Meso-mechanical anisotropy and fracture evolution of reef limestones from the Maldives Islands and the South China Sea

Lihui Li,Chnglong Li,Bixiu Huang,Jianguang Li,Shouing Li,c,Xiao Li,c

a Key Laboratory of Shale Gas and Geoengineering,Institute of Geology and Geophysics,Chinese Academy of Sciences,Beijing,100029,China

b Innovation Academy for Earth Science,Chinese Academy of Sciences,Beijing,100029,China

c College of Earth and Planetary Sciences,University of Chinese Academy of Sciences,Beijing,100049,China

d College of Geoscience and Surveying Engineering,China University of Mining and Technology,Beijing,100083,China

e AVIC Institute of Geotechnical Engineering Co.,Ltd.,Beijing,100098,China

Keywords:Reef limestone Mechanical anisotropy Failure mode Pore structure Fracture surface roughness

ABSTRACT Reef limestone is a biogenic sedimentary rock widely distributed in coral reef areas,acting as an important foundation for coast construction.Due to its special biogenic origin,reef limestone is different from conventional rocks both in terms of rock structure and mechanical properties.In this study,mesoscale uniaxial compression experiments with five different loading directions were conducted on two kinds of reef limestones from the Maldives Islands and the South China Sea,respectively.The realtime high-resolution videos and images of failure processes were recorded simultaneously to investigate the fracture evolution and fracture surface roughness of reef limestones.It demonstrated that the reef limestones belonged to extremely soft to soft rocks,and their uniaxial compressive strength(UCS)values fluctuated with high discreteness.The mesoscale mechanical properties of reef limestones were highly anisotropic and mainly controlled by pore structure.The occurrence of dissolution pores in reef limestone tended to intensify mechanical anisotropy.With the integration of the fracture initiation and propagation features of reef limestones,it is supposed that the intrinsic mechanism of anisotropy was probably attributed to the differences in coral growth direction and dissolution.Furthermore,the quantified fracture surface roughness was revealed to have a good consistency with density and UCS for the reef limestones from the South China Sea.The findings are helpful for providing theoretical and experimental references for engineering construction in coral reef areas.

1.Introduction

Reef is attracting more and more attention due to the ongoing development of“The Belt and Road”and the increasing importance of marine safety (Qiao et al.,2019).As a biomass limestone,reef limestone is formed by hermatypic corals and skeletons of marine organisms (Fournier et al.,2005;Raczyński et al.,2017;Turicchia et al.,2021;Vishnevskaya et al.,2022).The physical and mechanical properties of reef limestone are closely related to its microstructure,mineralogical composition,porosity,and pore structure.In contrast to some terrestrial rocks containing multiple mineral assemblages,reef limestone is relatively homogeneous in mineralogical composition(Zhu et al.,2014;Meng et al.,2022;Wei et al.,2022;Yu et al.,2022;Zhou et al.,2022).Gischler et al.(2013)analyzed the reef limestones from the Atlantic,Indian,and Pacific oceans and concluded that reef limestones were mainly composed of acicular aragonite crystals and massive calcite crystals.The geochemical analysis of reef limestones distributed in the South China Sea(Zhu et al.,2014;Lv,2016)showed that it was dominated by CaCO3,and the content of aragonite and calcite was more than 95%.Moreover,Sharma et al.(2021) found that biological function could alter the calcite content of reef limestones and influence its mechanical properties.However,the variations of marine environments,the developmental environment of biogenic reefs,and the historical events of evolution and extinction of reef-builders contributed to diverse types of biogenic reefs,resulting in highly complex morphology and structure of reef limestone(Riding,1982,2002).In the study of rocks in the Xisha Islands,Wei (2006) and Wei et al.(2008)found that the rising and falling of sea levels led to the dolomitization of reef facies carbonate rocks.Based on microscopic investigations into the reef limestones from the South China Sea,Shen et al.(2017)pointed out that reef limestones were porous and consisted of corals,algae,and biological debris,mainly cemented by acicular aragonite and granular calcite.And the cementation strength of these calcium carbonate particles would significantly affect the strength of reef limestone (Konstantinou et al.,2021).Shang et al.(2015) studied the reef limestones from well Xike-1 in the South China Sea and found that the formation of reef limestones was closely related to the living environment of reef-builders.Lu et al.(2020) verified the relationship among lithology,elemental geochemistry,biomarker compounds of reef limestones,and various indicators including seawater paleotemperature,nutrients,and clastic component input during deposition.

Due to the extraordinary geographical location of reef limestone,it is costly to drill reef limestone specimens,hereby the mechanical properties especially the anisotropic properties have not been studied thoroughly.Previous studies mainly concentrated on the density,porosity,permeability,wave velocity,and other physical parameters,with some attention on the mechanical properties of reef limestone(Zhong et al.,2020).For instance,some scholars(Sun et al.,2004;Liu et al.,2012)conducted point load tests on the reef limestones from Saudi Arabia,Vanuatu,and the Maldives Islands,and found that their strength values were in a range of 0.04-1.25 MPa,1.05-2.06 MPa,and 2.8-3.04 MPa,respectively.The uniaxial compressive strength (UCS) of reef limestones from the Maldives Islands,the Xisha Islands (China),and the Java Island(Indonesia)was 1.07-38.56 MPa(Tang and Zheng,2015;Yang et al.,2016;Xiao et al.,2018),with the tensile strength of 0.64-2.65 MPa(Zhu et al.,2016).The stress-strain curves of reef limestones under uniaxial compression conditions usually had an elastic stage at the beginning of loading and retained higher residual strength after failure,without an obvious initial compaction stage (Ren et al.,2016).The stress-strain curves of reef limestones under triaxial compression conditions could be divided into three stages: the initial elastic stage,the destruction stage,and the hardening or softening stage (Lagioia and Nova,1995;Wang et al.,2019).The fractures in reef limestone usually propagated along the growth line of coral and the failure modes were closely related to the skeletons(Boller et al.,2002).Meng et al.(2019)tested the dynamic properties of coral-reef limestone through Hopkinson bar techniques and pointed out that the tensile failure of coral-reef limestone mainly developed in the weak parts,such as the cementation surfaces between biological components,coral gravels,and coralline algae.

