The use of point load test for Dubai weak calcareous sandstones

Amr Farouk Elhakim

Department of Public Works,Faculty of Engineering,Cairo University,Giza,Egypt

The use of point load test for Dubai weak calcareous sandstones

Amr Farouk Elhakim*

Department of Public Works,Faculty of Engineering,Cairo University,Giza,Egypt

A R T I C L EI N F O

Article history:

Received 15 December 2014

Received in revised form

9 April 2015

Accepted 5 June 2015

Available online 25 June 2015

Point load test

Uniaxial compressive strength(UCS)

Rock characteristic elastic modulus

Dubai calcareous sandstone

Calcarenite

Intact rock is typically described according to its uniaxial compressive strength(UCS).The UCS is needed in the design of geotechnical engineering problems including stability of rock slopes and design of shallow and deep foundations resting on and/or in rocks.Accordingly,a correct measurement/evaluation of the UCS is essential to a safe and economic design.Typically,the UCS is measured using the unconfned compression tests performed on cylindrical intact specimens with a minimum length to width ratio of 2.In several cases,especially for weak and very weak rocks,it is not possible to extract intact specimens with the needed minimum dimensions.Thus,alternative tests(e.g.point load test,Schmidt hammer)are used to measure rock strength.The UCS is computed based on the results of these tests through empirical correlations.The literature includes a plethora of these correlations that vary widely in estimating rock strength.Thus,it is paramount to validate these correlations to check their suitability for estimating rock strength for a specifc location and geology.A review of the available correlations used to estimate the UCS from the point load test results is performed and summarized herein.Results of UCS,point load strength index and Young’s modulus are gathered for calcareous sandstone specimens extracted from the Dubai area.A correlation for estimating the UCS from the point load strength index is proposed.Furthermore,the Young’s modulus is correlated to the UCS.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

The uniaxial compressive strength(UCS)of rock is the most commonly used parameter in the characterization of intact rock.It is needed for different applications including the design of foundations resting on and/or in rocks and the stability of rock slopes. The UCS is typically determined from the axial loading of unconfned intact rock specimens.The uniaxial compression test should be performed on cylindrical specimens with a length to width ratio of 2-2.5.The standard specimen height should range between 100 mm and 300 mm.The specimen ends perpendicular to the cylinder axis should be fat,smooth and parallel as per ASTM (2008a).Alternatively,the UCS may be estimated using the point load test,which is conducted on specimens in the form of cores, blocks or irregular pieces with a diameter of 30 mm and 85 mm, respectively(ASTM,2008b).The point load test is especially useful when core specimens cannot be extracted from fractured or weathered rock masses.Furthermore,the point load test is simpler and more economical compared to the UCS test.

2.The point load test

The point load test gradually applies a concentrated compressive force using conical platens on the rock specimen until it fails by splitting.The loading system consists of a loading frame,a hydraulic jack,and a pressure gauge.The test can be conducted in the feld or in the laboratory.The failure load is recorded and used to calculate the point load strength indexIs,according to the following equation(ASTM,2008b):

wherePultis the failure load(N),andDeis the equivalent core diameter(mm).

It has been found that the point load strength index depends on the specimen size(Thuro and Plinninger,2001).According to ASTM (2008b),the standard specimen diameterDis 50 mm.However,it may not always be possible to obtain specimens having a 50 mm in diameter(Brook,1980).Therefore,it is common to perform the test onspecimensofdifferentsizesanddeterminethepointloadstrength indexIs.The size is corrected to obtain the value ofIswhich would have been measured by a diametrical test withD=50 mm and isgiven the symbolIs50(ASTM,2008b).Several correction schemes for size have been developed over the years since the beginning of the pointload test(e.g.Broch and Franklin,1972;Brook,1985;Thuro and Plinninger,2001;ASTM,2008b).The specimen size correction proposed by ASTM(2008b)is implemented in this paper.

