Compressibility characteristics of bio-cemented calcareous sand treated through the bio-stimulation approach

Yijie Wng ,Ningjun Jing,* ,Alexnr Clrà Srho ,Ogul Doygun ,Ynjun Du ,Xiole Hn

a Institute of Geotechnical Engineering,Southeast University,Nanjing,China

b Department of Civil and Environmental Engineering,University of Hawaii at Manoa,Honolulu,USA

c Department of Engineering,Cambridge University,Cambridge,UK

d Geosyntec Consultants,Inc.,Huntington Beach,USA

Keywords:Calcareous sand Bio-cementation Bio-stimulation Compressibility

ABSTRACT Calcareous sand is widely present in coastal areas around the world and is usually considered as a weak and unstable material due to its high compressibility and low strength.Microbial-induced calcium carbonate precipitation (MICP) is a promising technique for soil improvement.However,the commonly adopted bio-augmented MICP approach is in general less compatible with the natural soil environment.Thus,this study focuses on the bio-stimulated MICP approach,which is likely to enhance the dominance of ureolytic bacteria for longer period and thus is deemed more efficient.The main objective of this paper is to investigate the compressibility of calcareous sand treated by bio-stimulated MICP approach.In the current study,a series of one-dimension compression tests was conducted on bio-cemented sand prepared via bio-stimulation with different initial relative densities(Dr).Based on the obtained compression curves and particle size distribution (PSD) curves,the parameters including cementation content,the coefficient of compressibility (av),PSD,relative breakage (Br),and relative agglomeration (Ar) were discussed.The results showed that av decreased with the increasing cementation content.The biocemented sand prepared with higher initial Dr had smaller (approximately 20%-70%) av values than that with lower initial Dr.The specimen with higher initial Dr and higher cementation content resulted in smaller Br but larger Ar.Finally,a conceptual framework featuring multiple contact and damage modes was proposed.

1.Introduction

The biogenic fraction of calcium carbonate(CaCO3)in calcareous sediments is primarily composed of skeletons of reef-dwelling creatures.Because of the potential foundation problems associated with calcareous soil sediments,such as large settlement and low bearing capacity,understanding the behavior of calcareous soils has drawn great attention among the geotechnical community(Poulos and Chua,1985;Dyson and Randolph,2001;Wang et al.,2011).Calcareous sand is normally widespread along the coastlines in tropical regions and many port facilities located in these regions enhance the necessity of research into its engineering properties,as calcareous sand often serves as foundation and backfill materials.However,the plastic deformation of calcareous sand often results in substantial ground settlement (Wang et al.,2011).Thus,it is important to understand the compressibility behavior of calcareous sand in coastal regions so that appropriate measures can be taken to mitigate the large settlement induced by this sand.

Over the past decade,the compressibility and associated particle breakage behaviors of calcareous sand have been extensively investigated via a variety of testing methods,such as onedimensional (1D) compression test (Altuhafi and Coop,2011;Xiao et al.,2020a,b),consolidated undrained or drained triaxial test(Dehnavi et al.,2010;Shahnazari and Rezvani,2013),and impact loading test (Xiao et al.,2018;Lv et al.,2020).It is found that calcareous sand is more compressible and can be crushed more easily than silica sand due to its higher internal porosity (Coop et al.,2004;Lv et al.,2019;Xiao et al.,2019,2020b).The factors influencing compressibility and particle breakage behaviors of calcareous sand mainly include soil gradation(Wang et al.,2020a),particle shape(Wei et al.,2020),grain size (Liu et al.,2020),initial density (Shahnazari and Rezvani,2013;Xiao et al.,2017),external loading (Shahnazari and Rezvani,2013;Xiao et al.,2020b),and carbonate content(Bryant et al.,1974).Considering that calcareous sand is widely used as foundation or backfill materials in coastal regions,it becomes more and more urgent to implement suitable ground improvement methods to reduce its compressibility.

Recently,microbial-induced calcium carbonate precipitation(MICP) has become a promising technique for granular soil improvement (Martinez et al.,2013;Liu et al.,2021;Jiang et al.,2022).Ureolysis is one of the most common processes to achieve MICP.The microbial urease involves in the bio-cementation process by hydrolyzing urea into ammonium and carbonate ions.When free calcium ions are available,the calcium carbonate precipitation is generated and serves as a cementing agent to bridge adjacent sand particles.The most common approach to implement MICP is through bio-augmentation,in which exogenous ureolytic bacterial solution is injected into soil matrix,followed by the cementation solution injection (Cheng et al.,2014,2019;Jiang and Soga,2017;Jiang et al.,2019).While bio-augmentation in general is likely to achieve higher ureolytic activity,the injected bacteria are normally less competitive compared with existing native bacteria and thus their abundance is likely to diminish quickly (Graddy et al.,2018).On the other hand,the bio-stimulation approach,in which indigenous ureolytic bacteria in soil are selectively enriched by providing appropriate nutrient media,is likely to enhance the dominance of ureolytic bacteria for longer period and thus is deemed more efficient to achieve MICP (Gat et al.,2016;Gomez et al.,2017,2018;Wang et al.,2020b).

Since MICP,either via bio-augmentation or bio-stimulation,could cement loose sand particles,it could be used for reducing the compressibility of calcareous sand.Currently,only a few studies have been conducted to examine the compressibility behavior of bio-cemented sand.These studies mostly focus on silica sand treated through bio-augmented MICP.For instance,Xiao et al.(2020a) conducted 1D compression tests on bio-augmented MICP-treated silica sand at varying cementation levels.The results indicated that bio-augmented MICP treatment could effectively restrain particle breakage,and thus reduce the compressibility of silica sand.Xiao et al.(2021) investigated the effect of gradation on the compression behaviors of bio-cemented silica sands by bio-augmentation MICP.The results revealed that the compressibility of specimens increased with increasing coefficient of uniformity.Arboleda-Monsalve et al.(2019) studied the compressibility behavior of bio-cemented loose silica sands.They pointed out that the MICP treatment was suitable for vertical effective stress levels below 200 kPa.Lin et al.(2016) conducted confined compression tests on two MICP-treated silica sands.It was found that the compressibility of the treated soil specimens decreased as the CaCO3content increased.Cardoso et al.(2016)conducted confined compressibility tests on MICP-treated sands,and they found that the compressibility index was very similar between the MICP-treated and untreated sands though the reduction of porosity was obvious.To the authors’knowledge,there have not been any reported studies on the compressibility behaviors of bio-stimulated MICP-treated calcareous sand.

The objective of this study is to investigate the compressibility behavior of calcareous sand treated via the bio-stimulated MICP approach.A series of 1D compression tests was conducted to obtain the compressibility of bio-cemented calcareous sand,which was manifested by the compression curves and particle size distribution(PSD)curves.Then,the relevant parameters including cementation content (CC),the coefficient of compressibility (av),relative breakage(Br),and relative agglomeration(Ar)of the bio-cemented sand based on the method proposed by Hardin (1985) were discussed.

2.Materials and methods

2.1.Calcareous sand

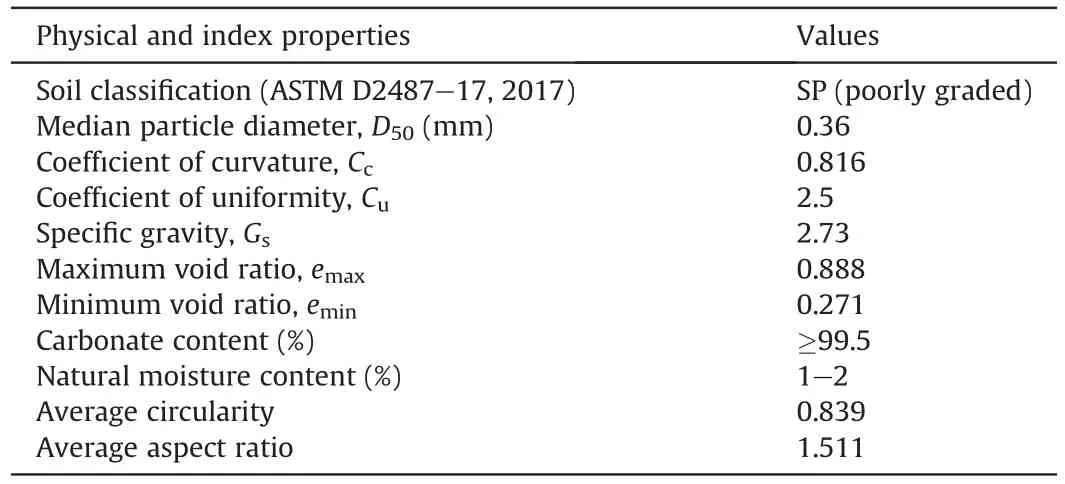

The calcareous sand used in this study was sampled from the shallow surface of Waikiki Beach,Oahu Island,Hawaii,USA.After taken to the laboratory,the sand was firstly sieved through US No.10 sieve(2 mm opening size)to remove oversized grains as well as twigs and grass.The basic physical properties of the post-sieving calcareous sand are listed in Table 1.