In addition to the basic mechanical properties of reef limestones,some scholars also studied the mechanical differences of reef limestones under different conditions.Zhu et al.(2016,2017)revealed that the saturated reef limestones with different structures had various stress responses.In the studies of reef limestones with different cementation types,including gravelly calcareous sandstone,calcareous conglomerate,and coral limestone,Wang et al.(2008) and Wang et al.(2020) identified that coral limestone was significantly stronger than the other two types in terms of UCS and point load strength.The physical and mechanical properties of shallow and deep reef limestones were also different,which was attributed to the differences in mineralogical composition,pore structure,and lithology caused by various degrees of rock cementation with different depths(Ma et al.,2021).Meanwhile,He et al.(2022) found significant anisotropy in the stiffness of calcareous sand in the study of carbonate rocks.Liu et al.(2021)demonstrated that the crack initiation stress of micritized framework reef limestones in the South China Sea was about 52%-69% of the peak stress under a confining pressure of 0-8 MPa,which increased with the increase in confining pressure.In summary,the structure of reef limestones in different marine areas varied significantly because of different biological communities owing to different climatic environments.Previous mechanical investigations of reef limestones usually focused on the peak strength,the influence of pores and cementation on strength and failure characteristics (Ren et al.,2015;Yuan et al.,2016;Zheng et al.,2020).While the mechanical anisotropy of reef limestone has been rarely reported,which is vital for mechanical characterization considering structure.Many foundations of coast engineering along the “The Belt and Road” are reef limestones,the bearing capacity,stability,and uneven settlement,especially the damage,due to inadequate understanding of its anisotropic properties might cause the failure of the engineering projects.Hereby,more thorough studies should be carried out on the anisotropic mechanical properties of reef limestone.

This study aimed to investigate the mesoscale mechanical anisotropy of reef limestones from the Maldives Islands and the South China Sea,respectively.A real-time loading-observingacquiring system,i.e.an integrated miniature tensile instrument(MTI)-light microscope (LM) system,was utilized to conduct mesoscale uniaxial compression tests on the reef limestone specimens with five groups of loading angles.The initial structure and mineralogical composition of two types of reef limestones were observed and analyzed.Then the UCS anisotropy,differences in fracture initiation,and propagation characteristics of reef limestones with different structures were characterized.Eventually,the underlying mechanism of mechanical anisotropy of reef limestone was explored with a combination of the failure modes and quantifications of fracture surface roughness.

2.Specimens and methods

2.1.Specimen preparation and observation

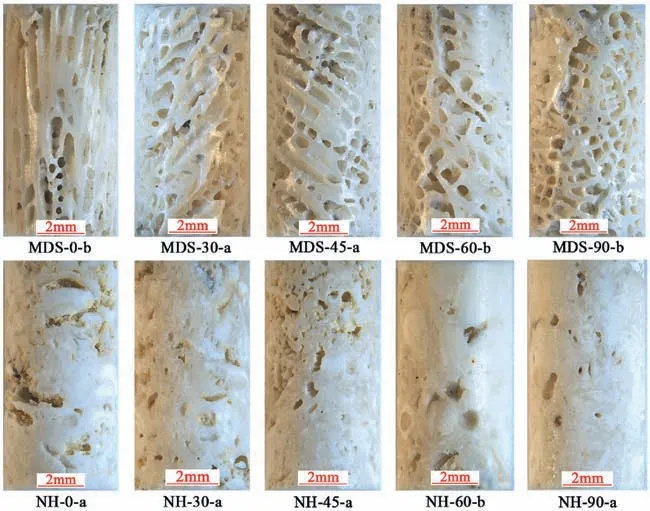

Due to the difficulty in acquiring adequate cores of reef limestones to conduct conventional macroscale mechanical tests,this study carried out uniaxial compression tests at the mesoscale to investigate the mechanical anisotropy of reef limestones.Two types of reef limestones were obtained,which were identified as the Maldivian reef limestones (MDS) and the South China Sea reef limestones (NH).In this study,the reef limestones were primarily distinguished from structures,namely the cementation of the bioclasts and the biological skeletons (Belopolsky and Droxler,2003;Fournier et al.,2005).The MDS were yellowish coral skeletal limestone,with a structure dominated by coral bones,which was relatively loose and had a large pore volume.Their primary pore structure was composed of coral skeletons,with clear directionality and extension direction suggesting the growing direction of coral,which played an important role in the mechanical anisotropy of reef limestone.The MDS maintained the original skeleton structure of coral,with lattice pores developed inside reef limestones and most of the skeleton dissolved (Fig.1a and b).The lattice pores were heavily filled and dominated by biological debris,micrites,and internal sediments (Fig.1c).

The NH specimens were coral gravel limestones,consisting of coral skeletal fragments of varying sizes,and were cemented by other biological debris.The surfaces of the NH specimens were yellowish and interspersed with white.This reef limestone was dense,without apparent primary pores or growth lines and other coral biological structure features.It was developed with multiple macroscopic pores formed by secondary dissolution,which were unevenly distributed,and irregular in size and shape(Fig.1d and e).The partial densification of the NH specimens disrupted the connectivity of the primary pores,resulting in the random distribution of irregular pores,with the most independent pores.The NH specimens were also mainly composed of biological debris(Fig.1f).

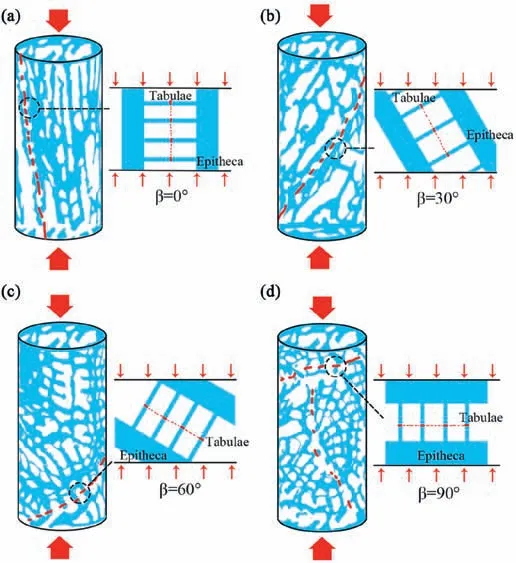

To study the effects of the anisotropic characteristics on the reef limestones from different sea areas,the mesoscale uniaxial compression tests were performed on cylindrical cores with 10 mm in height and 5 mm in diameter.Cylinders were made from preserved cores with wire-electrode cutting,and the size deviation of an ideal specimen to be made was ±0.05 mm,with a parallel misalignment between the top and bottom faces of±0.02 mm and an axial angle deviation of less than 0.05°.The specimens were drilled with different angles (β) for loading,i.e.the angle between the drilling direction and the coral growth direction.Five groups of specimens with different angles (β=0°,30°,45°,60°,and 90°)were prepared.It should be noted that the coral growth direction of the MDS specimens can be determined easily by the geometry of the coral skeleton.However,the NH specimens had no obvious directional biological features,such as coral growth lines,and the angleβ=0°was defined for specimens obtained parallel to the core,andβ=90°for specimens prepared perpendicular to the core.Three specimens for each angleβwere prepared and numbered a,b,and c,respectively.The specimens were distinguished by“placeangle-number”.For instance,“MDS-0-b” means the second MDS specimen having an angle ofβ=0°,as shown in Fig.2.

Fig.2.The reef limestone specimens with different angles prepared for the mesoscale uniaxial compression test.

