基于四基色的全色域混色模型构建及彩色纱纺制

李娟娟 薛元 徐志武 于健 曾德军

摘 要:为了解决色纺纱产品研发与生产中的颜色模型构建等关键共性技术,基于四基色纤维以12.5%的离散梯度网格化混配构建全色域混色模型;结合构建的全色域混色模型和三通道数控纺纱技术,阐述了“多通道牵伸比-色纤维混合比-成型纱线颜色值”的三要素调控机理,提出了调控成形纱线色相、明度及彩度的工艺方法,设计了纺制全色域混色纱的工艺;利用三通道数码纺纱机纺制了等明度不同色相、等色相不同明度、等色相不同彩度的三个系列的彩色纱,并对纱线的条干、毛羽及力学性能进行了测试,将测试数据与本色纱性能指标进行对比分析。结果表明:文章提出的基于全色域混色色谱纺制全色域彩色纱线的工艺具有可行性,纺制的彩色纱各项性能指标均可达到本色纱的一等品要求。

关键词:混色纱;四基色;网格化混色;全色域混色模型;性能指标

中图分类号:TS85.1 文献标志码:A 文章编号:1009-265X(2023)06-0117-13

与传统的色纺纱生产工艺相比,现有的色纺纱工艺采用将短纤维先染色再进行纺纱的生产方式,一方面可减少接近50%的废水污染;另一方面,色纺纱工艺调色灵活,能适应小批量多品种生产[1]。但由于不同种类纤维具有不同的光学特性[2-3],不同的加工混合方法会导致纱线内部异色纤维的不均匀混合[4-6],环境光的差异会导致色纺纱及其织物呈现出不同的色彩[7-8],所以调控及再现色纺纱及其织物的色彩一直是色纺产品生产中的关键。

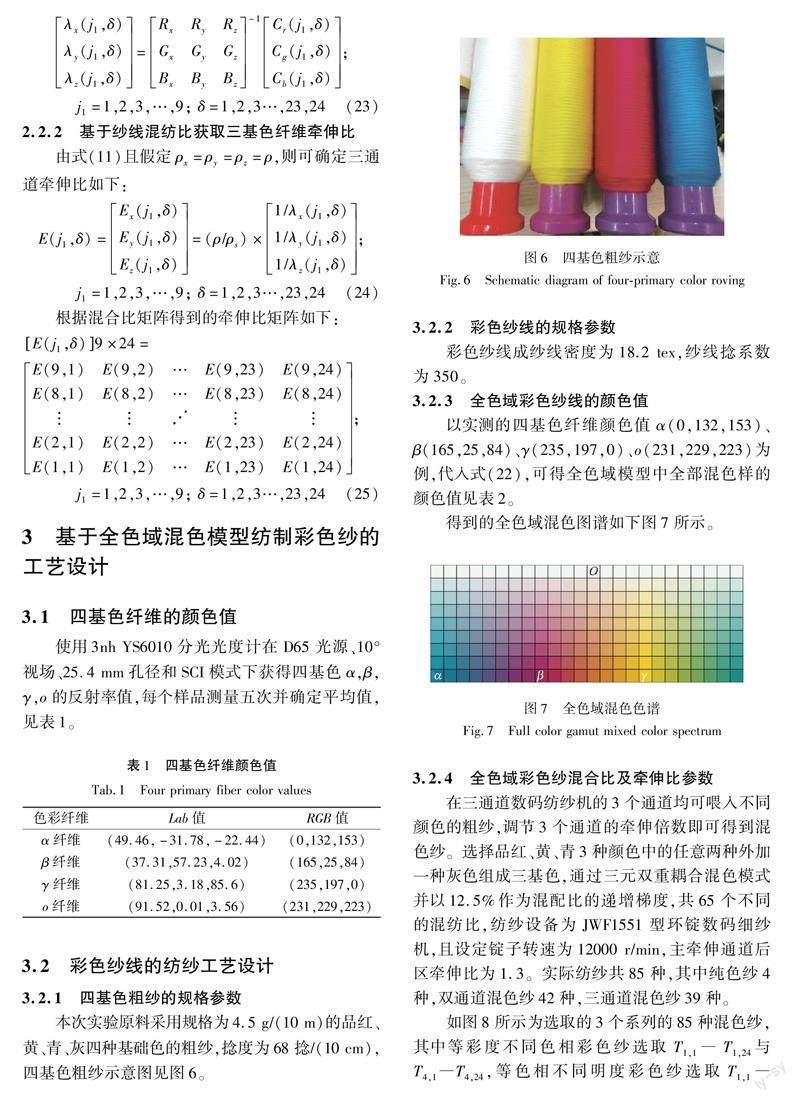

为了解决色纺纱及其织物的颜色调控及再现问题[9-10],本文从两个方面展开研究,首先在配色模型上提出基于四基色纤维混色构建全色域混色模型,希望解决通过四基色纤维混合比获取全色域彩色纱的颜色值;其次是在工艺方法上,通过染色、开清棉、梳棉、粗纱等工序,获取品红、黄、青、灰四基色纤维的粗纱,基于三通道数控纺纱技术构建“多通道牵伸比—色纤维混合比—成型纱线颜色值”三要素的调控机理,希望能借此实现对成型纱线色相、明度及彩度的在线全色域调控,并可基于前述构建的全色域混色模型纺制全色域彩色纱。

