Key technologies of drilling process with raise boring method

Zhiqiang Liu,Yiping Meng

aInstitute of Mine Construction,Tiandi Science and Technology Co.,Ltd.,China Coal Mine Engineering Co.,Ltd.,Beijing 100013,China

bSchool of Civil Engineering,Hefei University of Technology,Hefei,Anhui 230009,China

Key technologies of drilling process with raise boring method

Zhiqiang Liua,*,Yiping Mengb

aInstitute of Mine Construction,Tiandi Science and Technology Co.,Ltd.,China Coal Mine Engineering Co.,Ltd.,Beijing 100013,China

bSchool of Civil Engineering,Hefei University of Technology,Hefei,Anhui 230009,China

A R T I C L E I N F O

Article history:

Received 9 October 2014

Received in revised form

8 December 2014

Accepted 26 December 2014 Available online 9 May 2015

Raise boring machine

Upward reaming

Rock fragmentation

Stability of shaft wall

Development trend

Winze

This study presents the concept of shaft constructed by raise boring in underground mines,and the idea of inverse construction can be extended to other felds of underground engineering.The conventional raise boring methods,such as the wood support method,the hanging cage method,the creeping cage method, and the deep-hole blasting method,areanalyzedand compared.In addition,the raise boring machines are classifed into different types and the characteristics of each type are described.The components of a raise boring machineincluding the drill rig,the drill string and the auxiliarysystem arealso presented.Based on the analysis of the raise boring method,the rock mechanics problems during the raise boring process are put forward,including rock fragmentation,removal of cuttings,shaft wall stability,and borehole deviation control.Finally,the development trends of raise boring technology are described as follows:(i)improvement of rock-breaking modes to raise drilling effciency,(ii)development of an intelligent control technique,and(iii)development of technology and equipment for nonlinear raise boring.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

According to the site-specifc conditions of mines in China,most mineral resources need to be exploited by shaft access mines.As tunnels enter into the ore body,vertical and inclined shafts are constructed from the surface to the desired depth.When the shaft excavation reaches the designed mining level,some horizontal roadways for transportation,ventilation and pedestrian access to the ore body can then be driven.According to the distribution characteristics of the ore body,a variety of shafts should be constructed,such as blind vertical or inclined shafts connecting with ore body at different levels,ore bins storing minerals,ore passes for slipping minerals to the collection level,etc.There is no outlet on the ground for these underground shafts,and due to the dimensions of the shafts,drilling equipment and support facilities are restricted or forbidden in a narrow space.Therefore,the reverse sinking method,called the raise boring method,is generally used on site.The raise boring method is suitable for production of vertical or inclined shafts from bottom to top in underground mining operations.Generally,a small-diameter hole,called pilot hole,is frst drilled,through which the cuttings fall to the lower level.The raise is a type of excavation that can be constructed by the raise boring method.Raise boring is very important in the mining industry,and it is also applied to other underground engineering, such as water conduits,air shafts,elevator hoistways and cable shafts in hydropower stations and pumped-storage power stations, ventilation shafts and exit passageways of long tunnels for highways,railways and subways,and underground nuclear waste storages and military installations(Zhu,2004;Su and Wang,2010; Guo and Zhang,2012;Liu,2013a,b;Sun,2013).These excavations are important and diffcult parts during a project’s construction.

According to industry and construction practices,there are a variety of reverse sinking construction processes.In the past,due to factors like complex formations,weak self-supporting ability of rock, and harmful gases in coal mines,the wood-supported raise method, also called conventional raise mining,was generally used in the coal industry in China.With this method,workers frst build crossbracing,ladders and platforms from bottom to top,and then drilling,chargingandblastingoperationsarecarriedoutontheplatform. After ventilation,loading and scaling,the next blasting cycle starts, and wood is used as support structures to maintain the stability of roadways.The creeping cage method was generally used in the hydropowerindustry,andwasadoptedastransportationequipmentfor workers and working platforms for excavation operations.The hanging cage method was generally used in metal and nonmetal mines.In these raise boring methods,workers need to enter the working face to apply operations of drilling,charging,blasting and supporting and as a result are liable to be affected by water gushing, harmful gases,rock caving and so on,leading to frequent accidents and low work effciency.To solve the above safety problems of construction,the deep-hole blasting method was developed.A set of parallelboreholesisdrilledalongtheaxisoftheshaftatthetopbythedrill rig,charging is carried out from the upper level,and blasting is applied piecewise from bottom to top.The accuracy of drilling holes limitstheconstructiondepthofthismethod.Therefore,newmethods and equipment were needed.In 1850,a percussion-type drilling machinewasfrstusedtodrillasmalldiametershaft.Inthe1930s,the rotary rig was adopted for drilling vertical shafts,and the tunnel boring machine(TBM)was applied in tunneling gradually.In the 1950s,miners applied the rock-breaking mechanism of shaft drilling machines and TBMs to raise boring,and gradually the modern raise boring machines were developed.However,raises constructed by raise boring machines have small diameters and often act as pilot holes.Thus,othermethodsareneededtoreamthepilotholesbyraise boring machines to the designed sections.This study presents the concept of shaftexcavation by raise boring machines.To this end,the large raise boring machine,drilling process,rock breaking and shaft wall stability during raise boring should be studied(Liu,2001;Zhang et al.,2008,2010).

