Identifying the enhancement mechanism of Al/MoO3 reactive multilayered films on the ignition ability of semiconductor bridge using a one-dimensional gas-solid two-phase flow model

Jianbing Xu , Yuxuan Zhou , Yun Shen , Yueting Wang ,Yinghua Ye *, Ruiqi Shen

a School of Chemistry and Chemical Engineering, Nanjing University of Science and Technology, Nanjing 210094, China

b Micro-Nano Energetic Devices Key Laboratory of MIIT, Nanjing 210094, China

c Institute of Space Propulsion, Nanjing University of Science and Technology, Nanjing 210094, China

Keywords:Ignition enhancement mechanism 1D gas-solid two-phase flow Al/MoO3 reactive multilayered films Semiconductor bridge Miniaturized ignition device

ABSTRACT Energetic Semiconductor bridge (ESCB) based on reactive multilayered films (RMFs) has a promising application in the miniature and intelligence of initiator and pyrotechnics device.Understanding the ignition enhancement mechanism of RMFs on semiconductor bridge(SCB)during the ignition process is crucial for the engineering and practical application of advanced initiator and pyrotechnics devices.In this study,a one-dimensional(1D)gas-solid two-phase flow ignition model was established to study the ignition process of ESCB to charge particles based on the reactivity of Al/MoO3 RMFs.In order to fully consider the coupled exothermic between the RMFs and the SCB plasma during the ignition process,the heat release of chemical reaction in RMFs was used as an internal heat source in this model.It is found that the exothermal reaction in RMFs improved the ignition performance of SCB.In the process of plasma rapid condensation with heat release, the product of RMFs enhanced the heat transfer process between the gas phase and the solid charge particle, which accelerated the expansion of hot plasma, and heated the solid charge particle as well as gas phase region with low temperature.In addition, it made up for pressure loss in the gas phase.During the plasma dissipation process, the exothermal chemical reaction in RMFs acted as the main heating source to heat the charge particle,making the surface temperature of the charge particle,gas pressure,and gas temperature rise continuously.This result may yield significant advantages in providing a universal ignition model for miniaturized ignition devices.

1.Introduction

In recent years, with the development of weapon miniaturization, integration and intelligence, miniature electro-pyrotechnic initiator devices have been widely investigated [1-3].In the early stage, the traditional pyrotechnic initiator is made of metal resistance wire with several hundred micrometers, such as NiCr alloy,which heats subsequent agents by joule heat[4,5].With the size of initiator decreasing,the main challenge is how to improve its safety and reliability as well as ignition ability.By changing the output energy form of the igniter, the semiconductor bridge (SCB) has attracted great attention from many researchers,which can replace the metal resistance wire in military and civilian applications,such as detonation of weapon system.This type of igniter is designed as a bridge shape with several micrometer thicknesses, which can easily generate a plasma with high temperature by an electrical explosive reaction when high voltage is placed across the thin film igniter[6-8].The heated plasma spread rapidly to the subsequent charges to ignite it.The plasma has high ignition performance compared with joule heating, so the characteristic size of SCB igniter can be reduced to several hundred microns [9-12].

However, due to the limitation of bridge mass and excitation energy in SCB,the output energy of SCB is too low to directly ignite the insensitive igniting charge.The igniting charge contains primary explosives with high sensitivity, such as lead styphnate(LTNR),which weaken the essential safety of SCB to a certain extent[9,10].Therefore,it is essential to improve the ignition performance of SCB to ignite the insensitive charge directly,which is expected to solve defects of insufficient ignition ability of SCB and remove its sensitive charges to improve the essential safety of SCB.In this scenario, the energetic SCB (ESCB) based on reactive multilayered films (RMFs) have outstanding advantages.

RMFs is a two-dimensional energetic film prepared by depositing two or more kinds of chemical materials to a certain thickness periodically and alternately, which can release a large amount of heat in a limited space with a fast burning-rate under external stimulus [13-15].Thus, the ignition ability of SCB could be improved by integrated RMFs on SCB.Compared with a single SCB,the duration of electrical explosion,flame length and brightness of ESCB are improved several times [16,17].In addition, RMFs can be integrated with electronic devices by Micro-electromechanical Systems (MEMS) technology, which enables micro SCB, microcharge, micro-mechanical parts and a micro-logic electronic circuits to be integrated on the same substrate [18-22].This makes pyrotechnics initiator more integrated, intelligent and miniaturized.In the ignition process of ESCB,the charge particles are ignited by the double-action of high-temperature plasma produced by the electric explosion of SCB and the chemical reaction of RMFs [23].However, the energy coupling mechanism between the chemical reaction of RMFs and high-temperature plasma at the micro-scale is still unclear.Understanding the ignition enhancement mechanism of RMFs on SCB during the ignition process is crucial for the engineering and practical application of advanced initiator and pyrotechnics devices.

In our previous work,a principal component analysis(PCA)was utilized to evaluate the output energy magnitude of ESCB based on the parameters of the electrical explosion process [24], such as ignition duration, the maximum flame area, and reaction ratio.Although the thermal effect and thermal shock have been considered according to these ignition parameters, this evaluation model was based on data statistics, while the firing process of the ESCB involved complex physical and chemical reactions.In order to solve these problems, we propose to introduce a gas-solid twophase flow model to reveal the ignition enhancement mechanism of RMFs on SCB, which has two major attractions for this study.First, in gas-solid two-phase flow, the double-action between particles and fluid affects the heat and mass transfer [25,26].During the ignition of the ESCB to charge particles, the silicon vapor and the combustion products of RMFs act on the surface of the charge particles simultaneously, and the charge is heated and ignited[27,28].The two-phase flow model is very suitable to simulate the ignition process of charge particles.Second, since the ignition of ESCB is companied with transient high temperature at micro scale[11,17,29], it is very difficult to acquire reaction parameters in experiment, such as the temperature of charge particle.Many reaction parameters in the ignition process can be understood by using gas-solid two-phase flow simulation,which makes up for the defects of the experiment.