2.2.Mineralogical composition

X-ray diffraction analyses were conducted on two types of reef limestones to determine the mineralogical composition.The results showed that they were dominated by calcite and aragonite,with a content of about 95%,and the clay minerals were subordinate,as shown in Table 1.The coral skeletons of the MDS demonstrated the dominance of aragonite with less calcite,while the NH had more calcite than aragonite.There was an explanation given that the corrosion of marine organisms,physical erosion by currents,and chemical dissolution of water influenced the mineralogical composition (El-Sorogy et al.,2013).The different solubility of carbonate minerals resulted in the selective dissolution of rocks.The neomorphism of reef limestone diagenesis led to the conversion of aragonite and high-magnesium calcite to low-magnesium calcite,which was supposed to be responsible for the differences in the carbonate mineral composition of the reef limestones(Chave et al.,1962).In a word,different diagenetic environments not only influenced the rock structure but also modified the mineralogical composition of reef limestones.

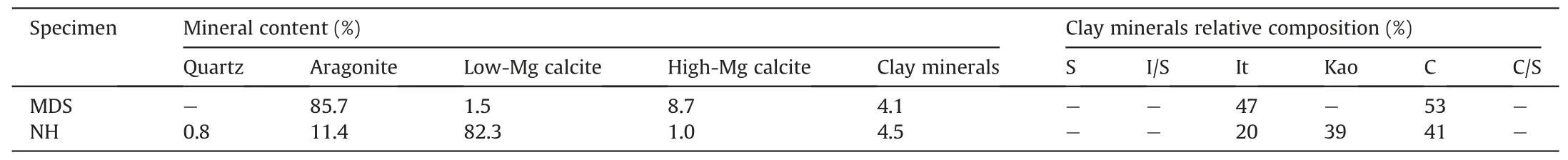

Table 1Mineralogical composition of the MDS and the NH specimens.

2.3.Pore structure

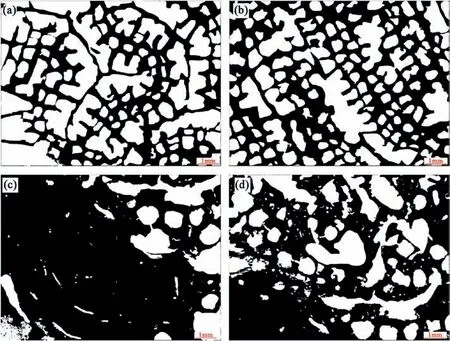

Macroscopic pores such as coral lattice pores and dissolution pores were revealed to have a significant effect on the mechanical properties of reef limestones.Herein the macroscopic pore structures of the reef limestones were recognized and quantified based on the thin section photomicrographs of specimens,with the main principle similar to the image recognition studies on scanning electron microscope (SEM) photographs by Tang et al.(2008) and Feng et al.(2019).The photomicrographs of the specimens were simplified as solid and porous areas.Then we extracted the porous areas with white color and blacked the solid areas,as shown in Fig.3.By defining the pixels of the black solid area and white porous area as 1 and 0,respectively,the porosity of specimens could be obtained according to the ratio of pixel numbers with a value of 0 to the total pixel numbers (Zhang et al.,2012):

Fig.3.Structure of the visible macroscopic pores in the reef limestones: (a,b) The MDS,and (c,d) The NH.Note that the black area represents the solid and the white area represents the pore.

whereVis the porosity,S0is the number of pixels with a value of 0,andS1is the number of pixels with a value of 1.

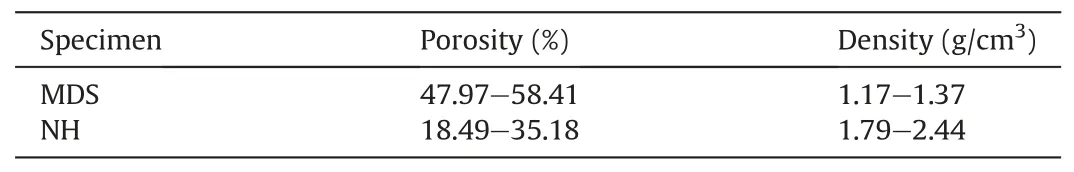

Considering the anisotropy of the porosity of reef limestones,especially the MDS,we characterized the pore structure of specimens with the thin sections perpendicular (Fig.3a) and parallel(Fig.3b)to the coral growth direction.Table 2 shows the density of specimens and the porosity quantified by the aforementioned image recognition method.Compared to the MDS,the NH had lower porosity and higher density.The MDS had a more regular pore structure and larger individual pores,with a porosity of 58.41%and 47.97% in the cross-sectional images perpendicular and parallel to the coral growth direction,respectively.While the pores in the NH were irregular in shape and uneven in size,with the majority being small and densely dissolved pores.The distribution of pores in the NH was also heterogeneous,with fewer dissolved pores in the area composed of coral gravel blocks (Fig.3c),and the calculated porosity was 18.49%.But the part composed of other biological remains was more fragile and had more dissolved pores (Fig.3d),with a porosity of 35.18%.

Table 2The macroscopic porosity and density of the reef limestones.

2.4.Experimental apparatus

The mesoscale experimental apparatus consisted of an integrated MTI-LM system.The MTI was a Fullam SEMTester 2000 tensile stage with automated servo control and data acquisition.The LM applied in this study was a Leica Microsystems M205A stereomicroscope.When the mechanical experimental system(i.e.MTI) was integrated with the image/video observation and acquisition system (i.e.M205A),the real-time digital images or videos of specimens were observable and the dynamic process of fracture initiation,propagation,and eventual failure could be captured.The fracture surface roughness could be quantified as well based on the three-dimensional depth maps obtained by the M205A stereomicroscope and relevant Leica software modules.The specimens were loaded at a constant displacement rate of 0.06 mm/min.The Leica Microsystems M205A stereomicroscope can record videos at 100 fps.The MTI and stereomicroscope were started together to simultaneously record the real-time mechanical data and capture videos of the whole compression process.In addition,the fracture morphologies of broken blocks were observed after the mechanical test,and the depths of focus data were obtained to conduct fracture surface roughness analysis.More details could refer to Huang et al.(2020)and Li et al.(2020).

