Key issues in water sealing performance of underground oil storage caverns: Advances and perspectives

Yuto Li, Bin Zhng,*, Lei Wng, Yiguo Xue, Hnxun Wng, Lei Shi, Zhenhu Peng,Junyn Li

a School of Engineering and Technology, China University of Geosciences (Beijing), Beijing,100083, China

b Department of Civil and Architectural Engineering and Construction Management, University of Cincinnati, Cincinnati, OH, 45221, USA

c CNOOC Petrochemical Engineering Co., Ltd., Qingdao, 266061, China

Keywords:

ABSTRACT Water sealing performance is important for underground water-sealed oil storage (UWSOS).The key issues concerning water sealing performance mainly include the permeability of fractured rock mass(FRM),water-sealed safety(WSS),water curtain performance,and prediction and control of water inflow.This paper reviews the progress of above four key issues on water sealing performances.First, the permeability of an FRM is the basis of water sealing performance, and several commonly used permeability test methods and spatial variation characteristics of permeability are outlined.Second,the current water sealing criteria are compared, and the evaluation methods of WSS are summarized.Third, the design parameters and efficiency evaluation of water curtain systems (WCSs) are introduced.The water inflow of oil storage caverns (OSCs) can reflect the water sealing effect, and the prediction methods and control measures of water inflow are also summarized.Finally, the advantages and disadvantages of the current research are discussed, and the potential research directions are pointed out, such as optimization of water sealing criteria and FRM model, quantitative evaluation of WCS efficiency, accurate prediction of water inflow, and improvement of grouting technology.

1.Introduction

Oil has been recognized as the basis for economic development.Therefore,oil reserves are of vital importance worldwide.Among the various oil storage methods, underground water-sealed oil storage(UWSOS) has been proven to be a safe, economical, and concealed method of oil storage (Makita et al., 1993; Sturk and Stille, 1995;Hepbasli, 2003; Kurose et al., 2014; Nilsen, 2021), and has become the major method of oil storage.UWSOS caverns are unlined rock caverns built below the stable groundwater level to store oil and gas energy.The operating principle of UWSOS can be summarized as“filling joints with water” and water-oil dynamic pressure balance,that is,the hydraulic pressure in a fractured rock mass(FRM)should be greater than the oil and gas pressure in the oil storage caverns(OSCs)(Lindblom,1997).The stability of the surrounding rocks and water sealing of OSCs are the focus of research on UWSOS (Zhang et al., 2013; Ma et al., 2016; Zhuang et al., 2017; Hassanpour et al.,2019; Zhao et al., 2020).The key issues in the research of water sealing performance of UWSOS are the permeability of FRM watersealed safety (WSS), the performance of water curtain systems(WCSs),and the prediction and control of water inflow.

The surrounding rocks of the OSCs are mainly of crystalline or metamorphic rocks,and the fractures are infilled with groundwater(Liu et al., 2018).The field testing methods for the permeability of the surrounding rocks include pumping/injecting water tests, slug tests,Lugeon tests,and pulse tests(Svenson et al.,2007;Selvadurai and Ichikawa,2013).Among them,the Lugeon test has been widely used.The seepage mechanism of FRM is studied by a single fracture model,and the cubic law is used to describe the seepage in ideally parallel plate fractures(Romm,1966).Considering the roughness of the rock fracture surface, many researchers have proposed the cubic law correction method based on roughness (e.g.Louis,1974;Olsson and Barton,2001; Li et al.,2008; Cui et al.,2021).With the deepening of understanding of seepage in FRM, the spatial anisotropy of seepage in FRM has gradually gained more attention.

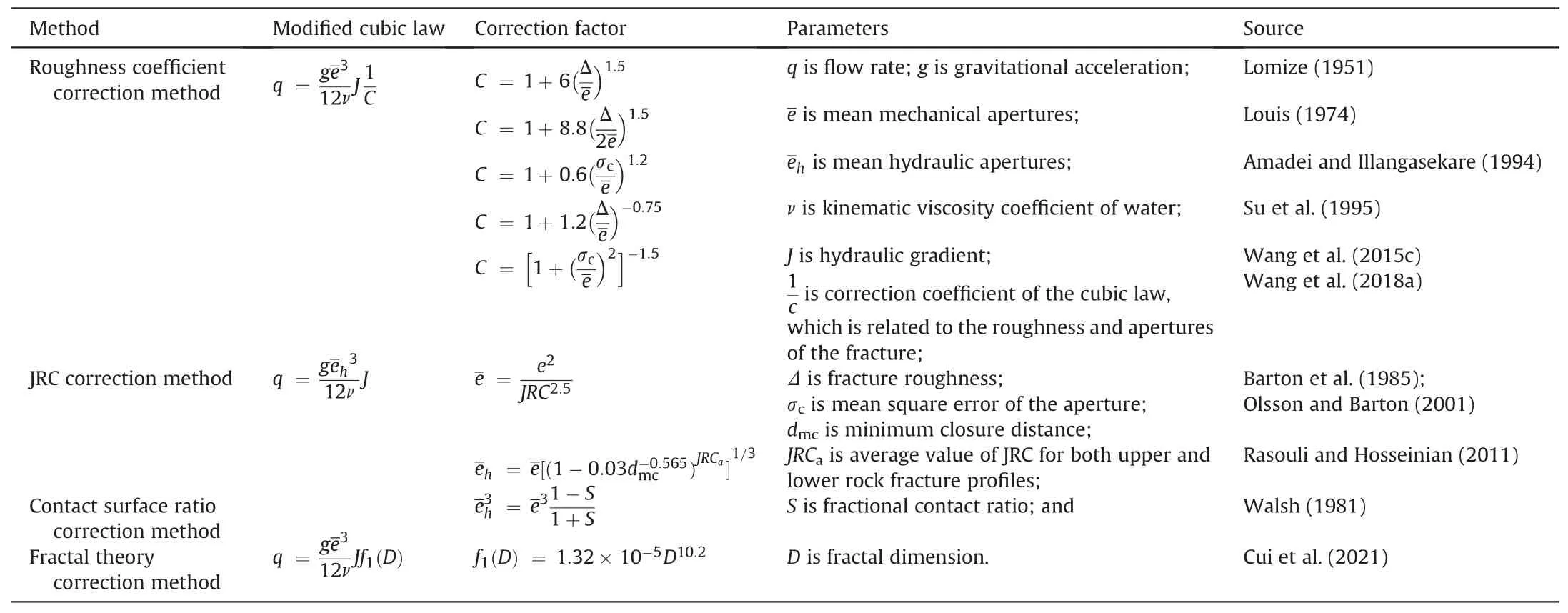

Table 1 Modified equation of cubic law.

WSS is the focus of UWSOS.The water sealing criterion is the basis to judge the WSS of UWSOS.Åberg(1977)first proposed the water sealing criterion with a vertical hydraulic gradient greater than 1.Later, the criterion was revised (e.g.Goodall et al., 1988;Zhang et al.,2020a).In engineering projects,empirical formulas are often used to judge the WSS, and groundwater level is used as a judgment index(Chung et al.,2009;Li et al.,2021).Field testing is a direct method to study the WSS of UWSOS.The current conventional field testing methods include hydrologic monitoring,airtightness tests of OSCs,and water curtain tests(Kim et al.,2000;Wang et al.,2015a;Shi et al.,2018).The numerical method is one of the common methods used to analyze WSS in the design and construction stage of UWSOS(Ji et al.,2017;Zhang et al.,2020a;Liu et al., 2021).For engineering scale models, the equivalent porous medium(EPM)is widely used.The discrete fracture network(DFN)model is limited by the difficulty in detecting and modeling of DFN which can represent a naturally FRM.The proposed DFN model cannot match the natural FRM, due to the difficulty in estimating fracture permeability parameters and the low computational efficiency.Therefore, it is difficult to carry out the DFN model simulations of the seepage field on an engineering scale.

WCSs are an important part of UWSOS.Research on the WCS mainly focuses on the optimization of the layout parameters and efficiency evaluation (Ebrahim et al., 2016; Li et al., 2020a).The layout of the WCS is mainly horizontal,vertical,or inclined(Wang et al., 2015a; Winn et al., 2019).The optimization objects of the WCS parameters include the water injection pressure, the horizontal distance between the water curtain boreholes (WCBs), and the vertical distance from the OSCs, which are mostly evaluated numerically.In situ water curtain tests are used to verify the effectiveness of the WCS, including water injection tests, water curtain connectivity tests (Wang et al., 2015a).The efficiency evaluation of WCSs is one of the hot topics (Shi et al., 2018; Wang et al., 2020a; Liu et al., 2021; Xue et al., 2022).At present, there is no universal quantitative characterization method for the efficiency evaluation of WCSs.

A reasonable water inflow is of great significance to the design and operation of OSCs, and analysis of the water inflow plays an important role in evaluation of the WSS (Xu et al., 2021).Water inflow is mainly controlled by the permeability of surrounding rocks and groundwater level.On one hand,excessive water inflow will endanger the long-term stability of OSCs;on the other hand,it will increase the cost of oily sewage treatment.In addition, it will increase the workload of grouting and plugging(Pal et al.,2015;Shi et al.,2019).The treatment measures for the excessive water inflow of OSCs are mainly grouting, and the water inflow must be controlled within a certain range (Liu et al., 2018).However, in engineering projects,due to the inability to ascertain the location of the advantageous seepage channels, the grouting efficiency is low,and there is a large room for optimization.

