Zeolitic imidazolate framework-8 modified poly(vinylidene fluoride-cohexafluoropropylene)/polyacrylonitrile composite separators for Li-ion batteries

Yanhuai Ding,Cong ZhangHao ZhengYi Han

1 Institute of Rheological Mechanics, Xiangtan University, Xiangtan 411105, China

2 School of Mechanical Engineering and Mechanics, Xiangtan University, Hunan 411105, China

ABSTRACT As one of the most stable metal-organtic framework(MOF),zeolitic imidazolate framework-8(ZIF-8)has been widely studied for applications in the field of energy storage,catalysis,and environment protection.In this paper,ZIF-8 was employed to enhance the electrochemical properties and thermal stability of the electrospun poly(vinylidene fluoride-co-hexafluoropropylene)/polyacrylonitrile (PVDF-HFP/PAN) composite separator.The results indicate that the test cells assembled with the composite separators show improved rate capability,high discharge capacity,and stable cycling performances.The addition of ZIF-8 can improve the affinity of PVDF-HFP/PAN toward liquid electrolytes,and further enhance the ionic conductivity of the composite separators.In addition,the thermal stability of the PVDF-HFP/PAN separator has been improved by ZIF-8 nanoparticles.This work can provide insight into the application of MOF materials in Li-ion batteries.

1.Introduction

The most widely used energy storage devices in modern society are Li-ion batteries (LIBs).As one of core components of LIBs,separators play an essential role in the electrochemical performance and safety of LIBs [1,2].In commercial Li batteries,microporous polypropylene (PP) membranes are widely used as separators because of their fascinating properties such as high tensile strength and chemical stability.However,the PP separators showed poor thermal stability and low wettability toward liquid electrolytes[3,4].Thus,a variety of polymer materials,including poly(ethylene oxide) (PEO) [5],polymethyl methacrylate (PMMA) [6],polyacrylonitrile (PAN) [7],polyvinylidene fluoride (PVDF) [8],polyurethane (PU) [2],polyvinylpyrrolidone (PVP) [9],and poly(vinylidene fluoride-co-hexafluoropropene) (PVDF-HFP) [10],and bacterial cellulose[11]have been explored for using as LIB separators.Among them,the PVDF-HFP exhibited low crystallinity,high dielectric constant and excellent chemical stability that satisfy the requirements for the long-term performance of LIBs.PAN has acceptable chemical/flame resistance and electrochemical stability.Recombination of PVdF-HFP and PAN may form highperformance LIB separators.Subramaniaet al.[12] developed PVdF-co-HFP-PAN separators as early as 2006.The results indicated that the PVdF-co-HFP-PAN separator showed higher ionic conductivity than the PVdF-co-HFP separator.This fact is also demonstrated in our previous work [10].Up to now,the preparation and electrochemical properties of PVDF-HFP/PAN composite separators have been extensively studied[13–15].The results indicated that the addition of nanoparticles and other components can further improve the electrochemical and mechanical properties of PVDF-HFP/PAN composite separators [16–18].

Recently,metal–organic frameworks(MOFs),defined as coordination compounds which consist of polynuclear metal nodes and organic linkers,have attracted much attention due to their high porosity,controlled pore sizes,and unique crystal structures [19–21].The application of MOF materials in LIB separators has been reported previously [22,23].Compared with the nanosized additives,the MOFs have the advantages of high affinity toward electrolytes and accessible ionic conductivity.As one of the most stable MOFs,zeolitic imidazolate framework-8 (ZIF-8) has been widely studied for applications in the field of energy storage,catalysis,and environmental protection[24–26].The ZIF-8 shows thermal stability up to 400 °C in air.In addition,ZIF-8 can adsorb molecules with kinetic diameters larger than the window size.The unique characteristics of ZIF-8 make it ideal for separator mod-ification.The addition of ZIF-8 can improve the affinity of PVDFHFP/PAN toward liquid electrolytes.In this paper,ZIF-8 was employed to enhance the electrochemical properties of the electrospun PVDF-HFP/PAN composite separator.The test cells assembled with the ZIF-8 modified PVDF-HFP/PAN separator show improved rate capability,high discharge capacity,and stable cycling performances.

2.Experimental

2.1.Chemicals and reagents

Zinc nitrate hexahydrate (Zn(NO3)2∙6(H2O)) and 2-methylimidazole (MeIM) were purchased from Xilong Scientific Co.,Ltd.and Shanghai Macklin Biochemical Co.,Ltd.,respectively.N,Ndimethylformamide (DMF) and methyl alcohol were purchased from Tianjin Hengxing Chemical Reagent Co.Ltd..PAN (Mw=250000) and PVDF-HFP (Mw=15000) were provided by Aladdin Reagent (Shanghai) Co.,Ltd.