2.Drilling process and constitution of raise boring machines

The raise boring method is a way to excavate shaft by back reaming the pilot hole using drill rigs.The drill rig plays a signifcant role in underground engineering,such as mineral exploration and blasting.For rotary type of drill rigs,the rotational torque and axial force are exerted to drill bit(called pilot hole drill bit for raise boring machines)along the drill pipe to create a circular hole. Generally,the cuttings are removed from the hole with the aid of fushing medium(as shown in Fig.1a).The construction process of the pilot hole by raise boring machines is the same as that by conventional drilling machines except the back reaming process introduced in the raise boring method.When the pilot hole breaks through into the lower level,the drill bit is removed and replaced with a large-diameter reaming head.The reamer is rotated and pulled back toward the drilling unit,and through this way a largediameter shaft is formed(Fig.1b).A complete set of raise boring machine includes drill rig,drill string and auxiliary system,as shown in Table 1(Sizer,1983;Liu,2012).

3.Classifcation of raise boring machines

Different from the conventional drilling machines,the cuttings usually fall down to the lower level by gravity during raise boring, which is the common characteristic for all types of raise boring machines.The above-mentioned conventional raise borer is only one type of raise boring machine,and the drilling process involves two steps,i.e.pilot drilling and back reaming.In fact,there are many types of raise boring machines.For example,they can be classifed into box type,frame type and column type according to the structure of the drilling frame;chain type and cylinder type according to the propulsion mode;motor-driven type and hydraulic motor-driven type according tothe rotational power source. However,these classifcations are not based on the essence of the raise boring machine.The raise boring machines can be classifed into two types according to the back reaming process,i.e.upward reaming type and downward reaming type.Table 2 briefy lists the characteristics of two types of raise boring machines.According to the reaming direction of the raise boring machine,the drilling process can be classifed into two categories,i.e.the upward reaming method(Fig.2a)and the downward reaming method (Fig.2b).The following conclusions can be drawn by comparing the two reaming methods:

(1)In the downward reaming method,the cuttings fall down through the annulus between the drill pipe and the hole wall to the lower level.The cuttings shattered by the cutter in different positions on the reamer head converge at the center of the head and are repeatedly broken by other cutters.In the upward reaming method,however,the cuttings usually fall down by gravity,and are rarely repeatedly broken,so its effciency is higher than the downward reaming method.

(2)In the downward reaming method,the pilot hole is the passage of the drill string and cuttings,thus the falling down of the cuttings can damage the drill string.In the upward reaming method,however,the pilot hole only serves as the passage ofthe drill string which needs small-diameter hole,so the drilling speed of the pilot hole is fast.

Fig.1.Raise boring method and correlated rock mechanics problems.

(3)Itiseasiertodrillpilotholeandcontrolholedeviationbyupward reaming than by downward reaming.In the downward reaming method,since the drill string is under compression during pilot drilling and easily bent,the quality of the hole is diffcult to control,and the drilling depth is limited.

(4)In the upward reaming method,since the workers operate the drilling machine in the upper level,the working condition is safer than that of the downward reaming method.In the downward reaming method,since the cuttings removal and drilling operations are carried out in the lower level,the working condition is poor.

Table 1Main functions and components of raise boring machine.

4.Main technical problems during raise boring

The raise boring machine has completely changed the working conditions in raise construction,and workers operate machines far away from the dangerous working face.All drilling processes are achieved bythe raise boring machine,which lays a good foundation for automatic and unmanned drilling technology.In the past decade,great achievements in raise boring technology and equipment research(Xu,2008;Liu and Xu,2011)have been made in China.The diameter and depth of drilling holes reach 5 m and 600 m,respectively,and the application of the raise boring machine is extending to other felds gradually.The progress in raise boring technology needs to address many important issues about basictheory and key equipment of raise boring machine.According to the drilling process of the conventional raise boring machine,a series of rock mechanics problems should be concerned,including stability of hole wall,interaction of drill string and rocks,drilling trajectory control of pilot hole,etc.(James,1997).

?

Fig.2.Photos of two types of reaming mothod:(a)Upward reaming;and(b)Downward reaming.

4.1.Pilot drilling

Pilot drilling is a process of drilling a pilot hole in a small diameter along the axis of shaft(Fig.4).When the pilot hole breaks through into the lower level,the roller bit is removed and replaced with a reaming head.The reamer is rotated and pulled back toward the drilling unit,and eventually the shaft is formed.The following requirements should be satisfed for pilot hole in raise boring:

(1)The axis of pilot hole should be linear as much as possible and its curvature cannot change too large.

