Strength properties of soft clay treated with mixture of nano-SiO2and recycled polyester fber

Foad Changizi,Abdolhosein Haddad

Department of Civil Engineering,Semnan University,Semnan,Iran

Strength properties of soft clay treated with mixture of nano-SiO2and recycled polyester fber

Foad Changizi*,Abdolhosein Haddad

Department of Civil Engineering,Semnan University,Semnan,Iran

A R T I C L E I N F O

Article history:

Received 6 December 2014 Received in revised form

19 March 2015

Accepted 23 March 2015

Available online 3 June 2015

Recycled polyester fber

Nano-SiO2

Strength properties

Elastic modulus

This paper investigates the effect of recycled polyester fber,produced from polyethylene(PET)bottles,in combination with nano-SiO2as a new stabilizer to improve the mechanical properties of soils.We intend to study the effect of adding nano-SiO2and recycled polyester fber on soil engineering properties, especially the shear strength and unconfned compressive strength(UCS),using clayey soil with low liquid limit.Three different combinations of fber-soil ratios ranging between 0.1%and 0.5%as well as three different combinations of nano-soil ratios ranging between 0.5%and 1%are used.The shear strength and UCS of treated specimens are obtained from direct shear test and unconfned compression test,respectively.Results of this study show that the addition of recycled polyester fber and nano-SiO2increases the strength of soil specimens.Both the shear strength and UCS are improved by increasing the contents of recycled polyester fber and nano-SiO2in the soil mixture.The increase in the nano-SiO2content leads to a reduction in failure strain,but the increase in the content of recycled polyester fber leads to an increase in failure strain.The increase in the contents of recycled polyester fber and nano-SiO2leads to an increase in elastic modulus of soils.Based on the test results,the addition of recycled polyester fber improves the mechanical properties of soils stabilized with nano-SiO2as well as the recycled polyester fber has a positive effect on soil behaviors.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

The purpose of soil stabilization is to increase the strength properties and reduce the settlement.The recycled materials in geotechnical engineering have many economic and environmental benefts for the nature.This approach reduces the cost of engineering projects.Thus,several studies have been conducted to investigate the use of recycled materials as a new stabilizer in soil stabilization projects.

For soil stabilization,fber,cement and different materials were used to increase the strength parameters of soils.The work of Hamidi and Hooresfand(2013)indicated that the addition of polypropylene fber leads to increases in shear strength parameters and failure stress of cemented soils.Park(2009)studied the infuence of polyvinyl alcohol(PVA)fber on compressive strength of cemented sand,and reported that the 1%fber makes the axial strain of cemented sand two times larger than that of normal sand. Mirzababaei et al.(2013)conducted a compaction test on clayey soils containing carpet wastage fber,and concluded that the addition of fber decreases the maximum dry unit weight of clay and also increases its optimum moisture,and these two parameters decrease the swelling pressure of clay.Park(2013)carried out a series of tests on the cemented sand reinforced by PVA,and found that the unconfned compressive strength(UCS)of sand with 2% cement and 1%fber becomes 3.5 times that of non-reinforcement soil.In a study conducted by Mohamed(2013),the addition of 1% dry straw decreases the maximum dry unit weight and shrinkage limit of clay.Estabragh et al.(2013)pointed out that,based on the totaland effective stresses,the increase in the contentof nylon fber leads to an increase in shear strength parameters of clay.Zulkifey et al.(2013)believed that the addition of cement and sodium bentonite results in signifcant reductions in liquid limit,plastic limit and plasticity index of clay.

Several studies have been conducted on the stabilization of soft clay using different materials,such as recycled materials,natural fber,and chemical materials.However,over the last twenty years, nanotechnology has evolved as an interdisciplinary area,which has attracted great interest.Pham and Nguyen(2014)carried out a series of tests on the clayey soils by adding nano-SiO2,and found that the addition of nano-SiO2leads to a reduction in the swelling index of clay.In a study conducted by Mohammadi and Niazian (2013),adding nano-clay increases the liquid and plastic limits ofsoil and also increases the shear strength parameters of treated specimens.The research conducted by Noll et al.(1992),Yonekura and Miwa(1993),and Zhang et al.(2004)indicated that the addition of nano-SiO2increases the strength and the Atterberg limits of clay and also decreases its permeability.Niroumand et al.(2013) studied the infuence of nano-clay on compressive strength of earth bricks as sustainable materials,and found that the nano-clay makes the compressive strength of earth bricks 4.8 times larger than that of normal earth bricks.Taha and Taha(2012)carried out numerous tests on clay behavior by adding nano-particles.They concluded that the addition of nano-Al2O3to the soil decreases both the values of expansive and shrinkage strains.In a study conducted by Luo et al.(2012),the addition of nano-Al2O3to the soil reduces the maximum dry unit weight and increases the optimum moisture content,and the addition of different amounts of nano-Al2O3to treated soil reduces the plasticity index values.

In the studies conducted by above-mentioned investigators,the recycled materials were used alone.In this condition,the recycled materials result in improvement of some engineering properties and deterioration of other properties of soils.Moreover,few previous papers have computed the infuence of mixture of recycled polyester fber and nano-SiO2on the strength properties of clay. Hence,the aim of this study is to investigate and evaluate the feasibility of using recycled polyester fber in combination with nano-SiO2as a new stabilizer to improve the mechanical properties of soft clay.

2.Materials and methods

2.1.Materials used

The expansive soil used was sampled from the Behbahan suburbs in Iran.The soil contains clay and sand.Nano-SiO2used was purchased from Nanosany Company in Iran,and recycled polyester fber used was purchased from Fiberarjan Company in Iran.

