雾收集用单向导湿针织物涂层摩擦制备及性能研究

摘要:随着人口爆炸、工业和高新产业发展的持续,工厂和居民对清洁用水需求日益增加,水雾收集器件不断涌现,而现有水雾收集器件多采用飞秒激光刻蚀等方式达到符合要求的浸润性表面,对设备要求较高。本文基于简便的室温自发胶凝作用,温和构建凝胶聚合物基质,通过引入反应组分以控制胶凝成形期间的微观形貌与表面能分布,经室温修饰形成超疏水聚合物复合材料。以针织物为基底、摩擦为手段构制Janus针织物涂层,利用其润湿不对称性实现单向导湿,进而在捕雾集水的同时减缓水蒸发以提升应用效率,达到低成本且高效的雾收集。

关键词:雾收集;单向导湿;针织物;涂层;摩擦制备;Janus

中图分类号:TS195.597

文献标志码:A

文章编号:10017003(2025)01004908

DOI:10.3969 j.issn.1001-7003.2025.01.006

基金项目:新疆维吾尔自治区自然科学基金青年科学基金项目(2022D01C68);新疆维吾尔自治区重点研发任务专项项目(2022B01045-4);新疆维吾尔自治区天池博士计划科研启动项目(TCBS202011);新疆大学博士启动基金项目(BS210215)

作者简介:张静(1999),女,硕士研究生,研究方向为纺织基雾收集功能材料。通信作者:陈诚,副教授,450548205@qq.com。

水是生命之源,但由于近百年来世界人口的急剧扩增、工业用水量的剧增和环境污染的进一步恶化,使得世界各地呈现不同程度的水资源危机,尤其在沙漠和基础设施有限的内陆地区,缺水问题已经对人类的基本生存造成了极大的威胁[1-2]。夜晚至清晨的时间段温度较低,近地面的水汽可在此时间段悬浮成液态水滴,这些小水滴积聚便可形成雾。雾中每立方厘米含有10~1 000个微小液滴[3],其尺寸为1~50 μm[3],总量占全球淡水资源总量的10%[4],因而雾滴被视为一种可获取的淡水资源。因此在沙漠或山地等淡水资源匮乏但富含水雾的环境下,基于有利地形和温度差异实施水雾收集是一种有效缓解淡水资源短缺的手段[5-6]。

当前水雾收集材料的润湿性能大致可分为超疏水和超亲水两类[7-8],制备方法大多为化学刻蚀法、3D打印法、模板法、浸涂法等[9-11]。Han等[12]以SiO2作为壳材,聚苯乙烯(PS)作为芯材,利用模板刻蚀法制得中空多孔二氧化硅材料,在其壳层上接枝聚吡咯(Ppy)后成功制备出超亲水性光热中空纳米胶囊(SPHN),该材料的特殊结构可吸附水雾达到蓄水储水作用;Zhang等[13]通过光蚀刻、酸蚀刻、阳极氧化和氟烷基硅烷改性等处理构建了一种耐久性良好的超疏水表面,可用于水雾收集。超疏水性水雾收集材料能够轻易地在其表面凝结雾滴,再不断汇聚为较大的液滴后收集以达到捕雾集水目的,但此类材料在大气中难以捕获较小的雾滴,致使雾收集效率受到限制;超亲水性水雾收集材料能够捕获空气中微小雾滴,并迅速发生浸润行为,但在润湿后会形成水膜,此时微小雾滴便难以再次在表面凝结,导致雾收集效率降低。另外,在长期的水雾收集过程中,上述仅具备单一润湿性能的水雾收集材料易受环境影响,进一步导致其水雾收集效率降低[14-15]。鉴于此,越来越多的科研人员致力于开发具备润湿不对称性的水雾收集材料,以期通过其特有的润湿梯度与差异提升收集淡水的效能。

本文基于简便易操作的室温自发胶凝作用,温和构建凝胶聚合物基质,通过引入高级烷基醇和纳米级无机生物质材料以控制胶凝成形期间的微观形貌与表面能分布,经室温修饰形成超疏水聚合物复合材料。以针织物为基底、摩擦为实施手段,构制特殊润湿性Janus针织物涂层,利用其润湿不对称特性实现单向导湿功能,可大幅降低收集水分的再蒸发率,使环境雾气自超疏水面定向输运至超亲水面,展现出高效的捕雾集水能力。

1 试 验

1.1 试剂与仪器

试剂:分析纯双季戊四醇五丙烯酸酯(5Acl)、分析纯支化聚乙烯亚胺(BPEI)、化学纯四氢呋喃(THF)、化学纯十八胺(OTCA)、化学纯十四醇(TD)(阿拉丁试剂(上海)有限公司),化学纯无水乙醇(EtOH)(天津市北联精细化学品开发有限公司),分析纯羟基磷灰石(HA)(上海麦克林生化科技有限公司),分析纯氢氧化钠(片)、分析纯亚甲基蓝(MB)(天津市北联精细化学品开发有限公司),商品级油溶红(河南金鸿彩化工产品有限公司),分析纯正己烷(天津市鑫铂特护工有限公司),DM5128无醛黏合剂(广东德美精细化工集团股份有限公司),分析纯二氯甲烷(天津市致远化学试剂有限公司)。

