Formation of quaternary all-d-metal Heusler alloy by Co doping fcc type Ni2MnV and mechanical grinding induced B2–fcc transformation

Lu Peng(彭璐), Qiangqiang Zhang(张强强), Na Wang(王娜), Zhonghao Xia(夏中昊), Yajiu Zhang(张亚九),

Zhigang Wu(吴志刚)2, Enke Liu(刘恩克)3, and Zhuhong Liu(柳祝红)1,†

1Department of Physics,University of Science and Technology Beijing,Beijing 100083,China

2School of Civil Engineering,Guangzhou University,Guangzhou 510006,China

3Beijing National Laboratory for Condensed Matter Physics,Institute of Physics,Chinese Academy of Sciences,Beijing 100190,China

Keywords: all-d-metal Heusler alloy,grinding induced phase transformation,phase stability

1. Introduction

All-d-metal Heusler alloy, as the name implies, all elements that compose the alloy are transition metal elements. This concept was first proposed by Liuet al. in 2015.[14]They reported that all-d-metal alloys Ni50Mn50-xTix,Mn50Ni50-xTix,and Ni–Mn–Co–Ti crystalized in the Heusler structure and exhibited martensitic transformation. They proposed that the physical mechanism of phase formation for the all-d-metal Heulser alloys is the d–d covalent hybridization,which has the same effect as the p–d hybridization in the conventional Heusler alloy, playing a crucial role in the stability of the Heusler structure. Subsequently, they reported the electronic behavior of another all-d-metal Heusler shape memory alloy Ni50-xFexMn35Ti15[15]during martensitic transformations (MT), and proposed a spintronic property based on the magnetic structure phase transition.

Strictly speaking, Heusler alloys usually have a highly ordered L21structure. However, the disorder between B and D sites as well as other sites in Heusler alloys is a very common phenomenon in practice,such as Co2MnSi and Ni2MnGa.[16,17]In this case, it is usually called the B2-type Heusler alloy.[18]The (dis)ordering behaviors and their effects on the physical properties of Heusler alloys have been widely studied.[19,20]Compared with the conventional Heusler alloys, all-d-metal Heusler alloys are more easily to form the B2-type or more ordered L21-type Heusler structure, i.e.,Ni50Mn50-xTix,Fe2CrV–Cr2FeV,and Co2MnTi.[14,21,22]As a new family of Heusler alloys, all-d-metal Heusler alloys bear a great advantage of high toughness,which is more important for practical engineering applications of functional Heusler alloys.[23–25]However, from the view of the chemical bonding, the covalent bonding ability between d–d is weaker than that of between p–d, so it is not easy to form the Heusler structure ifX,Y, andZare all transition metals. For example, as Cr contentx ≥0.5, Mn2NiGa1-xCrxalloys transform from the Heusler structure to the pure face-centered cubic(fcc)phase.[26]This implies that the all-d-metal alloys may exhibit multiphase competition upon phase formation, i.e., fcc-type disorderedγphase, fcc-type ordered L12structure, and B2-type phase.

The structure and the phase of the materials impose significant influence on the functional properties. For example,the hexagonal MnNi0.77Fe0.23Ge alloy can effectively change the magnetic structural transition temperature of this system by applying hydrostatic pressure, thus changing the associated MCE.[27]The tetragonal Heusler alloy Mn3Ga presents a large coercive field of 359 kA/m with saturation magnetic moment of 1.1μBat 5 K,[28]having the potential application for spin-transfer torque (STT) device, while fcc Mn3Ga alloy shows a typical antiferromagnetic nature.[29]In Heusler alloys with martensitic transformation, the mechanical property of the alloys can be enhanced by the presence of a little amount ofγphase. However, the martensitic transformation will be suppressed due to the large fraction of theγphase.Furthermore, the investigation of the functional properties of the alloys subjected to various deformation is important for practical applications.[30]So the mechanical properties of the Heusler alloys have also attracted much interest. In the Fe–Mn–Al[31]and Fe–Mn–Ga[32]alloys, stress induced B2→γphase transformation has been observed, making them have good cold deformation ability. In this regard,it is essential to investigate the formation and mechanical deformation of the all-d-metal Heusler phase.