2.2.Enrichment and cementation solutions

Two enrichment media were developed in this study to enrich native ureolytic bacteria in the collected calcareous sand.The first one,named YE,contained 20 g/L yeast extract plus urea and the second one,named NB,contained 20 g/L nutrient broth plus urea.Yeast extract and nutrient broth are both organic nutrients containing sufficient proteins and amino acids to facilitate the growth of bacteria.Besides,urea was added as a selective ingredient for the stimulation of ureolytic bacteria and elimination of non-ureolytic ones.The urea concentration used in the enrichment media was 0.17 mol/L (~10 g/L).The cementation solution consisted of equal mole concentration(0.3 mol/L or 0.5 mol/L)of urea and CaCl2plus 0.2 g/L yeast extract or nutrient broth accordingly.The purpose of adding trace amount of yeast extract or nutrient broth was to supply further nutrients to maintain the bacterial viability at the cementation stage.

2.3.Procedures for bio-stimulated MICP treatment

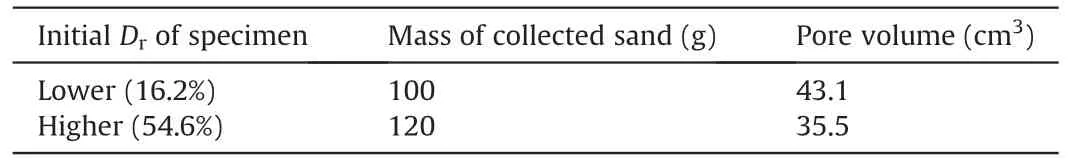

The bio-stimulated MICP treatment consisted of two stages:enrichment and cementation.Specimens were prepared using brass rings with height of 2.54 cm and inner diameter of 6.35 cm.Firstly,fresh calcareous sand was thoroughly mixed with 0.5 pore volume (PV) of either the YE or NB medium.Then,the moist sand was compacted in the brass ring to achieve two initial relative densities(16.2%and 54.6%).The detailed specifications of prepared specimens during bio-stimulated MICP treatment are presented in Table 2.After that,all specimens were left at room temperature and humidity for 48 h,which were found in previous study to be able to enrich sufficient amount of native urease-positive bacteria (Wang et al.,2020b).After the completion of the enrichment stage,the cementation solution was flushed through specimens via surface percolation once per day for consecutive 5 d or 10 d at a relativelysmall flow rate (2 mL/min) to avoid noticeable disturbance.The flow rate was controlled by a calibrated valve which was connected to the bottom of the solution container.The volume of flushed cementation solution each time was 1.5 PVs of the respective sand specimen.During the enrichment and cementation phases,all specimens were treated without any vertical stress.Upon the completion of the cementation stage,the specimens were flushed using 3 PVs of deionized water for 5 times to remove residual dissolved salts and then oven-dried at 105ºC for 24 h.It should be mentioned that to obtain sufficient cementation content,the amount of cementation solution in this study was excessive,which might cause a waste.The further study towards the efficiency of Ca source utilization is necessary.

Table 1 The physical and index properties of the collected calcareous sand after sieving.

Table 2 The specifications of prepared specimens during bio-stimulated MICP treatment.

2.4.Microbial community analysis of bio-stimulated specimens

Themicrobialcommunitypresentintheporefluidbeforeandafter the enrichment stage was determined by 16S metagenomic sequencing.The additional three soil specimens (i.e.untreated,YEtreated,and NB-treated) were made for the analysis.The deoxyribonucleic acid (DNA) was extracted from 1 g moisture soil specimens using Omega®Soil DNA Extraction Kit.The total extracted DNA concentrations were 0.43 ng/μL,10.13 ng/μL,and 5.99 ng/μL for untreated,YE-treated,and NB-treated specimens,respectively,measured with Quant-iT PicoGreen.Triplicate 16S V3-V4 amplicons for high-throughput analysis were generated using the primers(forward primer=5′TCGTCGGCAGCGTCAGAT GTGTATAAGAGACAGCCTACGGGNGGCWGCAG;and reverse primer=5′GTCTCGT GGGCTCGGAGATGTGTATAAGAGACAGGACTACHVGGGTATCTAATCC).

2.5.1D compression test

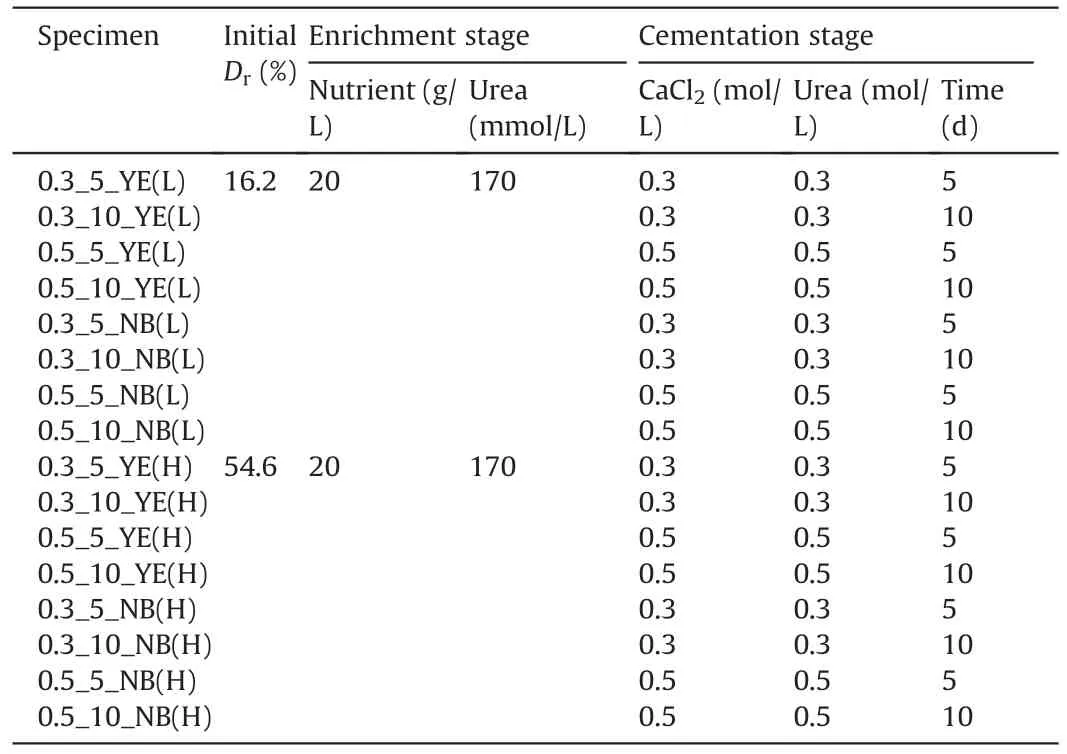

The 1D compression test was conducted using Geocomp®LoadTrac-II incremental consolidation system.The incremental loading from 12.5 kPa to 6400 kPa and unloading from 6400 kPa to 25 kPa were conducted and the deformation of specimen was recorded continuously for each loading and unloading sequence.Each loading/unloading step lasted for 24 h in the current study.All specimens were saturated prior to the compression test.The detailed experimental program of the 1D compression test is shown in Table 3.The designation “a_b_c(d)” represents the biocemented specimens treated withbflushes (d) ofamol/L cementation solution,cis the nutrient type(YE or NB),anddis the initialDrlevel (L representing low (16.2%),and H representing high(54.6%)).

Table 3 Experimental program of the 1D compression test.

2.6.Cementation content measurement

The cementation content(CC)was determined by measuring the increased mass of sand specimens after bio-stimulated MICP treatment and it could be expressed as

wherembtis the dry mass of sand prior to MICP treatment,andmatis the dry mass of sand after MICP treatment.

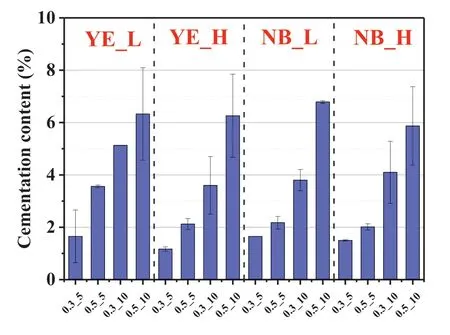

Fig.1.The cementation contents of bio-cemented specimens with varying treatment scheme and initial Dr.YE-Yeast extract,NB-Nutrient broth,L-Low initial Dr;HHigh initial Dr;0.3/0.5 -Concentration of cementation solution (mol/L);5/10 -Duration of cementation stage (d).

2.7.Sieve analysis

To assess the breakage properties of bio-cemented specimens,the mechanical sieve analysis was conducted based on ASTM D422-63(27)e2 (2007) after the 1D compression test.The opening size (D) designation of sieves used was 0.075 mm,0.106 mm,0.15 mm,0.18 mm,0.25 mm,0.425 mm,0.85 mm,2 mm and 12.5 mm in this study.

2.8.Microstructural observations and crystalline phase analysis

To characterize the microstructural features of the biocemented calcareous sand,optical microscopy imaging was performed using a Nikon SMZ1500 stereo microscope equipped with lenses providing a magnification in the range between 3.75 and 540.

