Experimental study on mechanical and frost heave behaviors of silty clay improved by polyvinyl alcohol and polypropylene fiber

JinKun Liu, Sergey Tsyel, XioQing Liu, Li Liu, XioKng Li, Xu Li,*

a School of Civil Engineering,Sun Yat-sen University, Zhuhai, Guangdong 519082, China

b Key Laboratory of Urban Un derground Engineering of Ministry of Education,Beijing Jiaotong University, Beijing 100044, China

Keywords: Frost heave Improved soil Subgrade fillers Polyvinyl alcohol Polypropylene fiber

ABSTRACT Silty clay is widely used as subgrade filler in cold regions, which suffer from frost heave in winter and mud pumping in spring.In this study,polyvinyl alcohol(PVA)and polypropylene(PP)fiber were used to improve the mechanical and frost heave behavior of silty clay in cold regions, and the direct shear test and one-dimensional frost heave test were employed in studying improvement effects.Moreover,improvement mechanisms of PVA and PP fiber were analyzed based on test results.The main findings are as follows.(1)Both PP and PVA can heighten the strength of silty clay and suppress frost heave, but the PVA solution has a more decisive influence on improving mechanical properties than PP fiber.(2) The improvement mechanism of the PVA solution is cementing.The improvement effect of 2% PVA solution is the best, which can increase the shear strength by approximately 40%–60% at different stress levels and decrease the frost heave ratio from 0.89% to 0.16% at optimal water content.(3) For 2% PVA improved samples, 0.25% PP fiber can further increase soil cohesion by approximately 20–30 kPa at different stress levels and further decrease the frost heave ratio from 0.16%to 0.07%at optimal water content.The improvement effect is neglectable when the PP fiber content exceeds 0.25%.Overall, 2% PVA with 0.25% PP fiber is the optimum combination to improve silty clay in cold regions.

1.Introduction

Fine-grained soil is widely used as a filling material in constructing subgrades for railways or highways, e.g., Daqin (Yang, 1989) and Shenhuang railways (Ye et al., 2015) in China.The fine-grained soil fillers with strong frost heave sensitivity often lead to frost heaven damage to the roadbed which decreases line smoothness.For example, the Shenshuo Railway subgrade in the seasonally frozen region frequently suffers severe frost heave in winter and mud pumping in spring,which seriously threatens train operation safety (Liu, 2020).Therefore, improvement of the fine-grained filler is of great significance in meeting roadbed construction and operation requirements in cold regions.

Typical soil improvement methods include chemical improvements,e.g.,stabilizing the soil through lime,cement,polymer,and geopolymer,and physical improvement, e.g., adding geosynthetics or short fibers(Santoni et al., 2002; Alazigha et al., 2016; Puppala, 2016; Hoy et al.,2017; Kua et al., 2017).In recent years, polyvinyl alcohol (PVA) and polypropylene fiber (PP fiber) have been proven suitable improvement materials(Brown et al.,2004).Babkov and Bezruk(1986)found that PVA can bind soil particles, which changes the soil skeleton structure.Mirzababaci et al.(2018) pointed out that hydrophobicity of PVA film increases water resistance and thus reduces or eliminates capillary water migration.Through laboratory tests,Krainiukov et al.(2020)proved that the shear strength of soil improved by 10%PVA solution can increase by 31%.Also,it has been confirmed that polypropylene fibers(PP fiber)can generate bonding between fiber and soil particles,and form an improved structure with higher strength characteristics(Wang et al.,2007;Ghazavi and Roustaie, 2010; Orakoglu and Liu, 2017; Kravchenko et al., 2018,2019).Besides, decreased thermal conductivity of fiber-improved soil also contributes to decreasing the frost depth of the improved subgrade and thus suppresses frost heave (Usowicz et al., 2013; Orakoglu et al.,2016;Zhang et al., 2018;Yuan et al., 2020).

Overall,previous studies have shown that PVA solution and PP fiber can increase soil strength when used alone.However, few research studies have investigated their combined improvement effect on soil's mechanical and frost-heave characteristics, which are influenced by multi factors such as water content, temperature and contents of improved materials.(Kraszewski and Rafalski, 2016; Wang et al., 2016,2021, 2023; Zheng et al., 2016; Ma et al., 2017; Lin et al., 2018; Huang et al., 2020;Miao et al.,2020;Li and Li, 2023;Li et al.,2023a,2023b).

The objective of this study is to explore the mechanical and frost heaven performance of silty clay fillers improved by polyvinyl alcohol and polypropylene fibers.In this research,individual and mixed addition of PVA and PP fiber were applied to improve silty clay.Direct shear and frost heave tests were conducted to explore the improved effect in the mechanics and frost-heave characteristics,respectively.Furthermore,the improvement mechanisms of PVA and PP fiber are analyzed,and optimal combination of improved materials is suggested.

2.Material and methods

2.1.Soil properties

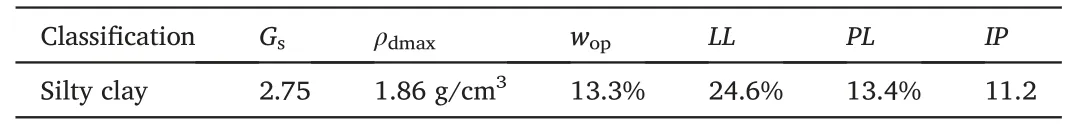

Soil materials in this study were taken from the left shoulder of the Shenshuo Railway at K223+100,with a depth of about 0.5 m.The basic physical properties are measured following the China code (CRFSDI,2011).Table 1and Fig.1 show the basic property parameters and gradation curve, respectively.The soil sample is classified as silty clay(CRFSDI,2011).

