Dislocation configuration evolution during extension twinning and its influence on precipitation behavior in AZ80 wrought magnesium alloy

Guo-Liang Shi ,Kui Zhang ,Xing-Gang Li ,Yong-Jun Li ,Ming-Long Ma ,Jia-Wei Yuan ,Hong-Ju Zhang

aState Key Laboratory of Nonferrous Metals and Process,Grinm Group Corporation Limited(GRINM),Beijing 100088,China

b GRIMAT Engineering Institute Co.,Ltd.,Beijing 101407,China

cGuobiao (Beijing) Testing and Certification.Co.,Ltd.,Beijing 101407,China

Abstract Thermomechanical treatment T10 (extension twinning+aging treatment) can largely enhance the precipitation strengthening effect of magnesium alloys.In this study,dislocation structure evolution and precipitation behavior during T10 treatment of an AZ80 extruded bar were analyzed mainly by two-beam diffraction in TEM.At a compressive strain of 1% in the extrusion direction (ED),a typical dislocation configuration,including basal I1 stacking faults (SFs) and

Keywords: Magnesium alloy;Extension twin;Dislocation;Stacking fault;Precipitation.

1.Introduction

Based on review analysis of over 3000 papers on magnesium and magnesium alloys indexed in SCI in 2020,the control of microstructures of Mg alloys to improve their mechanical properties through developing new alloys and advanced processing technology is still a main research focus[1].Extension twinning ({102}<101>twinning) is an important plastic deformation mechanism in magnesium alloys[2,3],and also beneficial to their recrystallization [4].Recent TEM studies show that a typical dislocation configuration including basalI1SFs and

When a single crystal of magnesium or its alloys is stretched in the c axis or is compressed perpendicularly to the c axis,extension twinning can readily be activated[3],and the critical resolved shear stress (CRSS) is only about 5–10 MPa[13],only slightly higher than the CRSS of basal slip.The CRSS of extension twinning in polycrystalline magnesium alloys increases;for instance,the CRSS in an AZ31B hot-rolled sheet is about 25–35 MPa[14],or 46.5 MPa in a recent report[15]and about 56 MPa in an extruded ZK60 bar [16].When the total compression strain perpendicular to the c axis or the total tensile strain along the c axis of a pure magnesium single crystal reaches about 5–6%,the single crystal completely transforms to an extension twin[7,13].Extension twinning includes three sequential processes:nucleation,propagation,and growth;moreover,it involves three growth directions: shear(forward) direction,twinning plane normal,and lateral direction=×;when an extension-twin thin crystal nucleates on the grain boundary,it first propagates alonganduntil it is blocked at the opposite grain boundary.It then starts to thicken along.All these processes include the formation and migration of TBs [17],which migrate by the slip of twinning dislocations [8].

Al is an important alloying element for magnesium alloys,because it can bring about higher strength and larger elongation at the same time [18].Thus,Mg–Al series alloys are currently the most widely used magnesium alloys,with Mg17Al12phases as their main aging hardening precipitates.This phase has two kinds of precipitation mechanisms:(1) discontinuous precipitation in which several discontinuous precipitates first nucleate at one grain boundary and then grow in a sheet shape,synchronously drives the grain boundary towards grain interior.A lamellar structure consisting of alternate layers of Mg17Al12andα-Mg is thus obtained.During the growth of precipitates,the grain boundary acts as a fast-diffusion channels of solute Al.However,the Al concentration abruptly changes from one side of the grain boundary to the other,hence the mechanism referred to as discontinuous precipitation.These sheet-shaped discontinuous precipitates cannot effectively hinder basal slip because their habit planes are parallel to the basal plane,and the spaces among them are always wide;(2) continuous precipitation: a large number of lath-shaped particles nucleate in the grain interior;the Al concentration at one point continuously decreases with aging time,so the mechanism involved is referred to as continuous precipitation.Continuous precipitates usually exhibit a high number density,so this mechanism can lead to a desirable hardening effect;moreover,dislocations can act as the preferred nucleation sites and the fast-diffusion channels of solute Al [19–24].Discontinuous precipitation consistently maintains its competitive advantage over continuous precipitation in conventional aging treatment;thus,Mg–Al series alloys often exhibit poor age-hardening effects [23].

