Recent development of catalytic strategies for sustainable ammonia production

Supeng Yu,Ting Xiang,Njud S.Alharbi,Bothaina A.Al-aidaroos,Changlun Chen1,,

1 Institute of Plasma Physics, HFIPS, Chinese Academy of Sciences, Hefei 230031, China

2 University of Science and Technology of China, Hefei 230026, China

3 Institute of Energy, Hefei Comprehensive National Science Center (Anhui Energy Laboratory), Hefei 230000, China

4 Department of Biological Sciences, Faculty of Science, King Abdulaziz University, Jeddah 21589, Saudi Arabia

Keywords:Thermocatalytic ammonia production Electrocatalytic,and photocatalytic ammonia production Thermodynamics process Electrochemistry Multiphase reaction

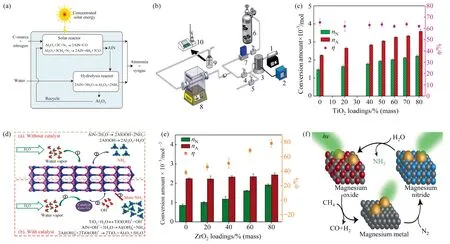

ABSTRACT Presently,ammonia is an ideal candidate for future clean energy.The Haber-Bosch process has been an essential ammonia production process,and it is one of the most important technological advancements since its invention,sustaining the explosive growth of military munitions industry and fertilizers in the first half of the 20th century.However,the process is facing great challenges: the growing need for ammonia and the demands of environmental protection.High energy consumption and high CO2 emissions greatly limit the application of the Haber-Bosch method,and increasing research efforts are devoted to‘‘green”ammonia synthesis.Thermocatalytic,electrocatalytic,and photocatalytic ammonia production under mild conditions and the derived chemical looping and plasma ammonia production methods,have been widely developed.Electrocatalytic and photocatalytic methods,which use low fossil fuels,are naturally being considered as future directions for the development of ammonia production.Although their catalytic efficiency of ammonia generation is not yet sufficient to satisfy the actual demands,considerable progress has been made in terms of regulating structure and morphology of catalyst and improving preparation efficiency.The chemical looping approach of ammonia production differs from the thermocatalytic,electrocatalytic,and photocatalytic methods,and is the method of reusing raw materials.The plasma treatment approach alters the overall ammonia production approach and builds up a new avenue of development in combination with thermal,photocatalytic,and electrocatalytic methods as well.This review discusses several recent effective catalysts for different ammonia production methods and explores mechanisms as well as efficiency of these catalysts for catalytic N2 fixation of ammonia.

1.Introduction

The Haber-Bosch method,one of the greatest inventions in the 20th century,used for ammonia synthesis derived from a mixture of hydrogen and nitrogen on iron-based catalysts came into being[1–3].It is still the basis for producing more synthetic fertilizers despite the requirement of high reaction temperature and pressure[4].Therefore,as a carbon-intensive industry,the Haber-Bosch process urgently needs to be replaced by a more advanced process that meets the environmental requirements under more moderate conditions[2,3,5].At the same time,ammonia is considered as the most attractive energy carrier due to its light density,carbon-free,easily detectable,high-yield,and high octane rating of 110–130[6].Based on the above situation,more environmentally friendly and mild-condition ammonia production methods with lowtemperature and low-pressure,and even normal temperature and pressure,have been explored.Generally speaking,main methods of ammonia synthesis are: thermal catalysis,electrocatalysis,photocatalysis,and plasma ammonia production.At the same time,chemical looping ammonia production is also derivative from the previous four preparation methods.Thermocatalysis has been continuously developed since the Haber process from the initial optimization of Fe3O4molten iron catalysts to Wüstite (Fe1–xO)catalysts [7].Because of the high activity of Ru metal elements at low temperatures and low pressure,a massive amount of emerging research is divided into many types according to different carriers,promoters,and precursors.Meanwhile,catalyst materials such as bimetallic composites and sporadic transition metals have also been reported [8,9].

Some unavoidable problems with the Haber-Bosch methods,such as high temperatures,high pressures,high pollution,large capital investments,and the uneven distribution of the ammonia industry,have forced scientists to develop simplified ammonia synthesis methods that can be operated under mild conditions.It is no doubt that electrocatalysis is at the forefront of these efforts.Pickett and Talarmin[10]reported the hydrolysis of the nitric compoundcis-[W(N2)z(PMe2Ph)4] to ammonia,which was the beginning of the electrocatalytic ammonia production.This paper summarizes noble metallic catalysts such as Au,Ag,as well as metallic Fe,Ni,Mo,and W-based catalyst and non-metallic Cbased,C-N combined catalysts,B-based,and P-based catalysts.From the point of view of the source,reactant type and morphological structure are crucial factors which affect the difficulty of nitrogen activation and the selectivity,namely the competition between hydrogen evolution reaction (HER) and nitrogen reduction reaction(NRR)[11].Plasma powered by renewable electricity can excite ground state-molecules to active molecule that may react at the surface of selected materials under thermally efficient conditions and at low pressures,which provides an alternative to conventional catalysis and leading to the outlook for the electrification of the chemical industry in future [12].The photocatalytic ammonia production is inspired by nitrogen fixation of photosynthesis.The kinds of photocatalytic ammonia synthesis catalysts are booming in TiO2,Bi base,sulfide,graphite carbon nitride (g-C3N4),layered double hydroxides(LDHs),semiconductor materials,bionic materials and so on.Poor operating stability and inefficient solar energy chemical conversion of photocatalysts are the two most important factors that hinder the efficiency of ammonia synthesis[13,14].The chemical looping ammonia production process,which has been silent for a long time since the invention of Haber-Bosch process,has been revived with the development of new energy sources.Coupling of renewable energy sources such as solar and wind energy with chemical looping processes,simplified and small-scale operations under atmospheric conditions can be achieved.By optimizing the experimental conditions such as reactants,temperature and pressure in each step,the problem of competitive adsorption of N2and H2or H2O can be avoided [15].This review focuses on discussing in detail the evolution as well as opportunities and challenges of various catalytic methods for ammonia production.It is urgently needed for updates on relevant advances since some summaries of ammonia synthesis having fallen far short of the pace of development.The aim of this review is to provide a concise but comprehensive overview of recent advances in the diverse synthesis of ammonia.First,we summarize recent work on the thermochemical ammonia generation and begin with a brief introduction of the mechanisms available for ammonia synthesis.Subsequently,we briefly describe recent advances in the nitrogen fixation capabilities of different types of electrochemical catalysts and even in the reduction of nitropollutants to ammonia.Then we point out the recent advances in photocatalytic catalysts,recent developments in chemical looping and plasma ammonia production are also be pointed out in the final section.

2.The History of Catalyst Development of Ammonia Synthesis

Nicodemus Caro and Adolphe Frank discovered the remarkably simple conversion of cyanide,made by the reaction of calcium carbide and nitrogen (CaC2+N2=CaCN2+C),into ammonia by a water vapor reaction (CaCN2+3H2O=CaCO3+2NH3).The cyanamide process,also named the Frank-Caro process,was the first commercial synthesis of ammonia on a global scale [16].Subsequent to the industrialization of sulphur dioxide oxidation and ammonia oxidation processes for several years,a series of metals active in ammonia synthesis were identified as Os,U,Fe,Mo,Mn,W,etc.In 1910,that German BASF modified Haber method of catalytic ammonia production with Os and U and selected iron catalysts containing Pb and Mg promoters was considered to be one of the first catalytic processes to be applied on a large scale.The new molten iron catalytic system,Fe1–xO system,only broke through the volcanic distribution diagram of activity to iron ratios(with a maximum activity of 0.5),marking a new period of development for ammonia catalysts,with catalysts such as A110-1,A110-2,A201,A301 and ICI3524 emerging [17].Over the last 80 years,although the catalyst formulations have varied and the industrial processes/equipment have been improved and perfected,there has not been much change in the nature of the catalysts,which have not yet been freed from the harsh conditions of high temperature and pressure.

The transition metal electron-donating (EDA) type ammonia catalysts proposed by Tamaru and Ozaki between 1968 and 1971 were not industrialized.By 1970s,the world was becoming increasingly energy-constrained and the cost of ammonia synthesis was rising.In order to reduce costs,countries around the world are committed to the development of low temperature and lowpressure high activity ammonia synthesis catalysts,for example,the British Petroleum and the United States KLG company jointly developed Ru-based ammonia synthesis catalyst[18].It is arguably the second generation of ammonia catalysts after iron catalysts.A suitable active predecessor is selected,a promoter is added and loaded onto the carrier by impregnation,which is transformed into the active component by reduction treatment under certain conditions.There are interactions among Ru,the carrier,the promoter and the facultative ingredients in the catalyst.

Inspired by Fe3O4in the same period,research on nanoscale oxides has flourished and nano-Fe3O4,Fe2O3,CuO,NiO,ZnO,MoO3have been studied successively.Due to the small size and special surface structure of nanomaterials,nano catalysts have special properties.Compared with conventional catalysts,the average selectivity of nano catalysts is 5–10 times higher and the activity is 2–7 times higher.

Since then,transition metal nitrides have been extensively studied as a class of intermetallic compounds with the properties of covalent compounds,ionic crystals and transition metals [19].High-surface-area transition metal nitrides are produced by the programmed temperature nitridation of oxide precursorsviaa‘‘local regularization reaction”under strict nitridation conditions that do not essentially destroy the crystal structure of the oxide precursors.Its surface properties and catalytic performance are similar to those of noble metals such as Pt and Rh,and it is known as a’quasi-Platinum catalyst.In order to break through the thermodynamic limitations,the photoelectric enzyme route to ammonia was explored in the late 1970s,but to date,the different methods still have more or less the same disadvantages of low conversion,high energy consumption and unclear mechanisms.

3.Thermal Catalytic Catalyst for Ammonia Synthesis

Ammonia synthesis,one of the most momentous developments in heterogeneous catalysis field,plays a vital role in the establishment of mechanism and application in many chemical reaction processes.There are two mechanisms can be used to explain how nitrogen molecules be reduced toward ammonia molecules over heterogeneous catalysts: dissociation and association(Fig.1).In dissociation mechanism,the N≡N triple bond is evidently break up leading to the formation of N atoms,which line up at the surface of the catalysts and then combine with hydrogens to form ammonia molecules.Association mechanism can be classified in two categories: associative alternating pathway and associative distal pathway,according to the order of hydrogenation.The typical characteristic of association mechanism is that the nitrogen atoms always are connected until the ammonia has formed,the peculiarity of the first category is that alternating hydrogenation occurs on two nitrogen atoms.When the final single bond has been broken,nitrogen at the far end form ammonia followed by NH2hydrogenation,which finally is liberated.The second type of association mechanism is characterized by the formation of ammonia taking place on the nitrogen atoms away from the catalyst surface by hydrogenation in turn and releasing a metal nitride,subsequent hydrogenation step occurs on another nitrogen atom,forming a second ammonia molecule [2,20,21].Since the N≡N triple bond is strong and is difficult to break,the Haber method,which follows the dissociation mechanism,requires extremely harsh conditions for the reaction to occur[20].For thermocatalytic ammonia production it is overall a variation of the Haber process,only revealing major differences in the catalysts.Multiple thermocatalytic effects have been explored,from ironbased to ruthenium-based catalysts to metal nitride catalysts,as shown in Table 1.

3.1.Molten iron catalyst

Iron catalysts for ammonia synthesis have become one of the most successful and thoroughly studied catalysts in the world[17].The synthesis of ammonia proceeds through several fundamental stages: The process entails the combination of N2and H2,each matched with iron followed by bond cleavage to atomic nitrogen and hydrogen,and then to progressively form ammonia through the transfer of successive hydrogen atoms to nitrogen.Among these basic steps,high bond energy of N2and its dissociative adsorption are the most vital steps[43].The evolution of molten iron catalysts has passed through two main stages.Iron-based catalysts have matured over more than a hundred years.From the initial magnetite base to the later wüstite-based catalysts(both all belong to molten iron catalysts),from iron alloy base to loaded/embedded iron particle carrier composites,the trend in ironbased catalysts has been to move more and more towards reducing the iron content and increasing the interaction of iron with other components,as shown as Fig.2.Conventional ammonia synthesis catalysts were developed in the early 20th century and were prepared from magnetite,which was also the original iron catalysts.Structural promoters were added to the catalytic system with small amounts of non-inducible oxides (usually Al,K and Ca),where Al and CaO were structural promoters and KOxwas an electron promoter to augment the total specific surface area of the catalyst and/or to stabilize the thermal stability of the porous system[44].Traditional iron catalysts with ferric oxide as precursors have been studied extensively for more than 100 years [7].As early as 1926,Almquist and Crittenden [45] investigated the activity of pure iron catalysts (without promoter),then other researchers found that the catalyst at the ratio of Fe2+to Fe3+up to 0.5 had the highest activity [7],with it at the ratio of Fe2+to Fe3+ranged from 0.4 to 0.8 showing the best catalytic activity(Fig.3(a)),which once seemed to be an unquestionable classical conclusion.Apart from that,ammonia synthesis over iron catalysts has a strong structural sensitivity.The order of catalytic activity of iron planes is [111] >[211] >[100] >[210] >[110] [50].In 1986,Liuet al.[17] discovered a new Wüstite-based catalyst based on pyrite(with Fe1–xO as precursor),which was the second major innovation in industrial iron-based ammonia synthesis catalysts.Wüstitebased catalyst displays a typical NaCl structure without magnetic properties and remains stable below 1000 °C,it is famous by the advantage of high activity and low reduction temperature,and complete reaction.In contrast,conventional magnetite-based catalysts possess a sub-stable spinel morphology[7].As shown in Fig.3(b),Liu and Han[7]demonstrated that the trend mentioned above was met at small Fe2+/Fe3+ratios,however,the activity increased again in response to the rise in Fe2+/Fe3+,with the gradual formation of Fe1–xO in the process,which extended the typical volcanic diagram above and overturned the classic conclusion that magnetite was the most reactive.The differences in the precursorand promoter structures lead to changes in the α-Fe active site and crystal plane growth and the formation of internal lattice defects.The sub-stable nanostructures formed by these variations are responsible for their high catalytic activity for ammonia synthesis.Si,Al,K,Ca,and other oxides are often used as promoters in fused magnetite-based catalysts.It is found that the promoter distribution is heterogeneous,where the promoter concentration between the grain boundaries of magnetite was higher than inside the crystal [51].These are where both soluble promoter and glass phases are present,obstructing the tungsten ferrite and calcium ferrite phases.The calcium ferrite between the magnetite particles exhibits an acicular or dendritic crystalline state,which is intertwined with tungsten ferrite without separation.The simultaneous presence of the glass phase occupies the other free space between the magnetite particles [52].Al2O3,K2O,CaO,MgO are the most prevalent promoters in magnetite and tungsten ferrite.In Fe3O4-based catalysts,Al forms substitutional solid solution with Fe3O4,and also forms solid solution FeAl2O4or MgFeAlO4with a small amount of FeO.The uniform distribution of Al2O3is explained by the fact that the solid solution before can form a new solid solution(FeO-Al2O3)-(Fe3O4)again.In Fe1–xO-based catalysts,FeO and Al2O3form a substituted solid solution(FeAl2O4),since the different crystal structures do not further form solid solutions causing Al2O3in the latter less uniformly than in the former [7].K,Al and Ca as the main promoters affect positively the performance and reduction behavior of wüstite-based ammonia synthesis catalysts,narrowing the reduction and disproportionation of sub-stable pyrite,thus allowing a more direct reduction with less magnetite at the final activation temperature [53].Fe1–xO catalysts are still produced by melting method,which has high energy consumption.The wüstite-based catalysts are prepared from natural magnetite with iron as reducing agent and can be melted directly in resistance or electric arc furnaces with controlled temperature to avoid disproportionation reactions(Fig.3(c))[46].The ammonia synthesis process with fused iron catalysts is well established so that Fe3O4/Fe1–xO-based iron catalysts perform well as solids with no extraordinary improvements other than the limited replacement of promoter and adjustments in structure.