Fig.1.Gradation curve of the soil sample.

Table 1Basic properties of soil sample.

2.2.Improved materials

2.2.1.Polyvinyl alcohol (PVA) solution

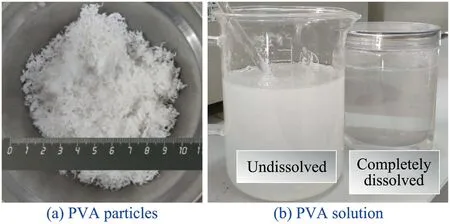

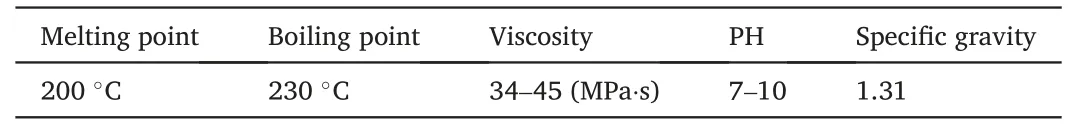

The PVA solution is composed of polyvinyl alcohol, boric acid, and water.The molecular formula of PVA is (C2H4O)n, which is a highmolecular organic compound, non-toxic and non-irritating to the skin.PVA contains many alcohol matrices with polarity and thus can form hydrogen bonds with water and is highly resistant to oil,acids,and alkali.Therefore, polyvinyl alcohol is an excellent emulsifying, bonding, and film-forming polymer with high tensile strength and flexibility.Polyvinyl alcohol is used in Fig.2a and its characteristics are presented in Table 2.

Fig.2.PVA dissolves in distilled water and boric acid.

Table 2Physical properties of PVA.

To prepare the PVA solution, (i) firstly, distilled water is heated to 80°C, at which the powdery polyvinyl alcohol has a good dissolution effect;(ii)boric acid(10%by weight of PVA)is added to water and serves as a cross-linker between water and PVA; (iii) after boric acid is uniformly distributed in water,PVA is added into water,and the solution is stirred at around 80°C until the polyvinyl alcohol completely dissolves;(iv) finally, the solution (Fig.2b) is cooled to room temperature and stored in a closed container.

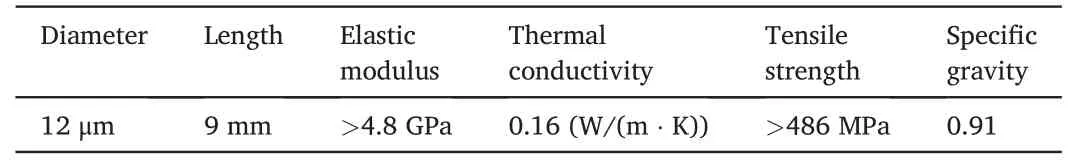

2.2.2.Polypropylene (PP) fibers

Polypropylene (PP) fibers (Fig.3) are used to reinforce test soils.Polypropylene is a waterproof material with high resistance to acids,organic solvents, alkali, and other inorganic aggressive components.They also have low moisture absorption in a wide temperature range.The physical properties of polypropylene fibers are presented in Table 3.The pre-experiment shows that 9 mm PP fiber has a good dispersion effect in the soil sample,which can strengthen the soil and avoid residual fiber on the sample surface.Therefore,9 mm PP fiber is selected as the improved material in this test.

Fig.3.Polypropylene fibers.

Table 3Physical property of PP fiber.

2.3.Test scheme

Laboratory tests were carried out to study the shear strength and antifrost heave performance of the improved soil.Further,the improvement mechanism and optimal combination for the improved soil will be discussed.

In laboratory tests, the effects of polypropylene fiber, polyvinyl alcohol,and their composite improvement on the mechanical properties of silty clay were first studied using direct shear tests.After that, onedimensional cooling-mode frost heave tests were conducted to study the influence of improved materials on frost heave characteristics of silty clay.The specific test scheme is presented in Table 4.

Table 4Test scheme.

Additionally, the anti-frost performance of improved soil under different initial water contents is also explored due to the sensitivity of frost heave to water content.According to the subgrade construction standard,the filler must be compacted at the optimal water content.On the other hand, the subgrade often bears the unfavorable working conditions of rainfall or accumulated snow.Therefore, three water content levels were set at optimal water content, saturated water content and mean value.

In Table 4,PP fiber content is defined as the ratio of fiber mass to dry soil particle mass.The fibers are sprinkled on the soil surface and mixed evenly by manual stirring.The PVA solution concentration is defined as the mass ratio of PVA to water in the solution.For example,PVA solution concentration of 2.0%means a solution containing 100 g water,2 g PVA,and 0.2 g boric acid.The initial water content means the mass ratio of pure water to soil mass.