(2)The maximum distance from axis of pilot hole to shaft axis must be kept within the engineering allowance,i.e.the deviation rate of the pilot hole should be minimized.

(3)In the drilling process,accidents must be avoided,and the

fnished pilot hole should be smooth and stable.

4.1.1.Rock breaking in pilot drilling

During pilot drilling,rocks are separated from the rock body by tricone roller bit.The mechanism of rock breaking by the drill bit has been researched extensively inpetroleum engineering and thus can be used in the raise boring.Different from petroleum drilling, raise boring aims to detect rock properties and geological structures in advance,and to provide a reference for selection of reamer and supporting method.On the basis of regression equation of drilling speed,weight on bit,rotational speed and torque during pilot drilling through different strata,rock drillability classifcation and relationship between back reaming parameters and pilot drilling parameters should be studied.

Fig.3.Sketch of rock-breaking cutter.

4.1.2.Cyclic cuttings removal in pilot drilling

The fushing media used for cuttings removal include mud, water,compressed air,etc.Introduced through the center of the drill pipe,the fushing media are sprayed out through the tricone bit nozzle with the aid of the pump.The rock broken by the cutter is separated from the hole bottom,and removed out of the borehole along the annulus between the drill pipe and hole wall.The basic condition for effective cuttings removal is that the speed of fushing media is higher than the sedimentation speed of cuttings in the fushing media.As a typical fushing media,the mud has good suspension properties,and it also can help to prevent the collapse of hole wall.However,the sudden loss of mud pressure when the hole breaks through into the lower level can result in hole collapse and drill devices buried in unstable strata.Therefore,water is often used instead of mud to remove cuttings from pilot hole.With the aid of water fushing,the unstable strata can be easily explored and addressed to prevent the accident after hole drilling.Compressed air can achieve effcient cuttings removal in the condition that the strata are relatively stable and hard,with abundant cracks and small caves,but the leakage of fushing fuid is serious.Thus the fushing medium and fow in different strata and reasonable parameters such as pressureneed to be studied.According todifferent fushing media and cuttings fow,the risk of strata should be determined to prevent drilling accidents.4.1.3.Deviation control of pilot hole

Deviation of pilot hole is that the centerline of pilot hole does notcoincide with the planned shaft axis.Deviation rate of pilot hole is a ratio of raise length to the maximum deviation.Deviation of pilot hole is generally caused by anisotropy of strata,machining accuracy of drilling devices,artifcial control,etc.In pilot drilling, rock is broken by drill bit.The drill bit is connected with stable drill pipe and ordinary drill pipe to form a drilling string to stabilize the drilling process and to reduce its impact on the borehole deviation. However,the machining cannot ensure that the axes of all drill pipes are connected in a line.Drilling tends to deviate from the designed direction,affected by the drilling pressure.Underground stratum is a typical anisotropic body which can produce uneven hole bottom and additional moment,making drilling deviate from the designed drilling direction.The interaction between the drillstring and hole wall can also bring in stress changes of drill string and infuence its normal operation.The adaptability of designed drilling schemes to the mechanics parameters of different strata, including drilling pressure,rotational speed,and torque,will also cause deviation of pilot hole.Therefore,the infuences of physicomechanical properties and anisotropy of strata,interaction of drill string and hole wall,and drilling parameters on deviation of pilot hole need to be studied,and automatic-correction drill string by terrestrial magnetism should also be developed.

Fig.4.Basic parameters of cutter.L-generatrix length;P-row spacing;D-diameter of large end of cutter;M-button spacing;θ-cone angle.

4.1.4.Pilot hole stability and accident control

When the deviation of pilot hole is beyond the engineering allowance,the pilot hole cannot be used anymore and has to be abandoned.In addition to this serious engineering accident,there are many other drilling accidents,such as drill string loss and pilot hole abandonment due to leakage of fushing fuid,hole shrinkage and collapse,and drill string burying induced by unfavorable geological conditions.The drill string is generally more expensive than the drill rig,thus the damage of drill string will cause greater economic losses.For this reason,cyclic cuttings removal,drilling parameters changes,vibration of drill rig and other factors should be studied todetermine strata conditions and early-warn accidents, and reinforcement and modifcation technology of strata in advance should be researched to prevent wall collapse of shaft with large section and no support in back reaming.