2.2.Preparation of materials

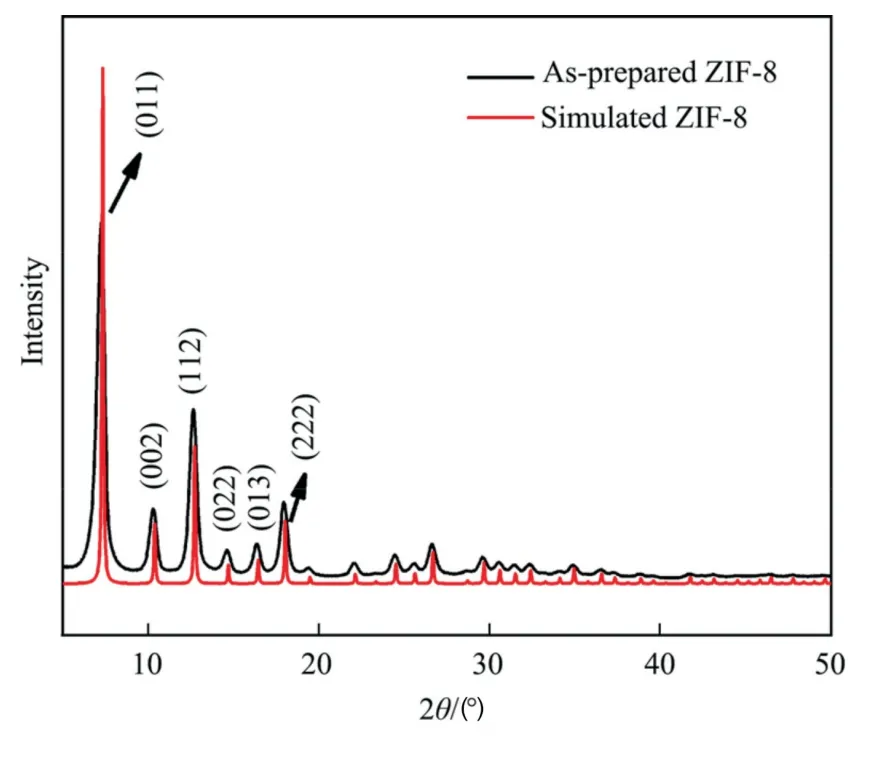

1.5 g(Zn(NO3)2∙6(H2O)was dissolved into 50 ml methyl alcohol under automatic stirring.3.3 g MeIM was added into 50 ml methyl alcohol.Then,the Zn(NO3)2solution was slowly added to the MeIM solution.The obtained milky solution was incubated 24 h at room temperature under automatic stirring.After that,the solution was first centrifuged at 4000 r∙min-1for 10 min.The collected precipitation was washed three times with ethanol and then dried at 60 °C for 6 h to obtain ZIF-8 crystals.∙

1.0 g PAN and 1.0 g PVDF-HFP were added into 20 ml DMF to prepare the electrospinning precursor A.As a comparison,0.5 g ZIF-8 was added into the mixed PAN and PVDF-HFP solution to prepare the electrospinning precursor B.The precursors were submitted to electrospinning with a voltage of 12 kV.The obtained porous separators were peeled off from the Al foil and then dried at 60 °C for 12 h.

2.3.Characterization of separators

The as-prepared samples were characterized by X-ray diffractometer (XRD,U1tima IV),scanning electron microscopy with energy dispersive X-ray spectrometry (SEM–EDX,Zeiss Ultra55),and a universal testing machine (Instron 5943).Test specimens were prepared in rectangular size of 5 mm×40 mm.The thickness of the pristine and ZIF-8 modified PVDF-HFP/PAN separators was 45 μm and 37 μm,respectively.The stretching rate was set to 5 mm∙min-1.

Fig.1. XRD patterns of as-prepared ZIF-8 sample.

2.4.Electrochemical test of the separators

The test cells were assembled with commercial PP,electrospun PVDF-HFP/PAN and ZIF-8 modified PVDF-HFP/PAN membranes as separators,LiFePO4as cathode,and Li foil as the anode.The cathode electrode was fabricated by LiFePO4powder(80%(mass)),Ketjen black (10% (mass)),and poly(vinylidene fluoride) (10% (mass))dissolved inN-methyl-2-pyrrolidone (NMP).The electrolyte

Fig.2. Morphological features of the electrospun pristine and ZIF-8 modified PVDFHFP/PAN separators:(a)PVDF-HFP/PAN;(b)ZIF-8 modified PVDF-HFP/PAN;(c)EDX analysis of ZIF-8 modified PVDF-HFP/PAN separators.

Table1 Porosity and electrolyte-uptake capability of the separators

The LSV curves of the test cells with the three different types of separators are shown in Fig.4(a).The results can reflect the electrochemical stability of the separators.For the ZIF-8 modified PVDF-HFP/PAN separator,the anodic potential window reaches up to 4.8 V,which is higher than that of the commercial PP separator (4.0 V).The results indicate that the ZIF-8 modified PVDFHFP/PAN separator is compatible with the carbonate electrolyte and can be used for most commercial cathode materials.The ionic conductivity of separators in stainless steel (SS)/separator/SS cells was measured by EIS spectra.As shown in Fig.4(b),the ionic conductivity of PP,pristine and ZIF-8 modified PVDF-HFP/PAN separators are 0.53 mS∙cm-1,0.85 mS∙cm-1,and 1.18 mS∙cm-1,respectively.As shown in Table 1,the electrospun separators show higher porosity than the PP separator.High electrolyte-uptakes can be obtained in the electrospun separators.The enhanced wettability and the high surface area of ZIF-8 result in enhanced ion transport in the PVDF-HFP/PAN separator.