In our previous work, we systematically investigated the ignition and combustion performance of Al/MoO3RMFs,as well as the characteristics of ESCB based on Al/MoO3RMFs [16,24].Therefore,in this study, a one-dimensional gas-solid two-phase ignition model in ESCB ignition process was established when the heat release of chemical reaction in Al/MoO3RMFs was used as an internal heat source based on its reactivity parameters.The effect of RMFs parameters on the ignition process of the charge was investigated systematically, so as to reveal the ignition enhancement mechanism of RMFs on SCB.

2.Model

2.1.Ignition model of one-dimensional gas-solid two-phase flow

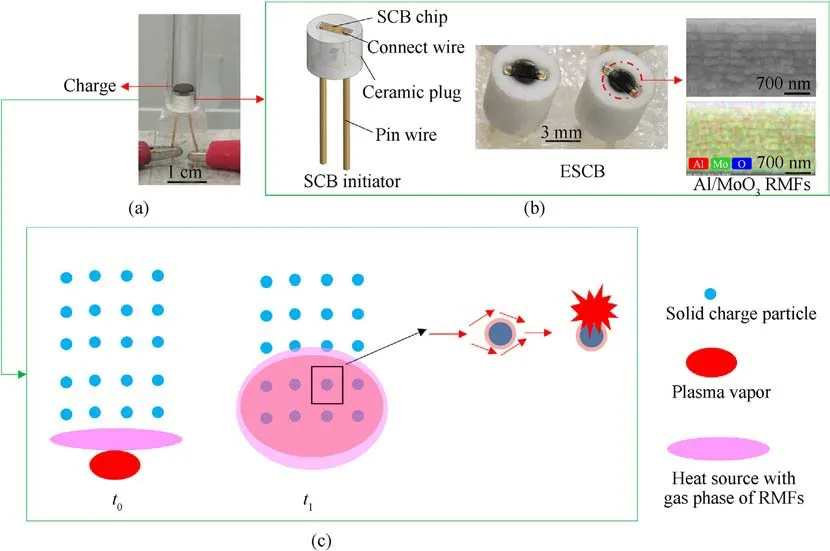

Fig.1.(a) Schematic of the ignition process of ESCB; (b) The detail of SCB initiator, ESCB and Al/MoO3 multilayer films; (c) Schematic diagram of the ignition process of charge particle after the electrical explosion of ESCB, in here,t0 was the primitive spatial and temporal distribution, the solid charge particle was stimulated with double effect of silicon plasma and gas heat source of RMFs at t1 moment.

The typical ignition process of ESCB is shown in Fig.1(a),where the charge particles are mounted on top of the ESCB.And the ESCB initiator was fabricated by depositing Al/MoO3RMFs on SCB with magnetron sputtering,as described in our previous work[24].The detail of SCB,ESCB and Al/MoO3RMFs are shown in Fig.1(b),where SCB is packaged in a ceramic plug.And the RMFs on SCB presented a multilayer distribution arrangement alternately with Al and MoO3.For the ignition process of the ESCB, silicon vapor plasma was generated when the polysilicon was ionized.Then, RMFs was ignited at a very short time (~10 μs), which produced hightemperature products.At this time, the surface of charge particle was ignited by the co-stimulations of silicon plasma and hightemperature products at the same time, as shown in Fig.1(c).Therefore, there was an energy coupling process of plasma and RMFs when studying the ignition process of ESCB to charge particles.And a one-dimensional gas-solid two-phase flow reaction model was utilized by considering the complex physical reaction of mass, momentum and energy exchange in this ignition process.Because of the rapid ignition process of RMFs (~10 μs) when compared with the ignition of charge particles (~ms), the exothermic chemical reaction of RMFs was coupled as a gas heat source to study the ignition process of ESCB to charge particles(Fig.1(c)).

According to the above process,the following hypotheses were first proposed:

(1) The charge particle group were uniformly distributed in the gas phase;

(2) The charge particle was inert substances, and their density was constant;

(3) The chemical reaction of Al/MoO3RMFs was treated as the gas heat source;

(4) The mass flow over the polysilicon was one-dimensional unsteady flow, and every flow parameters were functions of space x and time t.

Based on the above analysis hypothesis, the following conservation equation was established.