First-principles calculations have predicted that the hypothesis all-d-metal Heusler alloy Ni2MnV has martensitic transformation.[33,34]However, our experiment finds that it is difficult to crystalize in Heusler structure for Ni2MnV. It has been reported that Co2VMn has B2 structure with a Curie temperature (TC) of 670 K and a saturation magnetization of 145.1 emu/g.[35]It seems promising that using Co substitution partial Ni in Ni2MnV can stabilize the body-centered cubic(bcc)structure.So Co doping partial Ni in Ni2MnV is adopted in this research.

All-d-metal alloys Ni50-xCoxMn25V25(x= 0–50) are prepared in this study. It has been found that the pure Heusler phase formed by melt-spinning method as Co contentx >37, indicating that the d–d covalent bonding effect between Co/Mn and V atoms facilitates the B2-type Heusler phase formation. However, theγphase has been observed embedded in theβmatrix in the as-melted ingot in samples ofx >37.The fraction ofγphase gradually decreases with the increase of Co content. Furthermore, a grinding stress induced phase transformation from B2 to the mixture of B2 and fccγphase is observed. Accompanying with this structural transition, a magnetic change from ferromagnetic to weak magnetism occurs, suggesting the potential for multi-field–driven application.

2. Experiment and method

Ni50-xCoxMn25V25(x=0–50) ingots were prepared by arc-melting the high purity (99.99% or higher) Ni, Co, Mn,and V elements. The ingots were remelted at least four times for homogenization. Part of the ingots was subsequently melted in a quartz tube and rapidly cooled by spinning onto the surface of a copper wheel,spinning at a linear velocity of about 25 m/s. X-ray diffraction(XRD)patterns were recorded by the Rigaku Smartlab3 instrument with CuKαradiation to characterize the crystal structure. The step size of 0.02°and three seconds step time were adopted during the measurement. Differential scanning calorimetry (NETZSCH, DSC 214 Polyma)curves were obtained with a heating/cooling rate of 10 K/min to determine the characteristic temperatures of phase transformation and Curie transition. Magnetic properties were measured by superconducting quantum interference device(SQUID)magnetometer.

The electronic structures are calculated by using the Viennaab initiosimulation package(VASP)with the projectoraugmented wave (PAW) scheme based on the density functional theory (DFT).[36]The electronic exchange–correlation function is described by the generalized gradient approximation of Pardew, Burke, and Ernzerhof (GGA-PBE).[37,38]For Ni2MnV,ordered L21-type(Cu2MnAl-type with space groupFm3m, No. 225), XA-type (Hg2CuTi-type with space groupF¯43m, No. 216), and fcc-type (CuAu-type with space groupP4/mmm,No.123)structures(see Fig.1)are calculated to find the stabilization of the alloy. Furthermore,different magnetic configurations including ferrimagnetic (FIM), ferromagnetic(FM), and non-magnetic (NM) are also taken into consideration,where FIM indicates spins between the Mn and V atoms are anti-parallel, and the parallel case is FM. The cut-off energy of 500 eV and a self-consistent field of 10-7eV are used to achieve good convergence.

Fig.1. The schematic cells of ordered L21-type (a) XA-type (b) Heusler structures,and(c)fcc(123 space group)structure.

3. Results and discussion

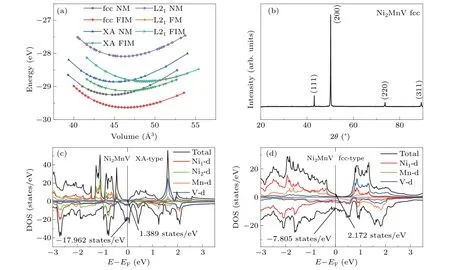

Figure 2(a)shows the calculated total energy of Ni2MnV as a function of volume for different crystal structures (ordered L21-type, XA-type Heusler structures, and fcc structure) and different magnetic configurations (FIM, FM, and NM). It is noted that the magnetic configurations of XA and fcc structures eventually converge to FIM whether the magnetic configuration is FM or FIM.This implies that magnetic configuration of FM cannot exist stably in XA and fcc structures. Therefore, only FIM/NM states are given in Fig. 2(a)for both XA and fcc structures. It can be found that the XAtype FIM structure has lower energy than that of the L21-type FIM structure, and the minimum energy difference between the two states is 0.50 eV/cell. The total energy of the fcc-type structure with FIM coupling is the lowest,which indicates that Ni2MnV is more inclined to form a FIM fcc structure. The calculated equilibrium lattice constant for the FIM fcc-type alloy isa=3.60 ˚A.Figure 2(b)shows the XRD pattern for the Ni2MnV ribbon sample. The characteristic peaks can be indexed to fcc structure with the lattice parameter ofa=3.63 ˚A,and they are consistent with the theoretical calculation.