4.2.Back reaming

4.2.1.Effcient rock breaking

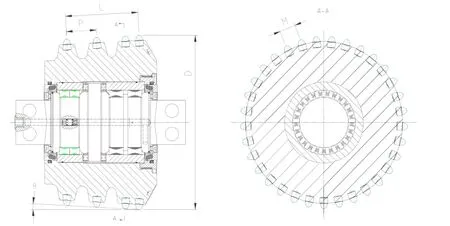

In back reaming,the raise boring machine drives the drill pipe rotation,and energy is transferred to the reamer head along the drill pipe.Then the cutter is driven tocrush down the rocks,and the cuttings fall down by gravity to the lower level,where they are mucked out using loaders.As shown in Fig.3,the cutter is composed of drill button,cutter shell,sealed bearing,saddle,etc. Two cutters are in a group and laid symmetrically to fnish rock breaking.As shown in Fig.4,the main technical parameters of the cutter include generatrix length,cone angle,diameter of large end, button spacing and rowspacing,etc.The buttonparametersinclude button shape,diameters,and so on.During back reaming process of raise boring machine,the reamer exerts certain force on the cutter in the drilling direction until the cutter presses into the rock,and the rock fails when the deformation is beyond its elastic limit. Meanwhile,the cutter rotates under the combined action of rocks and rotating reamer head,and the cutter buttons extrude and scrape the rock,bringing in button marks on it.These marks in similar size and depth cause gradually separating of rock fragment from rock body and formation of rock breaking with circular section,which can meet the project requirements.Therefore,mechanism of rock breaking by cutter,rock drillability,structure and shape of cutter,material and structure of cutter button,wear resistance,arrangementof cutters on the head,spatial arrangement of the head to satisfy effcient cuttings removal need to be studied.4.2.2.Stability of shaft wall

Although the back reaming of raise boring machine has minor disturbance to shaft wall,a variety of factors that affect stability of shaft wall still exist.

(1)Stratigraphic conditions.When the shaft is constructed in an unstable formation,the formed shaft wall after back reaming cannot support its stability,and phenomena like rock expansion and crushing bycontacting with water often occur and will cause partial collapse,rib spalling,caving of the shaft.

(2)Gushing water and cooling water in strata.When the pilot hole breaks through into the lower level,the fushing water leaks out,and the mud pressure on hole wall disappears,making the water contained in strata fush into pilot hole.As the exposed area of rock increases during back reaming,the water infow grows.In the back reaming process,heat produced by breaking rock results in a sharp rise in the temperatureof the cutter.Thus a nozzle is set in the reamer head to spray water to cool the cutter down.Meanwhile,the water mist can clean dust produced in rock breaking to reduce the infuence of dust on the lower production system.The gushing water and cooling water have adverse effects on strata stability,for example,they will fush cement of shaft wall rock,reduce cohesion and internal friction coeffcient of rock,and increase rock instability risk.

(3)Concentration and redistribution of stress.In the process of raise boring,the shaft gradually forms,and the original rock stress distribution gradually changes.Generally,stress concentration occurs on the pilot hole wall,shaft wall and interface between cutter and rock.In fractured strata,once the broken condition is satisfed,partial collapse will occur.

(4)Prolonged exposure of shaft wall.The exposure time varies in different parts of shaft wall using raise boring method.Theexposure time of the lower shaft wall is the longest,and it includes the time of back reaming,the time from the dismantling of the raise boring machine to the installation of support and lifting equipment,and the time of temporary support from top to bottom.As to the raise boring shaft with 400 m in depth and 5 m in diameter,back reaming generally lasts for 2-3 months, dismounting and mounting of lifting equipment and hanging scaffold for a week,and temporary support of anchoring and shotcreting generally for 1.5-2 months.Thus the exposure time reaches 110-160 d.The exposure time of shaft wall reduces gradually from bottom to top,and the infuence of exposure time on stability of shaft wall needs to be studied.

Fig.5.Structure of reamer head of the raise boring machine for shafts of 5 m in diameter.

5.Technology and equipment of raise boring

5.1.Application conditions and main technical parameters of raise boring machines

5.1.1.Application conditions

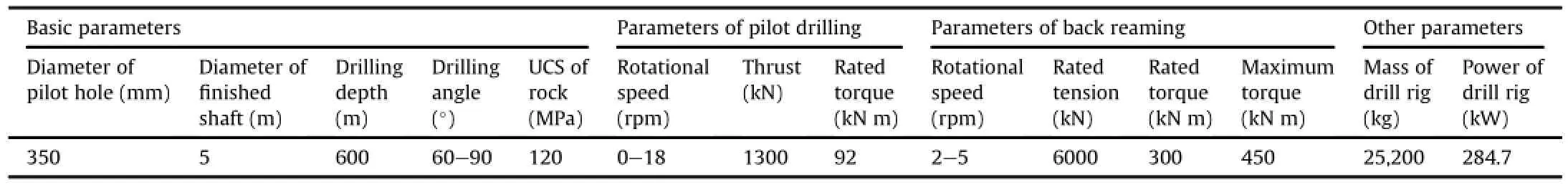

The study of raise boring technology was initiated from the construction of air shafts in coal mines,and then it was conducted in hydropower projects and other underground engineering.In these projects,the boring machines drill through rocks characterized with different properties.In coal mines,coal is one of the major types of sedimentary rocks with low uniaxial compression strength (UCS)(<120 MPa).The drilling depth in coal mines can reach 600 m,and the maximum diameter of back reaming reaches 5 m. The boring inclination ranges from 50°to 90°,and the maximum rate of back reaming is 0.8 m/h.In hydropower projects and other underground engineering,the rock masses are mainly composed of igneous rocks with high UCS of 120-200 MPa.The drilling depth can reach 600 m,and the maximum diameter of back reaming reaches 3.5 m.The boring inclination ranges from 40°to 90°,and the maximum rate of back reaming is 0.5 m/h.