2.4.Test apparatus

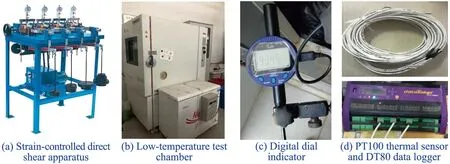

The main test apparatus include a strain-controlled direct shear apparatus, low-temperature chamber and data acquisition system, as shown in Fig.4.The pressure level of the direct shear apparatus is 50–400 kPa, and the shear speed has three levels of 0.02, 0.8 and 2.4 mm/min.The low-temperature chamber is used to control frost temperature.Temperature control ranged from 180°C to -40°C, and temperature fluctuation is less than 0.5°C.The data acquisition system includes a PT100 thermal sensor (measuring range from -50°C to 500°C and accuracy of 0.15°C),a digital dial indicator(measuring range of 0–25.4 mm and accuracy of 0.01 mm),and a DT80 data logger.

Fig.4.Test apparatus.

2.5.Test procedure

The preparation process of PVA-PP fiber improved soil materials is as follows.First, the dry soil was wetted with PVA solution to the target water content.Then,PP fiber was evenly mixed in the wet soil with the required mass content.Finally, the prepared sample was stored in a sealed bag for 24 h to evenly distribute the moisture.

The soil sample was prepared by the layered compaction method.According to China's codes for railway subgrade design(TB 10001-2016;TB 10625-2017), the compaction coefficient for the fined-grained filler should be higher than 0.93, so the compaction coefficient is selected as 0.95,and the corresponding dry density is 1.77 g/cm3.

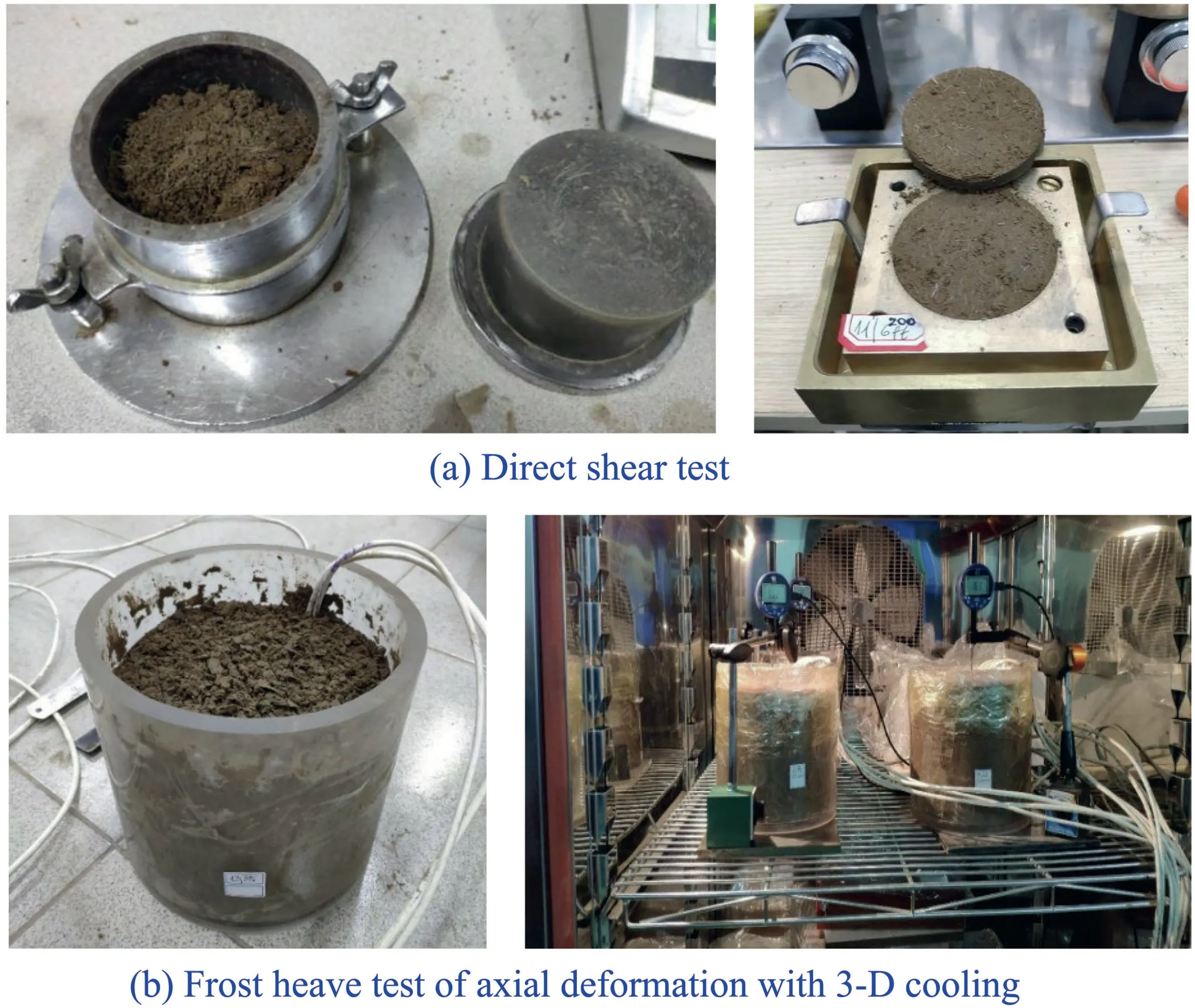

The direct shear test is carried out at room temperature by the“Code for Soil Test of Railway Engineering”(CRFSDI,2016).The specimen size of the direct shear test is 61.8 mm in diameter and 20 mm in height.The vertical pressure is chosen as 100,200,and 300 kPa.The quick shear is used to determine soil shear strength to shorten the test cycle.According to CRFSDI 2016,the shear rate of the quick shear test is 0.8–1.2 mm/min.Therefore,the shear rate was set as 0.8 mm/min,and the test stops when the shear deformation reaches 6 mm(as shown in Fig.5a).