3.Geology of Dubai in the United Arab Emirates

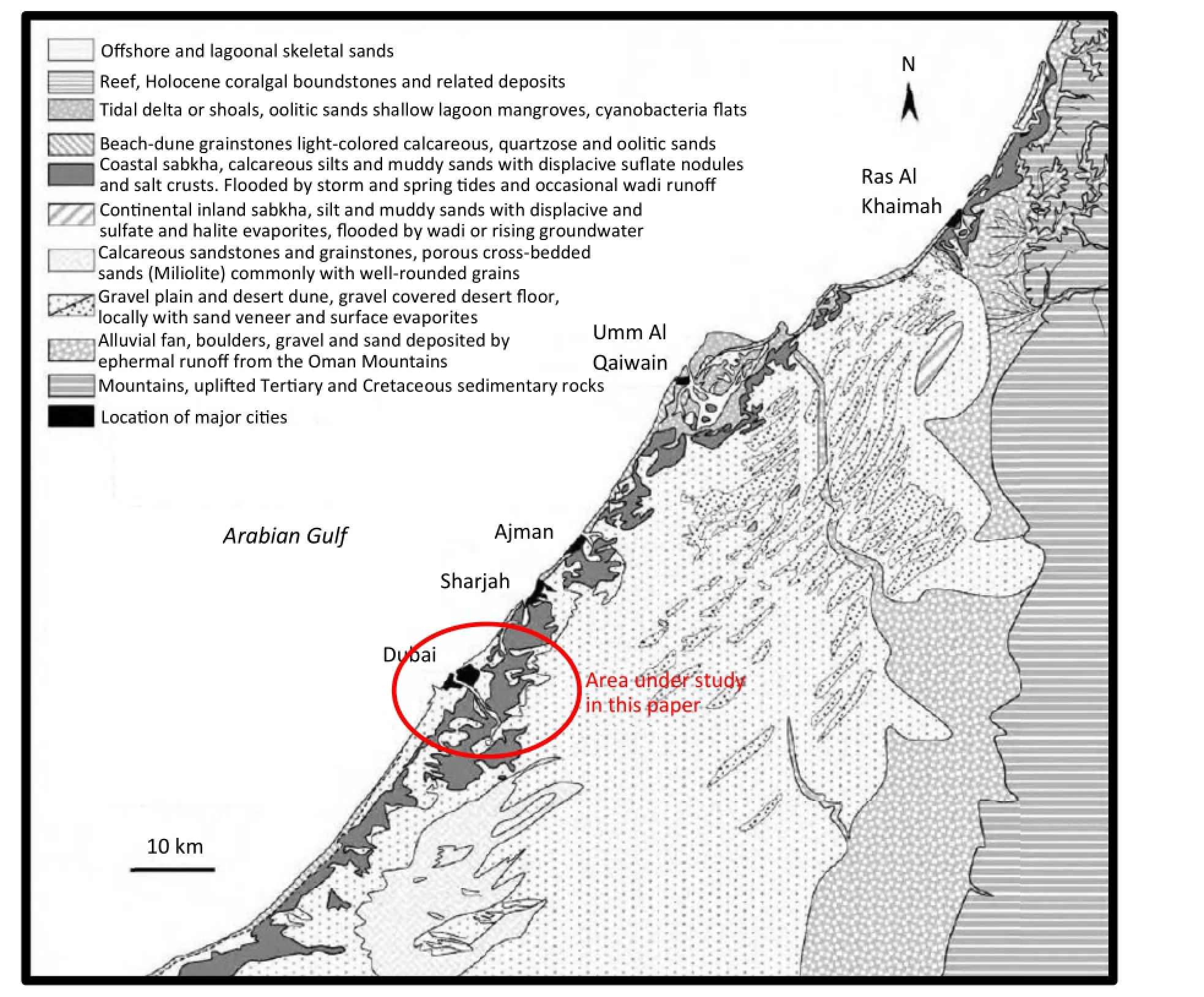

The near-surface geology of the United Arab Emirates can be divided into two groups:lower formation or‘Solid Geology’and upper formation or‘Superfcial Geology’.The Superfcial Geology comprises beach dune sands,marine sands and silts.The Solid Geology is composed of alternating beds of calcarenite/calcareous sandstone with some carbonate sand bands,gypsiferous sandstone with cemented sand layers,and calcisiltite and siltstone,from the top down(Beau et al.,2008).A geological map of the general location under investigation is presented in Fig.1,which shows the expected stratigraphy of the coastal areas of Dubai(Alsharhan and Kendall,2003).It consists of Quaternary marine,aeolian,sabkha and fuvial deposits that lie on the top of aeolianite and marine calcarenite(Ghayathi formation)which overlay the Barzman formation that is comprised of fuvial sediments characterized by poorly sorted conglomerates(Macklin et al.,2012).The rocks considered in this study belong to the Ghayathi formation described as marine calcarenite.