Fig.2. (a)The total energies as a function of volume for Ni2MnV alloy with ordered L21-type,cubic XA-type,and fcc structures in ferromagnetic(FM),ferrimagnetic(FIM),and non-magnetic(NM)states. (b)XRD pattern for Ni2MnV ribbon measured at room temperature. Calculated TDOS and PDOS of d electrons for Ni2MnV with cubic XA-type(c),and fcc(123 space group)(d)FIM structures.

The total density of states (TDOS) and partial density of states (PDOS) of d electrons for XA-type and fcc-type Ni2MnV(FIM state)are shown in Figs.2(c)and 2(d). For the TDOS of the XA-type alloy(see Fig.2(c)),the Fermi energy(EF) falls into a pseudo-energy gap in the spin-up direction.However,EFsituates in a relatively high narrow peak of 3d states in the minority spin direction of the TDOS curve,showing a high spin polarization of the alloy. This peak is mainly attributed to 3d electrons of Ni, Mn, and V, implying the strong d–d hybridization between them. The TDOS of the fcc Ni2MnV(see Fig.2(d))is different from that of the XA-type structure. For the spin-up direction,EFshifts to the left side of the pseudo-energy gap,having 2.172 states/eV per spin,whileEFfalls into a TDOS valley in the spin down direction,having 7.805 states/eV per spin. The degree of spin polarization of the charge carriers atEFis only 56.5%. It is generally considered that ifEFsituates at the peak of TDOS, the structure is unstable. This is called the DOS criterion to determine which structure is more stable.[39]Together with the energy–volume curve,it can be concluded that the fcc structure is more stable than XA-type Heusler structure for Ni2MnV as a consequence of the TDOS behavior.

下一步将在引入优良谷子品种基础上,进行谷子种业、谷子规模化种植、谷子及秸秆饲料化、小米深加工产品开发及产业化,全面发展小米“种植、养殖、加工”全产业链,立足保加利亚,形成可复制的盈利模式,并逐步辐射到欧洲其它国家,为我国农业“走出去”做出贡献。

Previous report has confirmed that Co2VMn has bcc structure.[35]It seems that Co can enhance the stabilization of Heusler structure. So,the element Co is selected to substitute partial Ni in the Ni2MnV. Figures 3(a)–3(c) show the XRD patterns of Ni50-xCoxMn25V25(x=0–50)melt-spun ribbons measured at room temperature. The plot shows that the pure fcc phase of Ni2MnV is kept when 0<x <30. The lattice parameter of fcc phase decreases with the increase of Co, as listed in Table 1. Extra peaks start to appear except for the main peaks of the fcc structure whenxincreases to 30. The extra peaks can be indexed to the Co1.9V3.1-type tetragonal phase (space groupP42/mnm).[40]We use the symbol T before the Miller indices to identify the peaks of the tetragonal structure. This tetragonal phase is different from the tetragonal Heusler structure, which has a space groupI4/mmmorI¯4m2.[41]The ratio of Co1.9V3.1-type tetragonal phase in the XRD pattern forx=32 increases compared withx=30. Further increasingxto 34, except for the tetragonal phase, the peak intensity of fcc weakens greatly and the peaks of the bcc structure appear. Both lattice parameters ofaandcfor the tetragonal phase decrease with an increase ofxfrom 30 to 34(see Table 1). The lattice parameter of fcc phase fromx=30 tox=34 also decreases gradually.Overall,the lattice parameter for the fcc phase decreases with the increase of Co content.Forx=37,the bcc phase dominates the structure of the alloy.