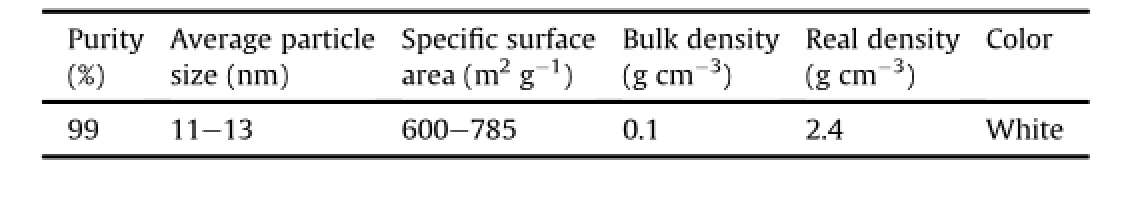

According to the unifed soil classifcation system,the soil used is classifed as clayey soil with low liquid limit.The liquid and plastic limits of soil are estimated to be 30 and 22,respectively.The grain size distribution curve of soil is illustrated in Fig.1.From this fgure,it can be observed that the soil contains 22%fne sand,29% silt,and 49%clay.The maximum dry density of soil is 16.4 kN/m3and the optimum moisture contentof soil is 15%.Recycled polyester fber,as shown in Fig.2,was used for reinforcement.Fiber used is made of the bottles waste by chopping them into small length with almost the same minimal diameter of 20μm.The length of recycled polyester fber is 20 mm.The physical properties of recycled polyester fber are presented in Table 1.The physical properties and chemical composition of nano-SiO2are presented in Tables 2 and 3, respectively.

2.2.Test methods

In order to evaluate the effect of nano-SiO2and random inclusion of fber on strength parameters of the specimens,twelve groups of specimens,including one group of natural specimens, one group of specimens reinforced with recycled polyester fber, one group of specimens stabilized with nano-SiO2,and nine groups of specimens treated with fber-nano-SiO2,were used in two tests, i.e.unconfned compression test and direct shear test.To evaluate the shear parameters of mixture,the direct shear tests were carried out in three normal stresses:100 kPa,200 kPa,and 300 kPa.To investigate the increase in UCS due to addition of recycled polyester fber and nano-SiO2,a series of unconfned compression tests was conducted on clay treated with recycled polyester fber and nano-SiO2and natural specimens.The laboratory tests were carried out with different contents of recycled polyester fber(0.1%,0.3%,and 0.5%of soil dry weight)and different contents of nano-SiO2(0.5%, 0.7%,and 1%of soil dry weight).

2.2.1.Sample preparation

Fig.1.Grain size distribution curve of soil.

Fig.2.Picture of recycled polyester fber.

Table 1Properties of recycled polyester fber.

Table 2Physical properties of nano-SiO2.

In this study,three various contents of nano-SiO2(i.e.0.5%,0.7%, and 1%of soil dry weight)were selected.In the laboratory,the soil was crashed by a hammer and then screened through sieves.In order to prepare specimens stabilized with nano-SiO2and recycled polyester fber,the soil was divided into fve layers and each layer was sprayed with the prescribed amount of nano-SiO2.Each layer was mixed alone by horizontally cylindrical mixer for at least 1 h. This procedure is the best method to obtain homogeneous samples (To et al.,2011).Because of the fact that the tests were performed under constant moisture content and due to the absorption ofwater by nano-SiO2,the mixing of soil with>1%nano-SiO2content leads to the lack of water in the soil/nano-SiO2mixture;consequently,the soil becomes less compressible.Thus,the optimum nano-SiO2content was 1%.Then recycled polyester fber was added to the composite of soil and nano-SiO2at various amounts from 0.1%to 0.5%.The composite of soil and nano-SiO2was divided into three layers and each layer was mixed with the prescribed amount of recycled polyester fber.Each layer was mixed alone by hands.It is diffcult to mix the soil with>0.5%recycled polyester fber and the fber was tangled together to form fber pockets.Hence,the optimum content of recycled polyester fber was 0.5%.The composite of soil,nano-SiO2and fber was mixed with the optimum moisture content obtained from standard Proctor compaction test. Thisnano-compositewasmixedinanimpermeablemetal container in order to reduce water loss,and it was used to evaluate the effect of recycled polyester fber and nano-SiO2on strength properties of the soft clay.When the nano-SiO2was used alone,the composite of soil and nano-SiO2was provided as described above; in addition,water was added to the composite if needed.When recycled polyester fber was used alone,the determined amount of recycled polyester fber was mixed with the soil by hands until all the fber was mixed thoroughly.Ultimately,the specifed amount of water was added.

Table 3Chemical composition of nano-SiO2.

2.2.2.Specimen preparation for direct shear test

The direct shear test is performed under fxed conditions and according to standard ASTM D3080-90.The mixture was flled in a cylindrical mold(101.4 mm in diameter and 116.5 mm in height)in three equal layers and each layer was compacted using a tamping device to attain the target density.In this study,the shear ring with the dimensions 60 mm×60 mm×25 mm was used.This ring was pushed into the soil mixture by hydraulic jack.Then the specimens were extruded into the shear box.In order to prepare the consolidated and saturated specimens,the specimens were kept in the shear box bowl flled with water for about 24 h;meanwhile,the normal stresses of 100 kPa,200 kPa,and 300 kPa were applied.The drainage was allowed from the top and bottom of the shear box. Then the specimen was sheared under undrained condition by applying the shear stress.The rate of horizontal displacement was maintained at 1.25 mm/min.For each combination of mixture, three specimens were prepared and the average of test data was obtained.In total,144 groups of direct shear tests were conducted by varying contents of recycled polyester fber and nano-SiO2.The effects of nano-material and fber on the shear parameters of soft clay were recorded up to a total horizontal displacement of 13 mm.

2.2.3.Specimen preparation for unconfned compression test

The unconfned compression test was performed under fxed conditions and according to standard ASTM D2166-87.The mixture was flled in a cylindrical mold(101.4 mm in diameter and 116.5 mm in height)in three equal layers and the number of blows required per layer was 25.The stainless steel tube of 38 mm in diameterand 100 mm in height was pushed intothe soil mixtureby hydraulic jack.Then the specimen was pushed into a stainless metal tube of 38 mm in diameter and 76 mm in height. Subsequently,the specimenwas pushed out fromthe stainless steel tube without disturbance and used for testing.For each combination of mixture,three samples wereprepared and the average value of test data was obtained.The rate of strain was maintained at 1 mm/min.In total,48 groups of unconfned compression tests were conducted by varying contents of recycled polyester fber and nano-SiO2.

3.Test results and discussions

In this study,different tests were carried out on four kinds of specimens,i.e.(1)natural clayspecimens,(2)specimens containing recycled polyester fber,(3)specimens containing nano-SiO2,and (4)specimens containing mixture of recycled polyester fber and nano-SiO2.The effects of recycled polyester fber,nano-SiO2and mixture of recycled polyester fber and nano-SiO2on clay behavior, shear strength and elastic modulus were evaluated.