仪器:CP153电子天平(奥豪斯仪器常州有限公司),JC2000D1接触角测量仪(上海中晨数字技术设备有限公司),A6100摄像机(索尼(中国)有限公司),KLS-088自动雾化喷雾器(中山市凯乐诗电器有限公司),DF-101Z智能集热式恒温磁力搅拌锅(巩义市英峪仪器厂)。

1.2 方 法

在离心管中加入特定质量的5Acl及适量的EtOH,摇晃至5Acl充分溶解后加入TD、HA,试验过程中多次调整HA的用量,用以探求最佳的物理构型与润湿性能,摇晃均匀后加入23%的BPEI。在室温条件下充分反应12 h,用无水乙醇进行充分清洗,随后加入适量THF、OTCA,摇晃至OTCA完全溶于THF中。在25 ℃反应48 h后用无水乙醇充分清洗,放置空气氛围自然晾干,最终制得十四醇 羟基磷灰石低表面能胶凝聚合物(Low Surface Energy-Gelatinization Polymer@Tetradecanol Hydroxyapatite,LSE-GP@TD OH)。

涤盖棉针织物的涤纶面呈超疏水,棉面呈超亲水,较其他织物而言,其本身具有单向导湿特性,且拥有良好的吸湿透湿性能,可通过相应的后续处理提升其单向导湿性能来实现水雾收集。因此,本文选取8 cm×8 cm的涤盖棉作为基材,配制一定比例的氢氧化钠溶液置于水浴锅中,待升温至95 ℃时,用镊子夹取涤盖棉织物,将其完全浸入氢氧化钠溶液,恒温处理1 h后取出织物烘干,制得超亲水性涤盖棉织物。利用DM5128黏合剂对LSE-GP@TD HA进行喷雾处理后,均匀摩擦至碱减量处理后的涤盖棉织物涤纶面对其进行超疏水整理,随后放至80 ℃烘箱进行固化,最终制得单向导湿织物。

1.3 性能测试及表征

1.3.1 接触角与滚动角

采用JC2000D1接触角测量仪,用5 μL的去离子水测量样品接触角、10 μL的去离子水测量样品滚动角。

1.3.2 傅里叶变换红外光谱(FTIR)

借助红外光谱仪在500~12 000 cm-1内进行扫描测试,对TD、HA、LSE-GP、LSE-GP@TD HA的特征官能团进行表征。

1.3.3 X射线衍射分析(XRD)

利用X射线粉末衍射仪测试TD、HA、LSE-GP、LSE-GP@TD HA的XRD曲线。

1.3.4 单向导湿效率

通过相机摄像,用针管吸取2 mL的去离子水滴加到对照样及样品表面,记录0、50、100 s时样品导湿状态及水滴完全透过单向导湿织物的时间。

1.3.5 单向导湿速率

采用相机摄像,分别滴加5 μL的去离子水在原始涤盖棉和LSE-GP@TD HA基单向导湿织物的涤纶面,记录水滴完全透过织物的时间。

1.3.6 水雾收集速率

采用KLS-088自动雾化喷雾器模拟自然界的雾气,喷口距各类样品的垂直距离为5 cm,将出雾速率固定在20 cm s,样品织物的大小为8 cm×8 cm,记录0、15、30、40、50、60 min时的集水量。

2 结果与分析

2.1 LSE-GP@TD HA的合成与性能分析

将5Acl和BPEI置于EtOH中使其发生凝胶化,引入TD、HA调控润湿性能,基于5Acl的丙烯酸酯基与BPEI的氨基的1,4-共轭加成反应构筑反应性微纳结构。将其浸泡在溶有OTCA的THF溶液中进行低表面能修饰,即OTCA的氨基与凝胶体系上未反应的丙烯酸酯基反应,从而使长烷基链接枝到凝胶产物以实现超疏水化。由图1(a)(b)可见,LSE-GP@TD HA展现出良好的抗水冲击性、内外结构完整且拒水性均匀。在各类基材表面分别均匀摩擦LSE-GP@TD HA后所形成的表面上,滴加亚甲基蓝染色水溶液,该液滴呈现圆球状,未发生浸润现象,说明上述摩擦表面达到明显的抗润湿效果。经润湿性能测试,发现砂纸上的摩擦表面接触角为153°,滚动角为1°;棉织物的摩擦表面接触角为162°,滚动角为10°;涤纶织物的摩擦表面接触角为158°,滚动角为10°;瓦楞纸的摩擦表面接触角为161°,滚动角为3°(图1(c))。综上,各涂层的接触角都大于150°,滚动角小于或等于10°,达到了仿荷叶效应的低黏附超疏水功能,表明合成产物通过在基材表面进行简单摩擦即可赋予其良好的抗润湿能力。