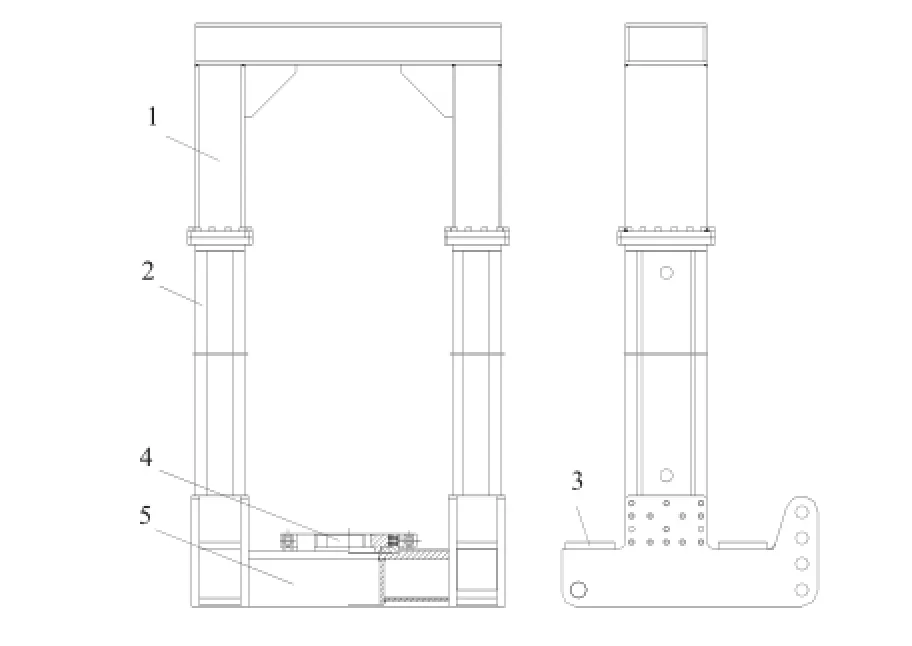

Fig.6.Structure of drilling frame of the raise boring machine ZFY5.0/600.1-beam;2 -guiding square columns;3-connecting fange of the propulsion cylinder;4-fashboard assembly;5-base.

5.1.2.Main technical parameters

(1)Drilling pressure,Pf

The reamer head of 5 m in diameter(Dr)contains 30 cutters on it,and the 3.5 m diameter head contains 18 cutters(Fig.5).When drilling is performed in the rocks with UCS less than 120 MPa,the pressure on cutters for breaking rocks should be approximately 35 kN,thus the drilling pressure for reamer head of 5 m in diameteris 1050 kN.When the UCS of rocks reaches 200 MPa,the pressure exerted on cutters should reach 80 kN to meet the target drilling rate,thus drilling pressure for reamer head of 3.5 m in diameter needs to be 1440 kN.

Table 3Main technical parameters of the self-developed raise boring machine ZFY5.0/600.