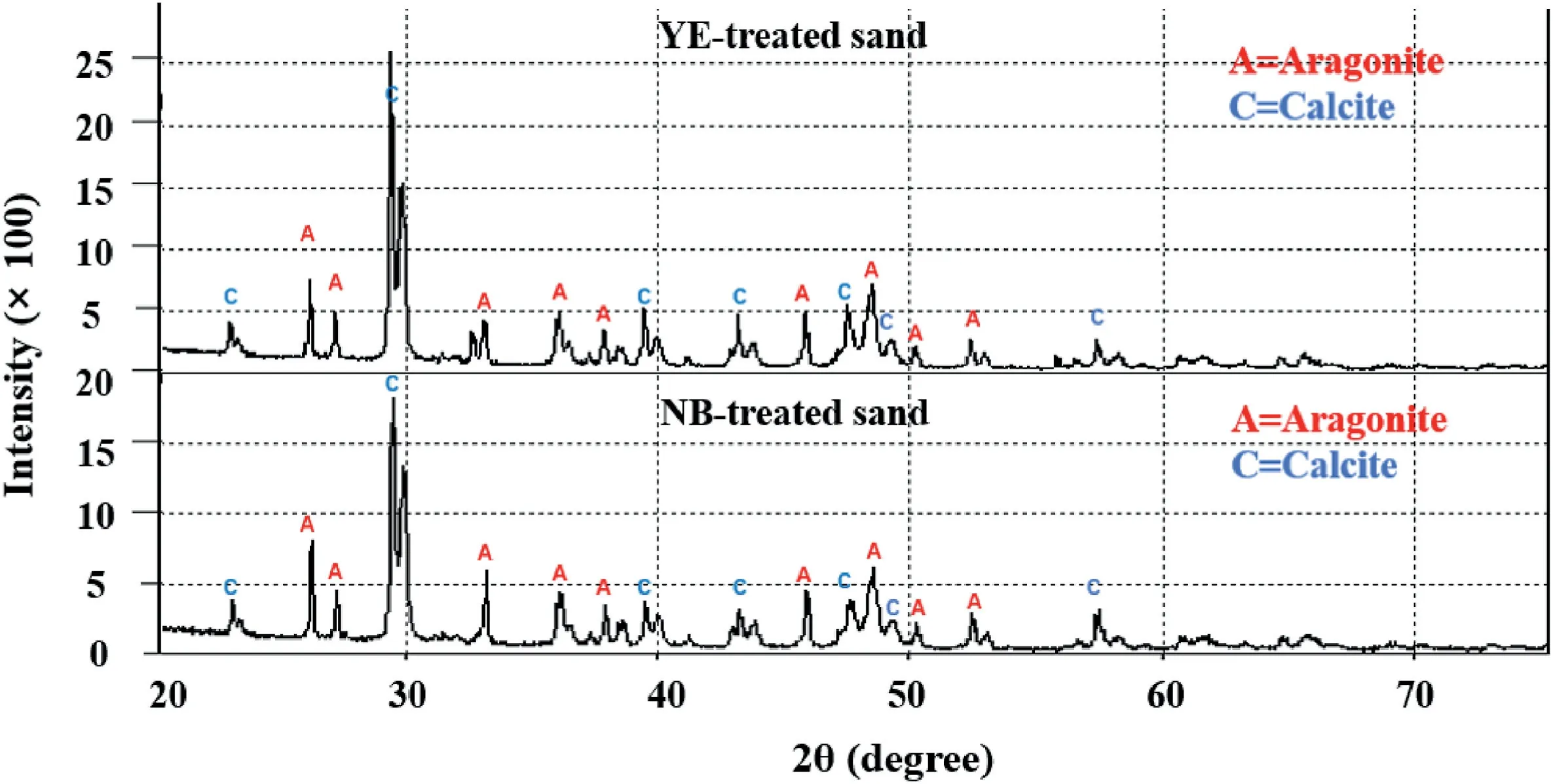

X-ray diffraction (XRD) analysis was conducted in this study to determine elemental composition and crystalline phase of precipitated specimens after bio-stimulated MICP process.The dry specimens (i.e.YE-and NB-treated sands) treated after 10-d cementation stage prepared under 54.6% initial relative density were included for XRD analysis.The XRD spectra were obtained using X-ray diffractometer to scan the fine-powdered specimens from 20ºto 75ºof 2θ.

3.Testing results and data interpretation

3.1.Cementation content and microbial community analysis

The cementation content of bio-cemented sand is one of the most important indices which reflects the overall efficiency of MICP treatment.Fig.1 shows the cementation content of bio-cemented calcareous sand subjected to varying treatment schemes.The measured cementation content for all specimens ranged from 1%to 6.8%.More specifically,for a given enrichment medium and initialDr,higher concentration of cementation solution (0.5 mol/L) and more treatment flushes (10 d) led to higher cementation content.Additionally,provided other same conditions,cementation content was found to be slightly higher in low initialDrspecimens in 7 out of 8 cases.The above observation,on one hand,was due to the less pore volume in the sand specimens with higher initialDrand on the other hand,due to the decreasing net surface area(Tsukamoto and Oda,2013;Rowshanbakht et al.,2016).

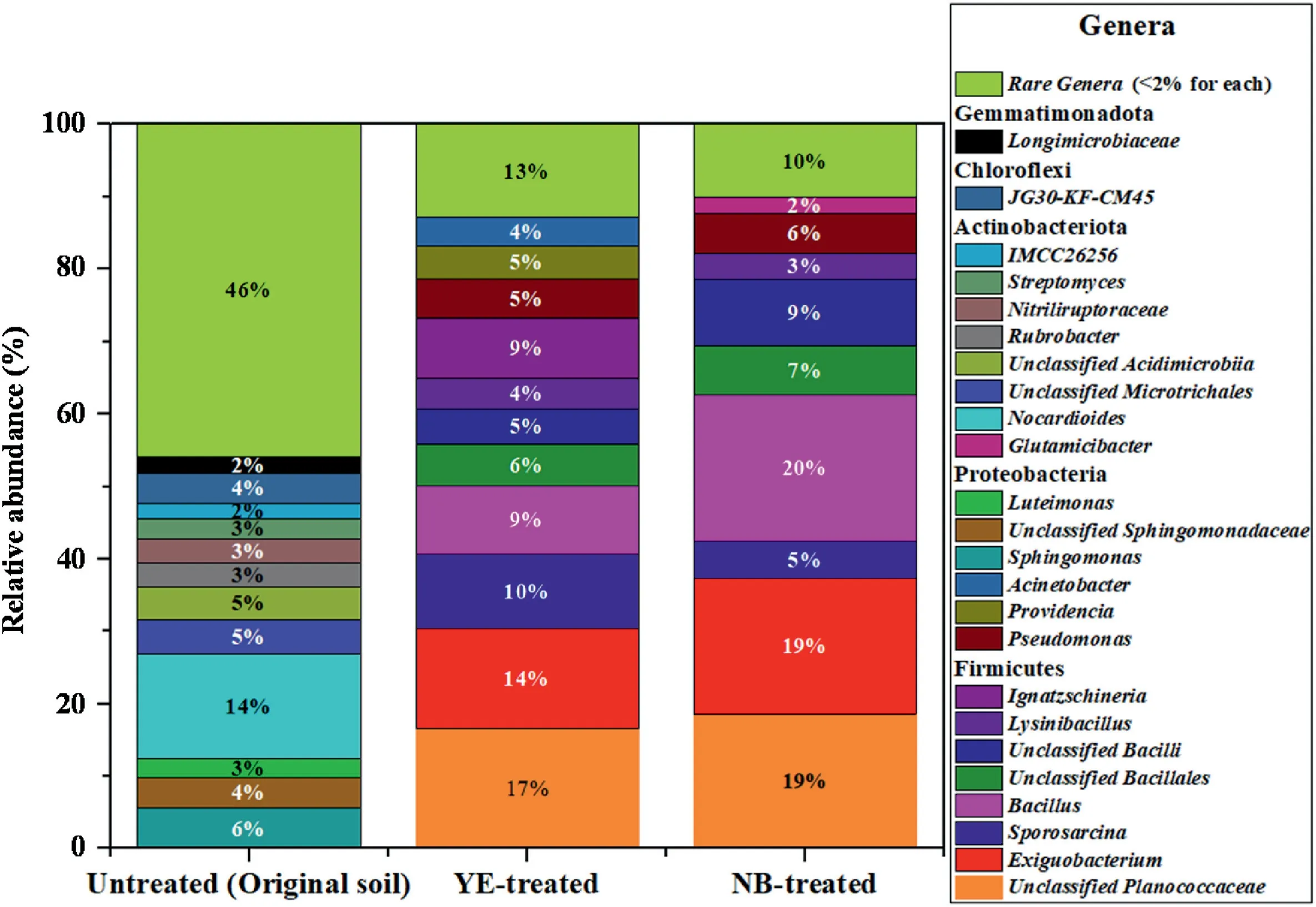

It was found that there was no significant difference regarding the effect of enrichment medium type (i.e.YE or NB) on the cementation content,indicating that these two enrichment media were functionally similar.The relative abundance of different microbial community presented in Fig.2 also confirmed such similarity.It was apparent that the microbial community changed significantly due to the enrichment process.In the original soil without treatment,the microbial genera were diverse and 39%were Actinobacteria,while Firmicutes took over after enrichment in both YE-and NB-treated soils.The microbial community exhibited a similar pattern in YE-and NB-treated soils where the abundance of common urease-positive genera such asSporosarcinaandBacillusincreased from less than 0.1%-19% and 25%,respectively.This was also shown in the study by Graddy et al.(2021).In addition,the existence of genusLysinibacilluswas found to contribute to MICP process (Kang et al.,2016;Ekprasert et al.,2020).Consequently,the results and discussion were mainly based on the cases treated by NB-based enrichment medium.