3.Mesoscale mechanical properties of reef limestones

3.1.Anisotropic strength of reef limestones

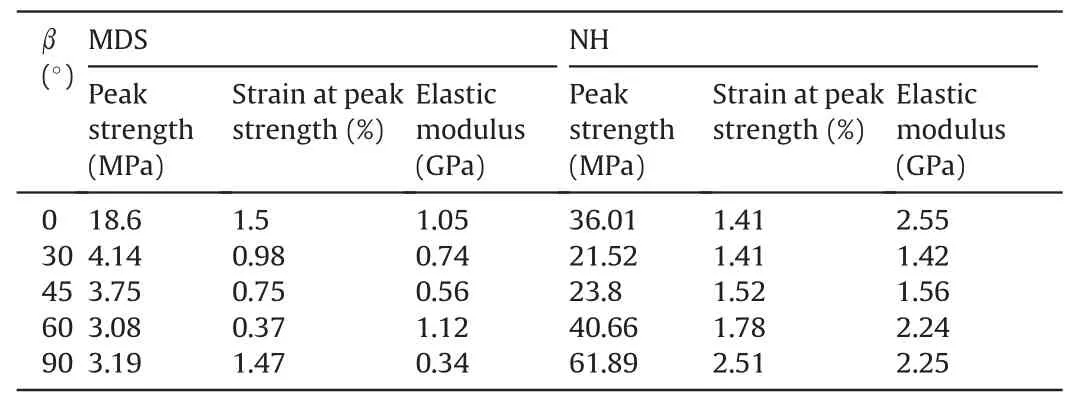

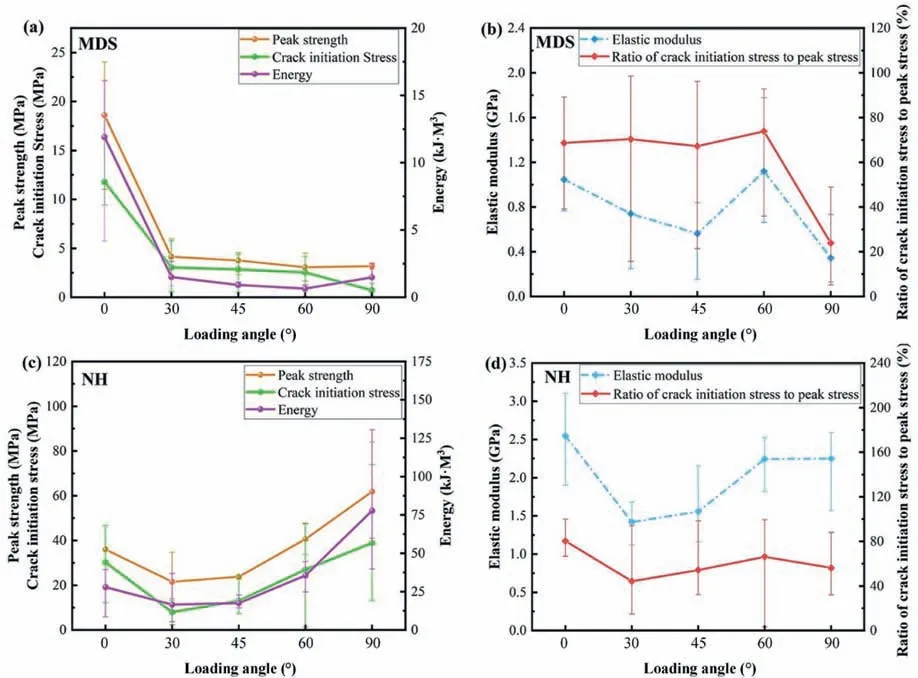

The stress-strain curves of two types of reef limestones with different angles were presented in Figs.4 and 5.The mechanical parameters of the specimens were shown in Table 3.The peak strengths of the MDS were not significantly different at four angles fromβ=30°toβ=90°,which were in a range of 3.08-4.14 MPa,as demonstrated in Fig.4.The specimens with an angle ofβ=0°were the exception,and their peak strengths were higher than the other specimens,with the minimum of 11.03 MPa and the maximum of 24.04 MPa.The peak strain was minimum at an angle of 60°and maximum at 0°and 90°,from 0.37% to 1.50%,with an overall Vshape.The elastic modulus of the specimens was calculated with the data plotted at 50% of the peak strength (GB/T 50266-2013,2013),namely 50% of the peak strength divided by the corresponding strain.It ranged from 0.34 GPa to 1.12 GPa,with the maximum atβ=60°and the minimum atβ=90°.The stressstrain curves of the MDS specimens had more sawtooth fluctuations,with multiple tiny peaks.

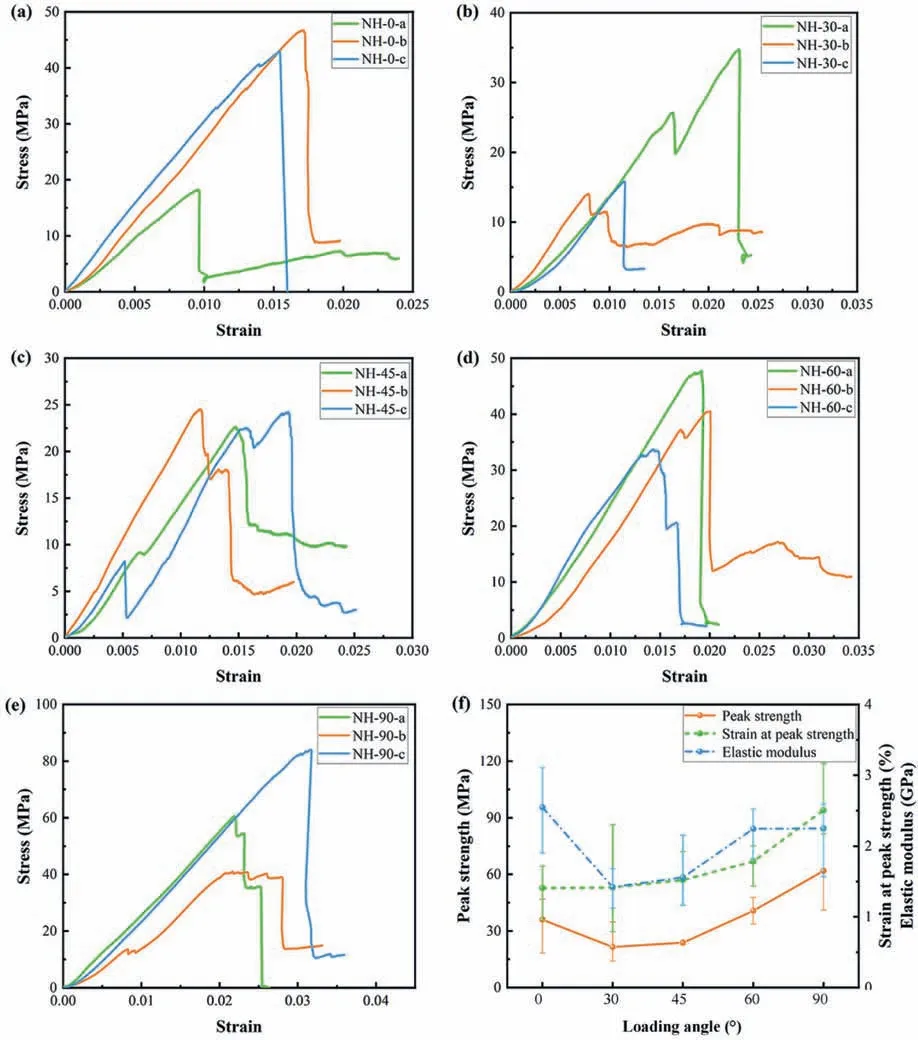

Table 3The mechanical properties of the reef limestones.

Fig.4.Stress-strain curves and average mechanical properties of the MDS with different loading angles based on the mesoscale uniaxial compression test.