Table1 Some generalizations about thermal catalysts for ammonia production

Fig.2. Evolution of iron-based catalysts.

Fig.3. (a) Classical volcano shaped activity curve.(b) Relationship between activities and Fe2+/Fe3+ of catalysts.Reproduced from Ref.[7] with permission of Elsevier,copyright 2017.(c)Preparation of Fe1–xO catalyst by melting method.Reproduced from Ref.[46]with permission of Elsevier,copyright 2020.(d)Construction of Fe3 clusters hosted on the surface of θ-Al2O3(010).Reproduced from Ref.[47] with permission of Nature Communications,copyright 2018.(e) Abbreviated reaction diagram of iron catalysts doped with silicon.Reproduced from Ref.[48]with permission of American Chemical Society,copyright 2020.(f)TiO2-xHy/Fe catalysts overcoming size relationship.Reproduced from Ref.[49] with permission of American Chemical Society,copyright 2020.

In recent years,Nb has been chosen as a potential promoter for ammonia synthesis of tungsten-based catalysts.Nb2O5has lower reduction temperature and faster reduction rate,less inhibition of strong hydrogen adsorption,lower desorption temperature and partially inhibits the formation or separation of solid solutions in the reaction unfavorable to bias or solid solution formation on the catalyst surface.However,the doping of Nb2O5facilitated the sintering of the active phase,while not promoted the growth of the relevant planes [22].The significant growth of single cluster catalysts indicated that there were homogeneous catalytic active centers on non-homogeneous solid surfaces,and authors presented a structure with an active central Fe3 cluster anchored on the surface of θ-Al2O3(0 1 0) (Fig.2(d)) that might be prepared by methods such as the soft-landing cluster method,owing to the fact that triangular Fe3 and conical Fe4 were the most stable clusters on alumina substrates and it was believed that the Fe3 cluster was more stable against aggregation kinetics [47].N2was activated effectively by Fe3/θ-Al2O3(0 1 0),attributing to its multi-step redox capability,large spin polarization and low oxidation state metal.The spin polarized charge was transferred from the 3d orbital of Fe to the π* orbital of N2,and the partially occupied N2β-spin π* orbital reduced the nitrogen bond order conferring the *N2radical property,which leads to N2activation following an association mechanism.The Si-doped Fe-bcc nanoparticles,presenting a Woolf structure,could considerably enhance the reaction by lowering the spin difference between 2 N and 4 N states (Fig.3(e)).The dopant might change the ratedetermining step.Fe-Si binary catalysts were suitable at 2.06 MPa/500 °C or 6.18 MPa/400 °C,substantially better than the harsh industrial conditions(20.6 MPa/500°C),which indicated that the same turnover frequency TOF as the current Haber-Bosch process could be maintained at lower pressure and temperature conditions[48,54].Valence bond analysis revealed that the doping of Si significantly decreases the spin difference between the 2 N and 4 N states compared to pure Fe,stabilizing the 2 N state and leading to a lower potential barrier.Metal-organic frameworks(MOFs)as a high-porosity inorganic–organic hybrid material,have great potential as versatile precursors.Yanet al.[23]proposed that K-promoted Fe/C catalysts with very high Fe loading(>50%(mass))could be prepared by pyrolysis of iron-based MOFs dry gels.K1-Fe-MDC(MOF-derived catalyst)catalysts were composed of spherical metal nanoparticles(NPs)uniformly embedded in a porous carbon matrix.The mass-specific reaction rate could reach 30.4 mmol∙g-1-∙h-1at 400 °C.MOFs were served as a metal and carbon source as well as a sacrificial structure-directed template.The alternating metal sites and organic linkers at the molecular level ensured a favorable dispersion of the metal.The introduction of potassium ions during the preparation process could promote charge transfer from K ions to iron and carbon on the surface,balancing the dissociative chemisorption between H2and N2and suppressing side reactions,thus improving the activity and stability.In bifunctional TiO2–xHy/Fe catalysts,N2and H2were readily dissociated on the iron nanoparticles.The overflow of hydrogen-laden oxygen vacancy (OV-H) on TiO2–xHydestabilized the ‘‘scaling relationship”(Fig.3(f)) between N2dissociation (Ea(N≡N)) and destabilization of NHzintermediates(z=0 to 2),which could vigorously activates the N2catalyst and at the same time hinders the conversion of NHzintermediates [49].

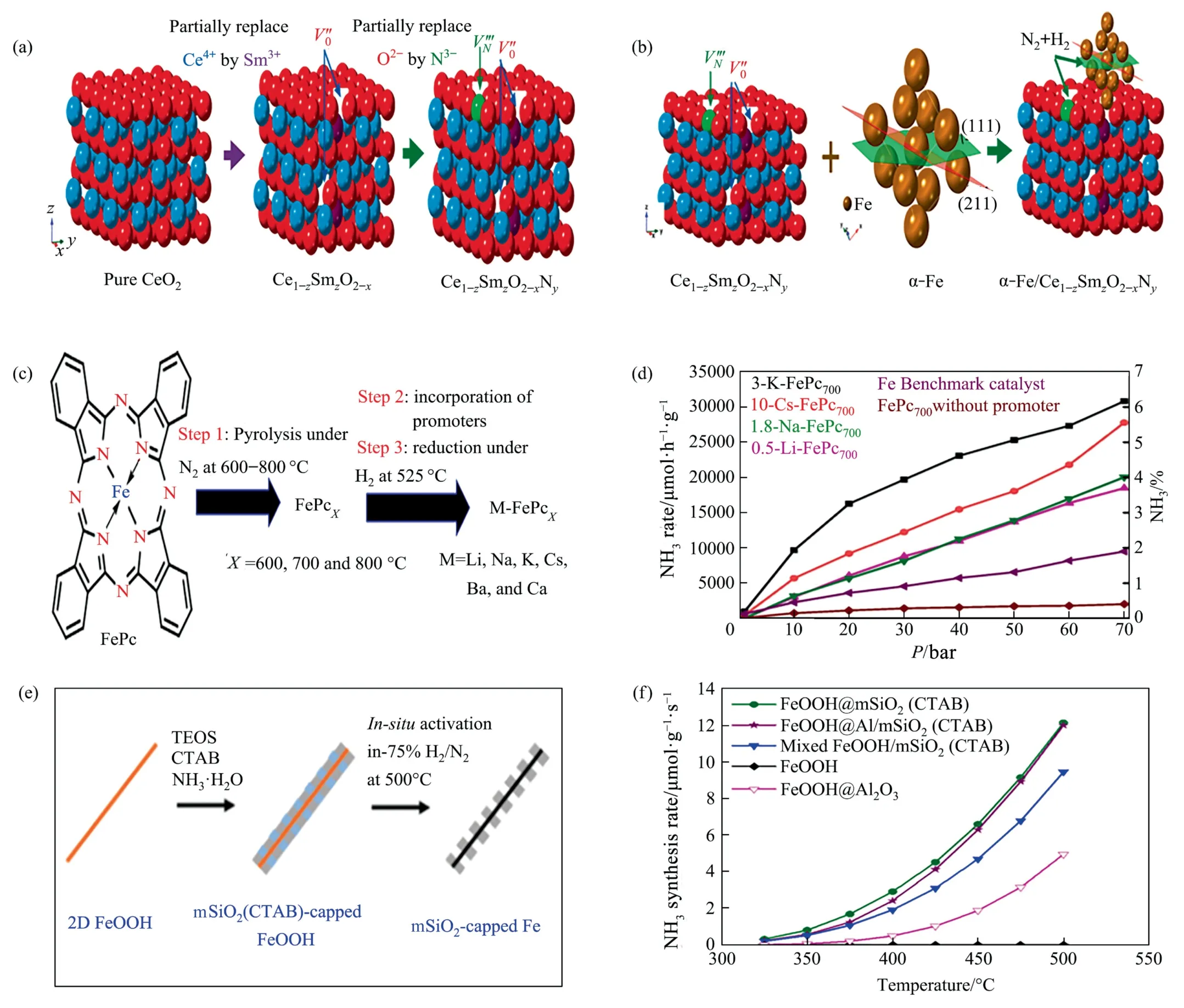

Fig.4. (a)Stepwise formation process of Ce1–zSmzO2–xNy.(b)Shape of Ce1–zSmzO2–xNy loaded with Fe.Reproduced from Ref.[24]with permission of Elsevier,copyright 2021.(c) M-FePcX formation process.(d) Comparison of ammonia production efficiency of FePcX containing different doses of different types of accelerators (1 bar=0.1 MPa).Reproduced from Ref.[25]with permission of Elsevier,copyright 2021.(e)Schematic representation of the fabrication process for the 2D core–shell Fe@mSiO2 catalyst.(f)Fe mass normalized NH3 production rates.Reproduced from Ref.[26] with permission of American Chemical Society,copyright 2021.

Doped oxynitrides with a large number of anionic vacancies,especially nitrogen vacancies,are excellent promoters/cocatalysts for ammonia synthesis.A material with fluorite structure,Ce1–zSmzO2–xNy(z≤0.5),was synthesized by an air combustion method [24].As shown in Fig.4(a),(b),the nitrogen content and the number of anion vacancies increased with higher Sm doping levels and the high concentration of anion vacancies in Ce1–zSmz-O2–xNyfacilitated the nesting/anchoring of Fe particles,resulting in the dependence of strong metal support interaction (SMSI) on stability.z≥0.3 for 80%(mass)Fe-20%(mass)Ce1–zSmzO2–xNycatalysts had an apparent activation energy of about 45 kJ∙mol-1.Based on the phenomenon that the cerium oxide lattice forms more Ce—H species when exposed to H2at high temperatures,the author speculated that the low activation energy and the presence of Sm ions might make the reaction indirectly form H ions through the intermediate of Ce1–zSmzO2–xNy,which might have the same or similar reaction mechanism as TM/BaCeO3–xNyHz.The optimal composition was 80% (mass) Fe-20% (mass) Ce0.5-Sm0.5O2–xNyshowing activity of 18.8 mmol∙g-1∙h-1at 400 °C and 3 MPa.Even when a significant proportion of impurities such as oxygen were injected in the reaction gas,the activity still reaches 70%.Phthalocyanine-based catalysts for ammonia synthesis have also been investigated.Maksoudet al.[25] produced iron-based catalysts by FePc pyrolysis shown in Fig.4(c),promoters were introduced and a constant molar content of alkali metal was ensured to be 0.77 mmol∙g-1.Spherical iron nanoparticles were evenly loaded on nitrogen-doped carbon,and the particle size was temperature-dependent.Carbon and alkali metals forming a multicoated structure in the shell were indistinguishable.Fe was located in the core,while Cs,C,and O were distributed on the shell.This close contact between Cs and Fe was likely to trigger strong metal promoter interactions,which might be the source of enhanced catalytic activity.They also partially suppressed the methanation of carbon that occurs during the H2pretreatment process.From Fig.4(d),the promoting activities of different promoters for FePc catalysts were in the order of K >Cs >Na ≈Li.The best catalytic performance was obtained for pyrolysis at 600 °C with 10% Cs doped and 700 °C with 3% K doped FePc.Two-dimensional (2D)FeOOH nanosheets encapsulated by mesoporous silica (mSiO2)FeOOH@mSiO2were prepared [26],as shown in Fig.4(e).Owing to the adhesion of the mSiO2coating and the limited space between them,the reduced Fe maintained its 2D morphology and exhibited high sintering resistance in the harsh Haber-Bosch process.A silica layer was successfully coated on FeOOH nanosheets.The distribution of Fe and Si in the coated samples was significantly more uniform than that in the supported samples.The ammonia production rate of the SiO2-coated FeOOH sample was 4.5 μmol∙g-1∙s-1at 425 °C,which was 50% more active than that of the SiO2-supported FeOOH sample (3.1 μmol∙g1∙s-1).Differential interactions of Fe with mSiO2and Al/mSiO2might induce another interfacial (metal-oxide) contact,thus changing the local Fe structure as well as the corresponding active sites.The catalysts containing two-dimensional Fe nanostructures (embedded in porous silica layers)were rich in surface step/kink sites.Compared to the catalysts containing Fe nanoparticles on silica spheres,the 2D Fe catalysts exhibited higher catalytic activity.Compared to the non-doped catalyst (Fe@mSiO2),the Al-doped mSiO2catalyst (Fe@Al/mSiO2) exhibited slightly lower activity and higher activation energy,indicating that the Al doping introduced structural and electronic effects,which negatively changed the nature of the active sites.Replacing part of the Fe with Co improved the activity of catalysts and positively affected the active sites(Fig.4(f)).Silicon dioxide was a better carrier than γ-Al2O3for both FeOOH nanosheets [55].