3.2.Compression curves

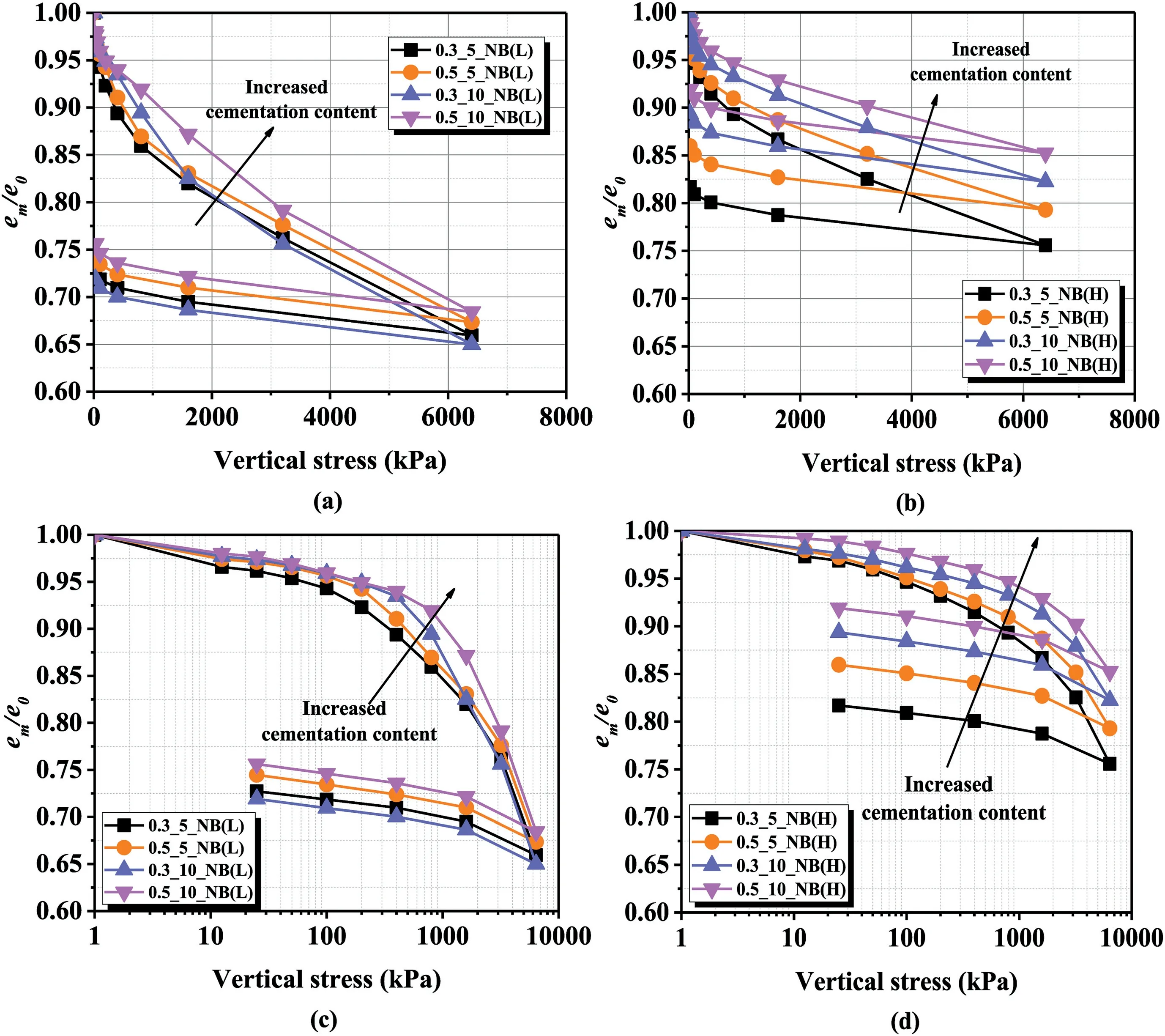

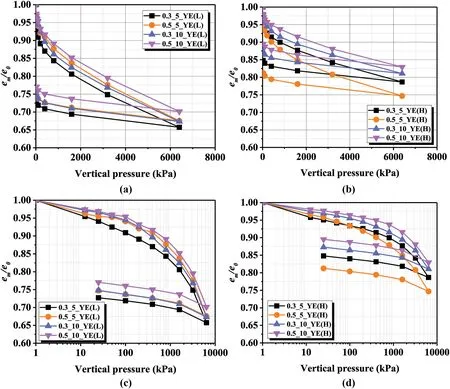

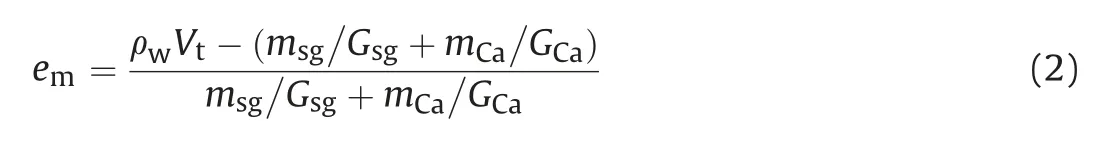

The representative compression curves(including bothe-pande-log10pcurves) of the bio-cemented calcareous sand treated by NB-based enrichment medium are shown in Fig.3.The rest compression curves are presented in Fig.4.The concept of normalized void ratio(em/e0)was adopted here,in whichemis the modified void ratio at the end of each loading,ande0is the initial void ratio.Jafari et al.(2020)used similar concept to investigate the isotropic compression behaviors of cemented paste backfill.In the current study,the formed bio-cementation within the voids of sand matrix was incorporated into the calculation of modified void ratio and thusemis defined as

Fig.2.High-throughput 16S community analysis.Plots are colored according to genus-level classification.

Fig.3.The representative compression curves of the bio-cemented sand treated by NB enrichment medium: (a,b) em/e0-p curves in linear scale;and (c,d) em/e0-log10p curves in semi-logarithmic scale.

Fig.4.The compression curves of the bio-cemented sand treated by YE enrichment medium:(a,b)em/e0-p curves in linear scale;and(c,d)em/e0-log10p curves in semi-logarithmic scale.

where ρwis the mass density of water;Vtis the total volume of specimen;msgandmCaare the masses of sand grains and CaCO3,respectively;andGsgandGCaare the specific gravities of sand grains and CaCO3,respectively(Xiao et al.,2020a).

Taking the NB-treated bio-cemented sand as an example,firstly,with the increase in the cementation content,a higher value ofem/e0was observed.This phenomenon was also reported previously in terms of other types of cemented soils treated by Portland cement or bio-augmented MICP (Rotta et al.,2003;Silva dos Santos et al.,2010;Xiao et al.,2020a).Then,it can be seen from theem/e0-log10pcurves (Fig.3c and d) that,at lower vertical stress ranging from 12.5 kPa to 400 kPa,all specimens’compression curves were approximately linear and showed smaller reduction inem/e0compared with the specimens at higher vertical stress,indicating that the bio-cementation provided effective interparticle bonding between sand particles.It was also found that,at low vertical stress range,the compression curve shifted upward with increased cementation content,which was due to the existence of more interparticle bonds verified by Amarakoon and Kawasaki (2018)through X-ray computed tomography (X-CT) tests.At higher vertical stresses,however,the compression curve began to change from linearity to curvature,indicating that more soil compression occurred at the same vertical stress increment.This was likely due to that the interparticle bonds were significantly broken as vertical stress increased (Xiao et al.,2020a).A distinct transition stress appeared at around 800 kPa ± 100 kPa for all specimens in this study.Thereafter,the breakage continued until all interparticle bonds broke.Due to the limit of maximum load that the device could provide,the complete interparticle bond breakage was not fully achieved in this study.

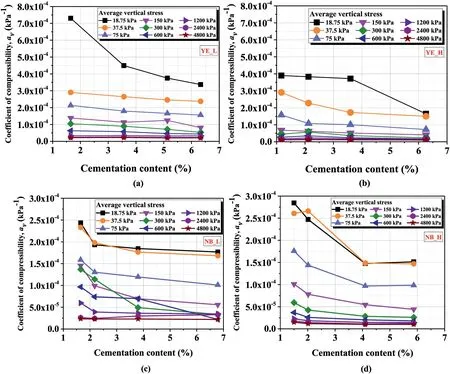

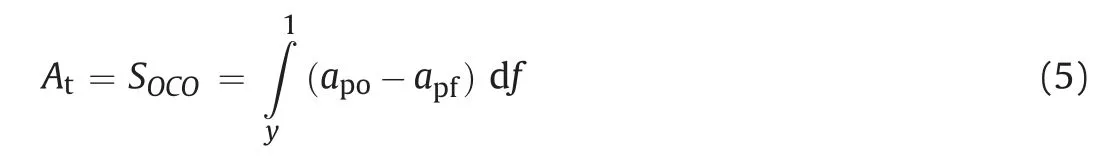

3.3.Coefficient of compressibility

The coefficient of compressibility (av) was calculated in this study to quantify the compressibility of bio-cemented sand.Theavis defined as the decrease in modified void ratio (Δem) per unit increase in effective vertical stress(Δp′),which can be derived from theeversusp′compressibility curves.