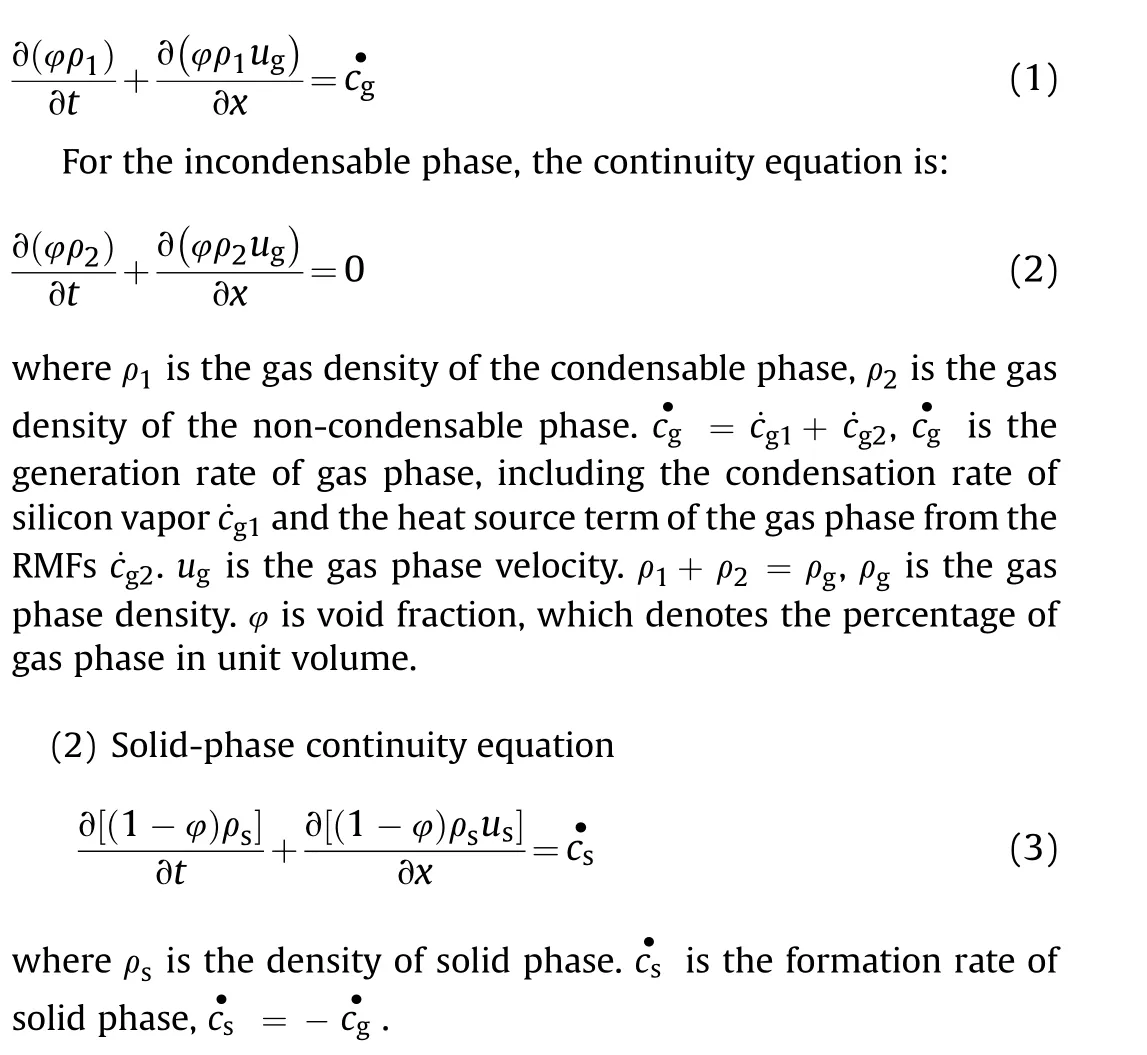

(1) Gas phase continuity equation

The gas phase consists of condensable silicon vapor,heat source of RMFs gas phase and air component of incondensable phase.The continuity equations for different components can be obtained.

For condensable phase gas, it is necessary to consider the heat release from the condensation of silicon vapor and the hightemperature product gas generated from the RMFs, and its continuity equation is:

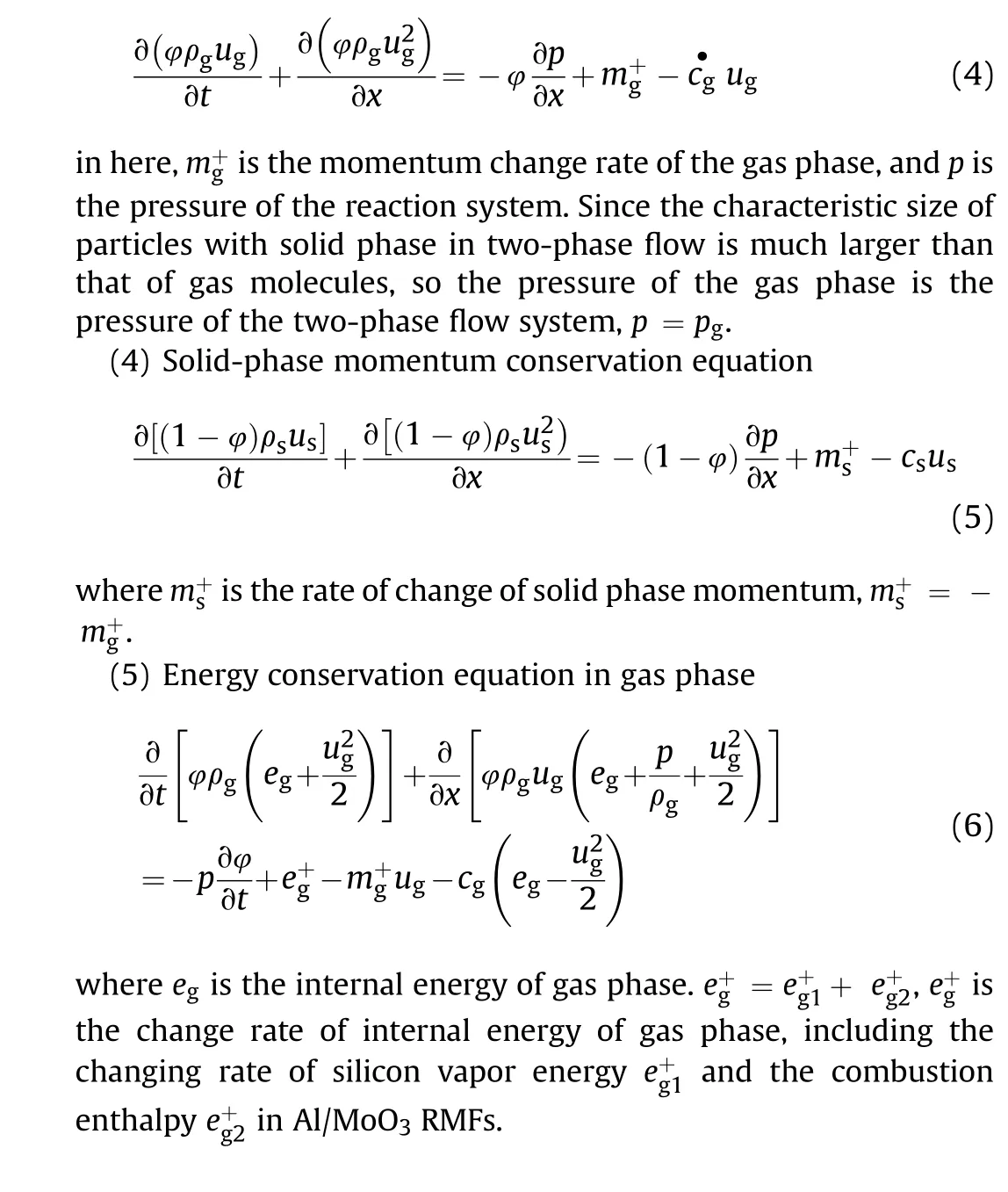

(3) Gas phase momentum conservation equation

2.2.The heat source analysis of RMFs in one-dimensional gas-solid two-phase flow

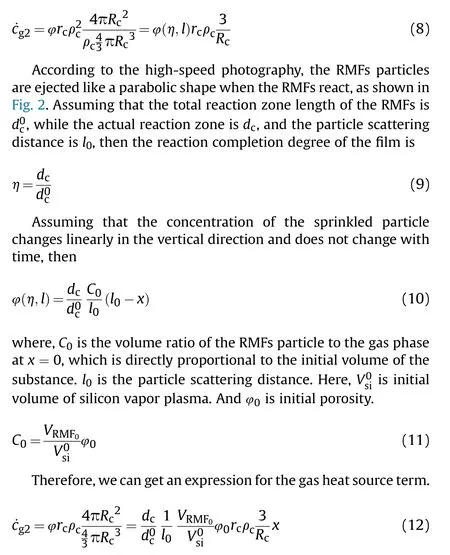

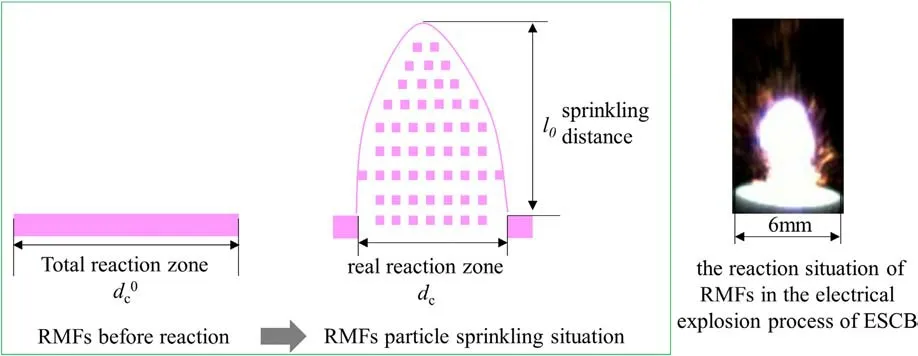

After the RMFs was ignited,it burned into fine particles and the reaction product of RMFs with brightness was sprinkled out.The heat source term of gas phase ˙cg2can be obtained by referring to the interior ballistic equations of gunpowder gas product generation formula [30,31]

where,Scis the transient surface area of a single RMFs particle.Mcis the mass of a single RMFs particle.ρcis the particle density of the RMFs.rcis the combustion rate of the RMFs.φ is the ratio of the volume of the RMFs’ sprinkled particles to the gas phase.φ is related to the degree of reaction completeness of the RMFs (η) as well as the sprinkling distance of the RMFs particles (l).When assuming the radius Rcis a single particle of the RMFs,the ˙cg2can be obtained as follows.

The reaction completion degree of the RMFs(η)can be obtained by the percentage of the reaction area of the RMFs.And l0is obtained from flame height of the high-speed photography in the electrical explosion process of ESCB.rcis measured from burning rate experiment.The particle size of the RMFs is assumed to be the same order of magnitude as the RMFs thickness Rc= 3 μm.

Fig.2.The schematic diagram of RMFs particle sprinkling after reaction.

Table 1 The electrical performance parameter of SCB and ESCB with three different modulation period of Al/MoO3 RMFs under 47 μF/30V.

In order to obtain the closed equations, the thermodynamic state equation of gas phase, the wall thickness equation of silicon vapor condensate particles and silicon vapor are needed [32].In addition, the dynamically changing source items, such as ˙cg1, ˙cg2,m+g, e+gin this system are also needed to be defined.The detailed description of these equations’ establishment was included in Supplementary Note 1.

2.3.Numerical computation method

The Computational Fluid Dynamics(CFD)was used to solve the one-dimensional two-phase flow model equation.The fluid flow control system of partial differential equations was solved by the means of computer to get the corresponding flow parameter such as velocity,pressure,temperature distribution of space and time.In addition, a self-written MATLAB program was developed to solve the above partial differential equations.What’s more,the boundary condition and initial condition was used to solve these equations.The detailed description of computational procedure, boundary condition as well as initial condition was included in Supplementary Note 2.