Embedded iron-based particles were likewise investigated.Liet al.[56] proposed computationally that Fe-N2complexes hosted on nanographene could facilitate N2fixation under ambient conditions.FeN3-graphene had a C3vsymmetric out-of-plane geometry with Fe atoms located outside the graphene plane and exposed at the top above the graphene layer,and the electron charge cloud being distributed near Fe,so Fe contributes the major spin moment.Because of its larger and more concentrated spin moment,the Fe site exhibited good N2adsorption and N2immobilization activity.N≡N bonds were first stretched by adsorption and then gradually elongated by hydrogenation until breakage.N2was trapped and could be either standing or recumbent in the formed complexes and was stable at room temperature,and the FeN3centre could be used in three ways to split the N≡N bond,each route being a 6-proton and 6-electron process.During subsequent hydrogenation,FeN3might participate in the reaction or acted only as a carrier for the transfer of electrons.And it was calculated that the energy required for the release of hydrazine during hydrogenation was not satisfied at room temperature.The stretching effect of the adsorption reaction was comparable to that of the hydrogenation reaction.The collaboration between graphene,as an electron reservoir,and FeN3,as an active site for N2immobilization and as a transporter for electron,assisted the system as a new catalyst for ammonia synthesis.

Simple iron-based catalysts can also be revitalized by alternative approaches.Hanet al.[57] achieved a final ammonia concentration of up to 82.5% (vol) better than the existing Haber process by using mechanochemical ball milling in a reaction,where the high defect density generatedin situby inexpensive untreated iron powder and the diverted energy from dynamic relaxation during severe impact accelerated ammonia production at mild conditions down to 45°C and 0.1 MPa.A series of unique properties were produced by the mechanochemical ball milling process in the iron catalyst used.Initially stable N2was attracted to the iron particle flaws and disintegrates into atomic N.Subsequently it was hydrogenated into NHx*species(x=1–3).Aided by extra transfer energy,the highly adsorbed NHx* species were then separated away from the Fe-surface.Eventually,the resulting ammonia is released.

3.2.Ru-based catalysts and other catalysts

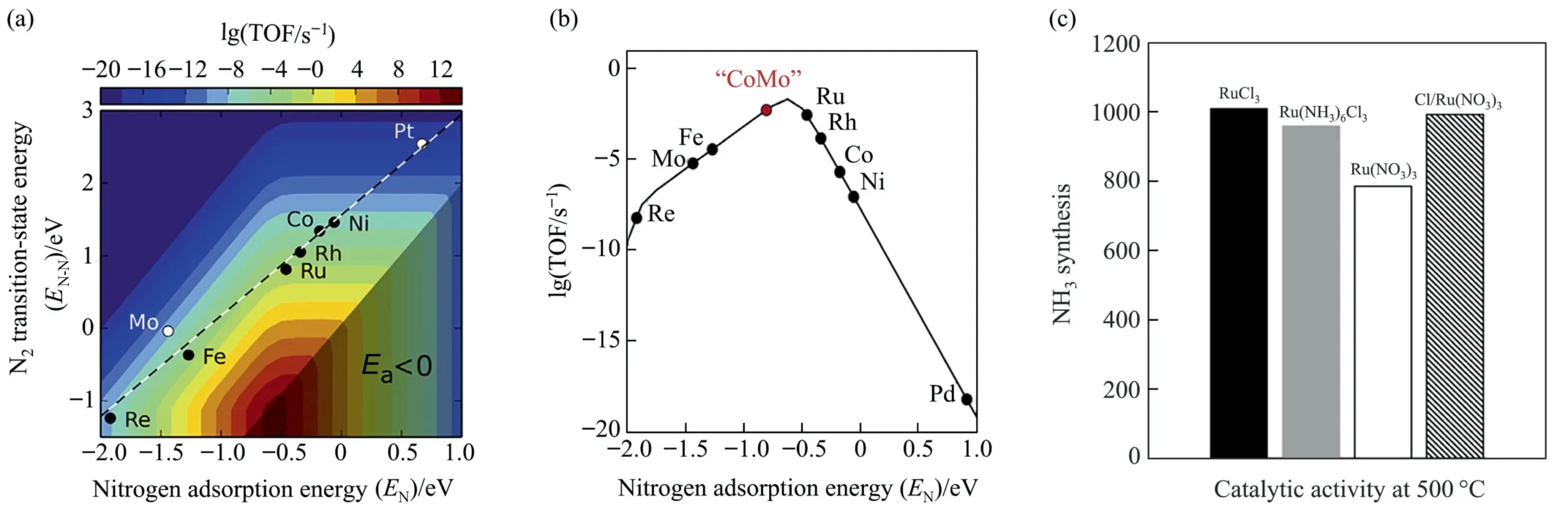

Considering Sabatier principle,the best catalysts should bind atoms and molecules at moderate strength: neither too weak to activate the reactants,nor too strong to desorb the products.An obvious linear scale relationship exists between the transition state energy of N2dissociation in ammonia synthesis and the adsorption energy of nitrogen which is a variable that can be used independently to quantify bond energies on the surface of the metal concerned [58].The Fig.5(a) reveals the relationship between the catalytic activity of different catalysts and the adsorption energy of nitrogen.N adsorption energy is a surface property that responds to surface-mediated interactions that can be detected between transition metals and nitrogen [59].It is a research hotspot since Ru element is located near the top region of the volcanic shape curve,as shown in Fig.5(b).Ru-based catalysts allow milder operating conditions,such as lower synthesis pressures (7–10.5 MPa) and lower synthesis temperatures,while maintaining a higher conversion rate than conventional systems.Ru generally has to be paired with a support body[60].Ru precursors exists in a variety of forms.The most common ones are Ru3(-CO)12and RuCl3.In catalyst samples prepared from RuCl3,the particle size homogeneity of Ru is poor,while the residual Cl ions tightly bound to the metal surface or to the carrier adversely affect the catalytic behavior.Ammonia production rates for silica-loaded Ru cluster catalysts obtained from Ru3(CO)12are faster than those on catalysts prepared from RuCl3[61,62].The Ru3(CO)12clusters are adsorbed on the surface of active carriers such as alumina,the metal particles highly are dispersed and immobilized on the active sites of the carriers after decomposition and reduction to metal [63].However,it is not absolute.It has been recently found that the activity of catalysts prepared with Cl-containing precursors was much higher than that of catalysts prepared with non-Cl precursors when loaded with 1%(mass)Ru on MgFe2O4support(Fig.5(c)).The RuCl3precursor provided the highest Ru dispersion,while in the non-Cl precursors Ru particles were deposited in aggregates on the surface of the MgFe2O4carrier.Perhaps the high acidity of the aqueous solution leads to the rearrangement of MgFe2O4elements,which increases the concentration of Mg on the surface and forms Mg films.The coexistence of Mg films and Cl can effectively obtain a high dispersion of Ru particles,thus improving their catalytic activity [27].Besides,K2RuO4and Ru(NO)(NO3)3are also available as precursors.

Fig.5. (a)Ammonia synthesis rates at FCC/HCP metal step sites and scale lines as a function of N2 adsorption energy and N2 dissociation potential.Reproduced from Ref.[59]with permission of Elsevier,copyright 2015 (TOF=turnover frequency).(b) Traditional volcano map.(c) Comparison of catalyst activity prepared using different precursor systems on MgFe2O4.Reproduced from Ref.[27] with permission of Chemistry Europe,copyright 2020.

Fig.6. (a)Ammonia synthesis efficiency at different temperatures for different Cs/Ru ratio catalysts,The curves in order from bottom to top referring to Ru/γ-Al2O3,0.5Cs-Ru/γ-Al2O3,0.75Cs-Ru/γ-Al2O3,1.5Cs-Ru/γ-Al2O3 and 5Cs Cs-Ru/γ-Al2O3.(b)Relationship between Cs/Ru ratio and ammonia synthesis efficiency.(c)Existence of three types of Cs/Ru ratio carrier surface species.Reproduced from Ref.[28]with permission of Elsevier,copyright 2022.(d)B5 locus structure.Reproduced from Ref.[68]with permission of Wiley Online Library,copyright 2001.(e)Sketch of ammonia production from Sr2Ta2O7 with promoters.Reproduced from Ref.[46]with permission of Elsevier,copyright 2020.

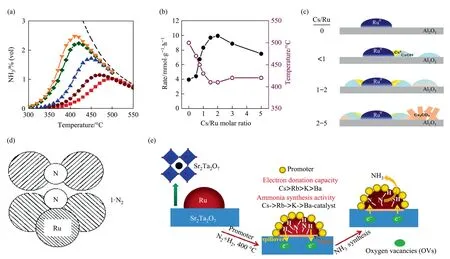

Carriers/promoters of Ru crystals supported by recent researchers are categorized as diverse:Al2O3[28],perovskite type[29],lanthanide[31,32,64,65],zeolite[33,66,67],hydride/nitride,Ru/C12A7,etc.Al2O3is already used as a frequent carrier in industrial catalytic technology by virtue of its porous and robust framework nature.Recently,the catalytic properties of Cs-Ru/γ-Al2O3with Cs/Ru molar ratios of 0.25–5 were investigated (Fig.6(a)) [28].As illustrated in Fig.6(b),the best performance was centralized on 1.5Cs-Ru/γ-Al2O3,which yielded ammonia at 300 °C with a maximumrNH3of 9.7 mmol∙g-1∙h-1at 410 °C.5Cs-Ru/γ-Al2O3had the potential to catalyze low-pressure,intermittent ammonia synthesis reactions with high activity,good stability,and fast responsiveness.The catalyst demonstrated maximum ammonia precipitation efficiency at H2/N2molar ratio of 1 due to hydrogen poisoning.The specific surface area (SBET) value,gross value and porosity of the prepared Cs-Ru/γ-Al2O3catalyst gradually decreased with increasing Cs/Ru molar ratio.The Cs firstly remained in the acidic position of γ-Al2O3and then adhered to the Ru boundary,as the Cs/Ru molar ratio increased in the range of 0.5–1.5.Cs2CO3was formed at high Cs/Ru molar ratio(>1.5)(Fig.6(c)).During reductive activation,the reduced metal Ru particles and the reduced CsOH achieved a maximum at a Cs/Ru molar ratio of 1.5 and showed high ammonia synthesis activity.Density functional theory(DFT)calculations indicated that CsOH diminished hydrogen poisoning caused by hydrogen spillover and provided new active sites for ammonia synthesis.In addition,electron-promoting effects were observed through hydrogen spillover when reduced Cs species were formed at the interface of Ru and CsOH active sites.The Cs0/CsOH-Ru active sites of Ru/γ-Al2O3catalyst not only generated new active sites,but also changed the surface alkalinity/stability,facilitating the adsorption and desorption of H2,N2and ammonia,and promoting the ammonia synthesis process as well [28].

Chalcogenide oxide Sr2Ta2O7,as a carrier for Ru NPs,exhibits high alkalinity and high electrical conductivity.Huanget al.[29]synthesized 2% (mass) Sr2Ta2O7carriers by hydrothermal impregnation method.Excessive addition of Sr(OH)2to the hydrothermal synthesis speeded up the dissolution and nucleation rate of Ta2O5in pure-phase Sr2Ta2O7crystals,resulting in the formation of nanowires with smaller diameters.It was anticipated that the alkaline reduction carrier Sr2Ta2O7nanowires could suppress hydrogen poisoning on Ru surface by hydrogen spillover induced SMSI,release more B5 active sites,promote the dissociative adsorption of N2,enhance the number of N atoms on Ru surface as well as strengthen the activation of N2molecules in ammonia synthesis reaction,further promoting its reaction with H atoms and kinetic NHxformation.The so-called b5-type site consists of three Ru atoms on a layer on the Ru(0001) platform and two Ru atoms on the upper layer (Fig.6(d)) [68].