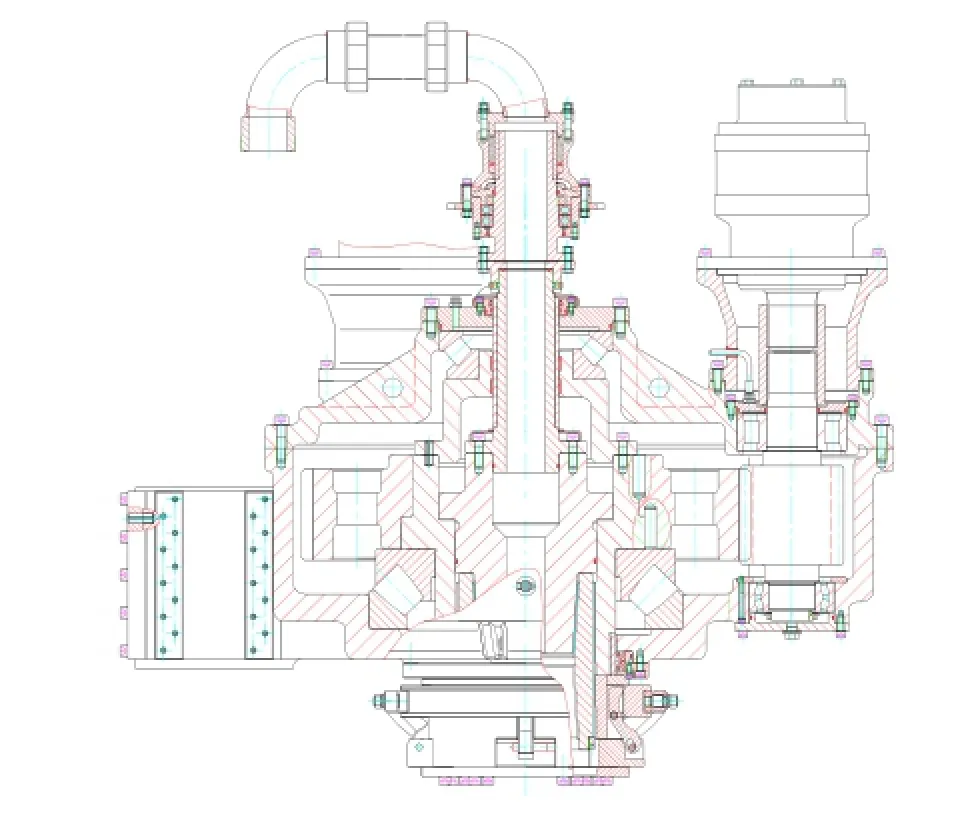

Fig.7.Structure of the multi-motor driving unit.

(2)Rotational speed,nr

In order toachievehigh effciencyof rock breaking and lowwear of cutter buttons,the time of cutter buttons in contact with rocks should be 0.02-0.03 s,and correspondingly the linear velocity(Vc) of side cutters should be controlled at 0.7-1.0 m/s.Through calculation,nr=60Vc/πDr=2.67-3.8 r/min,thus the designed maximum rotational speed of raise boring machine is 5 r/min.

(3)Torque,Ms

Based on the drilling rate and rotational speed,the drilling depth(hr)in each round is 1.6-2.7 mm.In addition to the drilling depth in each round(or the drilling rate),the maximum torque of rock breaking is also related with the diameter of the reamer head and the friction coeffcient of the cutter bearing.In rock breaking, the cutters require energy to separate rock from rock bodies,and the cutter bearing and friction between reamer head and rock can also consume some energy.Without considering some other minor factors,the torque can be calculated as

whereKris the required energy to break unit volume of rock by cutters,and it contains energy loss.The consumed energy in the laboratoryexperimentof UCS is low,and the common consumption value is 5×107-9×107J/m3.Dpis the diameter of the pilot hole.

The required torque for different drilling rates ranges from 156 kN m to 264 kN m.Considering other accident treatments,the torque of the raise boring machine is 300 kN m.5.1.3.Other parameters

Based on the rotational speed,torque,and drilling pressure,the tension of the raise boring machine is calculated.Considering the total weight(3160 kN)of drill pipe 600 m long(2700 kN),drill bit 5 m in diameter(400 kN),and driving unit(60 kN),the lifting force of the raise boring machine is 4610-4750 kN.Considering the machine’s capacity,the tension of raise boring machine is designed to be 6000 kN.

The main technical parameters of the self-developed raise boring machine ZFY5.0/600 for shafts 5 m in diameter are shown in Table 3.

5.2.Development of raise boring machine for large-diameter shafts

Fig.1 shows the schematic diagram of site application of the self-developed raise boring machine ZFY5.0/600.Considering the capacity improvement of the raise boring machine,there are 4 cylinders,2 guide posts(Fig.6)and 4 motors(Fig.7)in the drill rig. The main force-bearing components are bolted rigidly.The adjustable angle of the machine body is not less than 30°.The electrohydraulic control system is adopted in power and control system to ensure the fexibility,intelligence and safety of the drilling machine.The drill pipe is 1.5 m in length with 1:8 cone thread. The reamer head is composed of removable segments(as shown in Fig.6),facilitating underground transportation and installation.

5.3.Case illustration

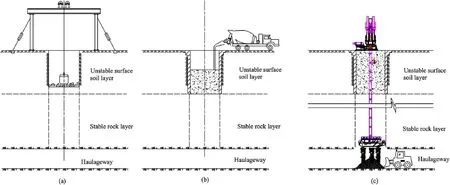

The auxiliary ventilation shaft in Baoxin coal mine of Lanhua Coal Industry Group in Guxian,Shanxi,China is 4.7 m in net diameter and 482.2 m in depth.The shaft passes through the rock strata of upper Shihezi group,lower Shihezi group,Shanxi group, and Taiyuan group,with UCS less than 100 MPa.The self-developed raise boring machine ZFY5.0/600 is adopted in this project.In order to ensure the stability of the shaft wall and safe construction,risk assessment should be frst performed using detailed geological exploration data,including rock composition,physico-mechanical properties of rocks,geologic structure,development of fssures and bedding,and underground water situation in strata.Secondly, pilot drilling should be considered.Based on the investigation of the exposed rock,leakage of drilling mud and drilling parameters, the stability of the shaft wall after back reaming can be determined. Through analyzing geologic exploration data,the upper unstable strata may lead to the collapse of the borehole by water fushing during drilling process,thus partial excavation and shotcreting are conducted(Fig.8).The unstable strata are removed from top to bottom and supported temporarily,and the stable strata are reinforced using low-grade concrete.As the concrete reaches certain strength,the raise boring machine is installed and the drilling starts.The drilling site of the raise boring machine is shown in Fig.9.The pilot drilling of the Baoxin coal mine took 25 d from March 15 to April 10,2012,within which 215 h is consumed for drilling.The fnished pilot hole is 350 mm in diameter and 482.2 m in depth,with deviation rate less than 0.2%.The back reaming started on April 25,2012,and ended on June 10,2012.