Fig.5 depicts the variations ofavwith cementation content at various average vertical stresses,which are defined as the average of the initial and final vertical stress for each load increment(Bohnhoff and Shackelford,2014).In general,the values ofavdecreased with increasing average vertical stress for all specimens,which was consistent with the observations by Yamamuro and Lade(1997) regarding the Nevada sand and Bohnhoff and Shackelford(2014) regarding a backfill soil.Moreover,it is found thatavdecreased gradually with the increase in cementation content for a given initialDrand enrichment medium,indicating that the more bio-cementation in soil matrix could work effectively as the interparticle bonds.However,it should be noted that such observation was more obvious at low average vertical stresses.More specifically,for the cases of YE_L,YE_H,NB_L,and NB_H,avdecreased from 7.3 × 10-4kPa-1to 3.4 × 10-4kPa-1,3.9 × 10-3kPa-1to 1.6 × 10-4kPa-1,2.4 × 10-3kPa-1to 1.8 × 10-4kPa-1,and 2.8 × 10-3kPa-1to 1.5 ×10-4kPa-1,respectively,at the average vertical stress of 18.75 kPa,whereas a reduction less than 5 × 10-6kPa-1could be seen at the average vertical stress of 4800 kPa for all specimens.This indicated that the bio-cementation lost its interparticle bonding function with the increase in vertical stress.Finally,when treated by a given enrichment medium,theavvalues of the specimens with higher initialDrwere approximately 20%-70% smaller than their counterparts with lower initialDr,especially within average vertical stress range between 18.75 kPa and 4800 kPa for YE-treated specimens,and between 150 kPa and 4800 kPa for NB-treated specimens.This was consistent with the results reported by Yamamuro and Lade (1997).

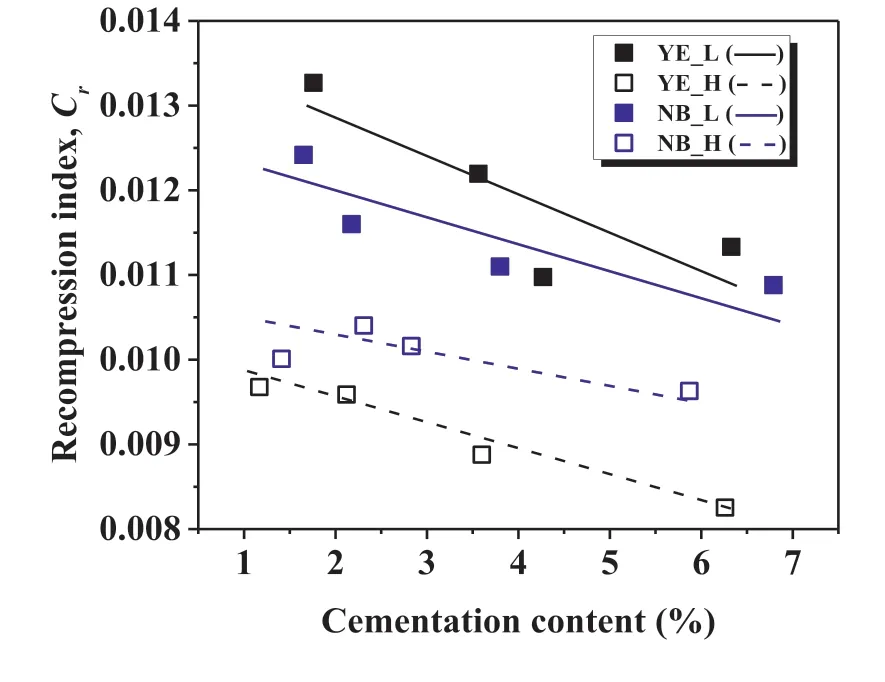

3.4.Recompression index

The recompression indexCrin this study was determined from the graphs representing the variation of modified void ratioemas a function of the vertical stress plotted in the semi-logarithmic scale during unloading period,which were not shown in this paper.The last three points were used for the calculation.Fig.6 shows the effects of cementation content and initialDron the variation ofCrfor all specimens.It is apparent that lower initialDrresulted in largerCr.Additionally,it was evident that theCrdecreased with increasing cementation content,which was consistent with the observation by Lee et al.(2013)on silty residual soil.In their study,theCrdeclined linearly with the amount of precipitated calcium carbonate.

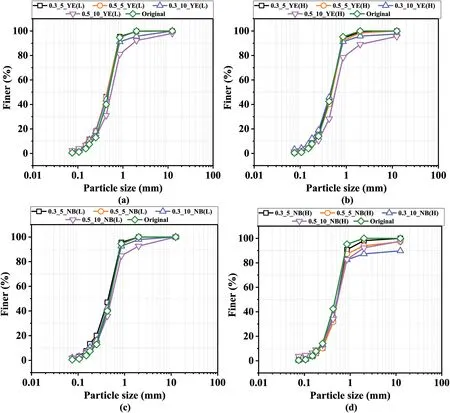

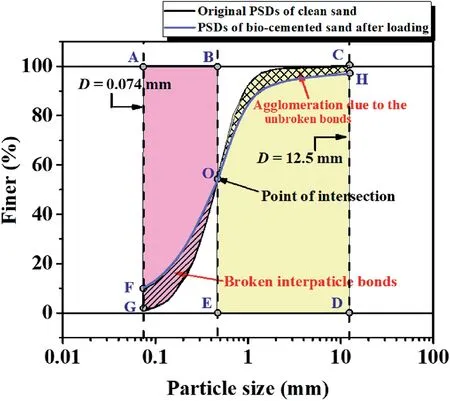

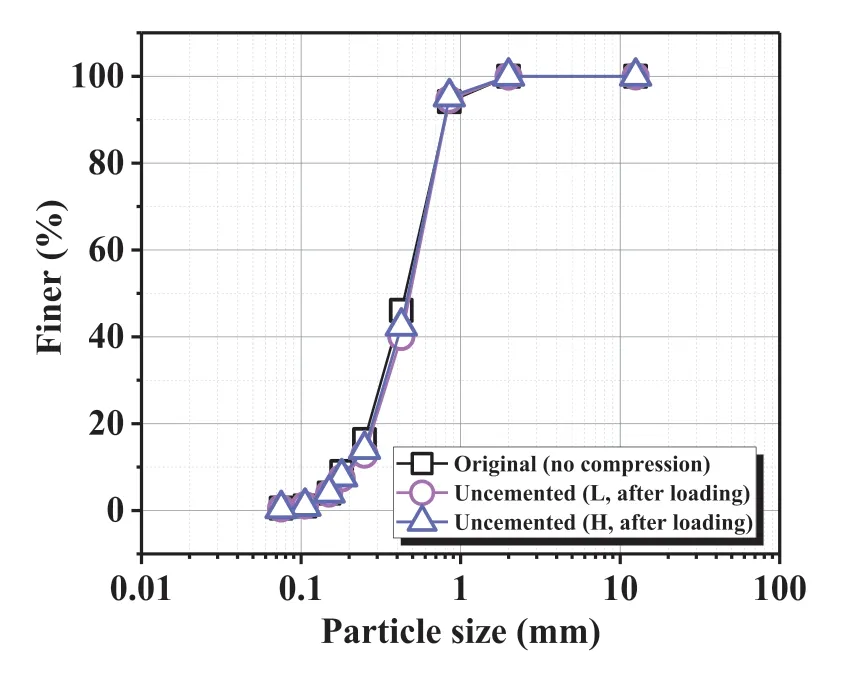

3.5.Interparticle bonding breakage

Fig.7 shows the PSD curves of the bio-cemented specimens and the original sand before and after the 1D compression test.Based on the sieve analysis results,a conceptual representation of how PSD curves are affected by bio-cementation is depicted in Fig.8.It can be seen that the intersection point divides the PSD curves of bio-cemented sand into two portions.At the intersection point,the same percent of sands pass through the corresponding particle size for both bio-cemented and clean sands.On the right-side portion(i.e.coarse portion),the downward shift of PSD curves means that larger size lumps are generated.On the left-side portion (i.e.fine portion),the upward shift of PSD curves indicates the increased percentage of fine particles.It should be noted that the interference of sand particle breakage could be excluded in terms of the abovementioned shifts of PSD curves,as it could be confirmed that no noticeable sand particle breakage occurred at the stress levels encountered in the current study (Fig.9).It is rational to assume that this behavior is common among cemented sandy materials.Therefore,the proposed conceptual representation can be potentially applied to interpret compressibility characteristics of other cemented sandy soils.Based on Fig.8,the extent of interparticle bonding breakage was quantified using the relative breakage (Br)which was proposed by Hardin (1985) and is defined as

whereBtis the total breakage;Bpis the breakage potential;andSFOGandSABOGare the patterned and pink areas in Fig.8,respectively.