Fig.5.Test procedure.

In the frost heave test, the soil sample is filled into a mold with a height of 18 cm and a diameter of 18 cm(shown in Fig.5b).The specimens were prepared by three-layer compaction.The selected compaction coefficient is 0.92 and corresponds to a dry density of 1.71 g/cm3.The specimens were kept at room temperature before freezing and then placed in a low-temperature chamber.According to Xu et al.(2001),with the decrease of temperature, the unfrozen water content of the closed sample has an insignificant change when the temperature is lower than-8°C,resulting in gentle frost heave.Therefore,freezing temperature of the test sample is set as-8°C.In the frost heave test,the temperature was maintained at-8°C and lasted for 24 h.

3.Test results

3.1.Mechanical property of soil improved by PVA solution and PP fiber

3.1.1.Stress-strain curves of natural soil and improved soil

Typical stress-strain curves of the natural soil and improved soil are presented in Fig.6.Fig.6 demonstrates that after improvement, the stress-strain curves of soils transfer from hardening to softening.That is to say,softening behavior is evident for the improved soil,while it is not prominent for the natural soil.

Fig.6.Typical stress-strain curves of natural and improved silty clay.

3.1.2.The effect of separate improvement on the shear strength

Fig.7a shows the shear strength results of single improved soil by the PVA solution.At each vertical pressure, the strength of improved soil is higher than that of natural soil, and soil improved by 2% PVA solution has the highest shear strength.When the concentration of PVA solution exceeds 2%, the improved soil's shear strength decreases.Overall,compared with natural soil, the shear strength of soil improved by 2%PVA solution increases by approximately 40%–60% under different vertical stress.

Fig.7b demonstrates the shear strength of soil improved by polypropylene fiber (PP).Shear strength generally increases with increased PP content.In particular,the shear strength of samples with 0.75%fiber is 17.5%higher than that of specimens without fiber.However,when the fiber content exceeds 0.75%,the improvement effect of PP fiber on shear strength is insignificant.