This paper reviews the state-of-the-art progress of water sealing performances of UWSOS and points out the knowledge gap for future research.Research on water sealing performance mainly focuses on the permeability of FRM, WSS, water curtain performance, and water inflow prediction and control.This paper analyzes these four aspects of water sealing performance,summarizes the advantages and disadvantages of existing research methods,and points out potential research directions in the future.

2.Hydraulic permeability of surrounding rocks

2.1.Basic: fracture seepage mechanism

UWSOS caverns are built in crystalline rocks,such as granite(SY/T 0610-2008, 2008).The crystalline rock is characterized by good integrity and stability,with high strength.There could be fractures in the FRM, which is a concern for permeability.To achieve the purpose of “water sealing”, OSCs are built below a stable water level.The surrounding rocks of OSCs is in a water-saturated state and has a certain hydraulic pressure.The hydraulic conductivity of the fractures is several orders of magnitude greater than that of the rock matrix (Xu et al., 2015; Ren et al., 2016), leading to groundwater in the FRM flowing along the connected fractures.The permeability of the FRM is mainly determined by the density,connectivity, and hydraulic aperture of the fractures (Cao et al.,2015; Chen et al., 2018).

The connected fracture network is the main seepage channel in an FRM (Alghalandis et al., 2014; Wang et al., 2015b; Li et al.,2020b).Numerical simulation is widely used in the research of fracture connectivity.The DFN is generated by simulation software,and the interconnected fractures are of research significance(Wang et al., 2013; Li et al., 2018; Huang et al., 2020).The fracture connectivity is sensitive to the fractal dimension, the number of fracture groups,and the angle of the fracture group.With increase of the fractal dimension, the fracture connectivity becomes worse.With increase of the fracture groups and the angle between fracture groups, the fracture connectivity becomes better (Li et al., 2020b;Zhu et al., 2021).Based on accumulated experiences, hydraulic connectivity fractures are relatively few among the fractures exposed on the inner surface of OSCs.Studies on fracture networks show that only approximately 10-20% of the total fractures are connected and form potential flow paths (Zhao,1998).

Based on the seepage experiments on parallel plates, the cubic law was proposed,that is,the flow rate is proportional to the cube of the fracture aperture(Lomize,1951;Romm,1966).The cubic law is applicable to the steady laminar flow of smooth parallel plates.Romm(1966)proposed that the cubic law is applicable to fractures with apertures greater than 0.2 μm.However, the natural fracture surfaces are rough.Many scholars have considered the effect of fracture roughness, tortuosity, and contact surface ratio on the equivalent hydraulic aperture and modified the cubic law(Table 1).The joint roughness coefficient(JRC)is an indicator commonly used in rock engineering to describe the roughness of the fracture surface.Barton and Choubey (1977) proposed 10 typical roughness profiles for the JRC range, which are recommended by the International Society of Rock Mechanics and Rock Engineering(Tse and Cruden,1979).To quantitatively characterize the roughness of the fracture surface more accurately, the fractal method is introduced(Lee et al.,1990; Zhang and Chai, 2020b).

2.2.Permeability test method of FRM

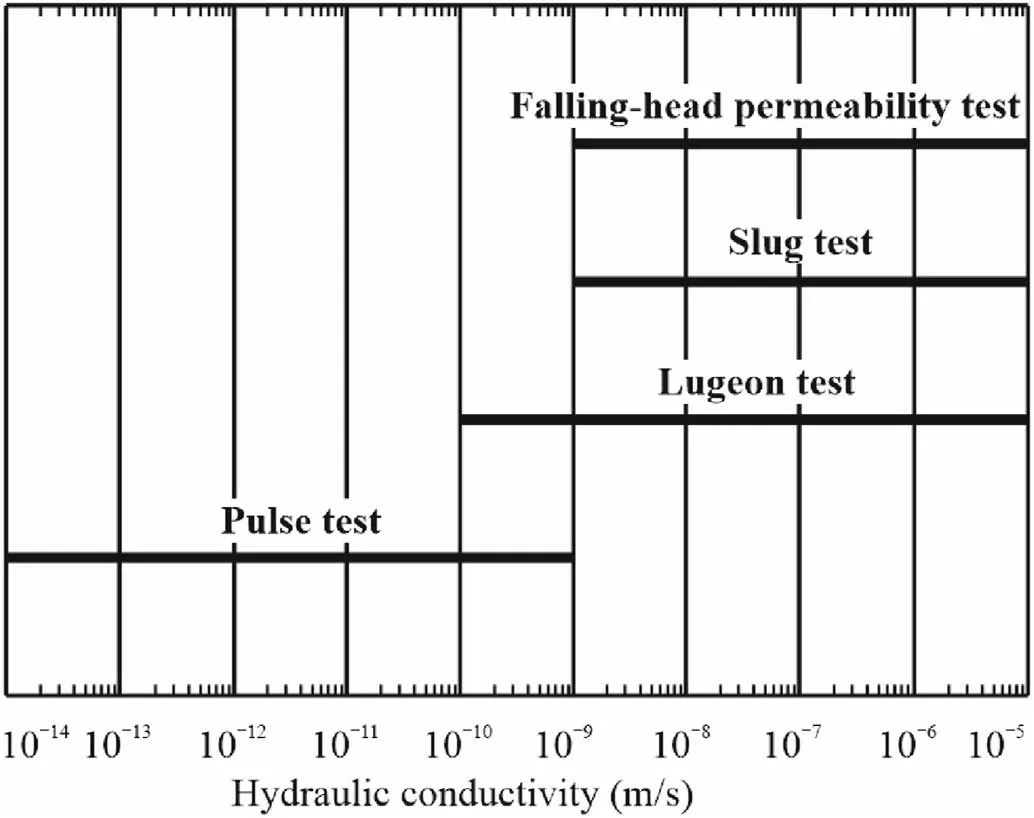

Fig.1.Application range of different permeability test methods(based on Mejías et al.,2009).

The permeability test is an effective method to measure the hydraulic conductivity of surrounding rocks of OSCs.According to the types of rock and soil, in situ test methods mainly include pumping (injecting) test, slug test, Lugeon test, and pulse test(Fig.1).The pumping (injecting) test is a common method to measure the hydraulic conductivity of rock and soil.Generally,the pumping test is suitable for strong permeable rocks.The slug test is widely used to measure the permeability of rocks.The slug test has the advantages of high efficiency, economy, simplicity, and less impact on the normal observation of groundwater.The disadvantage of the slug test is that this method can only be performed in saturated aquifers,and the test results only reflect the permeability of the FRM in the vicinity of the borehole.The test result is greatly affected by the conditions of the borehole wall, which is the socalled “well skin effect” (Svenson et al., 2007; Slack et al., 2013).The Lugeon test is the most common method for determining the permeability of rocks in UWSOS projects.It is suitable for weakly permeable rocks with good integrity and few fractures (Houlsby,1976).The Lugeon test can adjust the position of the test section flexibly, and the test results can be easily obtained.However,limited by the test pressure and the accuracy of the flowmeter,when the hydraulic conductivity of the surrounding rocks is too low(less than 10-10m/s),the Lugeon test is no longer applicable.In this case, the pulse test can be then used.The pulse test has high accuracy and is more suitable for measuring the permeability of a complete FRM with undeveloped fractures (Bredehoeft and Papadopulos, 1980; Chen et al., 2005; Selvadurai and Ichikawa,2013; Li et al., 2021).

2.3.Anisotropic permeability

The anisotropy of hydraulic conductivity has an important effect on the WSS (Chung et al., 2003; Kim et al.2007).The influence of the anisotropic permeability of an FRM on the water sealing performance of an UWSOS project is the main research direction.The theory of FRM permeability tensor was created by Romm (1966)and Snow (1969).A mathematical model describing the permeability of anisotropic FRM is proposed based on the tensor method(Louis,1974; Oda,1985; Tian and Wan,1989).

In the early years, studies on UWSOS mainly were focused on the difference in permeabilities between horizontal and vertical directions.It shows that with increase of the horizontal to vertical permeability ratio, the water inflow gradually decreases, the “critical gas pressure” gradually increases, and the overall WSS will decrease(Sun and Zhao,2010; Gao et al.,2018).Taking an UWSOS project as the research object,the concept of a conditional random field is introduced to analyze the WSS.The main focus of our study is the influence of the spatial variability of the hydraulic conductivity of the surrounding rocks on the WSS.The results show that the difference between the horizontal and vertical spatial correlation of the surrounding rocks has a significant influence on the water sealing effect of the WCS,and the optimal distance between the WCBs and OSCs can be determined according to the spatial correlation of hydraulic conductivity (Zhang et al., 2022).

3.Water-sealed safety (WSS)

3.1.Water-sealed mechanism

3.1.1.The principles of water sealing

The water sealing principle of UWSOS can be summarized as“filling joints with water” and water-oil dynamic pressure balance(Li et al., 2016).Fractures are the main seepage channels for groundwater.After oil storage in underground caverns, a sealing protective gas with a certain pressure is designed at the cavern roof.To ensure the WSS of the OSCs,it is necessary to fill the fractures in the surrounding rocks with water that flows in the downward direction with such a velocity that there is a hydraulic gradient in the rock (Åberg,1977;Li et al., 2019a).