After successful application to coal mines,the raise boring machine ZFY5.0/600 has constructed a dozen deep shafts in hard basalt layers with UCS larger than 150 MPa in Baihetan hydropower station,which further tests the capacity of the raise boring machine.

6.Development trend of raise boring technology

6.1.Improving rock-breaking method to increase drilling effciency

The cutter is the key component of raise boring machine to break rocks,and it is also the main consumable material.The energy consumption of cutting is much higher than that of conventional method like blasting.Therefore,effcient and low energy consumption cutter needs to be developed through the improvement of cutter body structure,cutter button structure and the useof new materials.Based on the physico-mechanical properties of rocks,auxiliary rock breaking technologies,such as high-pressure water jet,microwave vibration and chemical modifcation,need to be studied to further improve the effciency of rock breaking and drilling by raise boring machine.With the development of new technologies,such as laser,high-energy particle,and directionally controlled micro-blasting,current full-face rock breaking methods with which all the rocks are broken can be changed.By forming controllable and regularly shaped artifcial fssures,rocks can be separated from rock body.In the process of rock breaking,the shaft wall that needs to be stable can be melted and recrystallized,and the rock properties are fully used to solve the problems of breaking rock and preventing rock crushing.

Fig.8.Support process of upper unstable strata.(a)Excavation;(b)Pouring concrete;(c)Back reaming.

Fig.9.Drilling site of raise boring machine.

6.2.Intelligent control technology

With the development of raise boring machinery,it is increasingly used in various felds of underground construction,and it is suitable for all kinds of excavations from horizontal to vertical. Therefore,improving drilling accuracy and ensuring the drilling along the designed borehole axis become the most important issues for the raise boring machine.Development of pilot hole drill bit and drill string which can intelligently control the drilling direction is the key to solving the problems.There are some issues to be addressed,such as accurate positioning measurement and signal transmission of drill bit in three-dimensional space,servo-control of drilling direction,structure of small drill bit with these functions,energy supply method of drill bit,etc.

Some projects with nuclear radiation and overfow of harmful gases are not suitable for feld operations of workers,and these unfavorable conditions have an adverse impact on equipment performances,or interfere with data communication.Thus the intelligent remote control technology can be applied to effciently transmit the signals and achieve the unmanned operation of the raise boring machine.In various working conditions,supply,grab and positioning of drill pipes should be intelligently controlled.The raise boring machine has functions of judgment and pretreatment, and errors can be automatically diagnosed.The drilling work can be carried out by preprogrammed procedures and remote control.

To ensure the stability of the shaft wall,the remote shotcreting technology in conjunction with the raise boring needs to be studied.By timely reinforcement of the surrounding rocks,stability of shaft wall is improved,and accidents during back reaming are reduced.Firstly,intelligent recognition technology of surrounding rocks in the drilling process should be researched.Secondly, remote-controlled shotcreting devices and robot control technology should be studied to achieve intelligent detection of shotcrete layer,intelligent control of shotcreting,and shape control in formed shafts,and thus the following work can be well carried out.

6.3.Nonlinear drilling

To meet requirements of safe mineral exploitation under different geologic conditions,it is necessary to develop different types of raise boring machines.The raise boring machine with a drill pipe plays an important role in promoting the development of raise boring technology.However,due to the limit of drill pipe stiffness,the present raise boring machines can only drill in a straight direction which is diffcult to control.Therefore,raise boring machinery without drill pipe at early stage of development should be considered when the wire rope was acted as traction and guidance component.With the development of control technology, it is necessary to develop raise boring machines without guidance by the wire rope or so-called“hamster”type of raise boring equipment to exploit nuclear material,gold and other rare minerals along the mineral vein.Thus through tracing the minerals,the raise boring machine can reduce the ore dilution,decrease mining costs and impact on the environment,fnally achieving green mining.

7.Conclusions

The raise boring machine has made great progress in the last several decades.As a type of equipment used in site-specifc conditions,the raise boring machine can now be applied to many felds,including coal mines,hydropower stations,transportation, underground building,military engineering and other underground projects,with the maximum excavation diameter gradually increasing.Particularly,the successful development of the raise boring machine ZFY5.0/600 achieves large-diameter shaft construction,whilst former raise boring machines can only drill smalldiameter raises.The raise boring machine ZFY5.0/600 constructed a ventilation shaft 5 m in diameter in a coal mine and drilled a dozen deep shafts 3.5 m in diameter in hard basalt at the Baihetan hydropower station.However,many theoretical,mechanical and other technical issues about raise boring machines and the drilling process need to be further studied to solve problems on aspects of drilling effciency,energy savings,safety,unmanned operation and so forth.Optimization of the rock-breaking method,intelligent control technology,and nonlinear drilling of the raise boring machine need to be further researched and developed.As a reliable mechanized construction method,the raise boring technique is an ideal supplement to traditional shaft construction,and provides an effcient,mechanized construction method.Compared with the conventional drill-and-blast method,mechanized construction methods can greatly reduce the number of operating workers, improve safety in the construction of shafts,reduce injuries of workers and improve working effciency.Therefore,the development and application of raise boring technology are prospective.