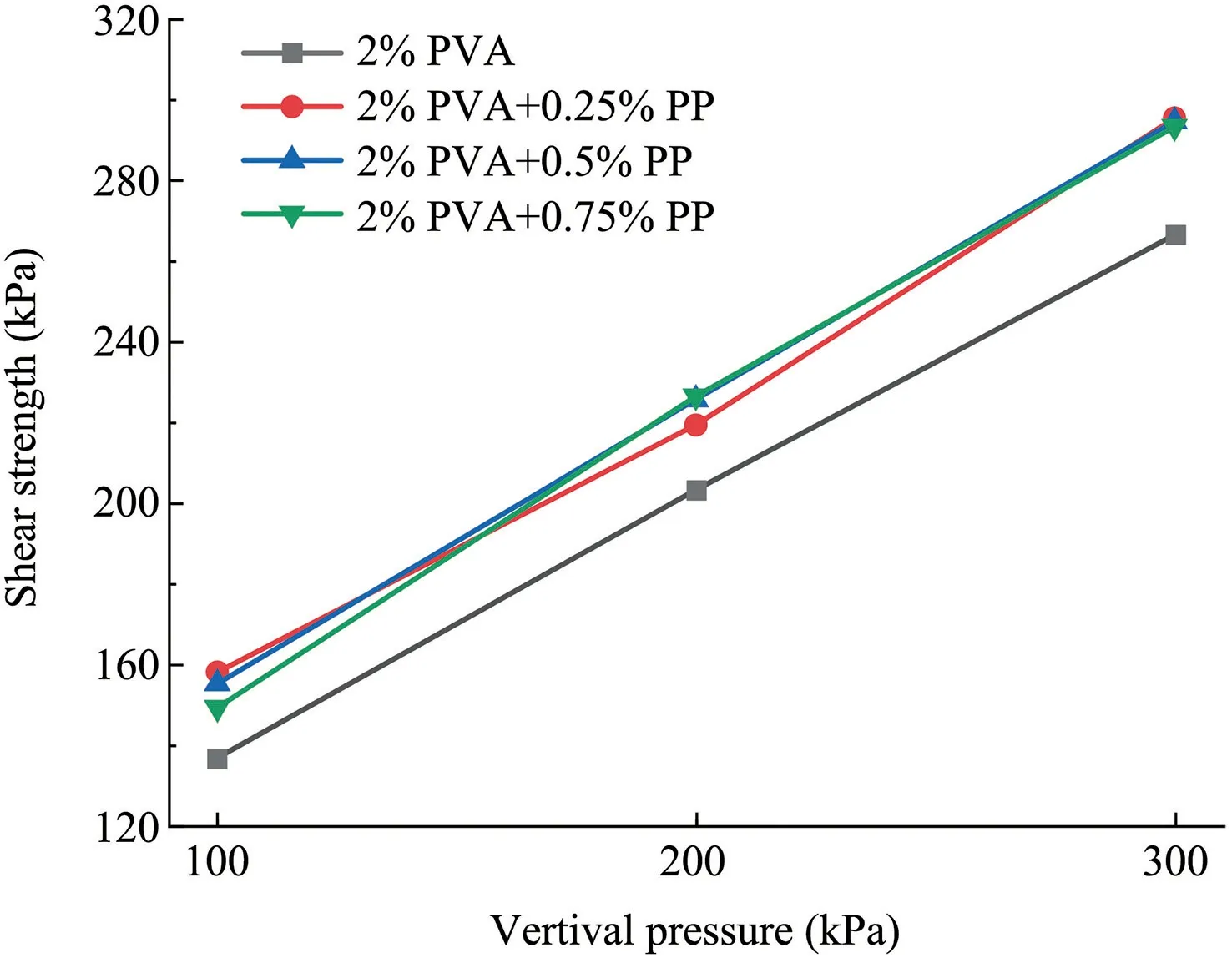

3.1.3.The effect of comprehensive improvement on shear strength

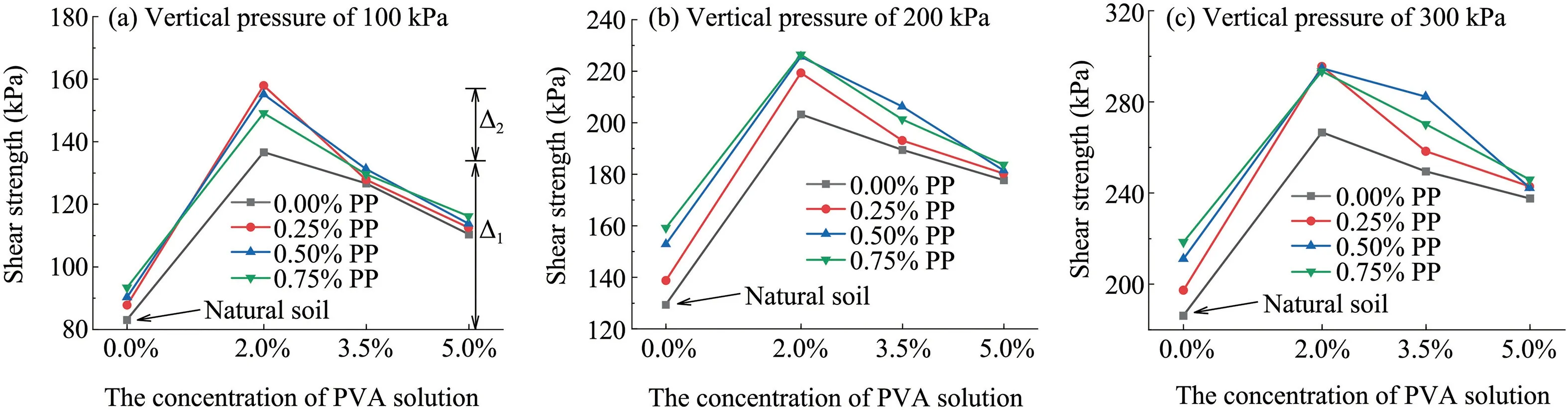

Fig.8 shows the increase of shear strength with PVA solution concentration under different polypropylene fiber(PP)contents at each level of vertical pressure.

Fig.8.Shear strength of comprehensively improved soil.

According to Fig.8, after comprehensive improvement with PP and PVA,the shear strength of soil increases.When PVA concentration is 2%,the shear strength of the comprehensively improved soil is the highest.The shear strength difference between soil singly improved by PVA solution and natural soil is defined as the improved performance of PVA(Δ1), and the shear strength difference between the comprehensively improved soil and the PVA-improved soil is defined as the improved performance of PP (Δ2).The Δ1is larger than Δ2in Fig.8, which indicates that the PVA solution is better than polypropylene fiber in improving soil strength.

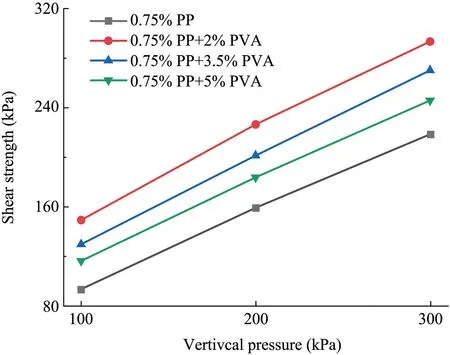

Taking 0.75%PP fiber as an example,the influence of vertical stress on the shear strength of soil under different PVA concentrations is summarized in Fig.9.It can be demonstrated that PVA concentration has a significant influence on soil strength, and the relations between shearing strength and vertical pressure show a characteristic of the Mohr-Coulomb strength criterion,which can be represented as Equation(1)

Fig.9.Effect of PVA solution concentration on shear strength of soil with 0.75% fiber.

where τ is shear strength (kPa), σ is vertical pressure (kPa), φ is the internal friction angle(°),and c is cohesion(kPa).

In Fig.9, the strength lines of improved soil with different PVA concentrations are almost parallel, indicating that the slopes (i.e., internal friction angle) are close.The strength line intercept (i.e., cohesion)changes with the PVA solution's concentration, and the highest concentration is 2%.This indicates that the improvement mechanism of the PVA solution is enhancing the cohesion.