According to the water sealing principle of UWSOS,the fracture water in the surrounding rocks will continuously seep toward the OSCs.When the groundwater supply in the surrounding rocks is insufficient,the groundwater level drops,and a cone of depression forms above the OSCs, reducing the WSS.Therefore, the construction of UWSOS usually requires setting up a WCS.The WCS adopts the form of horizontal WCBs,which are set at a certain height above the OSCs and play a role in replenishing the surrounding rocks seepage field through a certain water curtain pressure(Kjorholt and Broch,1992; Gao and Gu,1997; Wang et al., 2015a).

3.1.2.Empirical criterion of water sealing

The vertical hydraulic gradient criterion is the basis for judging the WSS of UWSOS.The water sealing criterion for UWSOS was first proposed by Åberg (1977), which was reflected by the water pressure of the surrounding rocks of liquefied petroleum gas(LPG)caverns and the oil pressure in the cavern.If the vertical hydraulic gradient is greater than 1, WSS can be guaranteed.However,Åberg’s criterion ignores the influence of capillary force.Furthermore, it is difficult to apply in practical projects because it has to identify the hydraulic gradient of all fractures on the surface of the OSCs.Later,an alternative criterion was proposed by Goodall et al.(1988),which is a generalization of Åberg(1977)proposal that the vertical hydraulic gradient should exceed 1.Goodall’s criterion insists that gas escape will not occur as long as the water pressure along all possible escape paths increases for some small distance in direction of the potential gas escape.Later, Zhang et al.(2020a)concluded that the exact criterion to evaluate if a steady flow field can be formed around the cavern is that the hydraulic head gradient is greater than 0, rather than 1.In terms of hydraulic pressure gradient,the criterion is that is greater than-1 above the cavern and greater than 1 under the cavern.The criterion proposed by Zhang et al.(2020a) is not consistent with the proposals by Åberg(1977)and Goodall et al.(1988).By contrast,Åberg’s criterion is more conservative than Zhang’s criterion, which is conducive to engineering safety.

Although the form of the vertical hydraulic gradient criterion is relatively simple,it is difficult to apply in engineering projects due to the complex spatial structure of natural fractures.Therefore, an empirical criterion for judging WSS based on the critical groundwater level is proposed.The Norwegian Tunnelling Society (2007)proposed an empirical formula for judging the WSS in UWSOS(Eq.(1)).The GB/T 50,455-2020 (2020) draws on engineering practice experience from an international perspective (Kiyoyama,1990; Norwegian Tunnelling Society, 2007) and puts forward an empirical criterion for evaluation of the WSS of UWSOS (Eq.(2)).Feng et al.(2014) established a gas escaping model for describing the migration of fracture water.According to the critical conditions of fracture water movement, a formula for calculating the critical groundwater level satisfying the WSS is deduced (Eq.(3)).Li et al.(2021) considered the effect of capillarity in fracture seepage on WSS and optimized the empirical formula for evaluating WSS (Eq.(4)),concluding that the empirical formula given in China’s current standard is reasonable but conservative:

where Prois the groundwater pressure at the top of the cavern(Pa),Pvais the vapor pressure of the liquid (Pa), ρwis density of water(m3/kg), g is gravity acceleration (m/s2), H is the vertical distance from the designed stable water height to the roof of the cavern(m),pgis the designed gaseous phase(nitrogen)pressure in the cavern(MPa),Pais the atmospheric pressure(Pa),γwis the unit gravity(N/m3),PcAis the capillary force at the bottom of the fracture(Pa),and PcBis the capillary force at the top of the fracture (Pa).

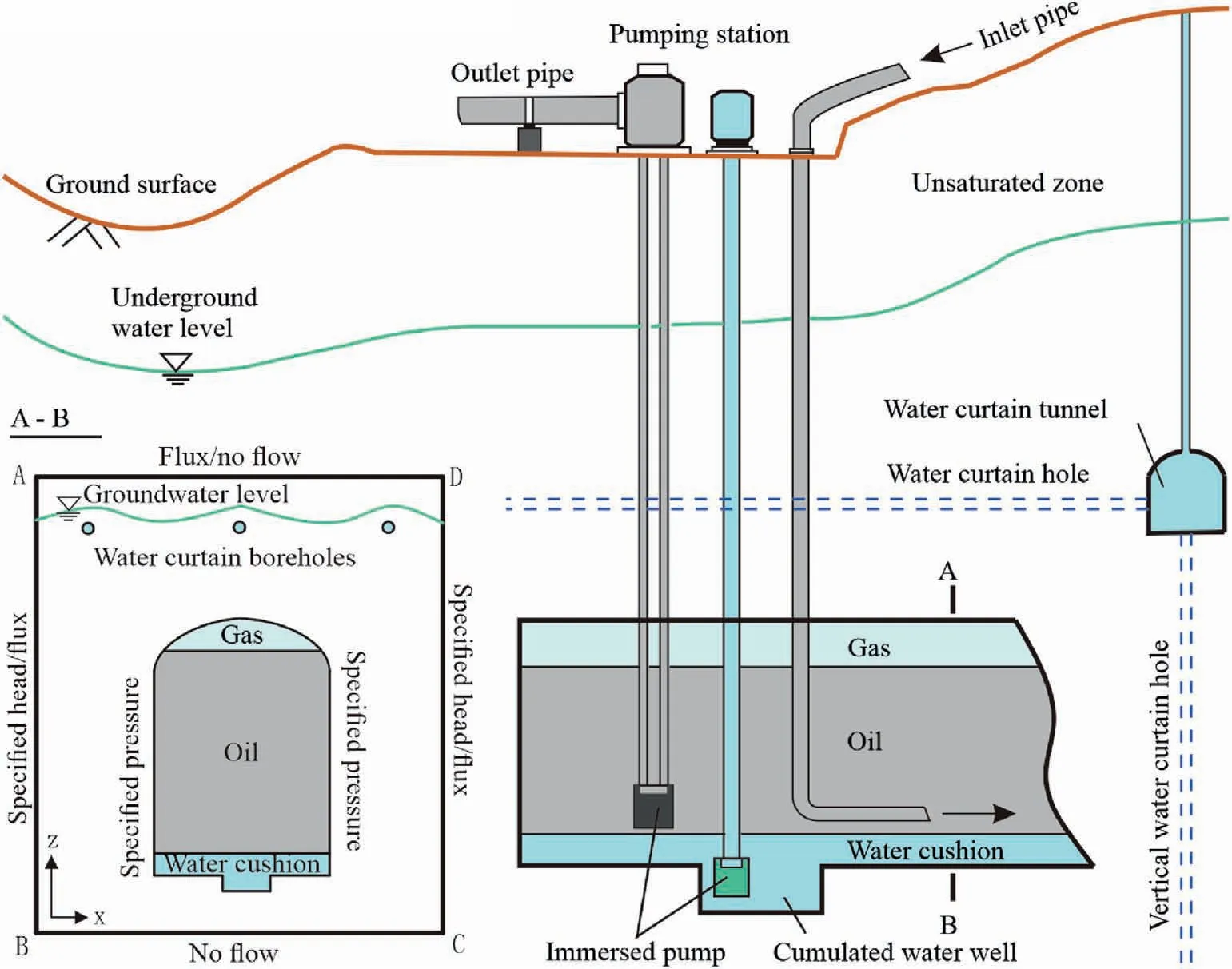

3.2.Hydrogeological models

Research on the WSS of UWSOS mainly focuses on the seepage field of surrounding rocks, permeability of FRM, natural groundwater recharge, and WCS (Lee et al.,1996; Dai and Zhou, 2014; Li et al., 2017a; Qiao et al., 2017).A proper and representative hydrogeological model is crucially important to the study of WSS.In the conceptualization of the hydrogeological model of UWSOS(Fig.2), an independent hydrogeological unit should be delimited according to the geological conditions of the study area(Xue et al.,2015;Li et al.,2016,2017b,2019b).Specific locations such as rivers and mountain ridges can be selected as the boundary of the hydrogeological units.Then, the boundary conditions of the conceptual model should be determined.Usually,a non-flow boundary is assumed at the bottom of the model.On the sides of the model,a specified head boundary is defined at the rivers, a non-flow boundary is assumed at the mountain ridges, and a specified flux boundary is applied at the borders without rivers and mountain ridges according to the measured groundwater velocity.A rainfall infiltration boundary or free boundary is assigned at the top of the model.For UWSOS, a specified head boundary with fixed atmospheric pressure is assigned at the caverns during the construction period because they were open to the surface air.After storing oil in the caverns, a time-dependent head boundary (the measured gas pressure inside the cavern was converted to a hydraulic head unit)is assigned at the caverns.A specified head boundary is defined at the WCSs (Lee et al., 2015).