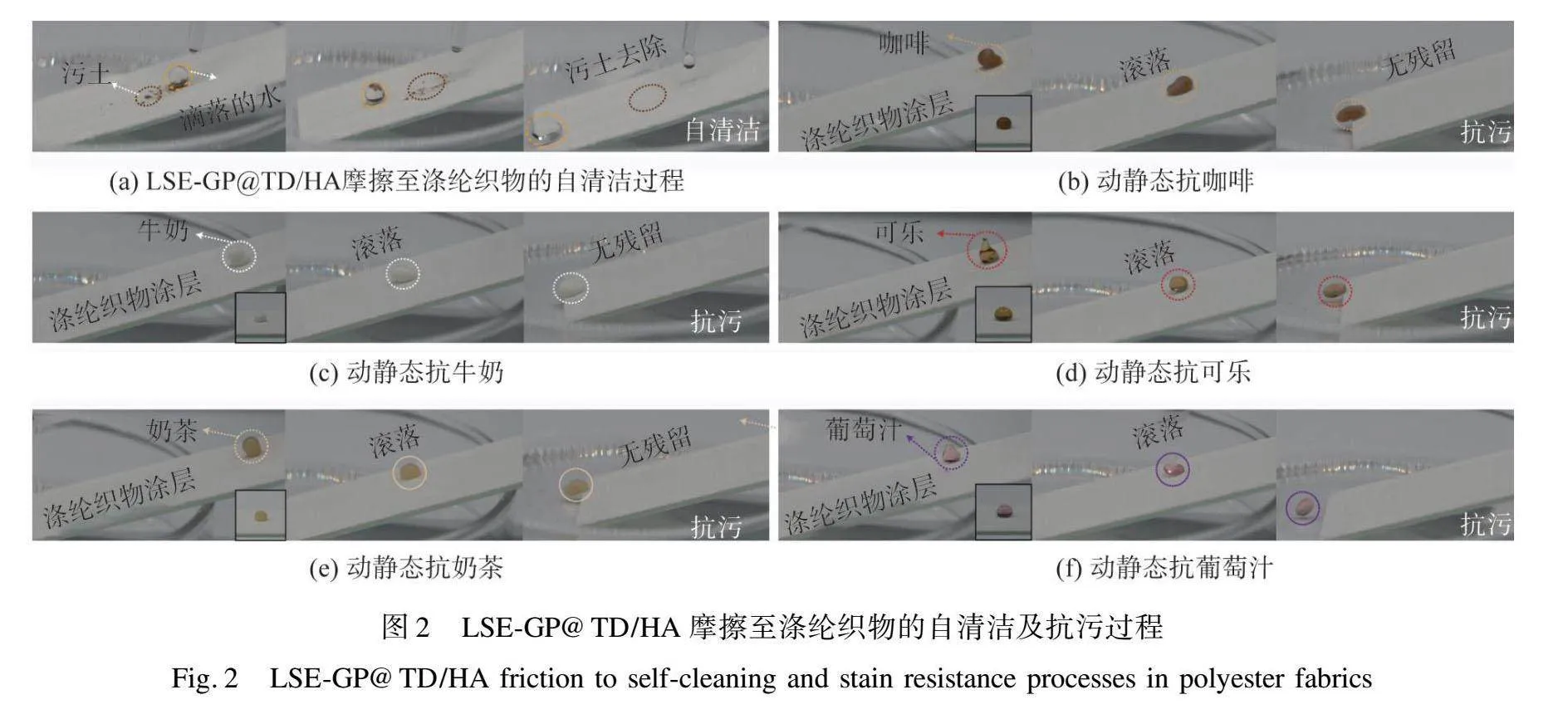

将LSE-GP@TD HA均匀摩擦至涤纶织物的倾斜表面,可见滴落在倾斜状态的涤纶织物摩擦表面的液滴携污垢滚落,且织物涂层表面不沾有任何污垢及液滴,如图2(a)所示;向涤纶织物摩擦表面滴加的各类污水滴可快速滚落,织物涂层表面没有任何液滴残留,如图2(b~f)所示;而将污水滴滴加到涤纶织物涂层的平面,其液滴呈现圆球状,并没有发生浸润铺展行为,上述结果表明LSE-GP@TD HA基涤纶织物涂层具有明显的仿荷叶效应的自清洁及动静态抗污效果。

2.2 LSE-GP@TD HA的理化信息表征

为研究LSE-GP@TD HA的化学信息,本文采用FTIR及XRD分析TD、HA、LSE-GP、LSE-GP@TD HA的特征官能团及衍射图谱,表征LSE-GP@TD HA的化学组成。由图3(a)可见,TD的FTIR特征图谱中,在2 920.11 cm-1和2 850.67 cm-1处出现明显的吸收峰,这归属于饱和C─H键的伸缩振动;另外在1 064.66 cm-1处出现的吸收峰来源于十四醇中所含伯醇的C─OH伸缩振动。HA的特征图谱中,在567.04 cm-1和601.76 cm-1处出现的伸缩振动峰对应于HA中O←P(OH)的弯曲振动,在3 068.17 cm-1处的弱吸收峰归属于HA的—OH基团;将LSE-GP的特征图谱与LSE-GP@TD HA的特征图谱进行对比观察可得,LSE-GP并未出现TD和HA的特征吸收峰,而LSE-GP@TD HA曲线中HA和TD的特征吸收峰明显存在,说明LSE-GP@TD HA中含有HA和TD成分。