Meanwhile,the increased coarse portion of bio-cemented sand compared with that of uncemented sand after compression was likely attributed to the agglomeration effect of the remaining unbroken interparticle bonding.Due to the unbroken interparticle bonds,some larger cemented lumps were generated after compression.To quantify how the coarse portion of bio-cemented sand PSD curves was affected by the cementation content after compression,an analogical concept of relative agglomeration (Ar)was proposed in the current study,which is defined as

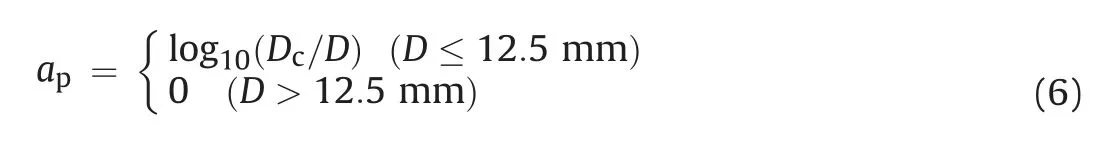

whereAtis the total agglomeration;Apis the potential of agglomeration for the whole sand specimen;andSOCHOandSOCDEare the patterned and yellow areas illustrated in Fig.8,respectively.The total agglomeration (At) is defined as

Fig.5.The variations of coefficient of compressibility with cementation content at different average vertical stresses:(a)Specimens treated by YE with low initial Dr;(b)Specimens treated by YE with high initial Dr;(c) Specimens treated by NB with low initial Dr;and (d) Specimens treated by NB with high initial Dr.

where dfis the differential of finer (%),apois the pre-compression potential for agglomeration,andapfis the post-compression potential for agglomeration.The potential of agglomeration(ap)for a given size fraction (D) is defined as

whereDc=12.5 mm is the maximum sieve opening size used in the current study.The potential of agglomeration (Ap) for the whole sand specimen can be expressed as

whereyis the finer(%)of the intercept point between PSD curves of original sand and PSD curves of bio-cemented specimen.

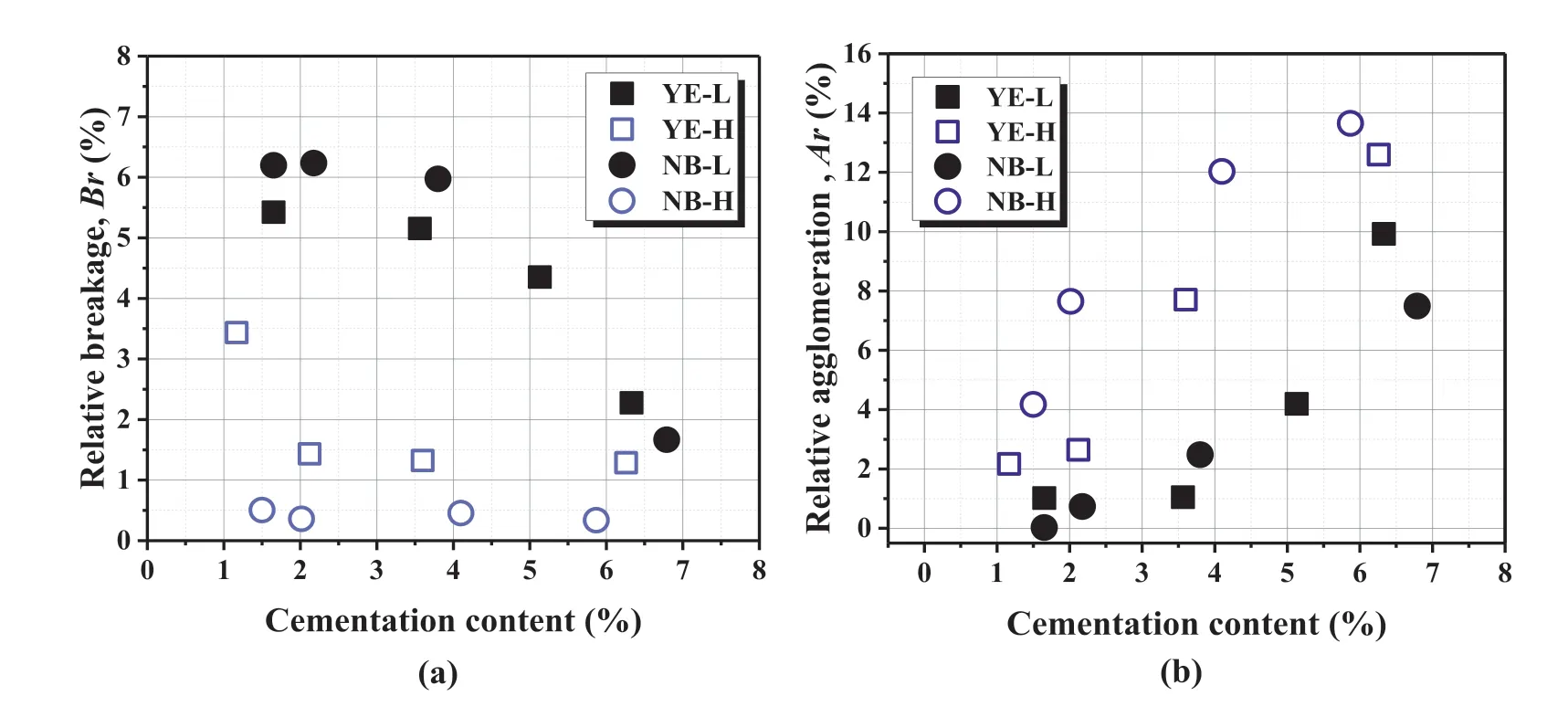

The calculatedBrandArare shown in Fig.10.Clearly,they were both significantly influenced by initialDrand cementation content.On one hand,at a similar cementation content,the specimens with higher initialDrhad smallerBrranging from 0.3% to 3.4%,while largerBrranging from 1.7%to 6.25%was observed in the specimens with lower initialDr.This observation implied that the dense packing reduced the distance between particles,and stronger interparticle bonds could be formed.In addition,it could be found thatBrgradually decreased with the increase of cementation content for a given initialDr,suggesting that elevated cementation content could also induce more interparticle bonds.On the other hand,in contrast toBr,the higher initialDrand more cementation content resulted in a largerAr.The largerArindicated that more interparticle bonds remained effective.These phenomena suggested that the interparticle bonding breakage during compression could be effectively reduced by increasing the initialDrand the cementation content.It should also be noted thatBrandArvalues in this study did not show significant difference between the specimens treated by YE and NB enrichment media.