Alkali (earth) metals (Rb,K,Cs,and Ba) as promoters were equally examined.The outcomes demonstrated that the enhancements of promoter were in the following order: Cs >Rb >K >Ba(Fig.6(e)).The alkali metal promoters could boost the electron density on the Ru surface,thus enhancing the dissociation of N2through electron transfer.The four promoters exhibited various enhancements to the ammonia synthesis,with 5Cs-2Ru4STO(promoter to Ru molar ratio of 5,2% (mass) Ru raw material Sr(OH)2/Ta2O5molar ratio of 4) showing the highest performance.The appearance of Cs generated more OVs which along with the Cs promoter provided electrons to the Ru catalyst[29].The performance of known highly active ammonia catalysts could also be improved using unconventional promotion techniques.Shadravanet al.[30]usedin situpreparation techniques to promote Ru/C catalysts directly by metal Cs vapor in a high pressure plug flow reactor without any air exposure and with minimal oxygen impurities(especially O2and water).The higher activity of thein-situpromoted catalysts was not due only to the smaller particle size,on the contrary,the size ofin-situcatalysts was larger.An essential point in the stability performance ofin-situpromoted catalysts was the virtual absence of compounds containing O Cs2O,CsOH,CsN3,and CsH were readily reduced during the process to form adsorbed Cs*,which was the critical species that reduces the dissociation transition state energy of N2as a promoter,while all other species increased the activation energy.The electric field evoked by adsorbed Cs was associated with attractive interactions between dipoles induced by surface transition state N2molecules.An increase in the stability of the transition state with increasing Cs coverage led to an increase in the stability of the transition state,solving the problem that the rate of ammonia synthesis over nonin situcatalysts hardly varies with the ratio of Cs/Ru.The three H*atoms around the active site needed to be removed before dissociation of N2from the pristine Ru surface can occur.In contrast to the low Cs coverage model where two additional H atoms need to be removed,for the high Cs coverage model,there is also less impact on H2poisoning as only one H atom needs to be removed for the two Cs atoms.

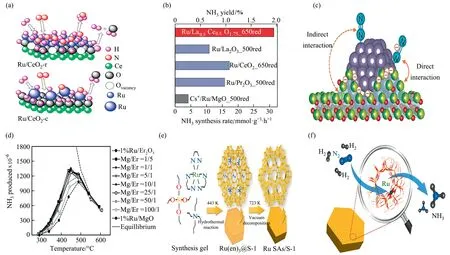

Lanthanides are capable of being both promoters and supporters.One of the effects of being a promoter is to alleviate hydrogen poisoning,which means that hydrogen seems to adsorb more strongly on the surface of Ru atoms and covers almost all the Ru surface.The strong adsorption of hydrogen inhibits the activation process resulting in a delayed activation of nitrogen [64].La2O3is an active promoter of Ru/MgO.The activation of catalysts with lanthanide promoters is approximately twice that of the promoterfree sample M (Ru/MgO) [65].The Ru/CeO2catalysts with various surface oxygen vacancies on CeO2nanorods and nanotubes were plotted against each other (Fig.7(a)).The conversion of Ce4+to Ce3+and the formation of Ru—O—Ce bonds on the surface of CeO2nanorods contributed to the amount of oxygen vacancies.The low crystallinity and high concentration of oxygen vacancies of Ru species enhanced the adsorption of hydrogen and nitrogen,and also led to the desorption of surface hydrogen in the form of H2,thus exhibiting a higher ammonia synthesis activity.In contrast,lower catalytic activity was attributed to the presence of metallic Ru particles on the surface of CeO2nanotubes with large particle size and low concentration of oxygen vacancies and most of the consumed hydrogen material during the formation of water[69].Recently,a combination of Ce and La elements(Ru/La0.5Ce0.5-O1.75) has been reported.This was a catalyst consisting of La0.5-Ce0.5O1.75solid solution: Ce and La were uniformly dispersed in the oxide carrier,and Ru particles are strongly anchored on La0.5-Ce0.5O1.75synthesized from CeO2and La2O3.As shown in Fig.7(b),it exhibited a high rate of ammonia synthesis(31.3 mmol∙g-1∙h-1) due to the intense interaction between many Ru active sites and the reduction carrier.The formation of solid solution complex oxides disturbed the adsorption of La2O3to water and the crystal growth of the oxidation carrier.Due to a result of the reduction of Ce4+to Ce3+and the formation of oxygen vacancies,the partially reduced carriers covered part of the Ru particles leading to a greatly enhanced electron transfer.The electron transfer to the antibound p orbital of N2,weaking the N≡N triple bond.The high pre-reduction temperature induced SMSI and promoted Ru site activity,but reduced the number of Ru active sites,which together resulted in an optimal pre-reduction temperature of 650°C,significantly higher than the reaction temperature of Ru-catalyzed ammonia synthesis.The Ru/La0.5Ce0.5O1.75,a solid solution homogeneously dissolved in a cubic elongate structure,had the optimal catalytic performance (Fig.7(c)) [31].

Combination of two or more metal oxides as vehicles are thought to yield diverse functionalities from each oxide,allowing new properties in catalysts.Mg and Er are regarded as common vehicles because of identical dispersion.Lanthanide oxides typically have lower surface area but higher catalytic ammonia synthesis activity than MgO,and mixtures of the two can better support Ru-based catalysts by obtaining higher surface area from MgO as well as electron donor promotion from lanthanide.1%Ru mixed oxide carriers of MgO-Er2O3with various molar ratios of Mg/Er were fabricated by co-precipitation method and the NH3efficiency varied with the value of Mg/Er ratio(Fig.7(d)).The excess Er2O3at Mg/Er ratio of 1/5 increased the crystallinity of MgO inhibiting the crystal growth and the MgO fraction remained in the amorphous or fine-grained state.The surface area grew with the content of MgO,and afterwards a more stable state was reached.A further increase in MgO content caused substantial structural changes,leading to a decrease in surface area and high growth inhibition of Er2O3crystal.The ammonia synthesis activity of Ru/MgO-Er2O3accompanied by a well dispersed Mg/Er molar ratio of 25/1 was comparable to that of pure Er2O3supported Ru catalysts,which somewhat mitigated the problem of expensive production cost [32].

Fig.7. (a) Different surface oxygen vacancies of Ru/CeO2 nanorods compared with nanotubes.Reproduced from Ref.[69] with permission of American Chemical Society,copyright 2018.(b)Ru/La0.5Ce0.5O1.75 Optimal ammonia synthesis efficiency.(c)Probable activation mechanism of N2 on Ru/Ce0.5La0.51.75_650 red.The gray ball is for Ru,the red ball is for oxygen atoms,and the two-color ball is for La/Ce.Reproduced from Ref.[31] with permission of Royal Society of Chemistry,copyright 2018.(d) The activity tendency of various Mg/Er ratio Ru catalysts produced with MgO-Er2O3 medium.Reproduced from Ref.[32] with permission of Elsevier,copyright 2020.(e) Monatomic Ru acquisition path.(f) RuSAs/S-1 simplified ammonia production process.Reproduced from Ref.[33] with permission of American Chemical Society,copyright 2019.

Since Ru planes are independent of N2dissociation,it is necessary to select suitable carriers and promoters as much as possible to make small Ru clusters reach the same active state as the bulk Ru metal.Zeolites are favored carriers for Ru metal.The dimensions of the pores or the cages of the zeolite constrain the particle size within the crystal and the basicity of the zeolite can be changed by cation alteration [66].Cisneros and Lunsford [67] also discovered that the activity of zeolite-supported Ru was firmly anchored by the presence of cations in the zeolite-the more basic the zeolite,the more active the catalyst.The intense basicity of the added promoter induced localized destruction of the zeolite framework.Zeolites also supplied acid-related active centers,which hindered the mechanistic elaboration of the sites.Pure silica zeolite-loaded Ru single-atom catalysts were employed to overcome this difficulty.As shown in Fig.7(e),single Ru atoms were obtained from [Ru-(NH2CH2NH2)3]Cl3,where Ru3+ions were latched by three glycoside ligands.The acquired samples had a nanoscale hexagonal prismatic morphology.According to some electron microscopic analyses,Ru atoms were distributed uniformly in the crystals of zeolite,and there were no subnanoclusters inside the zeolite crystal or outside the crystal surface.The induced Ru complexes resided in the zeolite channels rather than causing lattice defects.Suitable atmosphere,heat treatment temperature and Ru loading were critical factors for the successful preparation of single-atom catalyst (SAC).The catalytic activities of RuSAs/S-1 were all higher than those of Cs-Ru/MgO.The ammonia synthesis rate of Ba-RuSAs/S-1 obtained after the addition of promoter Ba ions reached 1389.5 μmol∙g-1∙h-1at 400 °C,which was approximately 2 orders of magnitude higher than that of the unpromoted catalyst.The oxidation state of a single Ru atom approaches that of RuO2,and the higher oxidation state led to a lower d-band center,which provided less electron feed back to the antibonding orbital of the N2molecule and less electrons to the H2molecule,inhibiting the H-poisoning phenomenon.N2* was adsorbed on the exposed Ru single atom position linearly.It had weaker affinity for the Ru δ+center compared to N2*,thus facilitating the physisorption of H2within the zeolite channel.The rate-determining step was the reaction of physiosorbed H2and adsorbed N2*,which yielded two ammonia molecules with simultaneous structure A release,completing the cycle.RuSAs/S-1 simplified ammonia production process is shown in Fig.7(f) [33].

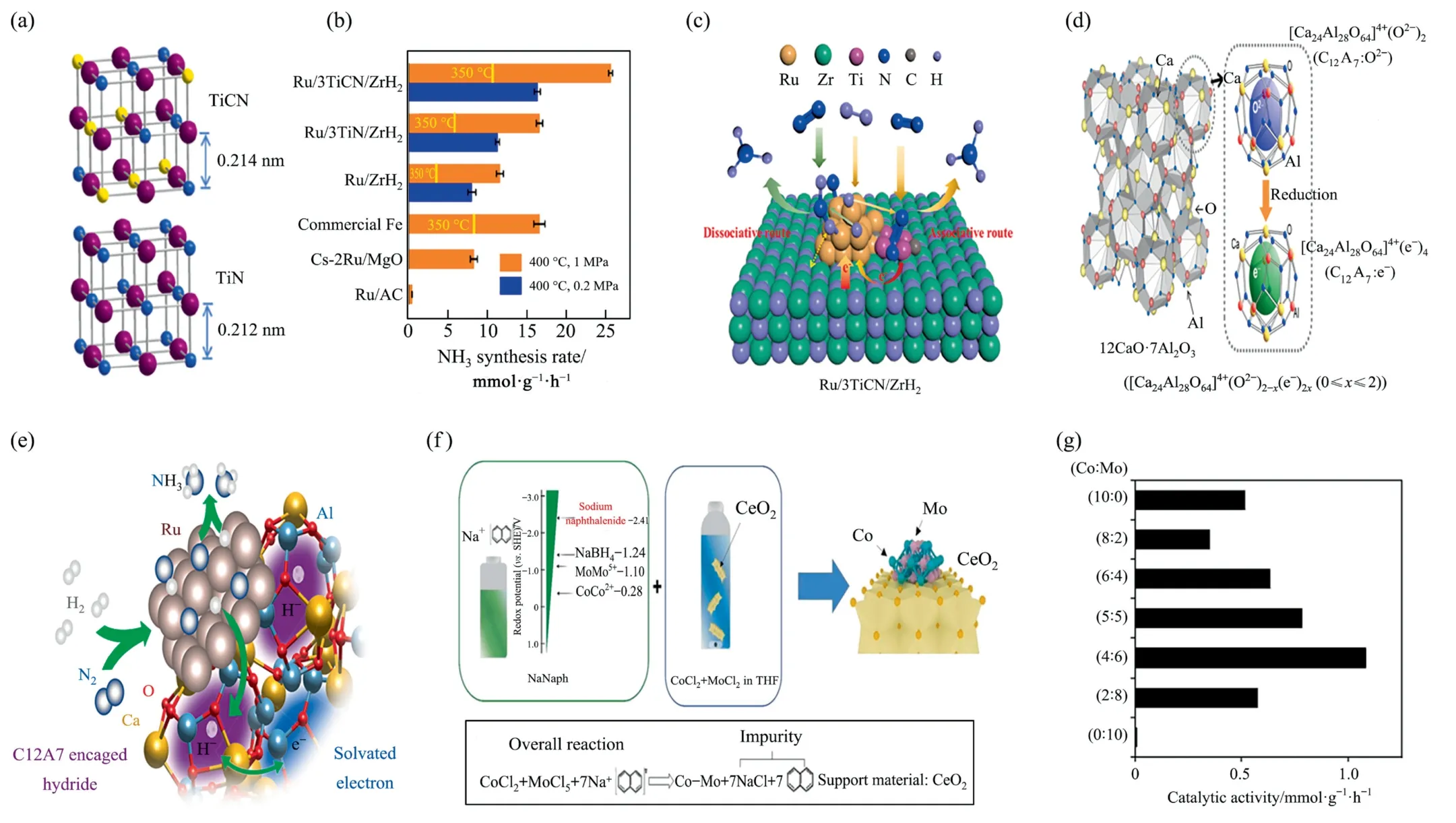

Ru-loaded titanium carbide nitride (TiCN) was synthesized by ball milling.Ru/3TiCN/ZrH2(3% (mass) Ru) catalyst was synthesized at 400 °C and 1 MPa with very low methane concentration in the side reaction[34].The incorporation of Ru—N bond between Ru metal and TiCN could successfully restrain the agglomeration of Ru particles and create more B5 sites,which promoted the transfer of electrons from Ru position to the antibonding orbital of N2.With the assistance of Ru,N vacancies on TiCN were prone to form*NNH by N2hydrogenation reaction which follows bonding mechanism.The generation energy of N vacancies in TiN was lower than that in TiCN (Fig.8(a)).The reversible hydrogen storage capacity of hydride(ZrH2)could effectively inhibit hydrogen poisoning.Unlike conventional Ru-based catalysts which usually follow dissociation mechanism,Ru/3TiCN/ZrH2followed integrated dissociation and binding mechanism,giving the reason of the superior ammonia synthesis rate of our catalysts under mild conditions(Fig.8(b),(c)).