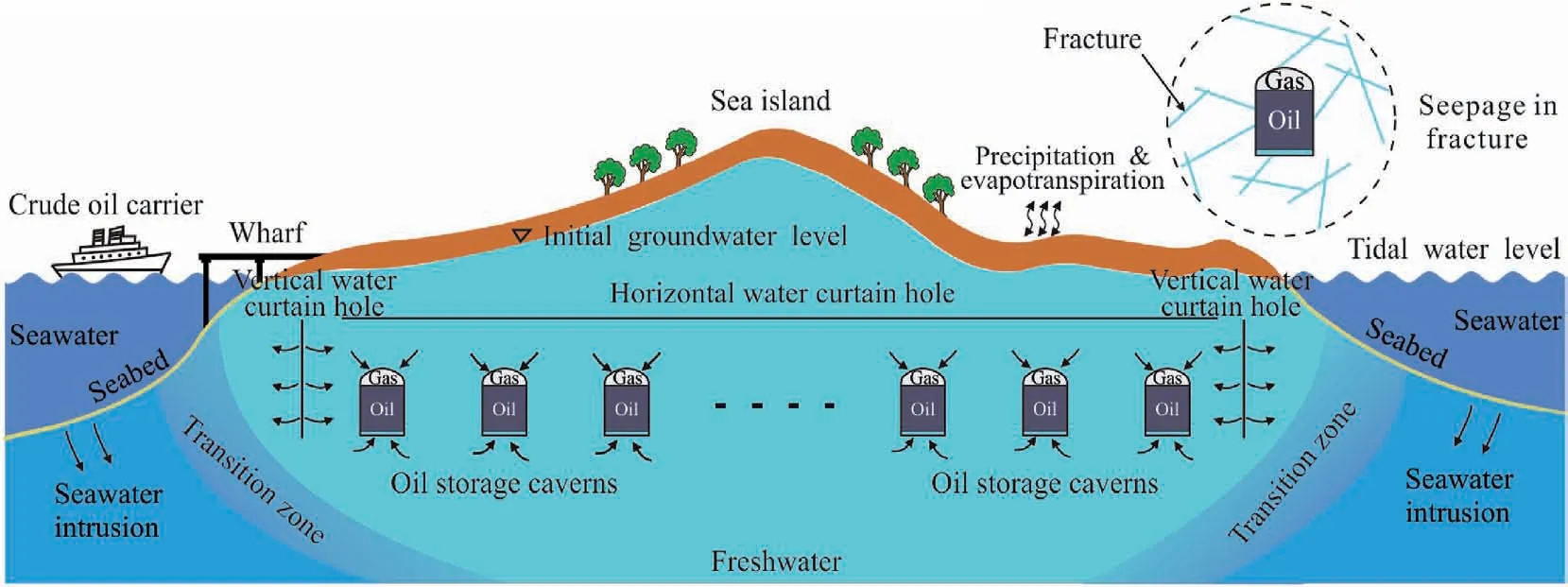

In particular,this study introduces the hydrogeological model of UWSOS in an island environment.The island environment has convenient shipping conditions, but the seawater intrusion and tidal dynamic boundaries make the groundwater seepage field in the study area be particularly complicated(Winn et al.,2019;Qiao et al., 2022) (Fig.3).The excavation of OSCs on islands will significantly affect the natural seepage field, leading to the risk of seawater intruding into the OSCs along dominant seepage channels(Lee et al., 2015).Seawater intrusion will not only corrode underground structural facilities (steel, concrete, oil pipelines, etc.) but also affect the quality of stored crude oil and groundwater in the study area.More seriously, it can destroy the original ecological balance inside the island, causing secondary environmental damage (Lee et al., 2007; Ueda et al., 2021).In addition, oil leaks will pollute the sea and damage marine environments.Therefore, the construction of UWSOS projects on islands also puts forward greater requirements for the WCS.In the project of excavating OSCs on islands, vertical WCBs were proven to be more advantageous,which can provide a water sealing effect and play a role in inhibiting seawater intrusion(Lim et al., 2013; Li et al., 2019a).

3.3.Evaluation of WSS

3.3.1.Field monitoring and testing methods

Field monitoring and in situ testing are the direct methods for the WSS evaluation of UWSOS.Conventional methods include groundwater level monitoring, groundwater osmotic pressure monitoring,and airtightness testing(Kim et al.,2000;Wang et al.,2020a; Qiu et al., 2021).

Fig.2.Conceptual model of UWSOS in rock caverns (modified by Li et al., 2016; 2017a).

Fig.3.Conceptual model of UWSOS in marine islands.

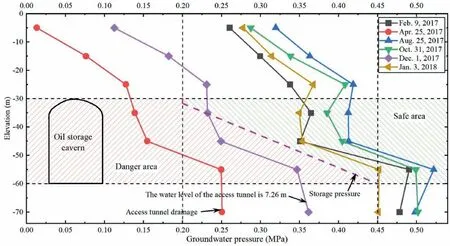

Based on the groundwater level monitoring data, it can be concluded that during excavation of the access tunnel, the groundwater level is significantly reduced.After the WCBs are injected with water, the groundwater level rises, and the groundwater level changes slightly during the subsequent excavation of the OSCs.This means that the WCS is important to WSS(Shi et al., 2018; Zhang et al., 2019).Osmometers are mostly installed between the water curtain tunnels and the OSCs to automatically monitor the water pressure in the surrounding rocks at different elevations.Taking the monitoring data of an UWSOS project in China as a study case, it can be seen that the water pressure in surrounding rocks increases approximately linearly with depth (Fig.4).By comparing the water pressure in the FRM and the oil storage pressure inside the cavern at the same elevation,it can be determined whether the UWSOS meets the requirements of water sealing or not.The airtightness test is used to test WSS under the operating conditions of OSCs and is carried out after cavern excavation is completed and before oil storage(Zhang et al.,2020c).

3.3.2.Numerical methods for WSS evaluation

Numerical method is the main method used to evaluate the WSS of UWSOS during design and construction stages.Based on seepage simulation results, the groundwater level, water pressure, vertical hydraulic gradient, and other indicators of surrounding rocks can be analyzed, and WSS is evaluated.

Fig.4.The monitoring curve of groundwater pressure.

Fig.5.WSS simulation of UWSOS (from Zhang et al., 2019): (a) Homogeneous medium model; (b) Groundwater pressure head of surrounding rocks; and (c) Vertical hydraulic gradient at different elevations.

In the current research, the surrounding rock mass is usually regarded as the EPM, that is, the FRM is equivalent to the porous medium according to the permeability (Lee and Chang, 1995;Ebrahim et al.,2016;Zhang et al.,2020a).In general,according to the hydraulic conductivity of the FRM obtained from the field permeability test, the average value of the hydraulic conductivity is calculated and assigned to the homogeneous medium model for numerical simulation (Fig.5).On this basis, the FRM in the study area can be partitioned horizontally and vertically according to the hydraulic conductivity.In addition, considering the spatial variability in hydraulic conductivity, the mean and variance in the hydraulic conductivity of the surrounding rocks are calculated(Zhang et al.,2022).The FRM is equivalent to an anisotropic continuum with a random hydraulic conductivity tensor based on the Monte Carlo random method(Gao et al.,2018).The EPM model is widely used in the WSS evaluation of UWSOS on an engineering scale (Li et al.,2017a; Zhang et al., 2019; Xue et al., 2022).Although fault structures are later introduced into the model,the evaluation results are only regarded as a reference for macroscale WSS evaluation because the complexity of FRM seepage has not been considered.

The seepage simulation of UWSOS based on the DFN model is a research focus currently(Rong et al.,2013;Yu et al.,2013;Li et al.,2020a).The generation of the DFN model is based on in situ fracture parameter measurements and statistics (including fracture aperture, occurrence, spacing, trace length, and structural surface roughness).Contrary to the EPM model,the DFN model ignores the permeability of the porous matrix, and groundwater only moves along the fractured network(Bogdanov et al.,2003;Li et al.,2014;Javadi and Sayadi, 2018).Therefore, the accuracy of the fracture parameters is a prerequisite for fracture network simulation(Rong et al.,2013;Liu et al.,2015;Javadi et al.,2016).For UWSOS projects,the spatial distribution and seepage characteristics of fractures from the WCS to OSCs are the focus of research.

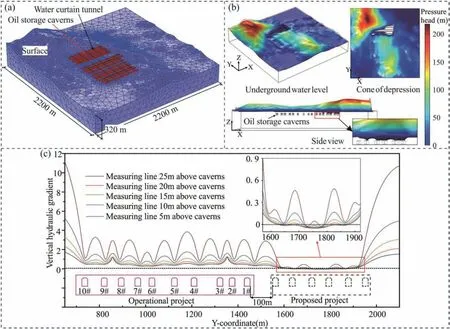

Model size has been regarded as a critical issue for the efficiency of DFN simulation (Wang et al., 2020b).Limited by computing power and efficiency, most of the current DFN simulations for UWSOS are two-dimensional (2D) models or simplified threedimensional (3D) models that only contain one or several OSCs.The effective connectivity of fractures is found to be a dominant factor in determining water-sealing effects.In addition,the fracture network is highly irregular in the flow domain, and the failure of WSS can occur locally (Lin et al., 2016a).The effect of the WCS on WSS is also affected by both fracture parameters and seepage characteristics (Fig.6).The DFN model can effectively identify the low-efficiency zones of the WCS and optimize the layout parameters of the WCS more accurately (Hu et al., 2019a; Li et al., 2020a;Liu et al., 2021; Tang et al., 2021).