1 四基色纤维双重耦合混色模式及全色域混色模型构建

1.1 混色用四基色纤维的制备

优选染料及优化染色工艺分别获取色彩纯净度最高的三组彩色纤维α、β、γ作为混色用三基色纤维。称取三组彩色纤维α、β、γ及一组无彩色纤维O的重量分别为Wα、Wβ、Wγ、Wo。设定四基色纤维的颜色值分别为Cα(Rα,Gα,Bα)、Cβ(Rβ,Gβ,Bβ)、Cγ(Rγ,Gγ,Bγ)、Co(Ro,Go,Bo)[8]。

1.2 四基色纤维离散化重量及其混色模式构建

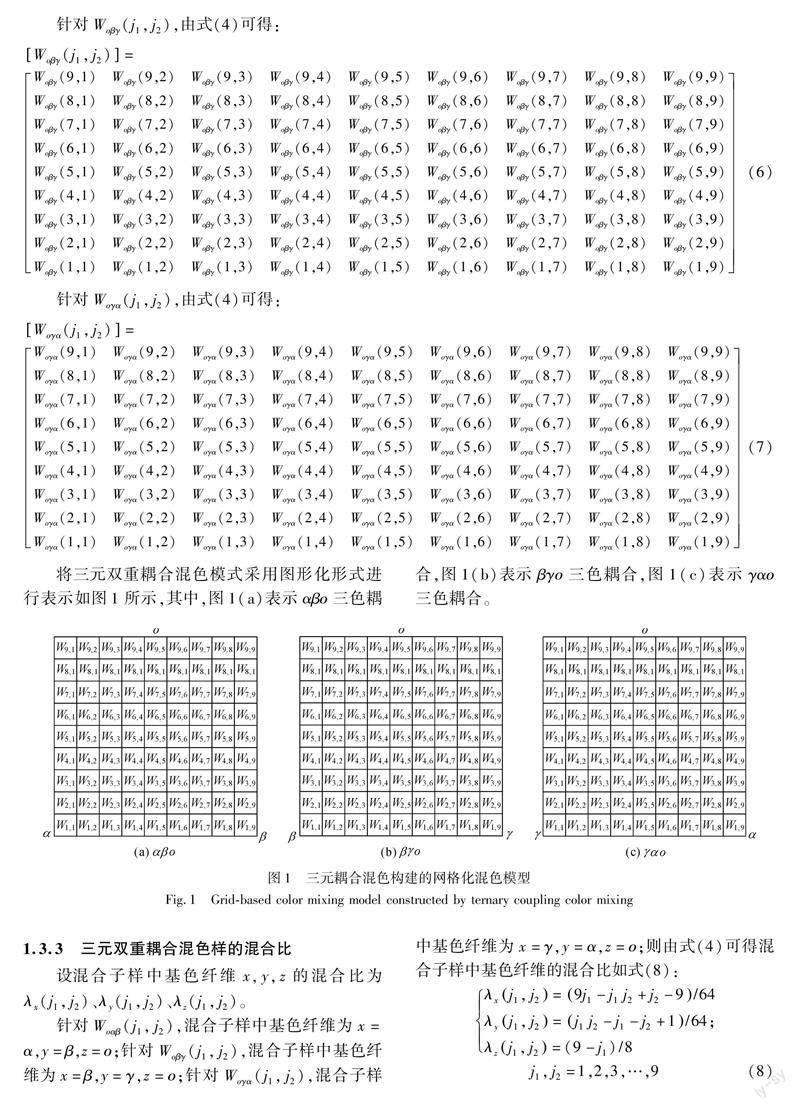

基于三元双重耦合混色的数学原理,若取四基色颜色值为 α(0,255,255)、β(255,0,255)、γ(255,255,0)、ο(128,128,128),则子模型混色色谱如图2所示。