图3(b)展示了TD、HA、LSE-GP、LSE-GP@TD HA的XRD图谱,可见TD曲线在21.83°和24.87°处出现特征峰,且峰形较尖锐、强度较高,说明十四醇的结晶性能较好,HA曲线在25.93°和32.01°附近有清晰的特征衍射峰,分别对应羟基磷灰石(002)和(211)晶面的特征衍射峰。LSE-GP@TD HA曲线中未观察到明显的TD特征衍射峰,原因可能为TD的含量较少,抑或是HA的引入影响了其结晶度;HA的特征峰在LSE-GP@TD HA出现的位置高度一致,说明产物结晶性能完整,同时进一步证实目标产物得以成功制备。

2.3 LSE-GP@TD HA基单向导湿织物的制备及性能分析

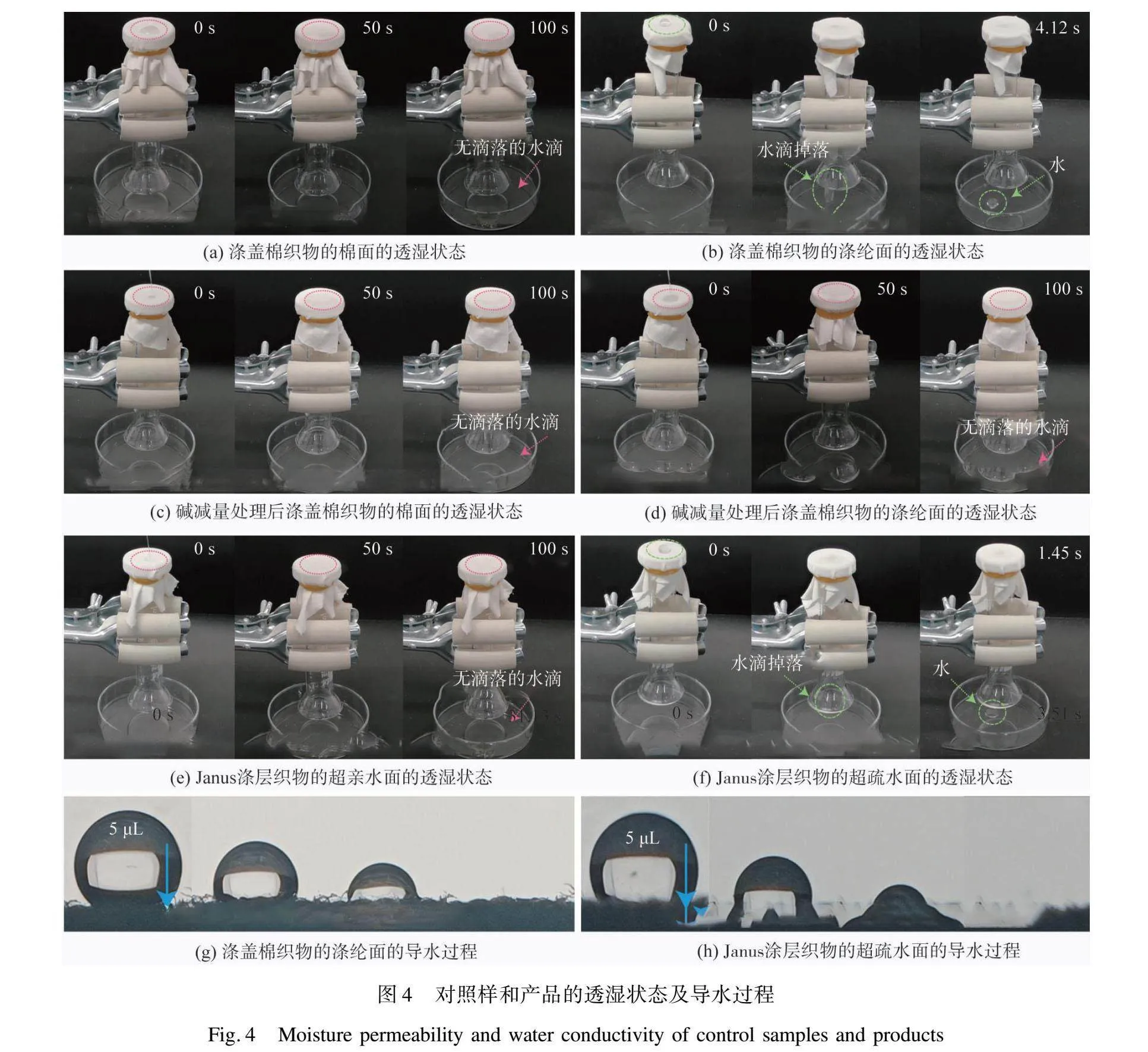

向涤盖棉的棉面滴加2 mL水滴,液滴完全铺展浸润,未发生运输现象,如图4(a)(b)所示;而滴加在涤纶面的水滴能从疏水面运至亲水面,然而其输运时间较长(4.12 s);随后对

其进行碱减量处理,处理后的涤盖棉织物双面具有良好的亲水性,如图4(c)(d)所示,水滴仅能润湿织物,而未发生定向水运输。由此可说明,碱减量处理后的涤盖棉织物不具备单向导湿能力,原始涤盖棉织物可实施定向水输运,但其速率较为缓慢。将经DM5128黏合剂喷雾处理后的LSE-GP@TD HA均匀摩擦至碱减量处理后的涤盖棉织物的涤纶面,从而制得LSE-GP@TD HA基涂层织物,如图4(e)(f)所示。据前述测试结果可知,该成形涂层织物一面为超疏水性,另一面呈超亲水性,达到显著的润湿不对称状态,当水滴滴至超亲水面,则立刻浸润铺展;与之相反,水滴能够从超疏水面迅速地运输到超亲水面,其时间仅为1.45 s,表明该Janus涂层织物展现出单向水输运特性。由图4(g)(h)可见,水滴需要31.13 s才能从原始涤盖棉织物的涤纶面输送至棉面,而Janus涂层织物的超疏水面输送水滴至超亲水面仅需3.51 s,这说明Janus涂层织物具有良好的单向导湿能力。