3.Results and discussion

By solving the one-dimensional gas-solid two-phase flow model, we can get a lot of parameters in the ignition process.In order to analyze the influence of Al/MoO3RMFs’ parameters on ignition process of ESCB,we focus on some main variable and then systematically analyses it, including the surface temperature of charge particle(Tinf),gas phase temperature(Tg),the pressure of the reaction system(Pg).

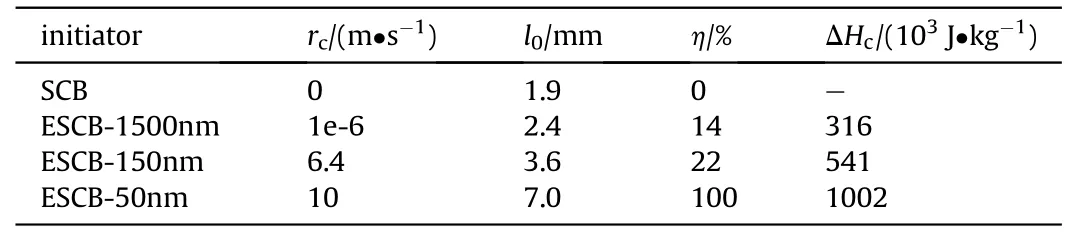

Fig.3.Changes in surface temperature of charge particle with time and space variation for SCB and three kinds of ESCB: (a) SCB; (b) ESCB-1500nm; (c) ESCB-150nm; (d) ESCB-50nm.

3.1.Effect of RMFs parameters on Tinf

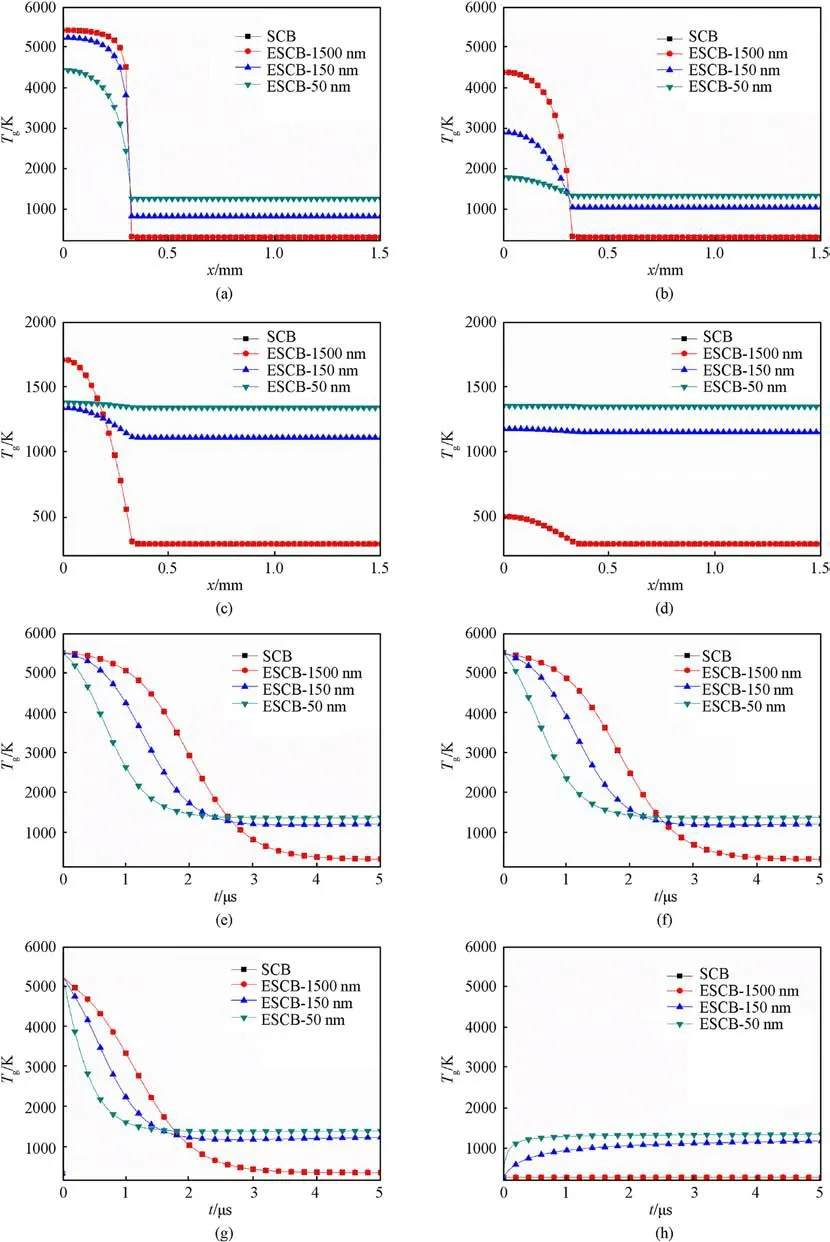

Fig.4.The Tinf variation of SCB,ESCB-1500nm,ESCB-150nm,ESCB-50nm at four typical moments:(a)t=0.5 μs;(b)t=1.5 μs;(c)t=2.5 μs;(d)t=3.5 μs and four typical positions:(e) x = 0.1 mm; (f) x = 0.2 mm; (g) x = 0.3 mm; (h) x = 0.4 mm.