1.4 全色域网格化混色模型构建

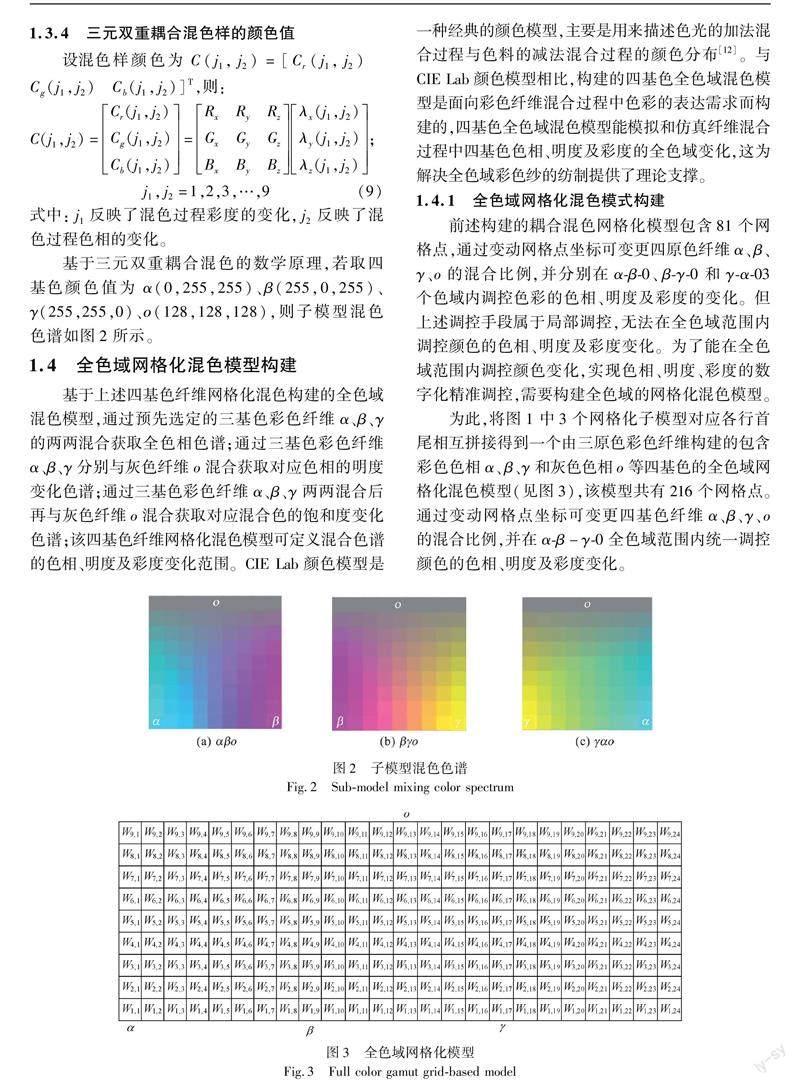

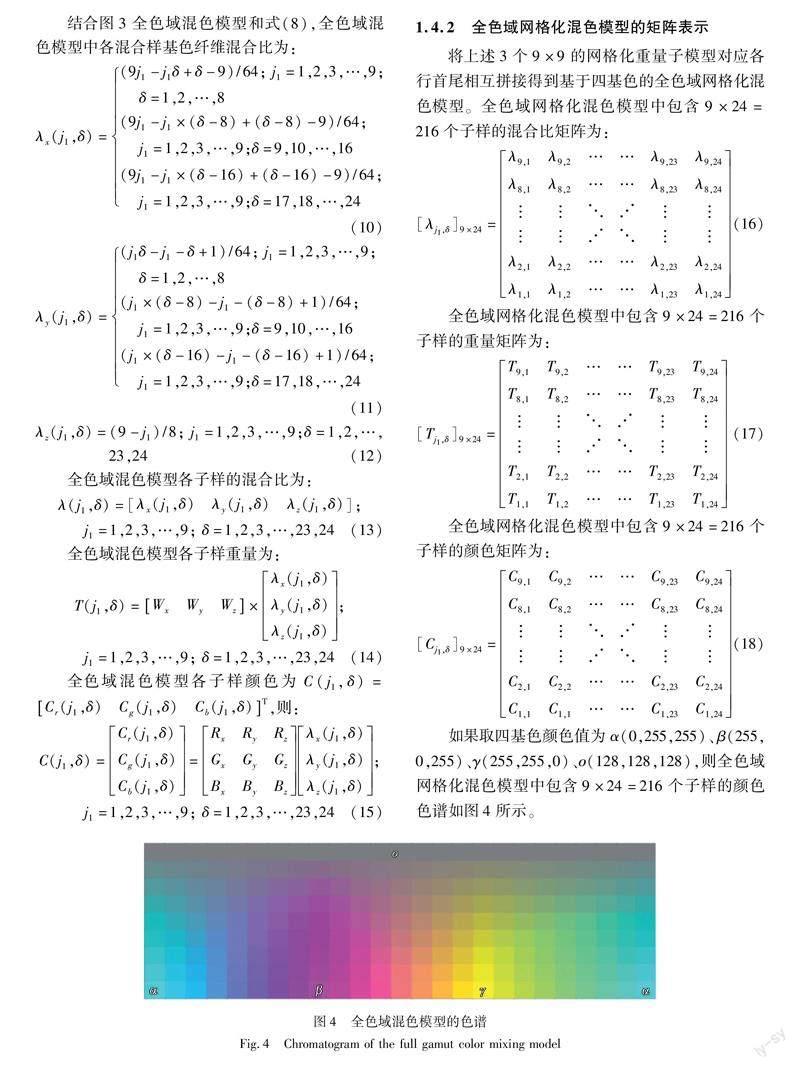

基于上述四基色纤维网格化混色构建的全色域混色模型,通过预先选定的三基色彩色纤维α、β、γ的两两混合获取全色相色谱;通过三基色彩色纤维α、β、γ分别与灰色纤维o混合获取对应色相的明度变化色谱;通过三基色彩色纤维α、β、γ两两混合后再与灰色纤维o混合获取对应混合色的饱和度变化色谱;该四基色纤维网格化混色模型可定义混合色谱的色相、明度及彩度变化范围。CIE Lab颜色模型是一种经典的颜色模型,主要是用来描述色光的加法混合过程与色料的减法混合过程的颜色分布[12]。与CIE Lab颜色模型相比,构建的四基色全色域混色模型是面向彩色纤维混合过程中色彩的表达需求而构建的,四基色全色域混色模型能模拟和仿真纤维混合过程中四基色色相、明度及彩度的全色域变化,这为解决全色域彩色纱的纺制提供了理论支撑。