Asx >37, the phase can be determined as a pure bcc phase (see Fig. 3(c)), which has the same structure as observed in all-d-metal Heusler alloys Ni–Mn–Ti,Fe2CrV,NiMnTi, NiCoMnTi, and Co2MnTi.[14,21,22,42]Since the lack of(111) superlattice peak, and only (200) superlattice peak can be observed,it is suggested that disorder formed between sites B and D,namely Mn and V,confirming the formation of B2-type Heusler phase.[14,21,22,43]It is proposed that the d–d covalent hybridization effect between the nearest neighboring 3d transition metals can stabilize the Heusler structure, such as the d–d covalent bonding between Ni/Mn and Ti can promote the formation of the Heusler phase of Ni2MnTi.[44]The phase of Ni50-xCoxMn25V25changes to the Heusler phase asx >37,which suggests that the d–d covalent bonding between Co–Mn and Co–V atoms is stronger than that between Ni–Mn and Ni–V,helping to stabilize the B2-type Heusler phase.

The lattice parameters for all-d-metal Heusler alloys Ni50-xCoxMn25V25(x= 0–50) are calculated according to XRD, as shown in Table 1. It can be found thatadecreases with the increase of Co content, changing from 5.8198 ˚A inx=37 to 5.8000 ˚A inx=50. As the increase of Co,the distances between Co–Mn and Co–V decrease, resulting in the enhancement of d–d covalent bonding.

Table 1.The lattice parameters of fcc,Co1.9V3.1-type tetragonal and B2-type Heusler phases in Ni50-xCoxMn25V25 (x=0–50)ribbons.

Fig.3. (a)–(c) XRD patterns of Ni50-xCoxMn25V25 (x=0–50) ribbons measured at room temperature. (d) XRD patterns of Ni50-xCoxMn25V25(x >37)as-melted ingots measured at room temperature.

Fig.4. (a)The DSC curves for Ni50-xCoxMn25V25 (x=38,40,45,47,50)ribbons. (b)The temperature dependence of magnetization M(T)of Ni50-xCoxMn25V25 (x=38, 40) ribbons measured at 100 Oe field. Inset(I)shows the dM/dT versus T measurements to calculate the Curie temperatures. Inset(II)shows TC as a function of Co content x.

To study the phase formation of all-d-metal alloy Ni50-xCoxMn25V25(x >37)ribbons with pure Heusler structure, the XRD spectrum of the as-melted ingots forx >37 is also investigated. The ingots are cut into slice and then directly measured the patterns at room temperature. Compared with the ribbon samples, the as-melted ingots are no longer pure Heusler phase. Mixed phases of fcc and B2 appeared,as shown in Fig. 3(d). Furthermore, the peaks of the fcc phase weaken gradually and the Heusler phase plays the dominant role with the increase of Co. There is only a rather small(111)peak of the fcc structure in Co2MnV. This also suggests that Co can help to stabilize the Heusler structure. The solidification rate in melt-spinning process is more rapid than that in arc-furnace melting process,thus it can avoid low temperature phase region and directly forms the high temperature phase,which impedes the formation of the fcc phase.

We perform DSC measurements on the ribbon samples through a heating and cooling process in the temperature range from 150 K to 873 K for Ni50-xCoxMn25V25(x >37) ribbons with pure Heusler structure. No phase transition is detected below room temperature, so we only give the curves from 300 K to 800 K, as shown in Fig. 4(a). A small endothermic transformation peak upon heating and an exothermic peak during cooling process occurring nearly at the same temperature can be observed, suggesting that the peak temperature is probably corresponding to the Curie transition of the alloy. In order to exclude whether these weak peaks are caused by order–disorder transformation,the thermomagnetization(M–T)curves for Ni50-xCoxMn25V25(x=38,40)ribbons under 100 Oe magnetic field are measured, as shown in Fig.4(b). It is obvious that both samples show a second-order Curie transition. The temperature dependence of dM/dTis shown in inset(I)of Fig.4(b). From the peak temperature of the derivative curve ofM(T),TCare determined to be 363.8 K and 399.7 K forx=38 and 40, respectively, which is consistent with the peak temperature of the DSC curves. This confirms that the weak peak temperature is indeedTC. Inset(II) shows theTCas a function ofx. It can be found thatTCincreases from 366.4 K forx=38 to 603.5 K forx=50, almost linearly with Co content with the slope of 19.8 K per Co atom. In the Ni50-xCoxMn25V25alloy, the Mn–Mn, Ni–Mn,and Co–Mn interactions dominate the Curie transition. The interaction between the nearest neighboring Co–Mn is usually stronger than that between Ni–Mn. More Co–Mn interaction is introduced by using Co atoms doping Ni atoms. The fraction of Co–Mn increases and Ni–Mn decreases, resulting in the increase ofTC. TheTCof our Co2VMn ribbon is lower than 670 K. TheTCof bulk material Co2VMn is reported by Ruanet al.[35]This may be attributed to different preparation method and small composition difference.