Extension twins can largely enhance the age-hardening effect of Mg–Al series alloys,because they can not only impede discontinuous precipitation but also improve the number density of continuous precipitates [10–12,25].Extension twin boundaries can strongly hinder the migration of grain boundaries thereby limiting the growth of discontinuous precipitates.A typical dislocation configuration including basalI1SF and

2.Materials and methods

Specimens in the current study were cut from an extruded AZ80 bar with a cross-section of 230 mm × 140 mm and the following chemical composition:Mg-8.87Al–0.62Zn–0.15 Mn–0.27Ce–0.0034Fe–0.02Si–0.0012Cu (wt.%).This bar has three characteristic directions,i.e.ED (extrusion direction),TD (parallel to 230 mm sides of the rectangular cross-section),and ND (parallel to 140 mm sides of the rectangular cross-section).A semi-continuous casting ingot was homogenized at 395°C for 16 h,and the bar was produced by“multi-direction forging (MDF)+extrusion+online cooling.” MDF was conducted at temperatures exceeding 350 °C,and a graphite–oil mixture was used as a lubricant.After MDF,the forged ingot was directly extruded at 350 °C with an extrusion ratio of 10 and an extrusion speed of about 0.35 mm/s.To maintain a high degree of supersaturation and weaken grain coarsening,the bar was quickly quenched using an on-line water quenching device as soon as it escaped from the mold.The specimens with dimensions 14 mm(ND) × 16 mm (TD) × 30 mm (ED) were compressed on a universal testing machine at RT,with the compression parallel to ED;this loading path facilitates the activation of extension twinning;graphite flakes were used between the specimen and anvils as the lubricant.

The twinning characteristics in samples with 1 and 7%strains were analyzed by EBSD.Dislocation configuration and precipitation behavior in extension twins were observed by two-beam diffraction technique in TEM.EBSD was conducted on JSM-7001F field-emission SEM equipped with the EBSD system produced by TSL-EDAX.Ultimately,EBSD samples were electrolytically polished in 20% (volume fraction) nitric acid solution in alcohol at a voltage of about 15–20 V,with the temperature set below 0 °C.The Burgers vectorof different dislocations can be distinguished using the·=0 invisibility criterion,and<110>and<113>zone axes are normally chosen for HCP metals.Meanwhile,[0002],[10],[100],[101],[10],and [011]are the commonly usedvectors;under the diffraction condition of=[0002],dislocations are invisible but dislocations with a

3.Results and discussions

3.1.Twinning characteristics

The engineering stress–strain curves of the as-extruded sample with a rectangular section during compression in the ED at RT have a typical S shape,as presented in Fig.1.Extension twinning is the dominant plastic mechanism in the early stages of compression;thus,the yield strength is relatively low at 160 MPa;when the strain reaches about 6%,non-basal slip of

Fig.1.Typical engineering stress–strain curve of as-extruded 14 mm(ND) × 16 mm (TD) × 30 mm (ED) sample during compression in the ED at RT (Graphite flakes were used between specimen and anvils as the lubricant;strain rate=0.0005 s-1).