1.4.1 全色域网格化混色模式构建

前述构建的耦合混色网格化模型包含81个网格点,通过变动网格点坐标可变更四原色纤维α、β、γ、o的混合比例,并分别在α-β-0、β-γ-0和γ-α-03个色域内调控色彩的色相、明度及彩度的变化。但上述调控手段属于局部调控,无法在全色域范围内调控颜色的色相、明度及彩度变化。为了能在全色域范围内调控颜色变化,实现色相、明度、彩度的数字化精准调控,需要构建全色域的网格化混色模型。

为此,将图1中3个网格化子模型对应各行首尾相互拼接得到一个由三原色彩色纤维构建的包含彩色色相α、β、γ和灰色色相o等四基色的全色域网格化混色模型(见图3),该模型共有216个网格点。通过变动网格点坐标可变更四基色纤维α、β、γ、o的混合比例,并在α-β-γ-0全色域范围内统一调控颜色的色相、明度及彩度变化。

3.2 彩色纱线的纺纱工艺设计

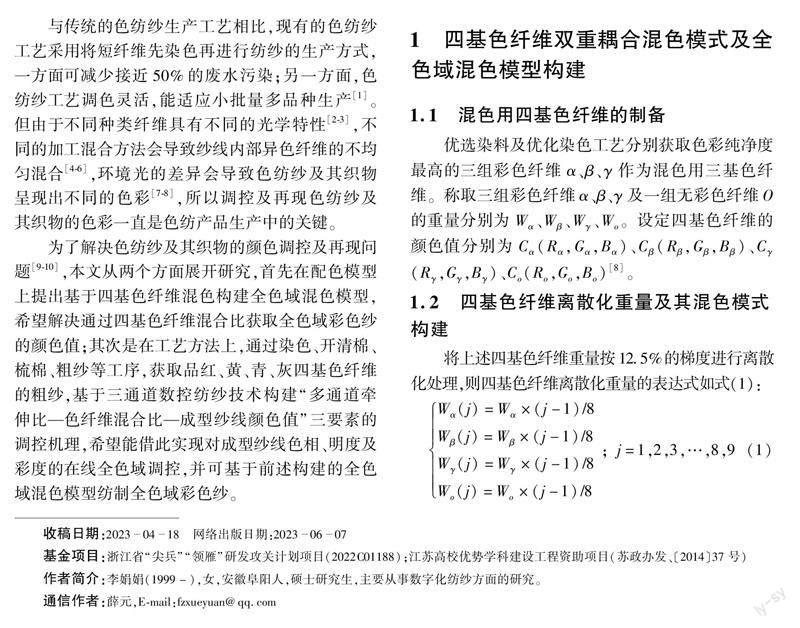

3.2.1 四基色粗纱的规格参数

本次实验原料采用规格为4.5 g/(10 m)的品红、黄、青、灰四种基础色的粗纱,捻度为68捻/(10 cm),四基色粗纱示意图见图6。

3.2.2 彩色纱线的规格参数

彩色纱线成纱线密度为18.2 tex,纱线捻系数为350。

3.2.3 全色域彩色纱线的颜色值

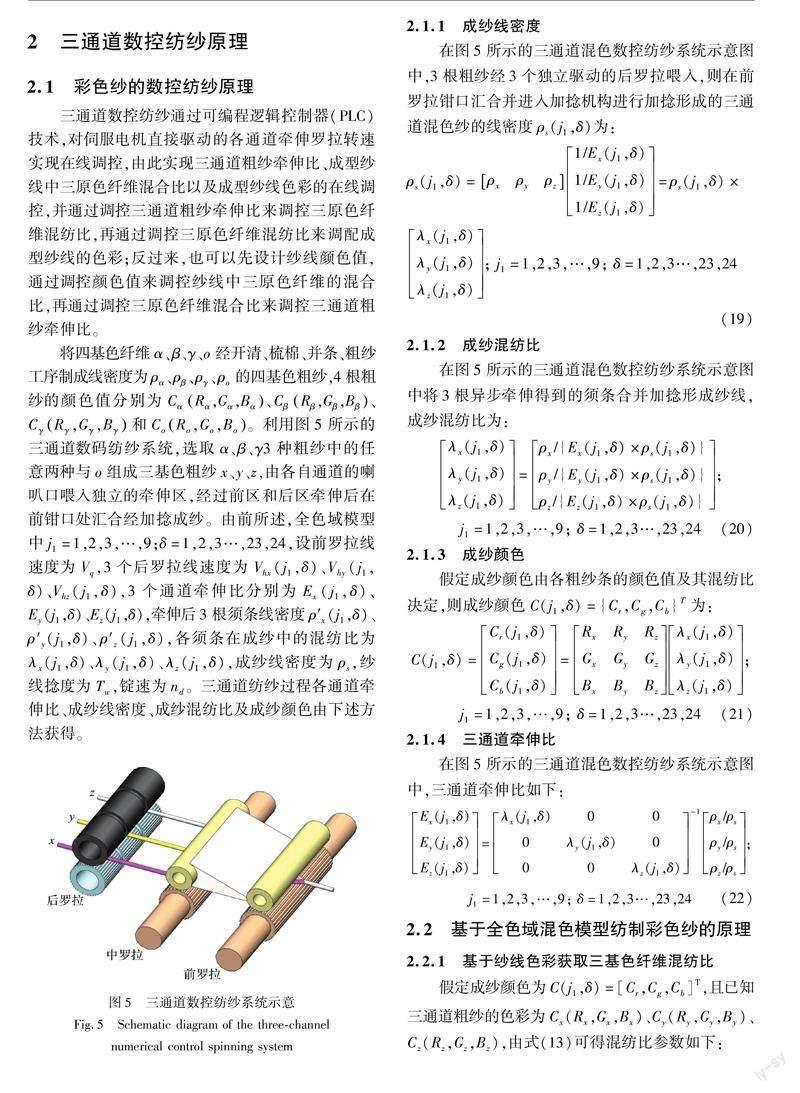

以实测的四基色纤维颜色值α(0,132,153)、β(165,25,84)、γ(235,197,0)、o(231,229,223)为例,代入式(22),可得全色域模型中全部混色樣的颜色值见表2。