The concept of a dual porosity model was first proposed by Barenblatt et al.(1960).This model assumes that both fractures and the porous matrix are permeable, and they are regarded as two media with different permeabilities but can exchange fluid.Compared with the EPM model and the DFN model, the dual porosity model has more advantages in the analysis of unsaturated seepage in rocks with well-developed fractures (small size, large number,and dense distribution)and large porous matrix pores.The dual porosity model could be further divided into dual-porosity single-permeability (DPSP) model and dual-porosity dual-permeability (DPDP) model.The DPSP model, ignoring fluid flow in the porous matrix and considering the exchange between the porous matrix and fractures, is applicable to the condition that the permeability of fracture is much larger than that of the porous matrix.The DPDP model is developed when the permeability difference between matrix and fracture is small.The dualpermeability model has been widely used in the fields of fractured reservoirs and shale gas multiphase seepage (Warren and Root, 1963; Gerke and Genuchten, 1993; Wei and Zhang, 2010;Zambrano et al., 2021).At present, research on dual-permeability models in the field of UWSOS is relatively scarce.

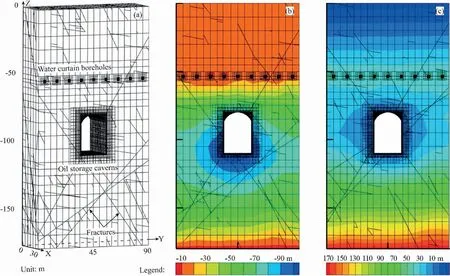

The fractured porous medium(FPM)model can benefit from the advantages of both the EPM models and the DFN models.In short,the FPM models have a broader perspective in modeling groundwater flow in strongly heterogeneous media.The FPM model is used for UWSOS, and it shows that such a model can correctly analyze the groundwater flow of surrounding rocks with complex fracture distributions(Lin et al.,2016a;Zhang et al.,2016,2021).In addition, Zhang et al.(2020a) used the EPM flow model to investigate the influences of borehole spacing on the seepage field.The results show that regardless of the EPM model employed in numerical analysis,a stable water covering layer of a certain thickness can be generated above the OSCs and that the generated seepage field can satisfy the water sealing criterion (Fig.7).

4.Performance of water curtain system (WCS)

4.1.Overview of WCS

UWSOS achieves water sealing through the synergy of natural and artificial WCSs(Wang et al.,2015a).The traditional WCS refers to water curtain tunnels and WCBs.The generalized WCS should also include access tunnels that are filled with water outside the sealing plug.

During excavation of the OSCs, due to the drainage effect of the OSCs, the groundwater level above the OSCs declines, forming a groundwater depression cone.According to the water sealing criterion of UWSOS,when the groundwater level drops to a certain height,water sealing failure will occur.To avoid the occurrence of water sealing failure,a WCS is adopted above the OSC(Kjorholt and Broch,1992; Lin et al., 2016b).However, the hydrogeological conditions,such as rainfall, groundwater level, and surrounding rocks permeability of OSCs, are critical to the development of depression cones above OSCs (Liang and Lindblom,1994; Wang et al., 2018b, 2020a).Therefore, the layout and parameters of the WCS should also vary according to different hydrogeological conditions(Kurose et al.,2016;Ebrahim et al.,2016;Zhang et al.,2020a).At present,research on the WCS mainly focuses on the optimization of layout parameters,working pressure design, water curtain connectivity testing, and water curtain efficiency evaluation(Lindblom,1989;Li et al.,2020a;Wang et al.,2020a).

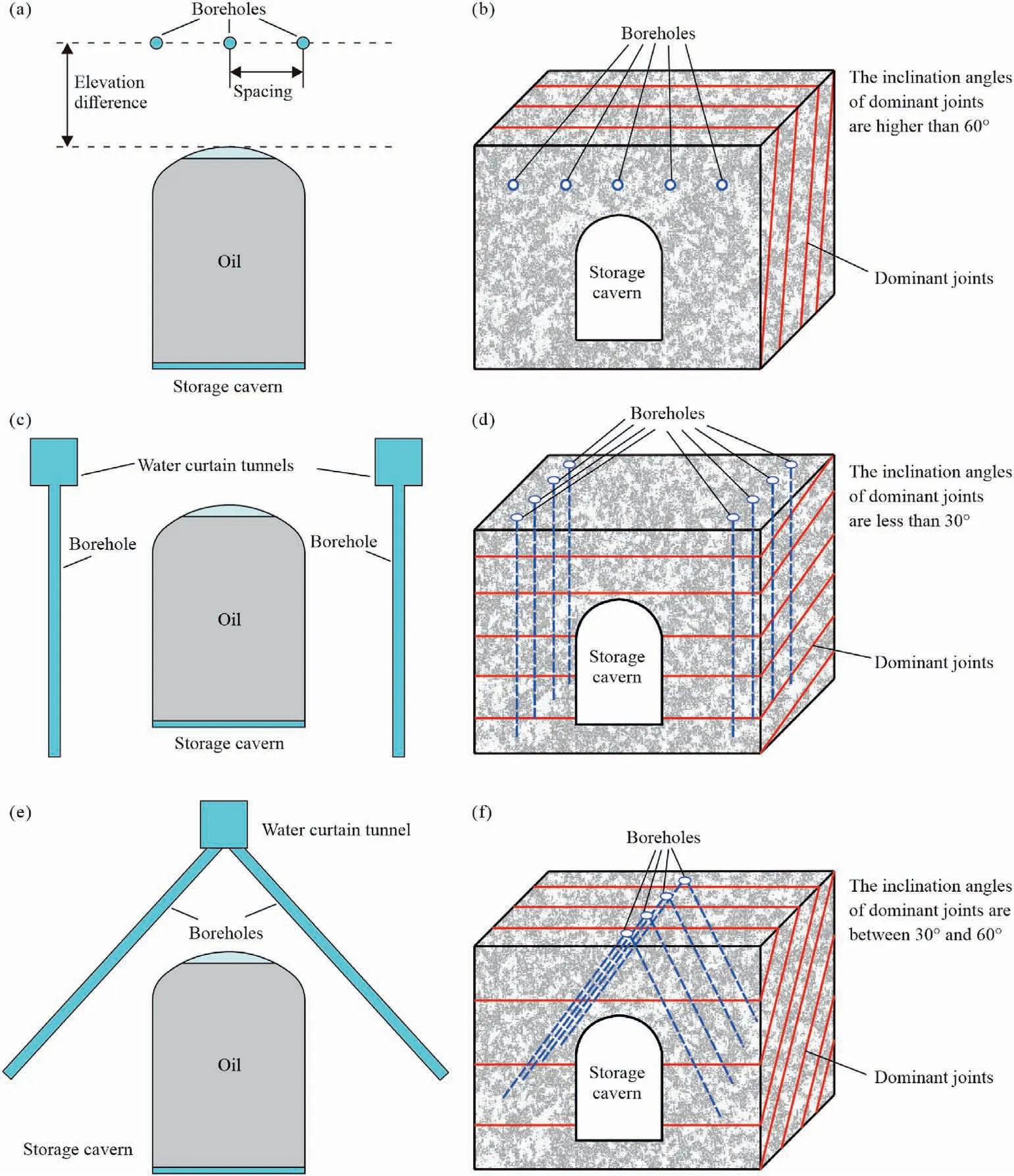

4.2.Design of WCS

The layout of the WCBs is determined according to the occurrence of the dominant fractures(i.e.dip direction and dip angle)in the surrounding rocks of the OSCs (Wang et al., 2015a; Ravandi et al., 2016).Theoretically, to improve the efficiency of the WCS,OSC perpendicular to the dominant fractures is the most ideal arrangement.The horizontal WCBs should be adopted when the dip angle of dominant fractures is greater than 60°.When the dip angle of dominant fractures is less than 30°, vertical WCBs should be adopted.When the dip angle of dominant fractures is between 30°and 60°,inclined WCBs or a combination form of horizontal and vertical WCBs could be adopted (Fig.8).It is still challenging to choose a suitable WCBs layout when there are two or more groups of dominant fractures with large dip angle differences in the study area.In this case,engineering experience,theoretical analysis,field hydraulic tests, and numerical model can be combined to analyze the water sealing effect and water curtain efficiency under various WCBs layouts.The water curtain efficiency should be as high as possible in order to ensure water sealing effect.In addition, the construction difficulty and economic factors should be considered to determine the optimal arrangement for the WCBs.