To test the mechanical deformation stability of all-dmetal Heuser alloy Ni50-xCoxMn25V25(x >37)ribbons,they are ground into powders. It should be noted that the all-dmetal Heuser alloy Ni50-xCoxMn25V25(x >37)ribbons transform from the pure Heusler phase to the mixed phases of fcc and B2 when the ribbons are ground into powders, as shown in Fig. 5. During the grinding process, it is found that the ribbons can only be ground into small pieces and are difficult to form fine powders, showing good ductility. This suggests that the induced fcc phase is ductileγphase. It is clear that there is a grinding stress induced phase transformation in Ni50-xCoxMn25V25(x >37)ribbons with B2-type Heusler structure, indicating that the B2-type phase is a metastable phase. The single high temperature phase of B2 can be retained by fast cooling.While the melted ingot sample is mixed phases of B2 and fccγ, as shown in Fig. 3(d). This implies that theγphase should be the low temperature phase compared with B2.When the stress is applied,a B2–γphase transformation is induced. Similar behavior has been observed in the conventional Heusler alloy Fe–Mn–Al.[31]They attribute this behavior to the stress-induced martensitic transformation.Our discovery indicates that all-d-metal Heusler alloys have the great potential of achieving cold-deformation.

Fig.5. Room temperature XRD patterns for Ni50-xCoxMn25V25 (x >37)ribbons after grinding into small pieces.