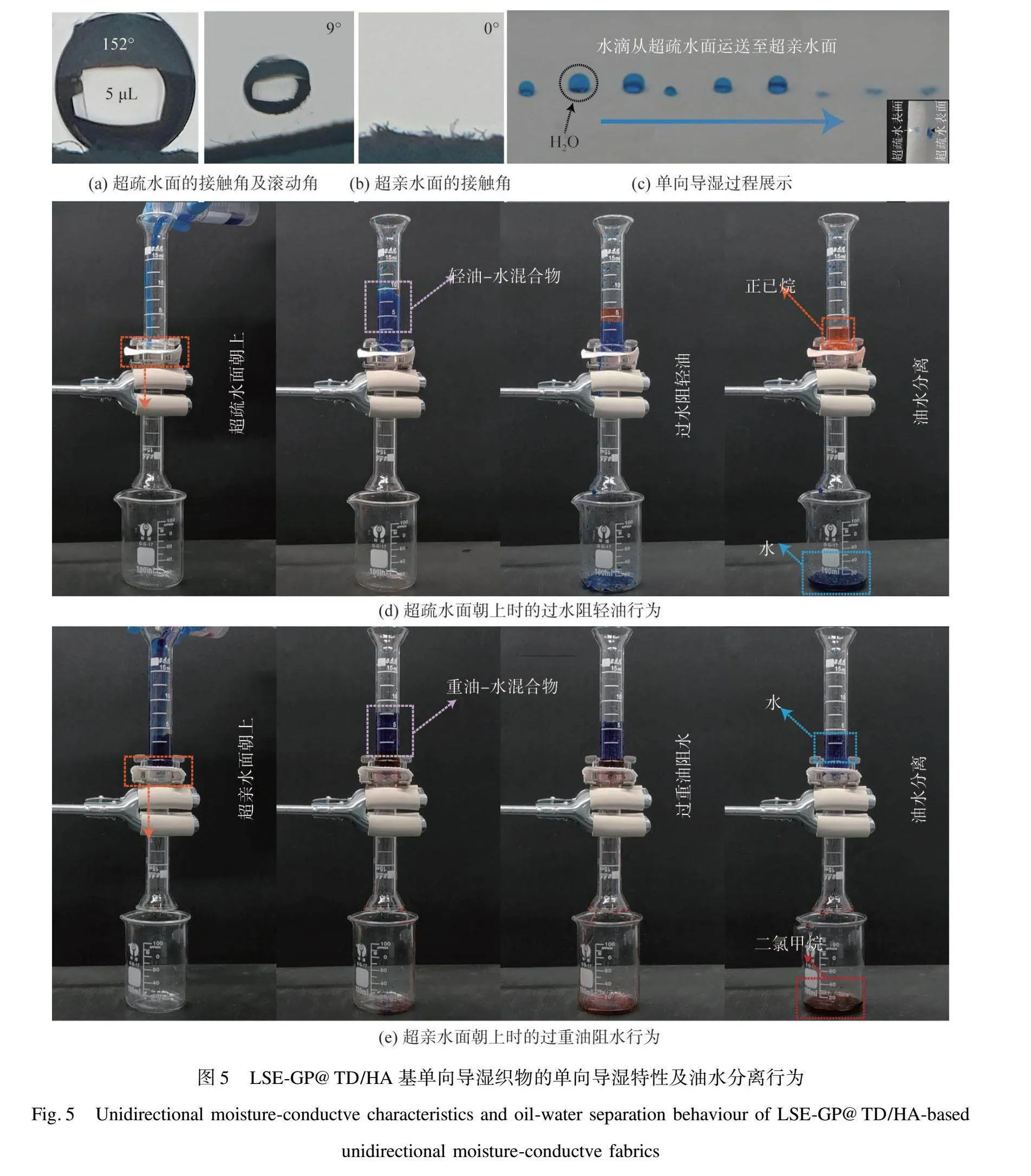

由图5(a)(b)可见,LSE-GP@TD HA基Janus涂层织物的涤纶面接触角为152°、滚动角为9°,呈超疏水性;棉面的接触角为0°,呈超亲水性。由图5(c)可见,亚甲基蓝染色水溶液会由超疏水面导向超亲水面,右下角展示织物正反两面,对比观察可得超亲水面液滴痕迹明显,证明其具有单向导湿特性。由图5(d)(e)可见,LSE-GP@TD HA基单向导湿织物超疏水面朝上时,水会从超疏水面透到超亲水面形成水膜,根据水油不互溶原理,此时展现过水阻轻油(正己烷)的分离行为;超亲水面朝上时,油会从超亲水透到超疏水面形成油膜,展现过重油(二氯甲烷)阻水的分离行为。因此,该单向导湿织物超疏水面朝上时,可过水阻轻油;超亲水面朝上时,可过重油阻水,从而实现选择性油水分离。