The EBSD images in Fig.2 present twinning behaviors in three typical grains in a sample compressed to 1%strain,with the horizontal directions of all images parallel to compression in ED and the vertical directions parallel to ND.The twinning characteristics in MA grain are exhibited in Fig.2(a) and (b),and the inverse pole figure (IPF) in Fig.2(a) demonstrates the orientation of MA—that is,compression is applied parallel to its c axis,which hinders the activation of extension twinning but facilitates the activation of contraction twinning.Several parallel needle-shaped contraction twins are thus observed in Fig.2(b).The c axis of grain MB is approximately normal to compression.Thus,two extension twin variants are activated,as labeled in Fig.2(c).Different twin variants can form an“apparent crossing” twin structure,which results from twin–twin boundary formation [32];meanwhile,the adjacent twins belonging to the same variant can merge together,as shown in Fig.2(c) and (d).Fig.2(e) presents the kernel average misorientation (KAM) distribution map of MB grain,and a large number of low-angle boundaries with a misorientation angle of about 2° are found near TBs and around compound particles,suggesting a considerably high dislocation density in these regions.As shown in Fig.2(f),the c axis of grain MC is strictly perpendicular to ED,which significantly contributes to the activation of extension twinning,and only one variant is activated.Individuals of the same variant can also form an“apparent crossing”twin structure,and extension twin appears to bypass compounds and continue propagating,as shown in Fig.2(g).The KAM distribution map in Fig.2(h) also indicates a considerably high dislocation density near TBs and around compound particles.

The twinning behaviors in the 7% strained sample are shown in Fig.3.In the earlier study,the area fraction of the extension twins rises to 90% when the compression strain in the ED reaches 6%;meanwhile,the extrusion fiber texture is completely transformed[9].The IPF image in Fig.3(a)shows that most grains are completely transformed into extension twins,but several original structures remain in some grains,labelled by arrows in Fig.3(a).The original extrusion fiber texture is (0001)‖ED (c axes⊥ED).After the strain increases to 7%,the texture is fully transformed into (0001)⊥ED (c axes‖ED) by extension twinning,as shown in Fig.3(d).The KAM distribution map in Fig.3(c) shows that most areas present a misorientation angle about 2 °,particularly near the grain boundaries and TBs and around compounds,indicating the high density of dislocations in most regions in the material.

Fig.3.Twinning behaviors in the 7% strained sample,horizontal directions of all images ‖ ED,and vertical directions ‖ ND.(a): IPF image;(b): IQ image;(c): KAM image (blue: KAM=0 °,red: KAM=5 °);(d): (0001) pole figure (For interpretation of the references to color in this figure legend,the reader is referred to the web version of this article.).

3.2.Dislocation configurations in extension twins

The dislocation configurations in an twin T1 of the 1%strained sample are analyzed by two-beam diffraction in TEM,as shown in Fig.4,with the electron beam along the〈20〉 zone axes of the T1.Fig.4(a) and (b) present the bright-and dark-field images,respectively,under a normal diffraction condition.Tangled dislocations exist in the matrix MD and basalI1SFs in the T1 can stretch across the entire twin,and a larger version of SFs is shown in the inset of Fig.4(b).With reduced strain (1%) and small thin thickness(~1 μm),this extension twin is most likely in the early stages of growth;TBs migrate and continuously react with thedislocations in the matrix to produce sessile Frank partial dislocations ofI1SFs in the extension twin,and these SFs can continue stretching with the migration of TBs [6].With the orientation of the T1 adjusted to the two-beam diffraction condition=[0002],the bright-and dark-field images of the T1 are presented in Fig.4(c) and (d).BasalI1SFs and

Fig.4.Dislocation configuration in the 1% strained sample,with an electron beam along 〈20〉 zone axes of T1.(a) and (b): normal diffraction condition;(c) and (d): two-beam diffraction condition of the T1 with =[0002];(e)–(h): =[010]for the T1.