Initially the soil stabilized with nano-SiO2was left for curing, then the X-ray diffraction(XRD)test was carried out to check if there is a chemical reaction for nano-material to the soil or not.The curves of natural clayspecimen and clay+0.7%nano-SiO2specimen obtained from XRD test are shown in Fig.3.From this fgure,one can conclude that the nano-SiO2cannot do chemical reaction with soil material by just mixing with water.

3.1.Direct shear test

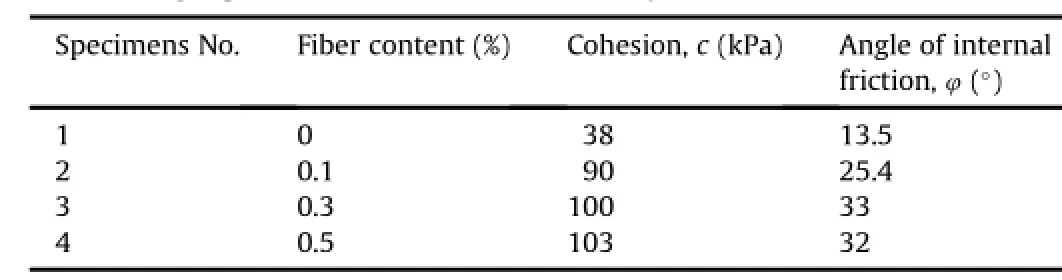

3.1.1.Effect of recycled polyesterfber on shear strength of clay

The relation between shear stress and horizontal displacement of clay reinforced with recycled polyester fber is illustrated in Fig.4.It can be seen from Fig.4 that the shear stress of clay reinforced with recycled polyester fber occurs at larger displacement in all specimens compared to the natural clay.With inclusion of recycled polyester fber in the clay,the increase in normal stressσncontributes to increase in the peak strength of clay.The main reason could be that by increasing the normal stress,the contact force and interlock between soil particles increase.The increase in the content of recycled polyester fber leads to an increase in shear strength of the mixture.From Fig.4,one can conclude that the addition of 0.5%recycled polyester fber leads to an increase inpeak shear stress from 111 kPa to 200 kPa,compared to the natural clay, indicating an increase in shear strength by 80%.Compared to the natural clay,the peak shear stresses increase by 20%and 67%, respectively,when the contents of recycled polyester fber are 0.1% and 0.3%.However,by further increasing fber content,as in the case of 0.5%,this increase is only 80%.Hence,addition of recycledpolyester fber more than 0.3%is not reasonable to increase shear strength.As a result,the optimum content of recycled polyester fber is found to be 0.3%.The shear strength parameters of specimens are illustrated in Table 4.It is clear from Table 4 that the specimens reinforced with recycled polyester fber exhibit an increase in the shear strength parameters.When the content of recycled polyester fber increases from 0.3%to 0.5%,the angle of internal friction and the cohesion increase by 19%and 8%,respectively.It means that recycled material performs a signifcant role in the increase in angle of internal friction.The fber surface is connected with plenty of clay particles which make the contribution to friction strength between the fber and clay particles. Consequently,the shear strength parameters of the treated specimens are improved.

Fig.3.XRD analysis of natural clay and clay stabilized with nano-SiO2.

Fig.4.Stress-displacement curves of clay reinforced by recycled polyester fber obtained from direct shear test.(a)σn=100 kPa,(b)σn=200 kPa,and(c)σn=300 kPa.

Table 4Shear parameters of fber reinforced clay.

Fig.5.Stress-displacement curves of clay stabilized with nano-SiO2obtained from direct shear test.(a)σn=100 kPa,(b)σn=200 kPa,and(c)σn=300 kPa.

Table 5Shear strength parameters of clay stabilized with nano-SiO2.

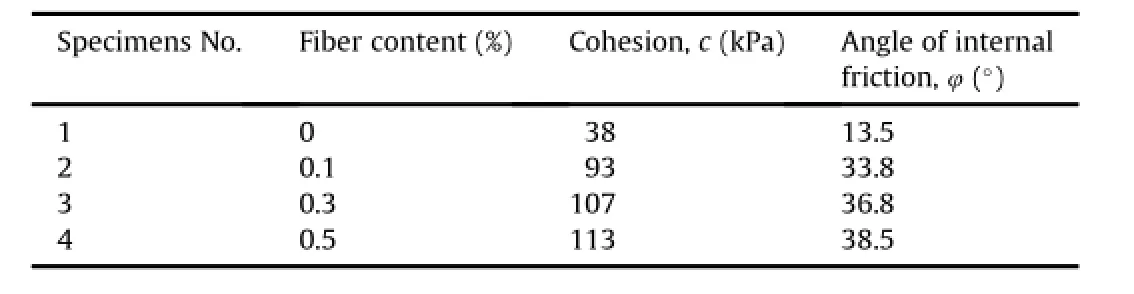

3.1.2.Shear strength parameters of clay improved by nano-SiO2

The relation between shear stress and horizontal displacement of clay stabilized with nano-SiO2is illustrated in Fig.5.It can be seen from Fig.5 that the shear stress of specimens stabilized with nano-SiO2occurs at larger displacement in all specimens compared to the natural clay.The observation of this fgure indicates that the increase in nano-SiO2content leads to an increase in shear stress of stabilized clay.With inclusion of nano-SiO2to the clay,the increase in normal stress contributes to the increase in shear strength of clay.At the normal stress of 300 kPa,the shear stresses,compared to the natural clay,increase by 42%,76%,and 90%for 0.5%,0.7%,and 1%nano-SiO2contents,respectively.It can be seen from Fig.5 that the shear stresses of clay stabilized with 0.7%and 1%nano-SiO2are close to each other.Hence,the optimum nano-SiO2content is found to be 0.7%.The shear strength parameters are presented in Table 5. It is shown that,with increase in nano-SiO2content,the shear strength parameters of clay stabilized with nano-SiO2increase.The increase ratios of the angleof internal friction and cohesion are 1.61, 2.1,2.2 and 1.06,1.11,1.18,respectively,for nano-SiO2contents of 0.5%,0.7%,and 1%.The results show that,with increase in nano-SiO2content,the increase rate of angle of internal friction is faster than that of cohesion.Therefore,the angle of internal friction of claystabilized with nano-SiO2is moreeffcient than the cohesion of stabilized soil in increasing the strength of soil.