Although valid promoters can be alkali/alkaline-earth metal hydrides or nitrides that confer sufficient electrons to Ru or stimulate electrostatic effects of Ru surface reactants to enhance catalytic activity,the possibility of forming metal amides by virtue of their own chemical activity in reaction with the resulting ammonia can cause instability [2,35].Ru-loaded charged metallic group [Ca24Al28O64]41(e–)4(C12A7),a crystalline cavity that captures electrons in the anion,has been discovered in recent years[70].The unit cell of the positively charged framework structure C12A7consists of 12 sub-nanometer sized cages,four of which contain four O2–ions as counter anions,connected with a monoxide layer to achieve electrical neutrality.The chemical reduction process compensates for the positive charge on the cage walls by extracting two O2–ions from the 12 cages and injecting four electrons into the two O2–ions in the cavities (Fig.8(d)) [70–72].The electrons encapsulated in the cage can easily form H–by heating in H2gas.The H–ion desorbs as an H2molecule at about 400 °C,leaving the electrons in the positively charged framework of C12A7.The hydrogen atoms on Ru can simply escape into the negatively charged framework of C12A7,thus preventing the hydrogen atoms from occupying the Ru surface while the electrons are transferred to Ru.The increase in the Fermi energy level of the metal leads to a significant decrease in the work function of Ru,thus allowing the H–ion to react with the N formed by the dissociation of N2to form NH3(Fig.8(e)),and the electrons wrapped in the negatively charged framework of C12A7are used repeatedly during the reaction [35,73].

Fig.8. (a)TiCN and TiN cell structure.(b)NH3 synthesis performance of Ru/3TiCN/ZrH2 and each control group at 400°C under 0.2 or 1 MPa.(c)Structure of Ru/3TiCN/ZrH2.Reproduced from Ref.[34] with permission of American Chemical Society,copyright 2022.(d) Framework structure of each part of C12A7.Reproduced from Ref.[70] with permission of American Chemical Society,copyright 2017.(e) Schematic diagram of Ru/C12A7 reaction.Reproduced from Ref.[71] with permission of American Chemical Society,copyright 2017.(f)Schematic diagram of the synthesis of Co-Mo(X:Y)/CeO2 catalyst.(g)Catalytic activity of various Co/Mo ratio catalysts for ammonia synthesis at 0.1 MPa and 400 °C.Reproduced from Ref.[9] with permission of Elsevier,copyright 2018.

However,the high cost of catalysts associated with Ru (noble metal) is a major drawback that has inspired the development of inexpensive non-precious metal catalysts.Combining metals on both sides of the volcano diagram,such as Co and Mo,or Ru/Co is an effective stage to achieve the desired interactions of intermediate N.Tsujiet al.[9]introduced CeO2into a tetrahydrofuran solution containing cobalt chloride and MoCl5in multiple steps to obtain Co-Mo/CeO2.Co and Mo were present in close proximity and synergistically interacted(Fig.8(f)).The authors identified that when Co/Mo equalled 4:6,the ammonia synthesis rate would reach a maximum value (1.08 mmol∙g-1∙h-1) shown in Fig.8(g).The reaction mechanism of ammonia synthesis was comparable to that of Co3Mo3N.N vacancies were formed more readily over Co-Mo/CeO2catalysts than over bulk Co3Mo3N.The N2dissociation step on Co3Mo3N nanoparticles was enhanced by the electronic contribution supported by reduced CeO2.A suitable proportion of Cr and K,serving as promoter,led to a well-developed porous structure.The total surface area and catalytic activity were increased by more than 50% compared with non-promoted catalysts [74].Ru atoms were inserted to form RuCo double monoatomic active sites on the surface layer where N of g-C3N4coordinates with Co.The developed RuCo dual single-atom catalyst(RuCoDSAC) had an ammonia synthesis rate of 1.24 mmol∙g-1∙h-1at 200 °C.The RuCoDSAC structure could effectively foster the transfer of electrons from pyrrole N to Ru atoms on the surface to promote adsorption,activation and hydrogenation of N2.N2adsorbed at the Co center to form hydrides was transferred to the Ru site to react with the activated N2to generate N2Hxintermediates.Meanwhile surface intermediates such as *N2Hxand *NH3were readily desorbed on RuCoDSAC with narrow d-band centers[36].

Ru nanoparticles(NPs)have been proven to be their active sites.Ru catalysts with large nanoparticles subject to over-adsorption on the H2surface,blocking N2activation.As per the theoretical model-the Wulff structure suggests that with the size of Ru entities due to the lack of active sites,the sub-nanoclusters should have little activity.However,it has been shown that narrowing down to sub-nanoprecious metal clusters,atomic clusters or even single atoms is an effective strategy to enhance ammonia synthesis.N2activation pathways change as clusters,single atoms fully expose the catalytically active edge or corner sites and generally exhibit significantly enhanced properties.By adjusting the precursors and/or loading,single atom,atomic clusters,and sub-nanocluster ruthenium catalysts are synthesized by breaking the limits of nanoparticles.The sub-nanocluster Ru catalysts not only exhibit different properties from the NPs,but also have different activation pathways for N2.The intense intracluster interactions of the Ru clusters enable the Ru d orbitals to form strong interactions with the s and p orbitals of the N2molecule,causing activation to occur more readily on the Ru ACC or sub-nanocluster than on the Ru NPs[75].The result is a weakening of the N2bond orbital.The adsorption,activation and hydrogenation of N2by the catalyst is significantly facilitated by the mechanism of association with a very small reaction energy potential barrier [76].

To prevent the polymerization of small size Ru,various approaches can be employed.Zhouet al.[37] employed the colloidal particle impregnation method to deposit colloidal Ru nanoparticles on BaCeO3carriers.The decrease in Ru size enhances the production of Ce3+and O vacancies in BaCeO3,thus providing electrons to the Ru centre,and subsequently the Ru 4d orbital gave electrons to the antibonding orbital of the N2molecule to reduce the N2activation potential barrier and also enhances hydrogen spillover from Ru to BaCeO3to relieve hydrogen poisoning for efficient ammonia synthesis.To reduce the particle size distribution of the catalyst,Liet al.[76] used a carrier with copious porous channels and cavities like MOF (MIL-101),superior to zeolites,to constrain the metal cluster size and anchor the reaction sites.Through a dual fit strategy of metal-linked porous materials,the metal-encapsulated MOF hosts were pyrolyzed after the addition of MgO or/and Cs2O,and the embedded metal clusters were eventually trapped in the shrinkage cavities.

3.3.Metal nitride catalyst

Rare earth metal nitrides such as CeN and LaN have received a lot of attention due to their nitrogen vacancy activation for ammonia synthesis,the nitrogen vacancy formation energy (NVFE) governs the catalytic performance and is a general rule for the design of nitride-based catalysts[38].The presence of N vacancies in CeN could activate both N2and H2during the reaction and its catalytic performance is much higher than other reported unloaded catalysts for ammonia synthesis.One of the attractions of LaN/Ni was its low NVFE.The reaction of the lattice N of LaN directly with dissociated hydrogen (H*) on the Ni surface yielded ammonia and N vacancies.where the N2molecule was subsequently adsorbed and activated at the N vacancy site and continuously reacts with H* to achieve a stable catalytic cycle.In the condition of a nitride loaded with Ni,H2and N2were activated at the Ni metal and VN sites individually.Without Ni loading,the VN site can activate both H2and N2to stabilise ammonia production.Yeet al.[39] also reported a synergistic mechanism for the binding and dissociation of Co/CeN in the synthesis of ammonia over catalysts under mild reaction conditions.The formation of N vacancies in CeN also promoted the efficient cleavage of N2on Co.