得到的全色域混色图谱如下图7所示。

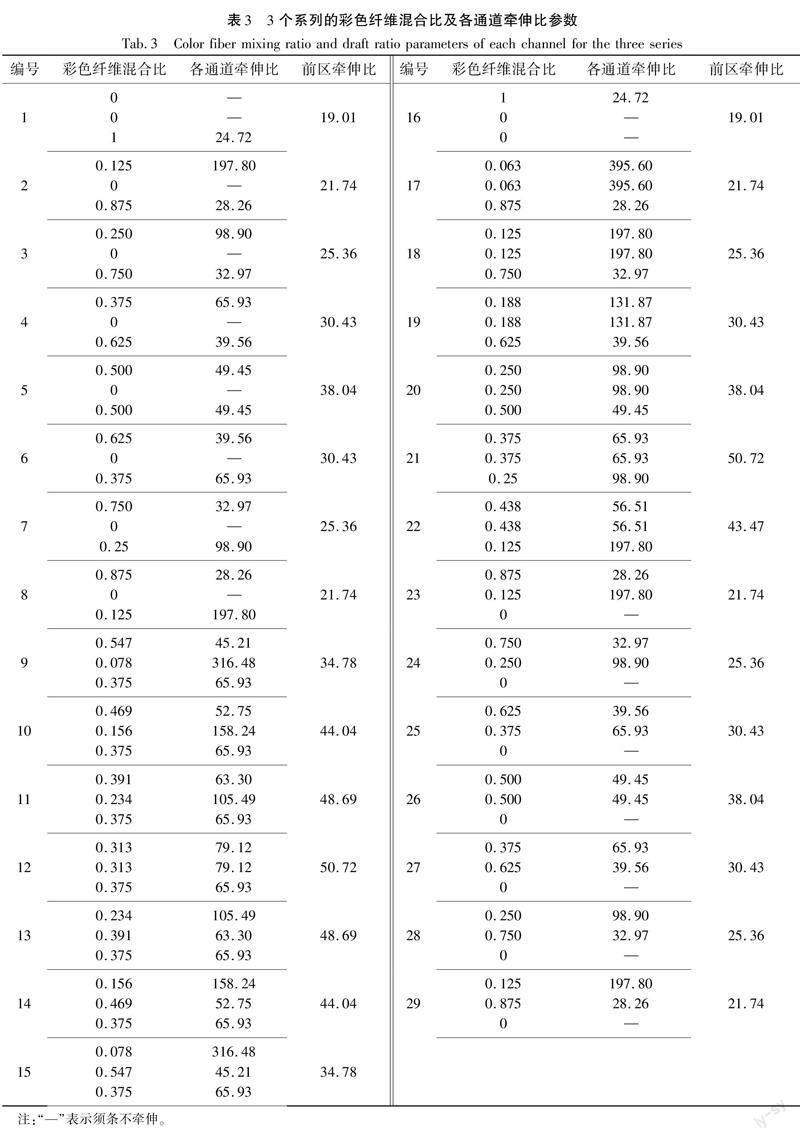

3.2.4 全色域彩色纱混合比及牵伸比参数

在三通道数码纺纱机的3个通道均可喂入不同颜色的粗纱,调节3个通道的牵伸倍数即可得到混色纱。选择品红、黄、青3种颜色中的任意两种外加一种灰色组成三基色,通过三元双重耦合混色模式并以12.5%作为混配比的递增梯度,共65个不同的混纺比,纺纱设备为JWF1551型环锭数码细纱机,且设定锭子转速为12000 r/min,主牵伸通道后区牵伸比为1.3。实际纺纱共85种,其中纯色纱4种,双通道混色纱42种,三通道混色纱39种。

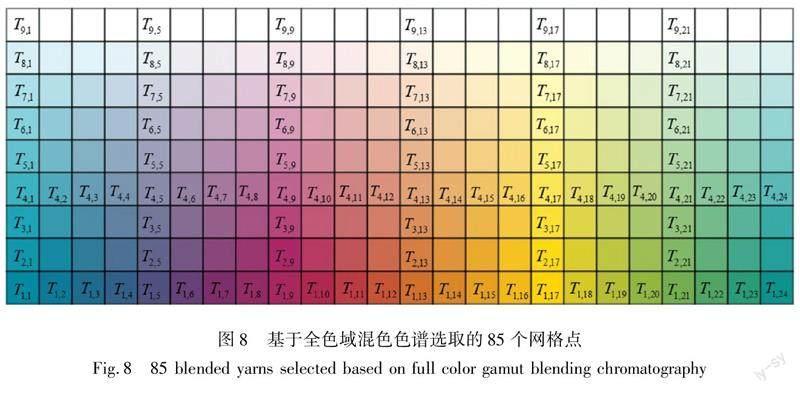

如图8所示为选取的3个系列的85种混色纱,其中等彩度不同色相彩色纱选取T1,1―T1,24与T4,1―T4,24,等色相不同明度彩色纱选取T1,1―T9,1、T1,9―T9,9与T1,17―T9,17,等色相不同彩度彩色纱选取T1,5―T9,5、T1,13―T9,13与T1,21―T9,21,共纺制85种混色纱。三通道的各区牵伸比及牵伸比如下表3所示。