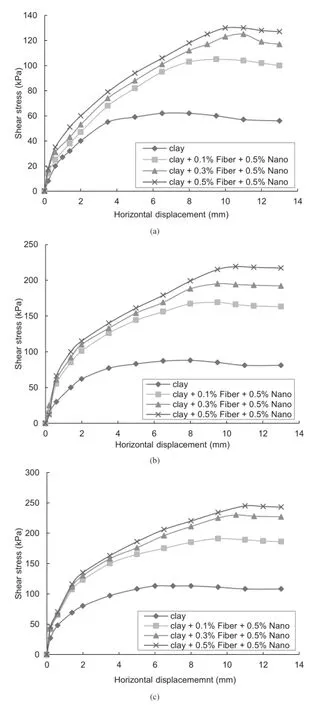

3.1.3.Shear strength parameters of clay improved by recycled polyesterfber and nano-SiO2

The results of direct shear test on clay improved by recycled polyester fber and nano-SiO2are shown in Figs.6-8.The observation of these fgures indicates that the increase in the contents of recycled polyester fber and nano-SiO2causes the increase in shear stress of clay.The shear stress of specimens treated with nano-SiO2and recycled material occurs at larger displacement in all specimens compared to the natural clay.With inclusion of nano-SiO2and recycled polyester fber to the clay,the increase in normal stress contributes to the increase in shear strength of clay.The maximum increase inpeak shear stress of treated specimens occurs at 1%nano-SiO2content.By adding 1%nano-SiO2,the peak shear stressesincrease by163%and 190%,respectively,when the contents of recycled polyester fber are 0.1%and 0.3%.However,by further increasing the fbercontent,as in the case of 0.5%fber,this increase is 200%,only a little larger than 190%.Because of this,the addition of recycled polyester fber more than 0.3%is not reasonable to improve the shear strength of clay.The optimum value of the shear strength is observed at 0.3%fber+1%nano-SiO2content,which is 3 times the shear stress of the natural clay,1.5 times that of the nano-SiO2treated specimens,1.62 times that of the recycled material treated specimens.The values of cohesion and angle of internal friction of specimens are presented in Tables 6-8.It is clear from Tables 6-8 that the contents of recycled polyester fber and nano-SiO2have a positive effect on the shear strength parameters of treated specimens.By adding 0.5%nano-SiO2,the increase ratios of the angle of internal friction and cohesion for treated specimen are 2 and 1.92,respectively,for fber content of 0.3%.Also by adding0.7%and 1%nano-SiO2,the increase ratios of the angle of internal friction and cohesion for treated specimen are 2.44,2.63 and 2.72, 2.81,respectively,for fber content of 0.3%.

Fig.6.Stress-displacement curves of clay reinforced and stabilized by 0.5%nano-SiO2. (a)σn=100 kPa,(b)σn=200 kPa,and(c)σn=300 kPa.

Fig.7.Stress-displacement curves of clay reinforced and stabilized by 0.7%nano-SiO2. (a)σn=100 kPa,(b)σn=200 kPa,and(c)σn=300 kPa.

Fig.8.Stress-displacement curves of clay reinforced and stabilized by 1%nano-SiO2. (a)σn=100 kPa,(b)σn=200 kPa,and(c)σn=300 kPa.

Table 6Shear strength parameters of fber-reinforced clay stabilized with 0.5%nano-SiO2.