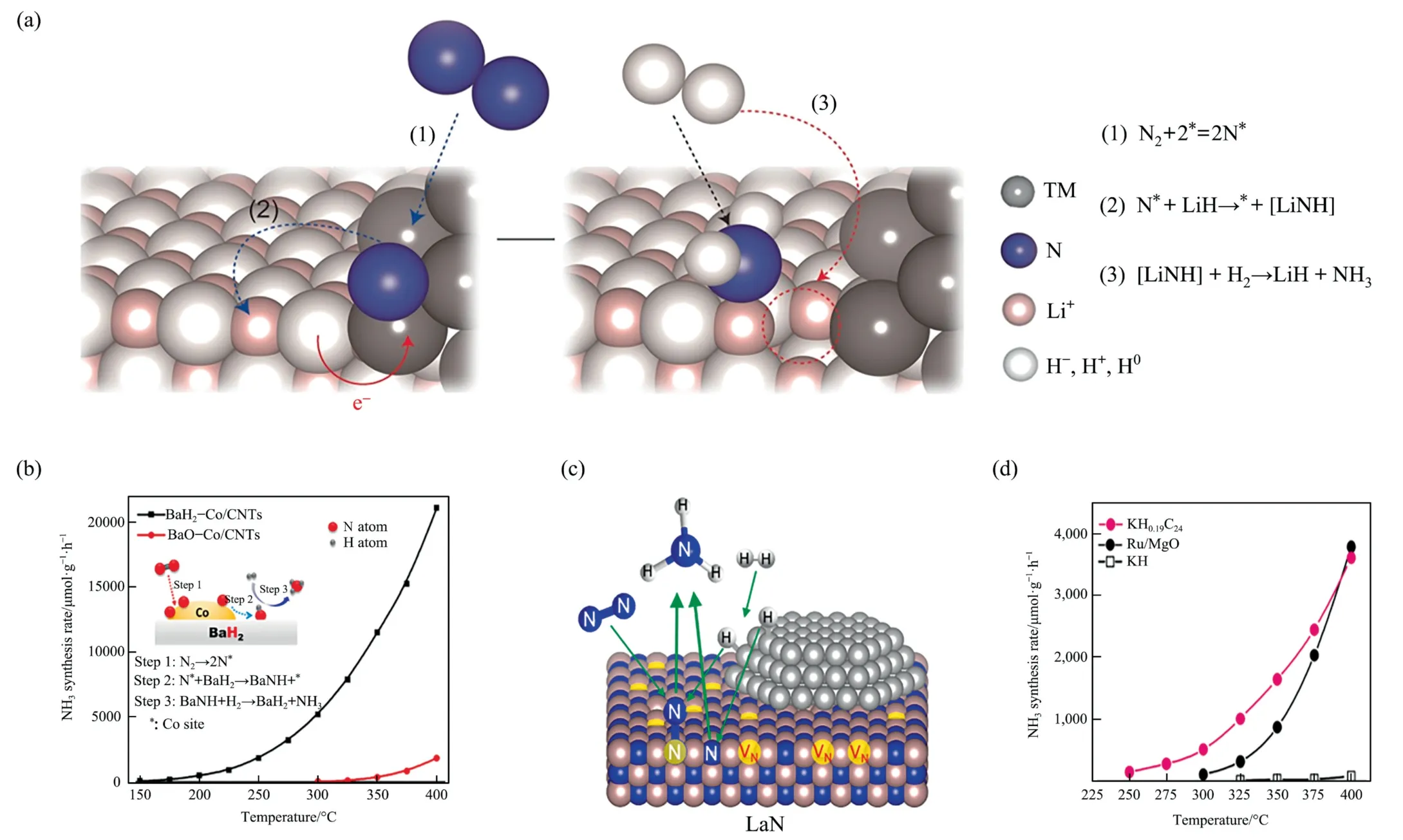

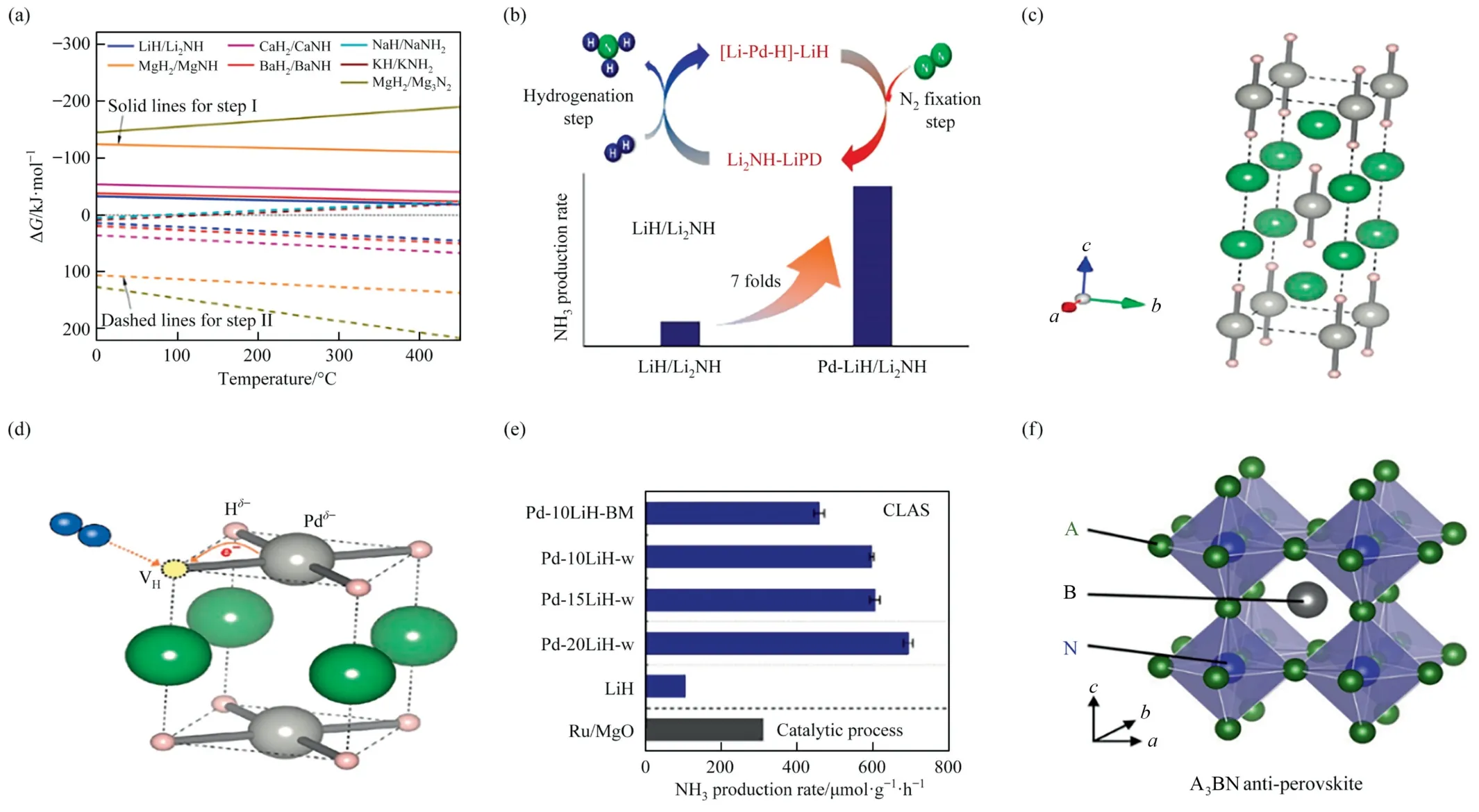

The finitely charged hydrogen atom in lithium hydride acting as a strong reducing agent eliminates the activated N atom from the transition metals (TM) or its nitride (TMN) and serves as a direct source of hydrogen which bonds with the N atom to form Li2NH/LiNH2to further heterolyze splitting H2,releasing ammonia and regenerating the lithium hydride (Fig.9(a)).Co-creation between TM(or TMN)and lithium hydride could usefully separate Nadfrom TM(N)to free TM site and then recycled the reaction[40].The combination of Co with BaH2formed the catalyst which had low temperature reaction activity (Fig.9(b)) [42].The nickel nitride with embedded nickel also obviated the common dual site mechanism of proportional relationship (Fig.9(c)) [41].In addition,the insertion of other substances into the hydride also allowed to obtain excellent ammonia production efficiency.As shown in Fig.9(d),ammonia productivity of KH0.19C24obtained by intercalating KH into the layers of the graphite host material at 250–400 °C and 1 MPa,was comparable to that of the classical noble metal catalyst Ru/MgO and the synthesis principle inclined to comply with the associative alternating pathway [8].

Fig.9. (a) Reaction mechanism of ammonia synthesis over TM(N)-LiH catalyst.The white balls represent H0,H– and H+,the basketball represents N,the powder ball represents Li+ and the gray ball represents TM.Reproduced from Ref.[40] with permission of Nature Publishing Group,copyright 2016.(b) Mechanism and efficiency of ammonia synthesis reaction over BaH2-Co/CNT catalyst.Reproduced from Ref.[42] with permission of Nature Publishing Group,copyright 2020.(c) Structure of ammonia synthesis over loaded transition metal catalysts (TM/LaN).Reproduced from Ref.[41] with permission of American Chemical Society,copyright 2017.(d) KH0.19C24 corresponds to the equivalent ammonia productivity of Ru/MgO at 250–400°C and 1 MPa.Reproduced from Ref.[8]with permission of Nature Publishing Group,copyright 2020.