Firstly, the influence of the RMFs parameters on the Tinfwas investigated.And the results are presented in Fig.3.It is clearly that there are two ignition regions in the spatial direction, which is plasma dominant region and RMFs dominant region.As can be seen from Fig.3(a), in the plasma dominant region, the surface temperature of particles in SCB rises to the maximum value about 2100 K within 0.1 μs,and then drops rapidly,approaching the state of room temperature at 4 μs.In the RMFs dominant region, Tinfis always at room temperature.This indicates that the charge particles only close to the plasma area are easy to be ignited in the spatial direction.The heating process of Tinfin ESCB-1500nm is similar to that of SCB.While in the heating process of ESCB-150nm and ESCB-50nm, in addition to the decline of Tinfin the plasma dominant region, the subsequent rise process appears.Different from SCB and ESCB-1500nm, Tinfin RMFs dominant region is also gradually increasing in these regions due to the enhanced effect of combustion heat generation of the RMFs, and the heating rate of ESCB-50nm is higher than that of ESCB-150nm.

To better investigate the Tinfvariation of SCB and three kinds of ESCB in detail, the Tinfat four typical moments (t = 0.5 μs,1.5 μs,2.5 μs,3.5 μs)and positions(x=0.1 mm,0.2 mm,0.3 mm,0.4 mm)were selected in Fig.4.Compared with Fig.3,the two regions in the heating situation of Tinfis more obvious in Fig.4.As can be seen from Fig.4(a), in the initial stage, the Tinfof four initiators in the plasma dominant region are basically the same, and the temperature drops rapidly in this area.While in the RMFs dominant region,the Tinfof ESCB-50nm, ESCB-150nm, ESCB-1500nm, SCB are maintained nearly at 1000 K,500 K,298 K and 298 K,respectively.As the ignition process goes on, the Tinfin the plasma dominant region gradually decreases, while the Tinfin the RMFs dominant region gradually increases,as shown in Fig.4(b).And then,the Tinfin the plasma dominant region rise again,as shown in Figs.4(c)and(d).At last,the Tinffall last close to room temperature in all spatial for SCB and ESCB-1500nm at ~3.5 μs, while the average Tinfrise to~1200 K for ESCB-150nm and ~2000 K for ESCB-50nm with Al/MoO3heat source.In summary,in the plasma dominant region,the Tinfdrop to room temperature at ~3.5 μs for SCB and ESCB-1500nm with no or less gas heat source, but the Tinfdrop at first and then rise again for ESCB-50nm and ESCB-150nm, as shown in Figs.4(e)and (f).In the RMFs dominant region, the Tinfare always at room temperature for SCB and ESCB-1500nm, while the Tinfgradually increases for ESCB-150nm and ESCB-50nm due to the exothermic reaction of RMFs,as shown in Fig.4(h).Interestingly,in the plasma dominant region, an inverted volcanic Tinfcurve appears in ESCB-50nm and ESCB-1500nm, which shows at shaded pink areas in Figs.4(b)-4(d).This indicates that the plasma effect is weakening with the diffusion of plasma in this region, and the chemical reaction of the RMFs just compensates for the influence of plasma weakening on the charge particles.

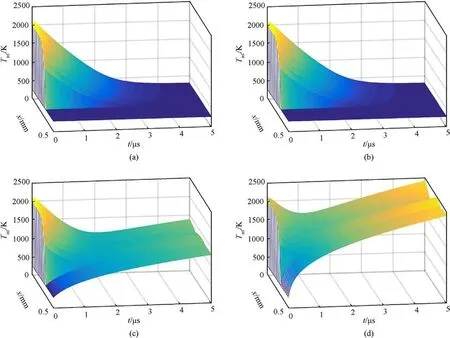

3.2.Effect of RMFs parameters on Tg

The variation of gas temperature Tgreflects the energy transfer of silicon vapor heat source and combustion heat source of RMFs to the reaction system,which is shown in Fig.5.The detailed changes of Tgat four different moments and positions were selected respectively,as shown in Fig.6.Combining Figs.5 and 6(e)-6(f),for SCB and ESCB-1500nm, Tgdecrease slightly within 1 μs, but significantly after 1 μs in plasma dominant region.Nearly at 4 μs,the Tgdecrease close to room temperature.Interestingly,Tgin ESCB-50nm and ESCB-150nm decrease significantly from the beginning of the reaction.Combined with Figs.6(a)-6(b), the Tgin ESCB-150nm and ESCB-50nm is significantly lower than that in SCB and ESCB-1500nm before 2.5 μs in the plasma dominant region.While at 3.5 μs, the Tgin ESCB-150nm and ESCB-50nm tends to a constant value in the whole reaction system, which is 1200 K and 1400 K, respectively, as shown in Fig.6(d).In the RMFs dominant region area, the Tgin ESCB-150nm and ESCB-50nm with internal heat source rise from room temperature to 1200 K and 1400 K,while the Tgin SCB and ESCB-1500nm without gas phase heat source remain at room temperature, as shown in Fig.6(h).This indicates that the presence of internal heat source accelerates the cooling of the high temperature plasma gas phase and heats the low temperature gas and solid phase region.The gas phase temperature in the RMFs dominant region rises rapidly to a certain value, which is related to the parameters of the internal heat source.This may be because the existence of internal heat source increases the content of gas phase and intensifies the energy transfer process between gas and solid phase, so that the high temperature gas cools rapidly, while the temperature of low temperature gas rises rapidly.

Fig.5.Changes in gas temperature with time and space variation for SCB and three kinds of ESCB: (a) SCB; (b) ESCB-1500nm; (c) ESCB-150nm; (d) ESCB-50nm.

Fig.6.The Tg variation of SCB,ESCB-1500nm,ESCB-150nm,ESCB-50nm at four typical moments:(a)t=0.5 μs;(b)t=1.5 μs;(c)t=2.5 μs;(d)t=3.5 μs and four typical positions:(e) x = 0.1 mm; (f) x = 0.2 mm; (g) x = 0.3 mm; (h) x = 0.4 mm.