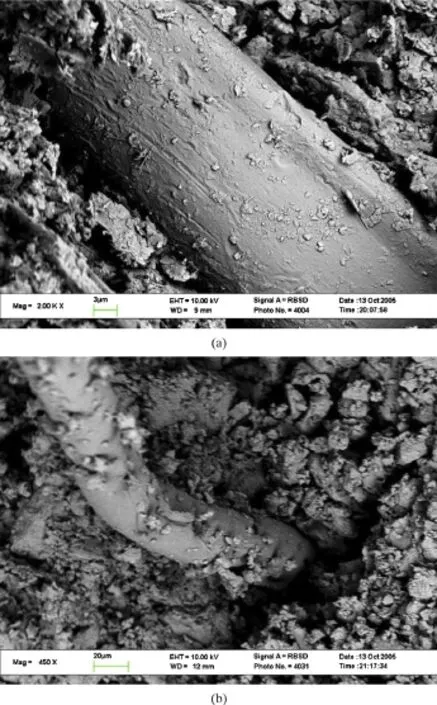

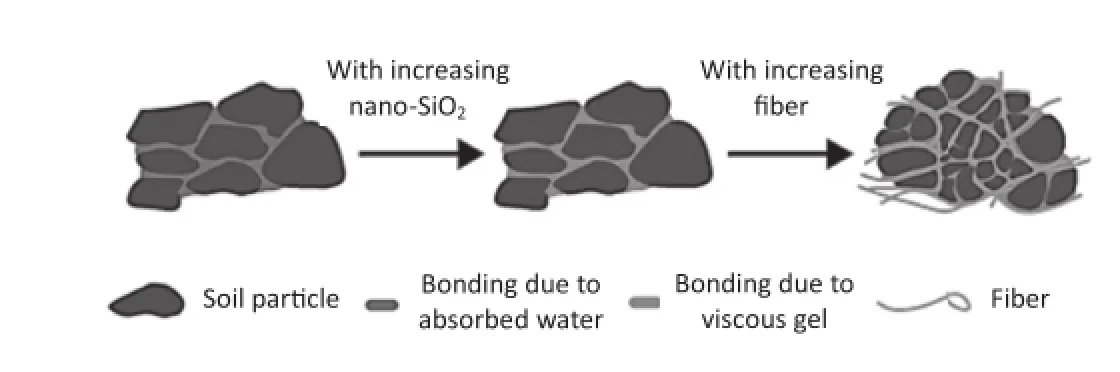

Visual observations indicate that the increase in the content of recycled polyester fber leads to the increases in unitary coherent mixture;hence,the tensile strength between soil particles is improved.It can be seen from Fig.9 that in terms of the frictionalstrength,the recycled material in the composite is diffcult to slip and the composite can withstand tensile stress.High-resolution feld emission scanning electron microscopy(FESEM)is achieved using a feld emission gun(FEG)in place of the more conventional tungsten hairpin or LaB6 flaments.A resolution of 0.5 nm has been achieved under ideal conditions and 5 nm is regularly achieved at 30 kV with conducting materials.The amount of clay data which can be acquired using back-scatter or conventional secondary electron imaging techniques is limited by the resolution of such instruments.For clay mineral studies,the optimal resolution is 0.5μm for back-scattered electron microscopy(BSEM)compared with 0.5 nm for FESEM.Good quality photomicrographs can be obtained at a magnifcation of×2000 for BSEM and×30,000 for FESEM.The scanning electron microscopy(SEM)images of soil reinforced by fber(Tang et al.,2010)are shown in Fig.10.It is clear that the shear stress increases with the increasing nano-SiO2content.The mechanism accounting for this increase in strength is not well understood,but probably there are three mechanisms.In the frst mechanism,by adding water to clay,nano-SiO2produces viscous gel in conjunctionwith water.Fig.11 shows that the viscous gel leads to contact between clay particles.The cohesion between clay particles due to viscous gel probably is stronger than that between clay particles due to absorbed water.The viscous gel leads to an increase in frictional strength between clay particles.In the second mechanism,the nano-SiO2makes the distance between clay particles smaller and causes a great number of clay particles to contact together.Due to the fact that the contact area between clay particlesincreaseswithincreasingnano-SiO2,thefrictional strength improves.Landman et al.(2014)pointed out that nano-SiO2leads to an increase in bond strength.FESEM images of clay stabilized with nano-SiO2are presented in Fig.12.In the third mechanism,the viscous gel adheres to the recycled materials surface and appreciably improves the interfacial bond characteristics and increases the frictional strength between the recycled materials surface and clay particles.This mechanism is shown in Fig.13. Recycled fber contributes to the creation of voids.By adding 0.5%-1%nano-SiO2to clay,the viscous gel occupies the voids,contributing totheincreasein angleof internal friction of the composite.In this regard,the increase in strength of composite is related to the friction created between soil particles,nano-SiO2,and recycled materials.This event contributes to the increase in angle of internal friction of composite.

Table 7Shear strength parameters of fber-reinforced clay stabilized with 0.7%nano-SiO2.

Table 8Shear strength parameters of fber-reinforced clay stabilized with 1%nano-SiO2.

Fig.9.Sketch drawing of interfacial mechanical behavior between soil particles and fber surface.

Fig.10.SEM images of embedded fber reinforcement in soil matrix(Tang et al.,2010). (a)Magnifcation of×2000,and(b)Magnifcation of×450.

Fig.11.Effect of nano-SiO2on bonding between clay particles.

Fig.12.FESEM images of soil specimens:(a)Untreated clay,and(b)Clay stabilized with nano-SiO2.

Fig.13.Sketch drawing of interfacial mechanical behavior of clay reinforced and stabilized with nano-SiO2.

3.2.Unconfned compression test

3.2.1.UCS of clay improved by recycled polyesterfber

Fig.14.Stress-strain curves of clay reinforced by recycled polyester fber obtained from unconfned compression test.

Fig.15.Elastic modulus(E50)of clay reinforced by varying contents of recycled polyester fber.

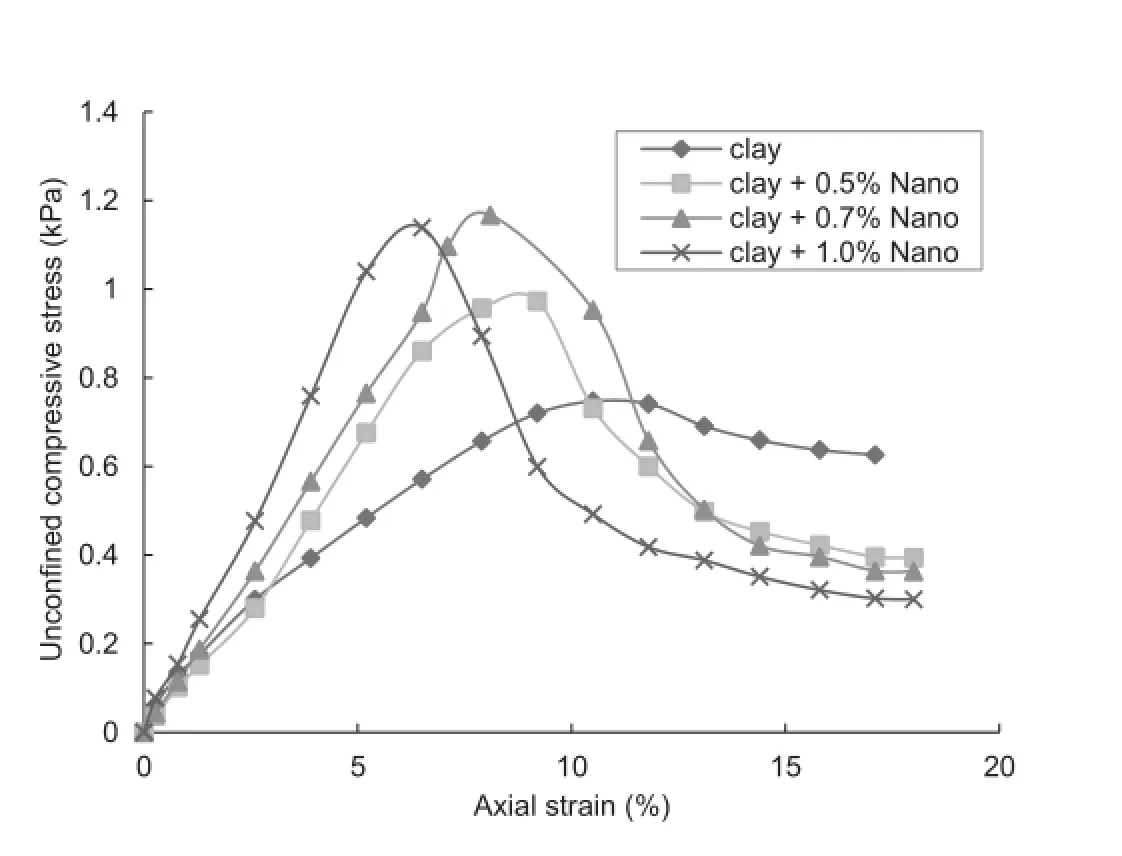

Fig.16.Stress-strain curves of clay stabilized with nano-SiO2obtained from unconfned compression test.