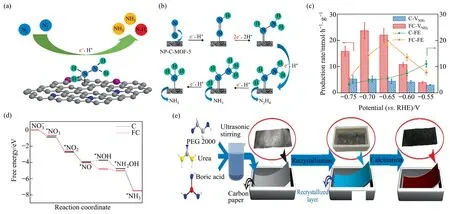

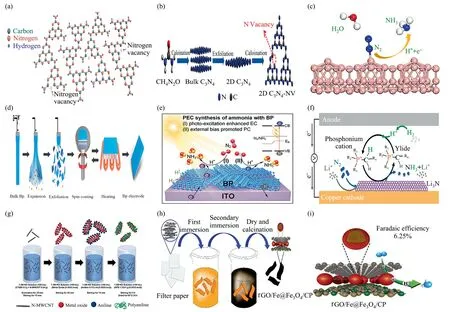

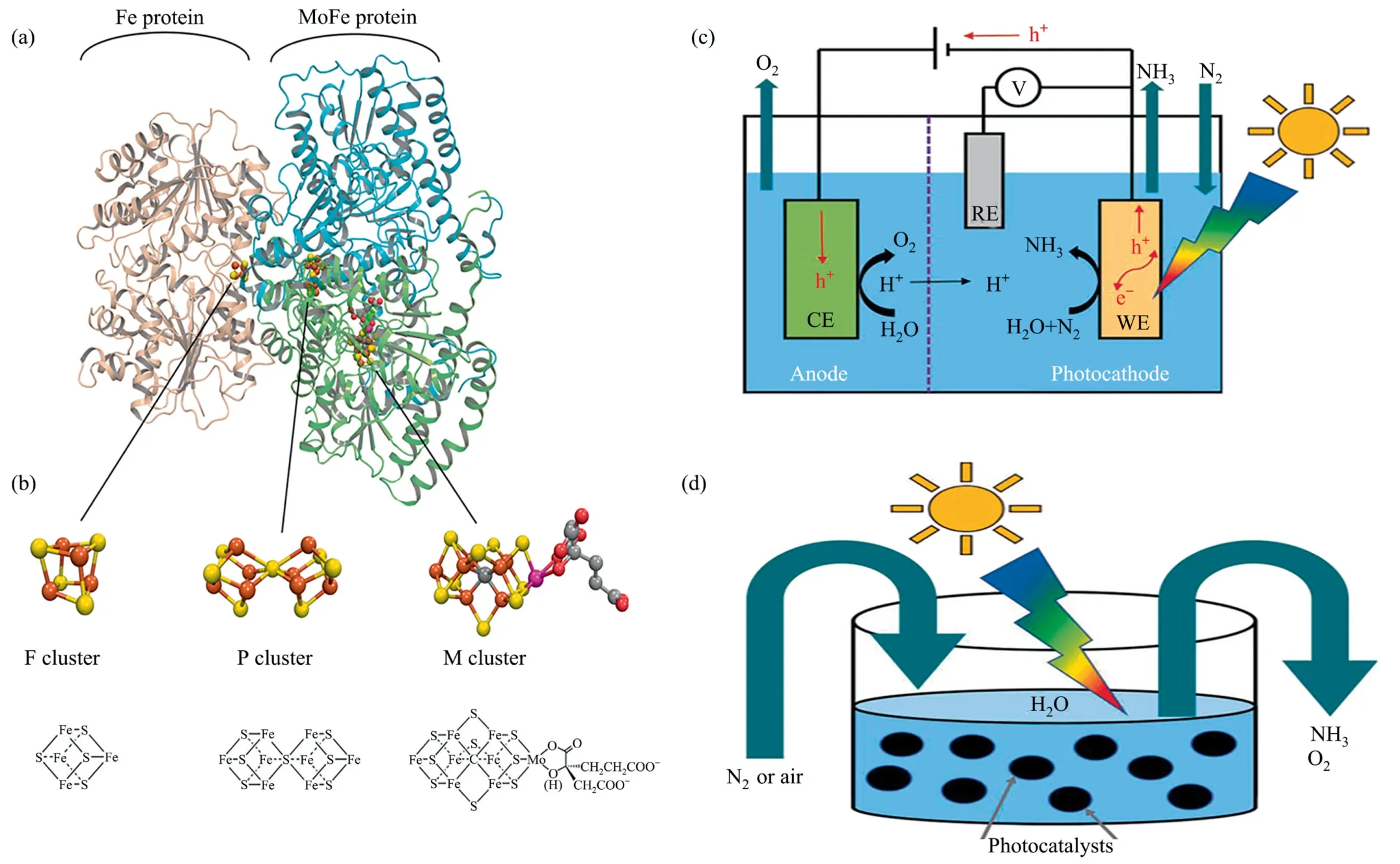

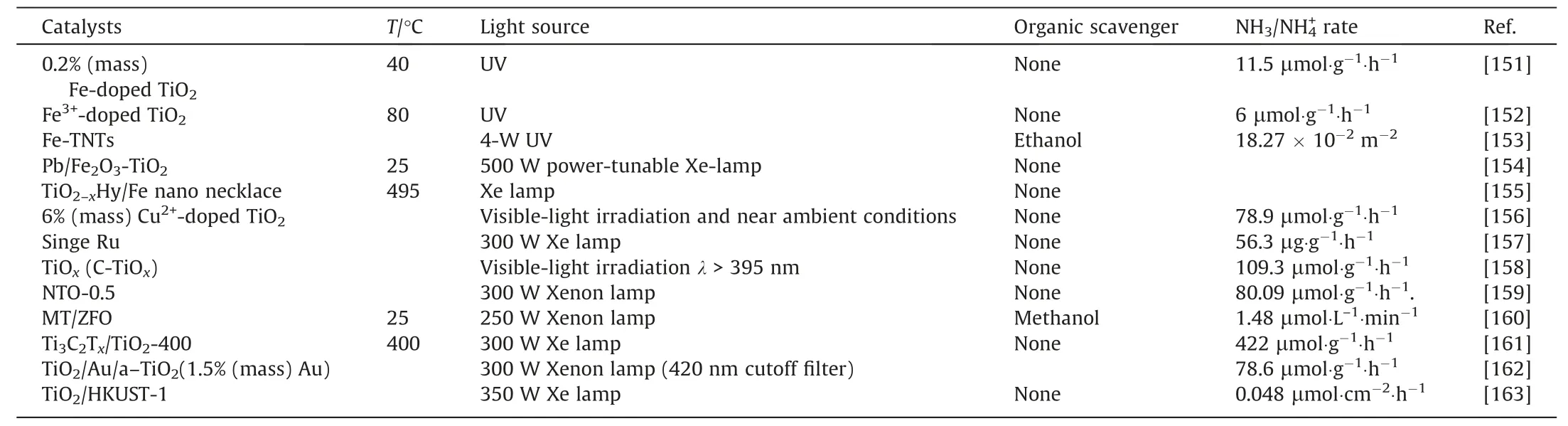

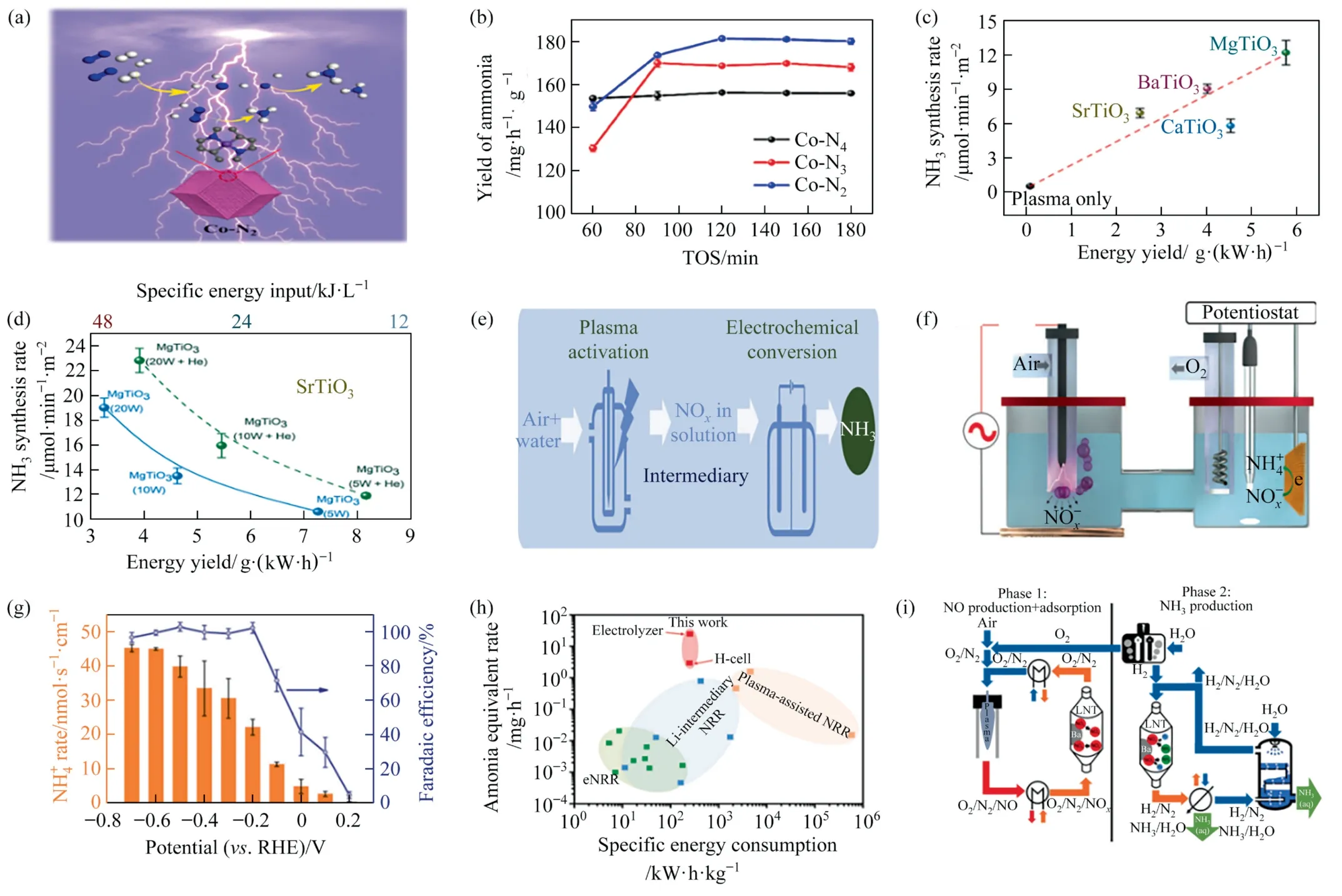

4.Electrocatalytic Synthesis of Ammonia

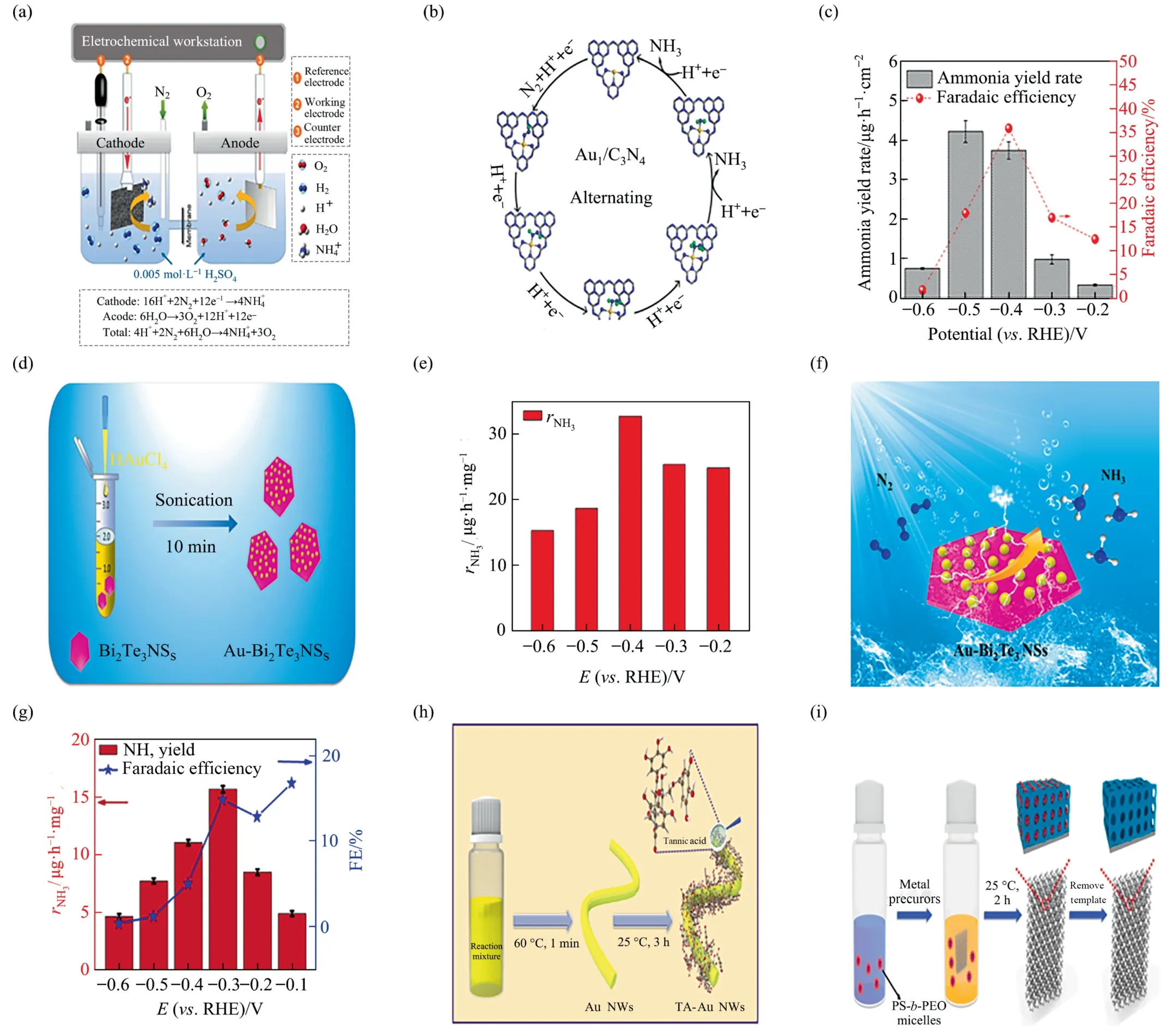

Electrocatalytic ammonia synthesis,an alternative to thermal catalysis,is one of the most widely used technologies,which provides a pathway to zero CO2emissions by greatly reducing the carbon footprint of the chemical industry due to its ability to produce ammonia from pollutant-free water at lower temperatures and pressures (Fig.10(a),(b)).Recently,lots of efforts have been made to develop electrochemical ammonia synthesis processes.The advantages of simple equipment and moderate efficiency permit the construction of electrochemical processes from small distributed facilities to large production plants.The high energy density,relatively abundant hydrogen content and ease of compression into liquid form for storage have also motivated the use of ammonia instead of hydrogen by electrolysis to address the current challenges in the context of today’s energy crisis[2,3,77,80,81].The electrocatalytic nitrogen reduction process on multiphase surfaces is inclined to follow a combination mechanism.More specifically,depending on the type of nitrogen adsorption and the order of hydrogenation,the combination mechanism can take place in three possible pathways: distal,alternating and enzymatic [11].The enzymatic pathway,which is the exact opposite of the Haber process in which the nitrogen adsorbed molecule is a lateral ligand model.Under these possible mechanisms,the reduction of nitrogen may lead to different products,including ammonia and hydrazine.

In general,there are four key points that make electrochemical ammonia synthesis difficult: (1) most of the catalysts explored have limited ability to bind and adsorb N2leading to unsatisfactory activation of N2in the first step of the reaction [82];(2) some strong binding and adsorption catalysts work well in the first step but produce intermediates that are difficult to protonate or cause the disappearance of ammonia;(3)electrocatalytic NRR in aqueous solution also has a strong competing side reaction,the hydrogen reaction (HER),which leads to low Faraday efficiency (FE) [83];(4)The ability of some metals to suppress HER is inconsistent with the ability to improve NRR.In principle,the electrocatalytic performance of NRR catalysts is characterized by three activity indicators: yield,FE and catalytic stability.The first two can be simply calculated by measuring physical quantities,and the last is obtained by time-dependent electrolysis tests[11].The electrocatalytic nitrogen reduction reaction(ENRR)has two additional mechanisms in parallel with the three previously mentioned in this review: the Mars-van-Klavern (MvK) process and Li making intermediary mechanism (Fig.10(c),(d)).In the MvK process,the crystalline lattice nitrogen atoms in the nitride form ammonia by hydrogenation,and the produced vacancies of nitrogen are then replenished by N2[78,83].During the lithium making intermediary mechanism,N2gets activated by reaction with lithium metal initially and then form lithium nitride,which can occur automatically in environmental conditions.Next,lithium nitride is protonated to form Limonium salt as well as ammonia.Ultimately,the Limonium salt is galvanically converted back to lithium metal,thus ending the cycle [79].

Fig.10. (a),(b) Flow chart of H-B process and electrochemical process for ammonia synthesis.Reproduced from Ref.[77] with permission of Royal Society of Chemistry,copyright 2021.(c)Mechanism of reactivity(right)and deactivation(left)of VN0.7O0.45.Reproduced from Ref.[78]with permission of American Chemical Society,copyright 2018.(d) Li-mediated mechanism.Reproduced from Ref.[79] with permission of Nature Publishing Group,copyright 2020.

Originating from the production of N2from nitrate,it is found that some catalysts are more selective for the generation of ammonia.Despite the need for three more electrons to convert nitrate to ammonia and the competition of N≡N bonds and other reactions like the formation of H2NOH,adsorbed N2O can be dissociated before conversion to N2at noble metal electrodes,skipping the generation of N≡N bonds,rendering nitrate-based electrocatalysis equally favored.Nevertheless,a variety of stable intermediates and products are implicated in the reaction process,such as nitrite,hydrazine,hydroxylamine,nitric oxide,nitrous oxide [84,85].

Galvanic NRR catalysts have various categorization methods following different classification criteria.For example,they can be classified by elements into several groups such as noble metals(Au,Ru,Rh,Pd,etc.),non-noble metals,and non-metals(including various composite materials).According to the operations performed,they can be further classified into types such as structural optimization,fabrication of vacancies,atomic doping,and nonstatic changes.This paper classifies the catalysts according to the required elements,summarizes the scientific research results that have emerged in recent years,and clarifies the development trend of electrochemical NRR catalysts.Table 2,Table 3 and Table 4 provide the summary of the performance of several relatively newly reported NRR processes.

4.1.Noble metal catalysts

Precious metals typically refer to platinum cluster metals as well as two monetary metals (gold,silver) and other eight metal elements,they possess strong chemical stability and hardly chemically react with other chemicals under general conditions[81,83].Au is the part of the optimal catalyst for electrochemical NRR[127],nevertheless,the limited availability and affordability of gold are serious obstacles to its massive industrial utilization.Construct proper morphology of Au-based catalyst is considered as a valid effective method for remarkable enhancement of electrocatalytic performance.

Inspired by activity of atomic dispersion catalyst [128],Wanget al.[86] added HAuCl4-4H2O aqueous solution dropwise into g-C3N4aqueous dispersion,an actual packing of 3.4% of atomically dispersed Au1/C3N4was obtained after a series of operations.As shown in Fig.11(a),the authors assembled a total electrolytic cell using platinum foil as the anode,Au1/C3N4as the cathode,the Ag/AgCl electrode as the reference electrode.A cation exchangemembrane separated the sulfuric acid aqueous solution electrolyte.Carbon fiber paper electrodes were loaded on both sides of the electrodes by means of a homogeneous ink acquired by distributing the prototype and the Nafion liquid with a volume ratio of 1:1.The gold atomic valence of 1 was studied by Extended X-ray absorption fine structure method and X-ray photoelectron spectroscopy (XPS).Au1/C3N4electrochemically reduced N2to NH4+under environmental circumstances with FE of 11.1% and the NH+4yield reaching 1305 μg∙mg-1∙h-1(approximately 22.5 times higher than Au NPs/C3N4),no hydrazine was detected in both the experimental and control groups.The calculations indicated that Au1/C3N4favored the pathway of N2reduction to ammonia by complex alternating catalysis (Fig.11(b)).Bader charge-buccal analysis affirmed that there was an appreciable charge removal from the gold atom to g-C3N4,causing the Au atom to generate a positive charge with 0.56 |e|.The electron exhaustion of the gold atom might relocate its d-orbit placement toward the Fermi energy level,thus strengthening its interaction with intermediates (e.g.,NNH*) and resulting in better NRR performance.Nazemiet al.[87] adjusted the peak localized surface plasmon resonance (LSPR) of hollow gold nanocages (AuHNCs) to regulate the dimensions and density of the pores.Hollow gold nanocages,who’s peak LSPR spectra shifted to the desired values of 635,715,or 795 nm,were prepared by the deionized water synthesis method that injecting HAuCl4into AgNCs solutions under vigorous stirring.AuHNCs-715 featured the maximum output of ammonia at–0.5 V(4.22 μg∙cm-2∙h-1)and the highest FE at–0.4 V (35.9%),which was a trade-off between greater amperage density and enhanced selectivity for HER (Fig.10(c)).As the position of the LSPR peak shifted from 635 to 795 nm,the gold concentration (% (mass)) in the microparticles grew from 33.0 to 64.7,accompanied by an augment in aperture size.The contradiction between the highest Au concentration and the lowest Au electrochemical surface area concentration appeared in AuHNCs-795.Excessive pore size obviously reduced surface area,however the existence of Ag lying in the hollow cavity of AuHNCs with smaller pore diameter (Ag capable of enhancing the evolution of H2)lowered the selectivity of electro-catalyst to NRR.Bismuth telluride with excellent micromorphology and surface attraction properties is a more suitable vehicle for synergists [129].Two-dimensional(2D)heterojunction Au-Bi2Te3nanosheets(AuBi2Te3NSs)are made up of bismuth telluride nanosheets with gold nanoparticles sedimented on[88].Because of the promising dispersion of Au nanoparticles and the outstanding cooperative effect of heterojunction composites,Au-Bi2Te3NSs showed sound nitrogen reduction reaction(NRR)performance in the ambient.The abbreviated synthesis method is given in the Fig.11(d).The dispersion solution prepared by mixing the catalyst with other solutions was applied uniformly on clean carbon writing paper and tested with carbon rods as counter electrode,Ag/AgCl served as reference electrode.The NH3yield of Au-Bi2Te3NSs was 32.73 μg∙mg-1∙h-1with FE of 20.39%at–0.4 V in 0.1 mol∙L–1sodium sulfate electrolyte (N2flooded) (Fig.11(e)).The reason why modulating the concentration of HAuCl4solution could change the gold content of the sample was attributed to that during the synthesis process,bismuth telluride and AuClcould undergo oxidation reactions resulting in the generation of electrons,which could be spontaneously transferred from bismuth telluride to AuCl,leading to the nucleation and growth of Au,forming Au nanoparticles.The characterization proved the hexagonal structure of Au-Bi2Te3NSs,with Bi and Te elements uniformly distributed throughout the nanosheets,while AuNPs were anchored on the surface of bismuth telluride NSs (Fig.11(f)).Tannic acid(TA)is an eco-friendly natural polyphenolic with many oxygenated phenolic hydroxyl functional groups on its rigid aromatic ring backbone,which is harder to rotate so that it can be used to obviate the agglomeration of catalysts.Hence,TA was pursued as a stimulator for precious metal nano-materials [130].The contribution of its structure to the electrochemical activity was demonstrated by the whopping 14.83%FE at–0.3 V with ammonia yield(15.71 μg∙mg-1-∙h-1) (Fig.11(g)) [89].TA-gold nanowires (AuNWs) were established by superficial amendment of AuNWs using oxygenenriched TA,but still retained the homogeneous nanowire structure of AuNWs(Fig.11(h)).The superior NRR reactivity and flexibility of TA-AuNWs could be ascribed to the unidimensional configuration of active Au,and the superficial amendment of oxygen-enriched TA.The hyperfine single dimension composition could deliver adequate reactive sites for NRR adsorption and activation of N2.In inclusion,the aerobic-rich TA lamination has lucrative interfacial adsorption locus,which enhances the reaction kinetics of NRR by increasing the probability of inter-collisions of the reaction species with the active site of the accelerator.