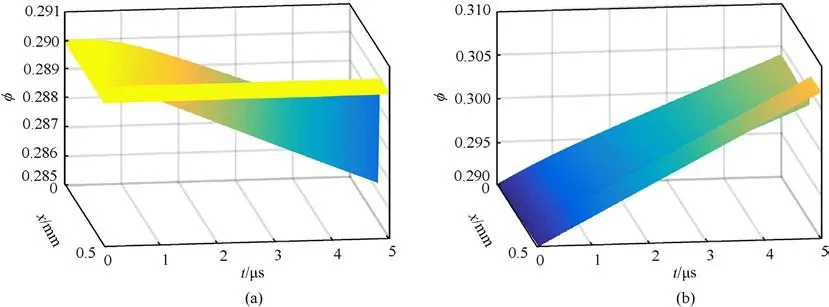

Fig.7 shows the content of gas phase in ESCB-50nm and SCB.In plasma dominant region, the content of gas phase in SCB reduces from 0.29 to 0.287 during 5 μs because of the diffusion of plasma,while the content of gas phase in ESCB-50nm with internal heat source increases gradually from 0.29 to 0.30 during 5 μs.In RMFs dominant region, the content of gas phase in ESCB-50nm rises faster compared that of plasma dominant region,while the content of gas phase in SCB remain unchanged.This further indicates that the addition of gas phase heat source enhances the heat transfer process between gas phase and solid phase.

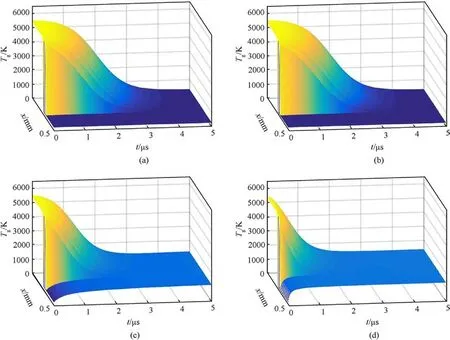

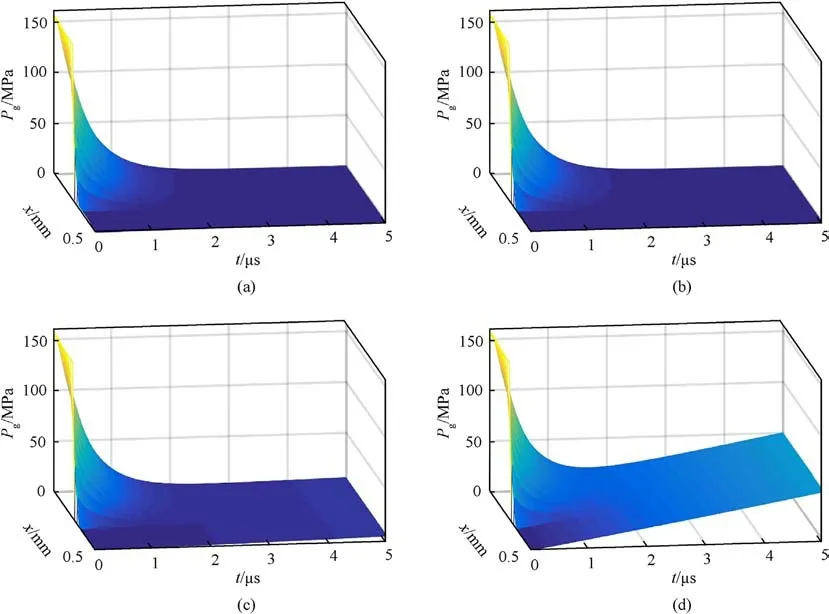

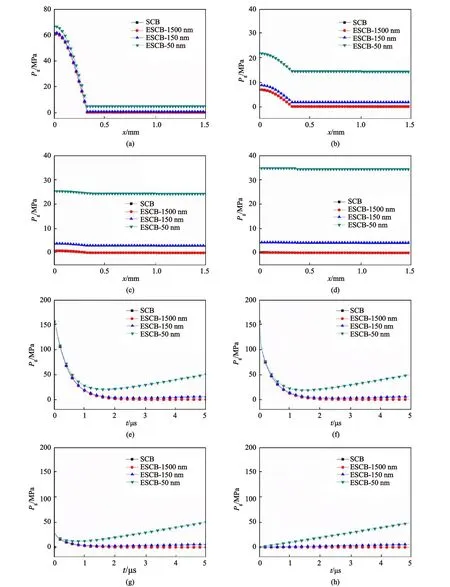

3.3.Effect of RMFs parameters on Pg

Fig.8 shows the pressure Pgvariation in the reaction system and the detailed Pgat four different times and different positions are shown in Fig.9.In the plasma dominant area, the pressure of gas phase at four kinds of initiators decreases rapidly within 1 μs,from 150 MPa to 20 MPa,which can be seen from Figs.8 and 9(e)-9(f).After 2 μs, the Pgin SCB and ESCB-1500nm drop to atmospheric pressure state, while the Pgin ESCB-150nm and ESCB-50nm rise slowly.In the RMFs dominant area,the gas pressure in ESCB-150nm and ESCB-50nm shows a trend of slow increase, as shown in Figs.9(g)-9(h).In terms of time dimension,the Pgof four kinds of initiators drop rapidly from 150 MPa to a constant pressure from the plasma dominant area to the RMFs dominant area at the early stage of the reaction, as shown in Fig.9(a).And then,the Pgin the plasma dominant area gradually decreases,while these in the RMFs dominant area gradually increases.The pressure at ESCB-50nm has the lowest rate of descent.At 2.5 μs and 3.5 μs, the Pgof the two regions is basically the same in Figs.9(c)-9(d).This means that in the late reaction stage,the gas-phase heat source of the RMFs is the main heating source in the ignition process of ESCB, which is the main factor to maintain the ignition pressure, thus improving the ignition ability of the ESCB.