The results of unconfned compression test of clay reinforced by various contents of recycled materials are presented in Fig.14.The observation of this fgure indicates that the increase in the content of recycled materials contributes to the increase in peak and residual UCSs of reinforced clay.The effect of recycled polyester fber on the increase in UCS is marginal when the content of recycled polyester is more than 0.3%.It is evident from Fig.14 that the UCSs due to 0.3%and 0.5%recycled materials are close to each other.As a result,the optimum content of recycled materials is found to be 0.3%.It is clear that the UCS of clay reinforced by recycled materials occurs at higher strain in all specimens compared to the natural clay.From Fig.14,one can conclude that the addition of 0.3%fberincreases the failure deformation from 10.5 mm to 19.7 mm,giving an increase of 88%in the failure deformation.Visual observations indicate that utilization of more than a certain amount of recycled materials results in reduction of the effectiveness of the increase in UCS.This phenomenon may account for the fact that,with increase in recycled fber content,the fber coheres to each other and cannot contact with soil particles completely.The elastic modulus(E50) was calculated from one half of peak UCS.The elastic modulus(E50) of clay reinforced by varying contents of recycled polyester fber obtained from unconfned compression tests is presented in Fig.15. It is evident from Fig.15 that,with the increase in the content of recycled polyester fber,the increase ratios of elastic modulus(E50) are 1.04,1.11,and 1.12,respectively,for the content of recycled polyester fber of 0.1%,0.3%,and 0.5%.

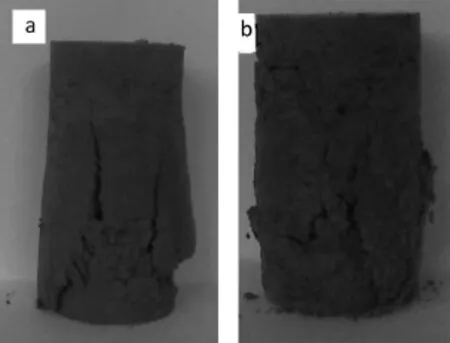

Fig.17.Effect of nano-SiO2on failure characteristics of soil:(a)Clay stabilized with nano-SiO2,and(b)Natural clay.

3.2.2.UCS of clay improved by nano-SiO2

Fig.18.Elastic modulus(E50)of clay stabilized with varying nano-SiO2contents.

Fig.19.Stress-strain curves of clay reinforced and stabilized with(a)0.5%nano-SiO2, (b)0.7%nano-SiO2,and(c)1%nano-SiO2.

The results of unconfned compression test of clay stabilized with various nano-SiO2contents are presented in Fig.16.The observation of this fgure indicates that,with increase in nano-SiO2content,the peak UCS of stabilized clay increases,but the residual UCS of stabilized clay decreases.The UCS increases with the increase in nano-SiO2content up to 0.7%,beyond which it decreases.Thus,the optimum nano-SiO2content is found to be 0.7%.By adding nano-SiO2,the increase ratios of peak UCS are 1.3, 1.56,and 1.5,and the decrease ratios of residual UCS of stabilized clay are 0.63,0.58,and 0.48,respectively for nano-SiO2contents of 0.5%,0.7%,and 1%.Visual observations indicate that,at constant moisture content,due to the absorption of water by nano-SiO2,the clay becomes less compressible which is worsened by increasing the nano-SiO2content.This may be the reason for the reduction ofpeak strength of stabilized clay with 1%nano-SiO2in comparison with clay stabilized with 0.7%nano-SiO2.From this fgure,it is clear that the increase in UCS of stabilized clay occurs at lower strain in all specimens compared to the natural clay.It is evident that the decrease ratios of failure strain for soil stabilized by nano-SiO2are 0.87,0.77,and 0.62,respectively,for nano-SiO2contents of 0.5%,0.7%,and 1%.Fig.17 presents the effect of nano-SiO2on the behavior of soil stabilized with different nano-SiO2contents.The observation of this fgure shows that specimens treated by nano-SiO2illustrate very brittle behavior and the tensile cracks due to brittle behavior lead to creation of the failure mechanism.It can be noted that the increase in nano-SiO2contents contributes to the creation of tensile cracks in the treated specimens.The elastic modulus(E50)of clay stabilized with varying nano-SiO2contents obtained from unconfned compression tests is presented in Fig.18.It can be seen from Fig.18 that,with the increase in nano-SiO2content,the increase ratios of elastic modulus(E50)are 1.2, 1.41,and 1.84,respectively,for nano-SiO2content of 0.5%,0.7%, and 1%.

Fig.20.Specimen deformation pattern for(a)clay stabilized with nano-SiO2and(b) fber-reinforced clay stabilized by nano-SiO2.

3.2.3.UCS of clay improved by recycled polyesterfber and nano-SiO2

The UCS values of clay reinforced by nano-SiO2and recycled material are shown in Fig.19.It is clear from Fig.19 that,by increasing the nano-SiO2content,the peak and residual UCSs increase.Hence,the optimum nano-SiO2content is found to be 1%.By adding 1%nano-SiO2,the peak and residual UCSs increase by from 120%to 165%and 120%to 182%,respectively,when the content of recycled polyester fber increases from 0.1%to 0.3%.However,by further increasing the recycled polyester fber,as in the case of 0.5% fber,the increases are only 181%and 200%,respectively.Hence,the addition of recycled polyester fber more than 0.3%is not reasonable to increase the UCS of clay,resulting in the optimum contentof recycled polyester fber of 0.3%.The optimumvalue of the peak UCS is observed at 0.3%fber+1%nano-SiO2content,which is 2.65 times the UCS of natural clay,1.56 times that of the nano-SiO2treated specimens,1.76 times that of the recycled material treated specimens.The recycled material along with nano-material has a signifcant effect on the clay behavior.The nano-SiO2samples obtained a different failure stress at an axial strain of 6.5%-9%under which the treated specimens declined;but the samples treated by recycled material illustrated ductile behavior.Thus,the addition of the recycled material to the specimens is more effcient than the nano-SiO2in improving the clay behavior.Fig.20 shows the behaviors of treated and untreated specimens.Fig.20a shows that the specimens treated by nano-SiO2illustrate very brittle behavior.The recycled material impedes the development of cracks,contributing to improvement of the tensile strength of composite.This phenomenon results fromfriction created byrecycled material and clay particles,which is evident in Fig.20b.The results of the unconfned compression tests show that the recycled material has not extremely infuence on the increase in stiffness of treated specimens.On the other hand,the nano-SiO2has a positive infuence onthe stiffness of treated specimens.The addition of the nano-SiO2to clay causes reduction in failure strain of specimens compared to natural clay and clay reinforced with recycled polyester fber.It can be noted that an increase in the content of recycled material is associated with a reduction in brittleness of treated specimens.By adding nano-SiO2,the failure of specimens is suddenly,but with increase in the content of recycled material,the failure mechanism of treated specimens changes;consequently,with increasing the content of recycled material,the residual UCS of composite increases.