Fig.5 presents the dislocation configuration in extension twins T2 and T3 in the 1% strained sample with an electron beam along the<20>zone axes of the extension twin T3.The bright-field image under normal diffraction condition in Fig.5(a) shows that high-density dislocations exist in both the matrix and the extension twins.Moreover,the orientation relationship between the extension twin and the matrix can be determined by their diffraction patterns in the insets in Fig.5(a) and is labeled in Fig.5(a) by basal plane traces.The angle between these two traces is about 86 °,consisting of the orientation transformation of extension twinning.Dislocation projections in the matrix are mainly arrayed along the basal-plane traces.Linear defects along basal planes also appear in the extension twin and are most likely basalI1SFs.With the orientation of the T3 adjusted to the=[010]diffraction condition,bright-and dark-field images are shown in Fig.5(b)–(f) with (b)–(e) for the T2 and (f) for the T3.Dislocation contrasts between the T2 and the T3 completely vary,indicating a large misorientation between them.In addition,T2 and T3 may belong to different variants and connect,similar to the case in Fig.2(d).A long basalI1SF with a length of 750 nm is found in the T2,which is connected to the right TB;however,many short SFs with the contrast of equal inclination fringes are connected to the left TB,as marked in Fig.5(b)–(e),implying that the migration in the right TB is longer than that in the left one.The long SF is speculated to have only a small part remaining in the TEM film sample,which may be the reason it does not present equal inclination fringes.Numerous dislocations are present in the T2,most of which are connected to TB and are most likely

Fig.5.Dislocation configuration inside two connecting extension twin variants T2 and T3 in the 1% strained sample,with an electron beam along the <20>zone axes of the T3.(a): normal diffraction condition;(b)–(f): =[010]for the T3;(e)– (h): =[0002]for the T3.

Our earlier study indicates that the same AZ80 extruded bar reaches its limit of compression deformation in ED at RT when the strain increases to 7%,and the volume fraction of the extension twins exceeds 90%,as shown in Fig.3.Under this condition,the dislocation configuration in the extension twins is analyzed in Fig.6.In the bright-field image in Fig.6(a) under normal diffraction condition,five boundaries divide the field of view into six zones,and four zones with larger thicknesses are most likely extension twins because the same basal-plane trace can be determined in these zones,and they are defined as T4,T5,T6,and T7.Meanwhile,the basalplane trace in the narrow zone in the middle varies from that of the extension twins and thus is most likely the matrix,defined as ME.By deduction,these extension twins are originally four entities belonging to the same variant,similar to the scenario in Fig.2(f);moreover,they continue to thicken with the strain,and when the strain approaches the maximum T4,T5,and T6 are completely merged,whereas,T4 and T7,separated by a narrow ME,are about to merge.Three new extension twins are activated at the narrowest site of ME,as denoted by arrows.As indicated in Fig.6(b),these three twins nucleate at the TB between ME and T7;they traverse ME and T4 and even the merging interface between T4 and T5,indicating a markedly higher local stress.Under the=[0002]diffraction condition for the T4 twin,bright-and dark-field images are presented in Fig.6(b)–(h).Fig.6(b) is a low-magnification image with a field of view roughly identical to that in Fig.6(a).Meanwhile,Fig.6(c)–(h) are high-magnification images revealing three fields of view in Fig.6(a) and (b),as marked by rectangular frames in Fig.6(a) and (b).Contrary to those in Fig.6(a),most dislocations are invisible in Fig.6(b),except for retained dislocation contrast in the vicinity of the narrowest site of ME where T4 and T7 are about to merge;and a much higher dislocation density can be predicted.Consequently,a strong local stress concentration is obtained,which activates three new twins.Moreover,dislocation contrast and secondarily activated twins also appear near the left TB of T7.Compared with the invisible dislocation contrast in the bright-field image,darkfield images can clearly show the basalI1SFs and

Fig.6.Dislocation configuration in the 7%strained sample,with the electron beam along the <20> zone axes of the T4 twin.(a): normal diffraction condition;(b)–(h): =[0002]for T4 twin;(i)–(n): =[010]for T4 twin.