Fig.10 shows the influence of PP content on the shear strength of silty clay improved by a 2%PVA solution.With the addition of fiber,the soil strength increases slightly.However, when the fiber content exceeds 0.25%, the increase of fiber content has a minimal effect on improving shear strength.For 2% PVA improved samples, 0.25% PP fiber can increase the cohesion of the soil by about 20–30 kPa at different vertical stress.Like the PVA solution, the strength envelopes of improved soil with different fiber contents are almost parallel, indicating that the internal friction angles are equal.The intercepts of the strength envelope(i.e.,cohesion)increase with the addition of PP fiber.As a result,it can be concluded that the increment of cohesion is mainly caused by adhesion between fiber and soil particles.

Fig.10.Effect of different fiber content on shear strength of soil with 2%PVA.

3.2.Frost heave resistance of soil improved by PVA solution and PP fiber

3.2.1.The result of the frost heave test

The frost heave test is conducted in a closed system;that is,external water is not supplied to the soil during the freezing process.The temperature and axial deformation of specimens are monitored by the thermal sensor at the sample center and the dial gauge at the top sample surface, respectively.The frost heave ratio signifies the percentage of axial frost heave to initial height.The one-dimensional cooling frost heave test is carried out to study the influence of the initial moisture content and improved materials on the soil's frost characteristics.Temperature and frost heave ratio changes of each sample are summarized in Fig.11.

Fig.11.Temperature and frost heave ratio with time.

According to Fig.11, before the temperature reduces to the supercooling temperature, the phase change of water in soil does not occur.After the temperature is below supercooling temperature,the water undergoes a violent phase change.Soil temperature rapidly increases to the freezing point, and the specimen begins to heave.When the soil temperature approaches ambient temperature (-8°C), free water in soil is insufficient,and frost heave tends to be stable.

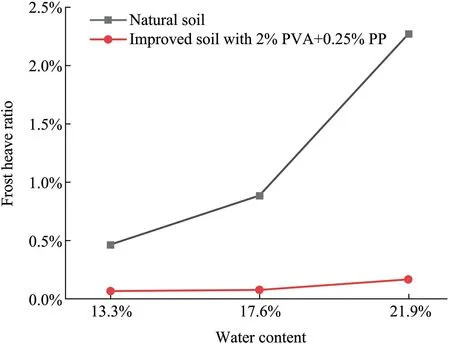

3.2.2.Effect of water content on frost heave

Based on the results in Fig.11, the relationship between the frost heave ratio and water content can be obtained after the frost heave test,as shown in Fig.12.It can be seen that water content significantly influences the frost heave ratio of natural soil.With water content increasing from 13.3% to 21.9%, the frost heave ratio increases from 0.46% to 2.27%.In contrast, amplification is smaller for improved soil.Although the frost heave ratio increases with water content, the frost heave ratio remains less than 0.2%.

Fig.12.Frost heave ratio of natural soil and improved soil changing with water content.

3.2.3.Effect of improved materials on frost heave

Fig.13 shows the effect of improved materials on the frost heave ratio specimens.It can be seen from Fig.13a that frost heave of the sample decreases with an increase of PVA solution concentration.Specifically,compared with natural soil at the optimal water content,the frost ratio is reduced from 0.89% to 0.16% when the PVA solution concentration reaches 2%.Subsequently,it can be demonstrated from Fig.13b that the frost heave of specimens decreases significantly with an increase of fiber content.When 0.25%fiber is added,the frost heave further decreases to 0.07%.The subsequent decrease of frost heave with increasing fiber content is neglectable.Therefore,the comprehensive improvement of 2%PVA and 0.25% PP fiber has the optimal frost heave resistance,decreasing soil frost heave ratio from 0.89% to 0.07% at optimal water content.

Fig.13.The effect of PVA solution concentration and PP fiber content on the frost heave ratio (w = 17.6).

4.Discussions

4.1.Strength improvement mechanism

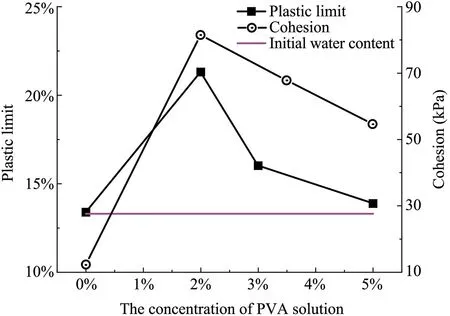

4.1.1.Cohesion

The plastic limit test was conducted to analyze the improvement mechanism of the PVA solution,and cohesions were calculated based on the shear strength test results, as presented in Fig.14.

Fig.14.The plastic limit and shear strength of the soil improved by PVA solution.

According to Fig.14,when the PVA concentration is lower than 2%,the plastic limit of improved soil increases with the PVA solution concentration.Therefore, with an increase of the PVA solution concentration,improved soil gradually changes from a plastic state to a semi-solid state under constant water content.In this process, the complex film attracts free water and transfers it into bound water, increasing soil cohesion.After PVA solution concentration exceeds 2%,the plastic limit decreases.That is to say, with the further increase of PVA solution concentration, the improved soil turns back to a plastic state.Besides, with the increase of PVA solution concentration, the lubrication between particles is improved.Thus the stability and cohesion of improved soil are reduced(Xu et al., 2001).