2.4 纺织基水雾收集器件的应用效果

对棉织物、涤盖棉织物、碱减量处理涤盖棉织物及LSE-GP@TD HA基单向导湿织物进行水雾收集测试,其中喷雾速率为20 cm s。将四种测试织物固定在漏斗上,漏斗下方放置10 mL量筒,喷雾口距离样品织物约5 cm,记录四种样品在0、15、30、40、50、60 min时收集的水量,如图6所示。由图6(a~c)可见,从40 min开始,棉织物、涤盖棉织物及碱减量处理涤盖棉织物收集的水量增加并不明显,经60 min测试后,观察到棉织物的水收集量为5.9 mL、涤盖棉织物的水收

集量为5.6 mL、碱减量处理涤盖棉织物的水收集量为6 mL。由图6(d)可见,LSE-GP@TD HA基单向导湿织物40 min时水收集量为5 mL,从此时间点开始的水雾收集量明显增加,50 min时的水收集量为7.8 mL,60 min后总收集水量为10.3 mL,相较于前述测试样品,其水雾收集效果突出。上述测试结果表明,LSE-GP@TD HA基单向导湿织物较对照样的水雾收集总量提高了42%~46%,因此该单向导湿织物具有用于构造纺织基捕雾集水器件的潜力,有望实现低成本、易操作地收集雾水。