The dislocation configurations in another extension twinned area of the 7% strained sample are shown in Fig.7 with the electron beam along the〈20〉zone axes of twinned area.The two-beam diffraction condition in Fig.7(a)–(d) is=[010]for the twinned area.Fig.7(a) demonstrates the macrograph of this twinned area,which consists of three merged twins labeled as T8,T9,and T10.The dislocation density in T8 is not uniform–that is,characterized by a lowdensity area in the upper part and a high-density area in the lower part.A magnified image of the top–left corner of Fig.7(a) is shown in Fig.7(b),and the merged TBs and the inhomogeneity of the dislocation density in T8 are clearly presented.The fields of view of the two dark-field images in Fig.7(c) and (d) are denoted by black rectangular frames in Fig.7(a).High density dislocation exists in both fields of view,and the dislocation density in the lower part of T8(Fig.7(d)) is higher than that in the upper part of T9(Fig.7(c)).Moreover,Fig.7(c) and (f) are two dark-field images of almost the same field of view under differentconditions,exhibiting completely different dislocation contrasts.By deduction,the dislocation contrast in Fig.7(a)–(d) originates partly from thecomponents.Fig.7(e)–(h) are under the=[0002]condition of the twinned area.Fig.7(e) clearly shows that the twinned area is consists of three merged twins,and the T10 area is enlarged upward,which may be attributed to a slight change in orientation on the edge of the ion thinning hole.The fields of view corresponding to Fig.7(f)–(h)are labeled with black rectangular frames as that in Fig.7(e).Fig.7(f) shows the dislocation configuration in the upper part of T9,with almost the same field of view as that in Fig.7(c),which includes densely arrayed basalI1SFs and

Fig.7.Dislocation configuration in extension twins in the 7% strained sample,with the electron beam along the 〈20〉 zone axes of the T9 twin.(a)–(d): =[010]for the T9 twin;(e)–(h): =[0002]for the T9 twin.

The following rules can be determined from the aforementioned analysis: (a) under strain conditions,several extension twins belonging to the same variant usually form simultaneously in one grain and ultimately merge,generating merged TBs that consist of high-density dislocation tangles;(b) during thickening of an extension twin,TBs migrate towards the matrix and react withdislocations in the matrix simultaneously,resulting in a typical dislocation configuration consisting of basalI1SFs and

3.3.Precipitation behavior in extension twins

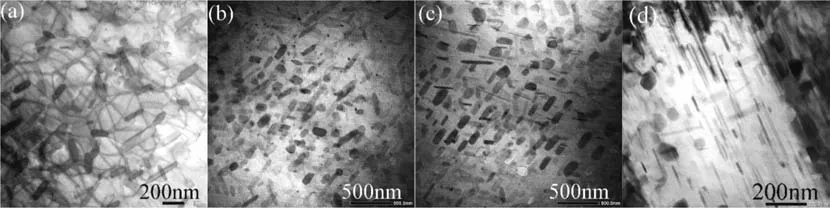

Fig.8 presents the dislocation configuration and precipitation behavior in the extension twins after treatment consisting of pre-compression with 7% strain+artificial aging at 150 °C for 2 h,with the electron beam along [20]of the T12 twin.The age-hardening curves at 150 °C for 50 h of the present AZ80 extruded bar with and without pre-deformation have been reported in the literature [11],from which the following conclusions can be drawn: (a) Cold compression with 6% strain in the ED increases the hardness from 73 HB (asextruded) to 90 HB by work hardening (increasing the dislocation density).After the sample undergoes aging for 2.5 h,the hardness is reduced to 86 HB by recovery (decreasing the dislocation density).The hardness increases rapidly to the peak value of 93 HB at 20 h and then remains stable until 94 HB at 50 h.(b) The age-hardening curve without predeformation has an incubation period of 15 h with hardness lower than 75 HB.The hardness then rises slowly but does not peak until the duration of 50 h(86 HB)is reached.Consequently,sufficient extension twinning can completely change the precipitation behavior,not only increases the peak hardness value,but also markedly reduces the time to peak.Moreover,after the sample undergoes aging for 2 h,the recovery stage is basically completed,and the dislocation density is reduced.Simultaneously,the nucleation stage of the precipitates basically ends,whereas the stage of fast growth begins;meanwhile the hardness rises sharply.Three extension twins with the same orientation are shown in Fig.8(a)—T11,T12,and T13.Fig.8(b)–(k) present the bright-and dark-field images from five fields of view.The two-beam diffraction condition in Fig.8(a)–(i) is=[0002]for the T12 twin.As shown in the figure,I1SFs and