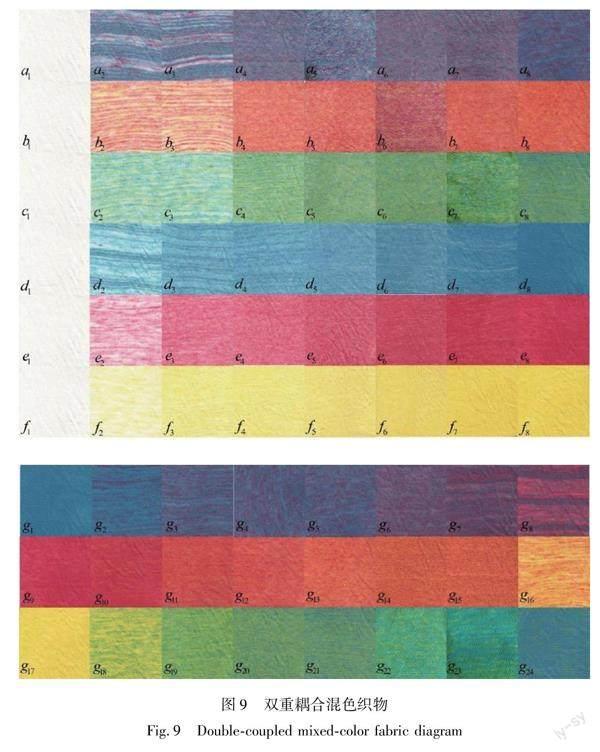

3.3 三通道数码混色纱织物的制备

为了能更好地呈现三通道数码混色纱的外观特征与视觉效果,实验选用16G宏成HC21K型纬编圆机将85种混色纱织造成平针织物。设计针织物主要规格如下:线圈长度为0.6 mm;横向密度为53行/(5 cm);纵向密度为90列/(5 cm)。

如图9所示,a1-a8、b1-b8、c1-c8为等色相不同彩度织物,d1-d8、e1-e8、 f1-f8为等色相不同明度织物,g1-g24为等彩度不同色相织物。

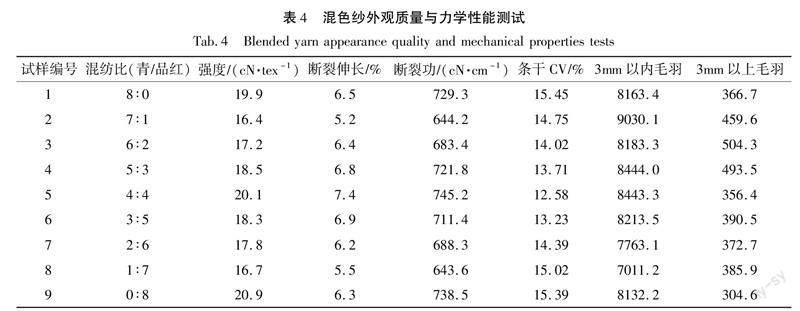

4 混色纱外观质量与力学性能测试

混色纱的力学性能与外观品质是否优良对色纺产品的视觉风格有着很大影响,本小节选取以青、品红为基色纺制9种不同混配比例、规格为Z捻向的18.2 tex混色纱,对混色纱的条干、力学性能及毛羽进行测试,并讨论彩色纱的性能是否符合国家标准[13-14]。

4.1 混色纱织物颜色对比

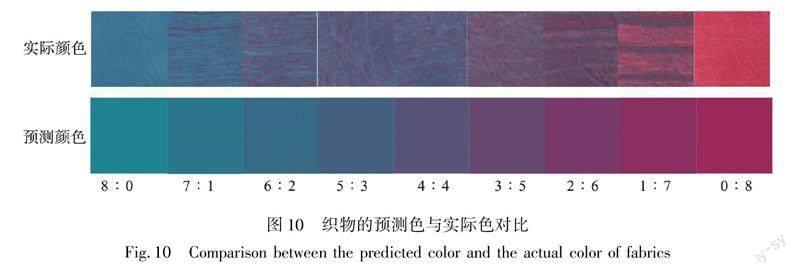

选定的青+品红混色纱,混纺比分别为8∶0、 7∶1、6∶2、5∶3、4∶4、3∶5、2∶6、1∶7及0∶8,共計9种纺制的针织物经扫描仪扫描如图10。

4.2 混色纱外观质量及力学性能测试

选用YG135G条干测试仪对纺制的彩色纱进行条干均匀度的测试,每个纱样测试5次求取平均值;选用YG068C型全自动单纱强力仪对单纱进行断裂强力、断裂伸长率等性能测试,拉伸速度250 mm/min,夹持距离为500 mm,每个混纺比测试次数为15次,取平均值;选用YG172A型纱线毛羽测试仪对纱线进行毛羽测试,测试速度为30 m/min,取10个片段,每个片段为100 m,记录3 mm以内毛羽根数及3 mm以上毛羽根数,实验数据见表4。