4.Mechanical and chemical characteristics of Dubai calcareous sandstone

Boreholes were drilled at a number of sites at Dubai in the United Arab Emirates.Rock samples were extracted using a double tube core barrel headed with diamond bit,producing a nominal core diameter of 76 mm.The boreholes extended into the rock at a depth of approximately 8 m(approximately-13 to-21 DMD (Dubai Municipality Datum)).Chemical testing of 21 specimens shows that the calcium carbonate(CaCO3)contents vary between 50.62%and 93.57%with an average of 71.32%.

According to ARGEMA classifcation of carbonate formations shown in Table 1(Le Tirant and Nauroy,1994),cemented formations with carbonate contents higher than 30%are defned as soft to hard carbonate rock.For geomaterials with calcium carbonate contents lower than 30%,the material performs as a silicate. Accordingly,it is warranted to describe such materials as“carbonate rock”(Le Tirant and Nauroy,1994).

The unconfned compressive strength is generally considered as the reference value for the compressive strength which is typically measuredusinguninstrumenteduniaxialcompressiontests (ASTM,2002a).The recorded values of the unconfned compressive strengths varied between 0.13 MPa and 15.75 MPa.Thus,the tested rock specimens were classifed as weak to very weak ones according to Mayne et al.(2001).

Fig.1.Geological map of the United Arab Emirates showing the area under study(Alsharhan and Kendall,2003).

Table 1ARGEMA classifcation of carbonate formations(Le Tirant and Nauroy,1994).

Alternatively,instrumented uniaxial compression tests may be used to defne the stress-strain response up to failure to determine the deformation characteristics of intact rock specimens in addition to its UCS(ASTM,2002b).The test is conducted byapplying an axial load to the specimen and recording the corresponding deformation.Young’s modulus(either secant or tangent)can be determined by plotting the stress-strain curves.In this study,the elastic modulus of the intact rock specimens is computed as the tangent value at 50%of the unconfned compressive strength and is known as the characteristic elastic modulus(ER50).The measured values of the characteristic elastic modulus(ER50)vary between 34.4 MPa and 1911.5 MPa with an average of 372 MPa,which are within the typical values reported for sedimentary rocks according to AASHTO (2012).

For the tested specimens,the Poisson’s ratio ranged between 0.22 and 0.365 with an average of 0.297.These values lie within the typical range of 0.1-0.46,with a mean of 0.29 proposed by Carmichael(1982)and Mayne et al.(2001).

5.Existing correlations between the point load strength index and UCS of rock

A plethora of correlations for estimating the UCS using the point load strength indexIs50have been developed over time.A selected summary of the available UCS-point load strength index correlations is presented in Table 2.More details about these relationships are given in corresponding references.One of the earliest and most widely used correlations was proposed by Broch and Franklin (1972)and Bieniawski(1975),based on tests performed on different rock types.Since then,several other correlations were formulated either for different types of rocks or for local formations.Most of the developed equations are linear with zero intercept,qu=kIs50(e.g.Broch and Franklin,1972;Bieniawski,1975; Beake and Suttcliffe,1980;Puech et al.,1988).The value of the constantkvaries between 3.1 and 25.This means that using the inappropriate equation may result in overestimating the UCS by approximately 800%.Other equations used to express the correlation betweenIs50and the UCS also include linear with non-zero intercept(e.g.Kim et al.,2004;Cha et al.,2007),power(e.g. Tsiambaos and Sabatakakis,2004;Min and Moon,2006;Salah et al.,2014),and exponential equations(e.g.Salah et al.,2014). The estimated UCSs using these correlations result in values with large variability.Thus,it is highly recommended to develop correlations to be used for specifc rock types and local geologies.

6.Correlation between the UCS and point load strength index for Dubai calcareous rock

The relationship between the point load strength index(Is50) and the UCS(qu)for Dubai calcareous sandstone is shown in Fig.2. As expected,the UCS increases with the point load strength index(Is50).Linear regression analysis is used to provide mathematical representation of the correlation between the point load strength index and the UCS.The best ft correlation is represented by Eq.(2). The coeffcientof determination(R2)for this equation is 0.65,which indicates a relativelygood relationship.It is also shown that most of the measurements are bounds by one standard deviation around the regression line.The standard error(calculated as the ratio of the standard deviation to the mean of the collected data)was computed as 40.6%. Alternatively,Eq.(3)represents a linear relationship between the UCS and point load strength index with a zero intercept with the results presented in Fig.3.This correlation has almost the same coeffcient of determination of 0.64 compared to Eq.(2).The standard error associated with Eq.(3)is computed to be 38.5%.