The anisotropy of the specimens was evaluated by the anisotropy ratio of the mechanical parameters such as elastic modulus,peak strength,and strain at peak strength.The anisotropy ratio is defined as the ratio of the above three mechanical parameters tested from two loading directions perpendicular to each other in the tests,andβ=0°andβ=90°were taken in this study.The anisotropy ratios of elastic modulus,peak strength,and strain at peak strength of the MDS were 3.05,5.83,and 1.02,respectively,which suggested a strong anisotropy.

The peak strength of the NH specimens ranged from 21.52 MPa to 61.89 MPa,with the minimum at a loading angle ofβ=30°and the maximum atβ=90°,showing an overall spoon-like shape,as demonstrated in Fig.5.The strain at peak strength increased with the loading angle,with a range of 1.41%-2.51%.The elastic modulus was from 1.42 GPa to 2.55 GPa,which showed approximately the same trend as the peak strength,with the minimum atβ=30°.The stress-strain curves were generally smooth until the stress peaked,and most of the specimens showed brittle failure characteristics.The anisotropy ratios of elastic modulus,peak strength,and strain at peak strength of the NH specimens were 1.13,1.71,and 1.78,respectively,suggesting a fair anisotropy.

Fig.5.Stress-strain curves and average mechanical properties of the NH with different loading angles based on the mesoscale uniaxial compression test.

3.2.Fracture propagation anisotropy of reef limestones

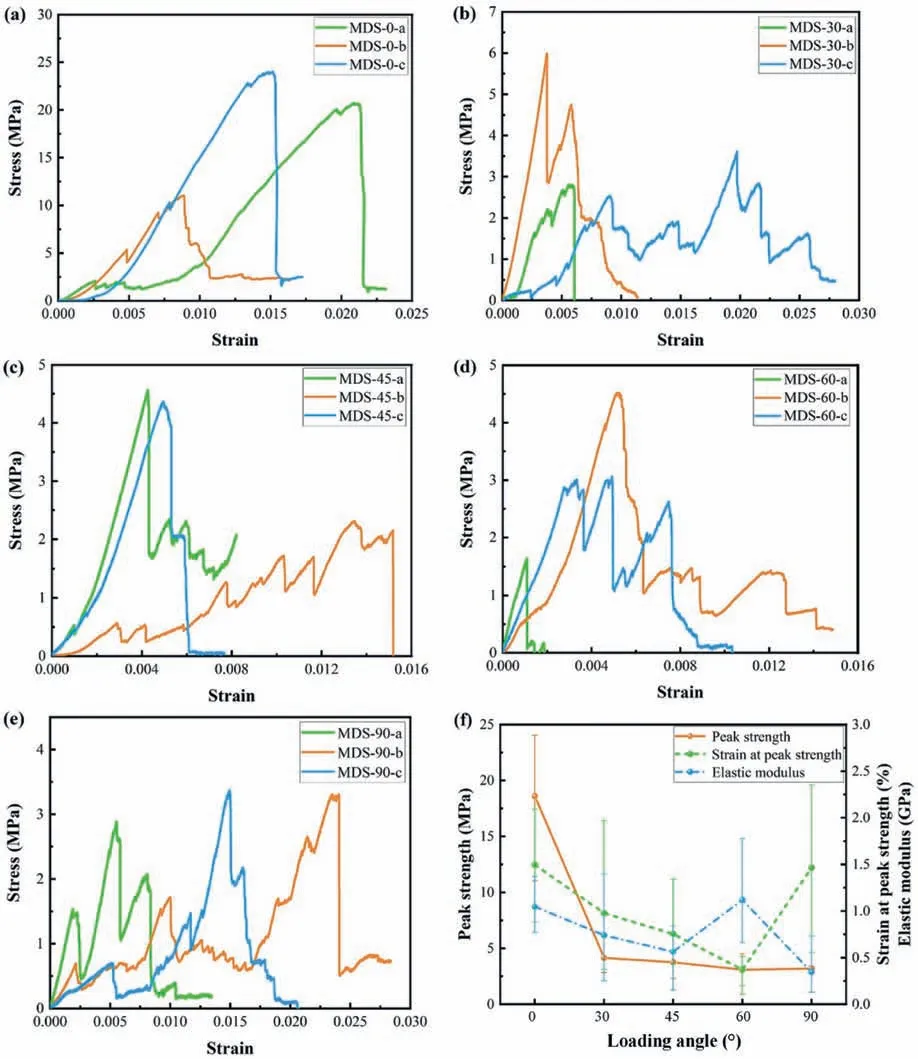

To illustrate the anisotropy of the fracture initiation,propagation,and failure under mesoscale uniaxial compression conditions,representative snapshots of reef limestone specimens with clear fracture features at loading angles from 0°to 90°were selected.Snapshots numbered 1-6 in the top left corresponded to the stages with the same reference numbers in the stress-strain curves,and the loading time was marked in the top right of each snapshot,as shown in Figs.6 and 7.

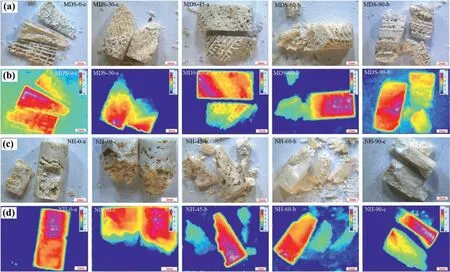

As for the MDS,the direction of main fracture propagation mostly coincided with the direction of coral growth.For the specimens with the loading angle ofβ=0°(Fig.6a),a fracture developed in the specimen at 49.41 s,which occurred in the fragile tabulae.The specimen stress peaked at 89.52 s,while the fracture of the tabulae in the same septal fossula of the specimen connected to develop a penetration shear fracture along the coral growth line direction.

For the specimens with a loading angle ofβ=30°(Fig.6b),a steep drop in the stress-strain curve was noticed once before the peak,but no significant fracture was observed on the surface of the specimen.When the peak stress was about to be reached,a partial fracture propagated on the surface of the specimen at 59.26 s.Immediately afterward,the specimen fractured along the coral growth direction and thus failed.

For the specimens with a loading angle ofβ=45°(Fig.6c),no significant fractures were noticed during the loading of the specimen until the stress peaked at 44.09 s.Immediately thereafter,main longitudinal penetration fractures were observed in the regions with more pores developed.The specimen still retained some residual strength after failure.

When the loading angle increased to 60°(Fig.6d),no visible fractures appeared during the loading of the specimen until the stress peaked at 52 s.However,there was no main fracture penetrating the specimen at this time,and the fracture propagation was only observed in the tabulae of the coral.The fractures continued to propagate during the subsequent continuous loading and formed a main fracture in the end.

For the specimens with a loading angle ofβ=90°(Fig.6e),a stress reduction was observed in the stress-strain curve several times,but without significant generations of fractures during the loading process.Shear slip fractures occurred at the end of the specimen and the pore structure started to collapse at 191.34 s.The stress peaked at 236.92 s,and a new fracture generated and then propagated longitudinally in the specimen.

In a word,the MDS specimens exhibited a “skeletonization effect”.The decrease in the effective area of the specimen to bear the load resulted in a decrease in the mechanical strength and the susceptibility to structural failure.