2.5 水雾收集机理分析

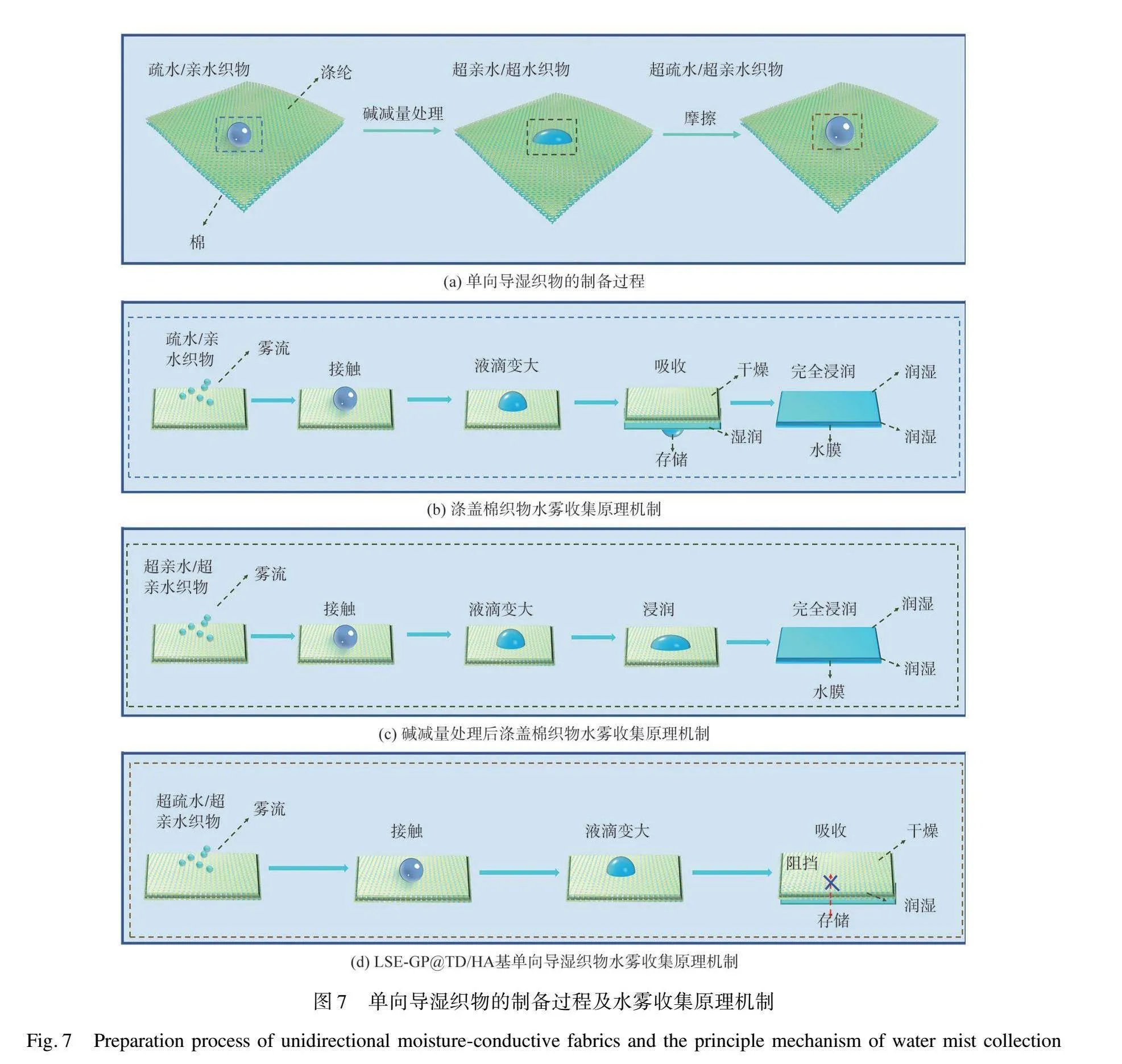

由图7(a)可见,涤盖棉的涤纶面具有疏水性,棉面呈亲水性,是疏水 亲水织物,将其进行碱减量处理后,涤棉两面都呈超亲水性,是超亲水 超亲水织物,再将LSE-GP@TD HA摩擦至涤纶面后,涤纶面具有超疏水性,棉面依旧呈现为超亲水性。由图7(b)可见,涤盖棉织物疏水面能够凝结水滴,运输至亲水面,但因涤纶面的疏水性并不显著,当实施长时间的水雾收集后,涤纶面的疏水性会被破坏即被打湿,继而形成水膜,此时疏水面便难以捕捉细小的雾滴,导致水雾收集速率下降。由图7(c)可见,雾滴能够在超亲水 超亲水织物表面快速浸润,但在形成水膜后,便很难再次捕获雾滴,导致其水雾收集速率降低。由图7(d)可见,当雾流接触到超疏水面时,小液滴会不断扩增成大液滴,并不断受到超亲水面的吸引,在静水压、毛细效应作用下自发地转移到超亲水面进行汇聚,最终捕集输送的水滴在重力的作用下掉落,达到集水目的;水雾收集期间超亲水面可形成水膜,导致前期收集的水分无法从超亲水面透过,使其再蒸发率大幅度降低。因此,基于摩擦制备的单向导湿涂层针织物可以在雾气氛围中实现有效的淡水收集。

3 结 论

本文构筑的LSE-GP@TD HA具有优良的超疏水特性,在碱减量处理涤盖棉织物涤纶表面上进行摩擦构制后,该织物呈现单向导湿特性;利用其定向水输运能力能够在雾气氛围中捕获水雾,进而聚集成水滴以实现淡水收集。与传统水雾收集材料相比,LSE-GP@TD HA基单向导湿织物的水雾收集效率为10.3 mL h,有解决装置制作工艺复杂、成本高等问题的可能性。同时,该单向导湿织物规避了一些常规水雾收集材料存在的收集水分再蒸发问题,能够改善或避免收集水分再蒸发,可为水雾收集材料提供新的研发思路。

参考文献:

[1]王煦漫, 卢俊龙, 张彩宁, 等. 超疏水棉织物制备及其雾收集性能[J]. 西安工程大学学报, 2024, 38(3): 1-7.

WANG X M, LU J L, ZHANG C N, et al. Preparation of superhydrophbic cotton fabric and its fog collection performance[J]. Journal of Xi’an Polytechnic University, 2024, 38(3): 1-7.

[2]TONG L H. Cyclodextrin Chemistry: Foundation and Application[M]. Beijing: Science Press, 2001.

[3]SALEHI M. Global water shortage and potable water safety: Today’s concern and tomorrow’s crisis[J]. Environment International, 2022, 158: 106936.

[4]MITTAL A, BRAJPURIYA R, GUPTA R. Solar steam generation using hybrid nanomaterials to address global environmental water pollution and shortage crisis[J]. Materials Today Sustainability, 2023, 21: 100319.

[5]AZEEM M, NOMAN M T, PETRU M. Surface wettability of vertical harps for fog collection[J]. Surfaces and Interfaces, 2022, 30: 101842.

[6]CASTELLI G, SANCHEZ A C, MESTRALLET A. Fog as unconventional water resource: Mapping fog occurrence and fog collection potential for food security in Southern Bolivia[J]. Journal of Arid Environments, 2023, 208: 104884.

[7]李慧慧, 王群, 贾伟科, 等. 多功能超疏水纺织品的制备及应用研究进展[J]. 现代纺织技术, 2022, 30(3): 39-46.

LI H H, WANG Q, JIA W K, et al. Recent advances in the fabrication and application of multi-functional super-hydrophobic textiles[J]. Advanced Textile Technology, 2022, 30(3): 39-46.

[8]赵文潇, 王群, 龚向宇, 等. 超疏水纺织品的构建及其应用研究[J]. 丝绸, 2023, 60(12): 42-50.

ZHAO W X, WANG Q, GONG X Y, et al. Study on the construction and applications of supergydrophobic textiles[J]. Journal of Silk, 2023, 60(12): 42-50.

[9]范郡哲, 孙文, 王立达, 等. 超疏水不锈钢网的制备与集雾性能研究[J]. 现代化工, 2022, 42(11): 100-105.

FAN J Z, SUN W, WANG L D, et al. Preparation of superhydrophobic stainless steel mesh and research on its performance in fog collection[J]. Modern Chemical Industry, 2022, 42(11): 100-105.

[10]LIANG Z H, FENG R, WU J M, et al. Temperature-gradient-induced enhanced fog collection on polymer brush surfaces[J]. Chemical Engineering Journal, 2023, 455: 140785.

[11]张笑迎, 王晗. PDMS超疏水表面的制备及集雾应用[J]. 化工管理, 2021(6): 9-11.

ZHANG X Y, WANG H. Preparation and fogging application of PDMS superhydrophobic surface[J]. Chemical Engineering Management, 2021(6): 9-11.