3.6.Microscopic observations and crystalline phase analysis

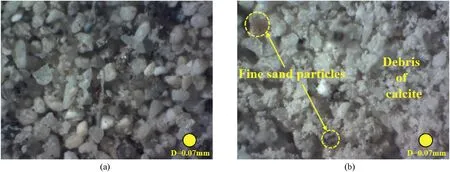

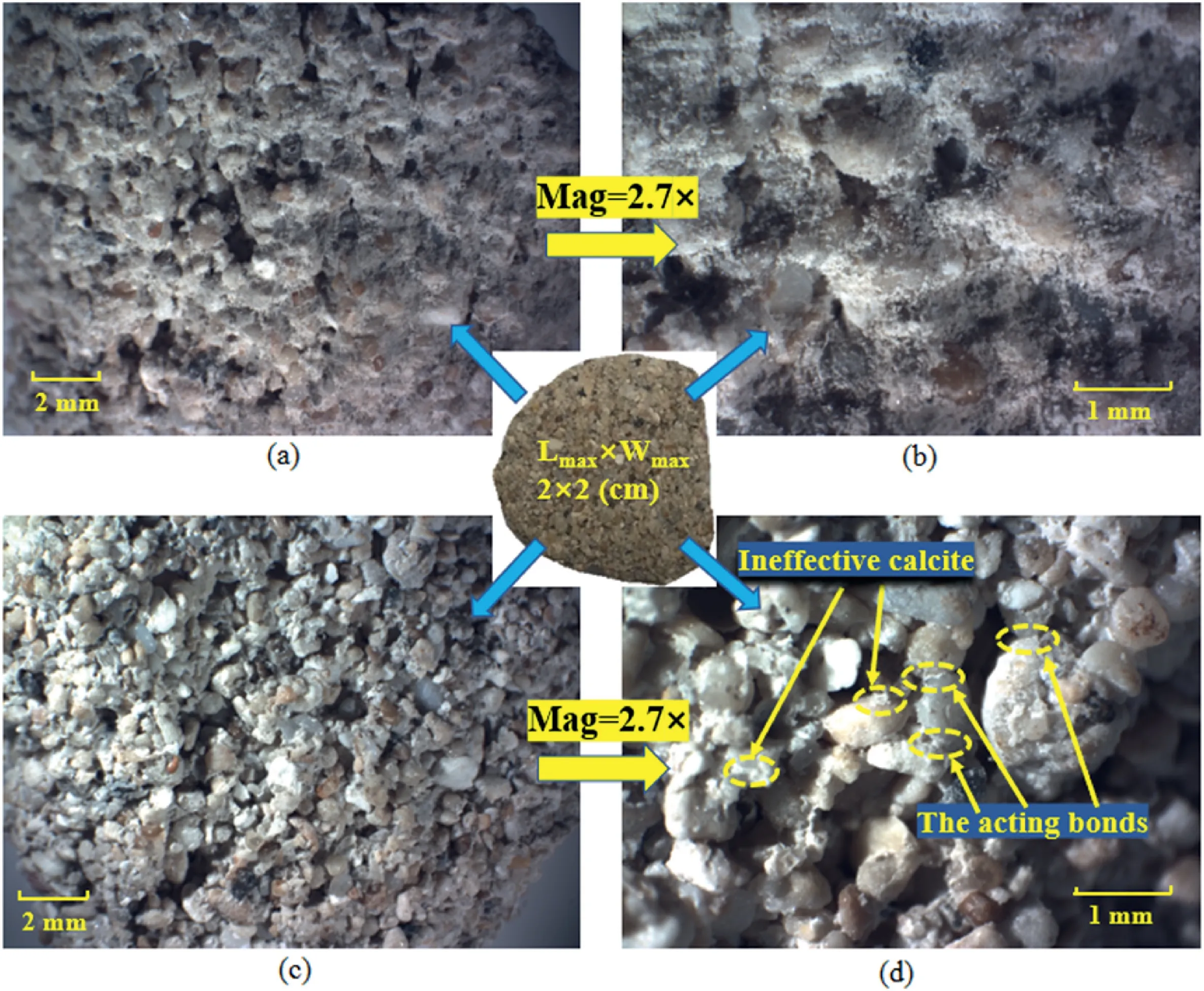

To further explain the features of the fine and coarse portions in the PSD curves of bio-cemented sand,the images of postcompression specimens passing through the 0.075 mm sieve and retained on the 12.5 mm sieve are shown in Figs.11 and 12,respectively.

Fig.6.Effects of cementation content and initial Dr on the variation of recompression index.

Firstly,the fine portion of the post-compression microscopic images of uncemented and bio-cemented sands (taking 0.5_10_YE(L)as an example)are presented in Fig.11.In the case of uncemented sand,individual small sand particles could be seen clearly without interparticle bonding.In contrast,in the case of biocemented sand(Fig.11b),the sand particles were covered by large amounts of white powders,which were presumably regarded as loose fine calcium carbonate crystals from the breakage of interparticle bonding.This observation was in agreement with the PSD results that the percentage of fine portion (D<0.075 mm)increased in bio-cemented sand after the completion of the 1D compression test.

Secondly,the representative micro-features of the lump with dimensions of 2 cm×2 cm(maximum length×maximum width)collected from the specimen 0.5_10_YE(L)are shown in Fig.12.The specimen shown in Fig.12c was the same as that in Fig.12a,but was carefully washed by deionized water to remove the loose debris around the lump.Fig.12b and d is the magnified images(2.7×)of Fig.12a and c,respectively.It could be found from Fig.12a and b that the entire lump was covered by many tiny loose white crystals on the surface of sand particles.These crystals possibly came from the breakage and abrasion of interparticle cementation bonding.Then in Fig.12c and d,in which the lump was carefully washed by the deionized water,the cemented sand particle aggregates could be observed.In summary,the microstructural observation results could reveal that most interparticle bonds of bio-cemented sand were broken at the stress level encountered in the current study.However,there were still some unbroken interparticle bonds remaining within the cemented sand aggregates.

Fig.7.The post-compression PSD curves of the original clean sand and the bio-cemented sand:(a) Specimens treated by YE with low initial Dr;(b) Specimens treated by YE with high initial Dr;(c) Specimens treated by NB with low initial Dr;and (d) Specimens treated by NB with high initial Dr.

Fig.8.The conceptual PSD curves of bio-cemented sand after compression.

Fig.9.The comparison of pre-and post-compression PSD curves of untreated Waikiki calcareous sand.

Fig.10.The relationship between cementation content and (a) relative breakage and (b) relative agglomeration.

Fig.11.The post-compression microscopic images of (a) uncemented sand and (b) bio-cemented sand (take 0.5_10_YE(L) as an example).

Fig.12.The micro-features of a representative lump collected from the specimen 0.5_10_YE(L)after compression test:(a)Filled with cementation debris;(b)The magnified image of (a);(c) Filled without cementation debris;and (d) The magnified image of (c).

In addition,the XRD test was performed to characterize the crystalline phases in the bio-cemented sands(as shown in Fig.13).The results have shown that calcite and aragonite are the primary crystalline phases in bio-cemented sands,regardless of the enrichment media.

4.Discussion

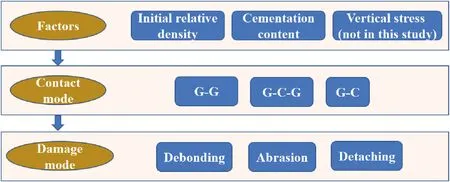

To facilitate a better understanding of the compressibility behavior of bio-cemented calcareous sand,a conceptual framework showing the external factors,interparticle contact mode,and damage mode was proposed in the current study,as shown in Fig.14.This framework was inspired by numerous previous studies on the compressibility of sand with fines.For instance,Yamamuro and Lade (1997) and Yamamuro and Wood (2004) presented a series of possible grain contacts (i.e.large particle-large particle,large particle-small particle-large particle,and large particlesmall particle-void) when silty sand was deposited among larger sand particles,which could have effect on the compressibility of silty sand.Analogous to the influence of silt grains in their studies,bio-cementation is present among large calcareous sand particles to form different contact modes and can be easily damaged during compression through different modes.Therefore,the evolution of bio-cementation during compression and the interactions between bio-cementation and its neighboring calcareous sand particles are critical to the compressibility behavior of bio-cemented sand.