The fractures in the specimens of the NH were mainly found in the weak pore walls around the secondary dissolution pores.For the specimens with a loading angle ofβ=0°(Fig.7a),tiny fractures were initiated during continuous loading of the specimen.The stress peaked at 96.91 s,while the fractures propagated in the weaker joints at the boundary of the dense reef limestone masses.There were secondary dissolution pores with large pore sizes and irregular pore shapes at the boundary.The specimen retained some residual strength after failure.However,the residual stress gradually increased soon afterward until it stabilized at 198.89 s.

Fig.7.Representative stress-strain curves of the NH at different loading angles (left),and corresponding snapshots showing the progressive failure of the specimen (right).

For the specimens with a loading angle ofβ=30°(Fig.7b),the propagation of fractures at the top of the specimen during the loading process was observed.A minor peak in stress emerged at 154.97 s,while a new fracture at the end of the specimen resulted in a temporary reduction in stress.The specimen failure occurred after the stress peaked at 216.3 s.

For the specimens with a loading angle ofβ=45°(Fig.7c),there were fractures persistently emerging at the end and in the area where the dissolution effect was more serious during the loading process.The stress peaked at 148.39 s and then decreased to retain residual strength of about 10 MPa.No significant abruptions were observed in the specimen when the stress peaked,and the fractures continued to propagate in the post-peak stage of the specimen.

When the loading angle increased to 60°(Fig.7d),there were no obvious variations until a minor peak in stress appeared at 171.54 s,and several fractures initiated at the end of the specimen.The stress peaked at 200.16 s.As the fractures on the surface of the specimen initiated and propagated,the compaction occurred at the end of the specimen,and the pore structure collapsed.The secondary fractures propagated from the end to the center of the specimen,but no obvious penetration fractures were observed.The specimen retained some residual strength after failure.

The specimens with a loading angle ofβ=90°were significantly denser with fewer pores(Fig.7e).Small fractures on the surface at the end of the specimen initiated before the stress peaked at 221.75 s.At 235.16 s,a nearly penetrating main fracture in the specimen resulted in the reduction of the strength of the specimen.The fracture eventually penetrated at 256.31 s and the specimen was then broken due to brittle failure.

With the synchronous videos taken by the stereomicroscope during the mesoscale uniaxial compression tests,it was possible to detect the crack initiation stress and the peak stress point of each specimen.The stress at the crack initiation point was obtained according to the first occurrence of fracture on the upper surface of the specimen and compared with the peak strength,as presented in Fig.8.In addition,the total input energy during loading was also calculated,which was considered as the work that the loading system had done on a unit volume of the specimen from the start of loading to the time when the stress reached its peak (Xie et al.,2005;Liu et al.,2019).In general,the peak stress,the crack initiation stress,and the total input energy changed similarly with the loading angle(Fig.8a and c).The fluctuation of elastic modulus and the ratio of crack initiation stress to peak stress with loading angle was also analogous,as shown in Fig.8b and d.There was an exception for the small loading angle of the MDS,and the ratio of crack initiation stress to peak stress did not show significant fluctuations with the loading angle.It is probably due to the existence of a large number of coral lattice pores and dissolution pores in the MDS.Meanwhile,the weaker tabulae at the edge of the pores tended to be prior to cracking,and such destruction usually localized,resulting in weak correlation with the final destruction of the specimens.Nevertheless,the appearance of cracks in the NH was more strongly correlated with the failure of the specimen as a whole,thus the variations of the ratio of crack initiation stress to peak stress and modulus of elasticity with loading angle were more significantly consistent than that of the MDS.

Fig.8.Changes in the crack initiation stress,the energy,ratio of crack initiation stress to peak stress,and mechanical parameters with loading angles:(a,b)The MDS,and(c,d)The NH.

3.3.Failure mode differences and fracture surface roughness variations

The fracture surface morphology or topography is of great significance in the study of fracture mechanics and stress analysis and fracture surface roughness is an important indicator for the quantitative analysis of the fracture surface morphology.Herein quantitative analysis of the fracture surface roughness was conducted on the representative blocks selected from typical specimens.The Leica Montage images were first taken and imported into the Leica Map Start to generate the depth(i.e.height)maps,then the fracture surface area of the failure specimen was selected with the polygon tool to calculate the height parameters in the software.Height parameters are a class of surface roughness parameters that quantify theZ-axis perpendicular to the surface.In this investigation,the root-mean-square(RMS)height(Sq)was used to quantify the roughness of the fracture surface,as demonstrated in Eq.(2).The roughness data of the major fracture surfaces of the rocks were averaged to investigate the relationship between roughness and strength of the rock specimens.

whereSqis the standard deviation for the amplitudes of the surface,which characterizes the RMS surface roughness in the selected area.