The PVA solution complex has strong viscosity, which binds the soil particles together and forms a large aggregate.These aggregates make the soil more cohesive and withstand the stresses at the soil frame interface.Thus,the shear strength of improved soil is greater than that of natural soil.There is a consensus on the improvement mechanism of PP fiber.SEM results show that polypropylene fiber's surface is uneven and closely contacted with soil particles (Kravchenko et al., 2018, 2019).Polypropylene fiber plays a role in reinforcement and finally improves soil shear strength(Abdi et al.,2008;Roustaei et al.,2015;Orakoglu et al.,2017;Mirzababaei et al., 2018).

4.1.2.Internal friction angle

Fig.9 indicates that the shear strength lines of improved soil with different PVA concentrations are almost parallel.The internal friction angle of improved soils under different PVA concentrations is close.Additionally,strength envelopes in Fig.10 show similar results such that the change of PP content has an insignificant effect on internal friction angle.

In summary, the strengthening mechanism of PVA solution and PP fiber is mainly to enhance cohesion rather than the internal friction angle.This is consistent with test results of Krainiukov et al.(2020).This can be explained by the cementing and reinforcement mechanism of PVA solution and PP fiber.PVA crystal enters the soil and binds particles,and PP fiber reinforces soil by tensile strength.Both mechanisms rarely involve the mutual movement and occlusion between particles, represented as the internal friction angle.Therefore,the internal friction angle changed a little before and after improvement.

4.1.3.Limitations of this study

This study investigated the mechanical performance of improved soil at room temperature.However, the direct shear test of improved soil under negative temperature is closer to the cold region background and thus has more significant engineering values.Due to the limitation of test equipment and space, we did not carry out the direct shear test at negative temperature, which is unfortunate.In a follow-up study, we intend to conduct the direct shear test in a particular low-temperature cabin to investigate the shear strength characteristics of various subgrade soils improved by PVA and PP fiber.