Table 2Correlations between the point load strength indexIsand the UCS.

Fig.2.Correlation between the point load strength index and UCS for Dubai calcareous sandstone(linear correlation with non-zero intercept).

Eq.(3)has an important advantage over Eq.(2)which yields a non-zero value for the UCS atIs50=0,implying that the rock has a quantifable strength although the measured strength is zero.The developed correlation is in close agreement with the equation proposed by Puech et al.(1988)for calcarenites of the Arabian-Persian Gulf.Considering the correlations reported for extremely soft rock(e.g.Puech et al.,1988;Elkateb,2009;Salah et al.,2014),a conversion factor(K)of 2.86-6.5 is suitable for such formations.

The relationship suggested by Broch and Franklin(1972)and Bieniawski(1975),which is one of the commonly used formulas, overestimates the UCS by approximately 800%when used for such rock formations.Such a large error is unacceptable and emphasizes the need for developing local correlations to estimate rock strength based on the point load test results.

Despite the relatively high scatter evident from the measured data presented in Figs.2 and 3,an acceptable correlation is still established with most of the data lying within one standard deviation from the proposed correlation.Part of the inconsistency may be attributed to the intrinsic variability in the physical and mechanical properties of rock due to its heterogeneous nature as indicated by Idris et al.(2011).The degree of natural variation in a specifc rock property depends on many factors such as the type of rock,the degree of weathering,the property investigated,etc. Kulhawy and Prakoso(2001)stated that there are substantial depositional variations in calcareous rocks leading to considerable ranges in rock properties.Their study showed that the coeffcient of variation reaches 39%and 59%for the strengths of calcareous rocks obtained using uniaxial compression and point load tests,respectively.Thus,the error in the predicted strengths may be partly explained by the natural variability in the rock properties.

Fig.3.Correlation between the point load strength index and UCS for Dubai calcareous sandstone(linear correlation with zero intercept).

7.Relationship between the UCS and elastic modulus

Therelationshipbetweentherockcharacteristicelastic modulusER50and the UCS is investigated using the ratio of rock elastic modulus to the UCS(modulus ratio),which was frst introduced by Deere(1968).The modulus ratio of the tested samples varied between 81 and 265 with an average of 140,which lie within the typical values reported by Mayne et al.(2001).The measured UCSs are plotted versus the characteristic elastic modulusER50as presented in Fig.4.The data are compared to the trend lines reported by Deere and Miller(1966)for sedimentary rocks.This classifcation describes the rock to be having high modulus ratio, which is greater than 1:500.For modulus ratios smaller than 1:200, the rock is described to be having low modulus ratio.Accordingly, the tested specimens,generally,have low modulus ratios.Lower values of the modulus ratio indicate that the rocks can sustainhigher deformation before fracturing compared to rock specimens with higher modulus ratios(Tziallas et al.,2009).

Fig.4.Characteristic elastic modulus versus the UCS of Dubai calcareous sandstone.

A best ft linear equation is used to represent the relationship between the rock elastic modulus and UCS,as presented in Fig.5, yielding the following relationship:

The coeffcient of determination(R2)for this equation is 0.96, indicating a strong correlation between the characteristic elastic modulus(ER50)and the UCS.Furthermore,the proposed correlation is in close agreement with the lower bound correlation for sedimentary rocks proposed by Tziallas et al.(2009),which estimates the rock modulus to be 124 times its UCS.

8.Conclusions

The point load test provides a fast and economic method for evaluating the UCS of rock specimens.The point load strength index(Is50)is empirically correlated to the UCS.There is a plethora of correlations for estimating the UCS from the point load strength index,as summarized in Table 1.A review of published literature shows the available correlations including linear,exponential and power functions.Existing correlations are typically developed using specifc data of certain rock types(e.g.Tsiambaos and Sabatakakis,2004)or regions(e.g.Puech et al.,1988;Elkateb, 2009).Alternatively,some of the published correlations are based on data collected from all rock types and/or different regions(e.g. Thuro and Plinninger,2001).The literature review shows that there is a large degree of variability in estimating the UCS from the point load strength index.Based on the data collected in Dubai,Eqs.(2) and(3)were derived for estimating the UCS of Dubai calcareous sandstone from the point load strength index.As discussed above, it is shown that the developedIs50-qucorrelation is considered acceptable despite the relatively large scatter.It is in close agreement with the equation proposed by Puech et al.(1988)for calcarenites of the Arabian-Persian Gulf.