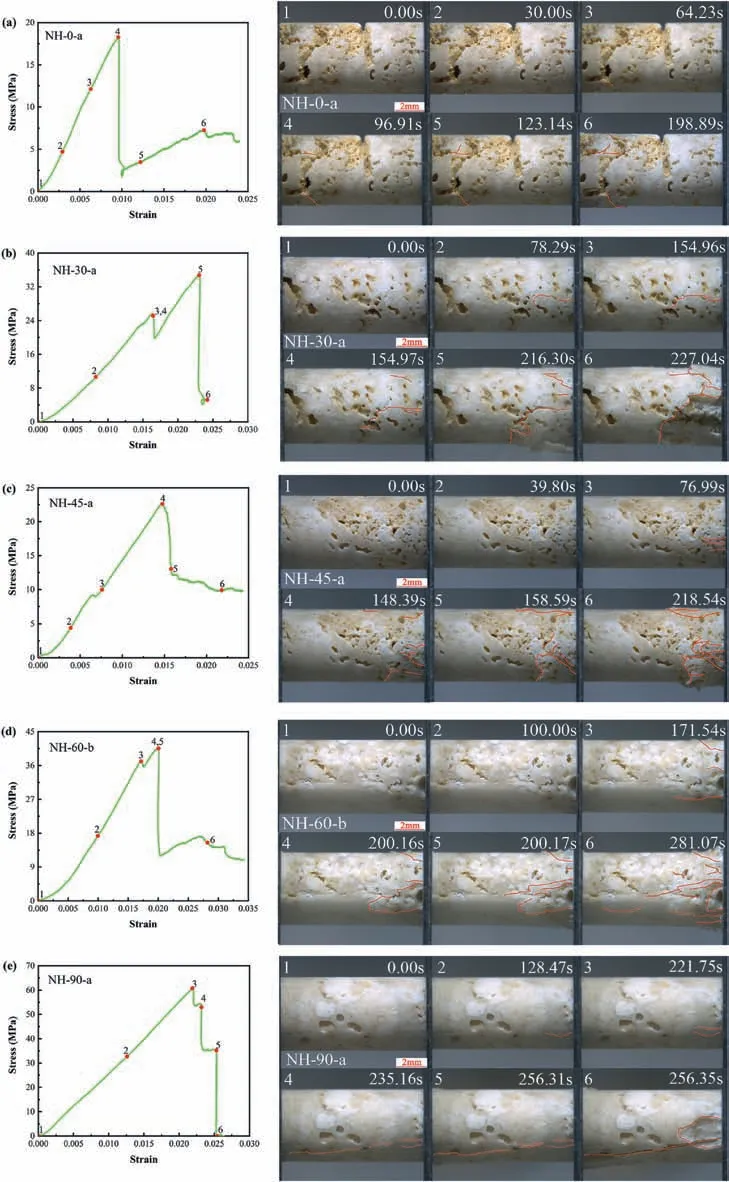

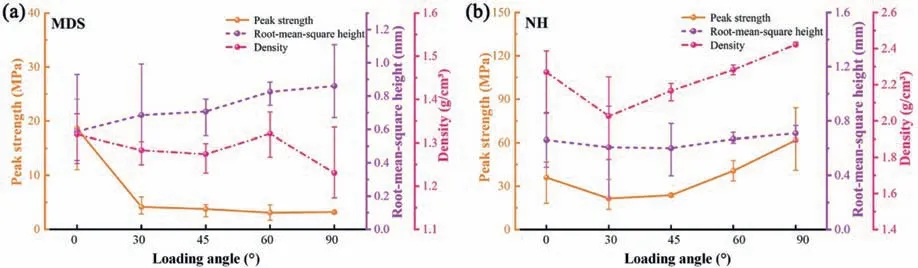

When the loading angles of the MDS were gentle,the fractures propagated along the texture and penetrated through the specimens,and the higher the loading angle,the more the fractures in the specimens that tended to initiate at the end.The fractures that penetrated through the specimens usually propagated along the significantly thin tabulae or septa.It is noteworthy that a clear pore structure was observable on one of the two sides of the fractured specimen,as illustrated in Fig.9a and b,while the other side was relatively flat.It indicated that the fracture occurred at the connection between the septa and the tabulae of the coral.The peak strengths of the specimens of the MDS were very low with no significant differences,except for the specimens with an angle ofβ=0°.There were also no obvious relations among the peak strength,fracture surface roughness,and density of the corresponding specimens (Fig.10a).Specimens mostly had a failure at the place where the pore structure was more developed,resulting in the slight influence of density on the mechanical properties of the rock compared to the rock structure.For the MDS specimens,the regions with more developed pore structures were the primary areas of fracture propagation.Since it tended to initiate more easily at the ends,the mechanical properties of specimens with more pores that developed at the ends were usually poorer.

Fig.9.Images of broken blocks and depth maps of (a,b) the MDS and (c,d) the NH specimens.

Fig.10.Relationship among peak strength,density,and fracture surface roughness of (a) the MDS and (b) the NH specimens.

In contrast to the failure of the MDS specimens due to the collapse of the pore structure,the NH specimens were denser and their failure modes tended to be brittle because of the underdeveloped pore structure.They were not composed of coral skeletons,but of various biological fragments,mainly coral gravels.These coral gravels were usually dense,while the loose structure of the rock was cemented with other bioclasts including brachiopods,echinoderms,and fusulinids.The failure modes of the specimens could be summarized as follows:(1)The main fracture propagated along the edge of the coral gravel,that is,the cemented surface of the coral gravel with other bioclasts.(2) The regions with developed pore structures were disrupted because of the initiation of multiple fractures,that is,disruptions at the cementation between bioclasts.(3) The failure of specimens at peak stress occurred mainly in specimens composed of coral gravels,and the failure mode of specimens without obvious weak cementation surfaces was approximate to the brittle failure of the conventional rocks(Fig.9c and d).The peak strength of the specimens was closely related to the density,and the fracture surface roughness of the specimens differed slightly at different angles,with a positive correlation with the peak strength of the specimens (Fig.10b).Moreover,the fracture surface in the regions with looser structure was uneven,while that of the denser specimens was relatively smooth,even though the components of the denser specimens were not completely homogeneous.

4.Discussion

Both the morphology and microstructure of the reef limestones from different sea areas showed significant differences,and the effects of the structure on the mechanical properties of the rocks were obvious as shown by the test results.According to the videos of the compression test and the stress-strain curves,the reef limestones had a porous structure,and most of specimens failed with pore collapse (e.g.MDS-90-b in Fig.6e).During the compression of such specimens,the stress usually went through one or even more drops before reaching peak stress,mostly occurring in specimens with high porosity and high loading angles.In the process of the pore wall from bearing to gradual destabilization failure,its microscopic bearing capacity was constantly decreasing,and the specimen would not present a decrease in the macroscopic stress value until most of the pore walls were suffering from destabilization failure.However,as part of the pores were compressed and compacted,the stress would redistribute and the entire system had new load-bearing capacity by new stress balance,resulting in the increase of macroscopic stress values.The accumulation and progression of pore collapse failure led to a significant increase in the energy absorption of highporosity rocks (Su et al.,2014).The presence of pores reduced the stiffness and strength of the reef limestones while achieving a toughening effect,which changed the macroscopic mechanical properties of reef limestones (He et al.,2019).The ductile fracture behaviors of reef limestones at failure were induced by the combination of the stress shielding effect of the pores and the localization behavior of the failure in the rock mass(Jia et al.,2021).

The experimental results indicated that the mechanical properties of reef limestones were essentially influenced by the pore structure.However,compared with conventional macroscopic rock mechanical properties,the compressive strength of the reef limestone specimens at mesoscale was not in good agreement with the traditional U-shaped strength-bedding angle curve.This curve usually presents the lowest strength atβ=30°and the highest strength in a direction parallel or perpendicular to the bedding(Crawford et al.,2012;Li et al.,2012;Liu et al.,2016).One explanation for this inconsistency is that the dissolution of the rocks caused the alteration of the pore size and pore shapes inside the rocks.The random distribution of dissolved pores may contribute to the significant unpredictability of the mechanical properties of the reef limestones.

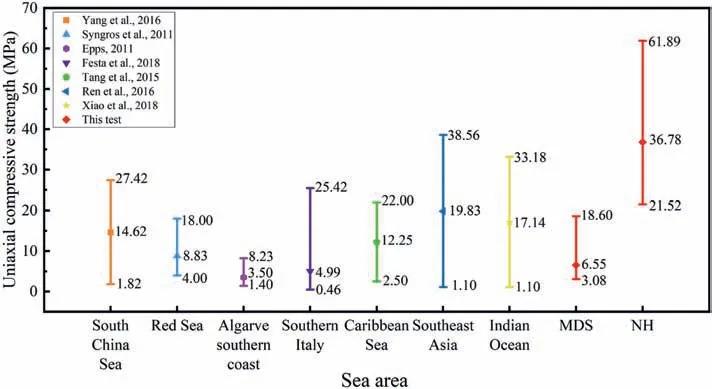

With the integration of the porosity of the MDS and the NH,it can be concluded that the specimens with higher porosity had lower UCS.In other words,the development of a large number of visible macroscopic pores in the reef limestones would weaken their strength.A literature review of reef limestones from different sea areas also revealed that most reef limestones generally had low UCS (Fig.11),with a range of 0-40 MPa.The UCS of the reef limestones in this study was approximate to the results of other scholars,except that some NH specimens presented higher strength.It is probably due to that the visible macroscopic pores tended to be prevalent in most reef limestones,while some NH specimens had fewer visible macroscopic pores,such as the NH-90-a,which resulted in higher UCS.