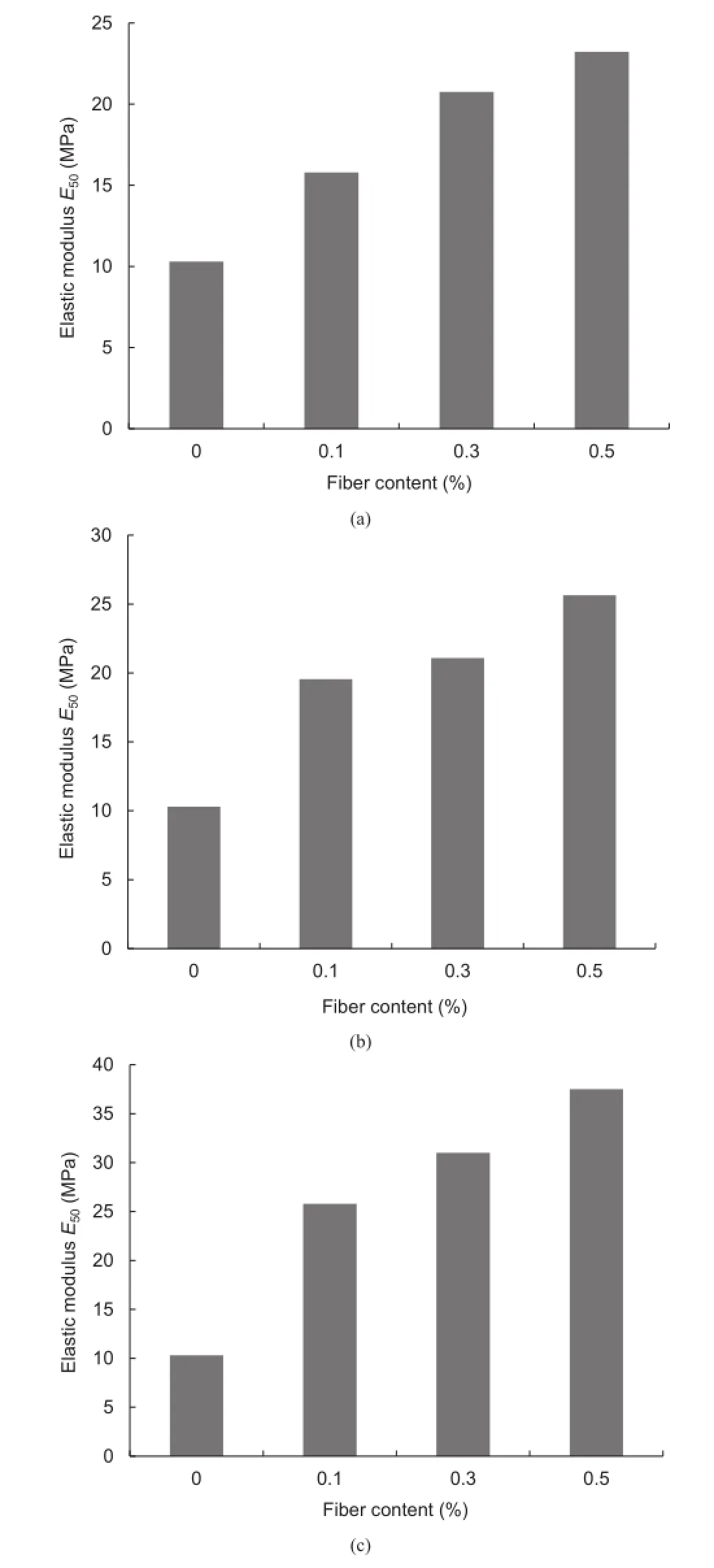

Fig.21.Elastic modulus(E50)of clay reinforced and stabilized with(a)0.5%nano-SiO2, (b)0.7%nano-SiO2,and(c)1%nano-SiO2.

3.2.4.Elastic modulus(E50)of recycled polyesterfber-reinforced clay improved by nano-SiO2

The elastic modulus(E50)of treated specimens with varying contents of nano-SiO2and recycled polyester fber obtained from the unconfned compression tests is presented in Fig.21.It can be seen from Fig.21 that the maximum value of the elastic modulus occurs at 1%nano-SiO2content.By adding 1%nano-SiO2,the elastic moduli(E50)increase by 150%,200%,and 264%for 0.5%,0.7%,and 1%fber contents,respectively.The maximum value of the elastic modulus is observed at 0.5%fber+1%nano-SiO2content,which is 3.65 times the elastic modulus of the natural clay,1.97 times that of the nano-SiO2treated specimens,and 3.24 times that of the recycled material treated specimens.

4.Conclusions

In recent years,research on the application of recycled fber has become a hot issue due to environmental benefts and cost effectiveness of geofber.Past studies show that the addition of waste products with chemical agents may improve the strength properties of soft clay.This study investigates the effects of recycled polyester fber and nano-SiO2on the mechanical properties of clay, based on the results obtained from a series of direct shear tests and unconfned compression tests.The following conclusions are drawn:

(1)For the compacted clay containing nano-SiO2and recycled polyester fber,the shear strength increases with the increase in the contents of nano-SiO2and recycled polyester fber.With 1%nano-SiO2,an increase of 190%in shear strength is observed for the mixtures with 0.3%recycled polyester fber. The shear stress of clay with 0.5%recycled fber only increases by about 10%in comparison with that of the clay with 0.3% recycled fber.

(2)The increase in the contents of nano-SiO2and recycled polyester fber leads to an increase in both angle of internal friction and cohesion.For all the cases,the maximum increase in angle of internal friction of composite is found at the contents of 0.3% fber+1%nano-SiO2.By adding 0.3%recycled polyester fber+1%nano-SiO2,the increase ratios of angle of internal friction and cohesion for treated specimens are 2.72 and 2.81, respectively.