Table2 A summarization of some newly developed noble metal electrocatalysts for NRR

Table4 A summarization of some newly developed non-metallic and three-component composite electrocatalysts for ammonia synthesis

Fig.11. (a) Schematic diagram of electrolier for N2 electro-reduction experiment.(b) Mechanism of alternating cycles on Au1/C3N4.Reproduced from Ref.[86] with permission of Elsevier,copyright 2018.(c) Ammonia production rates and FE of AuHNCs in 0.5mol∙L-1 LiClO4 aqueous solution at various potentials.Reproduced from Ref.[87] with permission of American Chemical Society,copyright 2018.(d) Synthesis pathway of AuBi2Te3NSs.(e) Ammonia yields over Au-Bi2Te3NSs catalysts at diverse potentials.(f)Reaction path of AuBi2Te3NSs as catalyst.Reproduced from Ref.[88]with permission of American Chemical Society,copyright 2021.(g)Comparison of FE and ammonia production at different potentials.(h)Synthesis steps of TA-AuNWs.Reproduced from Ref.[89]with permission of Elsevier,copyright 2021.(i)Schematic diagram for preparing the mAu3Rh/NF.Reproduced from Ref.[90] with permission of Elsevier,copyright 2021.

The conventional methods employed for the preparation of porous precious metals typically cannot control the dimensions of the pore.The micelle assembly method has been proven to produce porous metals directly in the medium of aqueous solutions [131],which has prompted Yuet al.[91]used micelle assembly to bypass the mesoporous Pt-based material (polymer binder resulting in low activity)to synthesize self-supported mesoporous Au3Pd films(mAu3Pd/NF)on nickel-based bubble compounds with polystyrene PS-b-PEO.HAuCl4aqueous solution and K3RhCl6aqueous solution as raw materials [131],where PS-b-PEO was used as a stomatal reformer and Ni foam was used as both a primer and a reductant.mAu3Pd/NF exhibited prominent NRR characterization in 0.1 mol∙L–1sodium sulfate with NH3yield of 24.02 μg∙mg-1∙h-1and FE of 18.16% at–0.1 V.Transmission electron microscope(TEM) and energy dispersive X-Ray spectroscopy (EDX) revealed that the resulting product is the combination of gold and palladium,and XPS measurements implied the existence of electron transfer between Au and Pd elements,giving rise to a strong electron effect.The spherical micelles of PS-b-PEO were the key contributor to the generation of mesopores.Along with the reaction,Pd and Au ions were progressively reduced to formulate AuPd alloys,in which mesopores were shaped.The uniform depth increment of film was accompanied with the increase of the synthesis reaction time.In comparison with samples of different Au/Pd ratios,the output of ammonia and selectivity of mAu3Pd/NF were better than mAu/NF and mPd/NF,even over 3 folds than that of no-porous Au3Pd/NF.The well-balanced mesoporous nanostructures provided rich active sites,superb specific surface area and barrier free delivery paths.The result of theoretical calculation showed that the high activity was attributed to the effects of the formation of mesopore direct inducting by PS-b-PEO micelles,AuRh bimetallic composition effect and electronic effect as well as the synergistic effect of self-loaded mesoporous membrane structures.As shown in Fig.11(i),Wanget al.[90] has also proposed thein situsynthesis of mesoporous Au3Rh membrane on Ni foam material (mAu3Rh/NF).Thanks to the bimetallic mesoporous structure,the FE of mAu3Rh/NF is 23.84%and the ammonia yield was 26.29 μg∙mg-1∙h-1in 0.1 mol∙L–1sodium sulfate at–0.1 V,which was superior to other NRRs catalyst with different Au/Rh ratios.Ruthenium-platinum alloy with molar rate of 1:1 distributed on a VulcanXC-72 carbon compound was adopted to act as the cathode for the electro-catalyst,and the rate of ammonia production was 5.1×10–9g∙s-1∙cm-2at 0.123 VvsRHE,with a decent Faraday efficiency(13.2%)[92].In contrast to solitary Ru&Pt metallic granules,RuPt alloys had synergistic effect towards electrocatalytic synthesis of ammonia,i.e.,N2was trapped on the Ru site,whilst Pt-H supplied hydrogen,following the reaction below (Eqs.(1)-(3)):

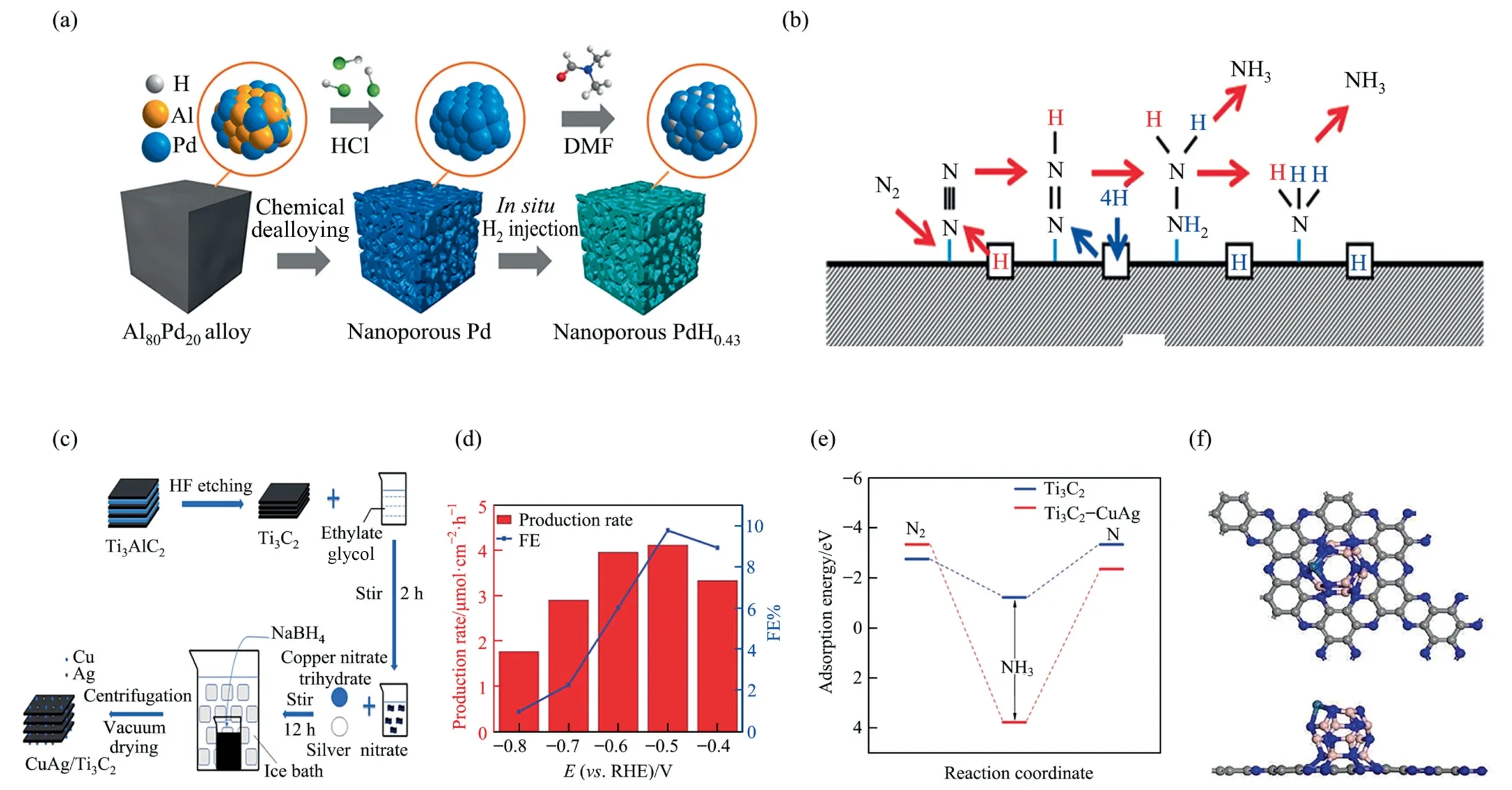

Bimetallic/alloy nanostructures could display characteristics relevant to each of these two separate metals.At a more negative cell potential,the velocity of ammonia generation was dramatically reduced as a result of the hydrogen evolution reaction.By shifting the potential from 0.123 to–0.077 V,the ammonia generation rate increased first and then decreases accompanied by a reduction in FE,which predicted that the NRR dominated at relatively low potentials while competes with HER at elevated potentials.The selectivity of NRR was measured at–0.077 V at 30,50 and 70 °C.Electro-chemical ammonia generation rose along with elevated temperature.The by-product hydrazine signal was consistently low and unchanged,and the RuPt/C electrode was found to exhibit significant stability with a current efficiency of 58%even after 45 h of experimentation.A-palladium hydride had reversible hydrogen storage properties and is a prospective NRR electrocatalyst.Nano porous Pd(np-Pd)was obtained through chemical etching of the alloy,followed byin situhydrogen injection to synthesize nano porous palladium hydride np-PdH0.43(Fig.12(a)) [93].The synthesized nano porous catalysts were subjected to electrochemical texts in 0.1 m phosphate buffer solution(PBS)comprising saturated high-purity Ar or N2.At–0.15 V,the ammonia yield of np-PdH0.43was 20.4 μg∙mg-1∙h-1with FE of 43.6%,almost three times that of np-Pd,and such a multiple was also present in the TOF measurements.np-PdH0.43had an ECSA of 0.39 cm2,17 percent greater than that of np-Pd.Isotope labeling experiments revealed that the H in np-PdH0.43was involved in the ammonia formation.The result of calculation showed that the enzymatic NRR pathway was more appropriate for both np-Pd and np-PdH0.43(Fig.12(b)).The formation of *N2H is the rate-limiting step and the ΔGof the*N2H layer of np-PdH0.43was much lower than that of np-Pd(0.65vs.0.91 eV).np-PdH0.43had a hybridized electronic state analogous to that of np-Pd,but the heterodimerization between the Pd and H atoms resulted in the d-band center of np-PdH0.43being closer to the Fermi energy level.Thus,hydrogen infusion could effectively change the d-electron structure of the Pd atom,thus increasing the stability of the *NxHyintermediate as well as improving the activation.CuAg/Ti3C2MXene was synthesized by the graph method using MXene and Ti3C2as carriers to load copper and silver double metallic particles (Fig.12(c)) [94].Experiments were carried out using rotating disk electrode (RDE) and the prepared catalysts were added to ethanol and Nafion solution and then transferred to a glassy carbon electrode in an electrolyte of 0.1 mol∙L–1potassium hydroxide solution.The ammonia yield and FE of the catalysts was 4.12 μmol∙cm-2∙h-1and 9.77% (–0.5 VvsRHE) (Fig.12(d)).The presence of four elements of Cu,Ag,Ti and C and the successful synthesis of CuAg/Ti3C2were demonstrated by various characterization methods.The DFT calculations revealed that N2was more easily adsorbed on the surface of CuAg/Ti3C2(adsorption energy of 3.34 eV) than Ti3C2(adsorption energy of 2.75 eV) (Fig.12(e)).Moreover,the adsorption energy of H on CuAg/Ti3C2(2.35 eV) and Ti3C2(3.33 eV) indicated that the competing HER processes were suppressed.The continuous distribution of DOS and PDOS surrounding the Fermi energy level of the CuAg/Ti3C2indicated that the catalyst is in a highly conductive metal state,which promoted the rapid electron transfer in the electrocatalytic process,and facilitated the achievement of higher electron conductivity.Compared with other control group,CuAg/Ti3C2exhibited a wider conduction band and valence band overlap.Os elements with the same number of electrons in the d-orbitals as Fe were studied by Yanget al.[132] The nitrogen reduction reaction(NRR) of Os1B11N12/C2N was analyzed and the results showed that the optimized structure of Os1B11N12/C2N was designed(Fig.12(f)).The stability of Os1B11N12/C2N was proved by the binding energy calculation,molecular dynamics simulations,charge density difference and partial states density.Rapid electron transfer might occur during N2activation.Intense hybridization of Os-5d with N-2s and bound state generation after N2adsorption suggested that electron transfer from the N2molecule to the Os atomic 5d orbital,while the Os-5d and N-2P exhibited robust hybridization to each other,with the 2π* orbital of N2gaining electrons through Os-5d,forming occupied or non-occupied orbitals near the Fermi energy level,which usefully attenuated the three-bond of N2.The reaction obeys a distal mechanism.It was evident from the Hirschfeld charge analysis that a positive charge was accumulated in the Os atom,leading to electrostatic repulsion with the proton,which inhibited HER.The BN cluster suitably modified the up-d-band edge of Os to obtain the excellent adsorption intensity on the intermediates,thus boosting up the NRR catalytic behavior of Os1B11N12/C2N.

Fig.12. (a)Nano porous palladium hydride synthesis.(b)The Latticed hydrogen reaction route by nitrogen reduction of palladium hydride.Reproduced from Ref.[93]with permission of Wiley Oline Library.(c) Schematic representation of the synthesis of CuAg/Ti3C2.(d)Optimal FE and yield obtained on CuAg/Ti3C2MXene.(e) The adsorption/desorption energies of Ti3C2 and CuAg/Ti3C2 surfaces were computed by DFT.Reproduced from Ref.[94] with permission of Royal Society of Chemistry,copyright 2020.(f)Improved construction of Os1B11N12/C2N.Reproduced from Ref.[132] with permission of Chemistry Europe,copyright 2022.

In general,numerous studies on Au,Rh,Ru and so on are available,whereas a shortage of reports on Ag,Os and Pt was found.