实验发现,利用三通道数码纺纱机可以纺制基于四基色纤维的全色域混合模型的等色相不同明度,等色相不同彩度及等彩度不同色相3个系列的彩色纱,对其中的等彩度不同色相的(青+品红)混色纱进行强力、条干及毛羽测试,参考GB/T 398—2018《棉本色纱线》精梳棉本色纱的一等品及优等品要求,混色纱的断裂强度均高于精梳棉本色纱的优等品要求,条干均匀度也达到了一等品要求,混色纱纺制的9种织物实际色彩与预测颜色也基本一致,证明基于全色域模型纺制3种系列的彩色纱这一方案是可行的。

5 结 论

本文以三通道数控纺纱系统为基础,将品红、黄、青、灰四基色以双重耦合模式进行混色,以12.5%的离散梯度构建了一个包含216个子样的全色域混色模型,并定义了四基色纤维网格化混配所构建的全色域混色模型的色相、明度及饱和度[15]。例如,色相的定义域:通过(青+品红)、(品红+黄)、(黄+青)的二元耦合混色模式所能达到的色相最大变化范围定义;明度的定义域:通过(青+灰)、(品红+灰)、(黄+灰)的二元耦合混色所能达到的明度最大变化范围;饱和度的定义域:通过(青+品红+灰)、(品红+黄+灰)、(黄+青+灰)的三元双重耦合混色所能达到的饱和度最大变化范围。基于该混色模型216个网格点,可以获取该网格点的位置坐标以及与网格点对应的四基色纤维混合比、颜色值和数控纺纱三通道牵伸比。通过上述工作,构建了混色纱线颜色值、四基色纤维混合比、三通道牵伸比、混色空间坐标值之间的转换关系,给出了调控成型纱线色相、明度及彩度的数字化加工方法,为实现彩色纺纱奠定了理论基础。

通过将全色域混色模型与三通道数码纺纱技术结合,利用品红、黄、青、灰四基色粗纱纺制了等明度不同色相、等色相不同明度、等色相不同彩度的3个系列合计85种色彩的彩色纱及其针织物,并对纺制彩色纱的条干、毛羽及强力进行了测试分析,验证了彩色纱的外观品质及力学性能优良,基于全色域色谱纺制的针织物实现了较为明显的色相、明度及彩度变化效果,为后续规模化生产全色域彩色纱线及色织物提供基础。

参考文献:

[1]张婷婷,薛元,徐志武,等.三通道数码纺混色纱色谱体系构建及其彩色纱性能分析[J].纺织学报,2019,40(9):48-55.

ZHANG Tingting, XUE Yuan, XU Zhiwu, et al. Color system construction of three-channel digital spinning mixed color yarn and performance analysis of colored yarn[J]. Journal of Textile Research,2019,40(9):48-55.

[2]袁理,熊莹,谷迁,等.染色纤维与色纺纱线间的颜色传递规律及其影响因素[J].纺织学报,2021,42(5):122-129.

YUAN Li, XIONG Ying, GU Qian, et al. Characteristics and factorial study of color transfer between dyed fiber and colored spun yarns[J]. Journal of Textile Research,2021,42(5):122-129.

[3]张毅,王妮,张瑞云,等.色纺纱成色机理的探讨[J].棉纺织技术,2019,47(4):18-24.

ZHANG Yi, WANG Ni, ZHANG Ruiyun, et al. Discus-sion on the coloring mechanism of colored spun yarn[J]. Cotton Textile Technology, 2019, 47(4): 18-24.

[4]刘建农,郑敏博,沈均,等.色纺纱混和方式及工艺优化[J].棉纺织技术,2021,49(10):59-63.

LIU Jiannong, ZHENG Minbo, SHEN Jun, et al. Blending method and process optimization of colored spun yarn[J]. Cotton Textile Technology, 2021, 49(10): 59-63.

[5]ZHU W S, XUE Y A, XU Z W, et al. Symmetrical circulation gradient color system construction and gradient color yarn spun by a three-channel numerical control spinning system[J]. Textile Research Journal 2022,92(11/12):2046-2060.

[6]王曦,焦国珍,胡力主,等.纤维混合方法和纺纱方法对色纺纱色差的影响[J].上海纺织科技,2022,50(12):49-52

WANG Xi, JIAO Guozhen, HU Lizhu, et al. Effect of fiber blending methods and spinning methods on color differences of colored yarns[J]. Shanghai Textile Science &Technology, 2022, 50(12): 49-52.

[7]何文婧.色纺纱针织物呈色效应研究[D].上海,东华大学,2019:19-29.

HE Wenjing. Study on Color Effect of Dyed Knitted Fabric[D]. Shanghai: Donghua University, 2019: 19-29.

[8]SUN X Q, CUI P, XUE Y A. Construction and analysis of a three-channel numerical control ring-spinning system for segment colored yarn[J]. Textile Research Journal, 2021, 91(23/24):2937-2949.