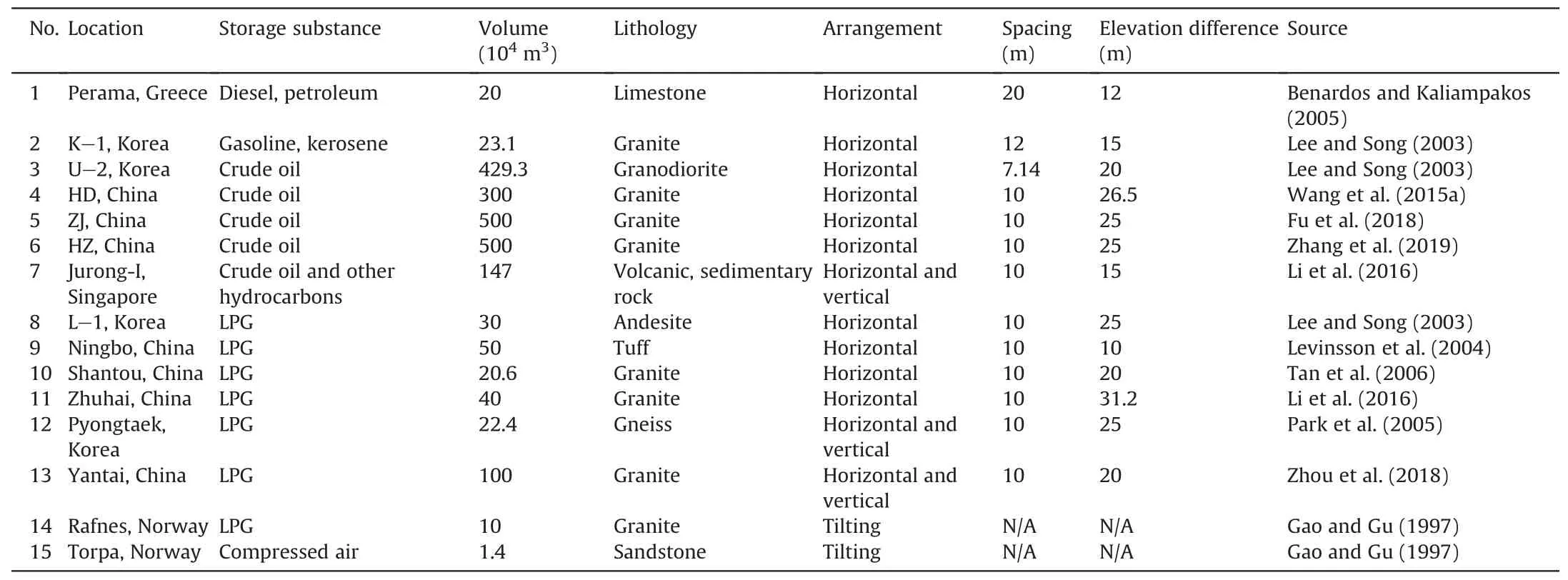

Table 2 lists the layout and parameters of the WCS for approximately 15 UWSOS projects.According to the data, as capacity of OSCs is large, horizontal WCBs are generally adopted.When the capacity of LPG caverns is moderate, horizontal or combination forms of horizontal and vertical WCBs are adopted.Among them,vertical WCBs are mostly adopted between adjacent caverns with different types of oils.Affected by geological conditions and construction difficulty, inclined WCBs are rarely adopted in engineering projects.

Fig.7.FPM flow model (from Zhang et al., 2020a): (a) 3D FPM model; (b) Distribution of the hydraulic head; and (c) Distribution of the hydraulic pressure head.

Fig.8.Arrangements of WCBs (based on Wang et al., 2015a): (a) and (b) horizontal WCBs; (c) and (d) Vertical WCBs; and (e) and (f) Inclined WCBs.

The vertical WCBs can form a vertical barrier, which has the function of “cutting off” the connection of the fractures in the horizontal direction.When expanding an operating UWSOS project,vertical WCBs should be adopted around the access tunnel and shaft of the operating project during excavation of the proposed project in order to ensure the WSS (Li et al., 2009).Following this,Zhang et al.(2019) proposed that a separation distance of 200 m was recommended between the operating and proposed projects,and the vertical WCBs adopted between the two projects can reduce the separation distance.In addition, when constructing an UWSOS project in coastal areas, vertical WCBs can function better than horizontal WCBs.The vertical WCBs adopted between OSCs and coastlines can play a role in water sealing and preventing seawater intrusion (Lee et al., 2015).However, the water inflow of the OSCs under the action of the vertical WCBs is larger than that of the horizontal WCBs (Li et al., 2019a).

The working pressure is a key parameter of the WCS, which determines the water supply of the WCSs and whether WSS can be realized (Yang and Kim, 1998; Li et al., 2009, 2020c; Hu et al.,2019b).The WSS worsens the increase in WCBs spacing (s) and the vertical distance from the OSCs(r)and the decrease in working pressure (p) (Rehbinder et al., 1988; Li et al., 2019c).The relative influences of WCS parameters on the water inflow of the OSCs are ranked as follows:p >s >r(Li et al.,2019c).The working pressure in the WCBs is dependent on the elevation of OSCs, oil and gas pressure in OSCs, and dynamic groundwater level during construction and operation.

4.3.Effectiveness of WCS

For UWSOS projects, in situ testing is a direct method for evaluating the performance of WCSs(Shi et al.2018;Li et al.,2022).The water curtain test can be used to identify the connectivity between the WCBs, as well as the connectivity between the WCS and the OSCs.It mainly includes the single-borehole water injection test,cross borehole interconnectivity test, WCS injection test.The single-borehole water injection test can be used to obtain the initial hydrostatic pressure of the FRM, the cross-borehole interconnectivity test is used to evaluate the connectivity between the boreholes,and the WCS injection test is performed to estimate the water inflow rates into the boreholes and the OSCs (Wang et al.,2015a).Based on the interconnectivity test, it can be concluded that the relatively intact rock mass can effectively block the leakage of oil or gas, so addition of the boreholes is unnecessary (Zhang et al., 2020a).The WCS injection test shows that the groundwater inflow into the OSCs is dominated by groundwater inflow in the rock fractures.That is,the dominant seepage channels between the WCS and the OSCs will directly determine the design of the WCS and selection of grouting measures.In addition, the transient electromagnetic method(TEM)can be used to detect the quality of a WCS during construction in LPG caverns because of its water sensitivity (Lin et al., 2016b).

Table 2 The layout and parameters of the WCS.

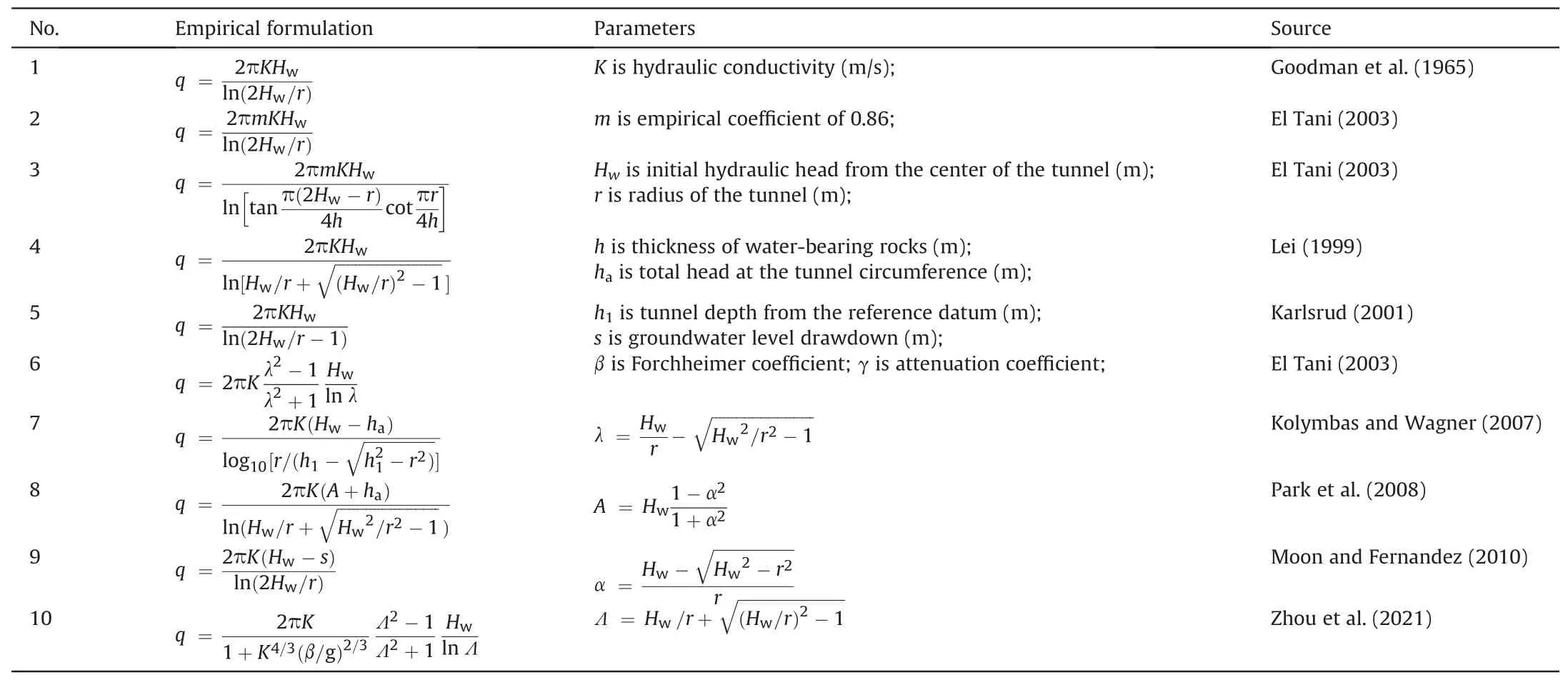

Table 3 Empirical formulations for water inflow estimation.