Fig.11.Comparison of UCS of reef limestones from different sea areas(Epps,2011;Syngros et al.,2011;Tang and Zheng,2015;Ren et al.,2016;Yang et al.,2016;Festa et al.,2018;Xiao et al.,2018).

Comparing the experimental results of reef limestones from different seas,it was obvious that the rocks with poorly developed pore structures would have higher strength.The initiation and propagation of fractures tended to occur at the weaker parts of the rocks,which were usually the edges of the pores.Therefore,the influence of coral growth direction on the mechanical properties of reef limestones was weaker than that brought about by the disruption of the rock structure induced by the dissolution.Although no obvious coral growth lines were visible in the NH specimens,the experimental results followed the strengthbedding angle curve of the conventional laminated rocks.One possible explanation was that it was attributed to the presence of certain weak angles of bioclastic cementation.

The MDS specimens presented extremely low compressive strengths because of their fragile structure,and the porous and loose structure severely affected their mechanical properties,except specimens with a loading angle ofβ=0°.The exception was probably because the coral growth direction of the specimens at this angle was oriented parallel to the loading direction so that the applied forces were supported by the harder and thicker epitheca of the coral,as shown in Fig.12a.For specimens with a certain angle between the loading direction and the coral growth direction,because of the absence of support from the epitheca,the specimens tended to fail due to the shear stress concentrations that occurred in the weaker tabulae (Fig.12b and c),or collapse of the tabulae(Fig.12d).Moreover,the denser specimens had higher strength because of the slight dissolution effect.

Fig.12.Schematic illustrating the stress states of the coral skeleton of reef limestone under different loading angles:(a)β=0°,(b)β=30°,(c)β=60°,and(d)β=90°.Note that the blue area represents the solid and the white area represents the pore.

Both reef limestones exhibited certain anisotropic mechanical properties,but the anisotropy of the MDS was more obvious than that of the NH.It was observed in the mechanical experiments that the fractures of the reef limestones mostly initiated and propagated at weak parts,which meant that the mechanical anisotropy of the reef limestones was primarily manifested in the differences of the rock structure.It was the presence of significant weaknesses within the rock mass that caused significant differences in the mechanical properties of the specimens when loaded in different directions.Meanwhile,it was found that as for the NH in this experiment,the higher the density of the rock,the higher the peak strength and the rougher the fractured surface of the rock at a constant loading rate without other influencing factors.The structure of the MDS was too loose and the strength obtained was generally too low to distinguish the relationship among the strength of the rock,its density,and fracture surface roughness.In general,the MDS showed mechanical properties of porous structures with coral skeletons as materials,while the NH showed mechanical properties of rocks with various bioclastic cementations.

In terms of the influence of the pore structure on the mechanical properties of the rocks,the reduction of porosity usually increased the bearing capacity and energy absorption of the rocks,but the shape of the pores would make the rocks respond differently to the external force conditions.The anisotropy exhibited in the same species of reef limestones was primarily attributed to the effects of pore shape and pore size,that is,dissolution disrupted the tabulae and septa of the coral to make the pores connected and thus changed the pore shape.However,the geometry of the pore arrangement influenced the mechanical parameters more than the pore diameter and the number of pores.The distribution of primary pores in the same species of reef limestone followed a certain regulation because of the approximately uniform structure of corals.But the secondary pores generated by dissolution were usually different from the primary pores in shape and diameter,and the random distribution of dissolution pores made the stress distribution of the specimens uneven when the load was applied,which was the primary reason for the anisotropy in the mechanical properties of the same species of reef limestones.The differences in pore structure between different species of reef limestones were more pronounced,and their primary pores already differed significantly in shape,size,number,and distribution,and the differences in the distribution of secondary dissolution pores formed afterward were even more pronounced.

To summarize,the differences in the mechanical properties of reef limestones were reflected in the same species of rocks as anisotropy,which was jointly generated by the coral growth direction and random distribution of dissolution pores.While the differences in the mechanical properties of different species of reef limestones resulted from the differences in pore shape,pore diameter,pore number,and pore distribution within the rock.The dispersion of mechanical properties exhibited in the mechanical tests of reef limestones was attributable to this random distribution when other extraneous disturbances were excluded.

5.Conclusions

In this work,a series of mesoscale uniaxial compression experiments were conducted with an integrated synchronous loading observing-acquiring system to investigate the mesoscale mechanical anisotropy of reef limestones.The experiments indicated that the overall values of UCS of the reef limestones were relatively low,and the strength was not uniform with high discreteness.The strength of the specimens was dependent on their pore structure and density.The dissolution disrupted the pore structure which reduced the strength of the specimens.The loose and porous rocks usually had a ductile failure and retained relatively high residual strength,while the dense reef limestones had the failure characteristics of brittle rocks.

In the reef limestone specimens,which were primarily composed of coral skeletons,the fractures did not always initiate and propagate along the coral growth direction but occurred at the weak parts of the specimens(tabulae of the coral or septa that were more fragile caused by dissolution).The specimens with higher loading angles usually failed at the end,and the fractures of specimens with lower loading angles tended to penetrate the specimens.

The elastic modulus of the specimens was approximate and correlated with the ratio of crack initiation stress to peak stress.The fracture surface roughness and the UCS varied with the loading angle with good consistency for the reef limestones from the South China Sea.

The pore structure of the specimens during compression affected the mechanical properties of the rocks most profoundly,its homogeneity and the consistency of coral growth direction both caused changes in the mechanical properties of the rocks,resulting in the mesoscale mechanical anisotropy of the reef limestones.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper

Acknowledgments

This work was supported by the National Natural Science Foundation of China(Grant Nos.41977248 and 42207219)and the Key Research Program of the Institute of Geology and Geophysics,Chinese Academy of Sciences (CAS) (Grant No.IGGCAS-201903).

Journal of Rock Mechanics and Geotechnical Engineering2023年12期

Journal of Rock Mechanics and Geotechnical Engineering2023年12期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Advances in joint roughness coefficient (JRC) and its engineering applications

- Preliminary estimation of rock-fall lateral dispersion by laboratory test

- Triaxial tension and compression tests on saturated lime-treated plastic clay upon consolidated undrained conditions

- Strain localization of Mohr-Coulomb soils with non-associated plasticity based on micropolar continuum theory

- Rapid testing and prediction of soil-water characteristic curve of subgrade soils considering stress state and degree of compaction

- Performance assessment of borehole arrangements for the design of rectangular shallow foundation systems