兴人,主要从事农业机械化工程研究。南京农业部南京农业机械化研究所,210014。Email:17366350354@163.com

胡志超,男,陕西蓝田人,研究员,主要从事农作物收获及产后加工技术装备的研究。南京农业部南京农业机械化研究所,210014。Email:nfzhongzi@163.com,中国农业工程学会高级会员:胡志超(E041200498S)

游兆延,胡志超,吴惠昌,张亚萍,颜建春,严 伟,周新星. 1MCDS-100A型铲筛式残膜回收机的设计与试验[J]. 农业工程学报,2017,33(9):10-18. doi:10.11975/j.issn.1002-6819.2017.09.002 http://www.tcsae.org

You Zhaoyan, Hu Zhichao, Wu Huichang, Zhang Yaping, Yan Jianchun, Yan Wei, Zhou Xinxing. Design and experiment of 1MCDS-100A typed shovel-sieve residual film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 10-18. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.09.002 http://www.tcsae.org