4.2.Anti-frost heave mechanisms

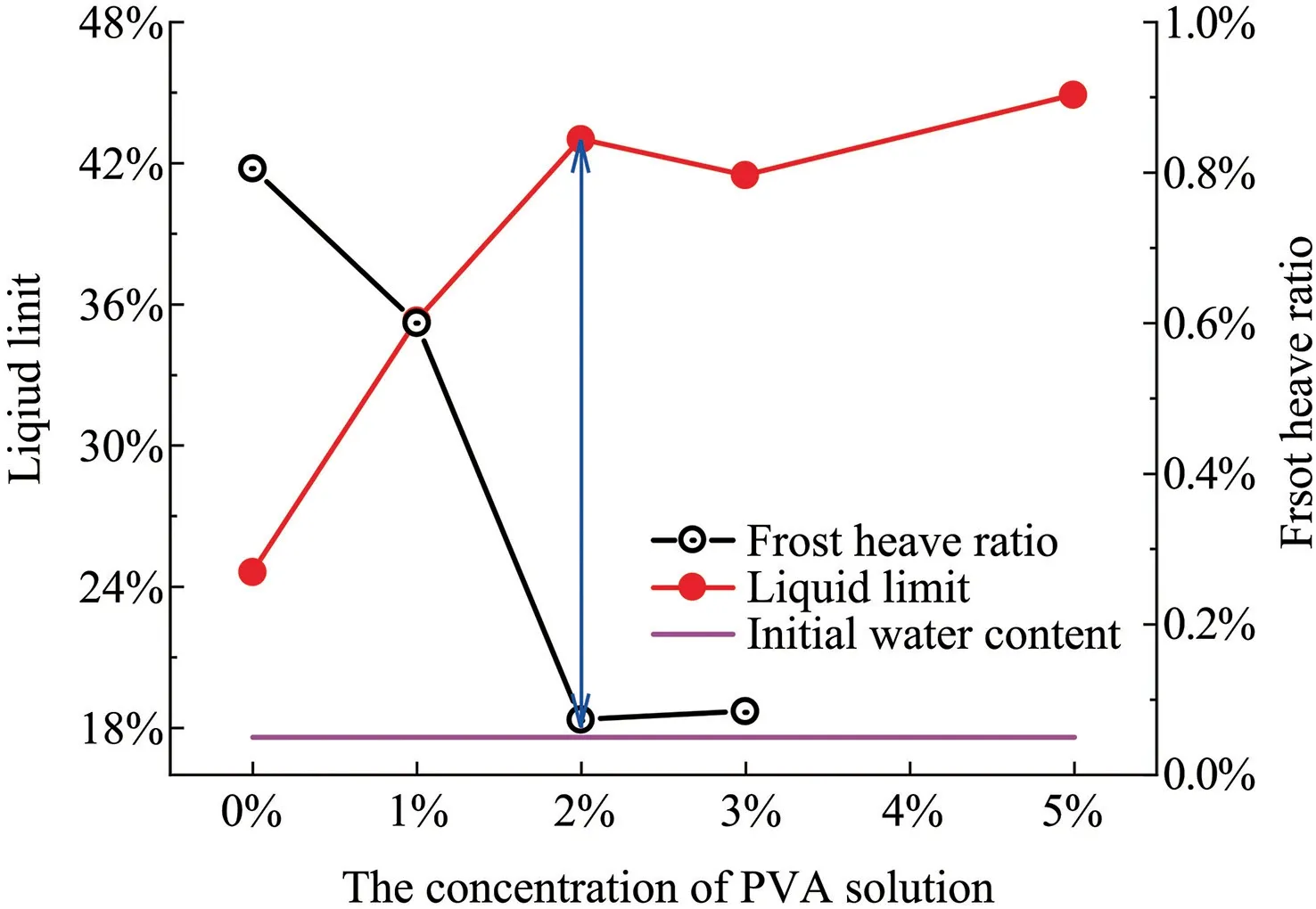

Upon cooling, free water and loosely bound water will freeze into ice.The formation of pore-ice crystals will destroy the soil fabric and cause frost heave deformation.Our test results indicate that the improved materials eliminate frost heave of the soil sample,in which the PVA solution plays a significant role.In this section,the liquid limit test were conducted to analyze the improvement mechanism.

Fig.15 shows the frost heave ratio and liquid limit of the improved soil.According to Fig.15,the liquid limit of the specimen increases after improvement.In particular, the liquid limit increases with the PVA concentration when it is less than 2%.After that,the liquid limit remains stable.Correspondingly,the frost heave ratio of improved soil decreases rapidly when the PVA concentration is lower than 2% and stabilizes when higher than 2%.

Fig.15.Liquid limit and frost heave ratio improved by 0.25% PP fiber and PVA solution.

The complex,formed by the PVA solution,transforms free water into bound water whose phase does not change during the freezing process,thus significantly reducing pore ice generation.The PVA solution forms a hydrophobic film on the soil particle surface(Bezruk,1971;Babkov and Bezruk, 1986), which can restrict water migration to the frozen fringe and inhibit the growth of pore ice.The complex formed by the PVA solution connects soil particles and improves the cohesion of improved soil,which can counteract the frost heave force caused by ice crystals and restrain frost heave deformation.In conclusion, the combined action dramatically improved the frost heave resistance of PVA improved soil.

Polypropylene fibers play a reinforcing role in improved soil,i.e.,the increase of soil tensile strength.Compared with natural soil,the volume force produced by segregation ice during the freezing process needs to be greater than the tensile strength of fiber-improved soil before the soil undergoes frost heave deformation.That is to say,when the frost-heave force is less than the tensile strength of improved soil, the frost-heave expansion force generated at the particle joint is offset by the tensile force of the fiber, avoiding the destruction of soil structure and restraining soil deformation (Abdi et al., 2008; Roustaei et al., 2015;Orakoglu et al., 2017).

4.3.Suggestions for improvement

The direct shear test shows that 2% PVA solution and 0.75% fiber lead to maximum strength under a single improvement method.However, the strength shows an insignificant increase with PP fiber content when the content reaches 0.25% in comprehensive improvement.Although PVA solution plays a significant role in strength improvement, the anti-freeze ability of fibers is also essential.The frost heave test results show that 2%PVA solution combined with 0.25%fiber content has the lowest frost heaven ratio.Therefore, 2% PVA solution and 0.25%polypropylene fiber to improve silty clay is suggested as the optimal improvement method.With this comprehensive improvement,improved soil has a slight frost heave ratio and high strength, so it is a better subgrade filler.

5.Conclusions

In this study,individual and mixed addition of PVA and PP fiber are applied to the improvement of silty clay.The improvement effect in the mechanics and frost-heave characteristics has been explored by the direct shear and frost heave test, respectively.Furthermore, the improvement mechanisms of PVA and PP fiber are analyzed, and the optimal combination of improved materials is suggested.The main conclusions are as follows:

(1) Both PP and PVA can heighten the strength of silty soil and suppress frost heave, but the PVA solution has a more decisive influence on improving mechanical properties than PP fiber.

(2) The improvement mechanism of the PVA solution is cementing.The improvement effect of the 2%PVA solution is the best,which can increase the shear strength by approximately 40%–60% at different stress levels and decrease the frost heave ratio from 0.89%to 0.16%at the optimal water content.

(3) The improvement mechanism of PP fiber is reinforcement.For 2%PVA improved samples, 0.25% PP fiber can further increase soil cohesion by approximately 20–30 kPa at different stress levels and further decrease the frost heave ratio from 0.16% to 0.07% at optimal water content.The improvement effect is neglectable when the PP fiber content exceeds 0.25%.

(4) Overall,2%PVA and 0.25%PP fiber is the optimum combination to improve silty clay in cold regions.

Acknowledgments

This research was supported by the National Natural Science Foundation of China(41731281;42071078),the National Key Basic Research Program of China (No.2012CB026104) and Science and Technology Project of Qinghai,China(2021-GX-121).

Sciences in Cold and Arid Regions2023年2期

Sciences in Cold and Arid Regions2023年2期

- Sciences in Cold and Arid Regions的其它文章

- Editor-in-Chief Yuanming Lai

- Temporal and spatial variation of cloud cover in arid regions of Central Asia in the last 40 years

- Parameter sensitivity analysis for a biochemically-based photosynthesis model

- Ecosystem changes revealed by land cover in the three-river headwaters region of Qinghai, China (1990–2015)

- Relationships between modern pollen and vegetation and climate on the eastern Tibetan Plateau

- Long-term feeding of sand rice (Agriophyllum squarrosum seed) can improve the antioxidant capacity of mice