[12]HAN X F, ZHONG L S, ZHANG L, et al. Efficient atmospheric water harvesting of superhydrophilic photothermic nanocapsule[J]. Small, 2023, 19(47): 2303358.

[13]BAI H Y, WANG X S, LI Z, et al. Improved liquid collection on a dual-asymmetric superhydrophilic origami[J]. Advanced Materials, 2023, 35(17): 2211596.

[14]ZHAN D Y, CHEN X G, XIA Y, et al. Improved fog collection on a hybrid surface with acylated cellulose coating[J]. ACS Applied Materials amp; Interfaces, 2024, 16(21): 27657-27667.

[15]YU A H, HE S P, FU F Y, et al. Solid-like slippery surface for anti-icing and efficient fog collection[J]. Materials Today Sustainability, 2024, 26: 100754.

A study on the rubbing preparation and performance of unidirectional moisture-conductive knitted fabric coatings for fog collection

ZHANG Jing, GUANG Jing, CHEN Chen

(1.Key Laboratory for Characteristic Textiles amp; Cleaner Dyeing and Finishing Technology, Xinjiang University, Urumqi 830017, China;

2.Key Laboratory for Smart amp; Green Textiles of Xinjiang, Urumqi 830017, China)

Abstract:Water is the source of life, but due to the rapid expansion of the world population, the dramatic increase in industrial water consumption and the further deterioration of environmental pollution in the last hundred years, the world has presented different degrees of water crisis, especially in the deserts and inland areas with limited infrastructure. The problem of water scarcity has posed a great threat to the basic survival of mankind, so it is urgent to develop fog harvesting technology to alleviate the water shortage problem. Fog is formed when water vapour nears the ground, and suspends as liquid water droplets during the cooler night to early morning hours to form fog. Fog containes 10-1 000 tiny droplets per cubic centimeter, with sizes ranging from 1-50 μm, and it accounts for 10 % of the freshwater resources in the world, and considers to be an accessible freshwater resource. Therefore, in environments such as deserts or mountains, where freshwater is scarce but fog is abundant, fog harvesting based on favourable terrain and temperature differences is an effective means of alleviating freshwater scarcity. Currently, the wetting properties of fog collection materials include superhydrophobic and superhydrophilic ones. Water droplets tend to condense on the surface of the hydrophobic material and grow into large droplets, and then they are removed from the surface. However, the superhydrophobic material surface could make larger droplets bounce back, causing it difficult to adhere the great mass of moisture in the mist. Droplets could be captured by superhydrophilic fog collection materials, but when the surface forms a water film, the tiny droplets would be difficult to condense on the surface again, leading to a reduction in fog collection efficiency. In addition, in the long-term process of fog collection, the single wetting performance of the fog collection material is vulnerable to environmental influences, which further leads to the reduction of the fog collection efficiency. In view of this, more and more researchers are committed to developing fog collection materials with wetting asymmetry in order to enhance the efficiency of freshwater collection through their unique wetting gradients.

In this paper, based on a simple spontaneous gelation at room temperature, a gel polymer matrix was mildly constructed, and superhydrophobic polymer composites were formed by room temperature modification through the introduction of advanced alkyl alcohols and nanoscale inorganic biomaterials to control the microscopic morphology as well as surface energy distribution during the gelation formation. The special wettability Janus knitted fabric coating was constructed by using knitted fabrics as the substrate and friction as the means of implementation. The unidirectional moisture conduction was achieved by using its wetting asymmetry property, which could significantly reduce the re-evaporation rate of the collected water, and made the ambient fog transported from the superhydrophobic surface to the superhydrophilic surface in a directional manner, showing the highly efficient ability of capturing the fog. The gelling polymer constructed in this paper has excellent superhydrophobic properties, and after rubbing the fabric on the polyester surface of alkali reduction-treated polyester-covered cotton fabrics, the fabrics exhibit unidirectional moisture conductivity. Its directional water transport capability coud be utilized to capture fog in the atmosphere, which could be aggregated into water droplets for freshwater collection. When the fog flow contacts the superhydrophobic surface of the coating, the small droplets would be continuously expanded into large droplets, and continuously attracted by the superhydrophilic water surface. Under hydrostatic pressure and capillary effect, fog spontaneously transferres to the superhydrophilic water surface for convergence, and ultimately falls under the action of gravity to achieve the purpose of water collection. The superhydrophilic water surface during the collection of fog could form a water film, which results in the fact that the collection of water could not be collected through the superhydrophilic water surface, leading to the significant reduction in the re-evaporation rate. Therefore, the unidirectional moisture-conducting coated knitted fabric prepared based on friction could achieve effective freshwater collection in a foggy atmosphere.

Compared with conventional fog collection materials, the Janus knitted fabric coating has a water collection of 5 mL at 40 min, and from this point onwards the fog collection increases significantly; the water collection at 50 min is 7.8 mL, and the total water collection after 60 min is 10.3 mL, which is an outstanding effect of fog collection in comparison with the cotton fabrics, polyester-covered cotton fabrics and alkali reduction-treated polyester-covered cotton fabrics. The Janus knitted fabric coating constructed in this paper has fog collection efficiency of 10.3 mL h, with the possibility of solving the problems of complexity and high cost of the device fabrication process.

Key words:fog collection; unidirectional moisture conduction; knitted fabric; coating; rubbing preparation; Janus