[9]CUI P, XUE Y A, LIU Y X, et al. Intelligent manu-facturing of color blended yarn: Color matching algorithm and manufacturing process through computer numerically controlled ring spinning system[J]. Journal of Engineered Fibers and Fabrics, 2021,16 :155892502110065.

[10]王建坤,蒋晓东,郭晶.色纺纱工艺与性能研究[J].纺织科学与工程学报,2018,35(4):10-14,85.

WANG Jiankun, JIANG Xiaodong, GUO Jing. Process and properties of colored spinning[J].Journal of Textile Science and Engineering, 2018, 35(4):10-14, 85.

[11]XUE Y, GAO W D, GUO M R, et al. Method and device for dynamically configuring linear density and blending ratio of yarn through three-ingredient synchronous/synchronous drafting:US15308365[P].2015-07-28.

[12]LI Q Z, ZHANG F Y, JIN X K, et al. Optimal yarn colour combination for full-colour fabric design and mixed-colour chromaticity coordinates based on CIE chromaticity diagram analysis[J]. Coloration Technology, 2014, 130(6): 437-444.

[13]XIA Z G, WANG H S, WANG X, et al. A study on the relationship between irregularity and hairiness of spun yarns[J]. Textile Research Journal, 2011,81(3):273-279.

[14]桂亞夫.色纺纱的质量评价[J].棉纺织技术,2019,47(6):43-47.

GUI Yafu. Quality evaluation of color spun yarn[J]. Cotton Textile Technology, 2019, 47(6): 43-47.

[15]SUN X Q, XUE Y A, LIU Y X, et al. Construction of circular-shaped chromatic model and spinning of full color gamut colored yarn by digital blending of three primary colored fibers[J]. Textile Research Journal,2023,93(1/2):140-160.

Construction of a full colorgamut mixing model based on four primary colors and color yarn spinning

LI Juanjuan1, XUE Yuan1, XU Zhiwu2, YU Jian2, ZENG Dejun2

Abstract: Color spinning yarn, as a kind of yarn formed by opening, carding, drawing, roving and spinning process of various colored fibers, has a production history of over 30 years in China. At present, the domestic color spinning yarn has more than 10 million spindles. With the progress of new spinning technologies and the gradual accumulation of production experience, the quality level and technological content of color spinning yarn are also gradually improved. Color spinning technology is a technique of spinning two or more colored fibers into a certain hue, lightness, and saturation according to a certain mixing ratio. The color spinning technology using fiber dyeing before spinning process not only greatly reduces pollution in the production process, which is in line with the green and environmental protection production concept, but also each fiber is dyed separately, reducing problems such as staining that may occur in the subsequent process. Nevertheless, as the yarn color cannot be intelligently controlled at the spinning stage, and its actual product application has great limitations, how to achieve innovation in color spinning technology and products has become a challenge for the color spinning industry.

To achieve key technologies such as precise control of yarn color during the development and production of color spinning yarn products, we, based on the double coupling color mixing model, constructed a full color gamut color mixing model by using a 12.5% discrete gradient grid based on four primary colors, constructed the three-element regulation mechanism of “three-channel draft ratio, color fiber mixing ratio, and yarn color value” based on three-channel digital spinning combined with the full color gamut color mixing model and digital three-channel spinning technology, proposed the process method for regulating the hue, lightness, and saturation of formed yarns, selected a number of grid points in the full color gamut blending chromatography and designed the spinning process for full color gamut blended yarns. To achieve online regulation of the blending ratio of colored fibers in the blended yarn by using a multi-channel digital ring spinning machine for three different color roving asynchronous drafting, gradient color matching, and convergence twisting, we spun three series of colored yarns with different hues of equal lightness, different lightnesses of equal hue, and different saturations of equal hue, and tested the evenness, hairiness, and strength of the colored yarn. The test data were compared and analyzed with the performance indicators of the natural color yarn. The results show that the combination of the full color gamut blending model and digital three-channel spinning technology can spin three series of color yarns of equal saturation and different hues, equal hue and different lightnesses, equal hue and different saturations. Under the same color fiber mixing ratio, the actual spun color yarn is basically consistent with the color comparison in the full color gamut model. The various performance indicators of the actual spun color yarn can meet the first-class requirements of ordinary natural color yarn, proving the feasibility of spinning colored yarn based on the full color gamut mixing model and three-channel digital spinning technology further.

Nowadays, people's requirements for textiles are no longer limited to comfort and durability. Textile products with unique styles and appearance effects are increasingly favored by consumers. As a diverse form of fancy yarn, blended yarn has been a hot spot of many scholars. On the one hand, color is an important appearance indicator, and the construction of full color gamut chromatography further expands the production range of blended yarn. On the other hand, different styles of fancy yarns can also be developed by integrating other spinning technologies, combining different raw materials and optimizing the process, and promoting the development of textiles in the direction of diversification of raw materials, color enrichment and more optimal production.

Keywords: blended yarn; four primary colors; gridded blending; full gamut color mixing model; performance indicators

收稿日期:20230418 網络出版日期:20230607

基金项目:浙江省“尖兵”“领雁”研发攻关计划项目(2022C01188);江苏高校优势学科建设工程资助项目(苏政办发、〔2014〕37号)

作者简介:李娟娟(1999-),女,安徽阜阳人,硕士研究生,主要从事数字化纺纱方面的研究。

通信作者:薛元,E-mail:fzxueyuan@qq.com