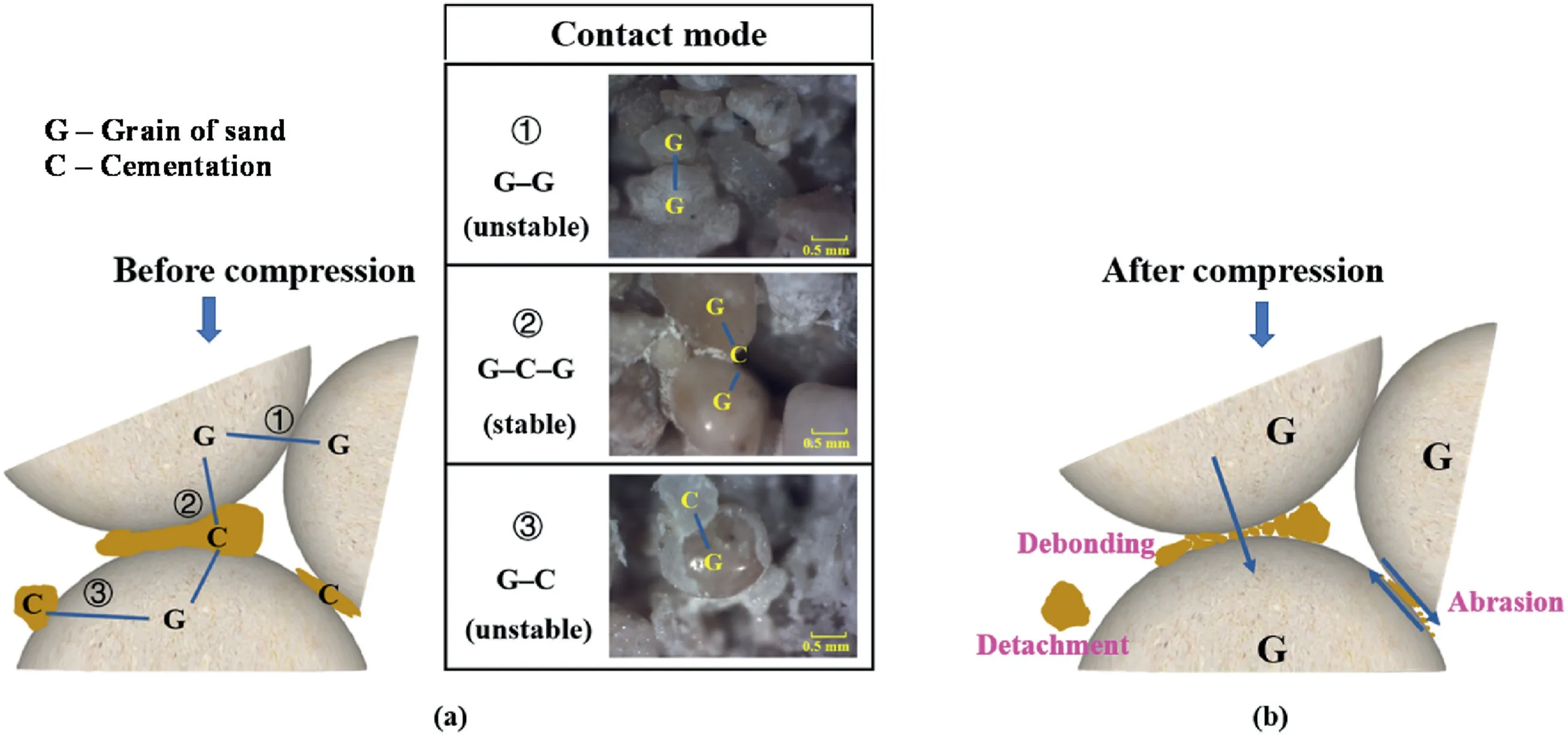

The core of this conceptual framework is the three interparticle contact modes: G-G (grain-grain),G-C-G (grain-cementationgrain),and G-C (grain-cementation),as demonstrated in Fig.15a.G-G contact is normally considered as a frictional and unstable contact in uncemented sand,and grain rearrangement may occur during compression or shearing.However,in bio-cemented sand,the presence of bio-cementation significantly reduces the G-G contacts (frictional contacts),and consequently the proportions of other contact modes related to bio-cementation (G-C and G-C-G)increase accordingly(Dadda et al.,2019).Since the existence of biocementation restricts the movement of sand particles,the unstable G-G contact in bio-cemented sand became less compared with the uncemented sand.Secondly,G-C-G contacts are the unique to biocemented sand.Bio-cementation,as a bridge,connects two adjacent sand particles and forms a force chain.The force transfer through G-C-G contacts is largely dependent on the abundance and strength of interparticle bonding,which can be seen as a stable contact.Thirdly,G-C is the weakest contact in the bio-cemented sand.Large amounts of calcium carbonate deposit on the surface of sand particles,which do not contact with other sand particles.The attached calcium carbonate can be easily detached during the rearrangement of sand particles.Finally,it worth mentioning that these three contact modes co-exist in a typical bio-cemented sand.

Debonding,detachment,and abrasion,as shown in Fig.15b,are the three proposed damage modes for bio-cemented calcareous under compression.Debonding refers to the breakage of the interparticle bonds under normal compressive stress.Detachment refers to the separation of attached or coated bio-cementation from sand particle surfaces.Abrasion refers to the bio-cementation that is ground into several much smaller pieces under tangential shear stress.The three damage modes discussed here were derived from either pure compression under normal stress or shearing under tangential stress.

The damage modes associated with the three contact modes(i.e.G-G,G-C-G,and G-C)are different during the compression test.The G-G contact,as a pure frictional contact mode in clean sand,is reduced substantially in the bio-cemented sand.Even if all interparticle bonds of bio-cementation are destroyed during compression,the damage to individual calcareous sand particles is still negligible at the stress levels set in the current study.Consequently,none of the three damage modes are associated with the G-G contact.However,sliding and particle rearrangement can still occur for the G-G contact,as those in the case of uncemented sand.For the G-C-G contact,firstly,debonding evolves with the increasing vertical stress,which is the main contributor for overall volumetric deformation.Then,with debonding and detachment damage progresses,abrasion becomes more and more predominant as particle rearrangement and relocation dominate at this stage.During particle rearrangement and relocation,the interparticle friction forces abrade the bio-cementation progressively and thus lead to further overall volumetric compression.Finally,for the G-C contact,the calcium carbonate deposited on the surface can be easily detached from its parent particle because of the particle rearrangement.The increased fine particles observed in Fig.8 are assumed to be the results of the combining effects of these damage modes.The detached fine calcium carbonate crystal particles simply reside or fill in the voids between larger grains and their primary role is to increase the density of specimen.

Fig.13.XRD pattern of the precipitated calcium carbonate.

With the proposed conceptual framework of contact and damage modes,the macro-scale irreversible volumetric deformation of bio-cemented sand could be associated with these contact and damage modes.In the following paragraphs,the effect of external factors (i.e.initialDr,and cementation content) on the compressibility behavior of bio-cemented calcareous sand will be interpreted based on the conceptual framework.

(1) InitialDr

At a given cementation level and vertical stress,the effect of initialDron the compressibility of bio-cemented sand is primarily attributed to the following three mechanisms: (i) Similar to the uncemented sand,increasing initialDrcan reduce the compressibility of bio-cemented sand by densification (i.e.sliding,rotation,etc.).(ii) By increasing the initialDr(i.e.reducing the interparticle distance),sand particles can be more readily bridged by biocementation.The interparticle bio-cementation is favorable to prevent the occurrence of particle rearrangement due to the bonding effect by forming the effective G-C-G contacts.(iii) The amounts of G-G contact can be increased by elevating the initialDr,which is a stable contact if particle rearrangement can be effectively constrained by G-C-G contacts around the G-G contact points.In this way,more G-G contacts could withstand the applied compressive force,thus reducing the crushing of interparticle cementation.This explains why the PSD curves shift upward on the left-side portion (i.e.fine portion) in Fig.8 and smallerBrvalues(Fig.10a)are obtained in the specimen with higher initialDr.With the combined role of the three above-mentioned mechanisms,the compressibility can be improved significantly in the specimens with higher initialDr,resulting in a 20%-70% smalleravvalue as observed in Fig.5.

(2) Cementation content

At a given initialDrand vertical stress,the effect of the cementation content on the compressibility of bio-cemented sand is due to the following two mechanisms: (i) The higher the cementation content is,the more effective the interparticle bonds(i.e.G-C-G contacts)are,and the stronger the interparticle bonding strength formed within the soil matrix.Consequently,a decreasingBris observed with the increasing cementation content (as shown in Fig.10a).Also,it should be noted that more interparticle bonds will not be broken with the increasing cementation content when the vertical load reaches up to 6.4 MPa in the current study,which explains the increase ofArwith the elevated cementation content(as shown in Fig.10b).(ii)The increasing cementation content can elevate the density of bio-cemented sand by filling pores to form more G-C and G-C-G contacts,and the space available for particle rearrangement is limited,which can make severe abrasion and result in the increase of much smaller fine particles.

Fig.14.A conceptual framework for understanding the compressibility behavior of bio-cemented sand.G -Grain;C -Cementation.

Fig.15.The explanation of conceptual framework: (a) The contact modes before compression;and (b) The damage modes after compression.

5.Implications for engineering practice

This study investigated the compressibility behavior of biocemented calcareous sand treated through bio-stimulated MICP.The results are likely to benefit the design and construction of structures on problematic calcareous sand by providing a technically sound and new soil stabilization method.

Many studies including the current one has clearly shown that bio-cementation can improve the compressibility of granular soils.The observations from the current study provide some implications for the application of bio-stimulated MICP in the field.The biocemented sand in the field may not experience an extremely high vertical stress to break all interparticle cementation bonds and even the sand particles.To ensure the bearing capacity of biocemented sand,such high stress that may cause the biocementation to lose the efficacy in resisting compressibility should be prevented.Therefore,prior to the field implementation of bio-cementation,it is crucial to accurately estimate the potential maximum vertical stresses that the bio-cemented calcareous sand may experience.

6.Conclusions

In this study,a series of 1D compression tests was conducted to investigate the compressive behaviors of bio-cemented calcareous sand treated using the bio-stimulated MICP approach.The main conclusions are drawn as follows:

(1) The value of coefficient of compressibilityavwas found to decrease with the increasing cementation content.Contrarily,the specimens with higher initial relative densityDrhad smaller (approximately 20%-70%)avvalues than their counterparts with lower initialDr.In terms of the recompression indexCrvalue,higher initialDrresulted in a largerCr,andCrdecreased with the increasing cementation content.

(2) Based on the analysis of PSD curves after compression,the specimen with higher initialDrand moreCCresulted in a smallerBrand a largerAr.More fines were generated in biocemented specimens with higher cementation content and lower initialDr.The increased fines mainly came from the debris of calcium carbonate,as revealed by microscopic images.Additionally,some larger lumps appeared as the result of residual agglomeration effect of some undamaged cementations.

(3) A conceptual framework based on the interparticle contact modes (i.e.G-G,G-C-G,and G-C) and their corresponding damage modes (i.e.detachment,debonding,and abrasion)during the compression tests was proposed.Compared with G-G and G-C modes,the G-C-G was the strongest contact mode for the bio-cemented sand.During compression,debonding and detachment firstly occurred in the G-C-G and G-C contacts mode,respectively.Abrasion damage mode then became predominant as debonding and detachment progressed during particle rearrangement and relocation.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This study was financially supported by the Natural Science Foundation of China (Grant No.42007246),the Fundamental Research Funds for the Central Universities (Grant No.2242022k30055),and Indo-U.S.Science and Technology Forum(Grant No.IUSSTF/AUG/JC/047/2018).

Journal of Rock Mechanics and Geotechnical Engineering2023年2期

Journal of Rock Mechanics and Geotechnical Engineering2023年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A multi-purpose prototype test system for mechanical behavior of tunnel supporting structure: Development and application

- Experimental investigations on effects of gas pressure on mechanical behaviors and failure characteristic of coals

- Strength and deformation characteristics of irregular columnar jointed rock mass: A combined experimental and theoretical study

- Spatial distribution and failure mechanism of water-induced landslides in the reservoir areas of Southwest China

- Characteristics of electromagnetic vector field generated from rock fracturing

- Hydraulic and volume change behaviors of compacted highly expansive soil under cyclic wetting and drying