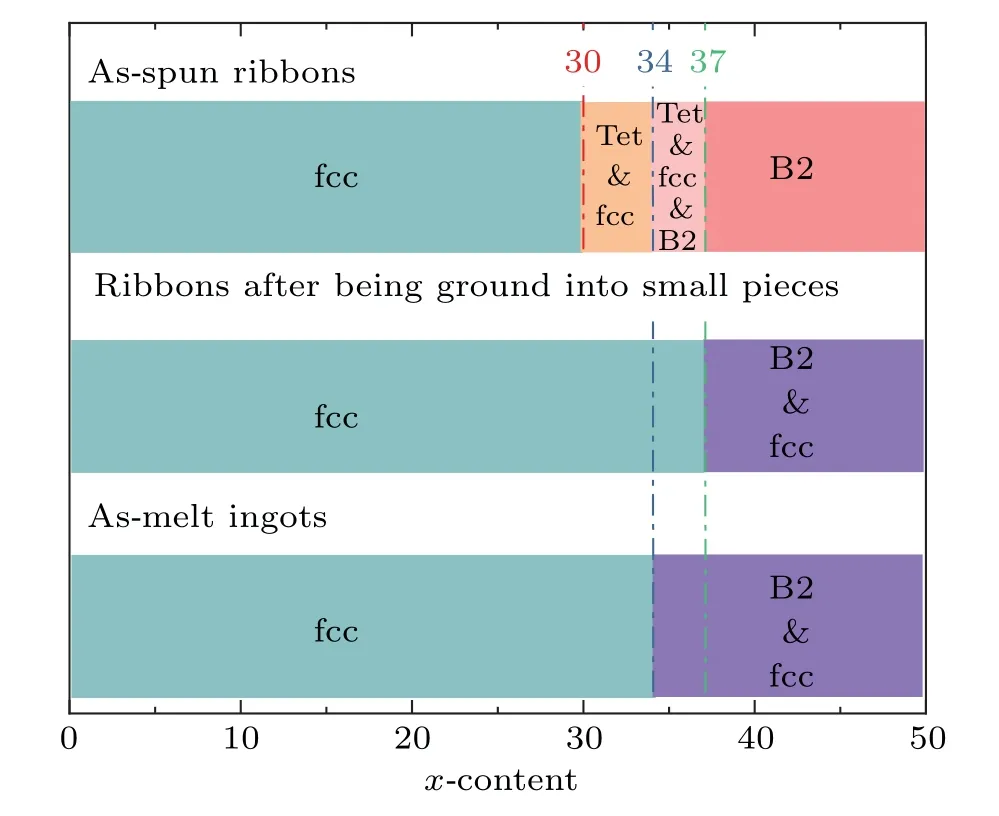

The schematic phase diagram for Ni50-xCoxMn25V25is given in Fig.6.The phase formation of the all-d-metal Heusler alloy for Co doping fcc Ni2MnV can be summarized. The B2-type Heusler phase starts to appear whenx >34 in both ribbons and as-melted ingots (see supplementary material), but the pure B2 phase is only formed in alloy withx >37 by meltspinning method. The grinding stress can induce partial B2→fcc phase transformation.

Fig.6. Schematic structural phase diagrams of experimental (We use the abbreviation Tet to identify the tetragonal structure).

Figure 7 shows the initial magnetization curves at 5 K for all-d-metal Heuser alloy Ni50-xCoxMn25V25(x >37) asspun ribbons and as-ground ribbon pieces. For both series samples,the saturation magnetization increases as Co content increases tox=47 and then decreases when increasing Co contentxto 50. It is worth noting that the spontaneous moment decreased greatly in as-ground samples, which is about 4.65μB/f.u. forx=38 ribbon, decreased to 2.25μB/f.u. for the as-ground sample with a reduction rate of 50% (see the inset of Fig. 7(a)). This demonstrates the presence of magnetic change from ferromagnetism to weak magnetism accompanied by the structural phase transition. At the same time,it is harder to achieve saturation in as-ground sample compared with as-spun ribbons,which should attribute to the appearance of the fcc phase and the internal stress caused by grinding.

Fig.7. Magnetization curves of Ni50-xCoxMn25V25 (x >37) as-spun ribbons(a)and as-ground ribbon pieces(b)measured at 5 K in magnetic fields up to 5 T.The inset plot shows the variation of saturation magnetic moment with Co content x.

4. Conclusion

First-principles calculations indicate that the Ni2MnV alloy prefers to crystalize in the FIM fcc-type structure with the equilibrium lattice constant of 3.60 ˚A, consisting with the experimental result. The lower DOS of the fcc state near the Fermi level can explain the stability of the fcc phase of Ni2MnV. The structure of Co doping Ni in fcc Ni2MnV is investigated simultaneously. It is demonstrated that pure Heusler phase is formed as Co contentx >37, indicating that the d–d hybridization between Co/Mn elements and lowvalent elements V stabilizes the Heusler phase. However,the as-melted ingot samples Ni50-xCoxMn25V25(x >37) show dual phase with fcc and B2. Furthermore,the pure Heusler alloy Ni50-xCoxMn25V25(x >37)is very sensitive to the stress.Grinding stress induced Heuser phase to dual-phase of fcc and B2 is observed in these all-d-metal Heusler alloys. Accompanying with this phase transition, a ferromagnetism to weak magnetism has been detected.These behaviors provide insight into the recently proposed all-d-metal Heusler alloys dominated by d–d covalent hybridization.

Acknowledgments

Project supported by the National Natural Science Foundation of China (Grant Nos. 51671024 and 52088101), State Key Lab of Advanced Metals and Materials(Grant No.2019-Z12), and the Fundamental Research Funds for the Central Universities(Grant No.FRF-BD-20-12A).

- Chinese Physics B的其它文章

- The coupled deep neural networks for coupling of the Stokes and Darcy–Forchheimer problems

- Anomalous diffusion in branched elliptical structure

- Inhibitory effect induced by fractional Gaussian noise in neuronal system

- Enhancement of electron–positron pairs in combined potential wells with linear chirp frequency

- Enhancement of charging performance of quantum battery via quantum coherence of bath

- Improving the teleportation of quantum Fisher information under non-Markovian environment