Furthermore,it is also shown that the tangentelastic modulus of the intact rock specimens at 50%of the unconfned compressive strength(ER50)is approximately equal to 125.7qu.Thus the results of the point load test are used to estimate the strength and deformation parameters of intact rock through the proposed empirical relationships.Finally,it is important to develop site-specifc correlations fordifferent rock types because of the largevariation in the published correlations.Using“generic”correlations could lead to unrealistic evaluations of rock strength and deformation parameters.

Confict of interest

The authors wish to confrm that there are no known conficts of interest associated with this publication and there has been no signifcant fnancial support for this work that could have infuenced its outcome.

Fig.5.Correlation between the characteristic elastic modulus and the UCS of Dubai calcareous sandstone.

American Association of State Highway and Transportation Offcials(AASHTO). AASHTO LRFD bridge design specifcations.AASHTO;2012.

Akram M,Bakar MZA.Correlation between uniaxial compressive strength and point load index for salt-range rocks.Pakistani Journal of Engineering and Applied Sciences 2007;1:1-8.

Alsharhan AS,Kendall CGStC.Holocene coastal carbonates and evaporites of the southern Arabian Gulf and their ancient analogues.Earth-Science Reviews 2003;61:191-243.

American Society for Testing and Materials(ASTM).D2938 Standard test method for unconfned compressive strength of intact rock core specimens.West Conshohocken,USA:ASTM International;2002a.

ASTM.D3148 Standard test method for elastic moduli of intact rock core specimens in uniaxial compression.West Conshohocken,USA:ASTM International;2002b.

ASTM.D4543 Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances.West Conshohocken,USA:ASTM International;2008a.

ASTM.D5731 Standard test method for determination of the point load strength index of rock and application to rock strength classifcations.West Conshohocken,USA:ASTM International;2008b.

Beake RH,Suttcliffe G.Pipe pile drivability in the carbonate rocks of the southern Arabian Gulf.In:Proceedings of the international conference on structural foundations on rock,Sydney,Australia.Rotterdam,Netherlands:A.A.Balkema; 1980.

Beau P,Maghazy M,Chiriotti E.Importance of geological and geotechnical model upgrading for the tunnel/station interface during the TBM breakthrough on the Dubaimetroproject.In:Proceedingsoftheworldtunnelcongress 2008-undergroundfacilitiesforbetterenvironmentandsafety;2008. p.1130-8.

Bieniawski ZT.The point-load test in geotechnical practice.Engineering Geology 1975;9(1):1-11.

Broch E,Franklin JA.The point-load strength test.International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts 1972;9(6): 669-76.

Brook N.Size correction for point load testing.International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts 1980;17(4):231-5.

Brook N.The equivalent core diameter method of size and shape correction in point load testing.International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts 1985;22(2):61-70.

Carmichael RS.CRC handbook of physical properties of rocks,vol.2.CRC Press; 1982.

Cha AR,Song JH,Choi HS,Chun BS.The study on the correlation between unconfned compressive strength and point load strength within the geniss complex in Gyunggi Province.Journal of the Korean Geo-Environmental Society 2007;8(1):21-6(in Korean).

Deere DU.Geological consideration.In:Stagg KG,Zienkiewicz OC,editors.Rock mechanics in engineering practice.New York:John Wiley&Sons Ltd;1968. p.1-20.

Deere DU,Miller RP.Engineering classifcation and index properties of intact rock. Technical Report No.AFWL-TR-65-116.Urana,USA:University of Illinois;1966.

Diamantis K,Gartzos E,Migiros G.Study on uniaxial compressive strength,point load strength index,dynamic and physical properties of serpentinites from Central Greece:test results and empirical relations.Engineering Geology 2009;108(3-4):199-207.

Egyptian code for soil mechanics,design,and construction of foundations,vol.2. Cairo,Egypt:Ministry of Housing,2001.pp.272-276.

Elkateb T.The point load test in the Persian Gulf carbonate rocks.In:Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering,Vol.1;2009.p.372-5.

Idris MA,Saiang D,Nordlund E.Numerical analyses of the effects of rock Mass property variability on open stope stability.In:The 45th US rock mechanics/ geomechanics symposium,San Francisco,USA.American Rock Mechanics Association(AMRA);2011.p.1530-40.