Fig.7.The variation of gas phase content φ in SCB and ESCB-50nm: (a) SCB; (b) ESCB-50nm.

Fig.8.Changes in pressure with time and space variation for SCB and three kinds of ESCB: (a) SCB; (b) ESCB-1500nm; (c) ESCB-150nm; (d) ESCB-50nm.

Fig.9.The Pg variation of SCB,ESCB-1500nm,ESCB-150nm,ESCB-50nm at four typical moments:(a)t=0.5 μs;(b)t=1.5 μs;(c)t=2.5 μs;(d)t=3.5 μs and four typical positions:(e) x = 0.1 mm; (f) x = 0.2 mm; (g) x = 0.3 mm; (h) x = 0.4 mm.

Fig.10.The density of gas phase ρg in SCB and ESCB-50nm: (a) SCB; (b) ESCB-50nm.

Fig.10 shows the density of gas phase in SCB and ESCB-50nm.It can be seen that the gas phase density in SCB decreases rapidly from 89 kg/m3to air density.While in ESCB-50nm, when the gas phase density drops to 40 kg/m3,the vapor products generated by the internal heat source begin to compensate for the material density loss of the silicon vapor plasma.Due to the rapid expansion and condensation of silicon vapor plasma, the temperature and density of the gas phase decrease sharply at early, as a result in a rapid decrease in gas phase pressure.Although gas phase products are produced in the initiator with internal heat source, such as ESCB-50nm,it is not enough to make up for the pressure loss at the beginning,but only causes the gas phase pressure to rise slowly in the later stage of reaction.

According to the above results,plasma condensation is the main way of energy exchange with charge particles in SCB, and the maximum surface temperature of solid phase charge particles rises close to 2100 K, and the whole process lasts ~3 μs.The energy transfer process in ESCB is not only plasma condensation, but also chemical reaction exothermic of RMFs.At the initial stage of the reaction,the heat exchange between the gas-solid phase is mainly by the condensation of the plasma to release heat.In this process, the pressure and temperature of the gas phase decrease rapidly.Compared with SCB,the heat transfer between gas and solid phase is accelerated because the heat source in the RMFs generates gas phase products.As a result,the temperature in the gas phase region of the high temperature plasma cool rapidly,and the low temperature gas and solid phase regions are heated.At the same time, the pressure loss caused by the condensation of silicon gas is compensated by the gas products generated by the combustion of the RMFs, and the decrease of gas pressure at this stage is somewhat weaker than that of SCB.In the second stage, with the dissipation of plasma, the exothermic reaction of RMFs is the main way of energy exchange between gas and solid.Therefore,the parameters of RMFs affect the energy transfer process at the second stage reaction.In this stage,the Tinfbegin to rise gradually,and the temperature and pressure in the gas phase also begin to rise.The Tinfin ESCB-1500nm doesn’t increase,while this value in ESCB-150nm and ESCB-50nm increase to 1400 K and 2500 K at 5 μs.This indicates that the stronger the reactivity of the RMFs is,the more obvious the effect of this stage on the ignition enhancement is.

4.Conclusions

In conclusion, an ESCB one-dimensional gas-solid two-phase flow ignition model was established by taking the heat release from chemical reaction of the Al/MoO3RMFs as the coupled internal heat source.By solving the differential equations for heat and mass transport, the model revealed the ignition process of charge particles after ESCB was exploded by electrical.And the variation of ignition parameters (including the surface temperature of charge particle, gas phase temperature, the pressure of the reaction system)of SCB and three kinds of ESCB (ESCB-1500nm,ESCB-150nm,ESCB-50nm) were systematically investigated.The simulations show that the presence of RMFs improved the ignition performance of SCB.In the plasma condensation process, the product of RMFs enhanced the heat transfer process between the gas phase and the solid charge particle.This speeds up the cooling process of plasma and makes up for pressure loss in the gas phase.The maximum gas temperature at 0.1 μs in ESCB-50nm, ESCB-150nm are 4500 K,5200 K respectively when compared with 5200 K in SCB.During the plasma dissipation process, owing to the exothermal chemical reaction in RMFs, the surface temperature of charge particle, gas pressure and gas temperature stopped to decrease.And later, the surface temperature of charge particle and gas pressure continued to rise.At 5 μs,the surface temperature of charge particle in ESCB-50nm reached 2500 K, exceeding the maximum temperature of which at plasma condensation heating process (2100 K).In addition,the surface temperature of the charge particle in ESCB-150nm reached 1400 K.However, ESCB-1500 nm didn’t have the enhancement effect due to the weak reactivity of the RMFs with the modulation period of 1500 nm, and its ignition ability was similar to that of SCB.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos.22275092, 52102107 and 52372084), the Fundamental Research Funds for the Central Universities(Grant No.30923010920).

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2023.08.010.

- Defence Technology的其它文章

- Evolution of molecular structure of TATB under shock loading from transient Raman spectroscopic technique

- MTTSNet:Military time-sensitive targets stealth network via real-time mask generation

- Vulnerability assessment of UAV engine to laser based on improved shotline method

- Free-walking: Pedestrian inertial navigation based on dual footmounted IMU

- Investigation of hydroxyl-terminated polybutadiene propellant breaking characteristics and mechanism impacted by submerged cavitation water jet

- Estimation of surface geometry on combustion characteristics of AP/HTPB propellant under rapid depressurization