Fig.9 presents the dislocation configuration and precipitation behavior in one grain MG when the aging time is extended to 50 h at 150 °C (pre-deformation strain≈6%),under the two-beam diffraction condition=[0002]for the T14 twin(electron beam‖[20]of the T14 twin).This grain MG has five extension twins—T14,T15,T16,T17,and T18—with the same orientation.The number density of the lathshaped precipitates is markedly higher in T14,T17 and T18 with large thickness because basalI1SFs and

Fig.10 presents the dislocation configuration and precipitation behavior of two extension twins—T19 and T20—in the same sample treated by pre-compression with 6% strain+artificial aging at 150 °C for 50 h.The two-beam diffraction condition of=[0002]for extension twins is used under the incident way of the electron beam ‖ [20]of the extension twins.Fig.10(a) and (b) correspond to the T19 twin,and (c)–(f) correspond to the T20 twin.The number density of continuous precipitates in the T20 is markedly higher than that in the T19 because the T20 has a higher dislocation density.In the T20,most giant short–thick laths are connected to several

For the engineering applications of the AZ80 wrought magnesium alloy with a larger cross-section,the preferred cold pre-deformation strain is about 6% in the ED or rolling direction which can induce a high volume fraction of extension twins.The average length,thickness,and length-tothickness ratio of the lath-shaped continuous precipitates are about 120 nm,40 nm and 4,respectively,after peak aging treatment at 150 °C for 20~50 h.

Scanning-transmission electron microscopy (STEM) images of continuous precipitates in the sample treated by precompression with 6% strain+artificial aging at 150 °C for 50 h are shown in Fig.11.The incident beam in Fig.11(a)–(c) is nearly parallel to the [0001]direction of the extension twins and shows largely diverse precipitation.Most continuous precipitates in Fig.11(a) present themselves as laths with six variants because of their Burgers orientation relationship with the matrix [21].In addition to laths,precipitates with equiaxial and needle-like morphologies are observed in Fig.11(b) and (c),dominated by only one variant.The incident beam in Fig.11(d) is nearly perpendicular to the [0001]of the extension twin,and the field of view is dominated by long–thin precipitates,in addition to few rod-shaped precipitates,which are perpendicular or nearly perpendicular to the basal plane.Such diversity in precipitation in extension twins is potentially caused by the diverse and complex dislocation configurations.

Fig.11.Scanning–transmission electron microscopy images of continuous precipitates in the sample treated by pre-compression with 6% strain+artificial aging at 150 °C for 50 h.

4.Discussions

In recent years,numerous studies have confirmed that extension twinning significantly enhances the age-hardening effect of wrought Mg–Al alloys [10–12,25],given that nanoscale particles continuously precipitated in extension twins gain a considerably higher number density than those in matrices and that TBs can hinder the growth of coarse discontinuous precipitates.On the basis of these findings,a new thermomechanical treatment referred to as T10 can be potentially developed for wrought Mg alloys.The characteristics,evolution,and formation mode of the dislocation substructure in extension twins—in addition to its influence on precipitation—should be elucidated to precisely control the strengthening effect of T10 treatment,which is the objective of the present study.

The dislocation substructure in {102} twins is formed by the interactions between matrix dislocations and TB,and studies on this subject can be traced back to 1950 s.One of the most representative early studies was conducted by M.Yoo and C.Wei concerning the growth of the {102} deformation twin in Zn.They proposed one important interfacial reaction on the {102} TB by correspondence matrices—that is,two [a1,3]dislocations in the matrix can be transformed to one [c±a2]dislocation on the prismatic plane of the twin and one double twinning dislocation on the TB [8].A large volume of TEM studies have recently revealed that a typical dislocation configuration is formed in {102} twins of HCP metals consisting of basalI1SFs and