Kahraman S.Evaluation of simple methods for assessing the uniaxial compressive strength of rock.International Journal Rock Mechanical and Mining Sciences 2001;38(7):981-94.

Kim HG,Koh YK,Oh KH.A study on the mechanical properties of the cretaceous tuffs in Goheung area.The Journal of Engineering Geology 2004;14(3):273-85 (in Korean).

Kim GM,Kim DH,Kang JS,Kang SS,Baek H.A study of the correlation between uniaxial compressive strength and point load strength index of limestone of Imgye area.Tunnel and Underground Space 2012;22(5):330-8(in Korean).

Kulhawy FH,Prakoso WA.Foundations in carbonate rocks and karst.In:Brandon TL, editor.Foundations and ground improvement.Reston,USA:American Society of Civil Engineers(ASCE);2001.p.1-15.

Le Tirant P,Nauroy JF.Design guides for offshore structures:foundations in carbonate soils.Technip Editions;1994.

Li D,Wong LNY.Point load test on meta-sedimentary rocks and correlation to UCS and BTS.Rock Mechanics and Rock Engineering 2013;46(4):889-96.

Macklin S,Ellison R,Manning J,Farrant A,Lorenti L.Engineering geological characterisation of the Barzaman Formation,with reference to coastal Dubai,UAE. Bulletin of Engineering Geology and the Environment 2012;71(1):1-19.

Mayne PW,Christopher BC,DeJong J.Manual on subsurface investigations-National Highway Institute Publication No.FHWA NHI-01-031.Washington,DC, USA:Federal Highway Administration;2001.

Min TK,Moon JK.A review of strength estimation method on Ulsan sedimentary rocks.Journal of the Korean Geotechnical Society 2006;22(8):63-75(in Korean).

Puech A,Beuce JP,Colliat JL.Advances in the design of piles driven into noncemented to weakly cemented carbonate formations.In:Proceedings of the International Conference on Calcareous Sediments,Vol.1;1988.p.305-12. Perth,Australia.

Salah H,Omar M,Shanableh A.Estimating unconfned compressive strength of sedimentary rocks in United Arab Emirates from point load strength index. Journal of Applied Mathematics and Physics 2014;2:296-303.

Singh TN,Kainthola A,Venkatesh A.Correlation between point load index and uniaxial compressive strength for different rock types.Rock Mechanics and Rock Engineering 2012;45(2):259-64.

Thuro K,Plinninger RJ.Scale effects in rock properties.Part 2:point load test and point load strength index.In:Rock mechanics-a challenge for society,proceedings of the ISRM regional symposium EuroRock 2001.CRC Press;2001. p.175-80.

Tsiambaos G,Sabatakakis N.Considerations on strength of intact sedimentary rocks.Engineering Geology 2004;72(3-4):261-73.

Tziallas GP,Tsiambaos G,Sarglou H.Determination of rock strength and deformability of intact rocks.Electronic Journal of Geotechnical Engineering 2009;14: 1-12.

Dr.Amr Farouk Elhakimis an assistant professor at the Faculty of Engineering,Cairo University.In July 1995,he earned his B.Sc.in Civil Engineering with honors degree. He worked as a teaching/research assistant in the Soil Mechanics and Foundations Research Laboratory of Cairo University.In the same year,he enrolled for a Masters program in Geotechnical Engineering in Cairo University, where he earned his M.Sc.in July 1998.He then joined the Geosystems Engineering Group at Georgia Tech,where he worked under the supervision of Prof.Paul W.Mayne.In May 2001,he earned another Masters in Geotechnical Engineering from Georgia Tech.He then fnished his Ph.D in Summer 2005 from the same university.He has several publications in the felds of in-situ testing,deep excavations,design of axially and laterally loaded piles,displacements of shallow foundations and the use of small strain soil modulus in foundation design.Furthermore,he has worked in geotechnical consulting in several projects.

*Tel.:+20 1111921320.

E-mail address:aelhakim@hotmail.com.

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.06.003

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

Journal of Rock Mechanics and Geotechnical Engineering2015年4期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A theoretical derivation of the Hoek-Brown failure criterion for rock materials

- Strength properties of soft clay treated with mixture of nano-SiO2and recycled polyester fber

- Case studies of high-sensitivity monitoring of natural and engineered slopes

- Key technologies of drilling process with raise boring method

- Analysis of horizontal displacement distribution caused by single advancing longwall panel excavation

- Susceptibility assessment of debris fows using the analytic hierarchy process method-A case study in Subao river valley,China