4.4.Efficiency evaluation of WCS

In recent years, the efficiency evaluation of the WCS has gradually attracted wide attention.Based on the correlation analysis method, Shi et al.(2018) studied the functional efficiency of artificial WCSs in the southeast coastal area of China with better hydrogeological conditions.His research proved a weak influence of the water supply of the WCS on the groundwater level.In addition, the amount of the water supply of the WCS had few contributions to the recharge of the groundwater.In other words,the efficiency of the WCS in this area is low.The contribution of the WCS to the groundwater level and water inflow of OSCs is analyzed according to the monitoring data.Furthermore, an evaluation method for water sealing efficiency is presented from the perspective of optimization of WCS parameters.

5.Prediction and control of water inflow

5.1.Prediction of water inflow

To ensure the WSS of the UWSOS,it is necessary to ensure that the water pressure in the FRM around the OSCs is greater than the oil/gas pressure in the OSCs.Therefore, under the effect of the pressure gradient,the groundwater in the surrounding rocks seeps into the OSCs.When the pressure gradient is large or the permeability of the surrounding rocks is large, it will cause excessive water inflow into the OSCs.On one hand, when the density of fractures is large, the long-term erosion of groundwater with high flow rates may increase the connectivity of fractures, which will endanger the stability of OSCs.On the other hand, it will increase the cost of oily wastewater treatment.In addition,it also increases the workload of grouting and plugging (Pal et al., 2015; Shi et al.,2019).

At present, the prediction methods for the water inflow are divided into the empirical formula method, engineering analogy method,and numerical simulation method.The empirical formula for predicting the water inflow is derived from the water inflow estimation method of horizontal wells and tunnels.According to the empirical formula, water inflow is determined by hydraulic conductivity of FRM,initial groundwater level and equivalent circle radius of the OSCs, and it has a linear relationship with the hydraulic conductivity(Table 3).The empirical formulas of Nos.1 and 4 in Table 3 are the most commonly used to estimate the water inflow into OSCs.These two empirical formulas belong to the category of semiempirical formulas since the empirical coefficients are added based on the traditional analytical formulas.

The engineering analogy method is an empirical method for predicting the water inflow of the proposed projects based on the field monitoring values(initial groundwater level,capacity of OSCs,and water inflow) of analogical projects.The analogical projects shall have the same or similar hydrogeological conditions as the proposed projects.The higher the similarity of the geological conditions of the two comparison projects,the higher the reliability of this method.The analogy formula used in China is(SY/T 0610-2008,2008):

where QBis the water inflow of the analogical project(m3/d),HBis the burial depth of the analogical project(m), VBis the capacity of the analogical project(m3),QAis the water inflow of the proposed project(m3/d),HAis the depth of the proposed project(m),and VAis the capacity of the proposed project(m3).

Numerical method for predicting water inflow mainly includes finite element method and finite difference method (Xu et al.,2018).According to on-site groundwater level monitoring data,the interpolation method is used to assign the initial groundwater level to the model, which makes up for the shortcomings of the empirical formula method that cannot take into account the topography.In addition, this method can establish a 3D model of UWSOS that is consistent with the study area,which makes up for the disadvantage that the empirical formula method can only be equivalent to a circular section.However,this method has the same problem as the empirical formula method, and the accuracy of water inflow estimation results depends on the representativeness of hydraulic conductivity obtained in the field.

5.2.Influence factors on water inflow

Based on engineering experience, the water inflow of OSCs is affected by the factors including permeability of surrounding rocks,groundwater level, and WCS.The water inflow of OSCs fluctuates greatly during the excavation period and tends to decrease steadily during the grouting period.In previous studies, research on the influence of the surrounding rocks permeability and groundwater level on water inflow was widely reported (e.g.Shi et al., 2018,2019; Xu et al., 2021).

The water inflow into OSCs is mainly affected by five factors in descending order of importance: fracture permeability, aperture,dip angle and spacing of fractures, and working pressure of WCSs(Liu et al.,2021;Xu et al.,2021).Thus,the influence of WCS on the water inflow of OSCs is also of interest.The working pressure (p),length of borehole (l), and dip angle (a) of borehole are positively correlated with water inflow of the OSCs,and the WCB spacing(s)is negatively correlated with water inflow of the OSCs.The relative influences of WCS parameters on the water inflow of the OSCs ranks as follows:p >l >s >a(Xu et al.,2018).It should be pointed out that the water inflow of OSCs is relatively less affected by the WCS under a sufficient natural groundwater supply (Shi et al.,2018).

In particular, the access tunnels outside the sealing plug are filled with water during the operation period,which will become a part of the WCS and provide stable working pressure for the WCSs.However, due to the large access tunnel cross-section, more fractures are exposed.Moreover,the access tunnel is close to the OSCs,so the access tunnel made a great contribution to the water inflow into OSCs(Shi et al.,2019).Therefore,to reduce the water inflow of the OSCs, it is recommended that the length of the access tunnel should be shortened as possible in the design stage.

5.3.Existing control measures of water inflow

The water inflow control measures of OSCs are mainly grouting,and the goal is to make the water inflow meet the operational design standard (Sun et al.,2013;Kobayashi et al.,2014).Grouting can significantly improve the quality of the water sealing effect of the WCS.When the groundwater level is raised, the hydraulic gradient of the surrounding rocks also increases (Pal et al., 2016;Ren et al., 2016; Lin et al., 2018; Xue et al.2022).In addition, fullface grouting has been proven to effectively prevent oil leakage and improve the water sealing performance of OSCs.Taking the UWSOS project in Huangdao, China, as an example, the optimal grouting thickness is approximately 5 m (Zhang et al., 2014).

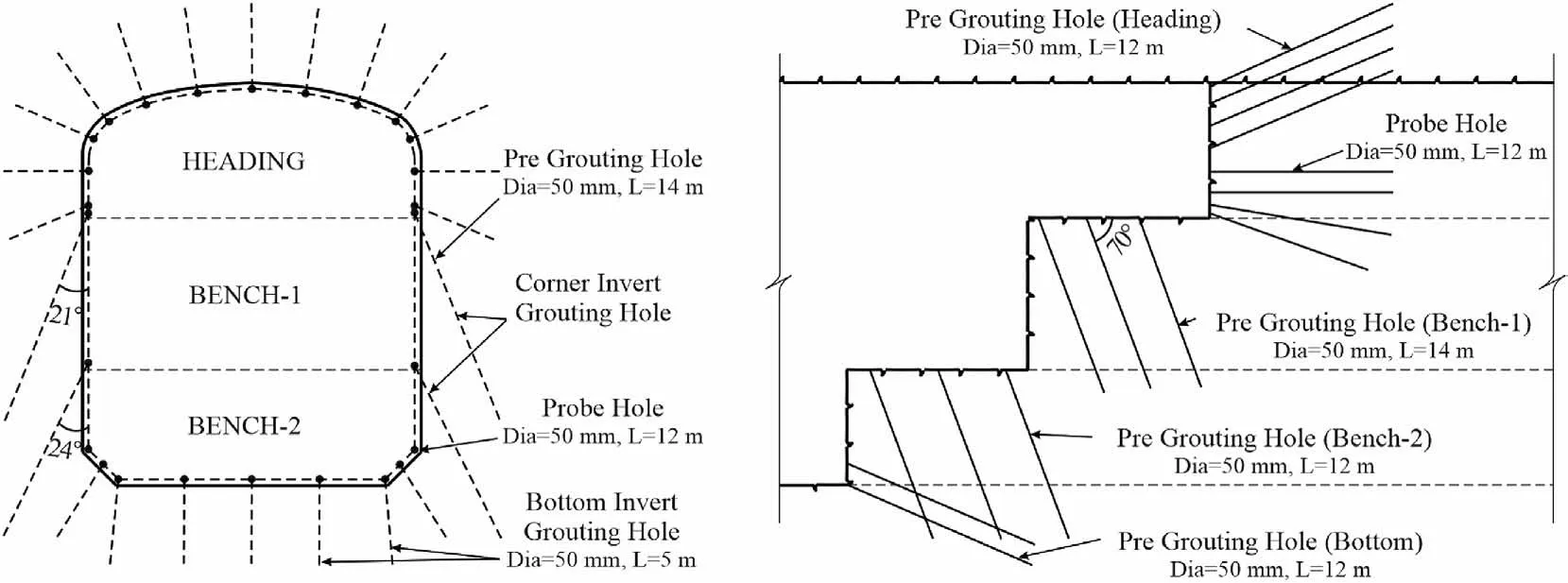

At present, the grouting methods for UWSOS are pre-grouting and post-grouting.The pre-grouting method plays a more important role in water inflow control of UWSOS (Lee et al., 1996;Woldmo and Grov,2013;Pal et al.,2015).During the excavation of the OSCs,according to the surrounding rock conditions revealed by geological drilling,the method of pre-grouting in the sections with large water inflow.After the excavation of the OSCs, the postgrouting method is adopted in the areas with large water inflow.Usmani et al.(2015) proposed that pre-grouting is the key to controlling the water inflow of OSCs and suggested that most of the measured water inflow inside the OSCs came from the corner invert and bottom covert of the OSCs(Fig.9).

Fig.9.Typical scheme of pre-grouting in OSC (from Usmani et al., 2015).