On the basis of findings reported in previous researches and the current study,a schematic of the complete microstructure evolution during the T10 treatment of wrought Mg alloys is presented in Fig.12.Fig.12(a) shows an original grain in the wrought material,which contains a large number of pre-existing basaldislocations (blue short lines in the matrix).High-density dislocations can be retained within the matrices by on-line quenching after hot deformation.The c axis of this grain is perpendicular to the compression direction(indicated by arrows in Fig.12(a)),which contributes to the activation of {102} extension twinning.After a nucleus of the extension twin is formed at the grain boundary,it rapidly propagates the whole grain and then starts to grow by the glide of twinning dislocations on TB.During twin growth,a typical dislocation configuration is continuously formed via the interaction between the migrating TB and basaldislocations in the matrix,as shown in Fig.12(b).

Fig.12.Dislocation structure evolution and precipitation behavior during the thermomechanical treatment T10: blue short lines in the matrix represent dislocations on basal planes;yellow lines denote TBs;short green lines in the twin indicate basal I1 SFs;red curves in the twin are

The fundamental physical mechanism [6]can be described as follows: (1)Formation of basal I1 SF.As one basaldislocation segment in the matrix is incorporated by the extension twin,it is first transformed into a 1/6<203>-type sessile Frank partial dislocation on the TB (yellow line);anI1SF (denoted by short green lines) is then emitted on the basal plane of the twin between the sessile Frank partial dislocation and the migrating TB,the boundaries of which include sessile Frank partials on the basal plane and retained twinning dislocation on the TB.The width of the basalI1SF increases with the TB migration.(2)Enclosed basal I1 SF.The emitted basalI1SF cannot be enlarged infinitely and can be enclosed when the second basaldislocation segment in the matrix strikes the TB only on the retained twinning dislocation of the SF.(3)Formation of a

The volume fraction of the extension twin increases with an increase in the local strain,as shown in Fig.12(c).As the local strain reaches about 6%,the extension twin can occupy the whole grain,as shown in Fig.12(d).Currently,extension twinning ceases,and the whole grain gains a completely different dislocation configuration.When local strain further increases,the dominant plastic mechanism changes to the non-basal slip of

5.Conclusions

In this study,the microstructural evolution of an AZ80 extruded bar during T10 treatment (extension twinning+aging treatment) was analyzed.Extension twinning was induced by cold compression in the ED and characterized by EBSD.Dislocation configurations and precipitation behaviors were analyzed by two-beam diffraction in TEM.The conclusions are thus summarized:

(1) When as-extruded polycrystal samples are coldcompressed in the ED,extension twinning can be readily activated.In the majority of cases,several extension twins belonging to the same variant simultaneously nucleate in one grain and can merge with an increase in strain.The volume fraction of extension twins exceeds 90% when compression strain reaches its limit value of~7%.

(2) Under 1% compression strain,a typical dislocation configuration,including basalI1SFs and

(3) After the 7% strained samples undergo aging at 150 °C for 2 h,masses of basalI1SFs and

Declaration of competing interest

There is no conflict of interest.

Acknowledgments

This study is supported by Beijing Natural Science Foundation (No.2194090).We thank Ting Li and Hai-Yan Yu for their careful operation of the TEM instrument during the twobeam diffraction analysis of the dislocation configuration in extension twins and Xiao-Lei Han for his expertise in EBSD operation.

Journal of Magnesium and Alloys2023年7期

Journal of Magnesium and Alloys2023年7期

- Journal of Magnesium and Alloys的其它文章

- Recent progress in MgB2 superconducting joint technology

- “Smart” micro/nano container-based self-healing coatings on magnesium alloys: A review

- Recent advances using equal-channel angular pressing to improve the properties of biodegradable Mg–Zn alloys

- Twin evolution in cast Mg-Gd-Y alloys and its dependence on aging heat treatment

- Effects of Ce content on the modification of Mg2Si phase in Mg-5Al-2Si alloy

- Solute drag-controlled grain growth in magnesium investigated by quasi in-situ orientation mapping and level-set simulations