(3)Both the recycled polyester fber and nano-SiO2have positive infuence on the increase in peak and residual UCSs of clay.In all samples,the maximum increase in both peak and residual UCSs is found at the contents of 1%nano-SiO2+0.3%recycled polyester fber.

(4)The addition of nano-SiO2is more signifcant than adding recycled polyester fber in increasing the stiffness of clay.The simultaneous use of recycled polyester fber and nano-SiO2has a signifcant effect on enhancing the elastic modulus of clay.

(5)Because of the fact that the nano-SiO2covers around the fber surface,the interlock force between fber surface and soil particles increases and bond characteristics improve.Also the use of nano-SiO2has a negative effect on the ductility of clay.

(6)The cracks on the surface are clearly observed.The narrower and shorter cracks are detected on the surface of compacted soil,nano-SiO2and fber mixture.The decrease in cracks can be attributed to the fact that fber acts as bridges between soil particles and cause matrix reinforcement.As a result,the recycled material provides strength to crack propagation and retains load transfer during tension.

In this paper,it can be noted that the method of clay stabilized with nano-SiO2and recycled polyester fber is a signifcantly applied method of ground improvement,which increases the shear strength,the UCS,and the elastic modulus of clay.Because of this,it increases the stability of structures,i.e.foundation and roadbed. With the development ofthe construction technology,this improvement technique can be considered as a practical method for improvement of mechanical behaviors of clay in civil engineering project.

Confict of interest

The authors wish to confrm that there are no known conficts of interest associated with this publication and there has been no signifcant fnancial support for this work that could have infuenced its outcome.

Acknowledgments

This study has been performed in Soil Mechanical Laboratory of Semnan University.The authors appreciate the Head of Soil Mechanics Laboratory of Semnan University,Mr.Doost Mohammadi, for his cooperation in this research.

Estabragh AR,Bordbar AT,Javadi AA.Mechanical behavior of a clay soil reinforced with nylon fbers.Geotechnical and Geological Engineering 2013;29(5):899-908.

Hamidi A,Hooresfand M.Effect of fber reinforcement on triaxial shear behavior of cement treated sand.Geotextiles and Geomembranes 2013;36:1-9.

Landman J,Paineau E,Davidson P,Bihannic I,Michot LJ,Philippe AM,et al. Effects of added silica nanoparticles on the nematic liquid crystal phase formationinbeidellitesuspensions.JournalofPhysicalChemistryB 2014;118(18):4913-9.

Luo HL,Hsiao DH,Lin DF,Lin CK.Sewage sludge ash/cement and nano aluminum oxide.Journal of Transportation Science and Technology 2012;1(1):83-100.

Mirzababaei M,Miraftab M,Mohamed M,Mcmahon P.Impact of carpet waste fber addition on swelling properties of compacted clays.Geotechnical and Geological Engineering 2013;31(1):173-82.

Mohamed AEM.Improvement of swelling clay properties using hay fbers.Construction and Building Materials 2013;38:242-7.

Mohammadi M,Niazian M.Investigation of nano-clay effect on geotechnical propertiesofRasht clay.Journalof AdvancedScienceand Technology 2013;3(3):37-46.

Niroumand H,Zain MFM,Alhosseini SN.The infuence of nano-clays on compressive strength of earth bricks as sustainable materials.Procedia-Social and Behavioral Sciences 2013;89:862-5.

Noll MR,Bartlett C,Dochat TM.In situ permeability reduction and chemical fxation using colloidal silica.Proceedings of the 6th National Outdoor Action Conference on Aquifer Restoration,Las Vegas,NV 1992:443-57.

Park SS.Effect of fber reinforcement and distribution on unconfned compressive strength of fber-reinforced cemented sand.Geotextiles and Geomembranes 2009;27(2):162-6.

ParkSS.Unconfnedcompressivestrengthandductility offber-reinforced cemented sand.Construction and Building Materials 2013;25:1134-8.

Pham H,Nguyen QP.Effect of silica nanoparticles on clay swelling and aqueous stabilityofnanoparticledispersions.JournalofNanoparticleResearch 2014;16(1):2137.

Taha MR,Taha OME.Infuence of nano-material on the expansive and shrinkage soil behavior.Journal of Nanoparticle Research 2012;14:1190.

Tang CS,Shi B,Zhao LZ.Interfacial shear strength of fber reinforced soil.Geotextiles and Geomembranes 2010;28(1):54-62.

To D,Sundaresan S,Dave R.Nanoparticle mixing through rapid expansion of high pressure and supercritical suspensions.Journal of Nanoparticle Research 2011;13(9):4253-66.

Yonekura R,Miwa M.Fundamental properties of sodium silicate based grout. Proceedings of the 11th Southeast Asia Geotechnical Conference,Singapore 1993:439-44.

Zhang G,Germaine JT,Whittle AJ,Ladd C.Index properties of a highly weathered old alluvium.Géotechnique 2004;54(7):441-51.

Zulkifey MTM,Ng TF,Raj JK,Hashim R,Bakar AFA,Paramanthan S,et al.A review of the stabilization of tropical lowland peats.Bulletin of Engineering Geology and the Environment 2013;73(3):733-46.

Abdolhosein Haddadobtained an M.Sc.degree from Iran University of Science&Technology,Tehran and a Ph.D. from Engineering School of Shiraz University,Shiraz,Iran. He is Assistant Professor of Geotechnical Engineering Department at the Semnan University and also Head of the School of Civil Engineering.He has been involved in geotechnical research,consulting and education for more than 15 years.He has authored or co-authored 3 books in Geotechnical Engineering and more than 50 scientifc papers.Also he is member of the Editorial Board of Journal of Rehabilitation in Civil Engineering(JRCE).

*Corresponding author.Tel.:+98 9166724282.

E-mail address:Foad.changizi@students.semnan.ac.ir(F.Changizi).

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.03.013

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A theoretical derivation of the Hoek-Brown failure criterion for rock materials

- Case studies of high-sensitivity monitoring of natural and engineered slopes

- Key technologies of drilling process with raise boring method

- Analysis of horizontal displacement distribution caused by single advancing longwall panel excavation

- Susceptibility assessment of debris fows using the analytic hierarchy process method-A case study in Subao river valley,China

- Optimal design of anchor cables for slope reinforcement based on stress and displacement felds