The water inflow control of UWSOS has strict requirements on the grouting materials, and chemical grout that reacts with oil should not be used.In addition, due to environmental risks, longterm durability, and oil/petroleum gas safety, chemical grout is not widely used in UWSOS.The most commonly used grout material is Portland cement (; Weideborg et al., 2001; Lee et al.,2004).Wei et al.(2017) proposed a new type of sulfoaluminate cement grouting material, and found that the sulfoaluminate cement can significantly improve the grouting speed and effect compared with Portland cement.Taking an LPG project built in granite as an example, Yoshida et al.(2013) analyzed the grouting characteristics of flow-path fractures in surrounding rocks and concluded that pre-grouting could not fully reduce the flow-path conductivity.Micro-sheeting type fractures contribute significantly to water inflow, but the grouting effect is poor.

6.Discussion

This study summarized the research progress on the key issues of water sealing performance of UWSOS,including permeability of FRM, WSS, performance of WCSs, and prediction and control of water inflow.Next, the existing problems and potential development directions in the future will be analyzed and discussed for the study of the four key issues in water sealing performances.

6.1.Hydraulic permeability of surrounding rocks

The permeability and spatial variation characteristics of the fractures in the surrounding rocks of OSCs are the basis of WSS.In terms of FRM seepage, the cubic law and its modified formula are the challenging issues in previous research.In addition, based on water sealing principle of UWSOS,study on water-oil displacement tests of FRM has attracted much attention.In past years, study on water-oil displacement tests was mainly carried out in the field of fractured reservoirs.In contrast,the dynamic balance of water and oil in rock fractures under the condition of circulating oil pumping and injection should be considered in UWSOS projects.However,there are few studies on the migration mode of oil in fractures after water sealing failure.After the oil leaks into the fractures, the working pressure of WCSs should be controlled to make the oil be pushed back to the OSCs.This study is of great significance to the understanding of water-sealed mechanism of UWSOS, the risk assessment of oil leakage, and the selection of water sealing remedial measures.

It is important to understand the spatial distribution of fractures more accurately for determining the location of the dominant seepage channels in the surrounding rocks of OSCs.The dominant seepage channels in the surrounding rocks of the OSCs will directly determine the design of the WCS and the selection of water inflow control measures.However, due to the unascertainable spatial distribution of fractures, the study of the permeability spatial variation law of FRM is needed.Developing more advanced rock fracture detection technology, formulating more scientific investigation schemes,and constructing more refined 3D FRM models are critical issues for future research.

6.2.Water-sealed safety

The water sealing criterion is used to judge the WSS.Although the vertical hydraulic gradient criterion proposed by Åberg (1977)is considered to be relatively conservative, no recognized alternative criterion is developed at present,and the criterion of a vertical hydraulic gradient greater than 1 is still used to identify WSS in most studies.Most of the empirical criteria of WSS are conservative and do not consider the permeability anisotropy of surrounding rocks.Application of these water sealing criteria to FRM requires knowledge of the connection between the fractures and the OSCs,the distribution of groundwater pressure within the fractures.However, it is difficult to discriminate the WSS of all fractures one by one practically, according to the water sealing criteria.Thus, a macroscopic empirical criterion for WSS based on the critical water sealing thickness was proposed.Although a stable groundwater level will be formed in the FRM above the OSCs and the criterion of water sealing can be satisfied, the hydraulic head and water pressure distribution show strong anisotropy due to the presence of fractures.Therefore, the lowest groundwater level should be used for WSS evaluation.

The numerical model is the main method used to evaluate the WSS of UWSOS in the design and construction stages.At present,limited by computing power and efficiency,the EPM model is used in the WSS evaluation of UWSOS from an engineering scale.However,in the local range,there is a great difference between the simulation results of the EPM and the anisotropic seepage of the natural rocks.In addition, the EPM model cannot describe the influence of the dominant seepage channel in the FRM on the groundwater seepage field.The dominant seepage channel is very important in the study of the WSS of UWSOS,which determines the water inflow of OSCs and the size of the groundwater depression cone formed above the OSCs.Although the anisotropy of an FRM can be considered in the DFN model, this method also has the following shortcomings.First, due to the limitations of current measurement methods, it is impossible to detect all fractures in a large study area.Second,the distribution of fractures is stochastic,so it is very difficult to establish the same DFN model as the engineering project.Third, the fracture permeability parameters are difficult to estimate.Finally, the computational efficiency of the DFN model is low.Therefore, the DFN model has poor operability and is difficult to apply to practical engineering.

6.3.Performance of the WCS

The WCS is a facility to ensure the WSS of UWSOS.Layout parameter optimization and efficiency evaluation of WCS are the focus of WSS research.Due to the geological conditions and other factors, horizontal WCBs are widely adopted in UWSOS, while vertical WCBs are mostly used to “cut off” the seepage channel between adjacent OSCs and prevent seawater intrusion.At present,the layout parameters of the WCS are primarily selected based on experiences.To ensure WSS,the layout parameters of the WCS are often too conservative.A need in future research is to form a more scientific design method for WCS.On the basis of sufficient preliminary investigation, reasonable layout parameters of the WCS should be conducted according to the site-specific geological conditions of the UWSOS project.In addition,during the construction period,the design parameters,such as the distance between WCSs in different sections, should be dynamically adjusted.

The efficiency evaluation of WCS is one of the present focuses.The layout parameters of the WCS are basically the same for the Huangdao oil storage project and another project on the southeast coast of China with different hydrogeological conditions.As a result, the water inflow of the oil storage project on the southeast coast of China is significantly greater than that of the Huangdao project.Therefore, the concept of the “excess water-sealed function” of an artificial WCS was proposed (Shi et al., 2018).To solve this problem, a method to quantitatively characterize the proportion of natural and artificial water sealing effects is needed.In addition,dynamic water recharge design can be carried out for the WCS according to the tempo-spatial distribution characteristics of natural recharge in the study area (for example, different working pressures of WCSs are adopted in different rainfall events, or even artificial WCSs recharge is stopped in seasons with abundant natural recharge) to form dynamic water recharge schemes and standards.

6.4.Prediction and control of water inflow

The prediction and control of water inflow in OSCs are one of the important means of WSS.Affected by the randomness and anisotropy of the permeability of an FRM, topographic relief and other factors, the accuracy of water inflow calculated by empirical formula method is low.According to engineering experiences, it is common for the predicted results to differ from the monitoring results by 300-500%.Therefore, it is necessary to optimize the empirical formula of water inflow prediction for UWSOS projects in the future.The numerical method makes up for some shortcomings of the empirical formula method.In the future,with the improvement of rock fracture detection technology and numerical computational efficiency, numerical methods will have a broad application in accurate prediction of water inflow.The engineering analogy method has high prediction accuracy in the expansion project of UWSOS, but low accuracy for the engineering projects with complex geological conditions.

Cement grouting is the direct and effective engineering measure to control water inflow into OSCs.Determining the dominant seepage channels in surrounding rocks is the key to grouting.According to engineering experience,cement is the main material for grouting in surrounding rocks of OSCs.Limited by the small fracture aperture of crystalline rocks,cement grouting is difficult.The water inflow after cement grouting in most areas cannot meet the design standards.Based on relevant biological studies,microbially induced carbonate precipitation (MICP) technology has the advantages of good fluidity and can generate cementation precipitation, which can have a good effect in the fields of seepage prevention and sealing.

7.Conclusions

This paper analyzed the permeability of FRM, WSS, the performance of WCSs,and the prediction and control of water inflow.The study shows that the permeability of the FRM is the basis of water sealing research.However, studies on the spatial structure and permeability of the natural fracture network are still insufficient.

(1) The current water sealing criterion is conservative and can be further optimized.The WSS evaluation method based on the EPM can basically achieve the expected goal, and engineering-scale WSS evaluation considering fracture networks is an urgent problem to be solved in the future.The design of WCS is the hot topic in the research of water sealing performances, and the optimization of layout parameters and working pressure of WCSs are the focus of the research.

(2) The quantitative evaluation of WCS efficiency is the main research direction in the future.Based on the efficiency of the WCS, a dynamic design method for the WCS should be formed in the future.The accuracy of the current water inflow prediction method is insufficient,and the method can be optimized in the future to propose a more suitable method for the evaluation of the water inflow of OSCs.I

(3) The main control measure of excessive water inflow is to use grouting.Therefore, the new grouting materials and processes are of significance in improving the grouting effect and reducing grouting expenses.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant Nos.41972300, 41572301, and 42107201).

Journal of Rock Mechanics and Geotechnical Engineering2023年10期

Journal of Rock Mechanics and Geotechnical Engineering2023年10期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A true triaxial strength criterion for rocks by gene expression programming

- Wetting-drying-freezing-thawing cycle effect on the hydro-mechanical behaviour of Yanji swelling mudstone

- Capability of discrete element method to investigate the macro-micro mechanical behaviours of granular soils considering different stress conditions and morphological gene mutation

- Permeability evolution mechanism and the optimum permeability determination of uranium leaching from low-permeability sandstone treated with low-frequency vibration

- Numerical analysis of bending property of bi-modulus materials and a new method for measurement of tensile elastic modulus

- Analysis of rockburst mechanism and warning based on microseismic moment tensors and dynamic Bayesian networks