Confict of interest

The authors wish to confrm that there are no known conficts of interest associated with this publication and there has been no signifcant fnancial support for this work that could have infuenced its outcome.

Guo DF,Zhang H.Application of raise-boring method in construction of underground water-sealing caverns.Tunnel Construction 2012;32(5):709-12(in Chinese).

James A.Catastrophic failure of a raise boring machine during underground reaming operations.Engineering Failure Analysis 1997;4(1):71-80.

Liu ZQ,Xu GL.Research on ZFY5.0/600 mode large diameter raise boring machine. Coal Science and Technology 2011;39(5):87-90(in Chinese).

Liu ZQ.Development and prospect of mechanical shaft boring technology.Journal of China Coal Society 2013a;38(7):1116-22.

Liu ZQ.Drilling technology and development of LM series raise boring machine.In: Cai MF,editor.Rock Mechanics:Achievements and Ambitions.Proceeding of the 2nd ISRM International Young Scholars’Symposium on Rock Mechanics. London,UK:CRC Press;2012.p.671-6.

Liu ZQ.Technology&equipment and development of raise boring machine.Coal Science and Technology 2001;29(4):9-12(in Chinese).

Liu ZQ.Technology of rapid constructing ventilating shaft in mining district by large-diameter raise boring machine.Journal of Mining and Safety Engineering 2013b;30(Supp.1):35-40(in Chinese).

Sizer RA.Raise boring:its potential in the environmental feld.Journal of the Mine Ventilation of South Africa 1983;36(10):97-106.

Su XM,Wang WS.Application of raise-boring method in Luohe iron mine.China Mine Engineering 2010;39(2):11-3(in Chinese).

Sun K.The application and improvement of bucket inverse method in the vertical shaft wall construction.Construction and Design for Project8;2013.p.151-3(in Chinese).

Xu GL.Development of BMC200 raise-boring machine.Coal Mining Technology 2008;13(6):61-2(in Chinese).

Zhang YC,Shi JS,Wang ZJ.Construction handbook of mine shaft drilling.Beijing, China:Coal Industry Press;2010(in Chinese).

Zhang YC,Sun J,Wang A.Drilling technology.Beijing,China:Coal Industry Press; 2008(in Chinese).

Zhu GG.Rapid construction of mining ventilation shaft with raise boring machine for nuclear mine.Coal Science and Technology 2004;32(2):48-9(in Chinese).

Zhiqiang Liuobtained his Ph.D.at the University of Science and Technology Beijing in 2014.He is the Vice Director of the Institute of Mine Construction,Tiandi Science and Technology Co.,Ltd.,a Key Scientist of China Coal Mine Engineering Co.,Ltd.,and the Director of the National EngineeringLaboratoryforDeepShaftConstruction Technology in Coal Mining.He has a long career in the research of coal mine construction,and raise boring and shaft sinking technology.He has fnished more than 30 research projects,including National Science and Technology Major Project,Science and Technology Support Programs.He has been awarded a national prize for Progress in Science and Technology,and has published more than 100 papers.At present,he is handling research on a shaft boring machine in mining granted by the National High-tech R&D Program (863 Program),China.With regards to the fundamental theory,equipment and process of raise boring,his research and application practices in recent years have laid foundations for Chinese raise boring technology.He has made great contributions to largediameter shafts construction using drilling methods,freezing technology for deep shafts,ground pre-grouting technology and so on.He has widespread infuence and recognition in the feld of underground engineering construction in coal mines,hydroelectricity and transportation.In February 2013,he obtained the special allowance of the government of China State Council,and he is the Man of the Year of Scientifc Chinese in 2012.

*Corresponding author.Tel.:+86 13901334274.

E-mail address:25944917@qq.com(Z.Liu).

Peer review under responsibility of Institute of Rock and Soil Mechanics, Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2014.12.006

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A theoretical derivation of the Hoek-Brown failure criterion for rock materials

- Strength properties of soft clay treated with mixture of nano-SiO2and recycled polyester fber

- Case studies of high-sensitivity monitoring of natural and engineered slopes

- Analysis of horizontal displacement distribution caused by single advancing longwall panel excavation

- Susceptibility assessment of debris fows using the analytic hierarchy process method-A case study in Subao river valley,China

- Optimal design of anchor cables for slope reinforcement based on stress and displacement felds