Fig.5. CV profiles collected in the range of 2.5– 4.2 V with a scanning rate of 0.1 mV∙s-1: (a) PP separator;(b) ZIF-8 modified PVDF-HFP/PAN separator.

The CV profiles collected in the range of 2.5–4.2 V with a scanning rate of 0.1 mV∙s-1.As shown in Fig.5,the CV curves of the test cells with PP and ZIF-8 modified PVDF-HFP/PAN separators show a pair of redox peaks,which are associated with the charge/discharge processes of LiFePO4cathode [29,30].For the composite separator,the potential polarization between the redox peaks is slightly smaller than that of the test cell with PP separator.Generally,the smaller polarization potential gap indicates better batterykinetics [31].The high porosity of the electrospun separator will promote ionic conductivity in the batteries.

Fig.6. Rate capability and cycling performance of the test cells with as-prepared separators: (a) rate capability;(b and c) cycling performance at 0.1 C and 1.0 C.

The rate capability of the test cells with the as-prepared separators was evaluated at indicated current densities as displayed in Fig.6(a).The cell assembled with ZIF-8 modified composite separator exhibits the best rate capability among the three test cells.Compared with the pristine PVDF-HFP/PAN separator,the composite separator exhibits better rate capability from 0.1 C to 5.0 C.The test cell with the composite separator can deliver a specific capacity of 167 mA∙h∙g-1at 0.1 C,almost 21 mA∙h∙g-1higher than the test cell with PP separator.With the increase in discharge current density,the gap of the specific discharge capacity between the test cells becomes large.The cell with ZIF-8 modified composite separator can deliver a discharge capacity~131 mA∙h∙g-1at 5.0 C.The results indicate that modification with ZIF-8 can greatly improve the rate capability of the PVDF-HFP/PAN separator.The longterm cycling performances of the test cells at 0.2 C are shown in Fig.6(b).The cell assembled with ZIF-8 modified composite separator exhibits very stable cycling performance up to 100 cycles.After 100 cycles,the specific discharge capacity of the cell can be maintained at 159 mA∙h∙g-1at 0.2 C,nearly 95% of the initial discharge capacity.In contrast,the test cell with the commercial PP separator shows a discharge capacity of 119 mA∙h∙g-1after 100 cycles.The Coulombic efficiency of the test cell with the ZIF-8 modified composite separator is also higher than that with the PP separator.As shown in Fig.6(c),with the current density increasing to 1.0 C,the test cell with ZIF-8 modified composite separator can still maintain high capacity retention after 100 cycles.

4.Conclusions

In this work,ZIF-8 modified electrospun PVDF-HFP/PAN composite separators have been successfully fabricated.The ZIF-8 modification greatly improves the mechanical properties and thermal stability of the PVDF-HFP/PAN separators.The breaking strength of the modified PVDF-HFP/PAN separators is 23.96 MPa,corresponding to a tensile strain at break~37.5%.The ionic conductivity of the composite separator reaches 1.18 mS∙cm-1.The test cell with the composite separator shows excellent rate capability and stable cycling performance.The composite separator has great potential for application in high performance LIBs.

CRediT Authorship Contribution Statement

Yanhuai Ding: Writing– review &editing,Project administration.Cong Zhang: Methodology,Investigation.Hao Zheng:Methodology,Investigation,Writing– original draft.Yi Han:Methodology,Investigation,Writing– original draft.

Data Availability

Data will be made available on request.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (12002295),Key Scientific Research Project of Education Department of Hunan Province,Xiangtan City,China (22A0113) and Major Science and Technology Projects of Xiangtan Science and Technology Bureau (GX-ZD202210011).

Chinese Journal of Chemical Engineering2023年10期

Chinese Journal of Chemical Engineering2023年10期

- Chinese Journal of Chemical Engineering的其它文章

- High catalytic performance of CuCe/Ti for CO oxidation and the role of TiO2

- Experimental and numerical studies of Ca(OH)2/CaO dehydration process in a fixed-bed reactor for thermochemical energy storage

- Volumetric and ultrasonic properties of thiamine hydrochloride drug in aqueous solutions of choline-based deep eutectic solvents at different temperatures

- Synthesis of zeolite A and zeolite X from electrolytic manganese residue,its characterization and performance for the removal of Cd2+ from wastewater

- Metal-organic framework-derived Co-C catalyst for the selective hydrogenation of cinnamaldehyde to cinnamic alcohol

- A pseudo transient nonequilibrium method for rigorous simulation of multicomponent separation columns